Evaluation of Combined Heat and Power (CHP) Systems Using Fuzzy Shannon Entropy and Fuzzy TOPSIS

Abstract

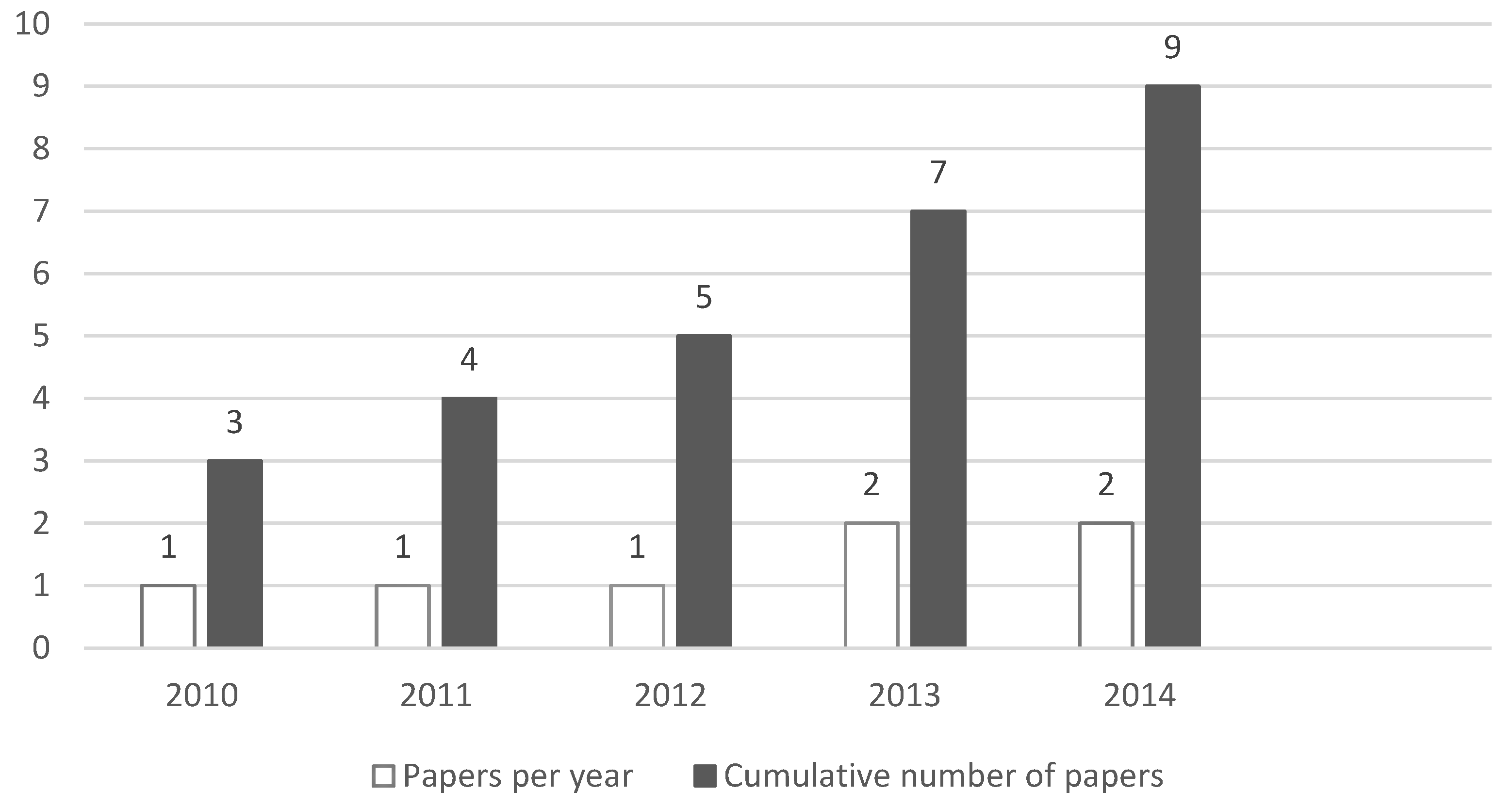

:1. Introduction

- the conversion and efficient use of energy in all the sectors of the economy associated with a decline in energy intensity;

- the diversification of the energy mix towards renewable energy sources and technologies for energy conversion with low carbon emissions for electricity, heating and cooling;

- the decarbonization of transportation by shifting to alternative fuels;

- the complete liberalization and interconnection of energy systems using smart information and communication technologies to provide a flexible and interactive (customers/operators) service network.

2. Fuzzy Set Theory: Preliminaries

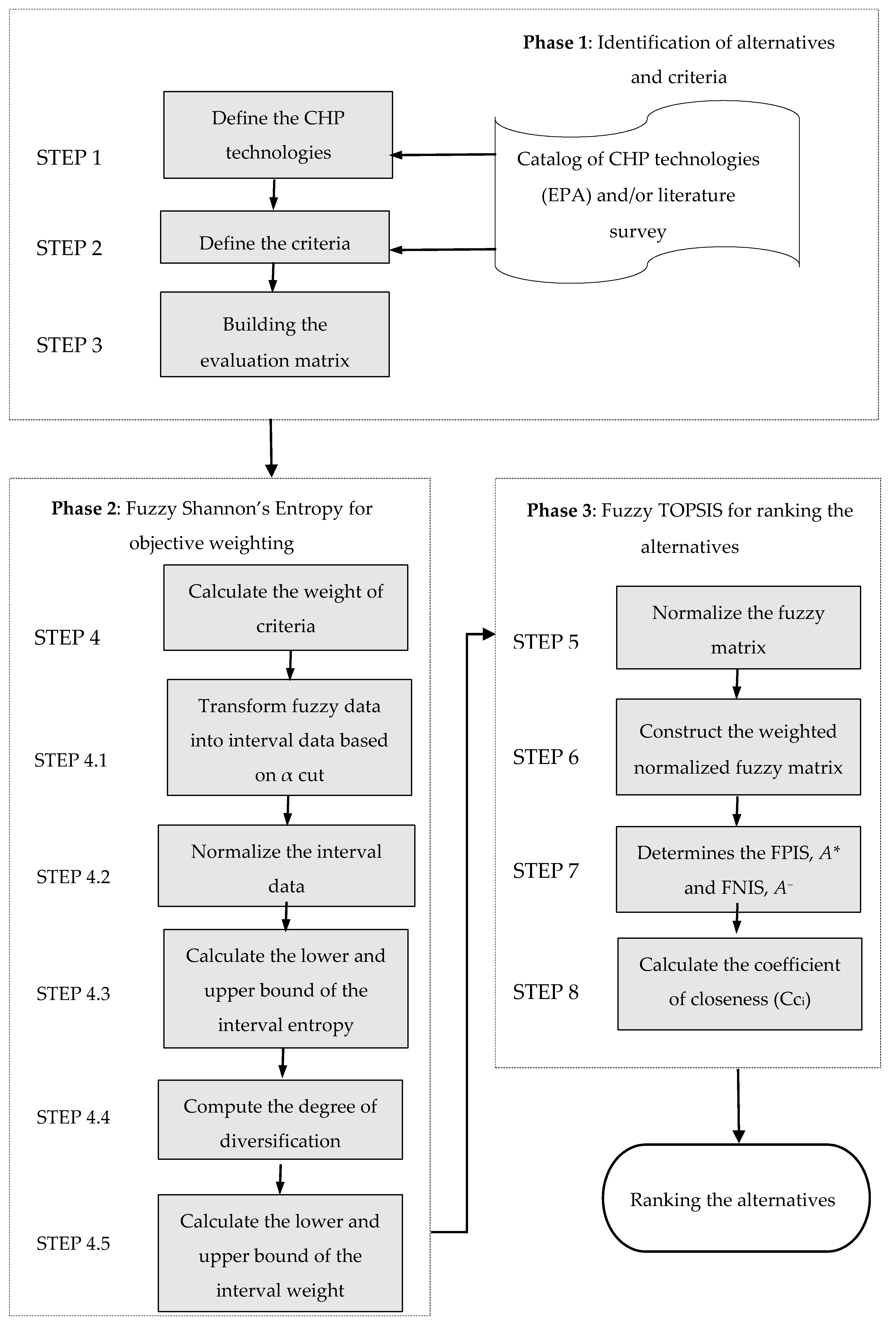

3. An Integrated Fuzzy Entropy and Fuzzy TOPSIS Approach

3.1. Shannon’s Entropy for Objective Weighting

3.2. Fuzzy Shannon’s Entropy Based on Αlpha-Cut

3.3. Fuzzy TOPSIS

4. Development of an Application for Ranking Combined Heat and Power (CHP) Technologies

4.1. Combined Heat and Power (CHP) Technologies

4.2. Algorithm and Results

- (1)

- Reciprocating engine: it is a well-known technology used in cars, trucks, construction equipment, marine propulsion and backup power applications and it can range in size from small hand equipment to power systems serving many homes. Reciprocating engines employ the expansion of hot gases to push a piston within a cylinder, converting the linear movement of the piston into power. The high level of maturity and low-cost reliability make this option very interesting for CHP application.

- (2)

- Steam turbine: this represents one of the most versatile and oldest prime mover technologies; in general, it is used to drive a generator or mechanical machinery. Steam turbines are well suited to medium- and large-scale industrial and institutional applications in which fuels, such as coal, biomass, various solid wastes and refinery residual oil, are available [86]. They can also be joined in a combined cycle using the waste heat from a gas turbine. In CHP applications, steam at lower pressure can be extracted from the turbine and used directly in industrial processes or for district heating or it can be employed to produce hot or chilled water [86]. For industrial applications, steam turbines are a simpler case of using CHP.

- (3)

- Gas turbine: this is an aeroderivative technology; indeed, it began to be used in aeroplane propulsion in the 1940s. Since 1990, this technology has been employed for power only generation or in combined heat and power (CHP) systems in stationary applications in many countries of the world. In many cases, gas turbines are utilized by utilities to cover the energy demand peak. Gas turbines, available in sizes ranging from 150 kW to 250 MW, produce high-quality exhaust heat that can be used in CHP layout to reach overall efficiencies (electricity and thermal energy) of 70%–80% [87]. This makes gas turbines very attractive for CHP applications.

- (4)

- Microturbine: this is an electricity generator that burns gaseous and liquid fuels that can be used in power-only generation or in CHP systems to produce both electricity and heat on a small scale. The microturbine technology was originally based on the truck turbocharger technology that exploits the energy in engine exhaust heat [88]. The size range is from 30 to 300 kW and they are able to operate with several fuels and, in (CHP) applications, they may take an increasing share of this market, offering more benefits compared with other technologies for small-scale power generation [89]. Microturbines are mechanically simple and very compact. Their small size and low weight per unit of power lead to reduced engineering costs, while the small number of moving parts produces less noise [90].

- (5)

- Fuel cells: these are electrochemical systems capable of converting chemical energy of a fuel (generally hydrogen) directly into electricity without any direct combustion and intermediate thermal cycle. Since the fuel is not combusted, fuel cells offer a clean and efficient power generation system with very minimal air pollution. In CHP applications, the recovered heat depends on the type of fuel cell and its operating temperature. The parameters determining the performance of the fuel cell are dependent on the electrolyte material and composition of the membrane electrode assembly MEA [91]. The relationship of the materials to the performance of the device is significant and many important contributions in this topic can be found in the literature [92,93,94,95,96,97]. There are several kinds of fuel cells classified on the basis of the electrochemical process utilized. The principal types include: alkaline (AFC), polimer electrolyte (PEFC), phosphoric acid (PAFC), molten carbonate (MCFC) solid oxide (SOFC) and direct methanol (DMFC).

- (C1)

- Electric efficiency. This is defined as the ratio of the electric power output and the input power. In general it differs by technology and by size: larger systems are usually more efficient than smaller systems.

- (C2)

- Overall CHP efficiency. This expresses the energy content of both electricity and steam. It represents the net electrical power output plus the net thermal output (of the CHP system) divided by the fuel consumed.

- (C3)

- Fuel utilization. This measures the CHP efficiency as the ratio of net electrical output to net fuel consumption, in which the net fuel consumption does not include the share of fuel that produces the heat output.

- (C4)

- Power to heat ratio. This specifies the quantity of power (electrical or mechanical) to heat energy created in the CHP system.

- (C5)

- Installed costs. This criterion includes the costs of the equipment installation, project management, engineering and interest. Larger-capacity CHP systems in general have lower installed costs than smaller capacity systems.

- (C6)

- O&M costs. These include all the costs relating to the plant, employees’ wages, materials and installations, preventive maintenance transport and hire charges. As with capital costs, also the O&M costs tend to be reduced for larger systems.

- (C7)

- GHG reduction. Because in CHP systems less fuel is combusted, greenhouse gas emissions such as carbon dioxide (CO2) and other air pollutants are decreased. This criterion expresses the avoided GHG emissions due to the CHP system.

- Step 4.1: transform fuzzy data (Table 1) into interval data based on the alpha-cut using Equation (13);

- Step 4.2: normalize the interval (alpha cut = 0.1, 0.5, 0.9) decision matrix according to Equations (15) and (16) (Table 2);

- Step 4.3: calculate the lower bound and the upper bound of the interval entropy by Equations (17) and (18);

- Step 4.4: compute the degree of diversification and using Equations (19) and (20);

- Step 4.5: finally, by applying Equations (21) and (22), we obtain the lower and upper bounds of the interval weight, as shown in Table 3.

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Commission of the European Communities. Communication from the Commission to the Council, the European Parliament, the European Economic and Social Committee and the Committee of the Regions; Commission of the European Communities: Brussels, Belgium, 2008. [Google Scholar]

- European Parliament; Council of the European Union. Directive 2004/8/EC of the European Parliament and of the Council of 11 February 2004 on the Promotion of Cogeneration Based on a Useful Heat Demand in the Internal Energy Market and Amending Directive 92/42/EEC; Official Journal of the European Union: Brussels, Belgium, 2004. [Google Scholar]

- Balli, O.; Aras, H. Energetic and exergetic performance evaluation of a combined heat and power system with the micro gas turbine (MGTCHP). Int. J. Energy Res. 2007, 31, 1425–1440. [Google Scholar] [CrossRef]

- Ertesvag, I.S. Exergetic comparison of efficiency indicators for combined heat and power (CHP). Energy 2007, 32, 2038–2050. [Google Scholar] [CrossRef]

- Biezma, M.V.; San Cristobal, J.R. Investment criteria for the selection of cogeneration plants—A state of the art review. App. Therm. Eng. 2006, 26, 583–588. [Google Scholar] [CrossRef]

- Kupecki, J. Off-design analysis of a micro-CHP unit with solid oxide fuel cells fed by DME. Int. J. Hydrog. Energy 2015, 40, 12009–12022. [Google Scholar] [CrossRef]

- Seijo, S.; Del Campo, I.; Echanobe, J.; García-Sedano, J. Modeling and multi-objective optimization of a complex CHP process. Appl. Energy 2016, 161, 309–319. [Google Scholar] [CrossRef]

- Wang, H.; Yin, W.; Abdollahi, E.; Lahdelma, R.; Jiao, W. Modelling and optimization of CHP based district heating system with renewable energy production and energy storage. Appl. Energy 2015, 159, 401–421. [Google Scholar]

- Rossi, F.; Velázquez, D.; Monedero, I.; Biscarri, F. Artificial neural networks and physical modeling for determination of baseline consumption of CHP plants. Expert Syst. Appl. 2014, 41, 4658–4669. [Google Scholar] [CrossRef]

- Kortela, J.; Jämsä-Jounela, S.-L. Modeling and model predictive control of the BioPower combined heat and power (CHP) plant. Int. J. Electr. Power 2015, 65, 453–462. [Google Scholar] [CrossRef]

- Sanaye, S.; Nasab, A.M. Modeling and optimizing a CHP system for natural gas pressure reduction plant. Energy 2012, 40, 358–369. [Google Scholar] [CrossRef]

- Cavallaro, F.; Ciraolo, L. Sustainability Assessment of Solar Technologies Based on Linguistic Information. In Assessment and Simulation Tools for Sustainable Energy Systems; Cavallaro, F., Ed.; Springer-Verlag: London, UK, 2013; Volume 129, pp. 3–25. [Google Scholar]

- Cavallaro, F. Electricity from renewable energy sources: A multi-criteria evaluation framework of technologies. In Leading-Edge Electric Power Research; O’Sullivan, C.M., Ed.; Nova Science Publishers, Inc. Hauppauge: New York, NY, USA, 2008; pp. 173–204. [Google Scholar]

- Cavallaro, F. A comparative assessment of thin-film photovoltaic production processes using the ELECTRE III method. Energy Policy 2010, 38, 463–474. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F.; Shi, G.H.; Zhang, X.T. A fuzzy multi-criteria decision-making model for trigeneration system. Energy Policy 2008, 36, 3823–3832. [Google Scholar] [CrossRef]

- Nieto-Morote, A.; Ruz-Vila, F.; Cánovas-Rodríguez, F.J. Selection of a trigeneration system using a fuzzy AHP multi-criteria decision-making approach. Int. J. Energy Res. 2011, 35, 781–794. [Google Scholar] [CrossRef]

- Pilavachi, P.A.; Roumpeas, C.P.; Minett, S.; Afgan, N.H. Multi-criteria evaluation for CHP system options. Energy Convers. Manag. 2006, 47, 3519–3529. [Google Scholar] [CrossRef]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F. Weighting methodologies in multi-criteria evaluations of combined heat and power systems. Int. J. Energy Res. 2009, 33, 1023–1039. [Google Scholar] [CrossRef]

- Ebrahimi, M.; Keshavarz, A. Sizing the prime mover of a residential micro-combined cooling heating and power (CCHP) system by multi-criteria sizing method for different climates. Energy 2013, 54, 291–301. [Google Scholar] [CrossRef]

- Carvalho, M.; Lozano, M.A.; Serra, L.M. Multicriteria synthesis of trigeneration systems considering economic and environmental aspects. Appl. Energy 2012, 91, 245–254. [Google Scholar] [CrossRef]

- Hyde, K.; Maier, H.R.; Colby, C. Incorporating uncertainty in the PROMETHEE MCDA method. J. Multi- Criteria Decis. Anal. 2003, 12, 245–259. [Google Scholar] [CrossRef]

- Troldborg, M.; Heslop, S.; Hough, R.L. Assessing the sustainability of renewable energy technologies using multi-criteria analysis: Suitability of approach for national-scale assessments and associated uncertainties. Renew. Sustain. Energy Rev. 2014, 39, 1173–1184. [Google Scholar] [CrossRef]

- Wang, H.; Jiao, W.; Lahdelma, R.; Zhu, C.; Zou, P. Stochastic Multicriteria Acceptability Analysis for Evaluation of Combined Heat and Power Units. Energies 2015, 8, 59–78. [Google Scholar] [CrossRef]

- Zadeh, L. Fuzzy sets. Inf. Control 1965, 8, 338–353. [Google Scholar] [CrossRef]

- Ross, T.J. Fuzzy Logic with Engineering Applications, 3rd ed.; John Wiley & Sons, Ltd: Chichester, UK, 2010. [Google Scholar]

- Bojadziev, B.; Bojadziev, M. Fuzzy Logic for Business, Finance, and Management; World Scientific Publishing: Singapore, 2007. [Google Scholar]

- Zimmermann, H.J. Fuzzy set theory. WIREs Compt. Stat. 2010, 2, 317–332. [Google Scholar] [CrossRef]

- Cavallaro, F. A Takagi-Sugeno Fuzzy Inference System for Developing a Sustainability Index of Biomass. Sustainability 2015, 7, 12359–12371. [Google Scholar] [CrossRef]

- Hosseinzadeh Lotfi, F.; Fallahnejad, R. Imprecise Shannon’s Entropy and Multi Attribute Decision Making. Entropy 2010, 12, 53–62. [Google Scholar] [CrossRef]

- Cavallaro, F. Fuzzy TOPSIS approach for assessing thermal-energy storage in concentrated solar power (CSP) systems. Appl. Energy 2010, 87, 496–503. [Google Scholar]

- Dawes, R.M.; Corrigan, B. Linear models in decision making. Psychol. Bull. 1974, 81, 95–106. [Google Scholar] [CrossRef]

- Jia, J.; Fischer, G.W.; Dyer, J.S. Attribute Weighting Methods and Decision Quality in the Presence of Response Error: A Simulation Study. J. Behav. Decis. Mak. 1998, 11, 85–105. [Google Scholar] [CrossRef]

- Chen, M.F.; Tseng, G.H.; Ding, C.G. Fuzzy MCDM approach to select service provider. In Proceedings of the 12th IEEE International Conference on Fuzzy System, St Louis, MO, USA, 25–28 May 2003; pp. 572–577.

- Barron, F.H.; Barrett, B.E. Decision Quality Using Ranked Attribute weights. Manag. Sci. 1996, 42, 1515–1525. [Google Scholar] [CrossRef]

- Stillwell, W.G.; Seaver, D.A.; Edwards, W.A. Comparison of Weight Approximation Techniques in Multiattribute Utility Decision Making. Organ. Behav. Hum. Perform. 1981, 28, 62–77. [Google Scholar] [CrossRef]

- Eckenrode, R.T. Weighting multiple criteria. Manag. Sci. 1965, 12, 180–192. [Google Scholar] [CrossRef]

- Kirkwood, C.W.; Sarin, R.K. Ranking with partial information: A method and an application. Oper. Res. 1985, 33, 38–48. [Google Scholar] [CrossRef]

- Wang, T.C.; Chang, T.H. Application of TOPSIS in evaluating initial training aircraft under a fuzzy environment. Expert Syst. Appl. 2007, 33, 870–880. [Google Scholar] [CrossRef]

- Hobbs, B.F. A Comparison of Weighting Methods in Power Plant Siting. Decis. Sci. 1980, 11, 725–737. [Google Scholar] [CrossRef]

- Schoemaker, P.J.H.; Waid, C.C. An experimental comparison of different approaches to determining weights in additive utility models. Manag. Sci. 1982, 28, 185–196. [Google Scholar] [CrossRef]

- Deng, H.; Yeh, C.H.; Willis, R.J. Inter-company comparison using modified TOPSIS with objective weights. Comput. Oper. Res. 2000, 27, 963–973. [Google Scholar] [CrossRef]

- Mareschal, B. Weight stability intervals in multicriteria decision aid. Eur. J. Oper. Res. 1988, 33, 54–64. [Google Scholar] [CrossRef]

- Triantaphyllou, E.; Sanchez, A. A sensitivity analysis approach for some deterministic multi-criteria decision making methods. Decis. Sci. 1997, 28, 151–194. [Google Scholar] [CrossRef]

- Shannon, C.E. Mathematical Theory of Communication. Bell Sys. Tech. J. 1948, 27, 379–423, 623–656. [Google Scholar] [CrossRef]

- Wang, T.C.; Lee, H.D. Developing a fuzzy TOPSIS approach based on subjective weights and objective weights. Expert Syst. Appl. 2009, 36, 8980–8985. [Google Scholar] [CrossRef]

- Hwang, C.L.; Yoon, K. Multiple Attribute Decision Making. Methods and Applications; Springer-Verlag Berlin: Heidelberg, Germany, 1981. [Google Scholar]

- Kapur, J.N. Measures of Uncertainty Mathematical Programming and Physics; Department of Mathematical Sciences Mellon College of Science: Pittsburgh, PA, USA, 1970. [Google Scholar]

- Güneralp, B.; Gertner, G.; Mendoza, G.; Anderson, A. Evaluating probabilistic data with a possibilistic criterion in land-restoration decision-making: Effects on the precision of results. Fuzzy Set Syst. 2007, 158, 1546–1560. [Google Scholar] [CrossRef]

- De Luca, A.; Termini, S. A definition of non-probabilistic entropy in setting of fuzzy set theory. Inf. Control 1972, 20, 301–312. [Google Scholar] [CrossRef]

- Singpurwalla, N.D.; Booker, J.M. Membership functions and probability measures of fuzzy sets. J. Am. Stat. Assoc. 2004, 99, 867–889. [Google Scholar] [CrossRef]

- Emptoz, H. Non-probabilistic entropies and indetermination process in the setting of fuzzy set theory. Fuzzy Sets Syst. 1981, 5, 307–317. [Google Scholar] [CrossRef]

- Burg, J.P. Maximum Entropy Spectral Analysis. In Proceedings of the 37th Meeting of the Society of Exploration Geophysicists, Oklahoma City, OK, USA, 31 October 1967.

- Rosenfeld, R. Adaptive Statistical Language Modeling: A Maximum Entropy Approach. Ph.D. Thesis, School of Computer Science Carnegie Mellon University, Pittsburgh, PA, USA, April 1994. [Google Scholar]

- Golan, A.; Judge, G.G.; Miller, D. Maximum Entropy Econometrics: Robust Estimation with Limited Data; John Wiley and Sons: New York, NY, USA, 1996. [Google Scholar]

- Esmaeili, A.; Kahnali, R.A.; Rostamzadeh, R.; Zavadskas, E.K.; Ghoddami, B. An Application of Fuzzy Logic to Assess Service Quality Attributes in Logistics Industry. Transport 2015, 30, 172–181. [Google Scholar] [CrossRef]

- Kildiene, S.; Kaklauskas, A.; Zavadskas, E.K. COPRAS Based Comparative Analysis of The European Country Management Capabilities Within The Construction Sector in The Time of Crisis. J. Bus. Econ. Manag. 2011, 12, 417–434. [Google Scholar] [CrossRef]

- Saparauskas, J.; Zavadskas, E.K.; Turskis, Z. Selection of Facade’s Alternatives of Commercial and Public Buildings Based on Multiple Criteria. Int. J. Strateg. Prop. Manag. 2011, 15, 189–203. [Google Scholar] [CrossRef]

- Susinskas, S.; Zavadskas, E.K.; Turskis, Z. Multiple Criteria Assessment of Pile-Columns Alternatives. Balt. J. Road Bridge Eng. 2011, 6, 145–152. [Google Scholar] [CrossRef]

- Son, C. Similarity measuring strategy of image patterns based on fuzzy entropy and energy variations in intelligent robot’s manipulative task. Appl. Intell. 2013, 38, 131–145. [Google Scholar] [CrossRef]

- Zhao, H.; Guo, S. Selecting Green Supplier of Thermal Power Equipment by Using a Hybrid MCDM Method for Sustainability. Sustainability 2014, 6, 217–235. [Google Scholar] [CrossRef]

- Won, K.; Chung, E.-S.; Choi, S.-U. Parametric Assessment of Water Use Vulnerability Variations Using SWAT and Fuzzy TOPSIS Coupled with Entropy. Sustainability 2015, 7, 12052–12070. [Google Scholar] [CrossRef]

- Erol, I.; Sencer, S.; Ozmen, A.; Searcy, C. Fuzzy MCDM framework for locating a nuclear power plant in Turkey. Energy Policy 2014, 67, 186–197. [Google Scholar]

- Erol, I.; Sencer, S.; Sari, R. A new fuzzy multi-criteria framework for measuring sustainability performance of a supply chain. Ecol. Econ. 2011, 70, 1088–1100. [Google Scholar] [CrossRef]

- Jahanshahloo, G.R.; Hosseinzadeh Lotfi, F.; Izadikhah, M. Extension of the TOPSIS method for decision-making problems with fuzzy data. Appl. Math. Comput. 2006, 181, 1544–1551. [Google Scholar] [CrossRef]

- Liang, G.S. Fuzzy MCDM based on ideal and anti-ideal concepts. Eur. J. Oper. Res. 1999, 112, 682–691. [Google Scholar] [CrossRef]

- Li, R.J. Fuzzy method in group decision making. Comput. Math. Appl. 1999, 38, 91–101. [Google Scholar] [CrossRef]

- Kahraman, C.; Cevik, S.; Ates, N.Y.; Gulbay, M. Fuzzy multi-criteria evaluation of industrial robotic systems. Comput. Ind. Eng. 2007, 52, 414–433. [Google Scholar] [CrossRef]

- Yong, D. Plant selection based on fuzzy TOPSIS. Int. J. Adv. Manuf. 2006, 28, 839–844. [Google Scholar] [CrossRef]

- Chen, C.T. Extension of the TOPSIS for group decision-making under fuzzy environment. Fuzzy Sets Syst 2000, 114, 1–9. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Shariati, S.; Yakhchali, S.H.; Zavadskas, E.K. Proposing a new methodology for prioritising the investment strategies in the private sector of Iran. Ekon. Istraz. 2014, 27, 320–345. [Google Scholar]

- Fouladgar, M.M.; Yazdani-Chamzini, A.; Zavadskas, E.K. Risk evaluation of tunneling projects. Arch. Civ. Mech. Eng. 2012, 12, 1–12. [Google Scholar] [CrossRef]

- Kaya, T.; Kahraman, C. Multicriteria decision making in energy planning using a modified fuzzy TOPSIS methodology. Expert Syst. Appl. 2011, 38, 6577–6585. [Google Scholar] [CrossRef]

- Doukas, H.; Karakosta, C.; Psarras, J. Computing with words to assess the sustainability of renewable energy options. Expert Syst. Appl. 2010, 37, 5491–5497. [Google Scholar] [CrossRef]

- Chamodrakas, I.; Martakos, D.A. Utility-based fuzzy TOPSIS method for energy efficient network selection in heterogeneous wireless networks. Appl. Soft Comput. 2011, 11, 3734–3743. [Google Scholar] [CrossRef]

- Boran, F.E.; Boran, K.; Menlik, T. The evaluation of renewable energy technologies for electricity generation in Turkey using intuitionistic fuzzy TOPSIS. Energy Sour. Part B 2012, 7, 81–90. [Google Scholar] [CrossRef]

- Yazdani-Chamzini, A.; Fouladgar, M.M.; Zavadskas, E.K.; Moini, H.H. Selecting the Optimal Renewable Energy Using Multi Criteria Decision Making. J. Bus. Econ. Manag. 2013, 14, 957–978. [Google Scholar] [CrossRef]

- Şengül, Ü.; Eren, M.; Eslamian Shiraz, S.; Gezder, V.; Sengül, A.B. Fuzzy TOPSIS method for ranking renewable energy supply systems in Turkey. Renew. Energy 2015, 75, 617–625. [Google Scholar] [CrossRef]

- Sianaki, O.A.; Masoum, M.A.S. A multi-agent intelligent decision making support system for home energy management in smart grid: A fuzzy TOPSIS approach. Multiagent Grid Syst. 2013, 9, 181–195. [Google Scholar] [CrossRef]

- Hawkes, A.D.; Leach, M.A. Cost-effective operating strategy for residential micro-combined heat and power. Energy 2007, 32, 711–723. [Google Scholar] [CrossRef]

- EPA—United States Environmental Protection Agency. Available online: http://www.epa.gov/chp/index.html (accessed on 16 October 2014).

- European Commission-SETIS section on Cogeneration, Cogeneration, or Combined Heat and Power (CHP). Available online: http://setis.ec.europa.eu/technologies/chp (accessed on 16 October 2014).

- UNEP-DTIE. Technical Report on Biomass fired Fluidised Bed Combustion Boiler Technology for Cogeneration; UNEP-DTIE: Paris, France, 2007. [Google Scholar]

- Vatopoulos, K.; Andrews, D.; Carlsson, J.; Papaioannou, I.; Zubi, G. Study on the State of Play of Energy Efficiency of Heat and Electricity Production Technologies; European Commission: Brussels, Belgium, 2007. [Google Scholar]

- International Energy Agency (IEA). Combined Heat and Power. Evaluating the Benefits of Greater Global Investment; International Energy Agency (IEA): Paris, France, 2008. [Google Scholar]

- EPA-Combined Heat and Power Partnership, Catalog of CHP technologies. Available online: http://www.epa.gov/chp/documents/catalog_chptech_full.pdf (accessed on 8 September 2014).

- EPA-Combined Heat and Power Partnership, Catalog of CHP technologies—Section 4. Technology Characterization–SteamTurbines. Available online: http://www.epa.gov/chp/documents/catalog_chptech_steam_turbines.pdf (accessed on 8 September 2014).

- EPA-Combined Heat and Power Partnership, Catalog of CHP technologies—Section 4. Technology Characterization–Gas Turbines. Available online: http://www.epa.gov/chp/documents/catalog_chptech_3.pdf (accessed on 8 September 2014).

- EPA-Combined Heat and Power Partnership, Catalog of CHP technologies—Section 4. Technology Characterization–Microturbines. Available online: http://www.epa.gov/chp/documents/catalog_chptech_5.pdf (accessed on 8 September 2014).

- Pilavachi, P.A. Power generation with gas turbine systems and combined heat and power. Appl. Therm. Eng. 2000, 20, 1421–1429. [Google Scholar] [CrossRef]

- Pilavachi, P.A. Mini and Micro-Gas Turbine for Combined Heat and Power. Appl. Therm. Eng. 2002, 22, 2003–2014. [Google Scholar] [CrossRef]

- Morse, J.D. Micro-fuel cell power sources. Int. J. Energy Res. 2007, 31, 576–602. [Google Scholar] [CrossRef]

- Steele Brian, C.H.; Heinzel, A. Materials for fuel-cell technologies. Nature 2001, 414, 345–352. [Google Scholar]

- Karpenko-Jereb, L.; Sternig, C.; Fink, C.; Hacker, V.; Theiler, A.; Tatschl, R. Theoretical study of the influence of material parameters on the performance of a polymer electrolyte fuel cell. J. Power Sour. 2015, 297, 329–343. [Google Scholar] [CrossRef]

- Awang, N.; Ismail, A.F.; Jaafar, J.; Matsuura, T.; Junoh, H.; Othman, M.H.D.; Rahman, M.A. Functionalization of polymeric materials as a high performance membrane for direct methanol fuel cell: A review. React. Funct. Polym. 2015, 86, 248–258. [Google Scholar] [CrossRef]

- Sahai, Y.; Ma, J. High Performance Polymer Hydrogel Based Materials for Fuel Cells. In Polymers for Energy Storage and Conversion; Mittal, V., Ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2013. [Google Scholar]

- Otomo, J.; Waki, K.; Yamada, K. Multicriteria Assessment of the Performance of Solid Oxide Fuel Cells by Cell Design and Materials Development: Design and Modeling Approach. J. Fuel Cell Sci. Technol. 2013, 10, 1–11. [Google Scholar] [CrossRef]

- Liso, V.; Zhao, Y.; Yang, W.; Nielsen, M.P. Modelling of a Solid Oxide Fuel Cell CHP System Coupled with a Hot Water Storage Tank for a Single Household. Energies 2015, 8, 2211–2229. [Google Scholar] [CrossRef]

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | ||

|---|---|---|---|---|---|---|---|---|

| Electric Efficiency (%) | Overall CHP Efficiency (%) | Fuel Utilization (%) | Power to Heat Ratio (%) | Installed Costs ($/kWe) | O&M Costs ($/kWhe) | GHG Reduction (%) | ||

| A1 | Recip. engine | (27,34,41) | (77,78.5,80) | (75,77.5,80) | (0.5,0.85,1.2) | (1500,2200,2900) | (0.009,0.017,0.025) | (31.50,35,38.5) |

| A2 | Steam turbine | (5,17.5,30) | (70,75,80) | (75,76,77) | (0.07,0.085,0.1) | (670,885,1100) | (0.006,0.008,0.01) | (38.70,43,47.3) |

| A3 | Gas turbine | (24,30,36) | (66,68.5,71) | (50,56,62) | (0.6,0.85,1.1) | (1200,2250,3000) | (0.006,0.00095,0.13) | (41.40,46,50.6) |

| A4 | Microturbine | (22,29,36) | (63,66.5,70) | (49,53,57) | (0.5,0.6,0.7) | (2500,3400,4300) | (0.009,0.011,0.13) | (47.70,53,58.3) |

| A5 | Fuel cell | (30,46.5,63) | (55,67.5,80) | (55,67.5,80) | (1,1.5,2) | (5000,5750,6500) | (0.032,0.035,0.038) | (50.40,56,61.6) |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | ||

|---|---|---|---|---|---|---|---|---|

| Electric Efficiency (%) | Overall CHP Efficiency (%) | Fuel Utilization (%) | Power to Heat Ratio (%) | Installed Costs ($/kWe) | O&M Costs ($/kWhe) | GHG reduction (%) | ||

| α = 0.1 | ||||||||

| A1 | Recip. engine | [0.143,0.208] | [0.204,0.211] | [0.213,0.226] | [0.107,0.234] | [0.090,0.162] | [0.101,0.249] | [0.125,0.150] |

| A2 | Steam turbine | [0.032,0.149] | [0.186,0.210] | [0.213,0.218] | [0.014,0.020] | [0.040,0.062] | [0.064,0.101] | [0.154,0.185] |

| A3 | Gas turbine | [0.127,0.183] | [0.175,0.187] | [0.143,0.174] | [0.126,0.216] | [0.074,0.167] | [0.065,0.130] | [0.165,0.197] |

| A4 | Microturbine | [0.115,0.143] | [0.167,0.184] | [0.140,0.160] | [0.102,0.139] | [0.148,0.241] | [0.095,0.132] | [0.190,0.227] |

| A5 | Fuel cell | [0.164,0.317] | [0.149,0.208] | [0.159,0.223] | [0.211,0.392] | [0.291,0.368] | [0.332,0.388] | [0.201,0.240] |

| α = 0.5 | ||||||||

| A1 | Recip. engine | [0.174,0.214] | [0.211,0.215] | [0.222,0.230] | [0.150,0.228] | [0.115,0.159] | [0.145,0234] | [0.136,0.150] |

| A2 | Steam turbine | [0.064,0.135] | [0.197,0.210] | [0.220,0.223] | [0.017,0.021] | [0.048,0.062] | [0.078,0.100] | [0.167,0.185] |

| A3 | Gas turbine | [0.154,0.188] | [0.182,0.189] | [0.155,0.172] | [0.161,0.217] | [0.103,0.159] | [0.086,0.125] | [0.179,0.197] |

| A4 | Microturbine | [0.134,0.151] | [0.176,0.185] | [0.149,0.160] | [0.122,0.145] | [0.184,0.240] | [0.111,0.134] | [0.206,0.227] |

| A5 | Fuel cell | [0.218,0.312] | [0.166,0.200] | [0.179,0.215] | [0.278,0.390] | [0.335,0.381] | [0.373,0.407] | [0.217,0.240] |

| α = 0.9 | ||||||||

| A1 | Recip. engine | [0.211,0.220] | [0.219,0.219] | [0.232,0.234] | [0.203,0.221] | [0.145,0.155] | [0.197,0.216] | [0.147,0.150] |

| A2 | Steam turbine | [0.103,0.119] | [0.208,0.211] | [0.228,0.229] | [0.021,0.022] | [0.059,0.062] | [0.095,0.100] | [0.181,0.185] |

| A3 | Gas turbine | [0.187,0.194] | [0.190,0.192] | [0.167,0.170] | [0.206,0.218] | [0.137,0.149] | [0.111,0.120] | [0.194,0.197] |

| A4 | Microturbine | [0.157,0.161] | [0.185,0.186] | [0.158,0.161] | [0.147,0.152] | [0.225,0.238] | [0.131,0.136] | [0.223,0.227] |

| A5 | Fuel cell | [0.285,0.306] | [0.185,0.192] | [0.199,0.207] | [0.362,0.387] | [0.387,0.397] | [0.421,0.429] | [0.236,0.240] |

| Α = 0.1 | Α = 0.5 | Α = 0.9 | |||||||

|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.022 | 0.743 | 0.38 | 0.033 | 0.420 | 0.23 | 0.065 | 0.142 | 0.10 |

| C2 | 0.001 | 0.152 | 0.08 | 0.001 | 0.082 | 0.04 | 0.003 | 0.018 | 0.01 |

| C3 | 0.005 | 0.189 | 0.10 | 0.007 | 0.109 | 0.06 | 0.015 | 0.036 | 0.03 |

| C4 | 0.106 | 0.876 | 0.49 | 0.155 | 0.607 | 0.38 | 0.275 | 0.383 | 0.33 |

| C5 | 0.064 | 0.774 | 0.42 | 0.104 | 0.530 | 0.32 | 0.209 | 0.313 | 0.14 |

| C6 | 0.063 | 0.783 | 0.42 | 0.104 | 0.537 | 0.32 | 0.213 | 0.320 | 0.27 |

| C7 | 0.006 | 0.227 | 0.12 | 0.009 | 0.130 | 0.07 | 0.017 | 0.042 | 0.03 |

| Α = 0.1 | Α = 0.5 | Α = 0.9 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| d+ | d− | Cci | Rank | d+ | d− | Cci | Rank | d+ | d− | Cci | Rank | |

| A1 | 6.043 | 1.001 | 0.142 | 4 | 6.345 | 0.686 | 0.098 | 4 | 6.558 | 0.467 | 0.066 | 4 |

| A2 | 5.975 | 1.066 | 0.151 | 2 | 6.281 | 0.744 | 0.106 | 2 | 6.490 | 0.526 | 0.075 | 2 |

| A3 | 5.950 | 1.095 | 0.155 | 1 | 6.267 | 0.764 | 0.109 | 1 | 6.484 | 0.541 | 0.077 | 1 |

| A4 | 6.151 | 0.858 | 0.122 | 5 | 6.419 | 0.587 | 0.084 | 5 | 6.607 | 0.398 | 0.057 | 5 |

| A5 | 5.987 | 1.053 | 0.150 | 3 | 6.312 | 0.712 | 0.101 | 3 | 6.546 | 0.470 | 0.067 | 3 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cavallaro, F.; Zavadskas, E.K.; Raslanas, S. Evaluation of Combined Heat and Power (CHP) Systems Using Fuzzy Shannon Entropy and Fuzzy TOPSIS. Sustainability 2016, 8, 556. https://doi.org/10.3390/su8060556

Cavallaro F, Zavadskas EK, Raslanas S. Evaluation of Combined Heat and Power (CHP) Systems Using Fuzzy Shannon Entropy and Fuzzy TOPSIS. Sustainability. 2016; 8(6):556. https://doi.org/10.3390/su8060556

Chicago/Turabian StyleCavallaro, Fausto, Edmundas Kazimieras Zavadskas, and Saulius Raslanas. 2016. "Evaluation of Combined Heat and Power (CHP) Systems Using Fuzzy Shannon Entropy and Fuzzy TOPSIS" Sustainability 8, no. 6: 556. https://doi.org/10.3390/su8060556