An Investigation of Sustainable Power Generation from Oil Palm Biomass: A Case Study in Sarawak

Abstract

:1. Introduction

- (a)

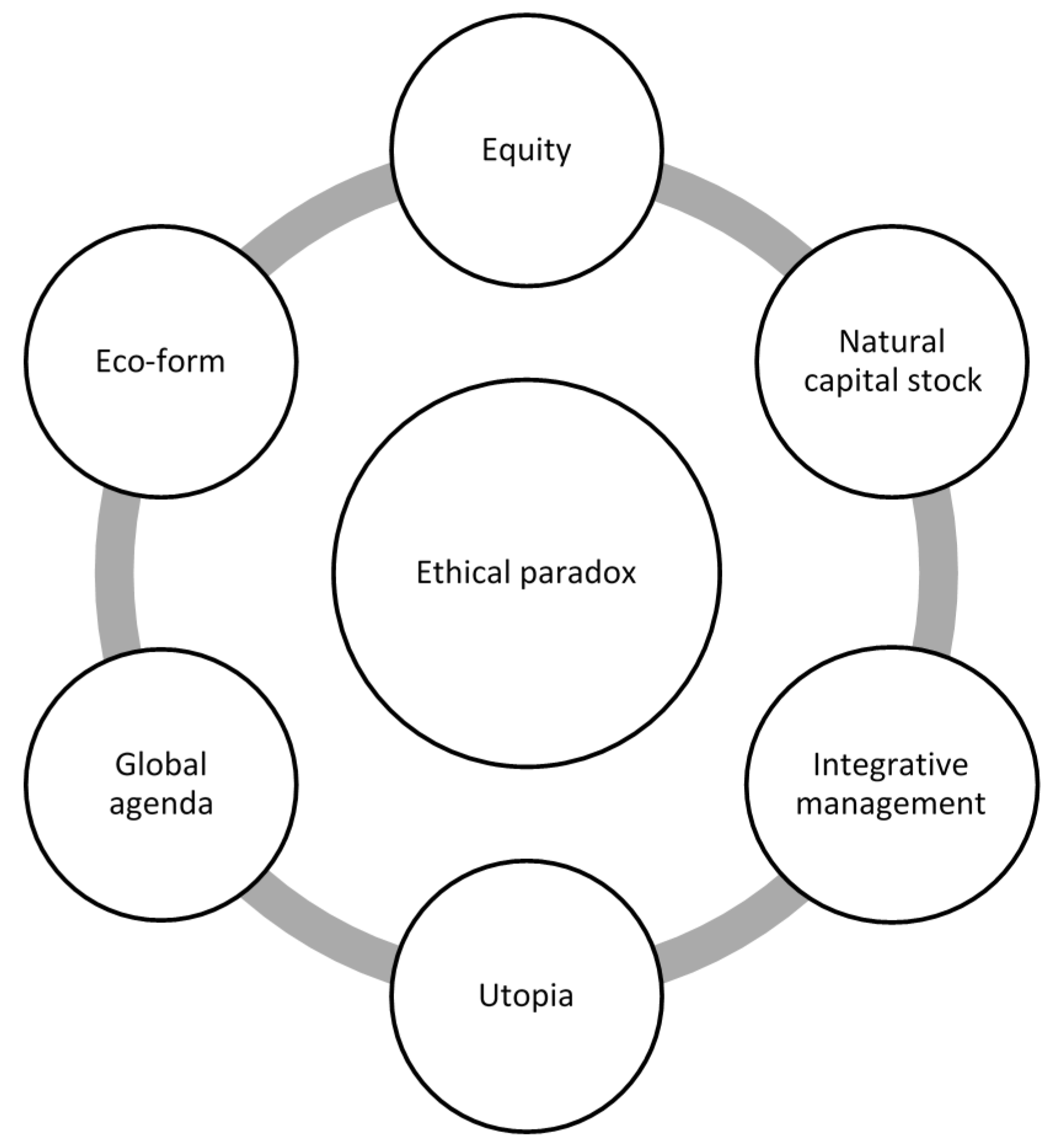

- Ethical paradox: This is the heart of the framework where ethics represents the paradox between sustainability and development [16].

- (b)

- Equity: This concept depicts the social aspect of sustainability. It embodies very wide concepts such as environmental, social equity, quality of life, democracy, freedom, participation and empowerment. Basically, sustainability works by sharing the capacity for the well-being of the current generation without adversely affecting the next generations [16].

- (c)

- Natural capital stock: This concept represents the environmental and natural resource assets of development and preservation which aims to keep the natural capital constant for the benefit of future generations [16].

- (d)

- Integrative management: This concept emphasizes that the integration of the three components—environmental, economic and social—in planning and management for sustainable development is critical for sustainability [16].

- (e)

- Utopia: This concept represents visions for human habitats in accordance with sustainability development where people live perfectly contentedly and flourish with nature [16].

- (f)

- Global agenda: This concept represents a global political environmental discourse reconstituted around the ideas of sustainability. The concept reflects the difference in demand between the Northern and Southern countries [16].

- (g)

- Eco-form: This concept derived from the ecologically-desired form of urban spaces and communities which focus on energy efficiency and sustain a long life [16].

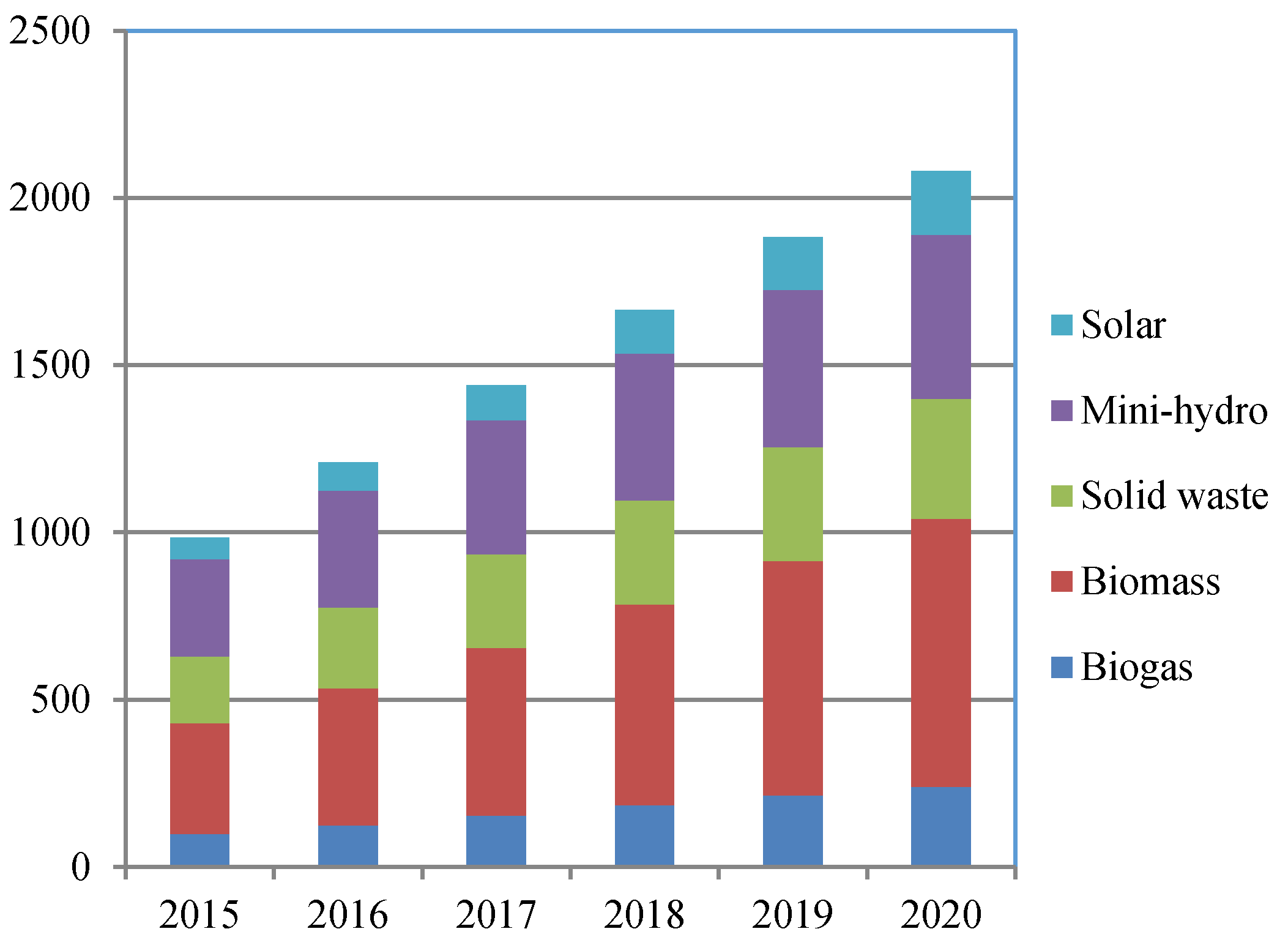

2. Renewable Energy Programmes

2.1. Small Renewable Energy Power (SREP)

2.2. The Feed-in-Tariff (FiT)

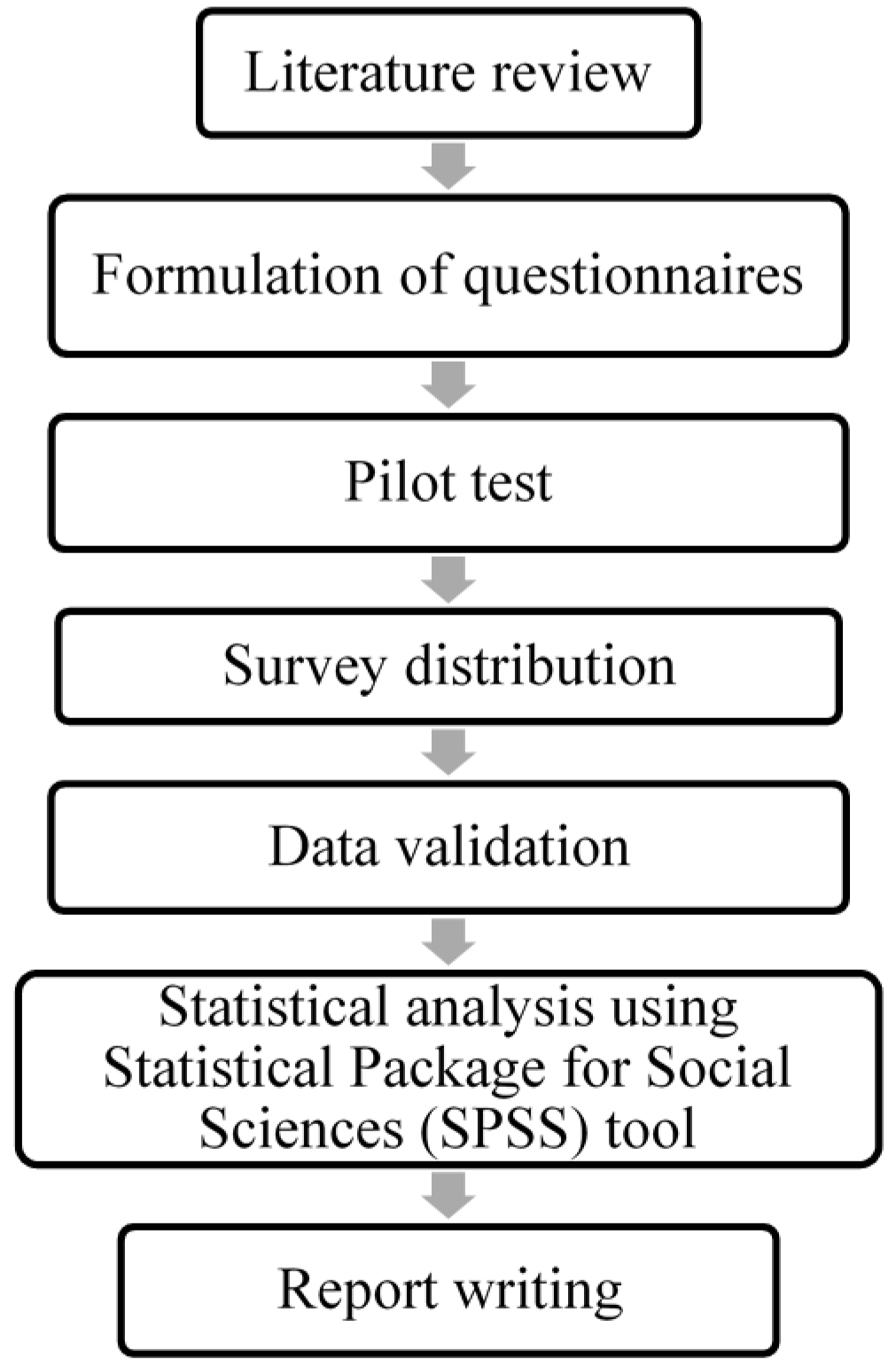

3. Methodology

3.1. Formulation of Questionnaires

- (1)

- Sustainability of biomass supply chain,

- (a)

- The questions are related to the capacity of the palm oil mill

- (b)

- Quantity of palm oil biomass produced in their mill

- (c)

- Quantity of biomass bought from outside supplier

- (d)

- Biomass utilization

- (e)

- Cost of the purchased biomass

- (2)

- Sustainability of conversion technology,

- (a)

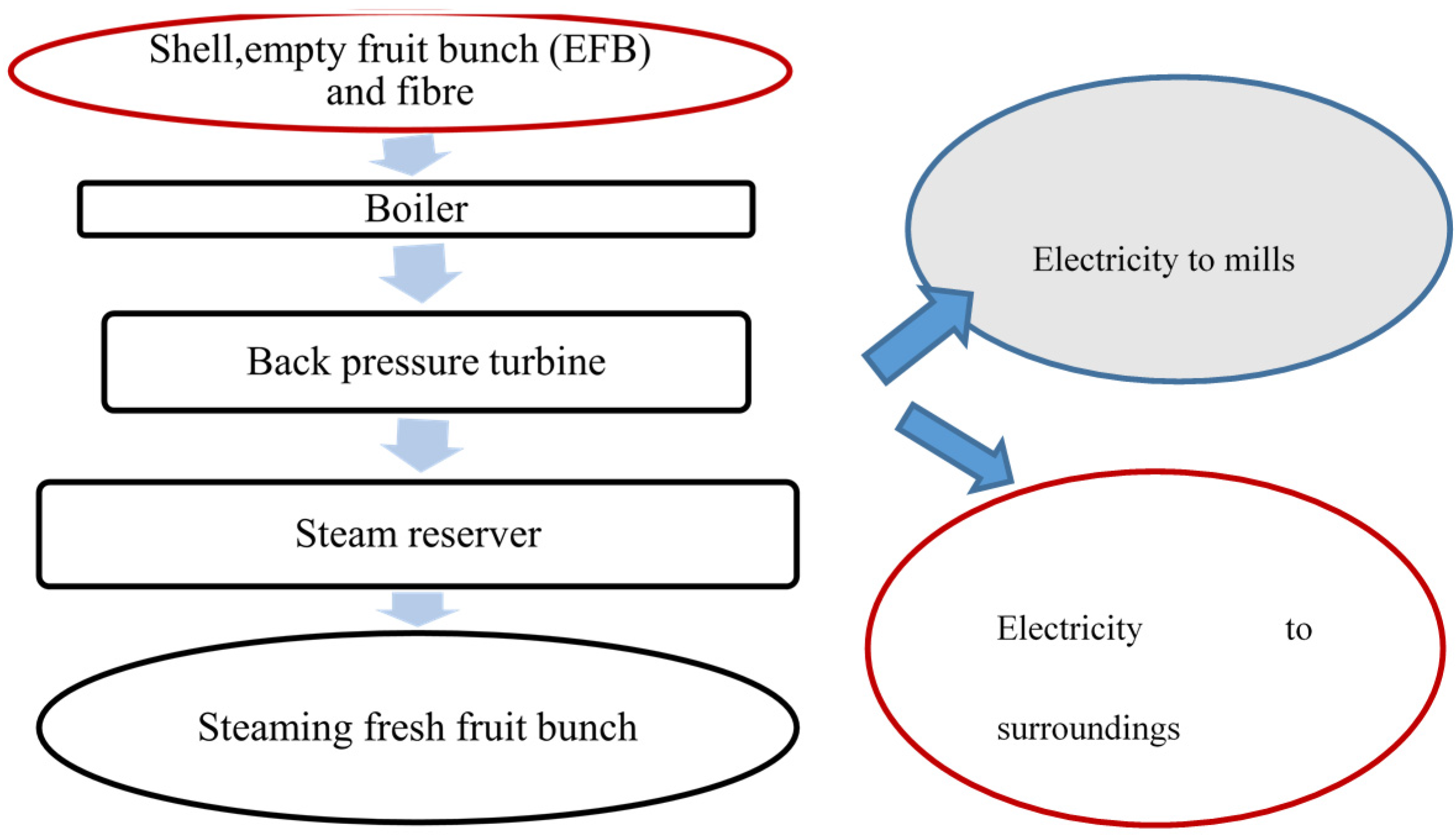

- Types of conversion technology used

- (b)

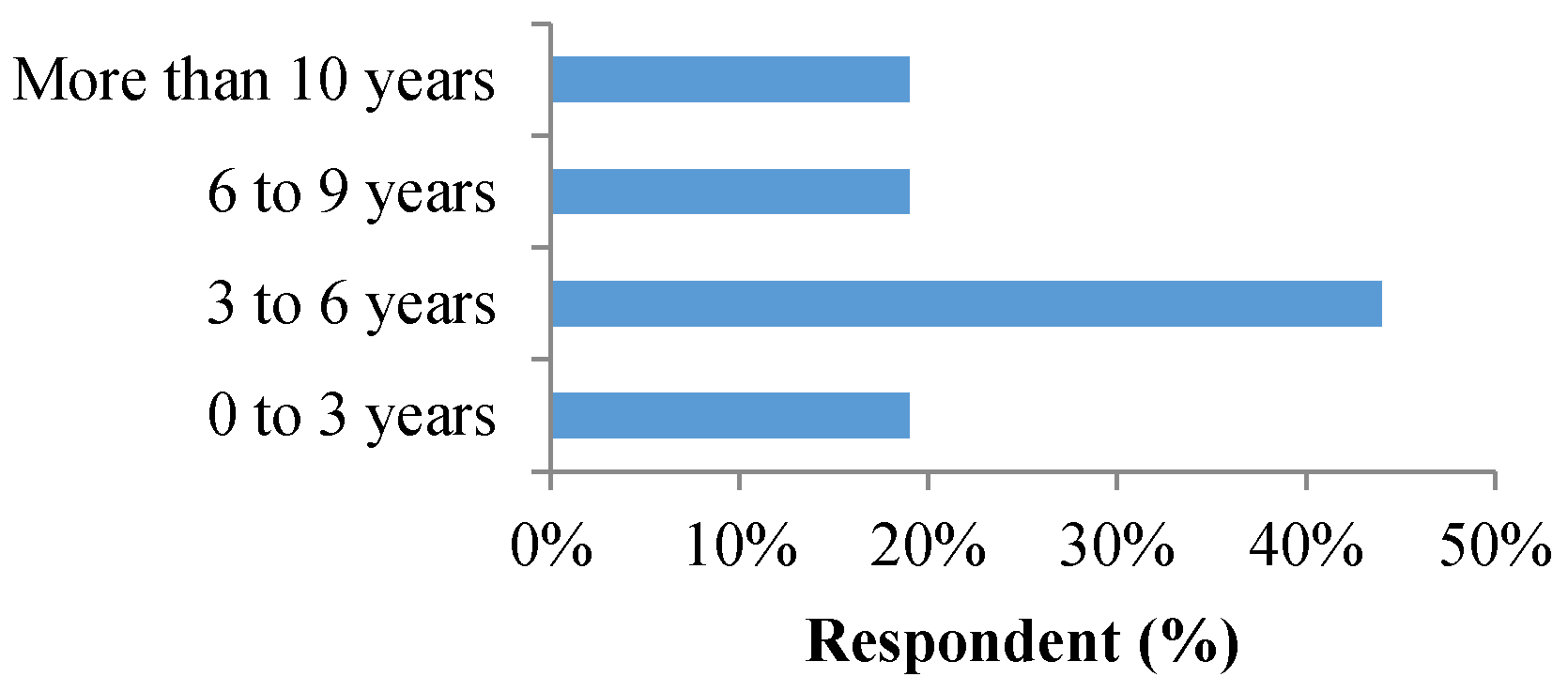

- Years of operation

- (c)

- Efficiency of biomass conversion technology

- (3)

- Sustainability of grid network system,

- (a)

- Usage of electricity generated from mill

- (b)

- Distance of nearest grid point

- (4)

- Key challenges and future prospect of power generation from palm biomass.

- (a)

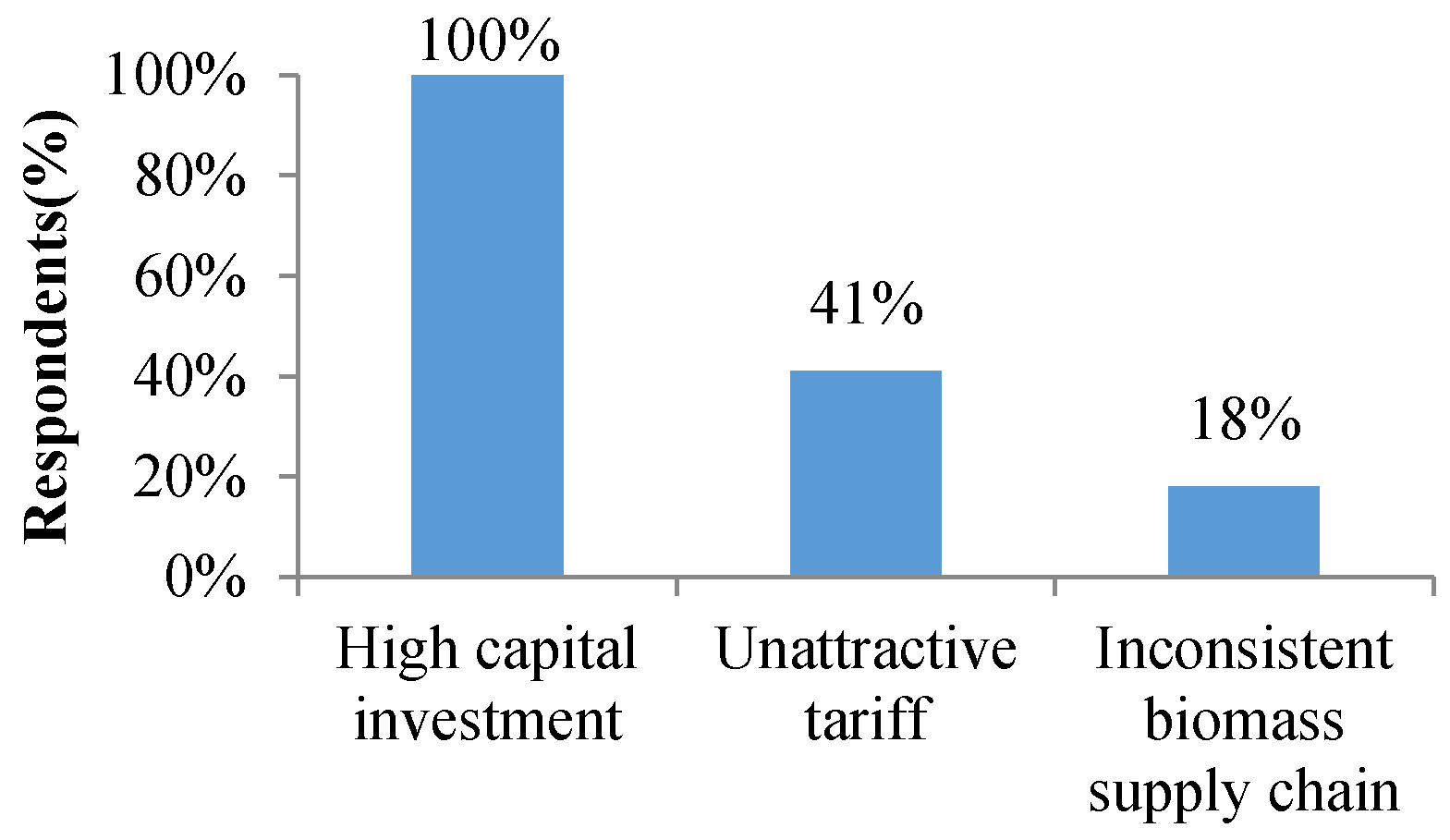

- Key challenges of power generation from palm biomass

- Inconsistent supply of biomass

- Cost

- Unattractive tariff

- Low expertise

- (b)

- Willingness to collaborate for joint-venture with other developers for high-efficient biomass conversion technology

3.2. Pilot Test

3.3. Sample Size

3.4. Survey Distribution

4. Results and Discussion

4.1. Sustainability of Biomass Supply Chain

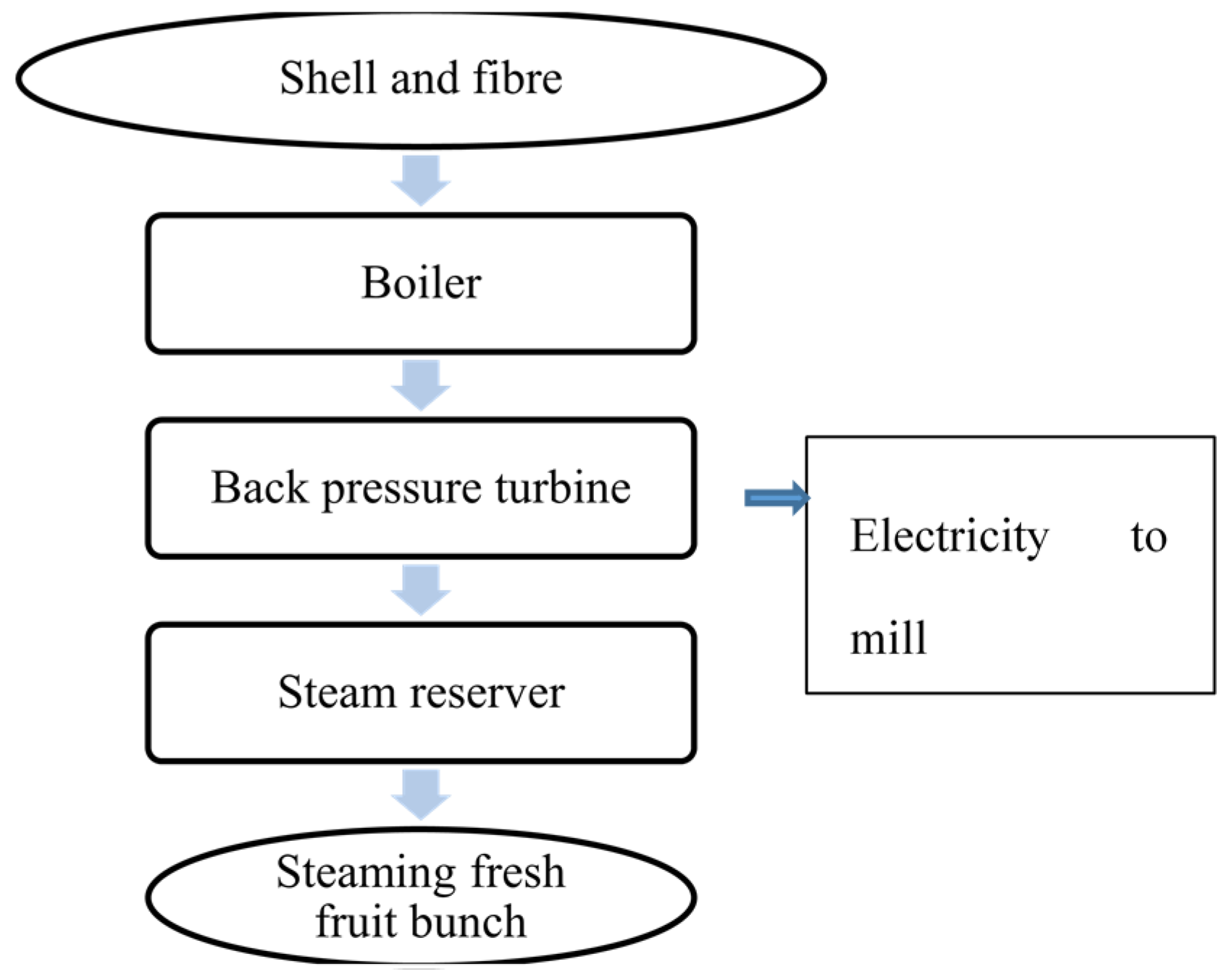

4.2. Sustainability of Conversion Technology

4.3. Sustainability of the Grid Network System

4.4. Key Challenges in Implementing Biomass Renewable Energy in Sarawak

4.5. Future Prospects of the Biomass Renewable Energy Business in Sarawak

4.5.1. Palm Biomass Power Plant Joint-Venture

Capacity of Power Plant

Sustainability of Biomass Supply Chain

Environmental Issues

Electricity Sales Revenue

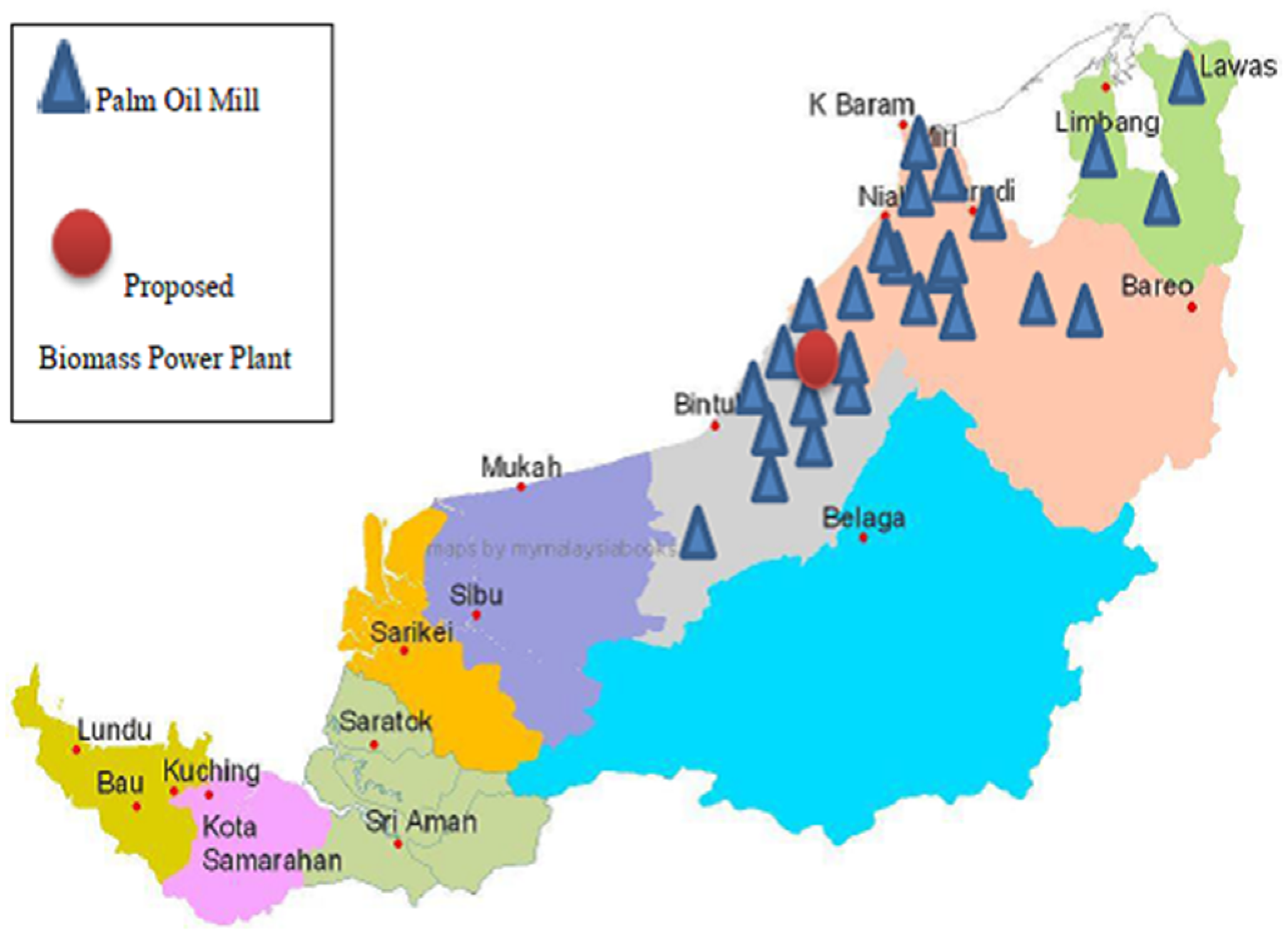

Location of the Proposed Biomass Power Plant

Incentives

4.5.2. Use of Palm Biomass as Fuel for Decentralized Power Generation for Rural Electrification

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Economics and Industry Development Division of Malaysian Palm Oil Board, Overview of the Malaysian Oil Palm Industry. Available online: http://bepi.mpob.gov.my/imagesoverview/Overview_of_Industry_2013.pdf (accessed on 21 April 2016).

- Agensi Innovasi Malaysia. National Biomass Strategy 2020: New Wealth Creation for Malaysia’s Biomass Industry; AIM: Selangor, Malaysia, 2013. [Google Scholar]

- Umar, M.S.; Jennings, P.; Urmee, T. Generating renewable energy from oil palm biomass in Malaysia: The Feed-in Tariff policy framework. Biomass Bioenergy 2014, 62, 37–46. [Google Scholar] [CrossRef]

- Mekhilef, S.; Saidur, R.; Safaria, A.; Mustaffaa, W.E.S.B. Biomass energy in Malaysia: Current state and prospects. Renew. Sustain. Energy Rev. 2011, 15, 3360–3370. [Google Scholar] [CrossRef]

- Kuo, P.-C.; Wu, W. Design, Optimization and Energetic Efficiency of Producing Hydrogen-Rich Gas from Biomass Steam Gasification. Energies 2014, 8, 94–110. [Google Scholar] [CrossRef]

- Griffin, W.; Michalek, J.; Matthews, H.; Hassan, M. Availability of Biomass Residues for Co-Firing in Peninsular Malaysia: Implications for Cost and GHG Emissions in the Electricity Sector. Energies 2014, 7, 804–823. [Google Scholar] [CrossRef]

- Shuit, S.H.; Tan, K.T.; Lee, K.T.; Kamaruddin, A.H. Oil palm biomass as a sustainable energy source: A Malaysian case study. Energy 2009, 34, 1225–1235. [Google Scholar] [CrossRef]

- Faaij, A. Bio-energy in Europe: changing technology choices. Energy Policy 2006, 34, 322–342. [Google Scholar] [CrossRef]

- Chiew, Y.L.; Shimada, S. Current state and environmental impact assessment for utilizing oil palm empty fruit bunches for fuel, fiber and fertilizer—A case study of Malaysia. Biomass Bioenergy 2013, 51, 109–124. [Google Scholar] [CrossRef]

- Halkos, G.E.; Tzeremes, N.G. Renewable energy consumption and economic efficiency: Evidence from European countries. J. Renew. Sustain. Energy 2013, 5, 041803. [Google Scholar] [CrossRef] [Green Version]

- Noumi, E.S.; Dabat, M.-H.; Blin, J. Energy efficiency and waste reuse: A solution for sustainability in poor West African countries? Case study of the shea butter supply chain in Burkina Faso. J. Renew. Sustain. Energy 2013, 5, 053134. [Google Scholar] [CrossRef]

- Shafeeyan, M.S.; Daud, W.M.A.W.; Shamiri, A.; Aghamohammadi, N. Adsorption equilibrium of carbon dioxide on ammonia-modified activated carbon. Chem. Eng. Res. Des. 2015, 104, 42–52. [Google Scholar] [CrossRef]

- Shafeeyan, M.S.; Daud, W.M.A.W.; Shamiri, A.; Aghamohammadi, N. Modeling of Carbon Dioxide Adsorption onto Ammonia-Modified Activated Carbon: Kinetic Analysis and Breakthrough Behavior. Energy Fuels 2015, 29, 6565–6577. [Google Scholar] [CrossRef]

- Pitt, J.; Lubben, F. The social agenda of education for sustainable development within design & technology: the case of the Sustainable Design Award. Int. J. Technol. Des. Educ. 2009, 19, 167–186. [Google Scholar]

- Qizilbash, M. Sustainable development: Concepts and rankings. J. Dev. Stud. 2001, 37, 134–161. [Google Scholar] [CrossRef]

- Jabareen, Y. A new conceptual framework for sustainable development. Environ. Dev. Sustain. 2008, 10, 179–192. [Google Scholar] [CrossRef]

- Redclift, M.; Sage, C. Strategies for Sustainable Development: Local Agendas for the Southern Hemisphere; John Wiley & Sons Ltd: New York, NY, USA, 1994. [Google Scholar]

- Berke, P.R.; Conroy, M.M. Are we planning for sustainable development? An evaluation of 30 comprehensive plans. J. Am. Plan. Assoc. 2000, 66, 21–33. [Google Scholar] [CrossRef]

- Ross, A. Modern interpretations of sustainable development. J. Law Soc. 2009, 36, 32–54. [Google Scholar] [CrossRef]

- Mokthsim, N.; Salleh, K.O. Malaysia’s Efforts toward Achieving a Sustainable Development: Issues, Challenges and Prospects. Procedia-Soc. Behav. Sci. 2014, 120, 299–307. [Google Scholar] [CrossRef]

- Mekhilef, S.; Barimani, M.; Safari, A.; Salam, Z. Malaysia’s renewable energy policies and programs with green aspects. Renew. Sustain. Energy Rev. 2014, 40, 497–504. [Google Scholar] [CrossRef]

- Hansena, U.E.; Nygaard, I. Sustainable energy transitions in emerging economies: The formation of a palm oil biomass waste-to-energy niche in Malaysia 1990–2011. Energy Policy 2014, 66, 666–676. [Google Scholar] [CrossRef]

- Abdullah, A.Z.; Salamatinia, B.; Mootabadi, H.; Bhatia, S. Current status and policies on biodiesel industry in Malaysia as the world’s leading producer of palm oil. Energy Policy 2009, 37, 5440–5448. [Google Scholar] [CrossRef]

- Mokhtar, H. Malaysian energy situation, Seminar on “COGEN 3: A Business Facilitator”. In Proceedings of the Grand Bluewave Hotel, Shah Alam, Malaysia, 2–3 September 2002.

- The Ninth Malaysia Plan: The First Step in the National Mission. Available online: http://www.epu.gov.my/epu-theme/rm9/english/Chapter1.pdf (accessed on 21 April 2016).

- Sarawak Energy. Palm Oil Biomass. Available online: http://www.sarawakenergy.com.my/index.php/r-d/biomass-energy/palm-oil-biomass (accessed on 18 September 2014).

- Shafie, S.M.; Mahlia, T.M.I.; Masjuki, H.H.; Andriyana, A. Current energy usage and sustainable energy in Malaysia: A review. Renew. Sustain. Energy Rev. 2011, 15, 4370–4377. [Google Scholar] [CrossRef]

- Ministry of Energy Green Technology and Water. The National Green Technology Policy. Available online: http://portal.ppj.gov.my/c/document_library/get_file?p_l_id=17335&folderId=27605&name=DLFE-4709.pdf (accessed on 21 April 2016).

- Sovacool, B.K.; Bulan, L.C. Energy security and hydropower development in Malaysia: The drivers and challenges facing the Sarawak Corridor of Renewable Energy (SCORE). Renew. Energy 2012, 40, 113–129. [Google Scholar] [CrossRef]

- Economic Planning Unit. Energy. In Percetakan Nasional Berhad: Malaysia. Available online: http://www.epu.gov.my/en/c/document_library/get_file?uuid=abfe885a-bd33-49e8-8f26-3e9f52d49bdc&groupId=283545 (accessed on 21 April 2016).

- Wee, N.C. Status of Feed-in Tariff in Malaysia, Sustainable Energy Development Authority (SEDA). In Proceedings of the 3rd International Sustainable Energy Summit 2016, Putrajaya, Malaysia, 5–6 April 2016.

- Umar, M.S.; Jennings, P.; Urmee, T. Strengthening the palm oil biomass Renewable Energy industry in Malaysia. Renew. Energy 2013, 60, 107–115. [Google Scholar] [CrossRef]

- Umar, M.S.; Jennings, P.; Urmee, T. Sustainable electricity generation from oil palm biomass wastes in Malaysia: An industry survey. Energy 2014, 67, 496–505. [Google Scholar] [CrossRef]

- Malaysia Energy Centre Barrier Analysis for the Supply Chainof Palm Oil Processing Biomass (Empty Fruit Bunch) as Renewable Fuel, 2006. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0ahUKEwjft867jLDMAhULESwKHcdwB9cQFggfMAA&url=http%3a%2f%2fonlinereview.segi.edu.my%2fpdf%2fvol3-no2-art1.pdf&usg=AFQjCNFG331GdBHpnQ8boyElI_q6YLAfOg&sig2=yKzt-G7qO4WXnZqL2hNOGw&bvm=bv.120853415,d.bGg&cad=rja (accessed on 21 April 2016).

- Lim, K.C.; Rahman, Z.A. The effects oil palm empty fruit bunches on oil palm nutrition and yield, and soil chemical properties. J. Oil Palm Res. 2002, 20, 1–9. [Google Scholar]

- Trummer, D.R. Biomass-fired CHP in Palm Oil Mills—A report prepared under the Malaysian—Danish Environmental Cooperation Programme Renewable Energy and Energy Efficiency Component. Available online: https://www.google.com/url?sa=t&rct=j&q=&esrc=s&source=web&cd=1&ved=0ahUKEwiFgYb98avMAhXjZpoKHWfEAOwQFggcMAA&url=https%3a%2f%2fcdm.unfccc.int%2fUserManagement%2fFileStorage%2f5SBRC0X9NIAHVZ1KLD82YJQ43M7EGO&usg=AFQjCNEfgXZCH7qyog9S04gJMLM-YAErVw&sig2=MpwYGNXumPr2xgKrLINF1g&bvm=bv.120551593,d.bGg&cad=rja (accessed on 21 April 2016).

- Hansen, U.E.; Ockwell, D. Learning and technological capability building in emerging economies: The case of the biomass power equipment industry in Malaysia. Technovation 2014, 34, 617–630. [Google Scholar] [CrossRef]

- Zhang, K.; Chang, J.; Guan, Y.; Chen, H.; Yang, Y.; Jiang, J. Lignocellulosic biomass gasification technology in China. Renew. Energy 2013, 49, 175–184. [Google Scholar] [CrossRef]

- The Star Palm Oil Mills’ Biogas Capture Implementation In Sarawak a Major Challenge. Available online: http://www.theborneopost.com/2014/11/07/palm-oil-millers-in-sarawak-adversely-affected-by-mandate-on-biogas-capture-says-soppoa/#ixzz3JWf94MlQ (accessed on 20 October 2015).

- Malaysia Palm Oil Board Oil Palm and the Environment. Available online: http://mpob.gov.my/ (accessed on 18 September 2015).

- Schakel, W.; Meerman, H.; Talaei, A.; Ramírez, A.; Faaij, A. Comparative life cycle assessment of biomass co-firing plants with carbon capture and storage. Appl. Energy 2014, 131, 441–467. [Google Scholar] [CrossRef]

- Green Tech Malaysia Clean Development Mechanism (CDM). Available online: http://cdm.greentechmalaysia.my/what-is-cdm/intro.aspx (accessed on 21 April 2016).

- Chiew, Y.L.; Iwata, T.; Shimada, S. System analysis for effective use of palm oil waste as energy resources. Biomass Bioenergy 2011, 35, 2925–2935. [Google Scholar] [CrossRef]

- Anyi, M.; Kirke, B.; Ali, S. Remote community electrification in Sarawak, Malaysia. Renew. Energy 2010, 35, 1609–1613. [Google Scholar] [CrossRef]

- United Nations Development Programme (UNDP). Study of Available Business Models of Biomass Gasification Power Projects in India under the Project “Removal of Barriers to Biomass Power Generation in India”; United Nations Development Programme: New Delhi, India, 2013. [Google Scholar]

| Small Renewable Energy Power (SREP) | Feed-in-Tariff (FiT) |

|---|---|

| Introduced in Eight Malaysia Plan | Introduced in Tenth Malaysia Plan |

| Renewable energy program under Fifth Fuel Diversification Policy | Renewable energy program under The National Renewable Energy Policy and Action Plan 2010 |

| Govern by Special Committee on Renewable Energy (SCORE) | Administered by Sustainable Energy Development Authority (SEDA) |

| Not legally contract | Legally contract under Renewable Energy Act 2011 and Sustainable Energy Development Authority Act 2011 |

| Unattractive payment structure | Guaranteed and fixed payment structure |

| Focus on six renewable energy sources | Focus on only four renewable energy sources |

| Capacity target: 5% or 500MW of energy mix in 2005 | Capacity target: 73% or 21.4GW of energy mix in 2050 |

| Region | Method Sent | Total by Region (Sent) | Method Received | ||

|---|---|---|---|---|---|

| Postal | Postal | ||||

| Miri | 4 | 9 | 13 | 2 | 6 |

| Bintulu | 3 | 7 | 10 | 3 | 4 |

| Limbang | - | 3 | 3 | - | 2 |

| Total Sent: 26 | Total Received: 17 | ||||

| Response rate percentage: 65.4% | |||||

| Biomass | Average Quantity Produced Per Month (Metric Tons) | Average Sustaining Period (Days) |

|---|---|---|

| Empty Fruit Bunches (EFB) | 6170 | 12 |

| Palm Kernel Shell | 1863 | 30 |

| Mesocarp Fibre | 4630 | 2 |

| Year | Power Output (MWh) | Total Capacity (MWh) | Electricity Sales Revenue (MYR) (Billion) | ||

|---|---|---|---|---|---|

| Empty Fruit Bunch (EFB) at 65% Moisture Content | Shell at 20% Moisture Content | Fibre at 50% Moisture Content | |||

| 2014 | 3911.9 | 2282.4 | 3196.0 | 9392.6 | 1.38 |

| 2015 | 4573.6 | 2425.0 | 3736.4 | 10,735.0 | 1.57 |

| 2016 | 5281.2 | 2801.2 | 4315.8 | 12,398.0 | 1.82 |

| 2017 | 3911.9 | 3203.2 | 4935.4 | 14,177.6 | 2.08 |

| 2018 | 4573.6 | 1815.6 | 5594.8 | 16,072.0 | 2.36 |

| 2019 | 5281.2 | 2042.5 | 6294.2 | 18,080.8 | 2.65 |

| 2020 | 3911.9 | 4564.8 | 7033.4 | 20,204.4 | 2.97 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Aghamohammadi, N.; Reginald, S.S.; Shamiri, A.; Zinatizadeh, A.A.; Wong, L.P.; Nik Sulaiman, N.M.B. An Investigation of Sustainable Power Generation from Oil Palm Biomass: A Case Study in Sarawak. Sustainability 2016, 8, 416. https://doi.org/10.3390/su8050416

Aghamohammadi N, Reginald SS, Shamiri A, Zinatizadeh AA, Wong LP, Nik Sulaiman NMB. An Investigation of Sustainable Power Generation from Oil Palm Biomass: A Case Study in Sarawak. Sustainability. 2016; 8(5):416. https://doi.org/10.3390/su8050416

Chicago/Turabian StyleAghamohammadi, Nasrin, Stacy Simai Reginald, Ahmad Shamiri, Ali Akbar Zinatizadeh, Li Ping Wong, and Nik Meriam Binti Nik Sulaiman. 2016. "An Investigation of Sustainable Power Generation from Oil Palm Biomass: A Case Study in Sarawak" Sustainability 8, no. 5: 416. https://doi.org/10.3390/su8050416