Within the chosen system boundaries, inventory flows were grouped into relevant inventory items of input flows relating either to land, built infrastructure, labour, substrate, water, energy, transport, manufacturing equipment or consumables and supplies. Following classical economic theory, a second level of clustering into primary and intermediate factors of production was conducted [

55]. This organisational procedure contributed to the harmonization of the different LCI models and allowed for an aggregated presentation (

Table 3). Inventories regarding the inputs “manufacturing equipment” (primary factors of production) and “consumables and supplies” are detailed in

Appendix D (

Table A6,

Table A7 and

Table A8).

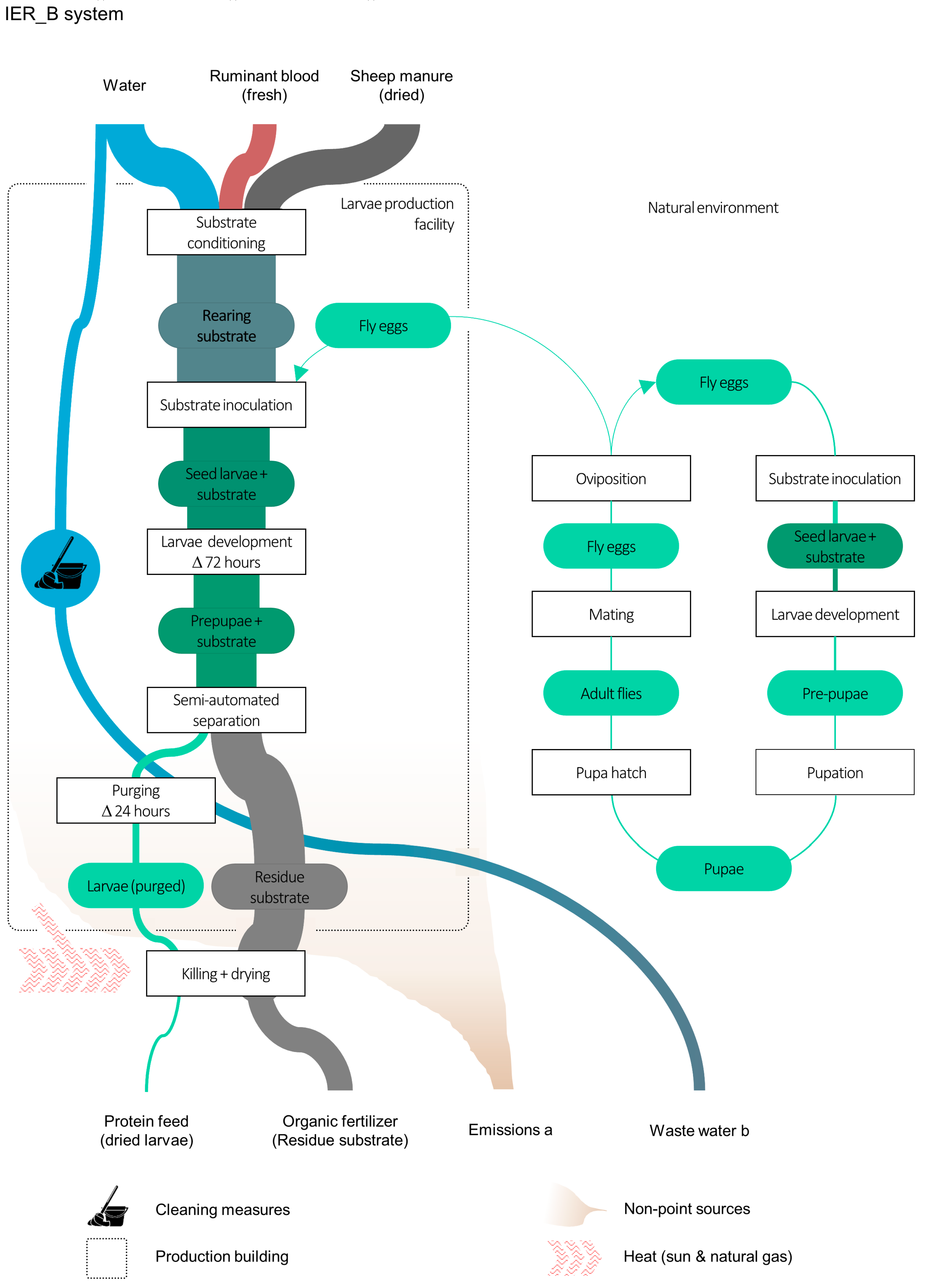

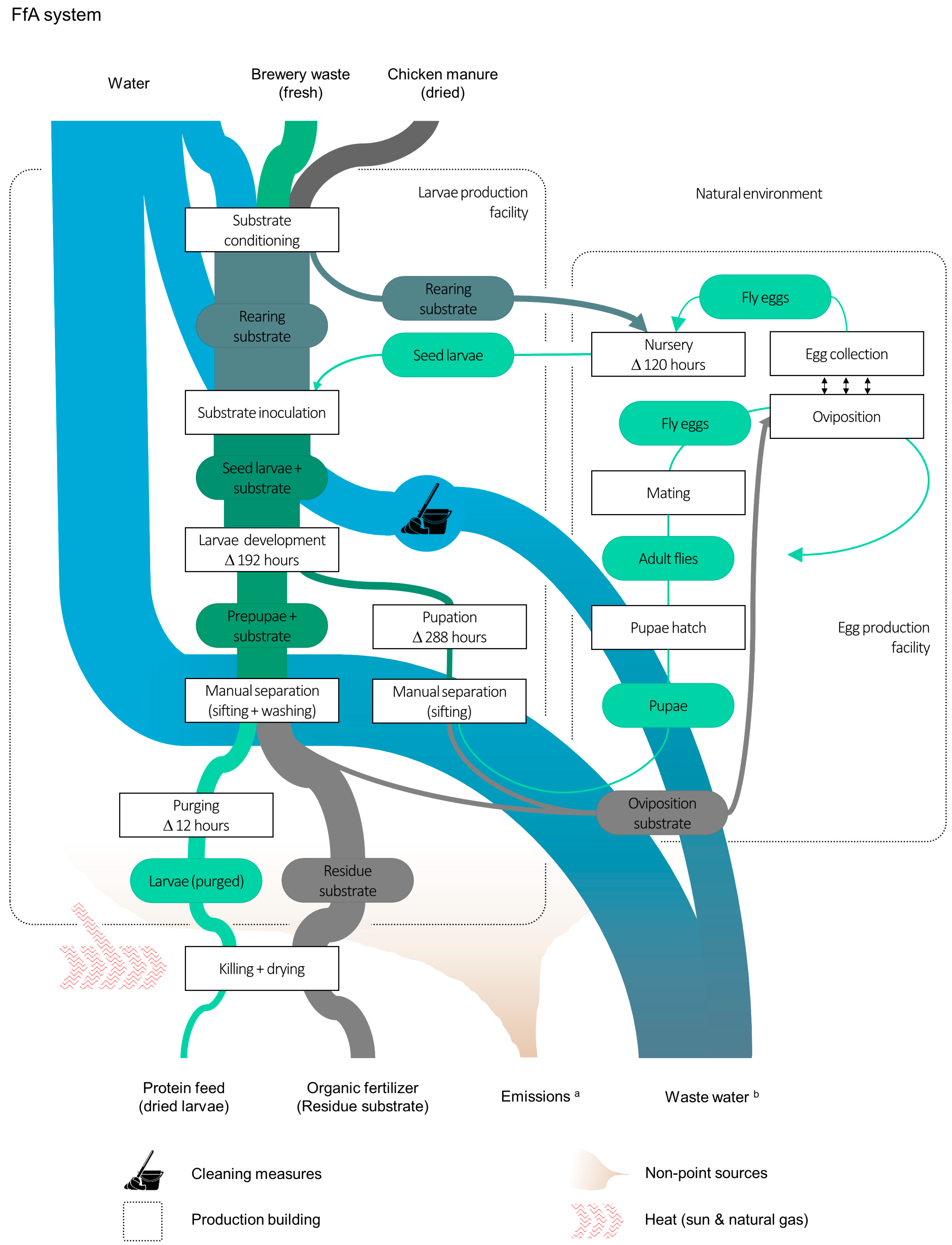

The LCIs reveal marked differences in input and output relations between the modelled IBF systems. As in any livestock production system, the input efficiencies in the IBF systems result from a complex interaction of feed quality, species specific growth characteristics, applied rearing techniques and climatic conditions. The following sections elucidate and discuss the performance determining factors and unravel their influence on the system specific input efficiencies.

3.1. Rearing Substrate

The efficiency and speed with which insect larvae build endogenous biomass depends on the nutritional and physical characteristics of the organic material they are feeding on [

60]. Being heterotroph organisms, the growth of insect larvae strongly depends on the residual energy content (i.e., calorie content) of substrates [

60]. The results of the LCI analysis reinforce this relationship, as the systems’ conversion efficiencies (i.e., substrate input per kg IBF output) increase with the gross energy content (GEC) of rearing substrates (

Table 3). Chicken manure, with 13.2 MJ per kg (DM), provided the lowest energy density of the substrate ingredients examined (

Table 1). Due to a high dry matter (DM) content of about 90%, the conditioning of chicken manure required larger amounts of water to achieve optimal moisture levels. The rearing substrate in the IER_A system (mixture of 40.0 kg chicken manure 59.9 L water) is calculated to have the lowest GEC of 4.8 MJ per kg fresh mass (FM) (

Table 3). Correspondingly, the IER_A system is assessed with the lowest conversion efficiency (100.0 kg moistened rearing substrate/kg IBF) and the highest co-product output (28.0 kg residue substrate). The mixture of sheep manure, ruminant blood and water (IER_B system) arrives at a higher GEC (5.6 MJ/kg FM), which likewise coincides with a higher conversion efficiency (62.8 kg rearing substrate/kg IBF) and lower unit output of residue substrates (16.0 kg). The highest conversion efficiency and lowest residue substrate output amongst the IBF systems is calculated for the FfA system. To produce 1 kg dried

H. illucens larvae and 7.1 kg residue substrate, the FfA system uses 26.8 kg substrate (mixture of dried chicken manure, fresh brewery waste and water) with a GEC of 5.5 MJ per kg FM (

Table 3). The mass contribution of different substrate ingredients in each system can be retraced from

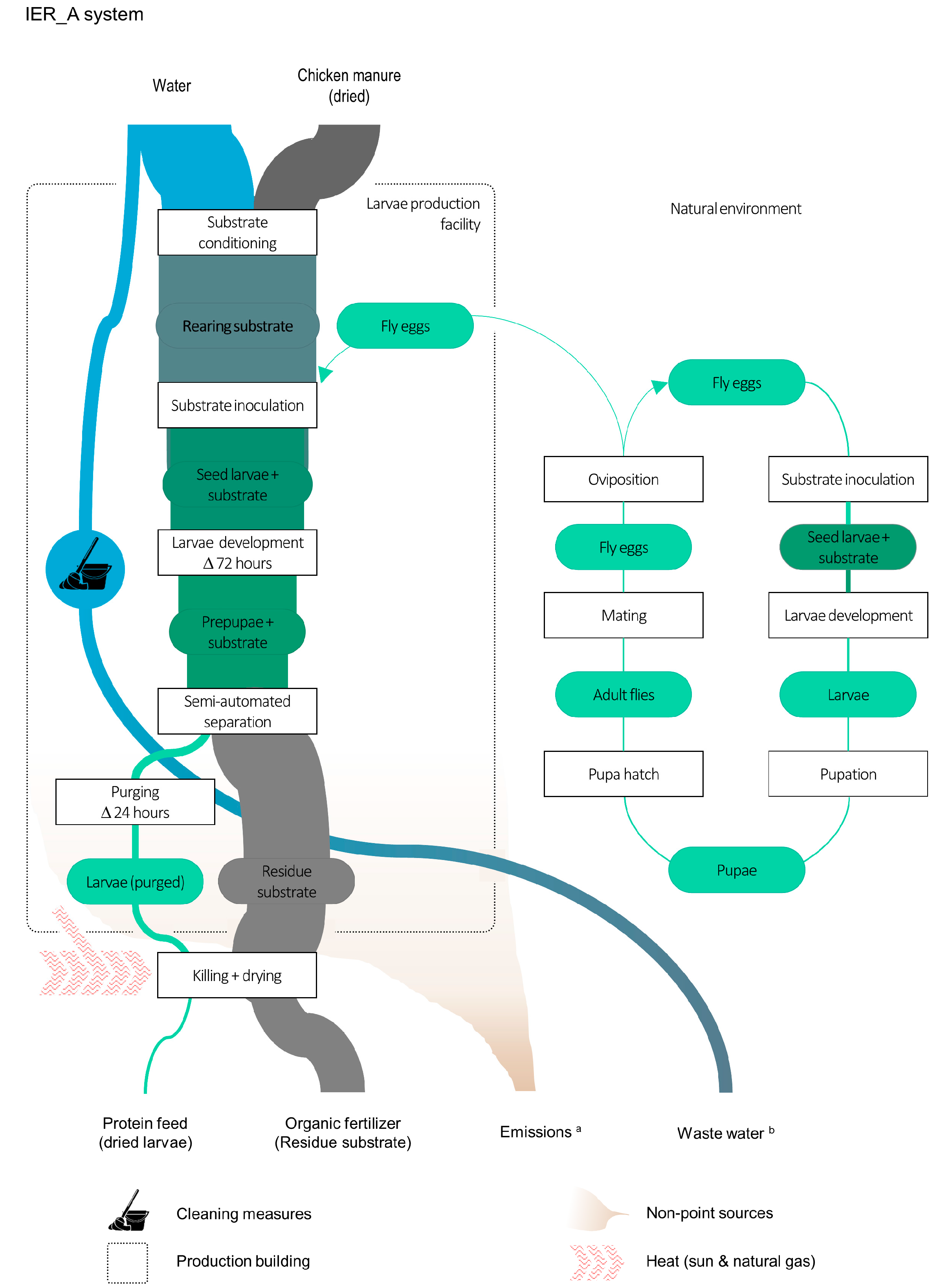

Figure 1A.

Differences in the conversion efficiencies are not solely due to differing energy densities of the substrate ingredients. Less obvious, but equally important are nutritional properties, such as protein content, and biophysical factors (e.g., porosity and aeration of the rearing medium) that affect the ability of insect larvae to extract nutrients from the substrates provided. The relationship between conversion efficiency and the output of residue substrate becomes clearer when comparing the systems’ conversion efficiencies by measurement of calorie input (

Figure 1B).

The IER_A system is the least efficient in terms of calorie utilisation, expending 476.2 MJ caloric energy to produce 1 kg IBF and 28 kg residue substrate. The IER_B and FfA systems follow with 348.6 MJ and 148.4 MJ per kg IBF, respectively (

Figure 1B). The specific biophysical cause-effects underlying the differences between the IER systems cannot be clarified from the available data. It can be presumed, however, that advantages of the IER_B system result of the high protein content of ruminant blood [

11,

30]. The efficient calorie utilisation of the FfA system, on the other hand, is probably cause of two concurrent effects; favourable substrate characteristics (i.e., energy and protein content, porosity, water holding capacity, etc.) and a longer lasting growth phase (see

Section 3.2).

Although the use of substrate combinations appears to benefit the conversion efficiency of the systems, it also comes at the cost of increased sourcing efforts, i.e., higher input of transportation and labour (

Figure 1C). Although all three systems are assumed to be in close proximity to the manure producing sites, the use of more than one substrate is associated with additional transportation needs. Using only chicken manure from a poultry farm nearby, transportation in the IER_A system is limited to the sourcing of production and ancillary material, as well as the sale of process products (i.e., miscellaneous). Frequent trips using a motorbike to a generic market within 10 km proximity of the insect rearing facility constitutes a unit input of 0.1 km per kg IBF, which represents the lowest input of transportation of the three systems (

Table 3 and

Figure 1C). As the IER systems basically share the same process setup (see

Section 2.1), there are no differences between the IER_A and IER_B system with regard to transportation for the sale of process products or collection of the chicken manure (

Figure 1C; miscellaneous). The use of ruminant blood, however, requires sourcing from a slaughterhouse within 10 km proximity. Transport is facilitated by a commercial vehicle (3.5–7.5 t), with the blood transported in 40 L plastic barrels. As blood is highly perishable, it necessitates a steady procurement (every second day), which ultimately increases the unit input of transportation by 0.7 km per kg IBF and the input of labour (trained staff) by 0.1 h per kg IBF (

Figure 1C and

Table 3). The comparatively high transportation needs in the FfA system (0.4 km/kg IBF) are primarily due to a higher demand for nondurable auxiliary equipment (plastic trays, mosquito mesh, cleaning materials, etc.) and gas bottle exchange (

Appendix D,

Table A8). Sourcing of brewery waste by truck (7.5–16 t) from a brewery within 20 km proximity added 0.1 km per kg IBF, which represents about 14% of the total input of transportation (

Table 3 and

Figure 1C).

Whilst the process related gaseous emissions draw on generic emission data, the calculated emission patterns (relation between emitted substances) are the same in all three IBF systems, but are a function of the time that rearing substrates are exposed to open air (see also

Section 2.1). With an output of 15.5 g CH

4, 0.3 g N

2O, 2.8 g NH

3 and 2.5 g volatile solids per kg IBF (emitted to air), the IER_A system is calculated to have the highest gaseous emissions. Despite conversion efficiency advantages, the FfA system gave the second highest emissions, due to the longer larval development time. The IER_B system gave the lowest gaseous emissions, with only about 64% the emissions of the IER_A system (

Table 3).

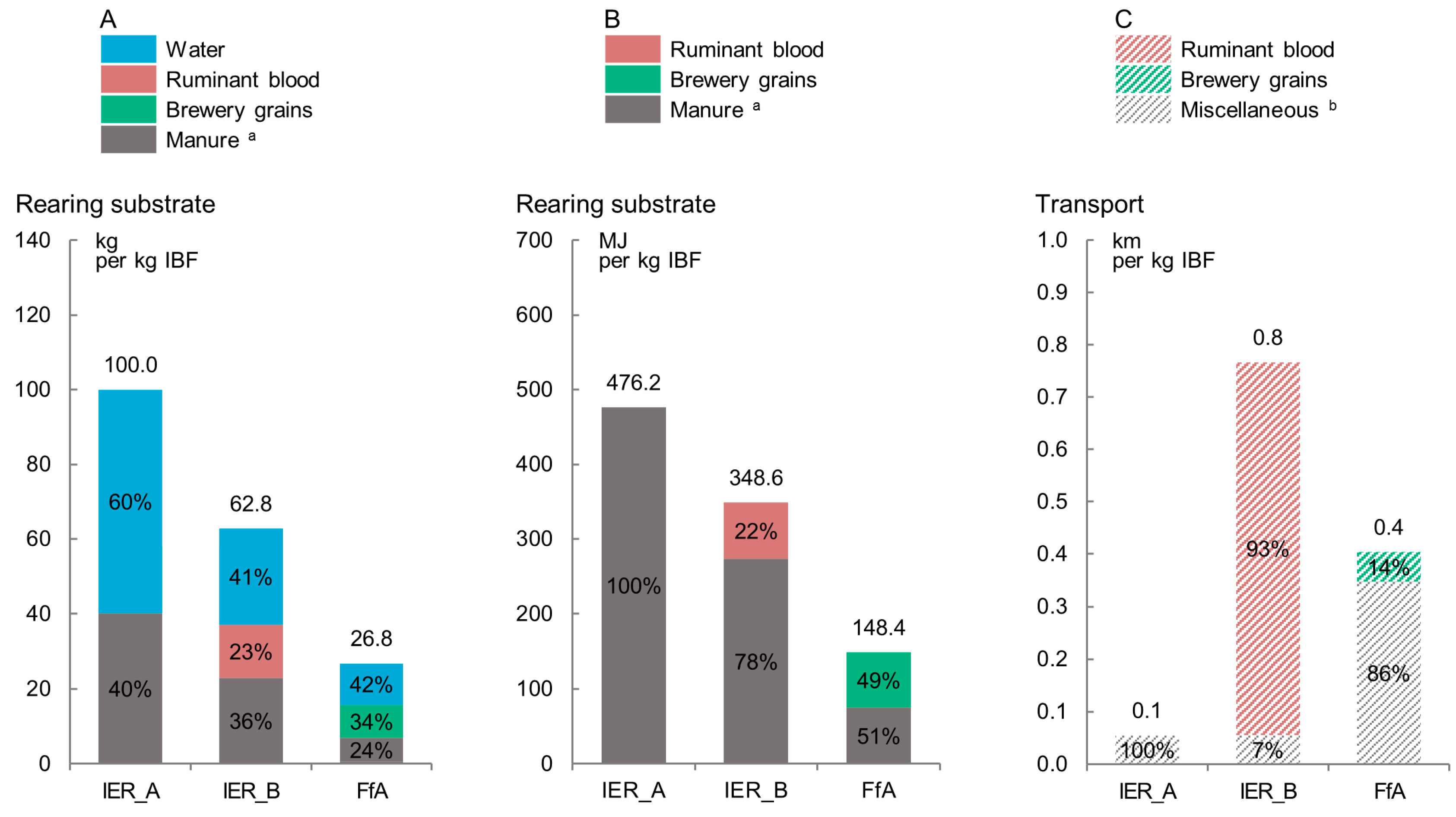

3.2. Rearing Technique and Insect Species

Other factors influencing the conversion efficiency for insect larvae are the inoculation method used and the duration of the larval development phase [

11,

61].

Hermetia illucens has a longer life cycle, and consequently larval development phase, than

M. domestica. The longer growth phase of

H. illucens and the higher mass of individual larvae fosters the effective penetration and mixing of the rearing substrates and a greater degree of feeding resulting in a more efficient substrate conversion. Inoculation with larvae (i.e., artificial inoculation), improves the manageability of the process and mass flows, as stocking densities can be adjusted according to substrate quality and quantity [

11,

61].

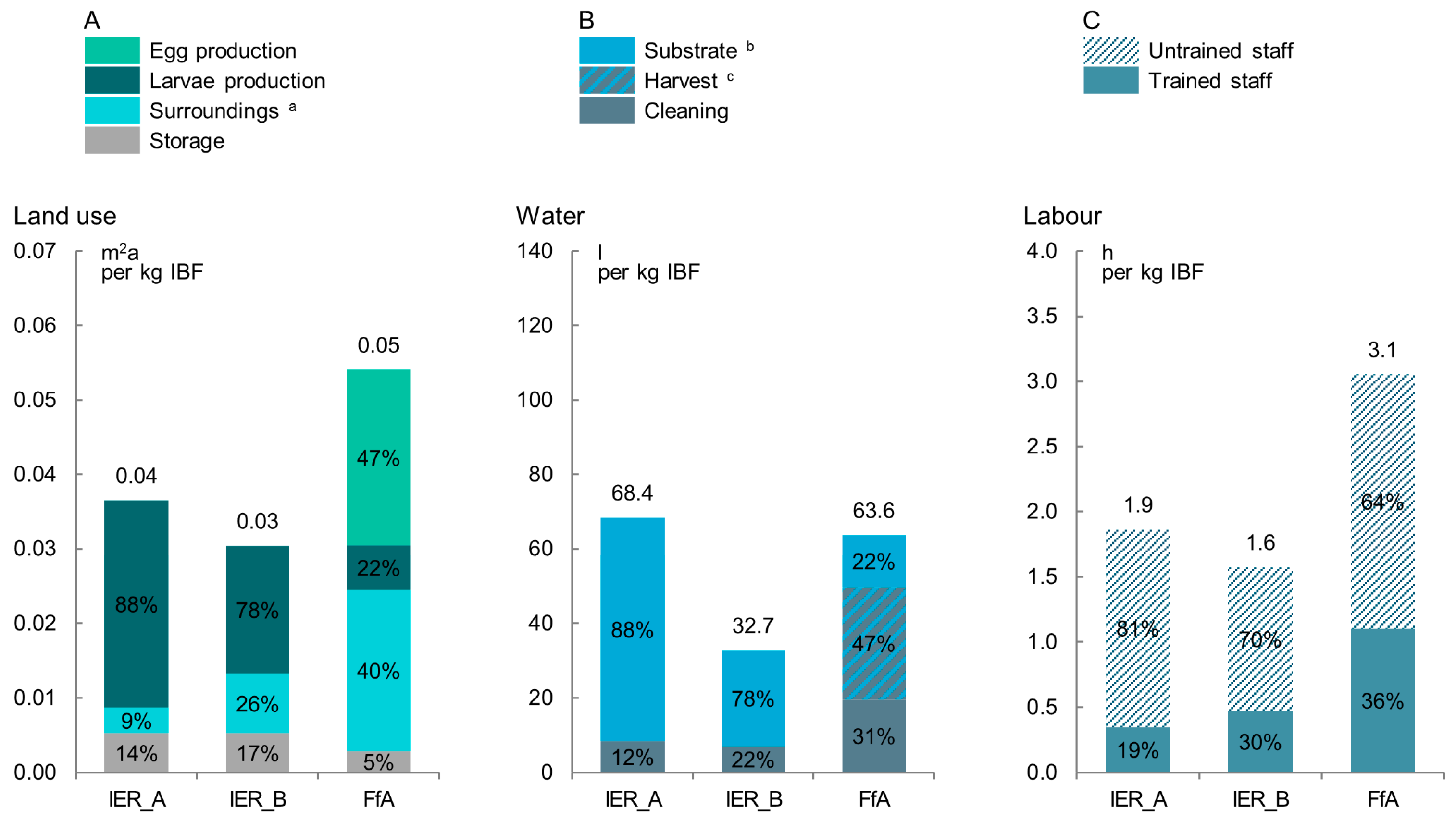

Although an artificial substrate inoculation and longer larval development period appear to benefit the system’s conversion efficiency, this results in adverse effects on the input efficiency of space, labour and water (

Figure 2).

Disadvantages of artificial inoculation are particularly apparent in the relative input of land (

Figure 2A). Like all land based animal production systems, the rearing of insect larvae involves the occupation of space over time. The unit input of land and built infrastructure are therefore a function of a system’s conversion efficiency, the species-specific life cycle and rearing technique. The effects of variable conversion efficiencies are best exemplified in the comparison of the IER_A and IER_B system (

Figure 2A). Both systems share a similar production setup and advantages in conversion efficiencies translate directly into lower input of land. With 0.02 m

2a per kg IBF (78% of total unit input) production of larvae in the IER_B system is more space efficient than larvae production in the IER_A system (0.03 m

2a/kg IBF).

Favourable conversion efficiency and the use of artificial inoculation lower the relative input of land in the larvae production. With 0.01 m

2a per kg IBF (22% of total land input), the rearing space in the FfA system is used most efficiently (

Figure 2A). However, space use advantages in the larvae production unit are offset through additional space claims associated with the employed inoculation method and rearing of

H. illucens adults for egg production. The maintenance of an egg production unit increases the space demand in the FfA system by 0.02 m

2a per kg IBF (

Figure 2A). Adding to this is a more intense use of the surrounding areas outside of the production facilities (0.02 m

2a per kg IBF) for harvesting and drying of larvae, and for exposure to the sun of adult cages to promote mating and oviposition.

Further disadvantages of

H. illucens and the artificial inoculation system arise from a more elaborate system design. The interplay between egg and larval production is organized through a sequence of complex operation steps that involve the use of additional production equipment, auxiliary materials, as well as consumables and supplies (

Appendix A). Adding to this are materials and equipment necessary to prevent parasitoids attacking the

H. illucens pupae before hatching [

20]. The segmented process organisation and a larger number of tools and equipment not only increase the transportation needs (see

Section 3.1), but also increase cleaning demands (

Figure 2B). With 19.6 L water per kg IBF, the production in the FfA system is associated with the highest cleaning efforts. The IER_A and IER_B system follow with 7.1 and 8.4 L per kg IBF, respectively (

Table 3). The breakdown of water input by activities further reveals that large amounts of water input in the FfA system are due to harvesting measures. To efficiently free the coarsely separated

H. illucens larvae of substrate remnants, separated larvae are washed in water (see

Section 2.1). The washing of larvae reduces the risk of a pathogen contamination of IBF, but eventually increases the water inputs in the FfA system to a total of 30.2 L per kg IBF (

Figure 2B).

The more complex process organisation in the FfA system further translates into lower efficiency of labour inputs (

Figure 2C). With a total of 3.1 h per kg IBF, the FfA system operates with the highest labour input of all the IBF systems. The operation of two interlinked production units requires additional monitoring and management needs resulting in relatively high employment of trained staff (l.2 h/kg IBF). The high labour input by untrained staff (1.9 h/kg IBF) is largely due to the more elaborate process organisation and longer process chain (see also

Section 2.1). A breakdown of labour inputs by operational activities provides more detailed insights in

Figure 3A.

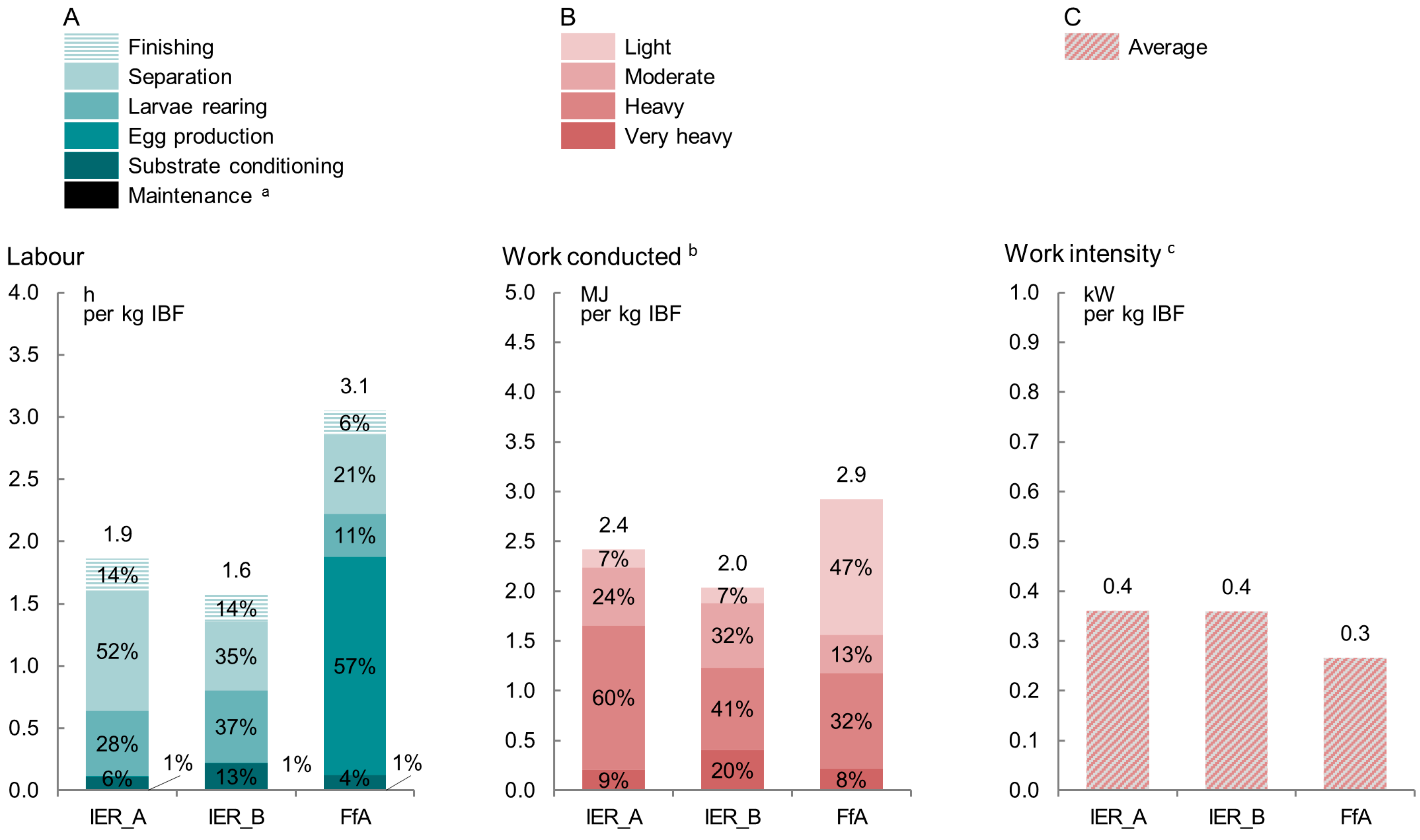

In general, the IER systems operate with a lower unit input of labour (

Figure 2C and

Table 3). By using natural oviposition (omission of a separate egg production unit), unit inputs of labour in the IER_A and IER_B system are considerably lower than the FfA system (

Figure 3A). The differences between the IER_A and IER_B system are due to differences in conversion efficiency. The higher unit output of residue substrate (28.0 kg/kg IBF) in the IER_A system increases the labour demand in the harvesting process (i.e., separation) up to 0.9 h per kg IBF (52% of total unit input). The IER_B system, on the other hand, shows higher labour demand in the substrate conditioning step (

Figure 3A) as mixing of two substrate ingredients amounts to a unit input labour of 0.2 h per kg IBF (13% of total unit input).

The comparison of the IBF systems by work input (i.e., energy or physical human work conducted) is in line with prior observations, but arrives at more balanced results (

Figure 3B). As labour inputs for egg production (1.8 h/kg IBF) are of “light work intensity” (0.7 MJ/h), the FfA system (2.6 MJ per kg IBF) shows comparable results to the IER_A (2.4 MJ/kg IBF) and the IER_B system (2.1 MJ/kg IBF). The differences in work input between the IER systems are due to the differing labour inputs in the separation step (heavy work intensity) and substrate conditioning step (very heavy work intensity). The IER_A system has the highest input of work with “heavy work intensity” (separation step), where a labour input of 1.0 h per kg IBF equals a work input of 1.4 MJ per kg IBF (60% of the total unit input). The IER_B system, on the other hand, has the highest share of work inputs of “very heavy work intensity” (substrate conditioning step), which accounts for about 20% (0.4 MJ per kg IBF) of the overall unit input of work (

Figure 3B).

The differences between the IBF systems are less pronounced when labour inputs are characterised by average work intensity (input of energy consumed per hour). Despite the differing labour and work inputs, the IER systems involve similar work intensities (0.4 kW). The FfA system, ranking highest in unit input of labour and work, has the lowest work intensity (0.3 kW) (

Figure 3C).

3.3. Climatic Conditions

The LCI results are also characterised by variation in climatic conditions, although this is a more indirect effect. While the warm and humid climate in tropical West Africa aids the rearing of the naturally occurring

H. illucens, it causes increases in the unit input of fossil energy. Frequent precipitation and the high air humidity do not allow for sun drying of larvae. Instead, the drying of larvae was facilitated through a gas oven with 8 kWh power. To produce 1 kg of dried larvae (≤10% water) the gas oven burned natural gas with an energy equivalent of 3.3 MJ (

Table 3). The IER systems, which only burn natural gas to support the killing of larvae in moments when exposure to sun is not possible (e.g., precipitation, cloud coverage), have a considerably lower unit input of fossil energy (0.7 MJ per kg IBF) (

Table 3). However, it ought to be noted here that energy inputs in the killing and drying process are also subject to the specific surface/volume ratio of larvae. If larvae of both species would be killed and dried under the same conditions, advantages would still be given to

M. domestica, as larvae are comparably smaller and of lower individual mass as the one of

H. illucens.

Climatic conditions also influence the unit input of the production infrastructure. The service life of the machinery and construction materials (i.e., depreciation) is calculated as a function of the varying climatic conditions in the IER systems (semi-arid climate) and FfA system (tropic climate). Due to accelerated wear and tear in the humid conditions of tropical West Africa, the expected service life of production equipment in the FfA system was shorter than that for the IER systems (see also

Appendix A). The effects are illustrated in the unit input of built infrastructure. With an expected service life of 15 years, the unit input of built infrastructure in the FfA system is about 3.3 times higher than the associated unit input of land (0.03 m

2a) (

Table 3). The built infrastructure in the IER systems is expected to last for 25 years, which results in lower unit inputs of 0.07 m

2a (IER_A system) and 0.04 m

2a (IER_B system) (

Table 3).

3.4. Scale of Production

The differences in scale of production (i.e., daily IBF output) between the IBF systems are due to capacity constraints set in the modelling of the systems (see

Section 2.2). The IER_A and IER_B system are modelled with a maximum daily output of 12 kg dried insect larvae (i.e., ≤10% water), which equates to production facilities with a surface area of 133.2 m

2 and 160.0 m

2, respectively (including storage facilities and surrounding outside areas). With the adult population restricted to the maintenance of 20,000 individuals (constant number), the FfA production system facilitates a maximum daily output of 9.6 kg dried insect larvae (i.e., IBF) and occupies a total surface area of about 189.0 m

2 (

Table 3).

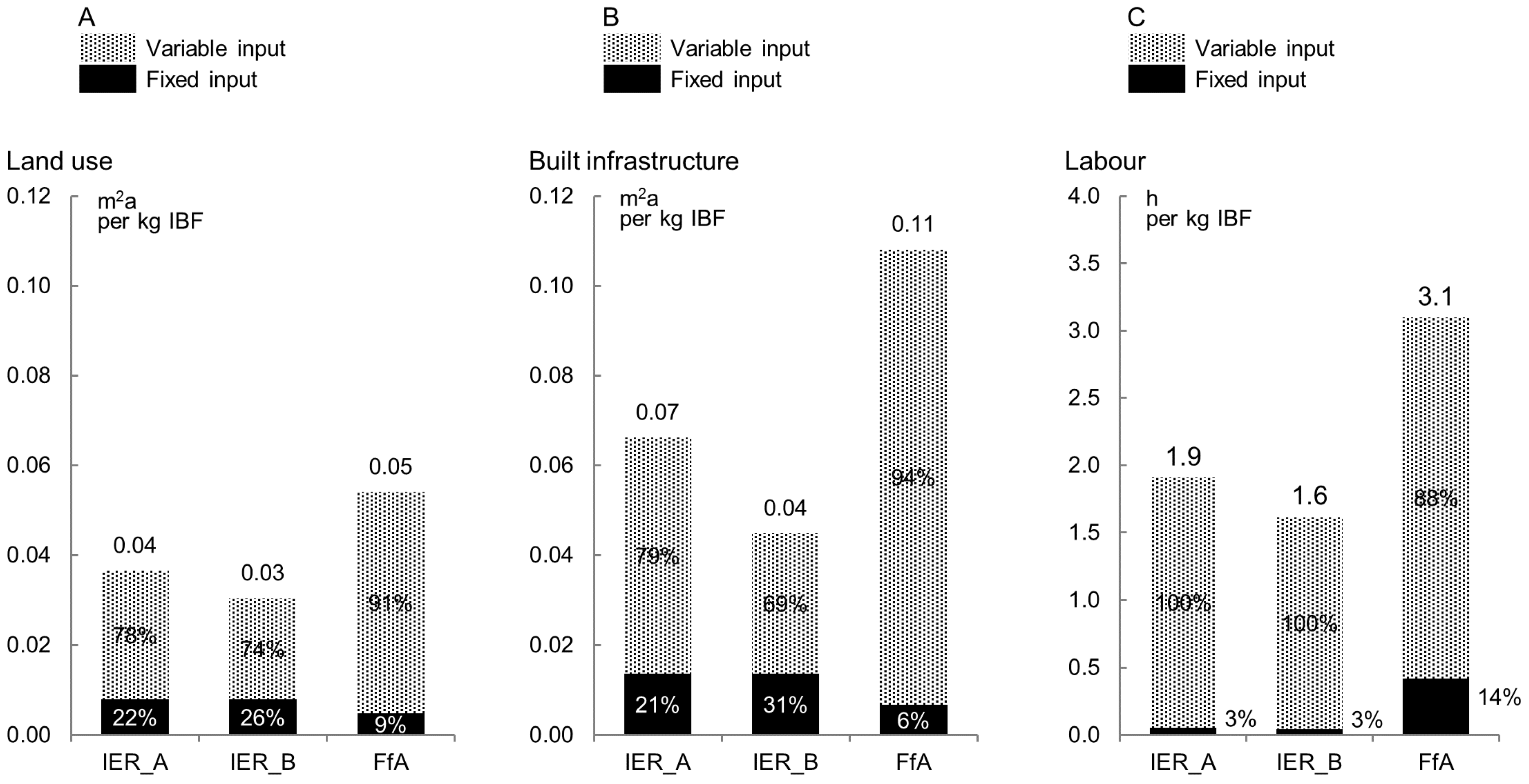

The effects of scale of production on the inventory results can be seen in the inputs of primary factors of production and their composition of scale dependent (variable) and scale independent (fixed, on short run) model parameters (

Figure 4).

The generally low share of fixed inputs reflects the low level of automation and simplistic process setups of the IBF systems (

Figure 4). The input of land (and built infrastructure) and labour are to a greater extent scale dependent, i.e., input changes are proportional to changes in output. The potential for efficiency gains through upscaling measures are therefore rather low. Economies of scale in the IER systems would primarily improve the input efficiencies of land and built infrastructure (

Figure 4A,B). A further upscaling of the FfA system, on the other hand, would show notable effects in a relative decrease of unit labour inputs (

Figure 4C).

Given the generally low conversion efficiencies, benefits of further upscaling would also depend on the availability of rearing substrates. Co-products, such as manure, blood and fresh brewery waste, are often already valorized in the form of fertilizers, food or feedstuff and thus an integrated part of agricultural value chains. Adding demand through IBF production would increase demand and prices of these co-products and in turn, may create shortages at other ends of the agricultural value chain (e.g., fertilizer, food or energy feeds). However, the output value of the co-product residue from IBF production, which is typically applied as a fertilizer to land, should also be considered. Whilst such reallocation effects seem feasible in the context of subsistence agriculture, it could potentially constrain a large-scale implementation of IBF in commercial operations.