Multi-Objective Optimization for Equipment Capacity in Off-Grid Smart House

Abstract

:1. Introduction

Contributions of This Paper

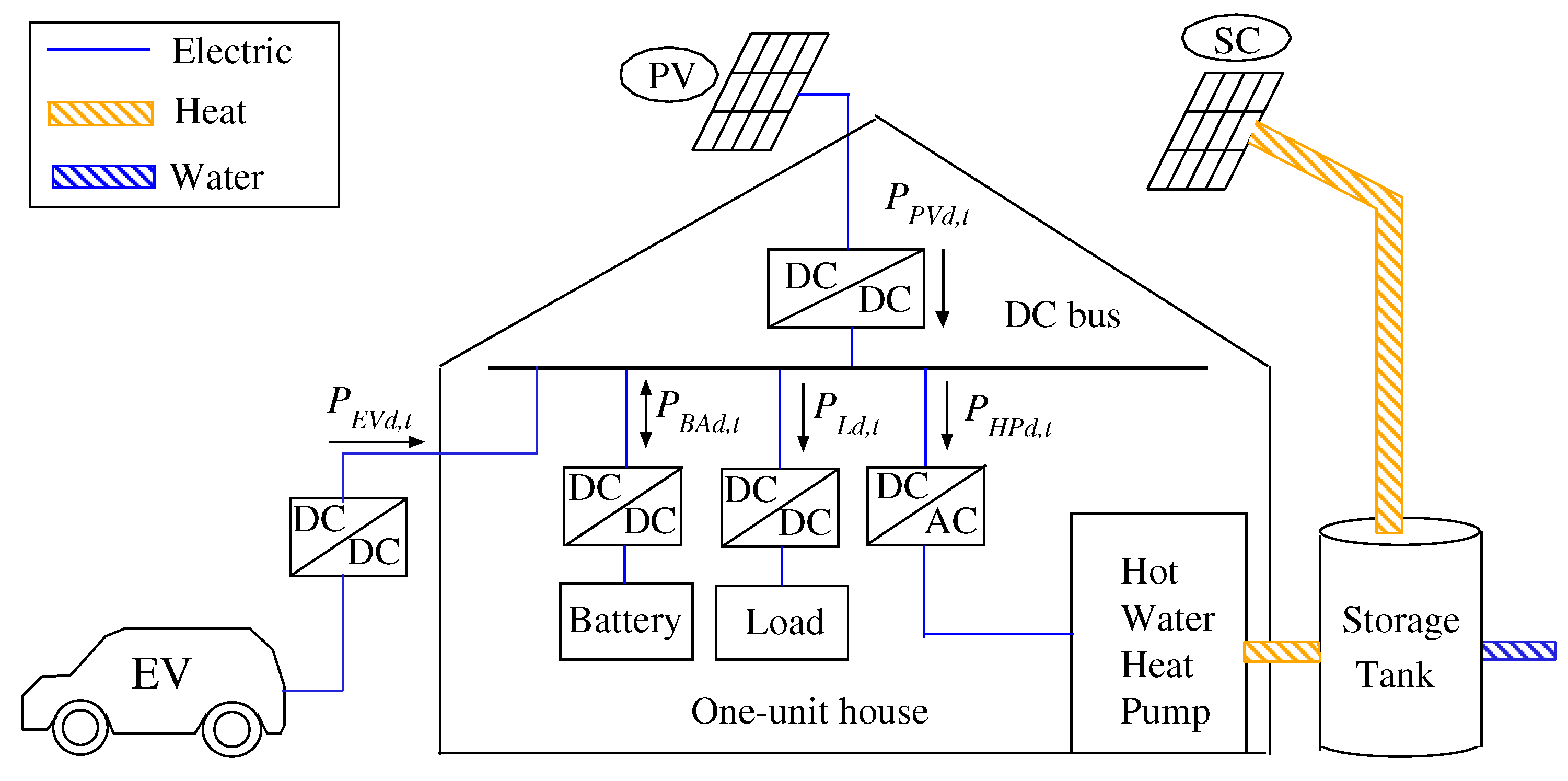

2. Off-Grid Smart House Model

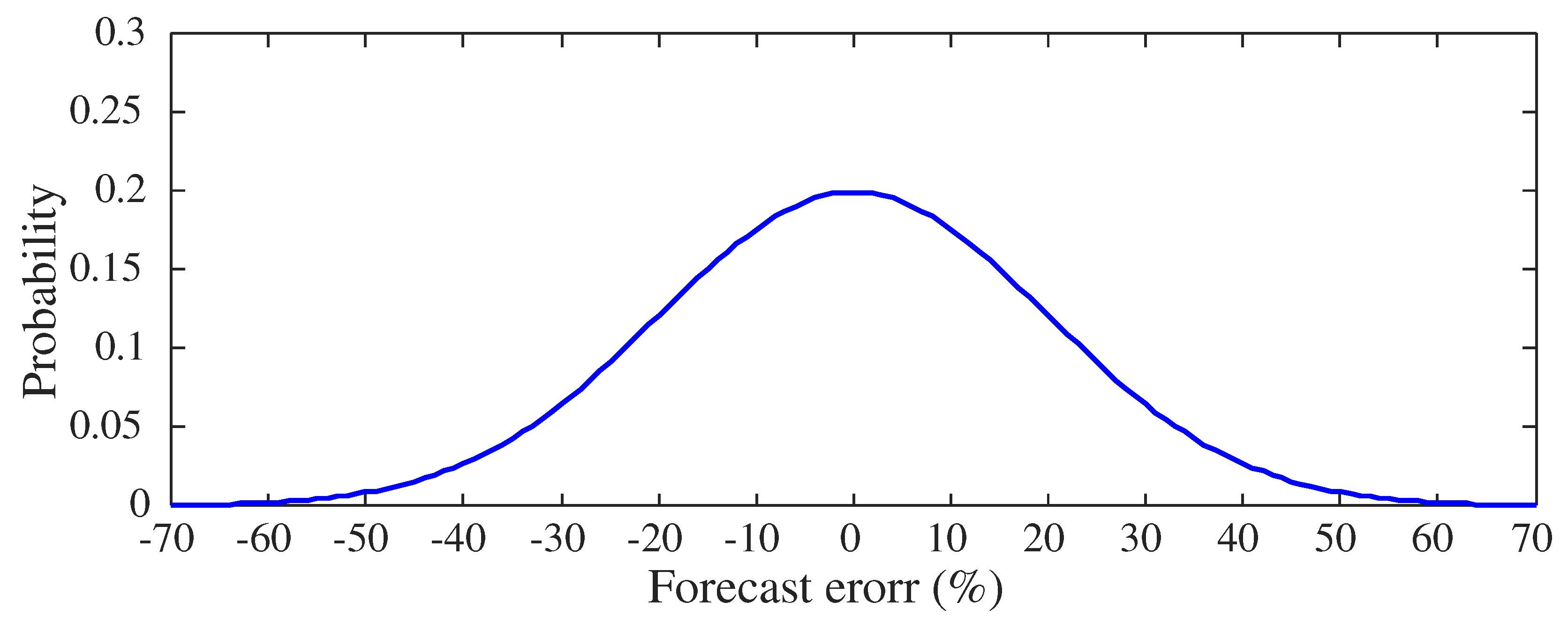

2.1. Photovoltaic System

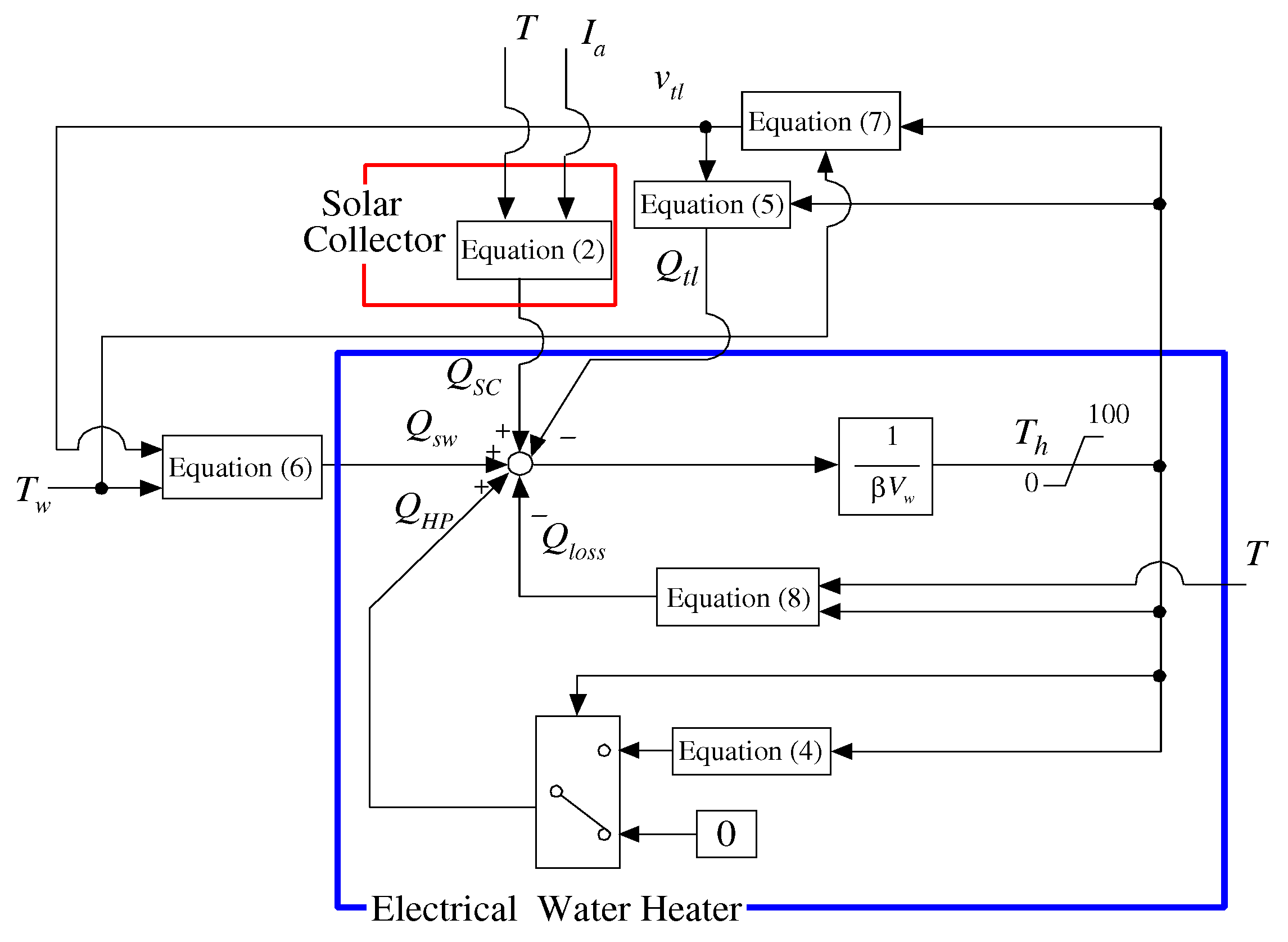

2.2. Solar Collector System

2.3. Fixed Battery Model

- Case A1:

- (): When the PV system of the smart house generates surplus power, according to the following equation, the fixed battery will be charged.where (kW) is the power supply from PV to the fixed battery, (kW) is the power supply from PV to EV, (%) is the charge and discharge efficiency of fixed battery and (hour) is length of time ( (hour)).

- Case A2:

- (): When the PV system of the smart house generates a shortage of power, according to the following equation, the fixed battery will be discharged.

3. Evaluation the Model of the System Capacity

3.1. Estimation of the Shortage of Power Supply

3.2. Estimation of Annual System Cost

3.3. Shortage of the Power Supply Compensation Model Using EV

- Case B1:

- ( occurs when the EV is connected)

- Case B2:

- ( occurs when EV is not connected)

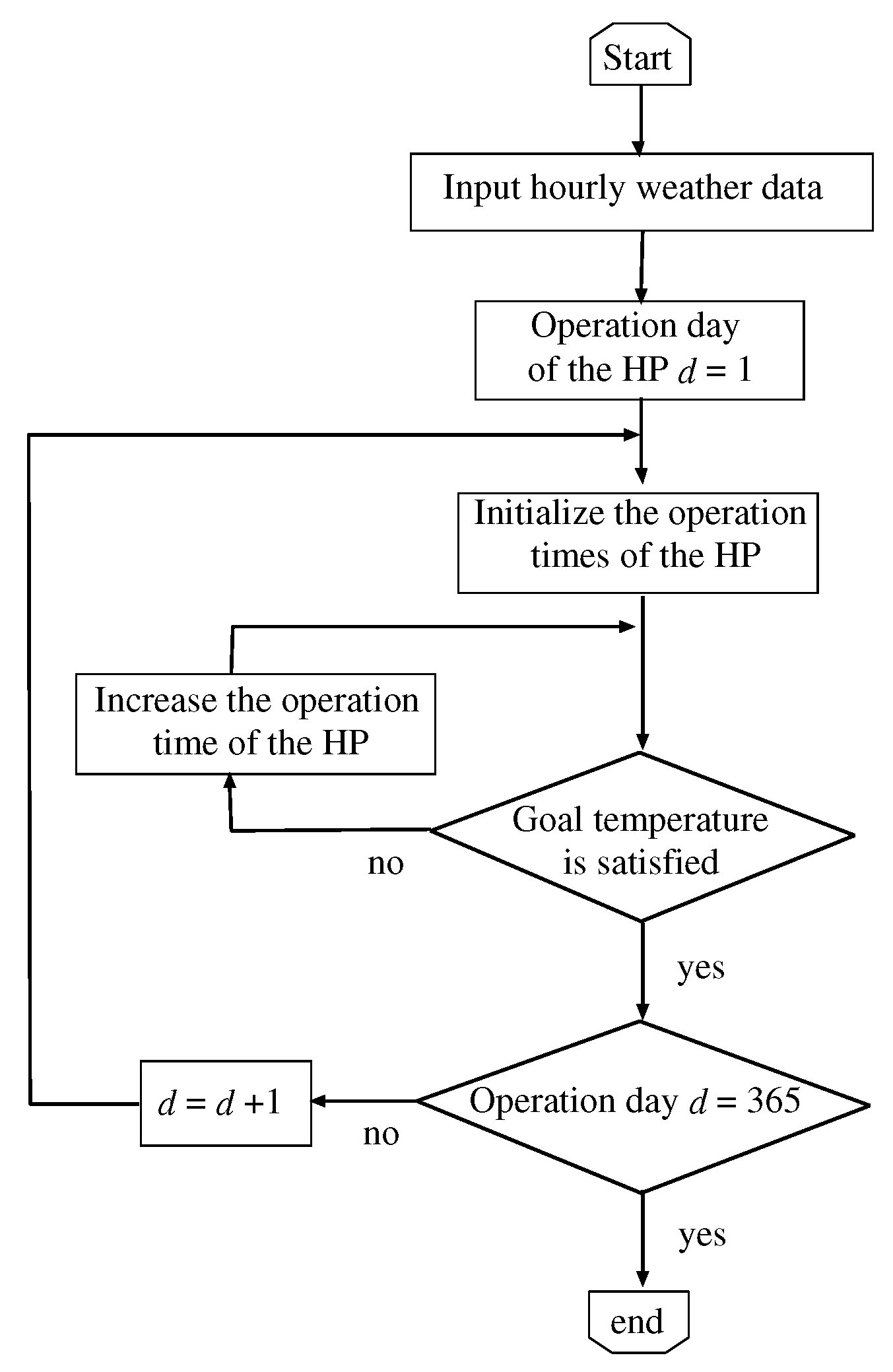

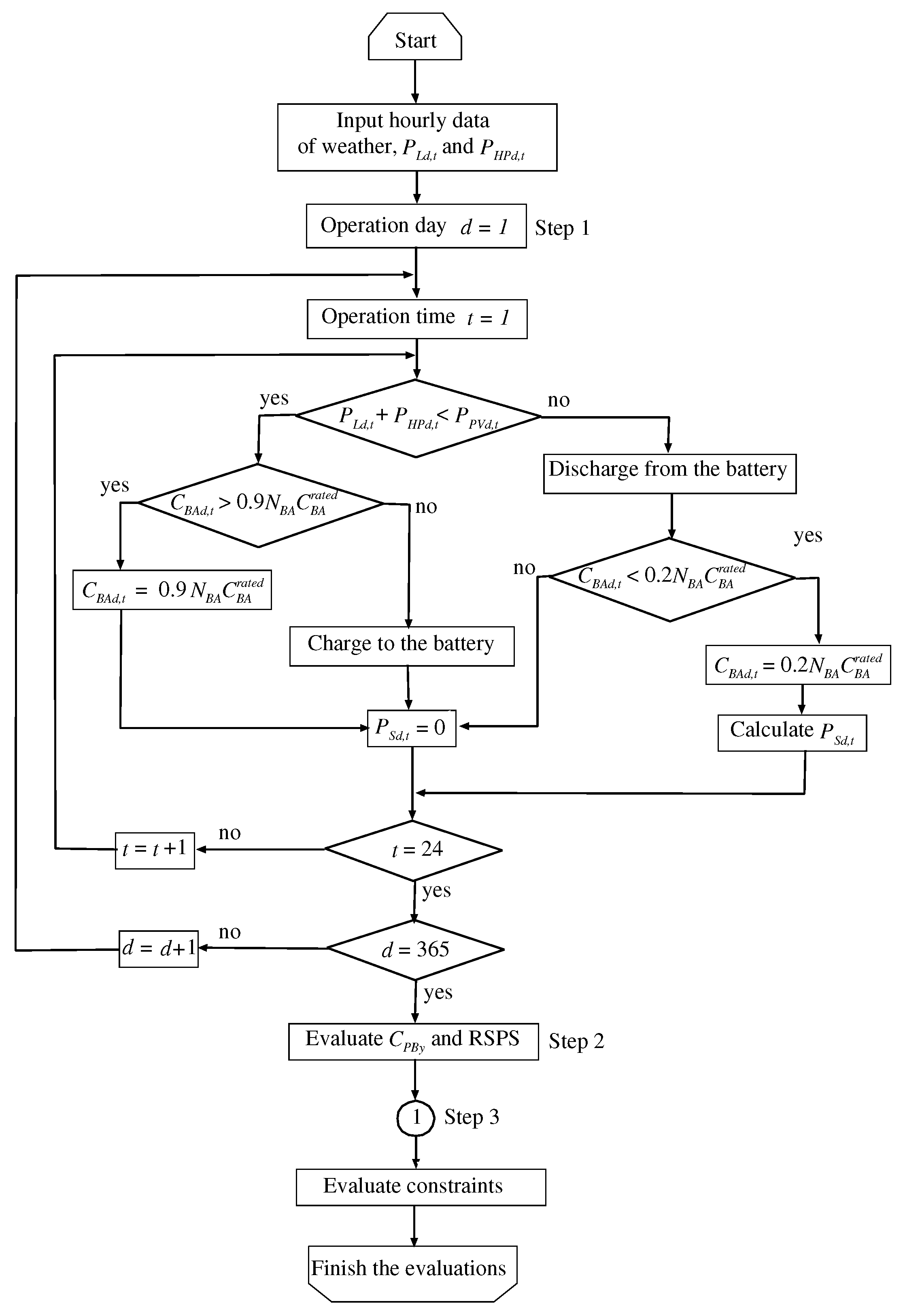

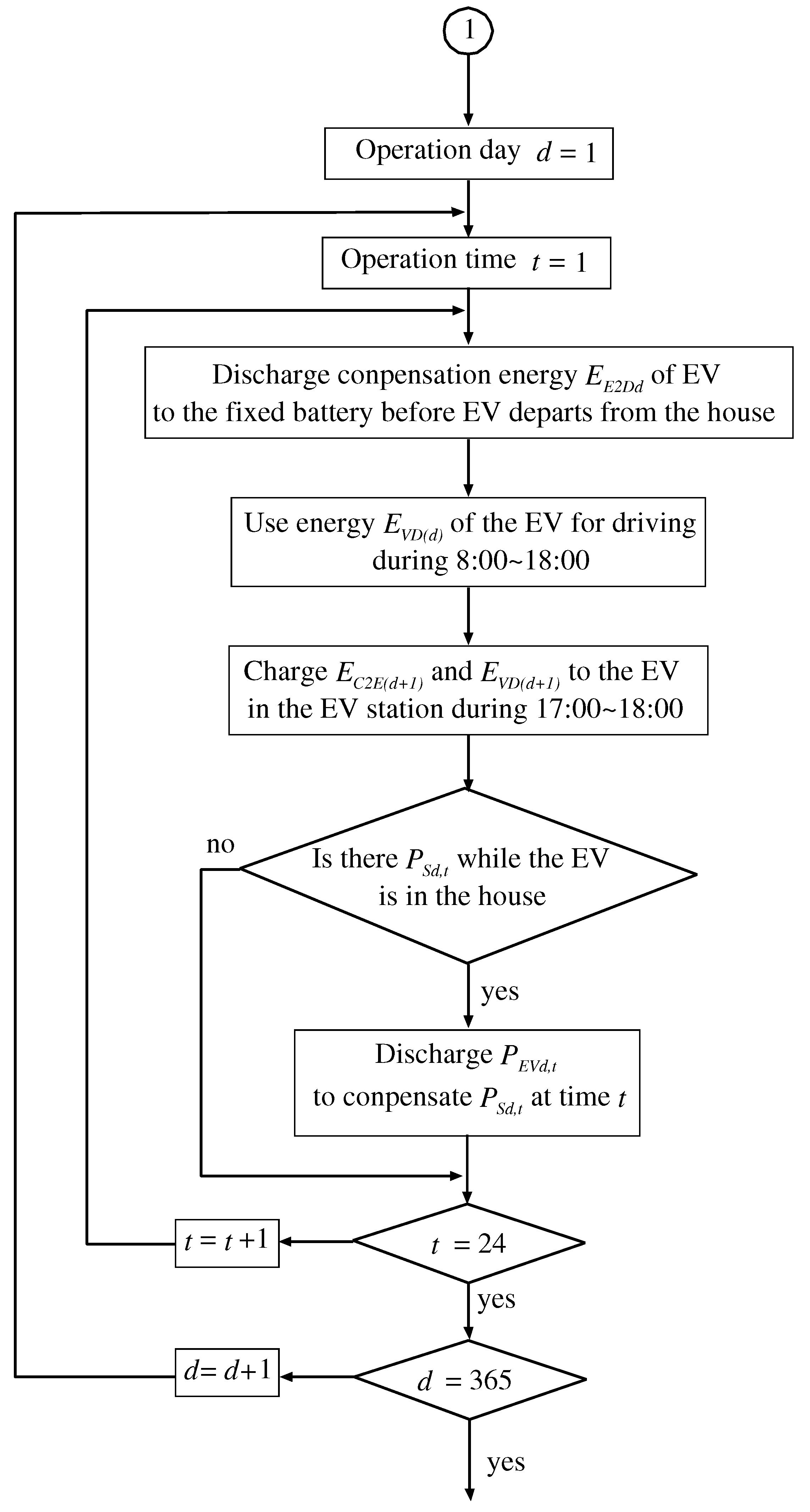

3.4. Capacity-Evaluating Algorithm

- Step 1:

- Calculate and from a given capacity.

- Step 2:

- Calculate system cost and the Rate of Supply Power Shortage .

- Step 3:

- Compensate annual shortage of the power supply from EV.

4. Problem Formulation and Optimization Method

4.1. Objective Function and Constraints

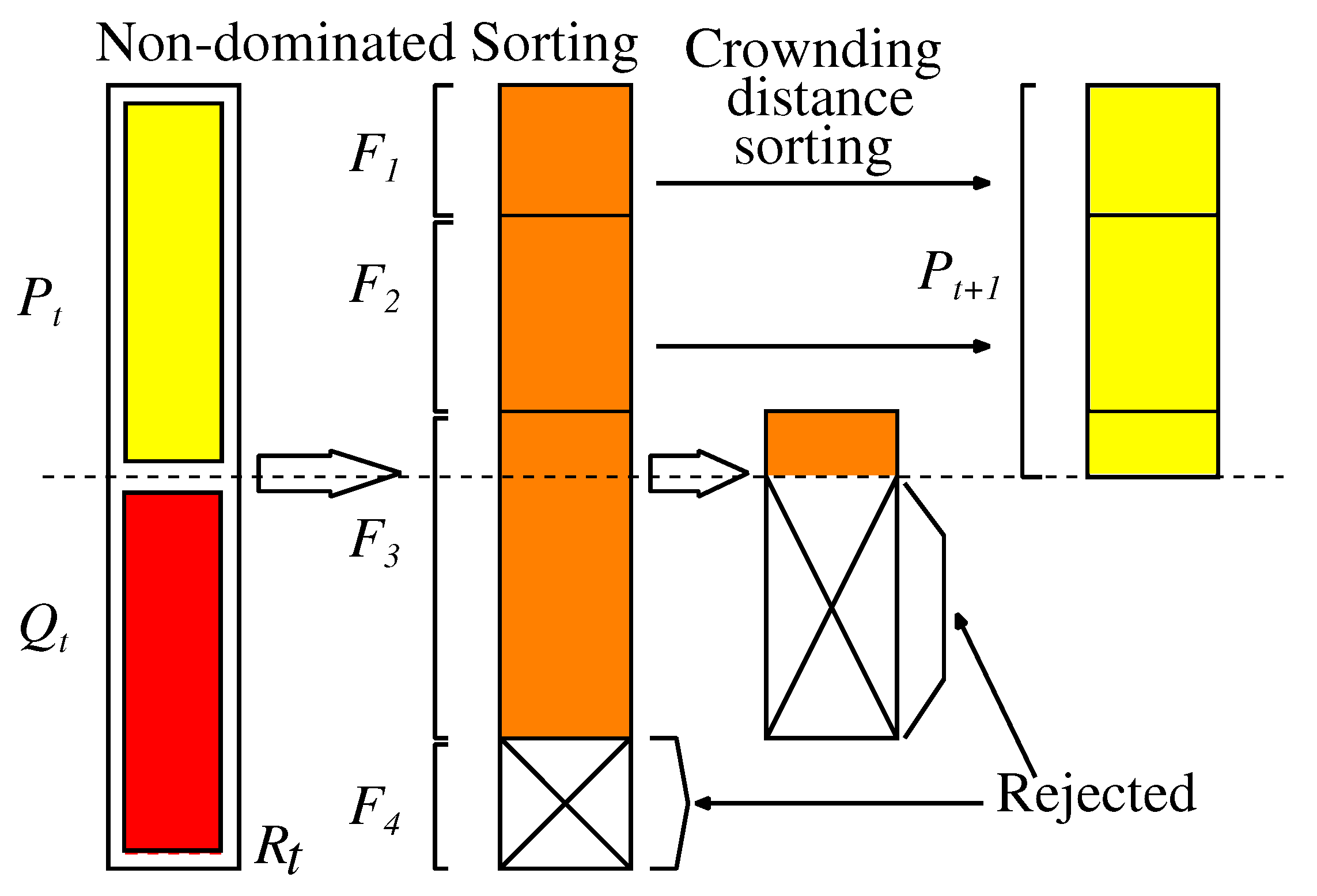

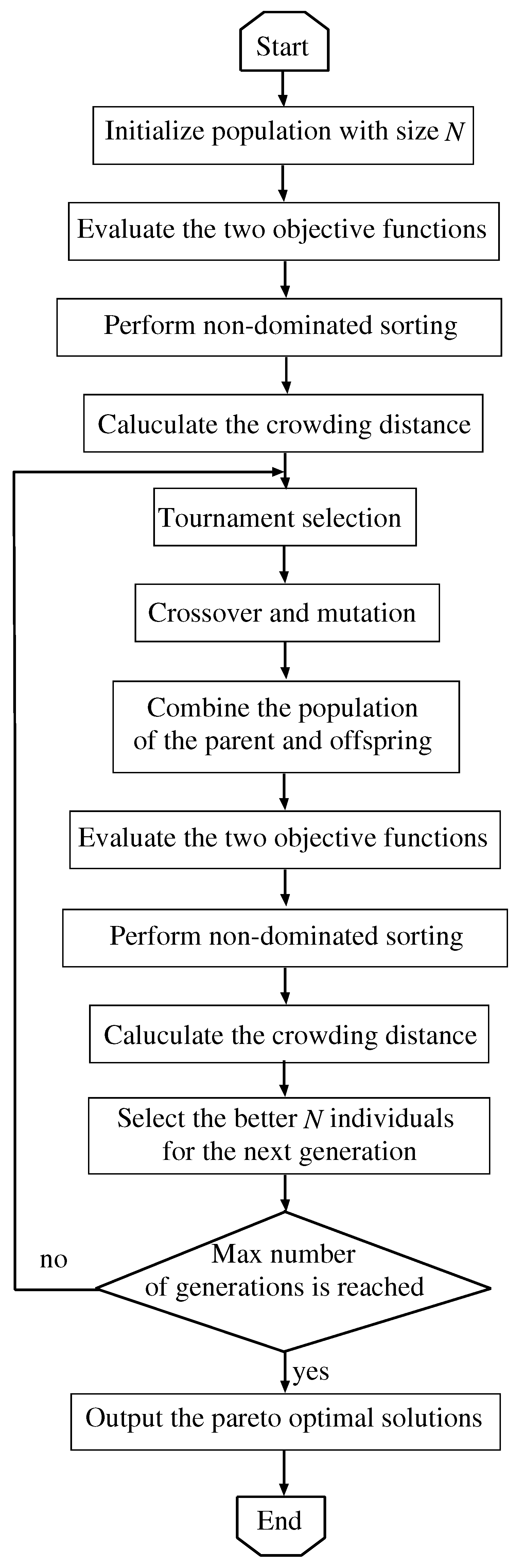

4.2. Multi-Objective Optimization Method

- Step 1:

- Making an initial population P of size N of solutions. P is the parent population.

- Step 2:

- Mutation and crossover are performed in the parent population to make offspring population Q of size N, and combining the parent population and the offspring population, R of size 2N is made.

- Step 3:

- Evaluating the objective function, the Pareto solution is ranked by non-dominated sorting.

- Step 4:

- Individuals in the population are chosen till its size is N from the upper rank Pareto solution, and its population is the parent population in the next generation. If the number of individuals is over size N when the same rank population is chosen, crowding-distance computation is performed.

- Step 5:

- If the generation reaches the max generation, the search is finished. Otherwise, the process returns to Step 2.

5. Simulation Results

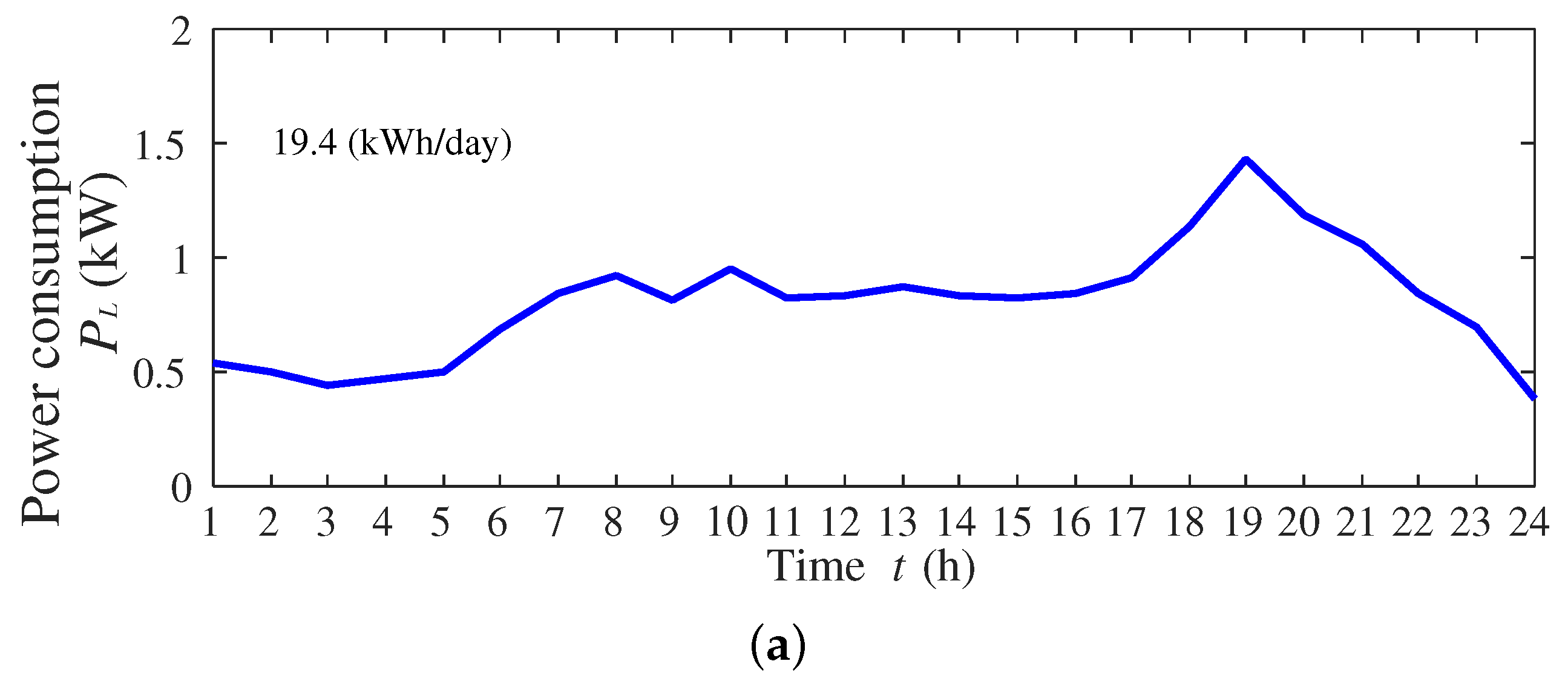

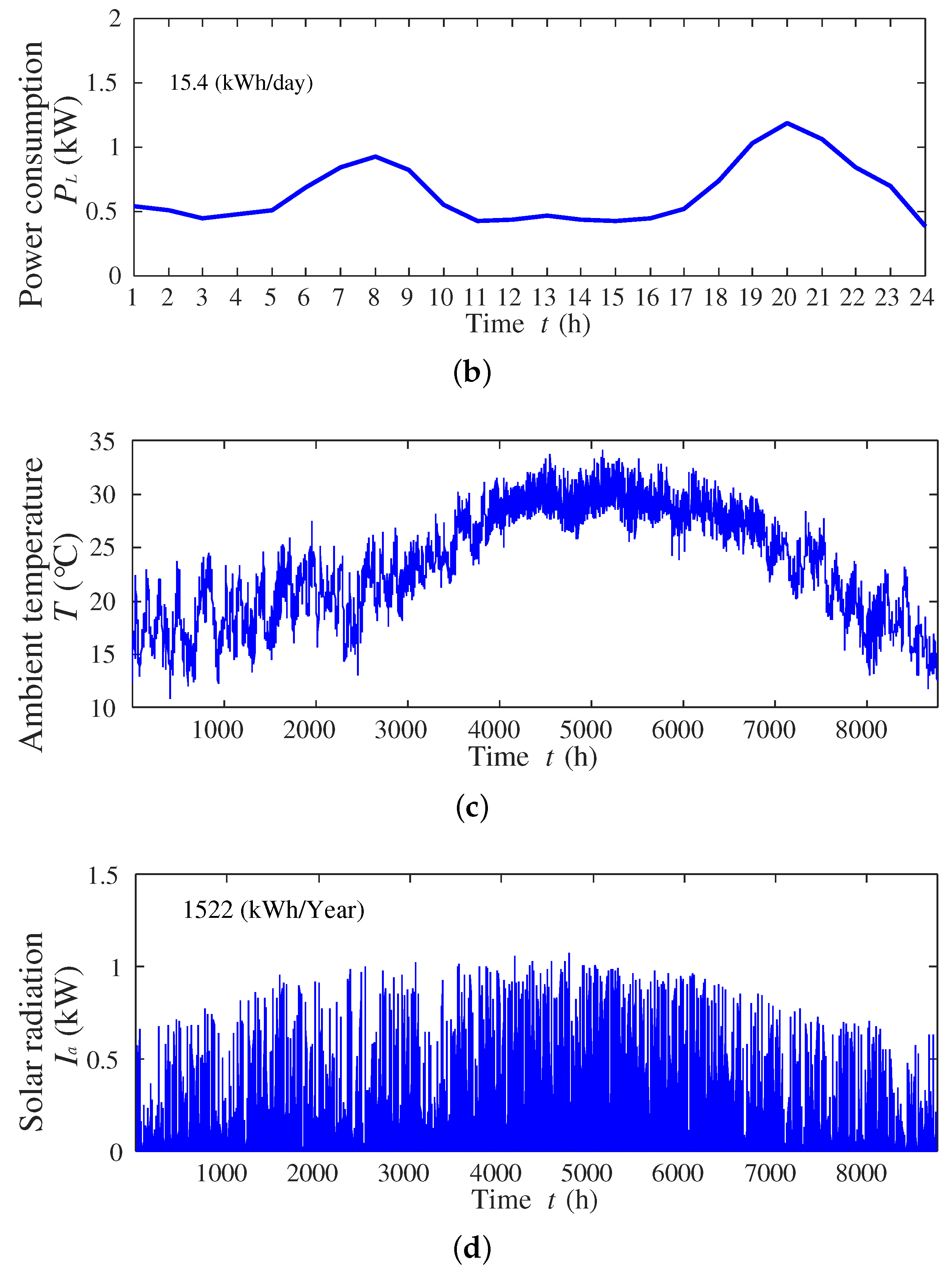

5.1. Simulation Conditions

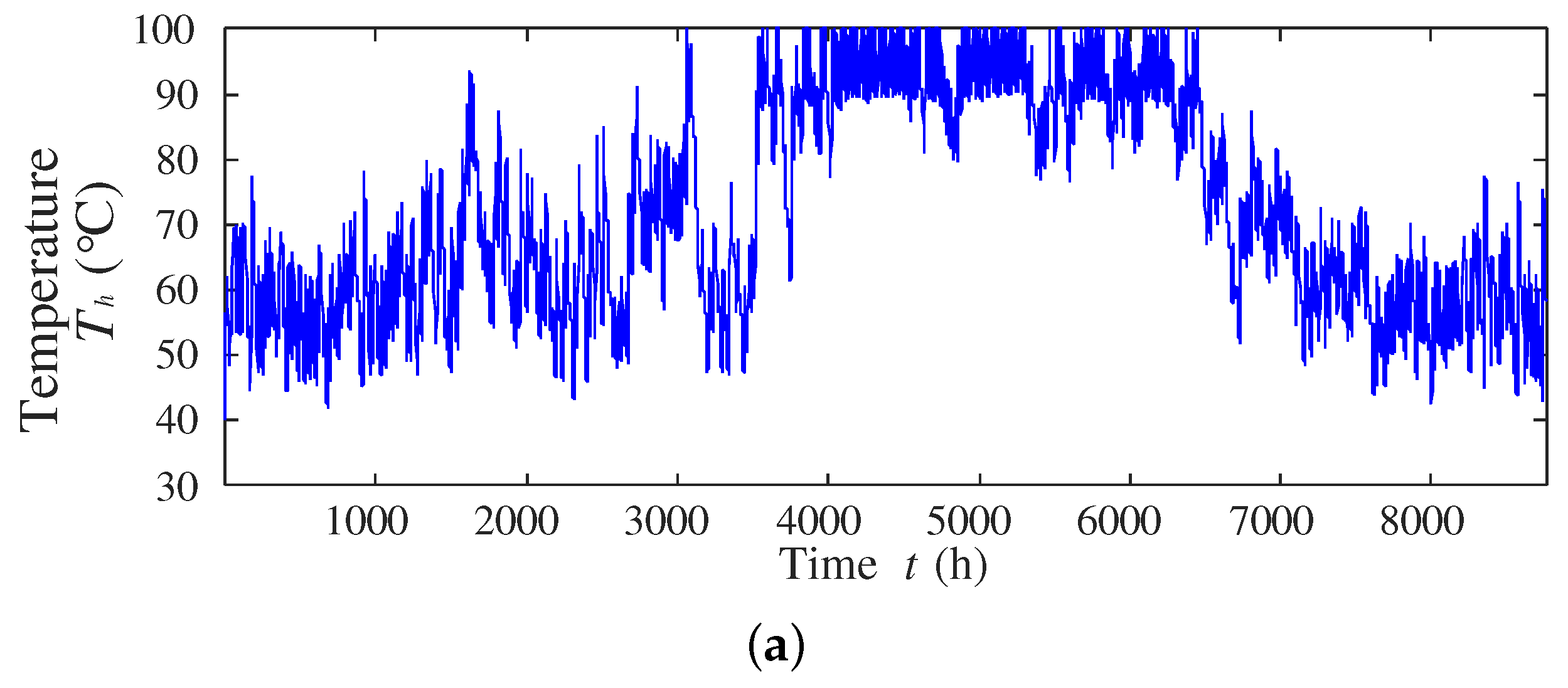

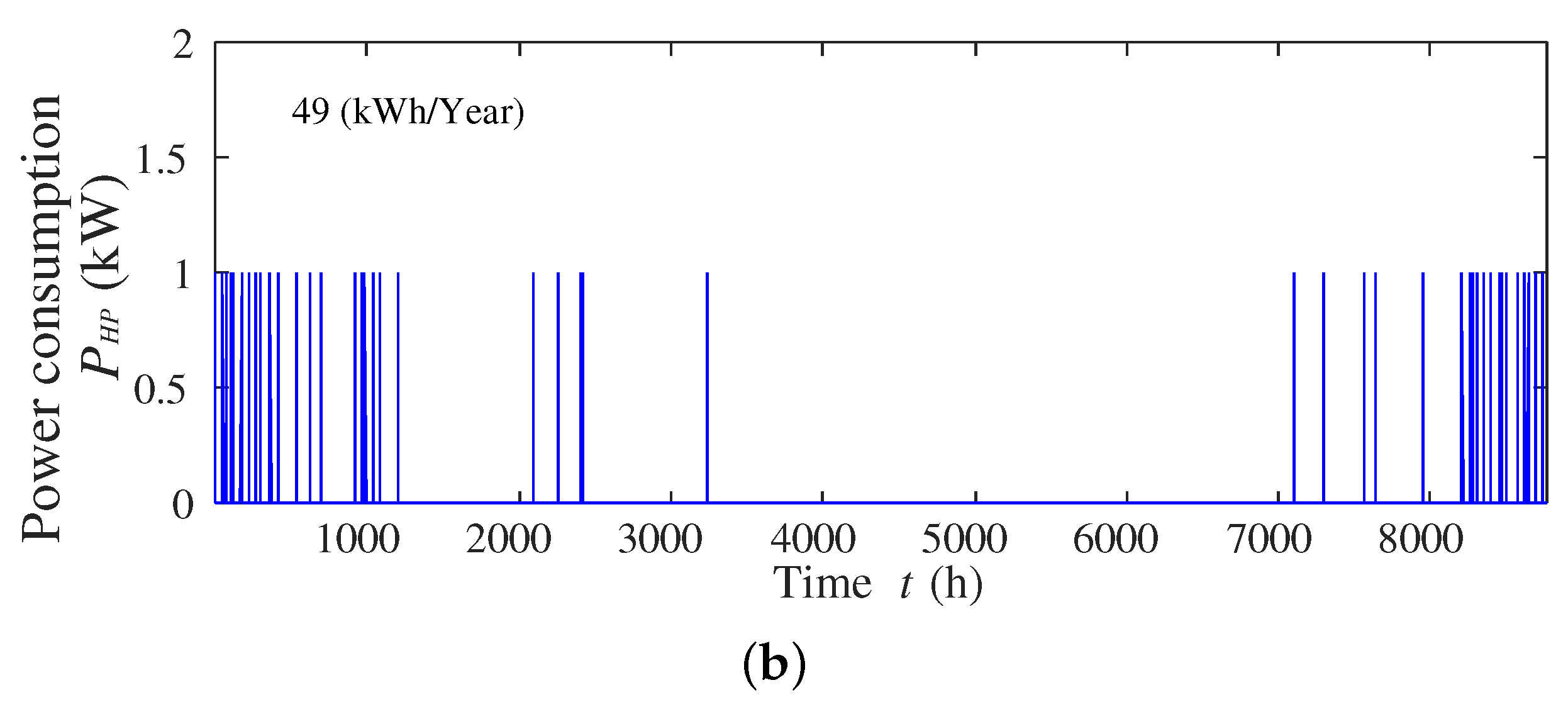

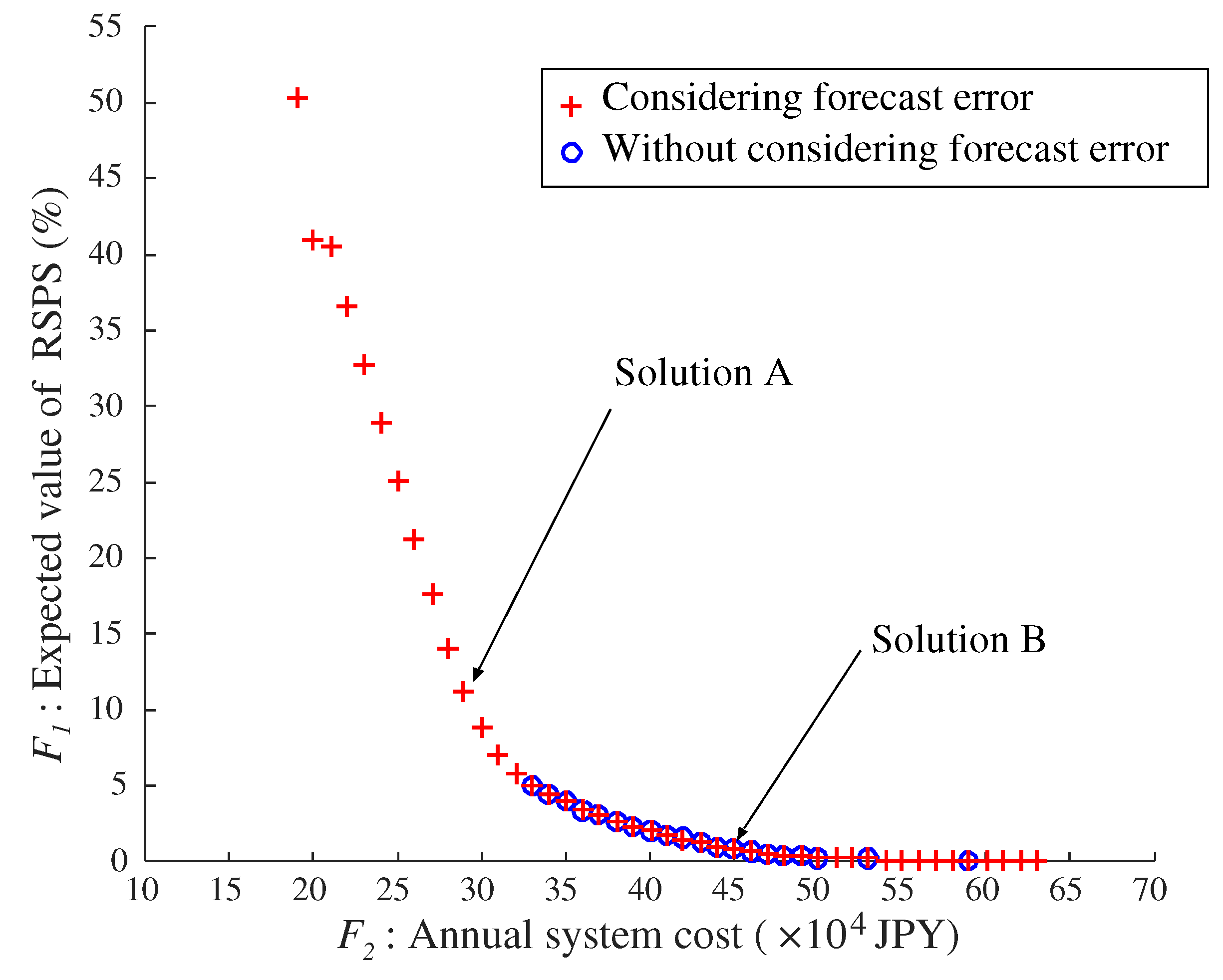

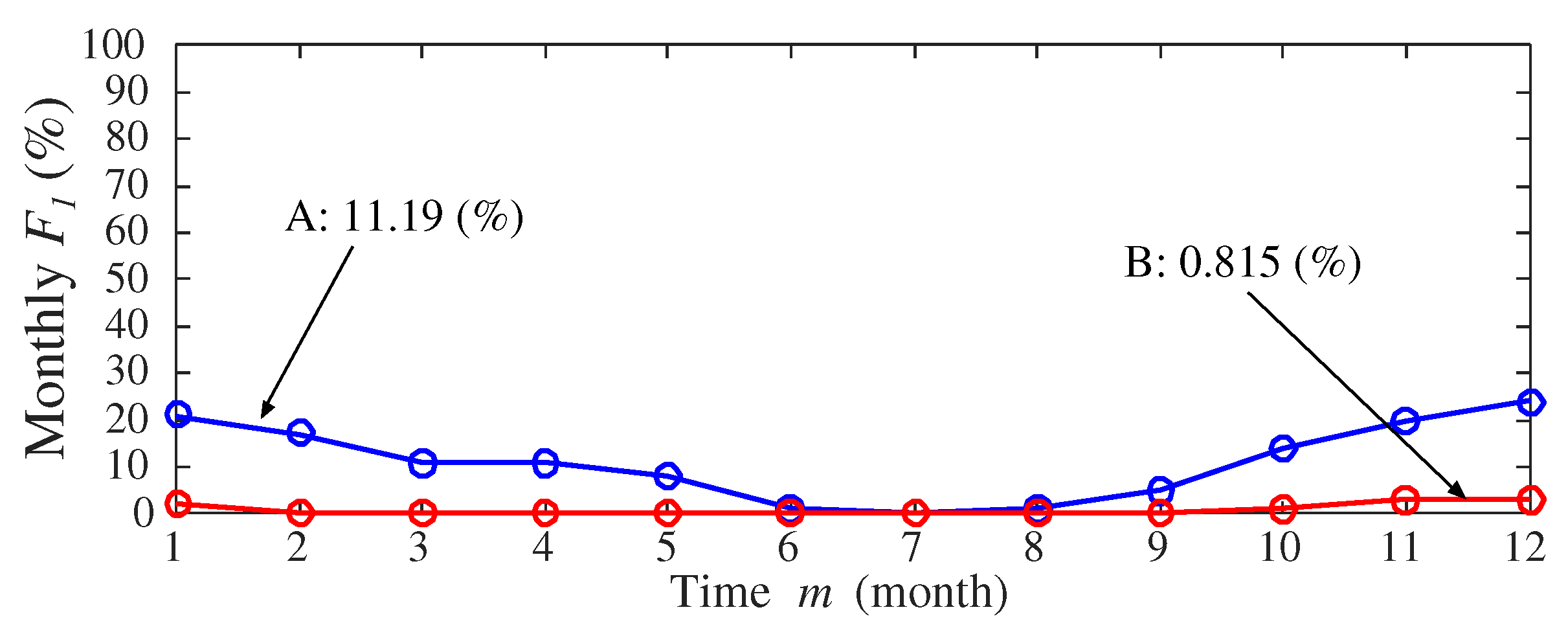

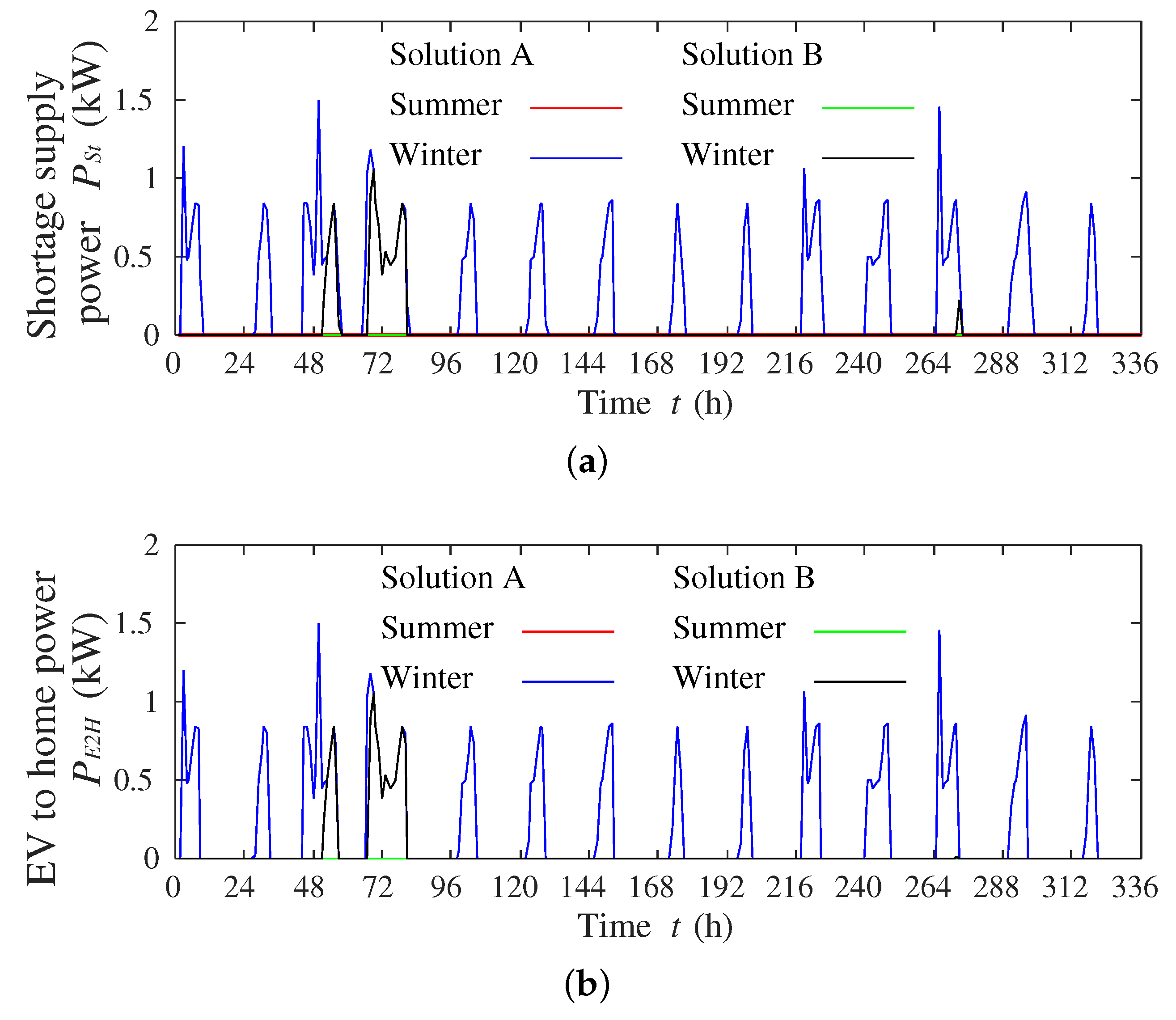

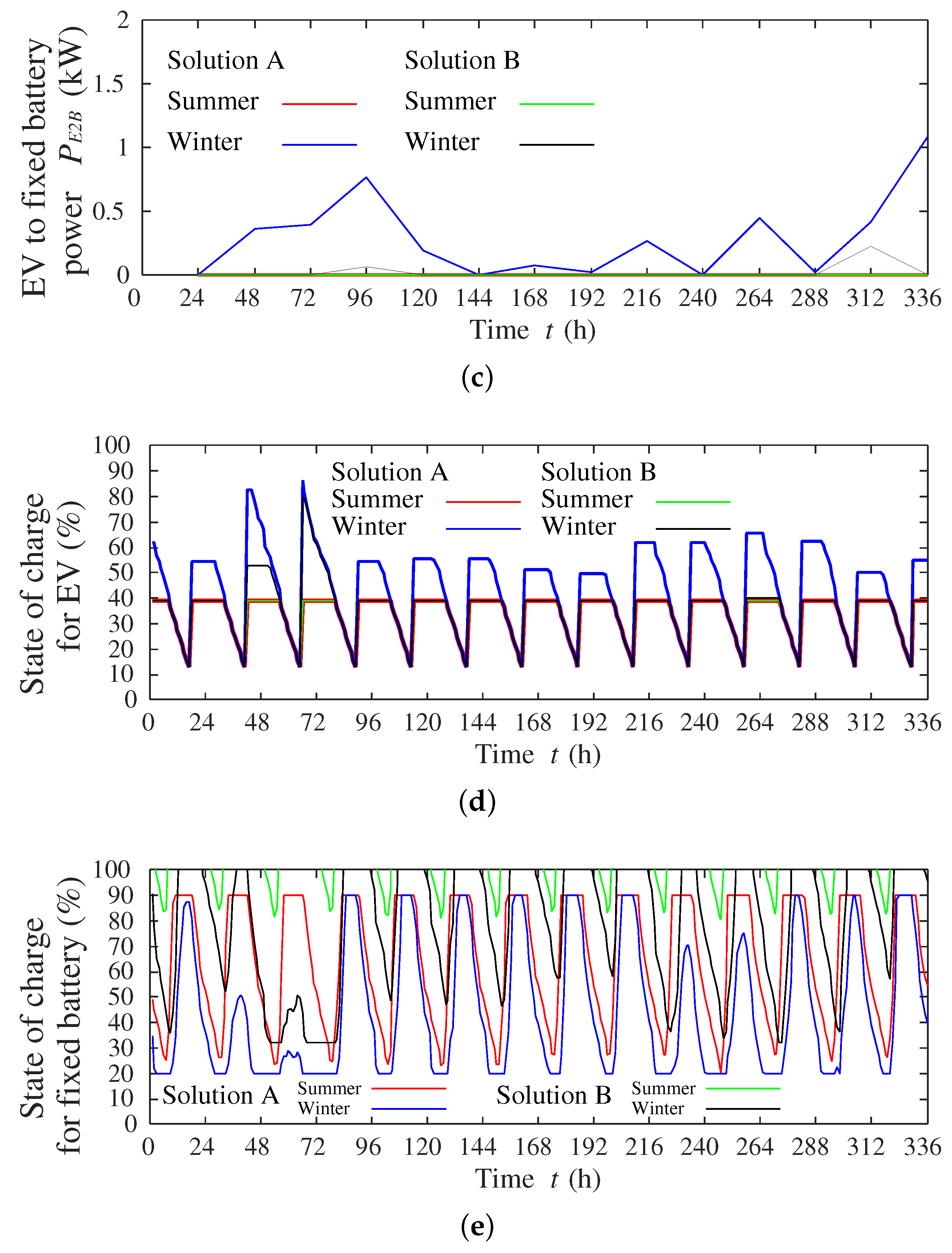

5.2. Simulation Results

6. Conclusions

Author Contributions

Conflicts of Interest

References

- Shimoji, T.; Tahara, H.; Matayoshi, H.; Yona, A.; Senjyu, T. Optimal Scheduling Method of Controllable Loads in DC Smart Apartment Building. Int. J. Emerg. Electr. Power Syst. 2015, 16, 579–589. [Google Scholar] [CrossRef]

- Yang, H.; Qiu, J.; Zhang, S.; Lai, M.; Dong, Z.Y. Interdependency Assessment of Coupled Natural Gas and Power Systems in Energy Market. Int. J. Emerg. Electr. Power Syst. 2015, 16, 525–536. [Google Scholar] [CrossRef]

- Akinyele, D.O.; Rayudu, R.K.; Nair, N.K.C. Grid-independent renewable energy solutions for residential use: The case of an off-grid house in wellington, New Zealand. In Proceedings of the 2015 IEEE PES Asia-Pacific Power and Energy Engineering Conference (APPEEC), Brisbane, Australia, 15–18 November 2015; pp. 1–5.

- Da Graça, G.C.; Augusto, A.; Lerer, M.M. Solar powered net zero energy houses for southern Europe: Feasibility study. Sol. Energy 2012, 86, 634–646. [Google Scholar] [CrossRef]

- Kapsalaki, M.; Leal, V.; Santamouris, M. A methodology for economic efficient design of Net Zero Energy Buildings. Energy Build. 2012, 55, 765–778. [Google Scholar] [CrossRef]

- Nedim, T. Minimization of operational cost for an off-grid renewable hybrid system to generate electricity in residential buildings through the SVM and the BCGA methods. Energy Build. 2014, 76, 470–475. [Google Scholar]

- Uchida, K.; Senjyu, T.; Urasaki, N.; Yona, A. Installation Effect by Solar Pool System Using Solar Insolation Forecasting. In Proceedings of the 2009 Annual Conference of Power & Energy Society, Tokyo, Japan, 18–20 August 2009; Volume 25, pp. 7–12. (In Japanese)

- Shimoji, T.; Tahara, H.; Matayoshi, H.; Yona, A.; Senjyu, T. Comparison and Validation of Operational Cost in Smart Houses with the Introduction of a Heat Pump or a Gas Engine. Int. J. Emerg. Electr. Power Syst. 2015, 16, 59–74. [Google Scholar] [CrossRef]

- Lu, X.; Liu, N.; Chen, Q.; Zhang, J. Multi-objective optimal scheduling of a DC micro-grid consisted of PV system and EV charging station. In Proceedings of the 2014 IEEE Innovative Smart Grid Technologies—Asia (ISGT Asia), Kuala Lumpur, Malaysia, 20–23 May 2014; pp. 487–491.

- Zhang, T.; Chen, W.; Han, Z.; Cao, Z. Charging Scheduling of Electric Vehicles With Local Renewable Energy Under Uncertain Electric Vehicle Arrival and Grid Power Price. IEEE Trans. Veh. Technol. 2014, 6, 2600–2612. [Google Scholar] [CrossRef]

- Reddy, S.S.; Abhyankar, A.R.; Bijwe, P.R. Co-optimization of Energy and Demand-Side Reserves in Day-Ahead Electricity Markets. Int. J. Emerg. Electr. Power Syst. 2015, 16, 195–206. [Google Scholar]

- Xia, S.; Ge, X. The Optimized Operation of Gas Turbine Combined Heat and Power Units Oriented for the Grid-Connected Control. Int. J. Emerg. Electr. Power Syst. 2016, 17, 143–150. [Google Scholar] [CrossRef]

- Tanaka, K.; Yoza, A.; Ogimi, K.; Yona, A.; Senjyu, T. Optimal operation of DC smart house system by controllable loads based on smart grid topology. Renew. Energy 2012, 39, 132–139. [Google Scholar] [CrossRef]

- Bracale, A.; Carpinelli, G.; Fazio, D.A.; Khormali, S. Advanced, Cost-Based Indices for Forecasting the Generation of Photovoltaic Power. Int. J. Emerg. Electr. Power Syst. 2014, 15, 77–91. [Google Scholar] [CrossRef]

- Nguyen, M.Y.; Nguyen, D.M. A Generalized Formulation of Demand Response under Market Environments. Int. J. Emerg. Electr. Power Syst. 2015, 16, 217–224. [Google Scholar]

- Li, Y.; Pedroni, N.; Zio, E. A Memetic Evolutionary Multi-Objective Optimization Method for Environmental Power Unit Commitment. IEEE Trans. Ower Syst. 2013, 28, 2660–2669. [Google Scholar] [CrossRef]

- Shadmand, M.B.; Balog, R.S. Multi-Objective Optimization and Design of Photovoltaic-Wind Hybrid System for Community Smart DC Microgrid. IEEE Trans. Smart Grid 2014, 5, 2635–2643. [Google Scholar] [CrossRef]

- Shi, Z.; Peng, Y.; Wei, W. Optimal sizing of DGs and storage for microgrid with interruptible load using improved NSGA-II. In Proceedings of the IEEE 2014 Congress on Evolutionary Computation (CEC), Beijing, China, 6–11 July 2014; pp. 2108–2115.

- Sheng, W.; Liu, K.; Liu, Y.; Meng, X.; Li, Y. Optimal Placement and Sizing of Distributed Generation via an Improved Nondominated Sorting Genetic Algorithm II. IEEE Trans. Power Deliv. 2015, 30, 569–578. [Google Scholar] [CrossRef]

- Kamjoo, A.; Maheri, A.; Dizqah, A.M.; Putrus, G.A. Multi-objective design under uncertainties of hybrid renewable energy system using NSGA-II and chance constrained programming. Int. J. Emerg. Electr. Power Syst. 2016, 74, 187–194. [Google Scholar] [CrossRef]

- Deb, K.; Pratap, A.; Agarwal, S.; Meyarivan, T. A fast and elitist multiobjective genetic algorithm: NSGA-II. IEEE Trans. Evol. Comput. 2002, 6, 182–197. [Google Scholar] [CrossRef]

| Rated output power | = 0.260 kW/panel |

| Efficiency | = 18.8% |

| Area | = 1.65 m2/panel |

| Cost | = 9.59 × 104 Yen/panel |

| Energy storage capacity | = 1 kWh/unit |

| Efficiency | = 90% |

| Inverter capacity | = 0.5 kW/unit |

| Cost | = 20 × 104 Yen/unit |

| Energy storage capacity | = 24 (kWh) |

| Inverter capacity | House (kW) |

| EV charging station (kW) | |

| Efficiency | |

| Power consumption | 0.114 kWh/km |

| Mileage | 61.4 km/day |

| Solution | F1 (%) | F2 × 104 (Yen) | NPV (panel) | NBA (unit) | NPV SPV (m2) | (kWh) | (kW) |

|---|---|---|---|---|---|---|---|

| A | 11.2 | 29 | 34 | 13 | 56.1 | 13 | 6.5 |

| B | 0.82 | 45 | 51 | 21 | 84.2 | 21 | 10.5 |

© 2017 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Miyazato, Y.; Tobaru, S.; Uchida, K.; Celestino Muarapaz, C.; Motin Howlader, A.; Senjyu, T. Multi-Objective Optimization for Equipment Capacity in Off-Grid Smart House. Sustainability 2017, 9, 117. https://doi.org/10.3390/su9010117

Miyazato Y, Tobaru S, Uchida K, Celestino Muarapaz C, Motin Howlader A, Senjyu T. Multi-Objective Optimization for Equipment Capacity in Off-Grid Smart House. Sustainability. 2017; 9(1):117. https://doi.org/10.3390/su9010117

Chicago/Turabian StyleMiyazato, Yasuaki, Shota Tobaru, Kosuke Uchida, Cirio Celestino Muarapaz, Abdul Motin Howlader, and Tomonobu Senjyu. 2017. "Multi-Objective Optimization for Equipment Capacity in Off-Grid Smart House" Sustainability 9, no. 1: 117. https://doi.org/10.3390/su9010117