Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill

Abstract

:1. Introduction

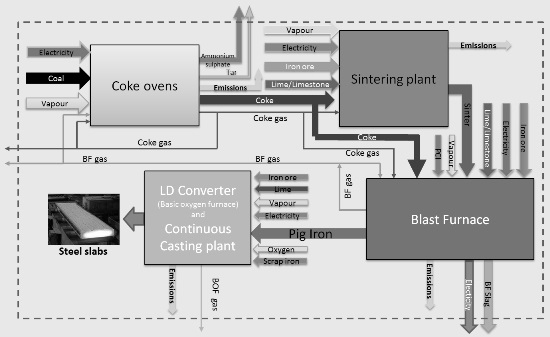

2. Materials and Methods

LCA Approach and Assumptions

- -

- Global warming: caused by greenhouse gasses emitted in atmosphere;

- -

- Ozone depletion: caused the emission of ozone-depleting substances (e.g., CFCs) in the atmosphere which then reach the stratosphere;

- -

- Human toxicity cancer effect: carcinogenic effect on human health due to the emission of toxic substances;

- -

- Human toxicity non cancer effect: negative effect (excluding carcinogenic one) on human health due to the emission of toxic substances;

- -

- Particulate matter: microscopic solid or liquid matter suspended in the atmosphere, which can have negative effects on climate, human health and vegetation;

- -

- Ionizing radiation: high-energy electromagnetic waves and subatomic particles, ions or atoms that can have negative effects on health;

- -

- Photochemical ozone formation: formation occurs when nitrogen oxides carbon monoxide and volatile organic compounds react in the atmosphere in the presence of sunlight, and has negative effects on health;

- -

- Acidification: formation of acid rain which can have effects on soil, plants, water, fish and wildlife and materials;

- -

- Terrestrial eutrophication: oversupply of nutrients which induces explosive growth of certain plants whilst hindering others;

- -

- Freshwater and Marine eutrophication: oversupply of nutrients which induces explosive growth of plants and algae which disrupts the normal functioning of the aquatic ecosystem;

- -

- Freshwater eco-toxicity: a result of emissions of toxic substances to air, water and soil which end up in freshwater systems;

- -

- Land use: the amount of land occupied/used for the activities related to the product system under assessment;

- -

- Water resource depletion: decline of quantity or quality of water resources;

- -

- Mineral fossil and renewable depletion: reduction/increase in scarcity of available mineral fossil and renewable resources.

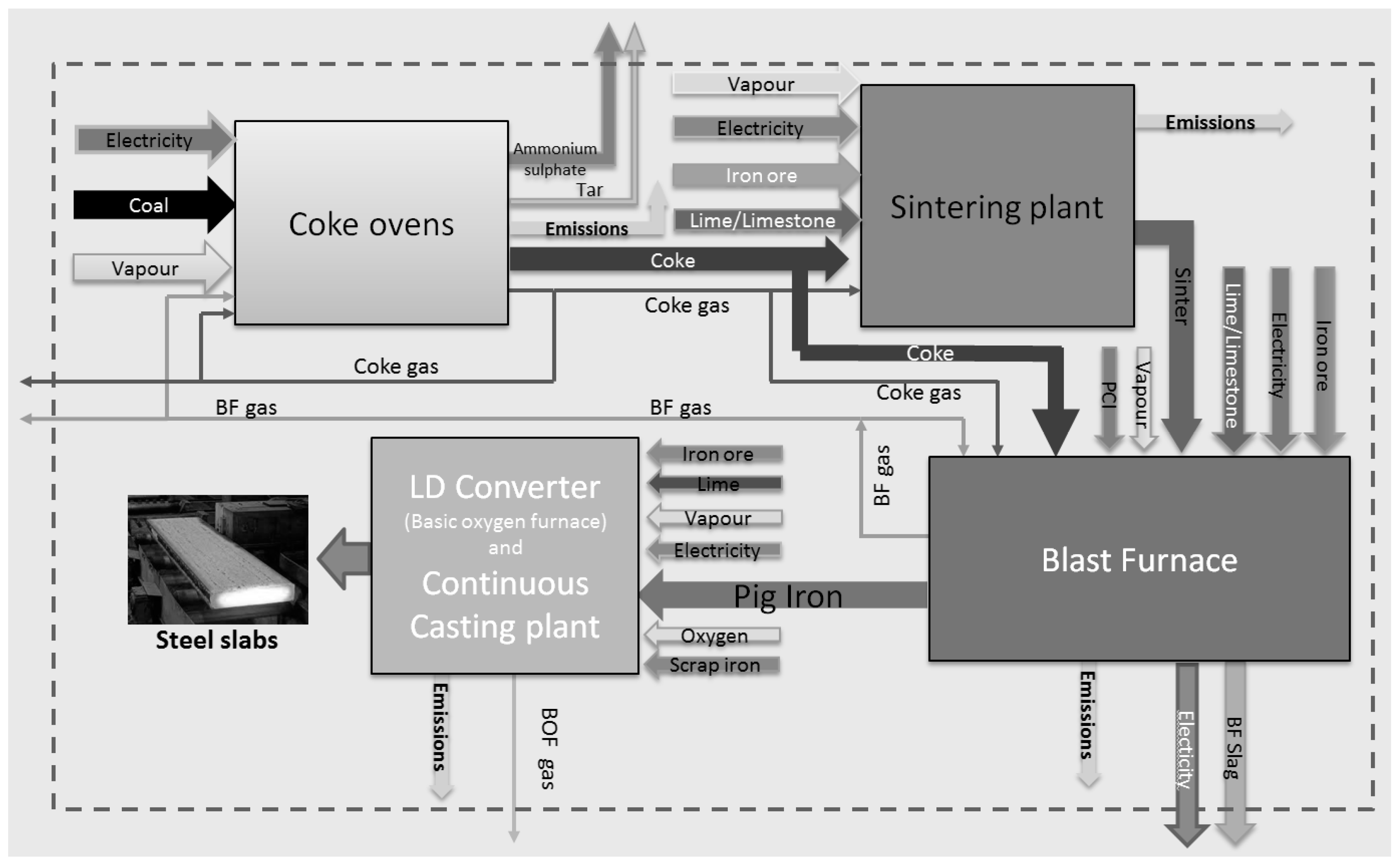

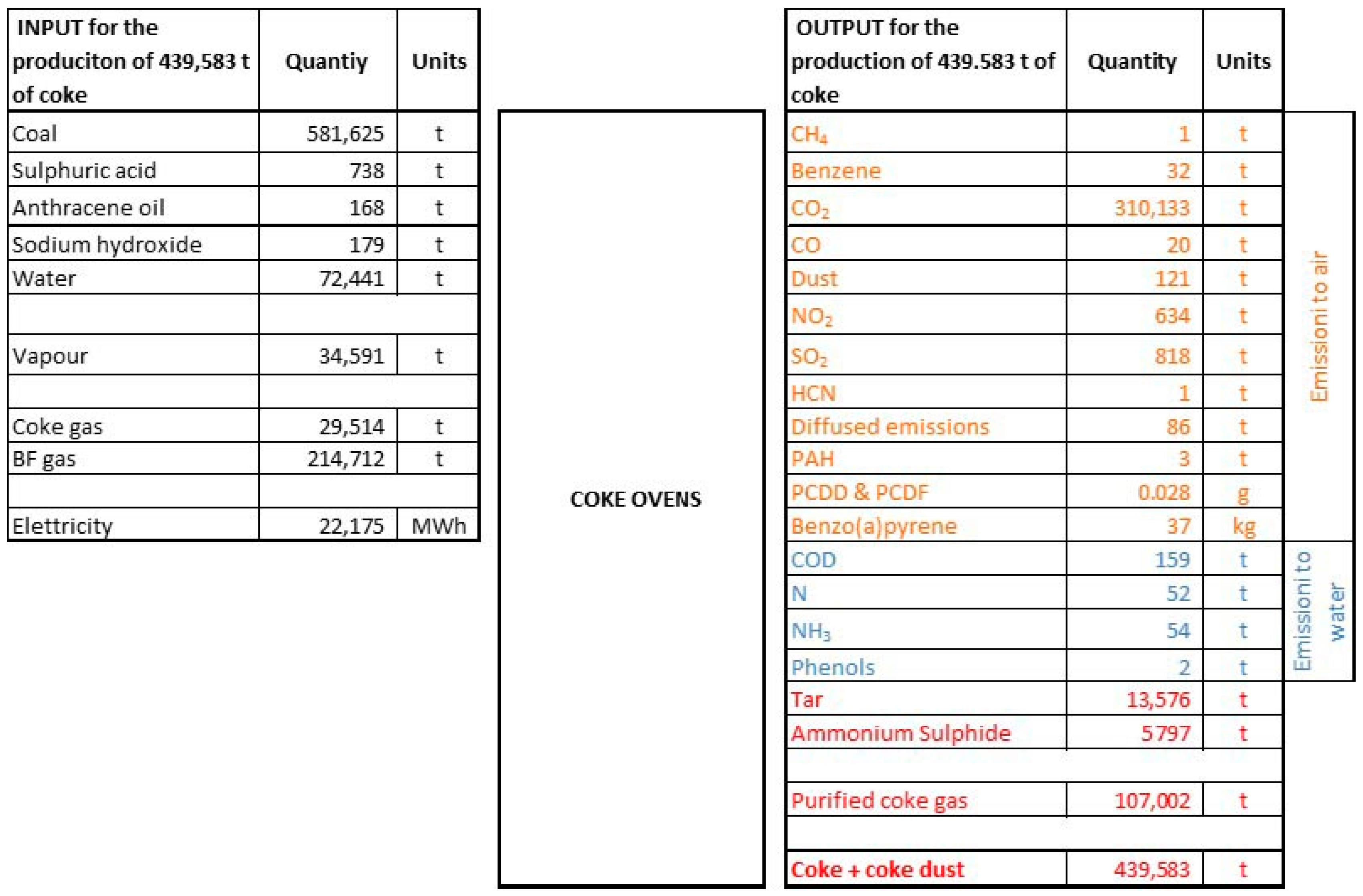

3. Inventory Analysis

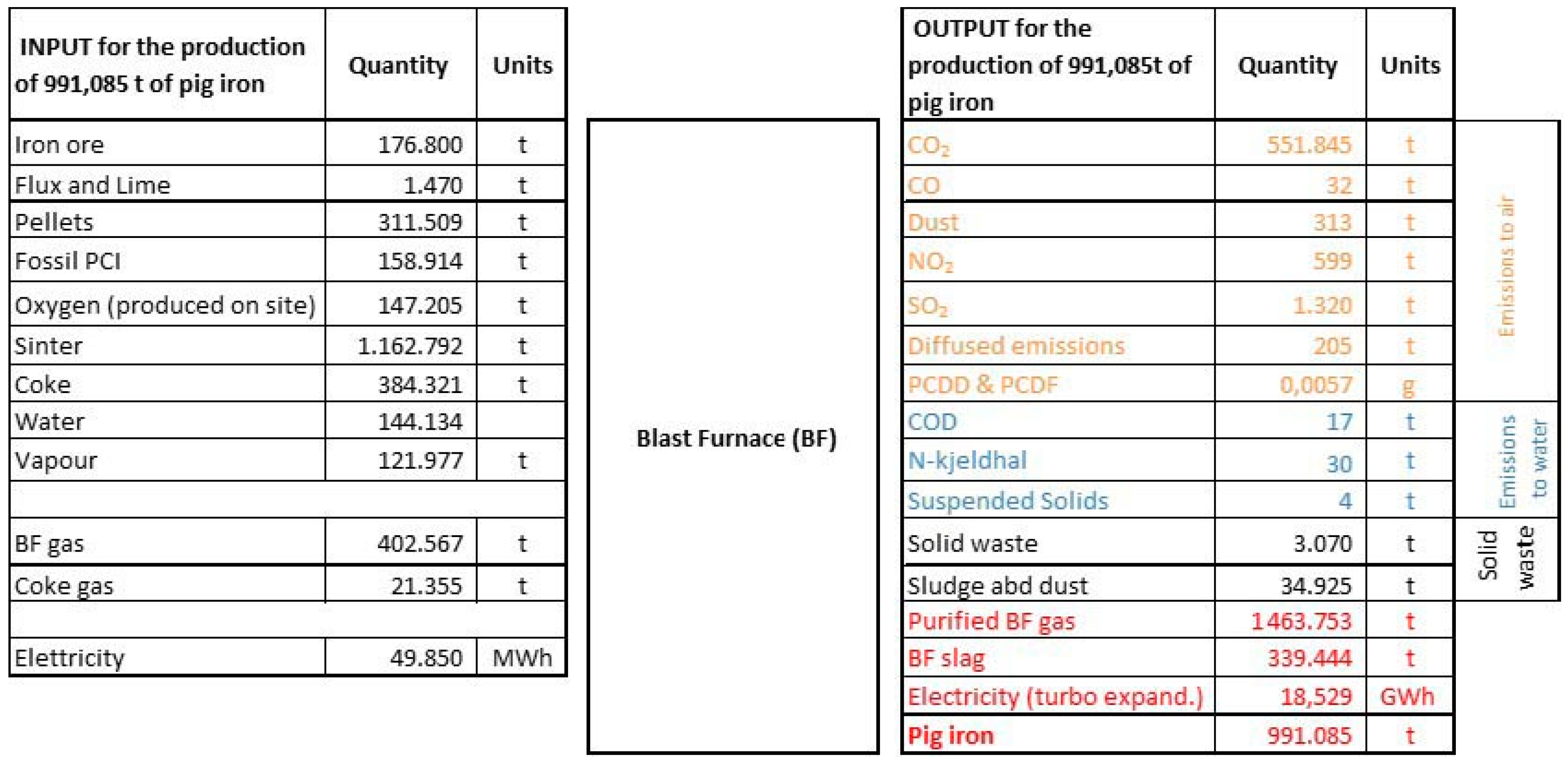

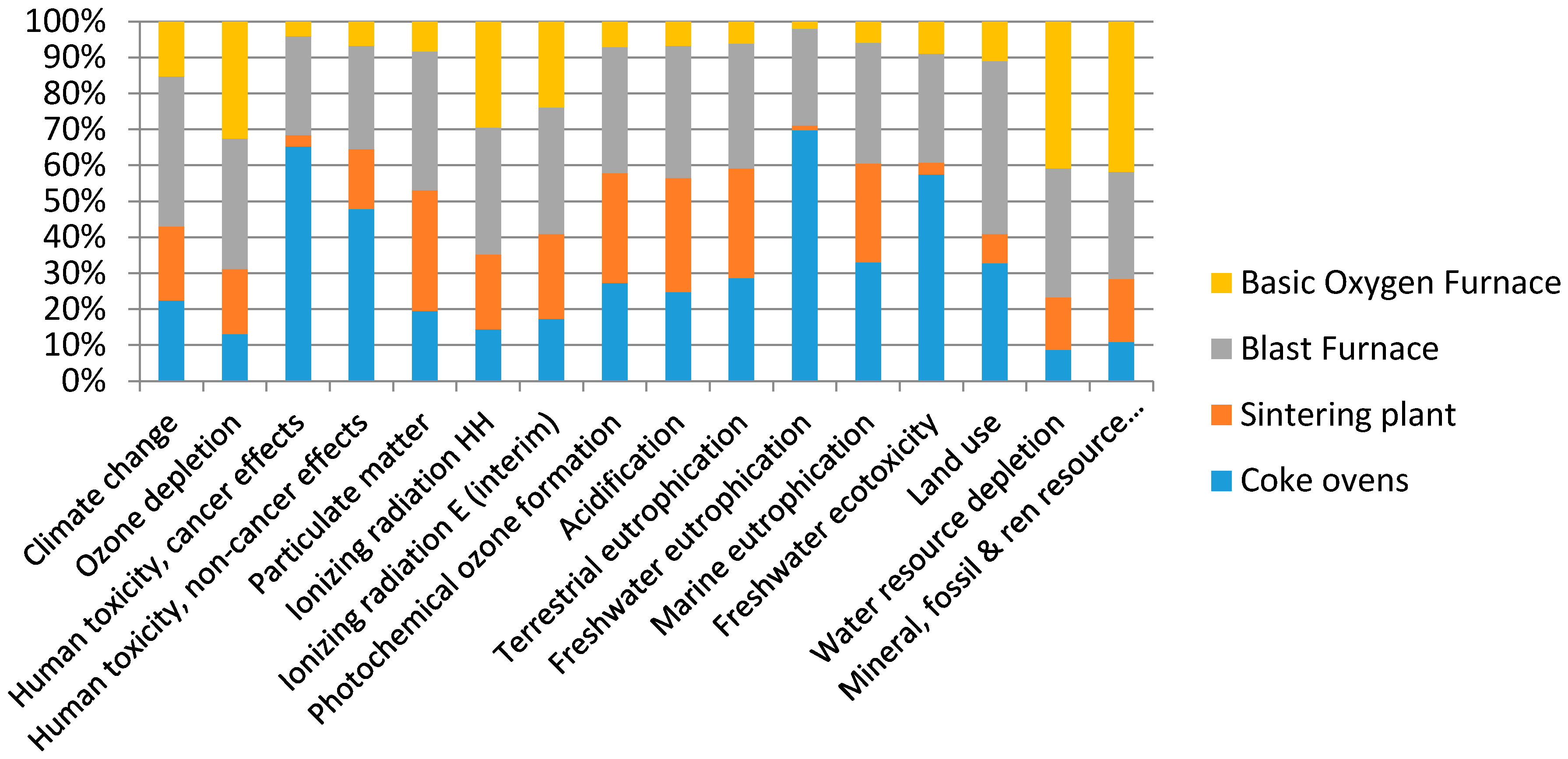

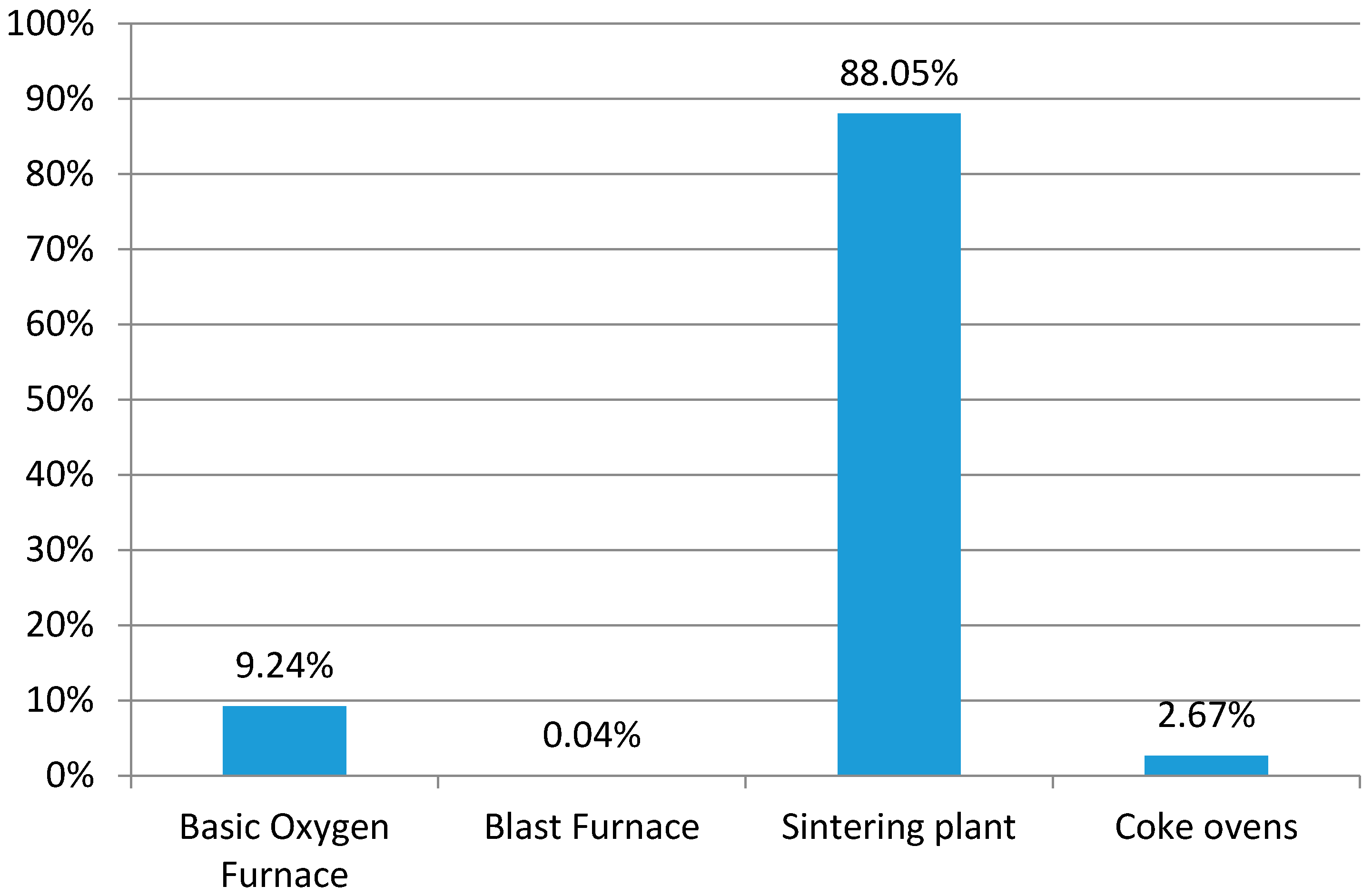

4. Impact Assessment, Results and Implications

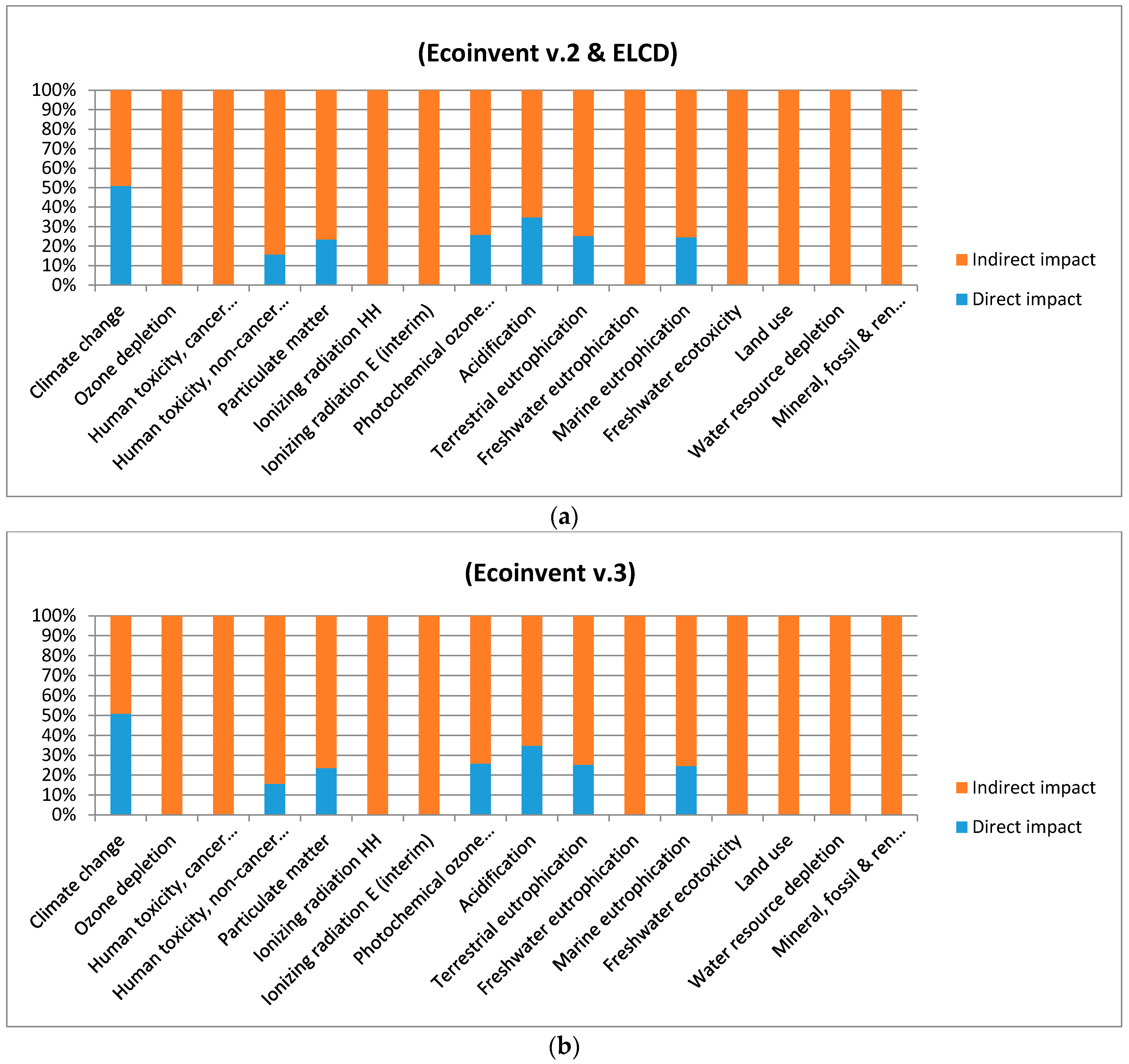

5. Discussion

- -

- there is a discrepancy, in terms of results, when assessing the same system, between toxicity modelling with site specific approaches such as the above-mentioned one and site independent approaches like LCA. This has often been highlighted as a critical issue of LCA [35], and it is demonstrated by the fact that many impact assessment models do not include characterisation factors (CFs) for all toxic substances, and, in many cases, one CF of one method may give very different results for the same CF of another method;

- -

- the calculated impact resulting from LCA studies is not necessarily that which actually occurs in specific areas due to the “potential” and site independent nature of the LCA indicator values. Hence, a large potential Human Toxicity impact, which is attributable to areas where iron ore mining and overseas transport activities occur, does not translate in an effective damage to humans due to the small presence of human beings in these areas. Vice versa, a small potential human toxicity impact can turn out to effectively cause widespread damage to human health, as in the case of Taranto, due to the high population density around the steelworks;

- -

- independently of the characterisation factor used to model an LCA potential impact, the results of the study have highlighted how shifting from an LCA database to another can, in some cases, give different results.

6. Conclusions

Author Contributions

Conflicts of Interest

Abbreviations

| LCA | Life Cycle Assessment |

| LCI | Life Cycle Inventory |

| ULCOS | Ultra-Low CO2 Steelmaking |

| BOF | Basic Oxygen Furnace |

| LD converter | Linz–Donawitz converter |

| BF | Blast Furnace |

| PCI | Pulverised Coal Injection |

| FU | Functional Unit |

| BREFs | Best Available Techniques reference documents |

| ELCD | European Reference Life Cycle Database |

| ILCD | International Reference Life Cycle Data System |

| CFs | Characterisation Factors |

| PAHs | Polycyclic Aromatic Hydrocarbons |

| PCDDs | Polychlorinated Dibenzodioxins |

| PCDFs | Polychlorinated Dibenzofurans |

| PCB | Polychlorinated Biphenyl |

| VOC | Volatile Organic Compounds |

| COD | Chemical Oxygen Demand |

References

- World Steel Association. Steel Facts, 2015. Available online: https://www.worldsteel.org/Steel-facts.html (accessed on 3 December 2015).

- Li, L.; Lei, Y.; Pan, D. Study of CO2 emissions in China’s iron and steel industry based on economic input–output life cycle assessment. Nat. Hazards 2016, 81, 957–970. [Google Scholar] [CrossRef]

- World Steel Association. World Steel in Figures 2015. Brussels, 2015. Available online: https://www.worldsteel.org/dms/internetDocumentList/bookshop/2015/World-Steel-in-Figures-2015/document/World%20Steel%20in%20Figures%202015.pdf (accessed on 3 December 2015).

- Federacciai. L’Industria Siderurgica Italiana nel 2014. 2015. Available online: http://www.federacciai.it/Assemblea/AttiAss2015/Relazione_Annuale_prima%20parte.pdf (accessed on 14 July 2016). (In Italian)

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Industrial symbiosis in the Taranto industrial district: Current level, constraints and potential new synergies. J. Clean. Prod. 2016, 122, 133–143. [Google Scholar] [CrossRef]

- Notarnicola, B.; Tassielli, G.; Renzulli, P.A. Environmental and technical improvement of a grape must concentration system via a life cycle approach. J. Clean. Prod. 2015, 89, 87–98. [Google Scholar] [CrossRef]

- European Commission. Communication on Integrated Product Policy (COM(2003) 302). Integrated Product Policy—Building on Environmental Life-Cycle Thinking. 2003. Available online: http://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2003:0302:FIN:en:PDF (accessed on 14 July 2016).

- World Steel Association. Life Cycle Assessment Methodology Report—Life Cycle Inventory Study for Steel Products, 2015. Available online: https://www.worldsteel.org/dms/internetDocumentList/bookshop/LCA-Methodology-Report/document/LCA%20Methodology%20Report.pdf (accessed on 3 December 2015).

- Eurofer. Methodology Report: Life Cycle Inventory on Stainless Steel Production in the EU, PE International; Eurofer: Brussels, Belgium, 2011. [Google Scholar]

- International Stainless Steel Forum. LCI Data for Stainless Steel Products, 2015. Available online: http://www.worldstainless.org (accessed on 3 December 2015).

- ATHENA Sustainable Materials Institute. Cradle-to-Gate Life Cycle Inventory: Canadian and US Steel Production by Mill Type; ATHENA Sustainable Materials Institute: Canada, 2002; Available online: http://calculatelca.com/wp-content/themes/athenasmisoftware/images/LCA%20Reports/Steel_Production.pdf (accessed on 3 December 2015).

- Environdec. The International EPD System, 2015. Available online: http://www.environdec.com/en/The-International-EPD-System/ (accessed on 1 July 2016).

- ULCOS. Ultra-Low Carbon Dioxide Steelmaking Consortium, 2015. Available online: http://ulcos.org/en/about_ulcos/home.php (accessed on 15 December 2015).

- Iosif, A.M.; Birat, J.P.; Mirgaux, O.; Ablitzer, D. Reduction of CO2 Emissions in the Steel Industry Based on LCA Methodology, 2009. Available online: http://www.ulcos.org/en/docs/Ref33%20-%20TMS_CO2_correct_1.pdf (accessed on 25 July 2016).

- Huang, Z.; Ding, X.; Sun, H.; Liu, S. Identification of main influencing factors of life cycle CO2 emissions from the integrated steelworks using sensitivity analysis. J. Clean. Prod. 2010, 18, 1052–1058. [Google Scholar] [CrossRef]

- Bieda, B. Life cycle inventory processes of the ArcelorMittal Poland (AMP) S.A. in Krakow, Poland—Basic oxygen furnace steel production. Int. J. Life Cycle Access. 2012, 17, 463–470. [Google Scholar] [CrossRef]

- Bieda, B. Life cycle inventory processes of the Mittal Steel Poland (MSP) S.A. in Krakow, Poland—Blast furnace pig iron production—A case study. Int. J. Life Cycle Access. 2012. [Google Scholar] [CrossRef]

- Burchart-Korol, D. Life cycle assessment of steel production in Poland: A case study. J. Clean. Prod. 2013, 54, 235–243. [Google Scholar] [CrossRef]

- Norgate, T.E.; Jahanshahi, S.; Rankin, W.J. Assessing the environmental impact of metal production processes. J. Clean. Prod. 2007, 15, 838–848. [Google Scholar] [CrossRef]

- International Standards Organisation (ISO). ISO 14044:2006, Environmental Management—Life Cycle Assessment—Requirements and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Rapporto Ambiente e Sicurezza. Ilva Riva Fire—Stabilimento di Taranto: Italy, 2011. Available online: http://archivio.fiom.cgil.it/siderurgia/ilva/11_rapporto_ambiente_sicurezza-ilva.pdf (accessed on 1 July 2016). (In Italian)

- Steel & Iron BAT, 2012. Available online: http://eippcb.jrc.ec.europa.eu/reference/ (accessed on 1 April 2015).

- ARPA Puglia. Agenzia Regionale per la Prevenzione e Protezione dell’Ambiente. Valutazione del Danno Sanitario Stabilimento ILVA di Taranto. 2013. Available online: http://www.arpa.puglia.it (accessed on 1 June 2016). (In Italian)

- Frischknecht, R.; Jungbluth, N.; Althaus, H.-J.; Doka, G.; Dones, R.; Heck, T.; Hellweg, S.; Hischier, R.; Nemecek, T.; Rebitzer, G.; et al. Overview and Methodology; Ecoinvent Report No. 1, v2.0; Swiss Centre for Life Cycle Inventories: Dübendorf, Switzerland, 2007; Available online: http://www.ecoinvent.org (accessed on 1 June 2016).

- EC-JRC. ELCD 3.2. European Reference Life Cycle Database. EU Joint Research Centre, 2016. Available online: http://eplca.jrc.ec.europa.eu/ELCD3/ (accessed on 1 July 2016).

- EC-JRC (Joint Research Centre), Institute for Environment and Sustainability. International Reference Life Cycle Data System (ILCD) Handbook: General Guide for Life Cycle Assessment—Detailed Guidance, 1st ed.; EUR 24708 EN; Publications Office of the European Union: Luxembourg City, Luxembourg, 2010. [Google Scholar]

- EC-JRC. Recommendations Based on Existing Environmental Impact Assessment Models and Factors for Life Cycle Assessment in European Context; Publications Office of the European Union: Luxembourg City, Luxembourg, 2011; Available online: http://eplca.jrc.ec.europa.eu/ (accessed on 1 July 2016).

- Pardo, N.; Moya, J.A.; Vatopoulos, K. Prospective Scenarios on Energy Efficiency and CO2 Emissions in the EU Iron and Steel Industry; JRC Scientific and Policy Reports; European Commission: Brussels, Belgium, 2012. [Google Scholar]

- Norgate, T.E. Metal Recycling: An Assessment Using Life Cycle Energy Consumption as a Sustainability Indicator; CSIRO Minerals: Waterford, Australia, 2004. [Google Scholar]

- Chatterjee, A. Sponge Iron Production by Direct Reduction of Iron Oxide, 2nd ed.; PHI Learning Pvt. Ltd.: New Delhi, India, 2012. [Google Scholar]

- Lunda, H.; Möllera, B.; Mathiesena, B.V.; Dyrelundb, A. The role of district heating in future renewable energy systems. Energy 2010, 35, 1381–1390. [Google Scholar] [CrossRef]

- Cipollone, R.; Bianchi, G.; Di Battista, D.; Contaldi, G.; Murgia, S. Mechanical Energy Recovery from Low Grade Thermal Energy Sources. Energy Procedia 2014, 45, 121–130. [Google Scholar] [CrossRef]

- Rosenbaum, R.K.; Bachmann, T.M.; Gold, S.K.; Huijbregts, M.A.J.; Jolliet, O.; Juraske, R.; Koehler, A.; Larsen, H.F.; MacLeod, M.; Margni, M.; et al. USEtox—The UNEP-SETAC toxicity model: Recommended characterisation factors for human toxicity and freshwater ecotoxicity in life cycle impact assessment. Int. J. Life Cycle Assess. 2008, 13. [Google Scholar] [CrossRef]

- Goedkoop, M.; Heijungs, R.; Huijbregts, M.; de Schryver, A.; Struijs, J.; van Zelm, R. ReCiPe 2008—A Life Cycle Impact Assessment Method Which Comprises Harmonised Category Indicators at the Midpoint and Endpoint Level, First Edition, 2009. Available online: http://www.leidenuniv.nl/cml/ssp/publications/recipe_characterisation.pdf (accessed on 1 July 2016).

- Hauschild, M.Z.; Huijbregts, M.; Jolliet, O.; Margni, M.; Van De Meent, D.; Rosenbaum, R.; McKone, T. Achieving Consensus on the Assessment of Toxicity in LCA; EM: Air and Waste Management Association’s Magazine for Environmental Managers: Pittsburgh, PA, USA, 2009; pp. 24–29. [Google Scholar]

| Input | Energy Input (MJ) | Output | Energy Output (MJ) | GJ/t Steel | |

|---|---|---|---|---|---|

| Coke ovens | Electric energy | 79,830,000 | Coke | 12,845,384,530 | 3.7 |

| Fossil fuels | 19,050,124,247 | Coke gas | 4,348,146,647 | ||

| BF gas | 565,821,301 | Tar | 138,475,200 | ||

| Coke gas | 1,199,334,593 | ||||

| Vapour | 103,773,000 | ||||

| Total | 20,998,883,141 | 17,332,006,377 | |||

| Sintering Plant | Electric energy | 174,801,600 | 1.9 | ||

| Coke gas | 95,616,802 | ||||

| Coke | 1,614,852,349 | ||||

| Vapour | 54,618,000 | ||||

| Total | 1,939,888,751 | - | |||

| Blast Furnace | Electric energy | 179,460,000 | Pig iron | 1,471,761,225 | 13.4 |

| Fossil PCI | 5,002,995,703 | BF gas | 3,857,363,340 | ||

| Coke | 11,230,532,182 | ||||

| Coke gas | 867,784,449 | ||||

| BF gas | 1,060,867,505 | ||||

| Vapour | 365,931,000 | ||||

| Total | 18,707,570,839 | 5,329,124,565 | |||

| Basic Oxygen Furnace | Electric energy | 290,037,600 | BOF gas | 969,152,322 | 0.8 |

| Pig Iron | 1,471,761,225 | Steel | 29,700,000 | ||

| Vapour | 21,846,000 | ||||

| Total | 1,783,644,825 | 998,852,322 | |||

| (Data referred to the production of 1 Mt of steel) | 19.8 | ||||

| Impact Category | Unit | Coke Ovens | Sintering Plant | Blast Furnace | Basic Oxygen Furnace | Total |

|---|---|---|---|---|---|---|

| Climate change | kg CO2 eq | 3.57 × 108 | 3.27 × 108 | 6.63 × 108 | 2.42 × 108 | 1.59 × 109 |

| Ozone depletion | kg CFC-11 eq | 6.34 × 100 | 8.86 × 100 | 1.77 × 101 | 1.58 × 101 | 4.87 × 101 |

| Human toxicity, cancer effects | CTUh | 8.21 × 101 | 4.10 × 100 | 3.45 × 101 | 5.10 × 100 | 1.26 × 102 |

| Human toxicity, non-cancer effects | CTUh | 2.37 × 102 | 8.26 × 101 | 1.42 × 102 | 3.35 × 101 | 4.95 × 102 |

| Particulate matter | kg PM2.5 eq | 1.44 × 105 | 2.49 × 105 | 2.85 × 105 | 6.12 × 104 | 7.40 × 105 |

| Ionizing radiation HH | kBq U235 eq | 1.08 × 107 | 1.55 × 107 | 2.63 × 107 | 2.20 × 107 | 7.45 × 107 |

| Ionizing radiation E (interim) | CTUe | 3.70 × 101 | 5.04 × 101 | 7.48 × 101 | 5.09 × 101 | 2.13 × 102 |

| Photochemical ozone formation | kg NMVOC eq | 1.97 × 106 | 2.21 × 106 | 2.53 × 106 | 5.11 × 105 | 7.23 × 106 |

| Acidification | molc H+ eq | 3.33 × 106 | 4.26 × 106 | 4.94 × 106 | 9.04 × 105 | 1.34 × 107 |

| Terrestrial eutrophication | molc N eq | 7.93 × 106 | 8.43 × 106 | 9.57 × 106 | 1.68 × 106 | 2.76 × 107 |

| Freshwater eutrophication | kg P eq | 9.97 × 105 | 1.95 × 104 | 3.84 × 105 | 2.76 × 104 | 1.43 × 106 |

| Marine eutrophication | kg N eq | 8.93 × 105 | 7.43 × 105 | 9.10 × 105 | 1.57 × 105 | 2.70 × 106 |

| Freshwater ecotoxicity | CTUe | 7.21 × 109 | 4.08 × 108 | 3.81 × 109 | 1.11 × 109 | 1.25 × 1010 |

| Land use | kg C deficit | 4.45 × 108 | 1.09 × 108 | 6.52 × 108 | 1.48 × 108 | 1.35 × 109 |

| Water resource depletion | m3 water eq | 8.75 × 107 | 1.47 × 108 | 3.63 × 108 | 4.12 × 108 | 1.01 × 109 |

| Mineral, fossil & ren resource depletion | kg Sb eq | 1.27 × 103 | 2.05 × 103 | 3.48 × 103 | 4.88 × 103 | 1.17 × 104 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Renzulli, P.A.; Notarnicola, B.; Tassielli, G.; Arcese, G.; Di Capua, R. Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability 2016, 8, 719. https://doi.org/10.3390/su8080719

Renzulli PA, Notarnicola B, Tassielli G, Arcese G, Di Capua R. Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill. Sustainability. 2016; 8(8):719. https://doi.org/10.3390/su8080719

Chicago/Turabian StyleRenzulli, Pietro A., Bruno Notarnicola, Giuseppe Tassielli, Gabriella Arcese, and Rosa Di Capua. 2016. "Life Cycle Assessment of Steel Produced in an Italian Integrated Steel Mill" Sustainability 8, no. 8: 719. https://doi.org/10.3390/su8080719