1. Introduction

As a traditional agricultural country, China is one of the largest producers of animal manure in the world, with an annual output of more than 3 billion tonnes [

1]. Disposal of animal manure usually involves aerobic composting and anaerobic fermentation [

2]. Pig slurry (PS) is primarily used as fertilizer in agricultural production to provide nutrients such as nitrogen (N), phosphorus (P), and potassium (K) to crops [

3,

4,

5,

6]. Tao et al. [

7] found that applying PS at 60–120 m

3·hm

−2 instead of chemical fertilizer at 30–60 kg N·hm

−2 during winter, at the panicle formation stage, could meet the high nitrogen demand utilization efficiency of wheat. Moreover, Gomez-Munoz et al. [

8] demonstrated that acidification of PS increased N availability from separated solid fractions but did not affect N

2O and CO

2 emissions.

However, continual application of high doses of PS can result in high concentrations of heavy metals, especially copper (Cu) and Zinc (Zn), which could lead to secondary contamination in a PS-amended soil [

9,

10]. Concentrations of Cu and Cd in grain and straw were dependent on the available Cu and Cd in the soils, and soil available Cu and Cd were significantly affected by the soil pH [

11]. Heavy metals in variable charge soil are highly bioavailable and easy to transfer into plants. The use of organic fertilizer such as biogas slurry in As-contaminated paddy soil can significantly alter the behaviour of As in a soil-rice system and enhance As accumulation in rice plants [

12]. The As concentrations in polished grain were reported to be positively and significantly correlated with As root-grain translocation factor [

13]. The Cu content in stems and leaves in anaerobically digested PS was reported be significantly higher (

p < 0.05) than that in a chemical fertilizer treatment [

14]. Although there is a potential risk of heavy metal pollution from PS, phytotoxicity caused by Cu and Zn did not occur, even after several years of PS application, because chemical species in soil tend to form complexes with dissolved organic carbon, and Cu and Zn in their free forms are only present at low levels [

15]. Engineered cultivars and low-accumulating genotypes could mitigate CH

4 emissions and reduce heavy metal accumulation in rice grown in pig biogas-fertilized fields [

16,

17]. It is essential to manage and utilize PS effectively in crop production, because it is not only a useful organic fertilizer, but also a potential risk to the environment.

Direct-seeding and transplanting are the most important rice cultivation methods [

18]. Rice cultivation in Asia is undergoing significant changes in response to economic factors and technological innovation in farming practices. One such change has been a shift from transplanting to direct-seeding methods for rice establishment. Compared with transplanting, direct-seeding has both advantages and disadvantages. Advantages include water- and labour-saving, higher economic returns, a shorter crop cultivation period, higher abundance and diversity in paddy fields, and lower CH

4 emissions [

18,

19,

20,

21]. In China, 83.2% of rice was grown by direct-seeding in Shanghai, as was 33.3% in Jiangsu province, and 39.7% in Zhejiang province in 2008 [

22]. Direct-seeding is now spreading rapidly to farms around the middle and lower reaches of the Yangtze River. Some of the challenges of the direct-seeding method include weed management, yield loss, and poor and erratic emergence [

23,

24]. In contrast, transplanting produces taller plants, a greater number of grains per panicle, and a higher 1000-grain weight, and tiller number, fertile tillers, kernel and straw yield, and the harvest index is also higher than in direct-seeding [

25,

26].

Our group previously tested PS in the production of rice and wheat, and found it can reduce the use of chemical fertilizer and protect the environment [

7,

27,

28,

29]. In transplanting rice, PS from pig farming can replace 70% of the chemical fertilizer used, while increasing crop yield and enhancing the content of beneficial elements, as well as altering the levels of heavy metals such as Hg, Cd and Cr [

28,

29]. To our knowledge, application of PS to direct-seeding rice has not been reported. We predict that PS may act as a chemical fertilizer to improve yield if applied at the appropriate times and spread in the appropriate way. However, whether PS can be applied safely without inducing the accumulation of heavy metals in grains remains unknown, as do the potential effects on rice quality.

In this study, we tested various doses of PS as a basal and panicle fertilizer for growing direct-seeding rice, and measured the effect on rice yield, dry matter accumulation, and trace element uptake in straw and grain at different growth stages. Rice edibility and the rapid visco analyser (RVA) profile were also studied, as was processing quality. These results provide insight into the suitability of PS application for direct-seeding rice production.

2. Materials and Methods

2.1. Study Site

This study was conducted at the Shanghai farm in Dafeng County, Jiangsu province (33°21.736′N, 120°32.012′E) in 2014. This area has a subtropical seasonal climate and a rice-wheat crop rotation system, with an annual mean precipitation of 1040 mm, an annual mean temperature of 14 °C, a frost-free period of 213 days, and annual sunshine totalling 2255 h. The previous crop was wheat. The soil is sandy loam with 19.32 g·kg−1 organic matter, 1.00 g·kg−1 total nitrogen, 75.21 mg·kg−1 alkali hydrolysable N, 23.48 mg·kg−1 Olsen-P, 216.78 mg·kg−1 exchangeable K, 11.35 mg·g−1 Ca, 8.52 mg·g−1 Mg, 0.71 mg·g−1 Na, 23.53 mg·g−1 Fe, 0.10 mg·g−1 Cd, 2.84 mg·kg−1 Cu, 1.00 mg·kg−1 Pb, 6.71 mg·kg−1 Zn, 18.81 mg·kg−1 As, 22.23 mg·kg−1 Cr, and 0.17 mg·kg−1 Hg.

Topsoil (0–20 cm) samples were collected and air-dried, ground into powder and passed through a 2 mm sieve. Only soil <2 mm was used for analyses. Total organic matter in soil was determined by mass loss upon ignition of oven-dried soil in a muffle furnace at 550 °C for at least 6 h. Total N content was determined by micro Kjeldahl digestion. Alkali hydrolysable N was determined by the alkali solution diffusion method. Olsen-P was extracted by NaHCO

3 and determined by the classic colorimetric method. Exchangeable K was extracted by ammonium acetate and determined by the flame photometric method. To extract the metal elements in soil, a 0.3 g soil sample was digested by a mixture of concentrated hydrochloric acid and nitric acid (3:1,

v/

v) using a CEM closed microwave system [

30]. The concentrations of metal elements in the extract , namely, Ca, Mg, Na, Fe, Cd, Cu, Pb, Zn, As, Cr and Hg, were determined by an inductively coupled plasma mass spectrometer (ICP-MS, Thermo Fisher Corporation, Munich, Germany).

2.2. Study Materials

PS was obtained from a closed pig slurry collection system. Pig manure, urine and partial flushing water entered the pretreatment tank system through pipelines. After anaerobically fermenting for 6 months, this substance was used in this study. Treated PS contained the following trace elements: 0.246 mg·L

−1 Cu, 0.577 mg·L

−1 Zn, 0.041 mg·L

−1 Pb, <5.0 × 10

−4 mg·L

−1 Cd, 0.063 mg·L

−1 Cr, 0.0283 mg·L

−1 As and <5 × 10

−4 mg·L

−1 Hg. The contents of trace elements in PS conform to the national standards of the irrigation water quality in China (GB5084-92) [

28]. The total nitrogen, alkali hydrolysable N, total P

2O

5, total K

2O and pH of PS were 1000 mg·L

−1, 540 mg·L

−1, 77.9 mg·L

−1, 416 mg·L

−1 and 7.92, respectively. The rice variety in all the treatments was Huaidao No. 5.

2.3. Field Experiment

The experiment included 11 treatments with three replicates of each treatment (

Table 1), including one unfertilized control treatment (CK1), one local conventional fertilization treatment (CK2) consisting of 150 kg·hm

−2 urea, 225 kg·hm

−2 compound fertilizer (N: P

2O

5: K

2O = 12:15:18) as base fertilizer, 112.5 kg·hm

−2 urea as tillering fertilizer and 150 kg·hm

−2 urea as panicle fertilizer [

28]. Nine treatments (T1–9) involved the combined application of PS and nitrogen fertilizer, and a randomized block design was employed. For basal fertilizer application, PS was applied at a dose of 60, 90 and 120 m

3·hm

−2. At the panicle fertilizer stage, PS was applied at a dose of 60, 90 and 120 m

3·hm

−2. At the tillering stage, urea was applied at a dose of 225 kg·hm

−2. The area of each block was 15.75 m

2 (4.5 m long × 3.5 m wide). The direct sowing rate was 112.5 kg·hm

2, and broadcast sowing was adopted. PS as basal fertiliser was applied on 16 June 2013 to allow soil to fully absorb nutrients ahead of seeding, and seeds were sown on 19 June 2013. The management of pests, diseases and weeds was performed using typical local procedures.

2.4. Determination of Trace Elements

A total of 10 rice plants were collected from each group at the jointing, heading and mature stages, and the dry weight of each component was determined by oven-drying at 70 °C to a constant weight. Oven-dried samples were then ground in a stainless steel grinder fitted with a 45-mesh sieve to determine the trace element content in the grain or other parts of the rice plant. Samples were digested using a CEM closed microwave system as follows: 0.48 g samples in nitric acid were digested for 5, 10 and 15 min at 100, 150 and 180 °C. The concentrations of trace elements in the extract, namely, Pb, Cr, Co, Ni, Cu, Zn, Fe, Mn, were measured using an inductively coupled plasma mass spectrometer (ICP-MS, Thermo Fisher Corporation, Munich, Germany).

For all elements tested, the average translocation factor (TF) from straw to grain was calculated as ratios between grain element levels and straw element levels [

31].

2.5. Determination of Rice Yield and Grain Quality

Rice grain was harvested from an area of 2.25 m

2 in each plot and adjusted to a moisture content of 14%. Aboveground biomass and yield were determined for plants sampled randomly from a 1-m

2 area (excluding the border region) in each plot. Evaluation of rice quality was conducted according to the China national standard for grain quality measurements (GB/T 17891-1999; Supervising Department of Quality and Technology of China, 1999) [

32], and all analyses were carried out in duplicate. Grains were dehulled to produce brown rice using a chaff removal machine (OHYA-25, Ohya Corporation, Tokyo, Japan) and the percentage of brown rice was determined. Brown rice was milled with a rice polishing machine (JMNJ-3/CPC 96-3, Hangzhou Qianjiang Instrument Corporation, Hangzhou, China) until a standard degree of milling was achieved (as estimated by the percentage of milled rice and head rice).

Milled rice samples were then oven-dried at 60 °C to a constant weight and ground with a stainless steel grinder (FW-100, Shanghai Chuding Instrument Corporation, Shanghai, China) fitted with a 100-mesh sieve to prepare samples for protein content, amylose content, gel consistency and starch viscosity analysis.

Amylose and protein contents were measured with an Infratec 1241 grain analyser (FOSS Tecator, Copenhagen, Denmark) and a near-infrared transmittance analyser, respectively, and calculated based on grain dry weight. Gel consistency was measured by the length of cold milled rice paste in a test tube in a horizontal position. Gelatinization temperature and starch viscosity were determined with a rapid visco analyser (RVA) (RVA-3D, Newport Scientific Inc., Warriewood, Australia) using procedures of the American Association of Cereal Chemists (AACC, 1995).

2.6. Statistical Analysis

Analysis of variance was performed using the SAS/STAT statistical analysis package (version 6.12, SAS Institute, Cary, NC, USA). Data from each sampling date were analyzed separately and met all requirements for analysis of variance. Differences between means were tested using the least significant difference test at the 0.05 probability level.

4. Discussion

Previous studies indicate that yield, heavy metal content and crop quality are all significantly affected by application of PS during crop production [

12,

33,

34,

35]. Li et al. [

11] found that pig manure increased the grain yield between 0.3- and 15.3-fold. In this research, we demonstrated that, when combined with 225 kg·hm

−2 urea at the tillering stage, the yield of high dosage of PS application treatment, T8 and T9, can reach or even exceed the yield of conventional chemical treatment (CK2). In each PS treatment, the chemical N applied was only 41.4 percent of that in CK2, saving 58.6 percent chemical N fertilizer. However, it is worthy to point out that, when the total PS application was 150 m

3·hm

−2, the total N input was 253.5 kg·hm

−2, equal to the CK2 treatment (250 kg·hm

−2). Thus, when the dosage of PS application was 180, 210 and 240 m

3·hm

−2, the total load of N exceeded CK2 by 13.4%, 25.4% and 37.4%. Therefore, we caution that when applying PS as fertilizer in rice production, other measures should be taken to avoid ammonia volatilization to the air, and nitrate loss in the water should be altered and avoided.

Successive pig slurry applications may increase soil Cu and Zn concentrations and change the proportions of free chemical species in solution when combined with plant cultivation [

13]. Additionally, organic fertilization, especially farmyard manure and straw, significantly reduced the cadmium content in selected vegetables [

36]. However, when soils were amended with biogas slurry, Bian et al. [

37] measured mean concentrations of Cr of 0.43 and 0.46 mg·kg

−1 in rice and wheat, respectively, which are close to the standard limit (0.5 mg·kg

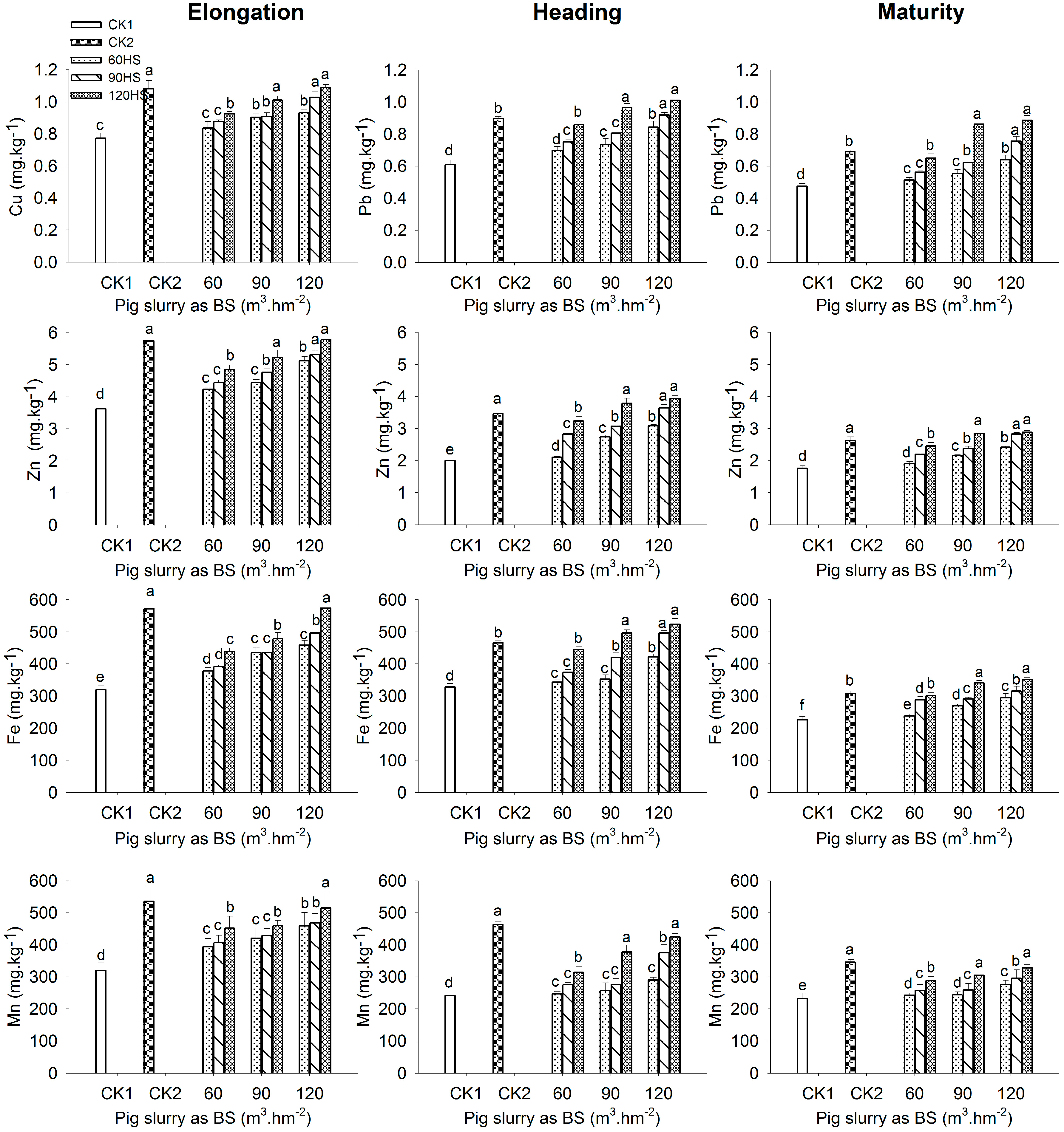

−1), and mean concentrations of Zn, Pb, and Cd exceeded the maximum permissible levels by 1.8-, 20.7-, and 2.6-fold, respectively. The reason for the apparent contradiction may be due to differences in heavy metal contents in the PS and biogas slurries applied, or differences in soil characteristics between experiments. In the present study, levels of Ni were highest in both plant material and grain in the CK2 treatment, followed by CK1, and lowest in the nine PS treatments. Cr and Co were highest in CK2, intermediate in PS treatments, and lowest in CK1, suggesting PS can alleviate toxicity of some heavy metals in direct-seeding rice. The Cr, Co and Ni contents decreased with increasing PS, whereas Pb showed the opposite trend. Even though the Pb content in grain was lower than the maximum allowed level, it is still important to be mindful of Pb pollution during long-term PS utilization.

Microelements such as Cu, Zn, Fe and Mn are indispensable for plant growth [

11,

35]. When Cu and Zn are used as pig feed additives, they can also be found in high concentrations in some animal manures and may be retained in the soil [

15,

17]. It has been shown that Fe, Mn, Cu and Zn in rapeseed increases with increasing biogas slurry application [

38]. Levels of Zn and Cu in stems and leaves were significantly higher in all anaerobically digested slurry treatments than in the control chemical fertilizer treatment, whereas comparable concentrations of Zn and Cu were observed in the rice grain among the treatments [

14]. In our study, Cu, Zn, and Fe increased with increasing PS application, consistent with a previous report [

38]. Cu, Zn and Fe decreased gradually from the jointing stage to the maturing stage, with the advancement of the reproductive period, and levels were higher than in the CK1 and CK2 treatments when PS was applied in combination with nitrogen fertilizer. Considering the total load of TE, the input quantities of Cu and Zn accompanied by PS were 112.7- and 39.5-fold higher in the T9 treatment when compared with CK2. Therefore, it is reasonable to interpret that contents of Cu and Zn were 9.08% and 30.7% higher than in the CK2 grains. These results indicate that PS can increase the content of some micronutrient elements in direct-seeding rice, but levels remained below the maximum allowed limits. However, concentrations of these elements in soil should continue to be monitored to avoid environmental pollution.

In previous rice research, less attention has been paid to the effects of PS on processing and eating quality. Liu et al. [

39] reported that biogas manure is an effective nutrient source for high-quality vegetable production, based on synergistic effects and its ability to enhance yield and improve quality, and to suppress nitrate accumulation. In the present study, application of PS combined with nitrogen fertilizer decreased the processing quality of direct-seeding rice only slightly, but in our previous study, Gao et al. [

28] found that application of PS to machine-transplanted rice enhanced brown, milled and head milled rice. Differences in the effects on processing quality may be attributed to different ways nutrients are absorbed under different cultivation methods. Indeed, Zhang et al. [

40] found that, compared with machine-transplanted rice, the nutrient absorption pattern of direct-seeding rice is stronger during the early growth stage and weaker during the late growth stage. The underlying mechanisms, however, are not fully understood. Even so, application of PS consistently decreased the amylase content and optimized the RVA profile in both cultivation methods, and therefore improved the overall rice grain quality.

5. Conclusions

In conclusion, with a total PS dosage of between 210 and 240 m

3·hm

−2 as basal and panicle fertilizer, the yield of direct-seeding rice reached or even exceeded that of regular chemical fertilizer. The Pb content increased gradually from the jointing stage to the maturing stage, but levels of many other metal elements decreased following PS application. Specifically, PS mitigated the accumulation of Cr, Co, Ni and Mn, but levels of Pb, Cu, Zn and Fe increased with increasing PS dosage, reaching a peak in treatment T9 (240 m

3·hm

−2) that remained below the maximum contaminants allowed in food (GB2762-2005) [

29]. Additionally, PS decreased the transfer of Pb, Cr, Co, Ni and Cu from vegetative plant parts to grain, but increased the transfer of Zn, Fe and Mn. Furthermore, PS had only a slight negative effect on grain processing quality, and significantly decreased the amylose content, enhanced gel consistency, and optimized the RVA profile, and improved the overall quality of direct-seeding rice.