4.2.3. Direct Cost Evaluation of Construction

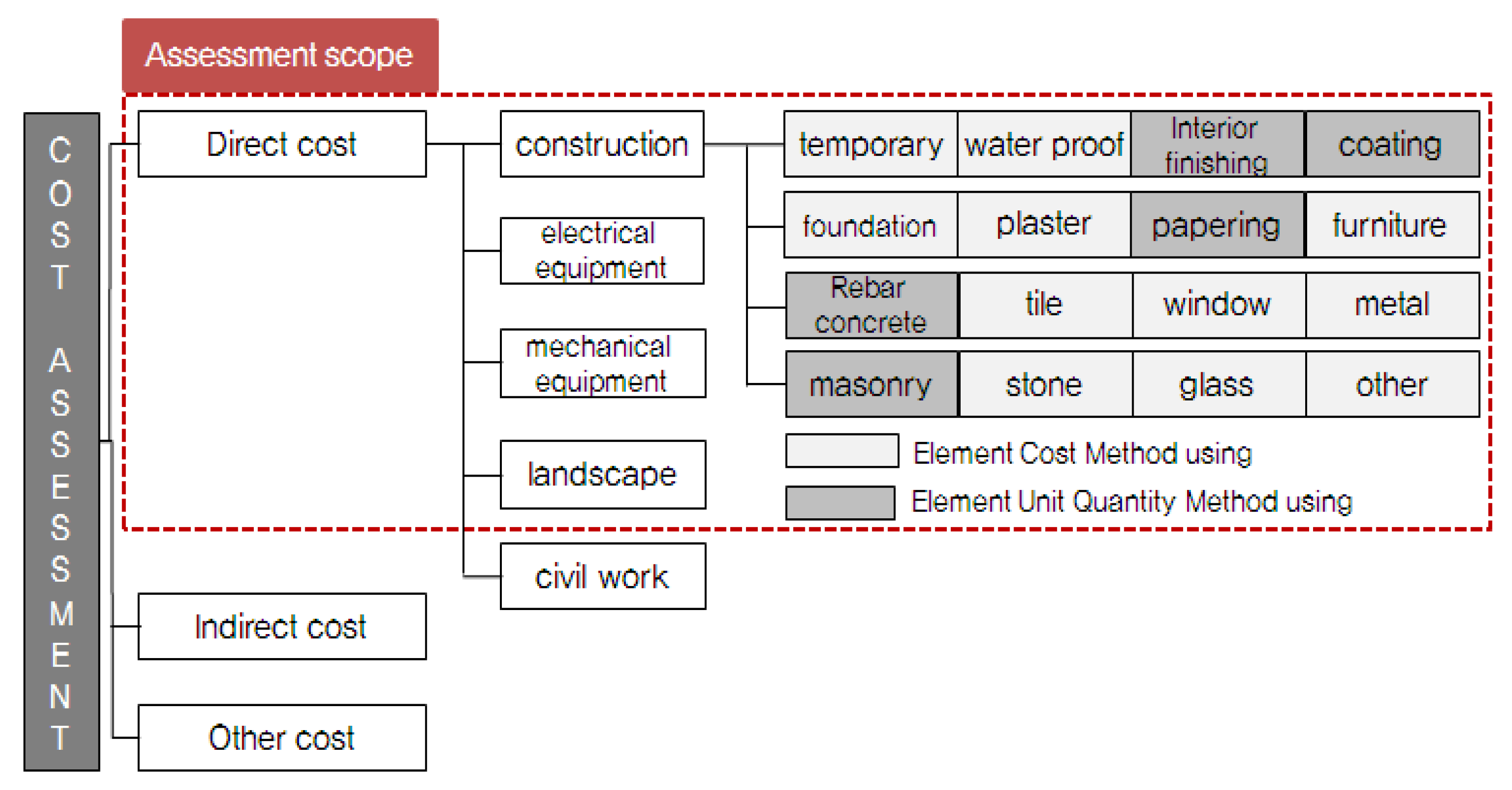

Economic feasibility during the construction step was assessed using the elemental cost method and elemental unit quantity method described earlier. Design documents were prepared for major construction types to compute cost by quantity, and historical cost data of similar construction types were utilized for remaining construction types to compute the construction cost per unit area [

54,

55]. This was multiplied by total floor area to calculate the required cost. The method of assessing economic feasibility using actual construction costs of similar constructions is a method widely used in developed nations, such as the United States and Japan [

56,

57]. Since this method is acknowledged for the reliability of the result, this method was paralleled in this assessment. On one hand, since the cost of construction work is affected by the construction period, the assessment result on the construction period must be reflected for an accurate economic assessment [

58,

59]. As the criteria for fluctuations in the construction cost according to change in the construction period should be established, analysis on the overall construction period was performed for a more rational economic assessment. After deducing processes that correspond to the critical path affecting the overall construction period, the result was simulated using a process table composed of the deduced processes and process management software called P3 (Primavera Project Planner, Oracle corporation, CA, USA). Construction work is characterized by slight differences in the construction cost shown by similar projects because each project has different construction methods, materials applied, and productivity of labor. Accordingly, it is necessary to precisely establish conditions of cost computation and assumptions prior to computation of construction costs [

60].

(1) First, only direct construction cost of one apartment building with 25 floors and 4-unit combinations was computed as the subject building.

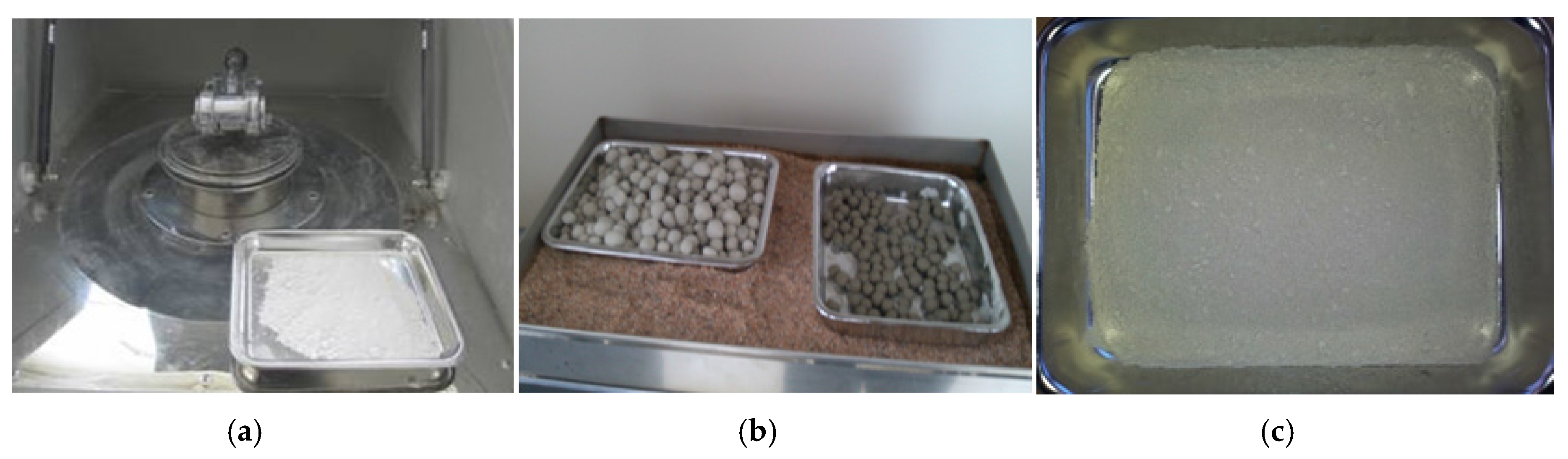

(2) Second, the elemental cost method and the elemental unit quantity method were paralleled as methods for computation of the construction cost. Reinforced concrete construction, masonry work, interior finishing work, papering work, and painting work were computed by unit cost after computation of quantity. Other construction types applied arithmetic means of prices from three similar constructions. However, if the time of computation of the construction cost was in the past, the price inflation rate was reflected using the “construction cost index” announced by the Korea Institute of Construction Technology.

(3) Third, the construction cost of the subject building was assessed using the result shown in

Table 9 computed with a structural analysis programs in Korea called MIDAS [

61] and BIM (Building Information Method) [

62]. The quality of the structure was calculated using the structure analysis program MIDAS ADS [

63]. In terms of structural analysis, the quantity of the subject buildings (apartments) was calculated, and the same quality was applied to all cases (Cases 1–4). After reviewing the structure of the subject building’s structure and deriving a member size, the quality of concrete, reinforcing rod, and forms was estimated through MIDAS. Based on the member size and architectural drawings derived through structural analysis, the subject buildings (apartments) were BIM-modeled, using ArchiCAD software. Then, the finished floor area and material quantity of the subject buildings (apartments) were derived based on the BIM modeling and the quantity of the structure. After applying the breakdown costs, then, the quality of a total of 81 different materials was calculated. After that, gypsum board walls were classified into the finished floor area estimate using the BIM model, partition walls, inner walls, and ceiling finishing. Then, the area of the walls (m

2) made of the following materials was calculated: general gypsum board (12.5 T), finish material gypsum board (9.5 T), and ceiling gypsum board (9.5 T) [

64,

65].

To estimate the consumption of gypsum board, wall construction was applied for each part. Then, the quantity of the materials associated with the consumption of gypsum board was estimated, using breakdown costs.

After summarizing the quantity of the said structure, finish materials, and gypsum boards, the consumption of major construction materials used for the subject buildings (apartments) was estimated as stated in

Table 9.

Direct construction costs during the construction step were computed using the computation result of the quantity of the subject building by applying the unit price from standard estimation, with the elemental unit quantity method applied for reinforced concrete work, masonry work, interior finishing work, papering work, and painting work. For other construction types, such as temporary work, foundation and designated works, waterproofing work, plaster work, tile work, stone work, window work, glass work, furniture work, metal work, and miscellaneous work, the elemental cost method was used to compute costs by converting actual cost data of similar constructions [

66].

Table 10 shows an example that applied the quantity of the subject building using the elemental unit quantity method.

For example, detailed construction costs for reinforced work is computed as follows. First, unit construction cost was analyzed by classifying into material cost, labor cost, and other expenses. Material cost is the price of major materials, such as reinforcing bar and binding wire. Labor cost is the cost for working forces, such as reinforcing bar placers and general workers [

67]. Other expenses include rent fees for tools and others. Using such a method, unit costs corresponding to the quantity of each construction was analyzed to compute the construction cost for reinforced concrete work, masonry work, interior finishing work, papering work, and painting work using the same method [

68]. In this assessment, among direct construction costs during the construction step, quantity computation for each material was performed for reinforced concrete work, masonry work, interior finishing work, papering work, and painting work. The elemental unit quantity method which computes required costs by multiplying the quantity with unit costs was used to draw conclusions.

Based on such conclusions, using the quantity and the supplied area of the subject building composed of a concrete wall structures with 108 m2, four-unit combinations, and 25 floors, items of direct construction costs for each case were computed. For easier comparison on direct construction costs with the overall costs of each construction type, direct construction costs were computed as per unit area (KRW/m2). As the result of the assessment, overall costs and cost per unit area of reinforced concrete work were found to be 1,386,821,005 KRW (Case 1), 1,361,091,055 KRW (Case 2), and 1,348,285,055 KRW (Case 3), and 163,251 KRW/m2 (Case 1), 160,222 KRW/m2 (Case 2), and 158,715 KRW/m2 (Case 3), respectively.

The overall cost and cost per area were 47,068,598 and 5541 (KRW/m

2) for masonry work, 332,193,765 and 39,105 (KRW/m

2) for interior finishing work, 97,276,846 and 11,451 (KRW/m

2) for papering work, and 43,749,846 and 5150 (KRW/m

2) for painting work [

69].

First, for computation of the unit price per area from actual data from similar constructions, the mean construction cost for each construction type of an apartment house with the similar size by four companies was applied. A cost assessment by construction type was deduced based on the supplied area of the subject building and actual data of similar constructions by four companies. As in the elemental unit quantity method, cost was computed as the overall construction cost and cost per unit area (KRW/m

2) of each construction type [

70]. Additionally, for electrical installation work, mechanical work, and landscape work that belong to the scope of this assessment, the elemental cost method was used as described above to perform the economic assessment on the building based on data from construction companies by applying the total floor area of the subject building. Using data from four companies, the construction cost per unit area of each construction type was multiplied by total floor area of the subject apartment to compute the cost for temporary work, foundation and designated works, waterproofing work, plaster work, tile work, stone work, window work, glass work, furniture work, metal work, miscellaneous work, electric work, and facility work. Costs for direct construction during the construction process was deduced [

71]. The overall direct construction cost of the subject building was 5,375,441,169 KRW (Case 1), 5,349,711,219 KRW (Case 2), 5,336,905,219 KRW (Case 3), and the cost per unit area was 632,776 KRW/m

2 (Case 1), 629,748 KRW/m

2 (Case 2), and 628,240 KRW/m

2 (Case 3), as shown in

Table 11 [

72].

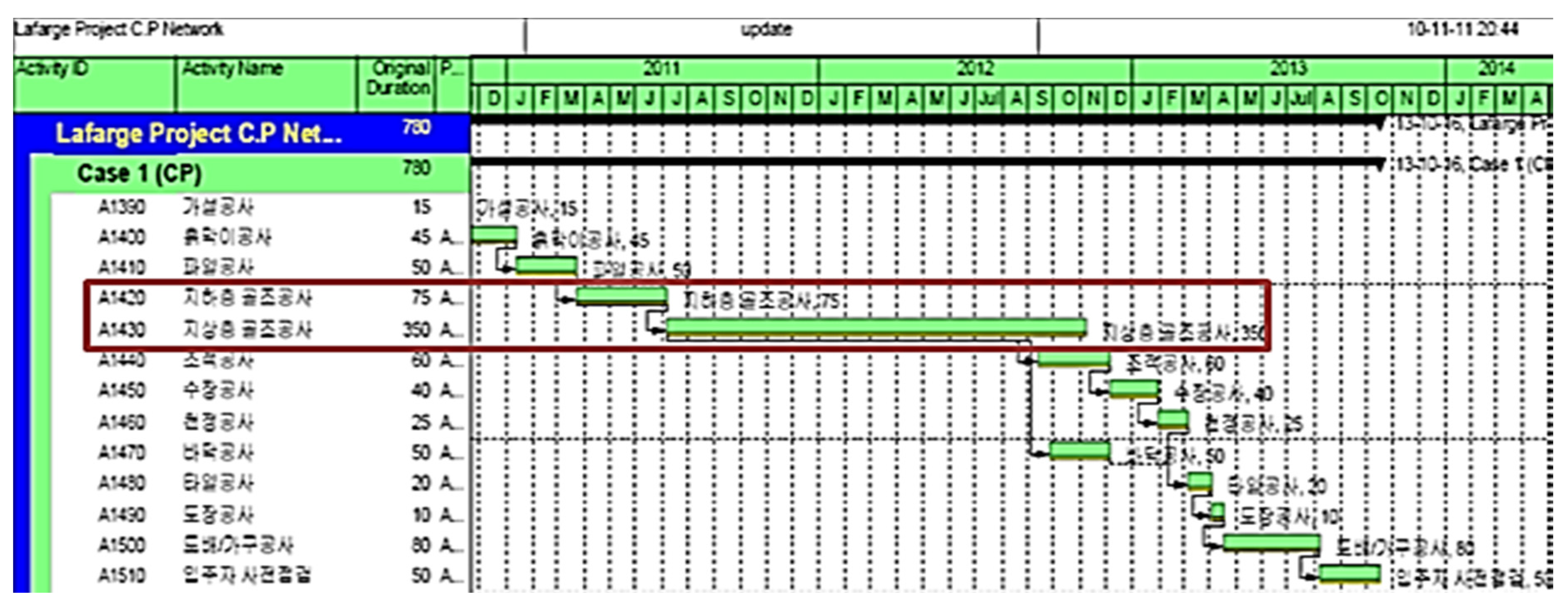

4.2.4. Cost Saving Due to Reduced Construction Period

Since construction cost is influenced by the increase and decrease in construction period, accurate economic analysis requires a reflection of changes in the construction period [

73]. In this assessment, the amount of change in the construction period for each case of the subject building was assessed according to a shortening by the use of A-BFS concrete.

Conditions of the construction period were configured as follows.

First, a single apartment building with 25 floors and four-unit combination was used, and only critical activity was taken into consideration. Critical activity refers to the longest path in the process table that determines the overall construction period. Additionally, for the number of days used in the process, working days, excluding holidays and non-working, days were used.

As early-age days of each case was shortened according to the ratio of A-BFS concrete, the construction period for one floor was assumed as six days for the standard building in Case 1, four days for Case 2 that applied 20% A-BFS concrete, and three days for Case 3 that applied 30% A-BFS concrete.

Processes that correspond to the critical path influencing the overall construction period were deduced. Based on this, the construction period of each construction type was assessed using process management software called P3 (Primavera Project Planner). In this assessment, the increase and decrease in the construction period of Case 1 were evaluated as shown in

Figure 5.

Table 12 shows the shortening of construction period for each case [

74]. Compared to Case 1, Cases 2 and 3, respectively, showed shortening of the construction period by 142 days (4.7 months) and 213 days (7.1 months). This is probably because the construction period for one floor was assumed from six days to four days and three days along with increased compressive strength at an early age.

The analysis results on the construction period were converted to costs and reflected in the economic assessment [

75].

The parts of construction cost that showed quantitative reduction with a shortening of the construction period were general management expense, headquarters management expense, and interest expense. General management expense is an expense spent for the operation and management of the construction site, which includes labor costs for dispatched employees and on-site expenses, and this item increases proportionally to construction period.

Headquarters management expense can be described as the headquarters operation expense that encompasses expenses supported by the headquarters at the site. Usually, the general management expense is within 5%–6% of the overall construction cost. Headquarters management expense is determined according to the number of projects being carried out by the construction company [

76].

In general, construction companies compute that the sum of the headquarters management expenses for all projects in progress as about 10%. Headquarters management expense is approximated by 1/n according to the number of projects. In the case of interest expense, almost no interest expense occurs with contracted constructions in general, but interest expense from borrowing of construction costs does occur in the case of self-construction by the company [

77].

As a result of analyzing the cash flow of four apartments built as self-constructions and computing the interest expense with consideration on the loan and a recent interest rate of 15%, the interest expense, on average, was found to be about 3.06% of the overall construction cost. The amount of cost reduced by a shortened construction period was computed based on such results, and the result is shown in

Table 9.

The construction cost for an apartment building with 25 floors and four-unit combinations was assumed as 6.2 billion won, and the construction period was assumed as 28 months. Economic effects from shortening by 4.7 months in Case 2 compared to Case 1 was about 106,654,762 KRW, and the effect from shortening by 7.1 months in Case 3 was about 159,982,143 KRW as shown in

Table 13.