Food Waste Drivers in Europe, from Identification to Possible Interventions

Abstract

:1. Introduction

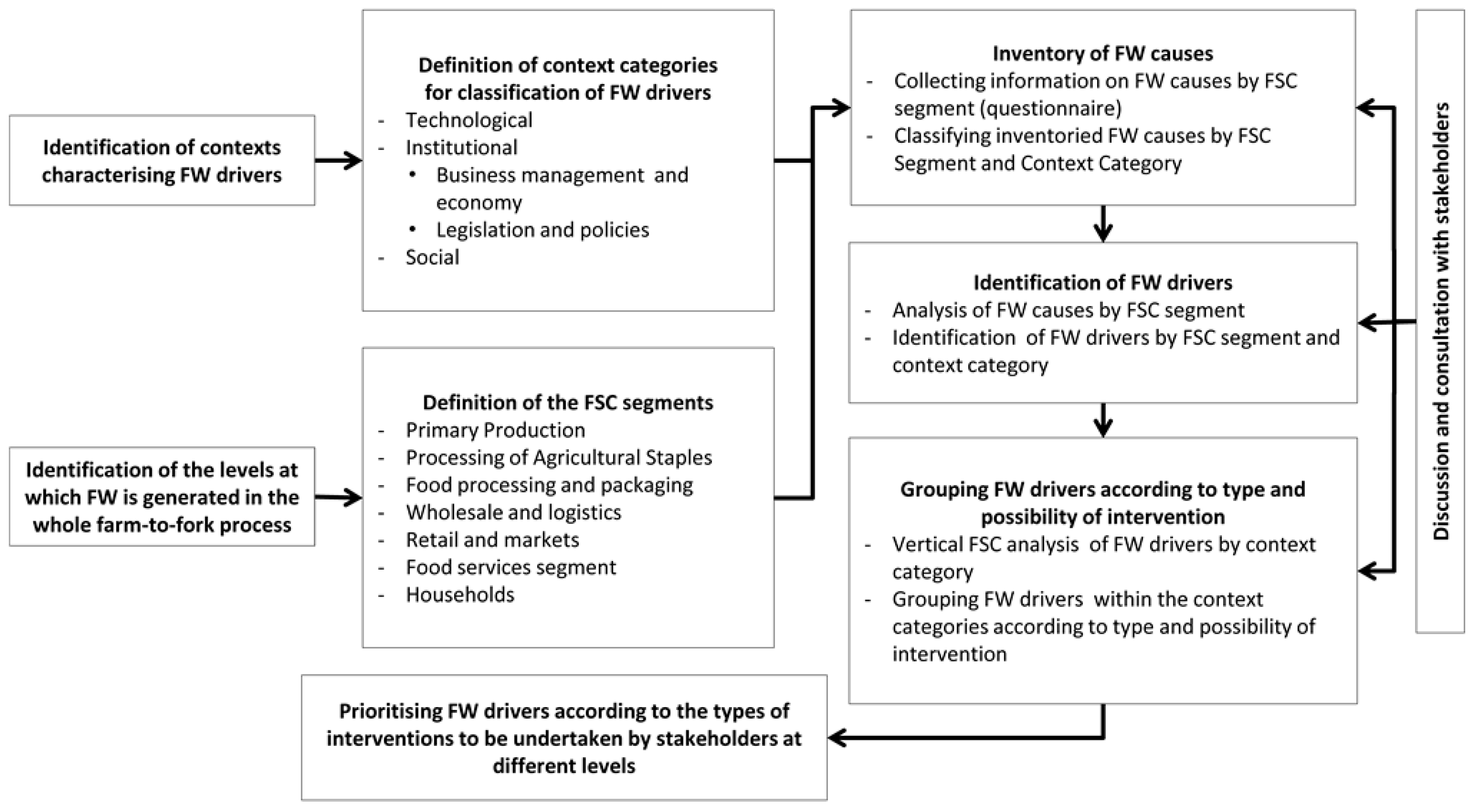

2. Materials and Methods

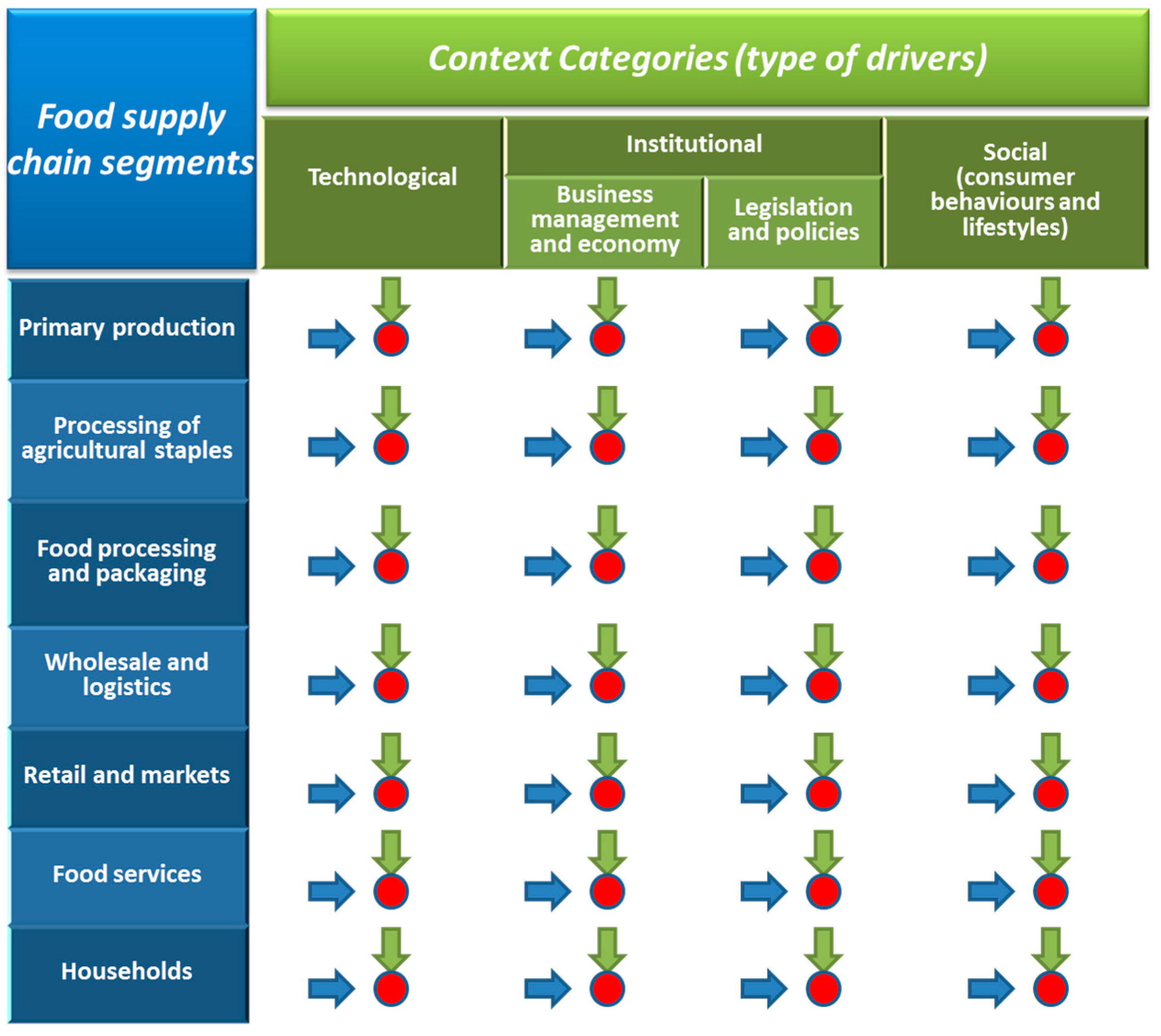

2.1. Setting Up the Structure of the Analysis

- i

- The Technological context is intended to gather the FW drivers related to misuse, failures, and limits of current FSC technologies;

- ii

- The Institutional context refers to the organizational aspects of food production and consumption in the perspective of both the private and the public sector. This implied the definition of two sub-contexts:

- The Business management and economy sub-context is related to the FW drivers depending on organization of food businesses and their integration along the FSC, and on management choices determined by economic variables;

- The Legislation and policy sub-context is concerned with FW caused by inefficient legislation in the food sector and in other connected fields, and by policy measures that may subordinate potential generation of FW to other priorities (e.g., food security, food safety, consumer information, low cost of waste disposal, etc.).

- iii

- The Social context refers to FW drivers related to consumer behaviours and lifestyles.

- (1)

- The primary production segment includes the production of food staples destined to processing or directly to final consumption;

- (2)

- The processing of agricultural staples segment refers to the first processing of agricultural staples producing ingredients mainly destined to further processing in the food industry;

- (3)

- The food processing and packaging segment is concerned with production and packaging of food products for consumers;

- (4)

- The wholesale and logistics segment relates to the activities of wholesaling of food products, including storage and transportation;

- (5)

- The retail and markets segment embraces the selling of food to consumers in supermarkets, shops and marketplaces;

- (6)

- The food services segment is related to the preparation of meals and dishes consumed outside the home;

- (7)

- The households segment refers to the preparation and consumption of food at home.

2.2. Inventory of Food Waste Causes and Identification of Drivers

3. Results: Food Waste Drivers in Context

3.1. The Technological Context

3.1.1. FW Drivers Inherent to the Characteristics of Food, and of Its Production and Consumption, Where Technology Has Become Limited (T1)

3.1.2. FW Drivers Related to Collateral Effects of Modern Technologies (T2)

3.1.3. FW Drivers Related to the Suboptimal Use of, and Mistakes in the Use of Modern Technology (T3)

3.2. The Institutional Context—(A) Business Management and Economy

3.2.1. FW Drivers Addressable by Management Solutions within One Single Business Unit (IBE1)

3.2.2. FW Drivers Addressable through Management Solutions Coordinated among Different FSC Operators (IBE2)

3.2.3 FW Drivers Depending on Broader Economic and Structural Variables, Not Readily Addressable by Management Solutions at the Level of Single Business Units or of the FSC (IBE3)

3.3. The Institutional Context—(B) Legislation and Policy

3.3.1. FW Drivers Related to the Agricultural Policy and to Food Quality and Marketing Standards (ILP1)

3.3.2. FW Drivers Related to Food Safety, Consumer Health and Information, and Animal Welfare Policies (ILP2)

3.3.3. FW Drivers Related to the Waste and Taxation Policies and to Other Policies (ILP3)

3.4. The Social Context

3.4.1. FW Drivers Related to Wide Social Dynamics That Are Not Readily Changeable (S1)

3.4.2. FW Drivers Related to Consumers’ Individual Behaviours that Are Not Readily Changeable (S2)

3.4.3. FW Drivers Related to Consumers’ Individual Behaviours Modifiable through Information and Increased Awareness (S3)

4. Discussion and Conclusions

4.1. Technological Drivers

4.2. Institutional Drivers Related to Business Management and Economy

4.3. Institutional Drivers Related to Legislation and Policies

4.4. Social Drivers

4.5. A Cross-Contextual Prioritization and Some Conclusions

- FW related to the characteristics of food products and the ways through which they are produced and consumed (e.g., perishability of food; limited predictability of supply and demand; limited capacity of control over many factors of production which constrains the possibility to adapt quickly the supply to the evolution of demand; limited possibility of consumers to accumulate individual stocks of food, etc.);

- FW related to social and economic factors and dynamics in population habits and lifestyles that are non-readily changeable (e.g., single-person households; young age of household members; young couples with small children; growing urban population; increased consumption of meals out-home; low price of food products; scarce finance for FSC infrastructures in developing countries, etc. All these are factors and long-lasting trends positively correlated with FW generation that cannot be modified in the short–medium term);

- FW related to individual behaviours of consumers that are non-readily changeable (this refers to behaviours depending on general expectations of consumers towards food, for example, good appearance; freshness; possibility of acceding to broad quantities and varieties of food independent of places, season, and time, etc. These expectations can determine a vicious circle between consumers’ bad attitudes that are a source of wastage and FSC operators’ marketing strategies that gratify such attitudes. Progress in technology and management can deal with the problem, but its originating causes—the consumers’ expectations—are unlikely to be eradicable);

- FW related to other priorities targeted by private and public stakeholders (the possibility of generating FW may be a minor concern with respect to other priorities of the private and public stakeholders. For example, for private companies, profit is a priority and this justifies choices in technology, management, and marketing solutions that balance potential wastage of food with increases in product sales, reduction of production costs or diminished risks of damages to the company’s brand image from non-complying with safety or other commercial standards. For public authorities, legislative provisions improving issues such as food safety, food security, consumer information, and animal welfare may overcome the concern for potential FW generation derived from such legislation);

- FW related to non-use or sub-optimal use of available technologies, organizational inefficiencies of supply chain operators, inefficient legislation, and bad behaviours of consumers depending on unawareness, scarce information, and poor food skills. This group includes a wide range of FW causes that could be considerably reduced by improving technological and organizational efficiency of supply chain operators, the quality of legislative provisions potentially impacting on FW, and the consumer behaviours and attitudes towards food.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| AHDB | Agriculture and Horticulture Development Board |

| BBSRC | Biotechnology and Biological Sciences Research Council |

| EEA | European Economic Area |

| EPA | Environmental Protection Agency |

| EPM | European meeting of the FUSIONS European Platform |

| EU | European Union |

| FAO | Food and Agriculture Organization of the United Nations |

| FSC | Food supply chain |

| FUSIONS | Food Use for Social Innovation by Optimising Waste Prevention Strategies—European Project of the 7th Framework Programme for Research and Technological Development of the European Commission |

| FW | Food waste |

| HGCA | Home Grown Cereals Authority |

| HLPE | High Level Panel of Experts of the Committee on World Food Security |

| IBE1 | Institutional food waste drivers related to business management and economy addressable by management solutions operated within one single business units |

| IBE2 | Institutional food waste drivers related to business management and economy addressable by management solutions coordinated among different operators of the food supply chain |

| IBE3 | Institutional food waste drivers related to business management and economy depending on broader economic and structural variables, not readily addressable by management solutions at the level of single business units or the supply chain |

| ILP1 | Institutional food waste drivers related to legislation and policies, specifically to the agricultural policy and to food quality and marketing standards |

| ILP2 | Institutional food waste drivers related to legislation and policies, specifically to food safety, consumer health and information, and animal welfare policies |

| ILP3 | Institutional food waste drivers related to legislation and policies, specifically to waste and taxation policies and to other policies |

| LEI | Landbouw Economisch Instituut (Agricultural Economics Institute) |

| NHSE | National Health Service England |

| NSW | New South Wales |

| OECD | Organisation for Economic Co-operation and Development |

| RPM | Regional meeting of the FUSIONS European Platform |

| S1 | Social food waste drivers related to wide social dynamics that are not readily changeable |

| S2 | Social food waste drivers related to consumers’ individual behaviours that are not readily changeable |

| S3 | Social food waste drivers related to consumers’ individual behaviours modifiable through information and improved awareness |

| T1 | Technological drivers inherent to the characteristics of food, and of its production and consumption, where technology has become limited |

| T2 | Technological drivers related to collateral effects of modern technologies |

| T3 | Technological drivers related to the suboptimal use of, and mistakes in the use of modern technology |

| UK | United Kingdom |

| UN | United Nations |

| USDA | United States Department of Agriculture |

| USEPA | United States Environmental Protection Agency |

| VAT | Value Added Tax |

| WRAP | Waste and Resources Action Programme |

Appendix A

| Type of Organisation | Number of Stakeholders | Countries |

|---|---|---|

| Food retailers | 13 | UK, Turkey, The Netherlands, Sweden, Italy, Denmark, Greece, Hungary. |

| Consumer groups, social organisations, charities, and other non-governmental organisations | 33 | UK, The Netherlands, Poland, Germany, Sweden Finland, Italy, Hungary, France, Russia, Estonia, Switzerland, Spain, Ireland, Greece, Czech Republic, Belgium. |

| Food service/Hospitality sector | 6 | Italy, UK, Hungary, Greece, Thailand, The Netherlands, Belgium. |

| Governments, Policy makers, Food safety authorities and Regulators | 24 | Greece, Italy, Sweden, The Netherlands, Belgium, UK, Ireland, Hungary, Finland. |

| Food producers/manufacturers | 8 | Denmark, UK, The Netherlands, Finland, Greece, Sweden. |

| Waste Management | 14 | Belgium, Austria, Sweden, Portugal, Finland, Germany, The Netherlands, Spain, Greece, Italy. |

| Other industry: Agriculture, food packaging, ICT, supplier companies, etc. | 26 | Italy, Finland, Sweden, Belgium, UK, Switzerland, Portugal, The Netherlands, India, USA, France. |

| Universities and knowledge institutes | 27 | Greece, UK, Germany, Sweden, The Netherlands, Denmark, Finland, Norway, Switzerland, Italy, Hong Kong, Spain. |

| Regional (RPM) and European (EPM) Meetings of the FUSIONS European Platform (2013–2014) | ||

| (1) RPM Central Europe: 16 May 2013, Hohenheim, Germany; | ||

| (2) RPM Southern Europe: 20 May 2013, Padua, Italy; | ||

| (3) RPM Scandinavia: 23 May 2013, Helsinki, Finland; | ||

| (4) RPM North West Europe: 7 June 2013, Paris, France; | ||

| (5) EPM: 17–18 October 2013, Amsterdam, The Netherlands; | ||

| (6) RPM Southern Europe: 14 March 2014, Athens, Greece; | ||

| (7) RPM Scandinavia: 6 May 2014, Stockholm, Sweden; | ||

| (8) FUSIONS Social Camp on “Social innovation for food waste prevention and reduction”: 8 April 2014, Bologna, Italy; | ||

| (9) RPM Central Europe: 9 May 2014, Düsseldorf, Germany; | ||

References

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Otterdijk, R.; Meybeck, A. Global Food Losses and Food Waste: Extent, Causes and Prevention; FAO: Rome, Italy, 2011. [Google Scholar]

- Lipinski, B.; Hanson, C.; Lomax, J.; Kitinoja, L.; Waite, R.; Searchinger, T. Reducing Food Loss and Waste. World Resour. Inst. 2013, 1–40. Available online: http://staging.unep.org/wed/2013/docs/WRI-UNEP-Reducing-Food-Loss-and-Waste.pdf (accessed on 11 April 2016). [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). Food Wastage Footprint. Impacts on Natural Resources; Summary Report; FAO: Rome, Italy, 2013. [Google Scholar]

- Bio Intelligence Service. Preparatory Study on Food Waste across EU 27; European Commission—DG Environment: Brussels, Belgium, 2010. [Google Scholar]

- European Commission. Roadmap to a Resource Efficient Europe—COM(2011) 571 Final; European Commission: Brussels, Belgium, 2011. [Google Scholar]

- European Parliament. European Parliament Resolution of 19 January 2012 on How to Avoid Food Wastage: Strategies for a More Efficient Food Chain in the EU (2011/2175(INI)); European Parliament: Brussels, Belgium, 2012; p. 8. [Google Scholar]

- United Nations. Transforming Our World: The 2030 Agenda for Sustainable Development-A/RES/70/1; United Nations: New York, NY, USA, 2015. [Google Scholar]

- European Commission. Closing the Loop—An EU Action Plan for the Circular Economy—COM(2015) 614 Final; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- Parfitt, J.; Barthel, M.; Macnaughton, S. Food waste within food supply chains: Quantification and potential for change to 2050. Philos. Trans. R. Soc. Lond. B Biol. Sci. 2010, 365, 3065–3081. [Google Scholar] [CrossRef] [PubMed]

- HLPE. Food Losses and Waste in the Context of Sustainable Food Systems. A Report by the High Level Panel of Experts on Food Security and Nutrition of the Committee on World Food Security; HLPE: Rome, Italy, 2014. [Google Scholar]

- Lanfranchi, M.; Calabrò, G.; De Pascale, A.; Fazio, A.; Giannetto, C. Household food waste and eating behavior: Empirical survey. Br. Food J. 2016, 118, 3059–3072. [Google Scholar] [CrossRef]

- Mondéjar-Jiménez, J.-A.; Ferrari, G.; Secondi, L.; Principato, L. From the table to waste: An exploratory study on behaviour towards food waste of Spanish and Italian youths. J. Clean. Prod. 2016, 138, 8–18. [Google Scholar] [CrossRef]

- Thyberg, K.L.; Tonjes, D.J. Drivers of food waste and their implications for sustainable policy development. Resour. Conserv. Recycl. 2016, 106, 110–123. [Google Scholar] [CrossRef]

- Visschers, V.H.M.; Wickli, N.; Siegrist, M. Sorting out food waste behaviour: A survey on the motivators and barriers of self-reported amounts of food waste in households. J. Environ. Psychol. 2016, 45, 66–78. [Google Scholar] [CrossRef]

- Secondi, L.; Principato, L.; Laureti, T. Household food waste behaviour in EU-27 countries: A multilevel analysis. Food Policy 2015, 56, 25–40. [Google Scholar] [CrossRef]

- Girotto, F.; Alibardi, L.; Cossu, R. Food waste generation and industrial uses: A review. Waste Manag. 2015, 45, 32–41. [Google Scholar] [CrossRef] [PubMed]

- Aschemann-Witzel, J.; de Hooge, I.; Amani, P.; Bech-Larsen, T.; Oostindjer, M. Consumer-Related Food Waste: Causes and Potential for Action. Sustainability 2015, 7, 6457–6477. [Google Scholar] [CrossRef] [Green Version]

- Neff, R.A.; Spiker, M.L.; Truant, P.L. Wasted food: U.S. consumers’ reported awareness, attitudes, and behaviors. PLoS ONE 2015, 10, e0127881. [Google Scholar] [CrossRef] [PubMed]

- Parizeau, K.; von Massow, M.; Martin, R. Household-level dynamics of food waste production and related beliefs, attitudes, and behaviours in Guelph, Ontario. Waste Manag. 2015, 35, 207–217. [Google Scholar] [CrossRef] [PubMed]

- Adams, A. Drivers of Food Waste and Policy Responses to the Issue—The Role of Retailers in Food Supply Chains; Institute for International Political Economy: Berlin, Germany, 2015. [Google Scholar]

- Principato, L.; Secondi, L.; Pratesi, C.A. Reducing food waste: An investigation on the behaviour of Italian youths. Br. Food J. 2015, 117, 731–748. [Google Scholar] [CrossRef]

- Stancu, V.; Haugaard, P.; Lähteenmäki, L. Determinants of consumer food waste behaviour: Two routes to food waste. Appetite 2015, 96, 7–17. [Google Scholar] [CrossRef] [PubMed]

- Betz, A.; Buchli, J.; Göbel, C.; Müller, C. Food waste in the Swiss food service industry—Magnitude and potential for reduction. Waste Manag. 2015, 35, 218–226. [Google Scholar] [CrossRef] [PubMed]

- Lebersorger, S.; Schneider, F. Food loss rates at the food retail, influencing factors and reasons as a basis for waste prevention measures. Waste Manag. 2014, 34, 1911–1919. [Google Scholar] [CrossRef] [PubMed]

- Graham-Rowe, E.; Jessop, D.C.; Sparks, P. Identifying motivations and barriers to minimising household food waste. Resour. Conserv. Recycl. 2014, 84, 15–23. [Google Scholar] [CrossRef]

- Abeliotis, K.; Lasaridi, K.; Chroni, C. Attitudes and behaviour of Greek households regarding food waste prevention. Waste Manag. Res. 2014, 32, 237–240. [Google Scholar] [CrossRef] [PubMed]

- Quested, T.E.; Marsh, E.; Stunell, D.; Parry, A.D. Spaghetti soup: The complex world of food waste behaviours. Resour. Conserv. Recycl. 2013, 79, 43–51. [Google Scholar] [CrossRef]

- Schneider, F. Review of food waste prevention on an international level. Waste Resour. Manag. 2013, 166, 187–203. [Google Scholar] [CrossRef]

- Oelofse, S.H.H.; Nahman, A. Estimating the magnitude of food waste generated in South Africa. Waste Manag. Res. 2012, 31, 80–86. [Google Scholar] [CrossRef] [PubMed]

- Koivupuro, H.K.; Hartikainen, H.; Silvennoinen, K.; Katajajuuri, J.M.; Heikintalo, N.; Reinikainen, A.; Jalkanen, L. Influence of socio-demographical, behavioural and attitudinal factors on the amount of avoidable food waste generated in Finnish households. Int. J. Consum. Stud. 2012, 36, 183–191. [Google Scholar] [CrossRef]

- Williams, H.; Wikström, F.; Otterbring, T.; Löfgren, M.; Gustafsson, A. Reasons for household food waste with special attention to packaging. J. Clean. Prod. 2012, 24, 141–148. [Google Scholar] [CrossRef] [Green Version]

- Baptista, P.; Campos, I.; Pires, I.; Vaz, S.G. Do Campo ao Garfo. Desperdício Alimentar em Portugal; CESTRAS: Lisboa, Portugal, 2012. (In Portuguese) [Google Scholar]

- Mena, C.; Adenso-Diaz, B.; Yurt, O. The causes of food waste in the supplier-retailer interface: Evidences from the UK and Spain. Resour. Conserv. Recycl. 2011, 55, 648–658. [Google Scholar] [CrossRef]

- Waarts, Y.R.; Eppink, M.; Oosterkamp, E.B.; Hiller, S.R.C.H.; van der Sluis, A.A.; Timmermans, T. Reducing Food Waste: Obstacles Experienced in Legislation and Regulations; Wageningen UR: Wageningen, The Netherlands, 2011. [Google Scholar]

- FUSIONS. Report on Food Waste Drivers for Reducing Food Waste and Barriers and Opportunities; EU FP7 FUSIONS Project (No. 311972)—Deliverable 1.5; FUSIONS: Bologna, Italy, 2013. [Google Scholar]

- WRAP. Sector Guidance Note: Preventing Waste in the Fruit and Vegetable Supply Chain Sector; WRAP: Banbury, UK, 2012. [Google Scholar]

- HGCA. Grain Storage Guide for Cereals and Oilseed, 3rd ed.; HGCA Publications: Stoneleigh Park, UK, 2011. [Google Scholar]

- Bhat, R.V.; Miller, J.D. Mycotoxins and food supply. Food Nutr. Agric. 1991, 1. Available online: http://www.fao.org/docrep/U3550t/u3550t0e.htm#mycotoxins and food supply (accessed on 10 September 2016). [Google Scholar]

- Food Standards Agency. Code of Good Agricultural Practice for the Reduction of Mycotoxins in UK Cereals; FSA/1170/0507; Food Standards Agency: London, UK, 2007.

- Atanda, S.A.; Pessu, P.O.; Agoda, S.; Isong, I.U.; Ikotun, I. The concepts and problems of post-harvest food losses in perishable crops. Afr. J. Food Sci. 2011, 5, 603–613. [Google Scholar]

- Davies, G.C.; Bruce, D.M. Fracture mechanics of oilseed rape pods. J. Mater. Sci. 1997, 32, 5895–5899. [Google Scholar] [CrossRef]

- Price, J.S.; Hobson, R.N.; Neale, M.A.; Bruce, D.M. Seed Losses in Commercial Harvesting of Oilseed Rape. J. Agric. Eng. Res. 1996, 65, 183–191. [Google Scholar] [CrossRef]

- Lundqvist, J.; De Fraiture, C.; Molden, D. Saving Water: From Field to Fork. Curbing Losses and Wastage in the Food Chain; SIWI Policy Brief; SIWI: Stockholm, Sweden, 2008. [Google Scholar]

- Brook, L.; WRAP. Helping Consumers Reduce Food Waste—A Retail Survey 2011; WRAP: Banbury, UK, 2012. [Google Scholar]

- Terry, L.; Mena, C.; Williams, A.; Jenney, N.; Whitehead, P. Fruit and Vegetable Resource Maps. Mapping Fruit and Vegetable Waste through the Retail and Wholesale Supply Chain; WRAP: Banbury, UK, 2011. [Google Scholar]

- Johnson, D.; Hipps, N.; Hails, S. Helping Consumers Reduce Fruit and Vegetable Waste: Final Report; RTL044-001; WRAP: Banbury, UK, 2008. [Google Scholar]

- Whitehead, P.; Palmer, M.; Mena, C.; Williams, A.; Walsh, C. Resource Maps for Fresh Meat across Retail and Wholesale Supply Chains; WRAP: Banbury, UK, 2011. [Google Scholar]

- Jayathilakan, K.; Sultana, K.; Radhakrishna, K.; Bawa, A.S. Utilization of byproducts and waste materials from meat, poultry and fish processing industries: A review. J. Food Sci. Technol. 2012, 49, 278–293. [Google Scholar] [CrossRef] [PubMed]

- Buzby, J.C.; Wells, H.F.; Axtman, B.; Mickey, J. Supermarket Loss Estimates for Fresh Fruit, Vegetables, Meat, Poultry, and Seafood and Their Use in the ERS Loss-Adjusted Food Availability Data. EIB-44; USDA—Economic Research Service, 2009. Available online: https://www.ers.usda.gov/publications/pub-details/?pubid=44309 (accessed on 2 August 2016). [Google Scholar]

- Rees, D.; Hipps, N.; Colgan, R.; Thurston, K. Ethylene and Microbial Hotspots in the Fresh Produce Supply Chain; WRAP: Banbury, UK, 2011. [Google Scholar]

- Ridoutt, B.G.; Baird, D.L.; Bastiaans, K.; Darnell, R.; Hendrie, G.A.; Riley, M.; Sanguansri, P.; Syrette, J.; Noakes, M.; Keating, B.A. Short communication: A food-systems approach to assessing dairy product waste. J. Dairy Sci. 2014, 97, 6107–6110. [Google Scholar] [CrossRef] [PubMed]

- Food and Agriculture Organization of the United Nations (FAO). Food Loss Assessments: Causes and Solutions Case Studies in Small-Scale Agriculture and Fisheries Subsectors. Kenya: Banana, Maize, Milk, Fish; FAO—Save Food Global Initiative on Food Loss and Waste Reduction: Rome, Italy, 2014. [Google Scholar]

- Beattie, B.B.; Folley, R.R.W. Production variability in apple crops. II. The long-term behaviour of the English crop. Sci. Hortic. (Amsterdam) 1978, 8, 325–332. [Google Scholar] [CrossRef]

- Ceglar, A.; Toreti, A.; Lecerf, R.; Van der Velde, M.; Dentener, F. Impact of meteorological drivers on regional inter-annual crop yield variability in France. Agric. For. Meteorol. 2016, 216, 58–67. [Google Scholar] [CrossRef]

- Barilla Center for Food and Nutrition. Food Waste: Causes, Impacts and Proposals; Barilla Center for Food and Nutrition: Parma, Italy, 2012. [Google Scholar]

- Milepost Consulting. Left-Out an Investigation of the Causes & Quantities of Crop Shrink; Milepost Consulting: New York, NY, USA, 2012. [Google Scholar]

- House of Lords—European Union Committee. Counting the Cost of Food Waste: EU Food Waste Prevention; HL Paper; Authority of the House of Lords: London, UK, 2014. [Google Scholar]

- Gunders, D. Wasted: How America is losing up to 40 percent of its food from farm to fork to landfill. IP:12-06-B. NRDC Issue Pap. 2012, 1–26. Available online: https://www.nrdc.org/sites/default/files/wasted-food-IP.pdf (accessed on 27 December 2016). [Google Scholar]

- Rutten, M.M. What economic theory tells us about the impacts of reducing food losses and/or waste: Implications for research, policy and practice. Agric. Food Secur. 2013, 2, 13. [Google Scholar] [CrossRef]

- Brook Lyndhurst. DEFRA Project FO0212—Future Trends on Waste Generation and Resource Efficiency in the Food Chain: A Scoping Study. Primary Production; Brook Lyndhurst: London, UK, 2010. [Google Scholar]

- Kelleher, K. Discards in the World’s Marine Fisheries: An Update; FAO: Rome, Italy, 2005. [Google Scholar]

- Diamond, B.; Beukers-Stewart, B.D. Fisheries Discards in the North Sea: Waste of Resources or a Necessary Evil? Rev. Fish. Sci. 2011, 19, 231–245. [Google Scholar] [CrossRef]

- Alverson, D.L.; Freeberg, M.H. A Global Assessment of Fisheries Bycatch and Discards; FAO: Rome, Italy, 1994. [Google Scholar]

- Ahokas, M.; Välimaa, A.-L.; Kankaala, A.; Lötjönen, T.; Virtanen, E. Perunan ja Vihannesten Sivuvirtojen Arvokomponenttien Hyötykäyttö; MTT Rapportti 67; MTT: Helsinki, Finland, 2012. (In Finnish) [Google Scholar]

- Willersinn, C.; Mack, G.; Mouron, P.; Keiser, A.; Siegrist, M. Quantity and quality of food losses along the Swiss potato supply chain: Stepwise investigation and the influence of quality standards on losses. Waste Manag. 2015, 46, 120–132. [Google Scholar] [CrossRef] [PubMed]

- Majewski, E.; Hamulczuk, M.; Malak-rawlikowska, A.; Gębska, M.; Harvey, D. Cost-effectiveness assessment of improving animal welfare standards in the European Agriculture. In Proceedings of the 2012 International Association of Agricultural Economists (IAAE) Triennial Conference, Foz do Iguaçu, Brazil, 18–24 August 2012.

- Menghi, A.; De Roest, K.; Porcelluzzi, A.; Deblitz, C.; Von Davier, Z.; Wildegger, B.; De Witte, T.; Strohm, K.; Garming, H.; Dirksmeyer, W.; et al. Assessing Farmers’ Cost of Compliance with EU Legislation in the Fields of Environment, Animal Welfare and Food Safety; AGRI-2011-EVAL-08; Centro Ricerche Produzioni Animali—European Commission, DG for Agriculture and Rural Development: Reggio Emilia, Italy, 2014. [Google Scholar]

- Harley, S.; More, S.; Boyle, L.; O’connell, N.; Hanlon, A. Good animal welfare makes economic sense: Potential of pig abattoir meat inspection as a welfare surveillance tool. Irish Vet. J. 2012, 65, 11. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Aviagen. Broiler Carcass Condemnation and Downgrade Management, Pocket Guide; Aviagen Group: Huntsville, AL, USA, 2014. [Google Scholar]

- St-Pierre, N.R.; Cobanov, B.; Schnitkey, G. Economic Losses from Heat Stress by US Livestock Industries 1. J. Dairy Sci. 2003, 86, E52–E77. [Google Scholar] [CrossRef]

- University of Kentucky. Poultry Production Manual; University of Kentucky—Kentucky Poultry Energy Efficiency Project: Lexington, KY, USA, 2014. [Google Scholar]

- Eisler, M.C.; Lee, M.R.F.; Tarlton, J.F.; Martin, G.B.; Beddington, J.; Dungait, J.A. J.; Greathead, H.; Liu, J.; Mathew, S.; Miller, H.; et al. Agriculture: Steps to sustainable livestock. Nature 2014, 507, 32–34. [Google Scholar] [CrossRef] [PubMed]

- Somsen, D. Production yield analysis in food processing—Applications in the French-fries and the poultry industries. J. Am. Stud. 2004, 22, 108–109. [Google Scholar]

- Svenberg, S.; Torgå, K. Waste analysis—An application of the DMAIC methodology at Lantmännen Axa. Independent Thesis Advanced Level (Professional Degree), Luleå Universitet, 2007. Available online: http://ltu.diva-portal.org/smash/get/diva2:1027485/FULLTEXT01.pdf (accessed on 31 July 2016). [Google Scholar]

- Stuart, T. Waste—Uncovering the Global Food Scandal; Penguin Books: London, UK, 2009. [Google Scholar]

- Ridgway, J.S.; Henthorn, K.S.; Hull, J.B. Controlling of overfilling in food processing. J. Mater. Process. Technol. 1999, 92, 360–367. [Google Scholar] [CrossRef]

- Brook Lyndhurst. DEFRA Project FO0212—Future Trends on Waste Generation and Resource Efficiency in the Food Chain: A Scoping Study. Manufacturing and Processing; Brook Lyndhurst: London, UK, 2010. [Google Scholar]

- Kantor, L.S.; Lipton, K.; Manchester, A.; Oliveira, V. Estimating and addressing America’s food losses. Food Rev. 1997, 20, 2–12. [Google Scholar]

- George, R.M.; Burgess, P.J.; Thorn, R.D. Reducing Food Waste through the Chill Chain; WRAP: Banbury, UK, 2010. [Google Scholar]

- WRAP; Hovis; Link Consumer Strategies; Campden BRI. Reducing Household Bakery Waste; WRAP: Banbury, UK, 2011. [Google Scholar]

- WRAP; French-Brooks, J. Reducing Supply Chain and Consumer Potato Waste; WRAP: Banbury, UK, 2012. [Google Scholar]

- Lee, P.; Willis, P. Waste Arisings in the Supply of Food and Drink to Households in the UK; WRAP: Banbury, UK, 2010. [Google Scholar]

- Concito. The Hidden Food Waste Mapping and Recommendations; Concito: Copenhagen, Denmark, 2011. [Google Scholar]

- Mena, C.; Whitehead, P. Evidence on the Role of Supplier-Retailer Trading Relationships and Practices in Waste Generation in the Food Chain; Cranfield University: Cranfield, UK, 2008. [Google Scholar]

- Stenmark, Å.; Hanssen, O.J.; Silvennoinen, K.; Katajajuuri, J.-M.; Werge, M. Initiatives on Prevention of Food Waste in the Retail and Wholesale Trades; Nordic Council of Ministers: Copenhagen, Denmark, 2011. [Google Scholar]

- Kranert, M.; Hafner, G.; Barabosz, J.; Schuller, H.; Leverenz, D.; Kölbig, A.; Schneider, F.; Lebersorger, S.; Scherhaufer, S. Ermittlung der weggeworfenen Lebensmittelmengen und Vorschläge zur Verminderung der Wegwerfrate bei Lebensmitteln in Deutschland; Universität Stuttgart und Abluft Universität für Bodenkultur Wien: Stuttgart, Germany, 2012. (In German) [Google Scholar]

- Andersson, E.; Köhlerstrand, M.; Lindqvist, M.; Mellgren, E.; Rydmark, H. Maten Som Försvann; SLU: Uppsala, Sweden, 2010. (In Swedish) [Google Scholar]

- Fehr, M.; Romão, D.C. Measurement of Fruit and Vegetable Losses in Brazil: A Case Study. Environ. Dev. Sustain. 2001, 3, 253–263. [Google Scholar] [CrossRef]

- Eriksson, M.; Strid, I. Food Loss in the Retail Sector—A Study of Food Waste in Six Grocery Stores; Swedish University of Agricultural Sciences—Department of Energy and Technology: Uppsala, Sweden, 2011. [Google Scholar]

- Schneider, F.; Scherhaufer, S. Aufkommen und Verwertung Ehemaliger Lebensmittel—Am Beispiel von Brot und Gebäck; Universität für Bodenkultur—Institut für Abfallwirtschaft: Wien, Austria, 2009. (In German) [Google Scholar]

- Eriksson, M. Retail Food Wastage a Case Study Approach to Quantities and Causes; Department of Energy and Technology, Swedish University of Agricultural Sciences, Licenciate Thesis: Uppsala, Sweden, 2012. [Google Scholar]

- Bjurkull, L. En Jämförelse Mellan Några Kravmärkta och Konventionella Livsmedel Med Avseende på Förpackningar, Svinn och Transporter. Master’s Thesis, Stockholm University—Stockholm Resilience Centre, Stockholm, Sweden, 2002. [Google Scholar]

- Jensen, C.; Stenmarck, Å.; Sörme, L.; Dunsö, O. Matavfall 2010 Från Jord till Bord; IVL Svenska Miljöinstitutet: Stockholm, Sweden, 2011. (In Swedish) [Google Scholar]

- Cordingley, F.; Reeve, S.; Stephenson, J. Food Waste in Schools; WRAP: Banbury, UK, 2011. [Google Scholar]

- USDA; USEPA. Waste Not, Want Not: Feeding the Hungry and Reducing Solid Waste Through Food Recovery; EPA 530-R-99-040; USEPA: Washington, DC, USA, 1999.

- Söderlund, M. Mot Minskat Matsvinn i Sollentuna Kommun—För Miljömässiga, Hälsomässiga och Ekonomiska Vinster; Stockholms Universitet—Institutionen för Naturgeografi och Kvartärgeologi, Examensarbete i Miljöskydd och Hälsoskydd: Stockholm, Sweden, 2012. (In Swedish) [Google Scholar]

- Silvennoinen, K.; Heikkilä, L.; Katajajuuri, J.-M.; Reinikainen, A. Food waste volume and origin: Case studies in the Finnish food service sector. Waste Manag. 2015, 46, 140–145. [Google Scholar] [CrossRef] [PubMed]

- Williams, P.; Walton, K. Plate waste in hospitals and strategies for change. E Spen Eur. E J. Clin. Nutr. Metab. 2011, 6, e235–e241. [Google Scholar] [CrossRef]

- Silvennoinen, K.; Koivupuro, H.; Katajajuuri, J.; Jalkanen, L.; Reinikainen, A. Ruokahavikki Suomalaisessa Ruokaketjussa. Foodspill 2010–2012-Hankkeen Loppuraportti; Rapporti 41; MTT: Helsinki, Finland, 2012. (In Finnish) [Google Scholar]

- Marthinsen, J.; Sundt, P.; Kaysen, O.; Kirkevaag, K. Prevention of Food Waste in Restaurants, Hotels, Canteens and Catering; TemaNord 2012:537; Norden—Nordic Council of Ministers: Copenhagen, Denmark, 2012. [Google Scholar]

- Sonnino, R.; McWilliam, S. Food waste, catering practices and public procurement: A case study of hospital food systems in Wales. Food Policy 2011, 36, 823–829. [Google Scholar] [CrossRef]

- Engström, R.; Carlsson-Kanyama, A. Food losses in food service institutions Examples from Sweden. Food Policy 2004, 29, 203–213. [Google Scholar] [CrossRef]

- Bloom, J. American Wasteland: How America Throws away Nearly Half of Its Food (and What We Can Do about It); Da Capo Lifelong Books: Boston, MA, USA, 2010. [Google Scholar]

- Glanz, R. Causes of Food Waste Generation in Households—An Empirical Analysis. University of Natural Resources and Applied Life Sciences. Master’s Thesis, Vienna and Cranfield University, Vienna and Cranfield, UK, 2008. [Google Scholar]

- NHSE Hospitality. Managing Food Waste in the NHS; Hospitality NHS Estates: Leeds, UK, 2005. [Google Scholar]

- Ofei, K.T.; Holst, M.; Rasmussen, H.H.; Mikkelsen, B.E. Effect of meal portion size choice on plate waste generation among patients with different nutritional status. An investigation using Dietary Intake Monitoring System (DIMS). Appetite 2015, 91, 157–164. [Google Scholar] [CrossRef] [PubMed]

- USDA Food and Nutrition Service. Plate Waste. HHFKA Implementation Research Brief Series; 2016. Available online: https://www.fns.usda.gov/sites/default/files/ops/HHFKA-PlateWaste.pdf (accessed on 11 December 2016). [Google Scholar]

- Ofei, K.T.; Holst, M.; Rasmussen, H.H.; Mikkelsen, B.E. How practice contributes to trolley food waste. A qualitative study among staff involved in serving meals to hospital patients. Appetite 2014, 83, 49–56. [Google Scholar] [CrossRef] [PubMed]

- Darlington, R.; Staikos, T.; Rahimifard, S. Analytical methods for waste minimisation in the convenience food industry. Waste Manag. 2009, 29, 1274–1281. [Google Scholar] [CrossRef] [PubMed]

- Salhofer, S.; Obersteiner, G.; Schneider, F.; Lebersorger, S. Potentials for the prevention of municipal solid waste. Waste Manag. 2008, 28, 245–259. [Google Scholar] [CrossRef] [PubMed]

- UK Science and Innovation Network. Workshop report W4, Expert Forum on the Reduction of Food Waste, “How Can Waste Reduction Help to Healthily and Sustainably Feed a Future Global Population of Nine Billion People?”; Foresight Project on Global Food and Farming Futures, Government Office for Sciences: London, UK, 2011.

- Benozzo, M. Il reso del pane nei rapporti tra panificatore e rivenditori al dettaglio: Alimento, mangime, rifiuto. Riv. Dirit. Aliment. 2011, 5, 1–30. (In Italian) [Google Scholar]

- Iacovella, V. Moltiplicato e buttato via: Lo scandalo quoditiano del pane. La Repubblica 2014. Available online: http://www.repubblica.it/fischiailvento/2014/04/23/news/pane_lo_scandalo_quotidiano-84243278/ (accessed on 11 August 2016). (In Italian)[Google Scholar]

- Pekcan, G.; Köksal, E.; Küçürkerdonmez, Ö.; Özel, H. Household Food Waste in Turkey; FAO: Rome, Italy, 2009. [Google Scholar]

- Swedish EPA. Svinn i Livsmedelskedjan. Möjligheter till Minskade Mängder; Rapport 5885; Naturvårdsverket: Stockholm, Sweden, 2008. (In Swedish)

- WRAP; Kantar Worldpanel. Investigation into the Possible Impact of Promotions on Food Waste; WRAP: Banbury, UK, 2011. [Google Scholar]

- Danish Minister of Environment. Katalog over Idéer til Initiativer til Begrænsning af Madspild. Jord og Affald. J. nr. MST-774-00001. 2011. Available online: http://docplayer.dk/5607309-Katalog-over-ideer-til-initiativer-til-begraensning-af-madspild.html (accessed on 27 December 2016). (In Danish)

- Griffin, M.; Sobal, J.; Lyson, T.A. An analysis of a community food waste stream. Agric. Hum. Values 2009, 26, 67–81. [Google Scholar] [CrossRef]

- Worldwatch Institute. State of the World 2011: Innovations that Nourish the Planet; Worldwatch Institute: Washington, DC, USA, 2011. [Google Scholar]

- Gray, S. Down the Drain. Quantification and Exploration of Food and Drink Waste Disposed of to the Sewer by Households in the UK; WRAP: Banbury, UK, 2009. [Google Scholar]

- AHDB Potatoes. War on waste in the potato supply chain. Grow. Gatew. 2012, 5. Available online: https://potatoes.ahdb.org.uk/news/war-waste-potato-supply-chain (accessed on 12 August 2016). [Google Scholar]

- Schneider, F.; Lebersorger, S. Barriers for The Implementation of Prevention Measures Concerning Food Waste. In Proceedings of the 3rd International Conference on Waste—The Social Context: People, Policies, Persuasion and Payoffs, Edmonton, AB, Canada, 8–11 May 2011; pp. 1–11.

- European Union. Commission Implementing Regulation (EU) No 543/2011 of 7 June 2011 Laying down Detailed Rules for the Application of Council Regulation (EC) No 1234/2007 in Respect of the Fruit and Vegetables and Processed Fruit and Vegetables Sectors. Off. J. Eur. Union 2011, L157, 1–163. [Google Scholar]

- Kling, W. Food Waste in Distribution and Use. J. Farm Econ. 1943, 25, 848–859. [Google Scholar] [CrossRef]

- Poppendieck, J. Sweet Charity?: Emergency Food and the End of Entitlement; Viking: New York, NY, USA, 1998. [Google Scholar]

- Hedley, C.; Catchpole, T. The Landing Obligation and Its Implications on the Control of Fisheries; The European Parliament: Brussels, Belgium, 2015. [Google Scholar]

- FUSIONS. Review of EU Legislation and Policies with Implications on Food Waste; EU FP7 FUSIONS Project (No. 311972)—Deliverable 3.1; FUSIONS: Bologna, Italy, 2015. [Google Scholar]

- European Union. Regulation (EC) No. 999/2001 of the European Parliament and of the Council of 22 May 2001 Laying down Rules for the Prevention, Control and Eradication of Certain Transmissible Spongiform Encephalopathies (Consolidated Version 03.02.2016); European Union: Brussels, Belgium, 2001; p. 98. [Google Scholar]

- European Union. Regulation (EC) No. 1069/2009 of the European Parliament and of the Council of 21 October 2009 Laying down Health Rules as Regards Animal by-Products and Derived Products not Intended for Human Consumption and Repealing Regulation (EC) No. 1774/2002 (Consolidated Version 01.01.2014); European Union: Brussels, Belgium, 2009; p. 64. [Google Scholar]

- European Union. Regulation (EU) No 1169/2011 of the European Parliament and of the Council of 25 October 2011 on the Provision of Food Information to Consumers. Off. J. Eur. Union 2011, L304, 18–63. [Google Scholar]

- WRAP. Evaluation of Courtauld Food Waste Target—Phase 1; WRAP: Banbury, UK, 2010. [Google Scholar]

- European Commission; TSN Political and Social. Flash Eurobarometer 425: Food Waste and Date Marking; European Commission, Directorate-General for Communication: Brussels, Belgium, 2015. [Google Scholar]

- Himmelsbach, E.; Allen, A.; Francas, M. Study on the Impact of Food Information on Consumers’ Decision Making; TSN European Behaviour Studies Consortium: Brussels, Belgium, 2014. [Google Scholar]

- Brook Lyndhurst. Consumer Insight: Date Labels and Storage Guidance; WRAP: Banbury, UK, 2011. [Google Scholar]

- WRAP; Leatherhead Food Research. Product Life—Feasibility Study; WRAP: Banbury, UK, 2012. [Google Scholar]

- Watson, M.; Meah, A. Food, waste and safety: Negotiating conflicting social anxieties into the practices of domestic provisioning. Soc. Rev. 2012, 60, 102–120. [Google Scholar] [CrossRef]

- Newsome, R.; Balestrini, C.G.; Baum, M.D.; Corby, J.; Fisher, W.; Goodburn, K.; Labuza, T.P.; Prince, G.; Thesmar, H.S.; Yiannas, F. Applications and Perceptions of Date Labeling of Food. Compr. Rev. Food Sci. Food Saf. 2014, 13, 745–769. [Google Scholar] [CrossRef]

- Perrin, C. Date Labelling and Food Waste: Letter Sent to the European Commission (DG SANCO); BEUC-X-2014-040-05/06/2014; Bureau Européen des Unions de Consommateurs: Brussels, Belgium, 2014. [Google Scholar]

- European Union. Regulation (EC) No. 178/2002 of 28 January 2002 Laying down the General Principles and Requirements of Food Law, Establishing the European Food Safety Authority and Laying down Procedures in Matters of Food Safety. Off. J. Eur. Union 2002, L31, 1–24. [Google Scholar]

- O’Connor, C.; Gheoldus, M.; Jean, O. Comparative Study on EU Member States’ Legislation and Practices on Food Donations; European Economic and Social Committee in Collaboration with Deloitte SA: Brussels, Belgium, 2014. [Google Scholar]

- The Economist Intelligence Unit. Food Loss and Its Intersection with Food Security; The Economist Intelligence Unit: London, UK, 2014. [Google Scholar]

- Fedrigo-Fazio, D.; Brink, P.; Volkery, A.; Russi, D.; Mazza, L.; McKenna, D.; Wunder, S. DYNAMIX Policy Mix Evaluation—Food Waste in the UK; Ecologic Institut: Berlin, Germany, 2013. [Google Scholar]

- Spinelli, F.J.; Corso, B. The Economics of Feeding Processed Food Waste to Swine. In Food Waste to Animal Feed; Westendorf, M.L., Ed.; Iowa State University Press: Ames, IA, USA, 2008; pp. 91–112. [Google Scholar]

- European Union. Council Directive 2006/112/EC of 28 November 2006 on the common system of value added tax. Off. J. Eur. Union 2006, L347, 1–118. [Google Scholar]

- Euroepan Parliament. Answer to a Written Question—Changing the Tax System to Encourage Supermarkets to Redistribute Food—E-002939/2013; Euroepan Parliament: Brussels, Belgium, 2013. [Google Scholar]

- Wenlock, R.W.; Buss, D.H.; Derry, B.J.; Dixon, E.J. Household food wastage in Britain. Br. J. Nutr. 1980, 43, 53. [Google Scholar] [CrossRef] [PubMed]

- Brook Lyndhurst; Cox, J.; Downing, P. Food Behaviour Consumer Research: Quantitative Phase; WRAP: Banbury, UK, 2007. [Google Scholar]

- Baker, D.; Fear, J.; Denniss, R. What a Waste. An Analysis of Household Expenditure on Food—Policy Brief n. 6; The Australia Institute: Manuka, Australia, 2009. [Google Scholar]

- Hamilton, C.; Denniss, R.; Baker, D. Wasteful Consumption in Australia—Discussion Paper n. 77; The Australia Institute: Manuka, Australia, 2005. [Google Scholar]

- Buzby, J.; Muth, M.K.; Kosa, K.M.; Nielsen, S.J.; Karns, S.A. Exploratory Research on Estimation of Consumer-Level Food Loss Conversion Factors Final Report—RTI Project Number 0210449.000.001; USDA, Economic Research Service: Washington, DC, USA, 2007.

- Ventour, L. The Food We Waste; WRAP: Banbury, UK, 2008. [Google Scholar]

- Lebersorger, S.; Schneider, F. Discussion on the methodology for determining food waste in household waste composition studies. Waste Manag. 2011, 31, 1924–1933. [Google Scholar] [CrossRef] [PubMed]

- NSW Environment Protection Authority. Food Waste Avoidance Benchmark Study; Environment Protection Authority: Sydney, Australia, 2012.

- Leung, K. How Social Practices cause Food Waste Generation? Case Study: Students of the University of East Anglia; University of East Anglia, School of Environmental Sciences: Norwich, UK, 2013. [Google Scholar]

- Ganglbauer, E.; Fitzpatrick, G.; Comber, R. Negotiating food waste: Using a Practice Lens to Inform Design. ACM Trans. Comput. Interact. 2013, 20, 1–25. [Google Scholar] [CrossRef]

- Exodus Market Research. We Don’t Waste Food! A Householder Survey; WRAP: Banbury, UK, 2007. [Google Scholar]

- Evans, D. Beyond the Throwaway Society: Ordinary Domestic Practice and a Sociological Approach to Household Food Waste. Sociology 2012, 46, 41–56. [Google Scholar] [CrossRef]

- Herath, D.; Felfel, A. Determinants of consumer food waste behaviour: Homo Economicus vs. Homo Moralis. In Proceedings of the Agriculture and Applied Economics Association Annual Meetings, Boston, MA, USA, 31 July–2 August 2016.

- Silvennoinen, K.; Katajajuuri, J.M.; Hartikainen, H.; Jalkanen, L.; Koivupuro, H.K.; Reinikainen, A. Food waste volume and composition in the Finnish supply chain: Special focus on food service sector. In Proceedings of the 4th International Symposium on Energy from Biomass and Waste, Cini Foundation, Venice, Italy, 12–15 November 2012.

- OECD—Environment Policy Committee. Househoold Food Consumption: Trends, Environmental Impacts and Policy Responses; OECD: Paris, France, 2001. [Google Scholar]

- Sonigo, P.; Bain, J.; Tan, A.; Mudgal, S.; Murphy-Bokern, D.; Shields, L.; Aiking, H.; Verburg, P.P.H.; Erb, K.K.H.; Kastner, T. Assessment of Resource Efficiency in the Food Cycle; ENV.G.4/FRA/2008/0112BIO; Intelligence Service, European Commission: Paris, France, 2012. [Google Scholar]

- Verghese, K.; Lewis, H.; Lockrey, S.; Williams, H. The Role of Packaging in Minimising Food Waste in the Supply Chain of the Future; RMIT University: Melbourne, Australia, 2013. [Google Scholar]

- Milne, R. Arbiters of waste: Date labels, the consumer and knowing good, safe food. Sociol. Rev. 2012, 60, 84–101. [Google Scholar] [CrossRef]

- Almeida, J. Food Losses and Food Waste: A Quantitative Assessment for Switzerland; University of Basel: Basel, Switzerland, 2011. [Google Scholar]

- Flanders, A. Economic Impact of Georgia Tomato Production Value Losses Due to the U.S. Salmonella Outbreak; Center Report; Athenaeum, Center for Agribusiness and Economic Development: Athens, Greece, 2008. [Google Scholar]

- Darlington, R.; Rahimifard, S. Hybrid two-stage planning for food industry overproduction waste minimization. Int. J. Prod. Res. 2007, 45, 4273–4288. [Google Scholar] [CrossRef]

- Quested, T.; Johnson, H. Household Food and Drink Waste in the UK; WRAP: Banbury, UK, 2009. [Google Scholar]

- Selzer, M. Die Entsorgung von Lebensmitteln in Haushalten : Ursachen—Flüsse—Zusammenhänge; Universität für Bodenkultur: Vienna, Austria, 2010. (In German) [Google Scholar]

- Corrado, M. Understanding Consumer Food Management Behaviour; WRAP: Banbury, UK, 2007. [Google Scholar]

- Rathje, W.; Murphy, C. Rubbish!: The Archaeology of Garbage; The University of Arizona Press: Tucson, AZ, USA, 2001. [Google Scholar]

- Evans, D. Blaming the consumer—Once again: The social and material contexts of everyday food waste practices in some English households. Crit. Public Health 2011, 21, 429–440. [Google Scholar] [CrossRef]

- Berlin, J.; Sonesson, U.; Tillman, A.-M. Product Chain Actors’ Potential for Greening the Product Life Cycle. J. Ind. Ecol. 2008, 12, 95–110. [Google Scholar] [CrossRef]

- Brook Lyndhurst. Research into Consumer Behaviour in Relation to Food Dates and Portion Sizes; WRAP: Banbury, UK, 2007. [Google Scholar]

- Brown, T.; Evans, J. Review of Literature about Freezing Food at Home; WRAP: Banbury, UK, 2012. [Google Scholar]

- Stefan, V.; van Herpen, E.; Tudoran, A.A.; Lähteenmäki, L. Avoiding food waste by Romanian consumers: The importance of planning and shopping routines. Food Qual. Prefer. 2013, 28, 375–381. [Google Scholar] [CrossRef]

- Farr-Wharton, G.; Foth, M.; Choi, J.H.-J. Identifying factors that promote consumer behaviours causing expired domestic food waste. J. Consum. Behav. 2014, 13, 393–402. [Google Scholar] [CrossRef]

- Yuan, Y.; Nomura, H.; Takahashi, Y.; Yabe, M. Model of Chinese Household Kitchen Waste Separation Behavior: A Case Study in Beijing City. Sustainability 2016, 8, 1083. [Google Scholar] [CrossRef]

- Grandhi, B.; Appaiah Singh, J. What a Waste! A Study of Food Wastage Behavior in Singapore. J. Food Prod. Mark. 2016, 22, 471–485. [Google Scholar] [CrossRef]

- Bulkeley, H.; Gregson, N. Crossing the threshold: Municipal waste policy and household waste generation. Environ. Plan. A 2009, 41, 929–945. [Google Scholar] [CrossRef] [Green Version]

- Barthel, M.; Adviser, S. The Food We Waste. In Presented at the Conference on Total Food 2009, Sustainability of the Agri-Food Chain, Norwich, UK, 22–24 April 2009.

- Tucker, C.A.; Farrelly, T. Household food waste: The implications of consumer choice in food from purchase to disposal. Local Environ. 2016, 21, 682–706. [Google Scholar] [CrossRef]

- Yates, S. Summary of Existing Information on Domestic Food Waste in New Zealand; WasteMINZ Behaviour Change Sector Group: Auckland, New Zealand, 2013. [Google Scholar]

- Karim Ghani, W.A.; Rusli, I.F.; Biak, D.R.A.; Idris, A. An application of the theory of planned behaviour to study the influencing factors of participation in source separation of food waste. Waste Manag. 2013, 33, 1276–1281. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Brook Lyndhurst. Research into Consumer Behaviour in Relation to Food Dates and Portion Sizes; WRAP: Banbury, UK, 2008. [Google Scholar]

- Smith, C.A.; Belles, R.D.; Simon, A.J. Estimated International Energy Flows 2007—LLNL-TR-473098; Lawrence Livermore National Laboratory: Livermore, CA, USA, 2011. [Google Scholar]

| Reference | Author | Segments of the FSC Addressed | Description and Methods | Geographical Coverage | Classifying FW Causes or Drivers |

|---|---|---|---|---|---|

| [11] | Lanfranchi et al. (2016) | Consumers/households | Questionnaire survey on a large sample of the population of the Province of Messina (Sicily–Italy) investigating households’ food purchase behaviours, reasons for wasting food and attitudes towards preventive actions | Italy | NO |

| [12] | Mondejar-Jimenez et al. (2016) | Consumers/households | Exploratory study, based on a survey involving 380 youths in Italy and Spain, investigating food waste behaviours in the framework of the Theory of Planned Behaviour. | Italy and Spain | NO |

| [13] | Thyberg and Tonjes (2016) | The whole FSC | Large review of historical premises and current main drivers of FW: modernisation of food systems, cultural, socio-demographic, and behavioural factors, and policies causing generation of FW | Mostly the USA | YES |

| [14] | Visschers et al. (2016) | Consumers/households | Investigation on the causes of self-declared FW in household through an e-mail survey (796 questionnaires) | Switzerland | NO |

| [15] | Secondi et al. (2015) | Consumers/households | Multilevel analysis on household food waste behaviour in the European countries based on the results of a Flash Survey of Eurobarometer | Europe | NO |

| [16] | Girotto et al. (2015) | Various | Analysis of FW generation in different FSC sectors under the perspective of recovery for industrial uses (literature review) | Unspecified | NO |

| [17] | Aschemann-Witzel et al. (2015) | Consumers/households | Results of a review of literature and 11 expert interviews on FW causes in households | Unspecified | NO |

| [18] | Neff et al. (2015) | Consumers/households | On-line survey to a representative sample of US consumers (1010 respondents) investigating awareness, attitudes, and behaviours about the waste of food | USA | NO |

| [19] | Parizeau et al. (2015) | Consumers/households | Survey of 68 households in a Canadian middle-sized town and measure of the FW produced. | Canada | NO |

| [20] | Adams (2015) | The whole FSC | Study investigating the role of retailers in the generation of FW across the food supply chain and assessing policy recommendations with respect to its reduction | Europe | YES |

| [21] | Principato et al. (2015) | Consumers/households | Assessment of the awareness on FW issues in a non-probabilistic sample of 233 Italian university students in Rome | Italy | NO |

| [22] | Stancu et al. (2015) | Consumers/households | Analysis of behavioural attitudes towards self-reported household FW in a sample of 1062 Danish consumers | Denmark | NO |

| [23] | Betz et al. (2015) | Food services | Quantification of FW produced by the food services of two big companies operating respectively in the education and in the business sectors | Switzerland | NO |

| [24] | Lebersorger and Schneider (2014) | Retail and markets | Quantification of waste for different categories of food products and investigation of related causes based on FW data collected from 612 Austrian food retail outlets and on a sorting analysis of discarded food in a small sample of the surveyed outlets | Austria | NO |

| [10] | High Level Panel of Experts (2014) | The whole FSC | Report by the High Level Panel of Experts of the Committee on World Food Security (HLPE) reviewing a wide range of causes of FW, and identifying broad categories and levels of causes | Global | YES |

| [25] | Graham-Rowe et al. (2014) | Consumers/households | Qualitative study based on semi-structured interviews to 15 UK households identifying motivations and barriers for FW minimisation | UK | NO |

| [26] | Abeliotis et al. (2014) | Consumers/households | Face-to-face interviews on the FW attitudes and the presence of behavioural good practices preventing FW of 231 Greek consumers | Greece | NO |

| [27] | Quested et al. (2013) | Consumers/households | Analysis on the results of studies on the behaviours of UK consumers towards FW, on how they have been used in public-awareness campaigns, and how they fit the main behavioural theories | UK | NO |

| [28] | Schneider (2013) | The whole FSC | Summary of international research on FW prevention with respect to different continents and food supply chain segments (literature review) | Global | NO |

| [29] | Oelofse and Nahman (2012) | The whole FSC | Estimation of total FW in South Africa based on available food supply data for the country and on estimates of average FW generation at each step of the food supply chain for sub-Saharan Africa | South Africa | NO |

| [30] | Koivupuro et al. (2012). | Consumers/households | Investigation, based on a questionnaire and on a FW diary study, about the influence of socio-demographical, behavioural, and attitudinal factors on the generation of FW in 380 Finnish households | Finland | NO |

| [31] | Williams et al. (2012) | Consumers/households | Study on FW causes in the Swedish household, especially related to packaging, based on the record of self-measured FW produced by 61 families along seven days | Sweden | NO |

| [32] | Baptista et al. (2012) | The whole FSC | Outcomes of a national research project (PERDA) aimed at estimating the total amount of FW in the Portuguese FSC through mass flow analysis, on line questionnaires, and interviews to experts | Portugal | NO |

| [33] | Mena et al. (2011) | Food processing, wholesale and retail | Based on data collected through 43 interviews with managers in food manufacturing, wholesaling and retailing in the UK and Spain, the study discusses the identified root causes of FW and good practices. | Spain, UK | YES |

| [1] | Gustavsson et al. (2011) | The whole FSC | Quantification of global losses occurring along the food supply chain and identification of causes and possible ways of FW prevention | Global | YES |

| [34] | Waarts et al. (2011) | The whole FSC | Investigation on legislation obstacles to food waste reduction based on interviews and two workshops with experts and stakeholders from different FSC segments | Netherlands | YES |

| [4] | Bio Intelligence Service (2010) | The whole FSC | Based on expert interviews and literature and data analysis, the study covers all main aspects of the FW issue in the EU (causes, quantification, environmental impacts, existing policies, and recommendations) | European Union | YES |

| [9] | Parfitt et al. (2010) | The whole FSC | Study based on an international literature review and interviews to food supply chain experts analysing FW definitions, estimates, and causes. | Global | YES |

| Contexts and Sub-Contexts | Clustering Criteria for the Identified Food Waste Drivers |

|---|---|

| Technological | T1—drivers inherent to the characteristics of food, and of its production and consumption, where technology has become limited; |

| T2—drivers related to collateral effects of modern technologies; | |

| T3—drivers related to the suboptimal use of, and mistakes in the use of modern technology; | |

| Institutional—(A) Business management and economy | IBE1—drivers addressable by management solutions operated within one single business unit; |

| IBE2—drivers addressable by management solutions coordinated among different operators of the food supply chain; | |

| IBE3—drivers depending on broader economic and structural variables, not readily addressable by management solutions at the level of single business units or the supply chain; | |

| Institutional—(B) Legislation and policy | ILP1—drivers related to the agricultural policy and to food quality and marketing standards; |

| ILP2—drivers related to food safety, consumer health and information, and animal welfare policies; | |

| ILP3—drivers related to the waste and taxation policies and to other policies; | |

| Social | S1—drivers related to wide social dynamics that are not readily changeable; |

| S2—drivers related to consumers’ individual behaviours that are not readily changeable; | |

| S3—drivers related to consumers’ individual behaviours modifiable through information and improved awareness; |

| Groupings of FW Drivers (Technology) | Identified FW Drivers (Technology) |

|---|---|

| T1—FW drivers inherent to the characteristics of food, and of its production and consumption, where technology has become limited |

|

| T2—FW drivers related to collateral effects of modern technologies |

|

| T3—FW drivers related to the suboptimal use of, and mistakes in the use of modern technology |

|

| Groupings of FW Drivers (Business Management and Economy) | Identified FW Drivers (Business Management and Economy) |

|---|---|

| IBE1—drivers addressable by management solutions operated within one single business unit |

|

| IBE2—drivers addressable through management solutions coordinated among different FSC operators |

|

| IBE3—drivers depending on broader economic and structural variables, not readily addressable by management solutions at the level of single business units or of the FSC |

|

| Groupings of FW Drivers (Legislation and Policy) | Identified FW Drivers (Legislation and Policy) |

|---|---|

| ILP1—drivers related to the agricultural policy and to food quality and marketing standards |

|

| ILP2—drivers related to food safety, consumer health and information, and animal welfare policies |

|

| ILP3—drivers related to the waste and taxation policies and to other policies |

|

| Groupings of FW Drivers (Social) | Identified FW Drivers (Social) |

|---|---|

| S1—drivers related to wide social dynamics that are not readily changeable |

|

| S2—drivers related to consumers’ individual behaviours that are not readily changeable |

|

| S3—drivers related to consumers’ individual behaviours that are modifiable through information and increased awareness |

|

| Cross-Contextual Prioritization of FW Drivers | Groupings of Drivers | Possibilities for FW Reduction |

|---|---|---|

| (A) FW related to the characteristics of food products and the ways through which they are produced and consumed | T1 | Mostly depending on progress in technology and FSC organisation |

| (B) FW related to social and economic factors and dynamics in population habits and lifestyles that are non-readily changeable | IBE3, S1 | Mostly depending on progress in technology and FSC organisation |

| (C) FW related to individual behaviours of consumers that are non-readily changeable | S2 | Mostly depending on progress in technology and FSC organisation |

| (D) FW related to other priorities targeted by private and public stakeholders | T2, IBE2, ILP1, ILP2, ILP3 | Mostly depending on policy measures stimulating FSC operators to improve good practices for FW reduction, within the business and through FSC agreements |

| (E) FW related to non-use or sub-optimal use of available technologies, organisational inefficiencies of supply chain operators, inefficient legislation, and bad behaviours of consumers depending on unawareness, scarce information, and poor food skills | T3, IBE1, ILP1, ILP2, ILP3, S3 | Mostly depending on the amendment of inefficient legislation and on improvements in the individual actions of consumers and FSC operators obtainable through increased awareness, skills, and correct application of available technology |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Canali, M.; Amani, P.; Aramyan, L.; Gheoldus, M.; Moates, G.; Östergren, K.; Silvennoinen, K.; Waldron, K.; Vittuari, M. Food Waste Drivers in Europe, from Identification to Possible Interventions. Sustainability 2017, 9, 37. https://doi.org/10.3390/su9010037

Canali M, Amani P, Aramyan L, Gheoldus M, Moates G, Östergren K, Silvennoinen K, Waldron K, Vittuari M. Food Waste Drivers in Europe, from Identification to Possible Interventions. Sustainability. 2017; 9(1):37. https://doi.org/10.3390/su9010037

Chicago/Turabian StyleCanali, Massimo, Pegah Amani, Lusine Aramyan, Manuela Gheoldus, Graham Moates, Karin Östergren, Kirsi Silvennoinen, Keith Waldron, and Matteo Vittuari. 2017. "Food Waste Drivers in Europe, from Identification to Possible Interventions" Sustainability 9, no. 1: 37. https://doi.org/10.3390/su9010037