Joint Environmental and Economical Analysis of Wastewater Treatment Plants Control Strategies: A Benchmark Scenario Analysis

Abstract

:1. Introduction

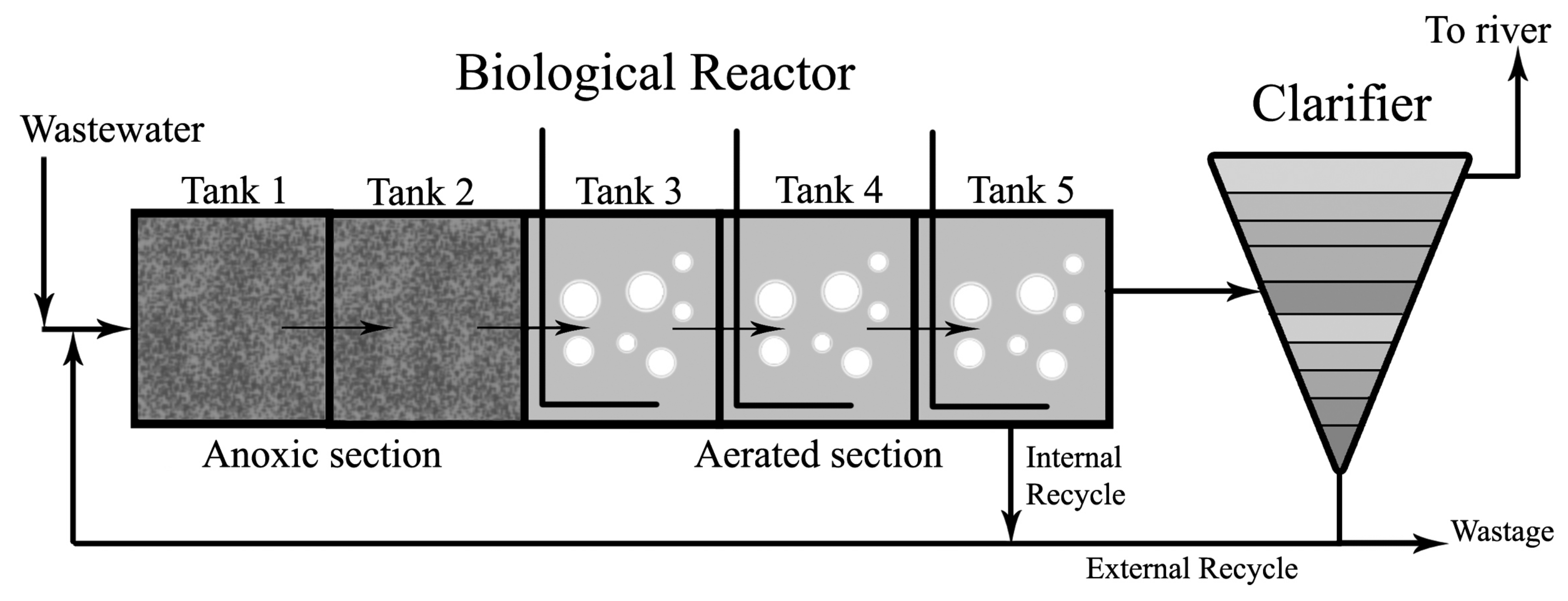

2. Benchmark Scenario: The BSM1

2.1. Simulation Procedure

2.2. Performance Assessment

2.2.1. Effluent Quality Index (EQI)

2.2.2. Overall Cost Index

3. Implemented Control Strategies

3.1. Feedback Control System

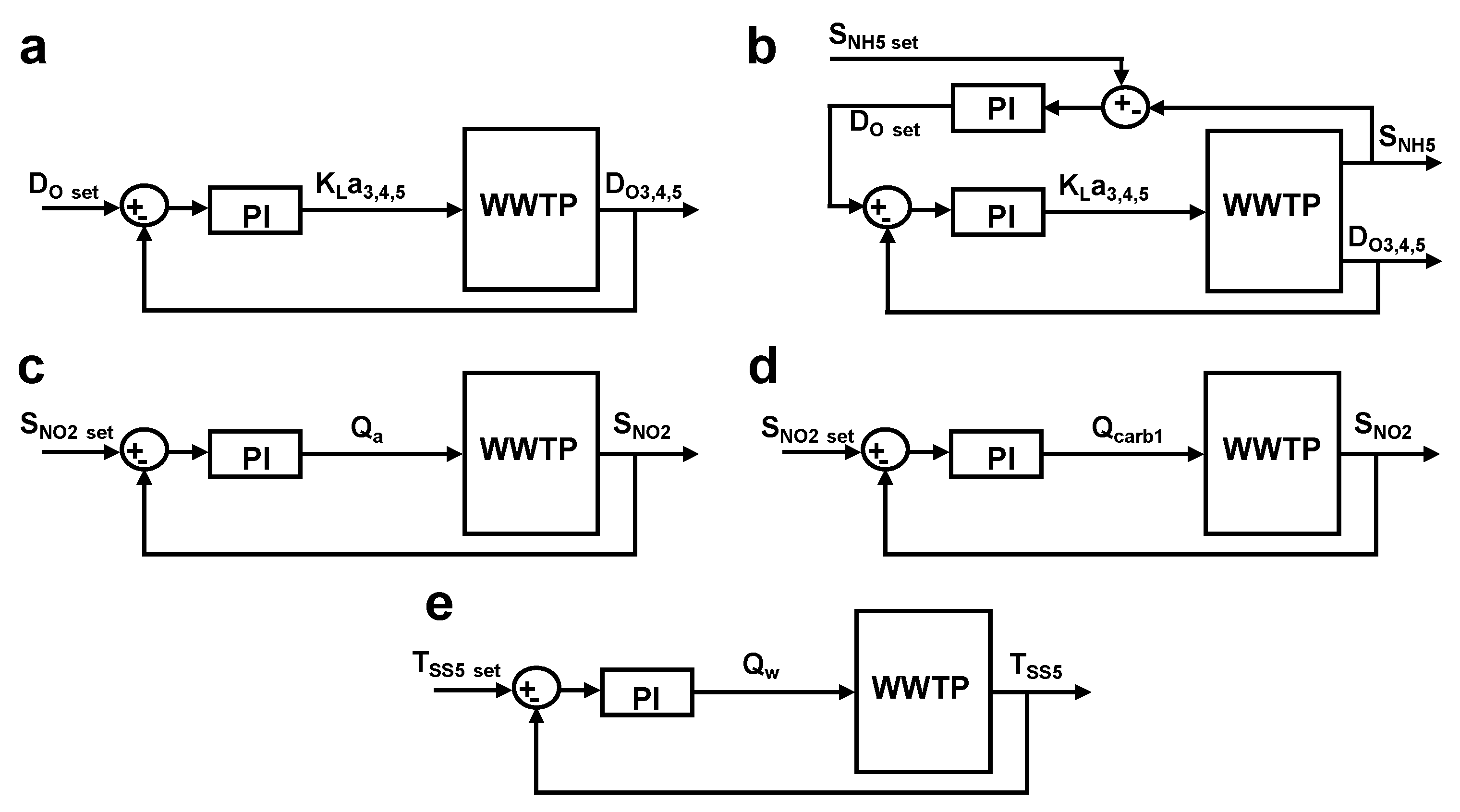

3.2. Simple and Composite Control Strategies

- S1: Control of the dissolved oxygen concentration in the aerobic reactors. The controlled variables are therefore by manipulating the respective oxygen transfer coefficients . In this case, three independent PI control loops are defined as shown in (Figure 3a). Details of this control strategy can be found in [35].

- S2: Control of the ammonia in the last aerobic tank. In this case, the purpose of the controller is to maintain at the desired level by manipulating the oxygen set-points, , in all of the aerobic tanks. As depicted in Figure 3b, this corresponds to a cascade control structure where the inner loops are defined along similar lines as S1. Details of this control strategy can be found in [41].

- S3: Control of the nitrate concentration in the last anoxic tank. In this case, we are interested in controlling by manipulating the internal recycle flow rate . This is one of the basic default control loops defined in the BSM1 scenario, as detailed in [10]. The corresponding block diagram is shown in Figure 3c.

- S4: Control of the nitrate concentration in the last anoxic tank. In this case, we are also, as in S3, interested in controlling , but now, the control variable that is manipulated is the carbon source flow rate into the first anoxic tank. The corresponding block diagram is shown in Figure 3d), whereas details on this control loop can be found in [42].

- S6: Control of (S2) + control of by manipulating (S3).

- S7: Control of (S2) + control of by manipulating (S4).

- S8: Control of (S2) + control of (S5).

- S9: Control of (S2) + control of by manipulating (S4) + control of (S5).

- S10: Control of (S2) + control of by manipulating (S3) + control of (S5).

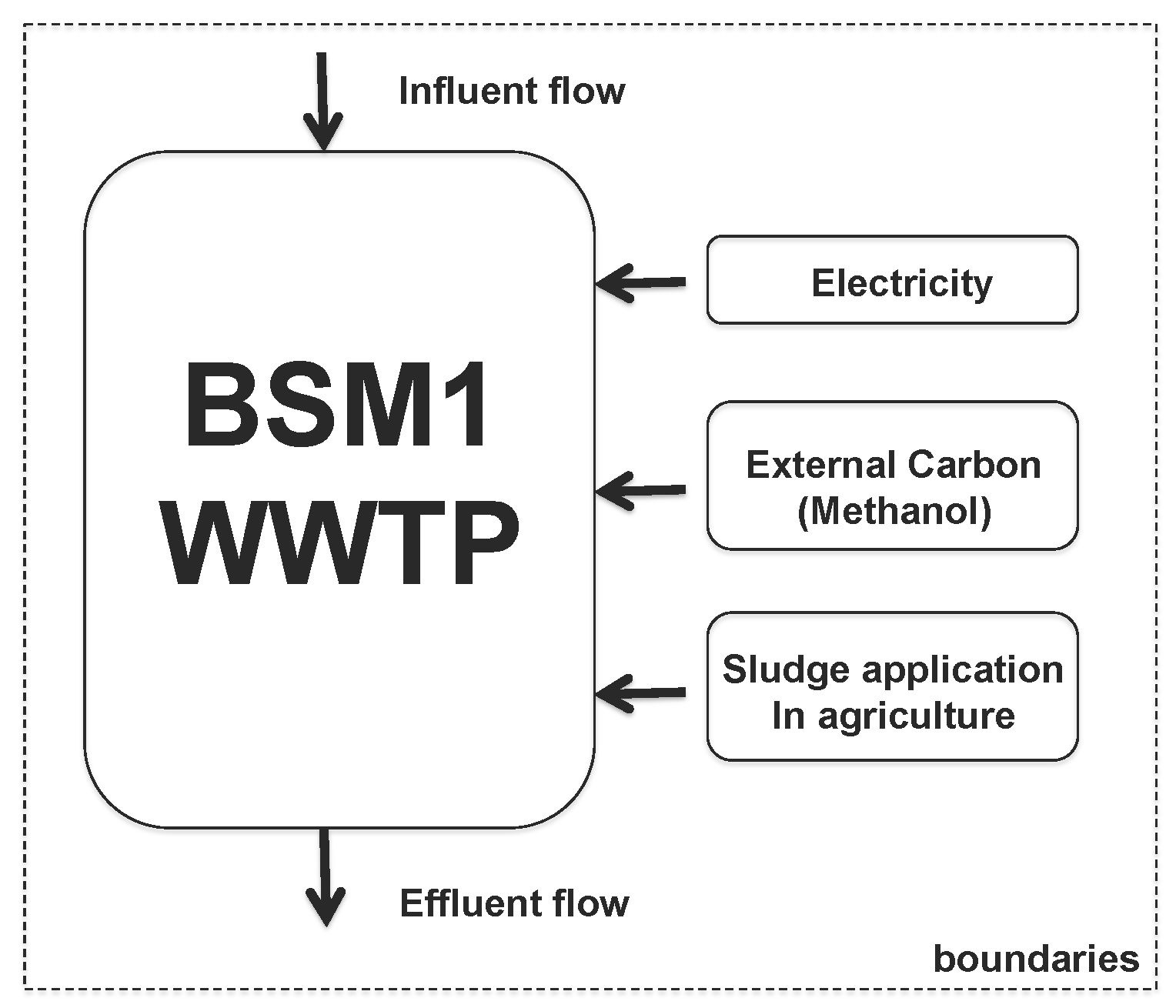

4. Analysis of WWTP Operation by Means of LCA

4.1. Definition of the Goal and Scope

4.2. Inventory Analysis

- Electricity and chemicals: The electricity production data were taken from Ecoinvent Database [44] taking into account the Spanish energy production profile. In the case of the chemicals used in the BSM1 plant, methanol has been selected as the external carbon source for enhancing the denitrification process.

- Fertilizers avoided: The application of sludge in agriculture reduces the use of chemical fertilizers. This results in benefits for the soil as long as the concentration of heavy metals in sludge is within the permitted limits [45]. The most common chemical fertilizers used in Europe are calcium ammonium nitrate (N-based) and triple superphosphate (P-based) [46]. The substitutability was assumed as 6.93 kg of triple superphosphate and 39.6 kg of calcium ammonium nitrate per ton of sludge [16].

- Heavy metals: Heavy metals’ concentration depends mainly on the amount of industrial wastewater in the influent flow. As the BSM1 influent does not contain measures of these concentrations, an alternative source has been used: the study [45] realized in several European countries that summarizes the average of heavy metals’ concentrations that can be found in dehydrated sludge.

- Sludge transportation: The transportation of sludge to the farms for agricultural purposes has been calculated by assuming that farms are located at an average of 50 km from the WWTP. Data for the calculation of the environmental loads caused by the sludge transportation in a 16-ton lorry have been taken from the Ecoinvent Database [44].

4.3. Impact Assessment

5. Results and Discussion

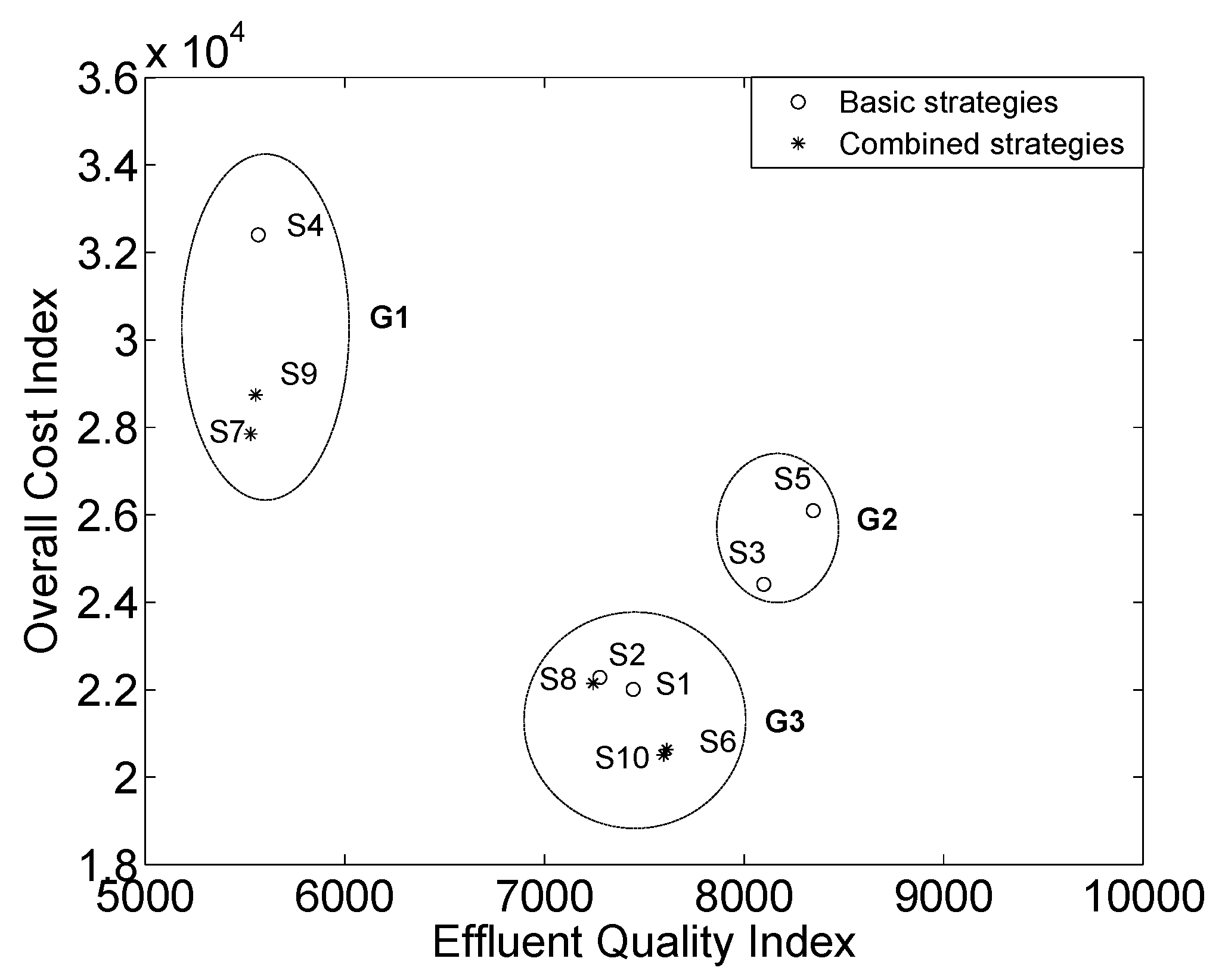

5.1. Analysis of the EQI vs. OCI Graphics

- Strategies with carbon source addition (Group 1 (G1)): Strategies S4 ( control in Unit 2 by manipulating ), S7 (combination of S2 and S4), and S9 (combination of S2, S4 and S5), are ranked with the largest OCI, but the lowest EQI (meaning a good effluent quality). Therefore, we get better water treatment, but at the expense of an associated high cost.

- Strategies without carbon source addition and no aeration energy control (G2): Strategies S3 ( control in Unit 2 by manipulating ) and S5 ( control in Unit 5 by manipulating ), are ranked with the largest EQI value (meaning a bad effluent quality), but with a lower OCI than G1. It is straightforward to see that the small decrease in cost has a large repercussion as concerns effluent quality. This clearly reflects the impact aeration control has on the plant operation quality.

- Strategies without carbon source addition and aeration energy control (G3): Strategies S1 ( control in all aerobic reactors by manipulating , and ), S2 ( control in Unit 5 by manipulating the set-point in Reactors 3, 4 and 5), S6 (combination of S2 and S3), S8 (combination of S2 and S5) and S10 (combination of S2, S3 and S5). This group of strategies has the lowest OCI and a larger EQI than G1, but lower than G2, therefore showing a better tradeoff. In this case, the reduction in cost is much higher than for strategies in G2.

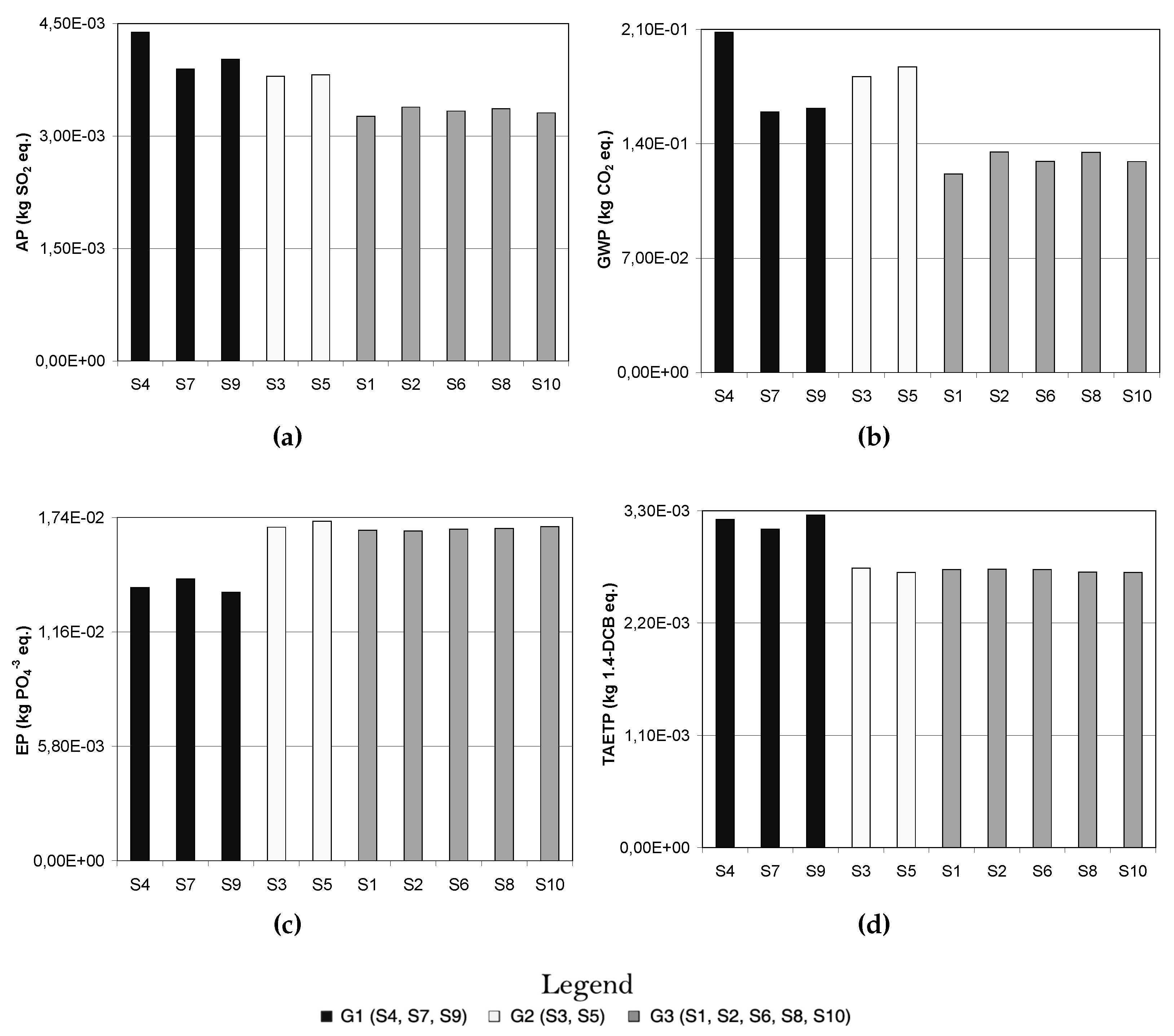

5.2. LCA Results

5.3. Overall Joint Analysis

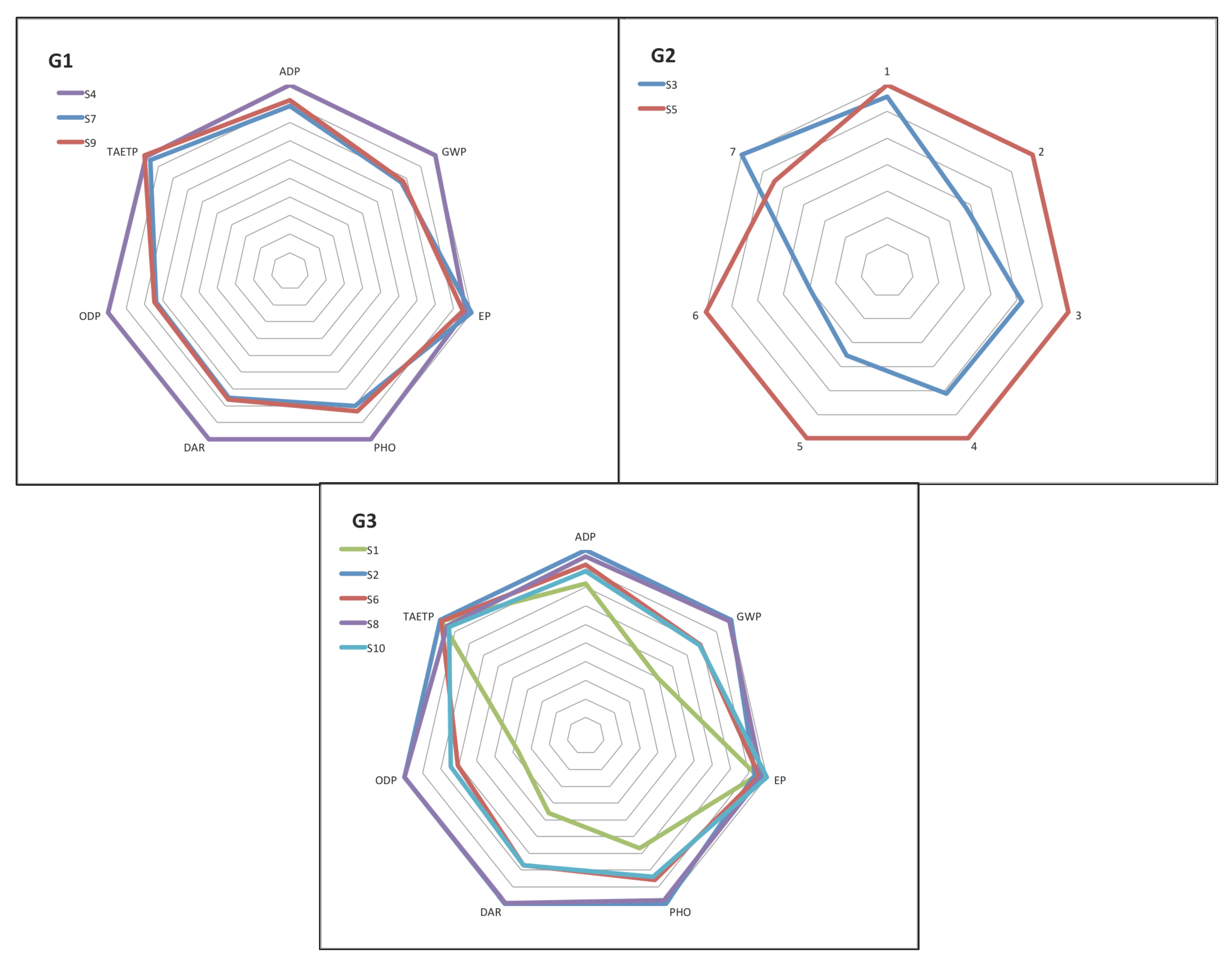

- Group G1: High effluent quality operation. For group G1, the analysis reinforces the fact of not choosing S4 ( control in Unit 2 by manipulating ). In fact, this strategy is the one that represents a major investment and does not provide better effluent quality than S7 (combination of S2 and S4) or S9 (combination of S2, S4 and S5). In addition, both S7 and S9 are almost identical from the environment impact they generate. The only difference is that S9 does include control in addition to the control loops already present in S7. Therefore, keeping S7 would be a very good option if the plant operation is for high effluent quality.

- Group G2: Low cost operation. For group G2, a wise selection is S3 ( control in Unit 2 by manipulating ). From an environmental point of view, it is drastically better, except for TAETP, than S5 ( control in Unit 5 by manipulating ). S3 also dominates S5 from a Pareto perspective (that is to say, it is better simultaneously in both the objectives EQI and OCI), even if slightly.

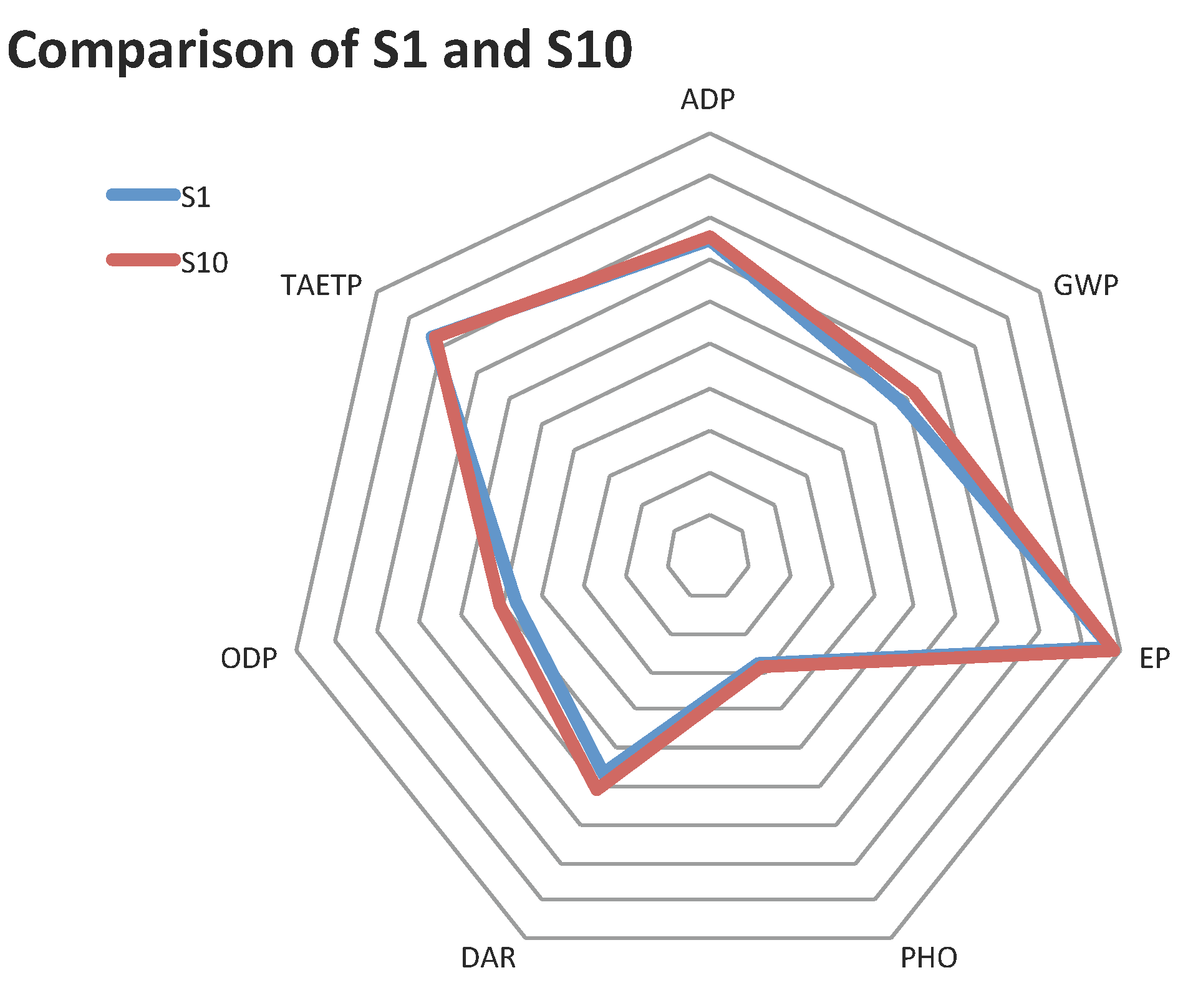

- Group G3: Quality/cost tradeoff operation. Regarding the strategies of group G3, the decision is not clear if we just concentrate on the EQI/OCI tradeoff. There are five control strategies in this group providing similar results. Therefore, it results in being quite difficult to really choose one control strategy within the group. It is at this level of decision making where the adding of different criteria that complement the ones defined within the BSM1 benchmark helps to decide. If we can consider that from the cost/quality point of view, the five control strategies are almost equal, its behavior may not be the same if we look at the environmental side. Figure 9 provides the radar chart for the strategies of group G3. It is clear that S1 ( control in all aerobic reactors by manipulating , and ) provides a clear superior behavior regarding the environmental impact. Therefore, it justifies the application of the most simple control strategy.

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

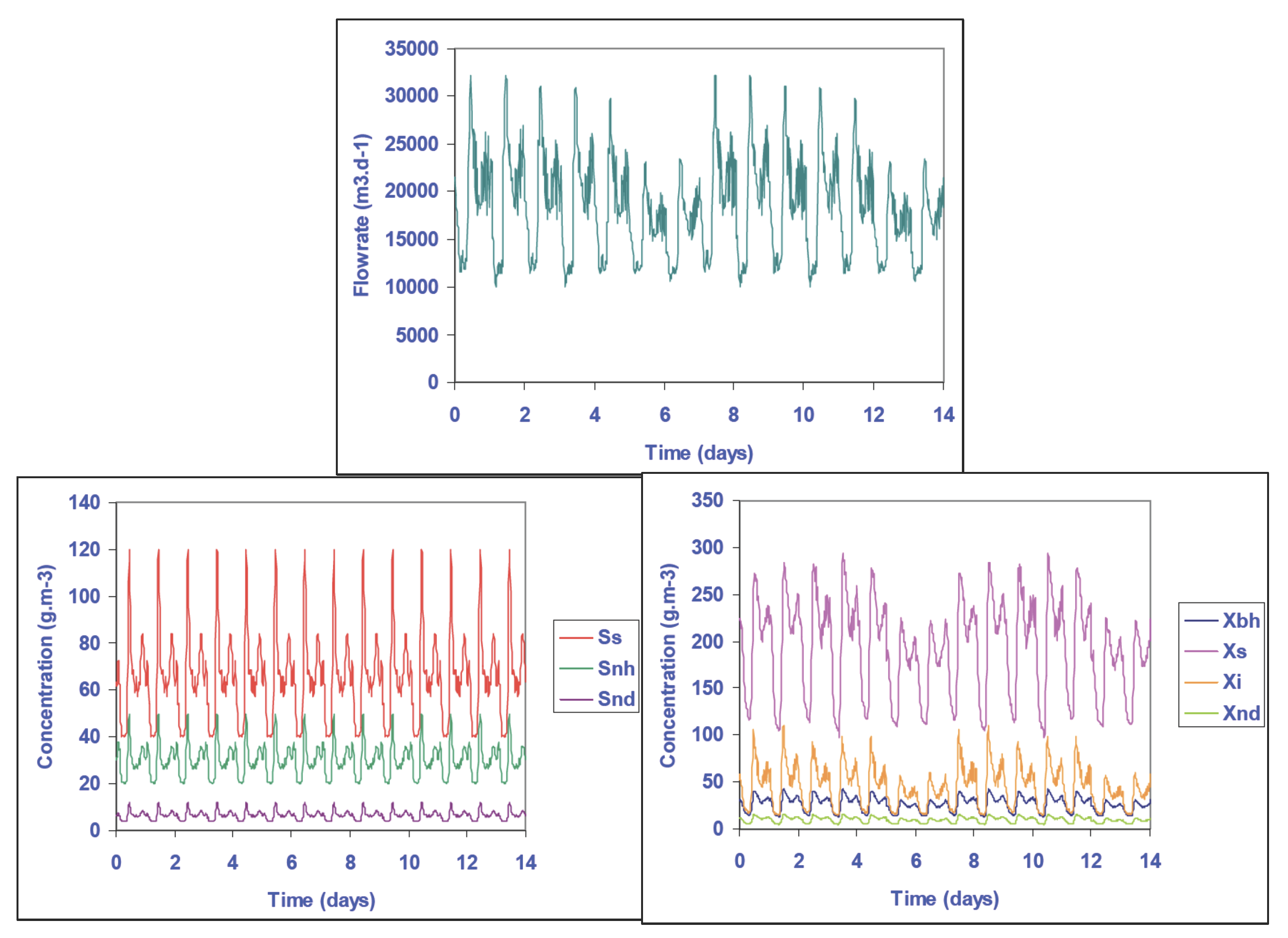

Appendix: Influent Data Profiles for BSM1

| Readily-biodegradable substrate | |

| Soluble biodegradable organic nitrogen | |

| + nitrogen | |

| Particulate inert organic matter | |

| Slowly-biodegradable substrate | |

| Active heterotrophic biomass | |

| Particulate biodegradable organic nitrogen |

References

- Flores, X.; Gallego, A.; Feijoo, G.; Rodriguez-Roda, I. Multiple-objective evaluation of wastewater treatment plant control alternatives. J. Environ. Manag. 2010, 91, 1193–1201. [Google Scholar] [CrossRef] [PubMed]

- Gernaey, K.V.; Jeppsson, U.; Vanrolleghem, P.A.; Coop, J.; Steyer, J.P. Benchmarking of Control Strategies for Wastewater Treatment Plants; Technical Report; IWA Publishing: London: UK, 2010. [Google Scholar]

- Stare, A.; Vrecko, D.; Hvala, N.; Strmcnik, S. Comparison of control strategies for nitrogen removal in an activated sludge process in terms of operating costs: A simulation study. Water Res. 2003, 41, 2004–2014. [Google Scholar] [CrossRef] [PubMed]

- Rojas, J.D.; Baeza, J.A.; Vilanova, R. Effect of the controller tuning on the performance of the BSM1 using a data driven approach. In Proceedings of the 8th International IWA Symposium on Systems Analysis and Integrated Assessment in Water Management, San Sebastián, Spain, 20–22 June 2011.

- Rojas, J.; Flores, X.; Jeppson, U.; Vilanova, R. Application of multivariate virtual reference feedback tuning for wastewater treatment plant control. Control Eng. Pract. 2012, 20, 499–510. [Google Scholar] [CrossRef]

- Vrecko, D.; Hvala, N.; Carlsson, B. Feedforward-feedback control of an activated sludge process: A simulation study. Water Sci. Technol. 2003, 47, 19–26. [Google Scholar] [PubMed]

- Vrecko, D.; Hvala, N.; Stare, A.; Burica, O.; Strazar, M.; Levstek, M.; Cerar, P.; Podbevsek, S. Improvement of ammonia removal in activated sludge process with feedforward-feedback aeration controllers. Water Sci. Technol. 2006, 53, 125–132. [Google Scholar] [CrossRef] [PubMed]

- Alex, J.; Beteau, J.F.; Copp, J.B.; Hellinga, C.; Jeppsson, U.; Marsili-Libelli, S.; Pons, M.; Spanjers, H.; Vanhooren, H. Benchmark for Evaluating Control Strategies in Wastewater Treatment Plants. In Proceedings of European Control Conference, Karlsruhe, Germany, 31 August–3 September 1999.

- Alex, J.; Benedetti, L.; Copp, J.; Gernaey, K.V.; Jeppsson, U.; Nopens, I.; Pons, N.; Rieger, L.; Rosen, C.; Steyer, J.P.; et al. Benchmark Simulation Model No. 1 (BSM1); Technical Report CODEN:LUTEDX/(TEIE-7229)/1-62/(2008); Department of Industrial Electrical Engineering and Automation, Lund University: Lund, Sweden, 2008. [Google Scholar]

- Copp, J.B. The COST Simulation Benchmark-Description and Simulator Manual; Office for Official Publications of the European Communities: Luxembourg, Luxembourg, 2002. [Google Scholar]

- Sobantka, A.; Pons, M.; Zessner, M.; Rechberger, H. Implementation of Extended Statistical Entropy Analysis to the Effluent Quality Index of the Benchmarking Simulation Model No. 2. Water 2014, 6, 86–103. [Google Scholar] [CrossRef]

- Guerrero, J.; Guisasola, A.; Vilanova, R.; Baeza, J. Improving the performance of a WWTP control system by model-based setpoint optimisation. Environ. Model. Softw. 2011, 26, 492–497. [Google Scholar] [CrossRef]

- Santin, I.; Pedret, C.; Vilanova, R. Applying variable dissolved oxygen set point in a two levelhierarchical control structure to a wastewater treatment process. J. Process Control 2015, 28, 40–55. [Google Scholar] [CrossRef]

- ISO14040. In Environmental Management-Life Cycle Assessment-Principles and Framework; International Organization for Standardization: Geneva, Switzerland, 2006.

- Gallego, A.; Hospido, A.; Moreira, M.T.; Feijoo, G. Environmental Performance of Wastewater Treatment Plants for Small Populations. Resour. Conserv. Recycl. 2008, 52, 931–940. [Google Scholar] [CrossRef]

- Pasqualino, J.C.; Meneses, M.; Abella, M.; Castells, F. LCA as a Decision Support Tool for the Environmental Improvement of the Operation of a Municipal Wastewater Treatment Plant. Environ. Sci. Technol. 2009, 43, 3300–3307. [Google Scholar] [CrossRef] [PubMed]

- Chai, C.; Zhang, D.; Yu, Y.; Feng, Y.; Sing Wong, M. Carbon Footprint Analyses of Mainstream Wastewater Treatment Technologies under Different Sludge Treatment Scenarios in China. Water 2015, 7, 918–938. [Google Scholar] [CrossRef]

- Pushkar, S. Life Cycle Assessment of Flat Roof Technologies for Office Buildings in Israel. Sustainability 2016. [Google Scholar] [CrossRef]

- Shen, X.; Kommalapati, R.R.; Huque, Z. The Comparative Life Cycle Assessment of Power Generation from Lignocellulosic Biomass. Sustainability 2015, 7, 12974–12987. [Google Scholar] [CrossRef]

- Arzoumanidis, I.; Raggi, A.; Petti, L. Considerations When Applying Simplified LCA Approaches in the Wine Sector. Sustainability 2014, 6, 5018–5028. [Google Scholar] [CrossRef]

- Barrios, R.; Siebel, M.; van der Helm, A.; Bosklopper, K.; Gijzen, H. Environmental and financial life cycle impact assessment of drinking water production at Waternet. J. Clean. Product. 2008, 16, 471–476. [Google Scholar] [CrossRef]

- Hospido, A.; Moreira, M.; Fernandez-Couto, M.; Feijoo, G. Environmental performance of a municipal wastewater treatment plant. Int. J. LCA 2004, 9, 261–271. [Google Scholar] [CrossRef]

- Hellweg, S.; Hofstetter, T.; Hungerbühler, K. Modeling Waste Incineration for Life-Cycle Inventory Analysis in Switzerland. Environ. Model. Assess. 2001, 6, 219–235. [Google Scholar] [CrossRef]

- Lim, S.; Park, J. Environmental impact minimization of a total wastewater treatment network system from a life cycle perspective. J. Environ. Manag. 2008, 90, 1454–1462. [Google Scholar] [CrossRef] [PubMed]

- Meneses, M.; Pasqualino, J.C.; Céspedes-Sánchez, R.; Castells, F. Alternatives for Reducing the Environmental Impact of the Main Residue From a Desalination Plant. J. Ind. Ecol. 2010, 14, 512–527. [Google Scholar] [CrossRef]

- Muñoz, I.; Rodríguez, A.; Rosal, R.; Fernandez-Alba, A. Life cycle assessment of urban wastewater reuse with ozonation as tertiary treatment: A focus on toxicity related impacts. Sci. Total Environ. 2009, 407, 1245–1256. [Google Scholar] [CrossRef] [PubMed]

- Pasqualino, J.C.; Meneses, M.; Castells, F. Life Cycle Assessment of Urban Wastewater Reclamation and Reuse Alternatives. J. Ind. Ecol. 2011, 15, 49–63. [Google Scholar] [CrossRef]

- Vimal, K.; Vinodh, S. LCA Integrated ANP Framework for Selection of Sustainable Manufacturing Processes. Environ. Model. Assess. 2015. [Google Scholar] [CrossRef]

- Corominas, L.; Foley, J.; Guest, S.; Hospido, A.; Larsen, H.F.; Morera, S.; Shaw, A. Life Cycle assessment applied to wastewater treatment: State of the art. Water Res. 2013, 47, 5480–5492. [Google Scholar] [CrossRef] [PubMed]

- Bordons, C.; García-Torres, F.; Valverde, L. Optimal energy management for renewable energy microgrids. RIAI-Revista Iberoamericana de Automática e Informática Industrial 2015, 12, 117–132. [Google Scholar] [CrossRef]

- Garrido-Baserba, M.; Hospido, A.; Reif, R.; Molinos-Senante, M.; Comas, J.; Poch, M. Including the environmental criteria when selecting a wastewater treatment plant. Environ. Model. Softw. 2014, 56, 74–82. [Google Scholar] [CrossRef]

- Mannina, G.; Ekama, G.; Caniani, D.; Cosenza, A.; Esposito, G.; Gori, R.; Garrido-Baserba, M.; Rosso, D.; Olsson, G. Greenhouse gases from wastewater treatment? A review of modeling tools. Sci. Total Environ. 2016, 56, 551–552. [Google Scholar]

- Corominas, L.; Larsen, H.; Flores-Alsina, X.; Vanrolleghem, P. Including Life Cycle Assessment for decision-making in controlling wastewater nutrient removal systems. J. Environ. Manag. 2013, 128, 759–767. [Google Scholar] [CrossRef] [PubMed]

- Meneses, M.; Concepción, H.; Vrecko, D.; Vilanova, R. Life Cycle Assessment as an environmental evaluation tool for control strategies in wastewater treatment plants. J. Clean. Product. 2015, 107, 653–661. [Google Scholar] [CrossRef]

- Alex, J.; Benedetti, L.; Copp, J.B.; Gernaey, K.V.; Jeppsson, U.; Nopens, I.; Pons, M.N.; Rieger, L.; Rosen, C.; Steyer, J.P.; et al. Benchmark Simulation Model No. 1 (BSM1). 2008. Available online: http//www.iea.lth.se/publications/Reports/LTH-IEA-7229.pdf (accessed on 8 April 2016.).

- Henze, M.; Gujer, W.; Mino, T.; van Loosdrecht, M.C.M. Activated Sludge Models ASM1, ASM2, ASM2d and ASM3; Technical Report; IWA Publishing: London, UK, 2000. [Google Scholar]

- Takács, I.; Patry, G.G.; Nolasco, D. A dynamic model of the clarification thickening process. Water Res. 1991, 25, 1263–1271. [Google Scholar] [CrossRef]

- Vanrolleghem, P.; Jeppsson, U.; Carstensen, J.; Carlsson, B.; Olsson, G. Integration of WWT plant design and operation - A systematic approach using cost functions. Wat. Sci. Tech. 1996, 34, 159–171. [Google Scholar] [CrossRef]

- Vilanova, R.; Visioli, A.E. PID Control in the Third Millennium: Lessons Learned and New Approaches; Advances in Industrial Control, ISBN 978-1-4471-2424-5; Springer: Berlin, Germany, 2012. [Google Scholar]

- Alcántara, S.; Pedret, C.; Vilanova, R. On the model matching approach to PID design: Analytical perspective for robust servo/regulator tradeoff tuning. J. Process Control 2010, 5, 596–608. [Google Scholar] [CrossRef]

- Lindberg, C.F.; Carlsson, B. Nonlinear and set-point control of the dissolved oxygen concentration in an activated sludge process. Water Sci. Technol. 1996, 34, 135–142. [Google Scholar] [CrossRef]

- Yuan, Z.; Bogaert, H.; Vanrolleghem, P.; Thoeye, C.; Vansteenkiste, G.; Verstraete, W. Control of external carbon addition to predenitrifying systems. J. Environ. Eng. 1997, 123, 1080–1086. [Google Scholar] [CrossRef]

- Lech, R.F.; Grady, C.P.L.; Lim, H.C.; Koppel, L.B. Automatic control of the activated sludge process-II. Efficacy of control strategies. Water Res. 1978, 12, 91–99. [Google Scholar] [CrossRef]

- Swiss Center for Life-Cycle Inventories. Ecoinvent Database. 2009. Available online: http//www.ecoinvent.org (accessed on 8 April 2016).

- European Commission. European Commission, Environmental, Economic and Social Impacts of the Use of Sewage Sludge on land Final Report Part II: Report on Options and Impacts. 2008. Available online: http://ec.europa.eu/environment/archives/waste/sludge/pdf/part_ii_report.pdf (accessed on 8 April 2016).

- Eurostat. Agricultural Statistics. Main Results-2006–2007. Available online: http://ec.europa.eu/eurostat/documents/3930297/5962526/KS-ED-08-001-EN.PDF/185d1969-b77a-4791-b29d-5af9ee774e3b (accessed on 8 April 2016).

- Lundin, M.; Bengtsson, M.; Molander, S. Life Cycle Assessment of Wastewater Systems: Influence of system Boundaries and Scale on Calculated Environmental Loads. Int. J. Life Cycle Assess. 2000, 34, 57–64. [Google Scholar] [CrossRef]

- Hobson, J. CH4 and N2O Emissions from Waste Water Handling. Good Practice Guidance and Uncertainty Management in National Greenhouse Gas Inventories. Available online: http://www.ipcc-nggip.iges.or.jp/public/gp/bgp/5_2_CH4_N2O_Waste_Water.pdf (accessed on 8 April 2016).

- Gernaey, K.V.; Jorgensen, S.B. Benchmarking combined biological phosphorus and nitrogen removal wastewater treatment process. Control Eng. Pract. 2004, 12, 357–373. [Google Scholar] [CrossRef]

- Guinée, J.; Gorrée, M.; Heijungs, R.; Huppes, G.; Kleijn, R.; de Koning, A.; van Oers, L.; Wegener Sleeswijk, A.; Suh, S.; Udo de Haes, H.; et al. Handbook on Life Cycle Assessment. Operational Guide to the ISO Standards. I: LCA in Perspective. IIa: Guide. IIb: Operational annex. III: Scientific Background; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2001. [Google Scholar]

- Vanhooren, H.; Nguyen, K. Development of a Simulation Protocol for Evaluation of Respirometry-Based Control Strategies; University of Gent: Gent, Belgium; University of Ottawa: Ottawa, QC, Canada, 1996. [Google Scholar]

| Factor | |||||

|---|---|---|---|---|---|

| Value (g pollution unit·g) | 2 | 1 | 30 | 10 | 2 |

| Characteristics | |||||

|---|---|---|---|---|---|

| Controller | Cascade Controller | Controller | Controller | Controller | |

| [35] | [41] | [10] | [42] | [43] | |

| Controlled variable | 2, 2 and 2 | ||||

| Set-point (gm) | (variable in cascade controller) | 1 | 1 | 1 | 4000 |

| Manipulated variable | set-point | ||||

| Control algorithm | PI | Cascade PI | PI | PI | PI |

| Used in control strategy | S1, S2, S6, S7 S8, S9 and S10 | S2, S6, S7 S8, S9 and S10 | S3, S6 and S10 | S4, S7 and S9 | S5, S8, S9 and S10 |

| Strategies | S1 | S2 | S3 | S4 | S5 | S6 | S7 | S8 | S9 | S10 |

|---|---|---|---|---|---|---|---|---|---|---|

| Inputs | ||||||||||

| From the background system | ||||||||||

| Electricity (kWh) | 0.21 | 0.22 | 0.31 | 0.31 | 0.31 | 0.22 | 0.24 | 0.22 | 0.24 | 0.22 |

| Carbon source (kg) | 0 | 0 | 0 | 0.08 | 0 | 0 | 0.06 | 0 | 0.06 | 0 |

| Outputs | ||||||||||

| Emissions to soil | ||||||||||

| Sludge for disposal (kg) | 0.12 | 0.12 | 0.12 | 0.15 | 0.12 | 0.12 | 0.14 | 0.12 | 0.15 | 0.12 |

| Heavy metals in the sludge | ||||||||||

| Cd (mg) | 1.23 | 1.23 | 1.23 | 1.45 | 1.21 | 1.23 | 1.41 | 1.22 | 1.47 | 1.22 |

| Cr (mg) | 124 | 124 | 124 | 145 | 122 | 124 | 141 | 123 | 148 | 122 |

| Cu (mg) | 124 | 124 | 124 | 145 | 122 | 124 | 141 | 123 | 148 | 122 |

| Hg (mg) | 1.23 | 1.23 | 1.23 | 1.45 | 1.21 | 1.23 | 1.41 | 1.22 | 1.47 | 1.22 |

| Ni (mg) | 37 | 37 | 37 | 43 | 36 | 37 | 42 | 36 | 44 | 36 |

| Pb (mg) | 92 | 92 | 92 | 109 | 91 | 92 | 106 | 91 | 111 | 91 |

| Zn (mg) | 309 | 309 | 309 | 363 | 304 | 309 | 353 | 306 | 369 | 306 |

| Emissions to water | ||||||||||

| Total COD (g) | 49 | 49 | 49 | 50 | 49 | 49 | 50 | 49 | 49 | 49 |

| Total BOD(g) | 2.8 | 2.8 | 2.8 | 3.1 | 2.8 | 2.8 | 3.1 | 2.8 | 3.0 | 2.8 |

| NO (g) | 12.7 | 12.3 | 14.8 | 7.37 | 15.4 | 13.2 | 7.12 | 12.2 | 6.95 | 13.2 |

| S (g) | 1.27 | 1.28 | 0.98 | 1.22 | 0.91 | 1.21 | 1.45 | 1.21 | 1.85 | 1.14 |

| Total N (organic) (g) | 2.01 | 2.01 | 1.99 | 2.14 | 2.03 | 2.01 | 2.12 | 2.02 | 2.08 | 2.02 |

| Phosphorus (g) | 4.06 | 4.06 | 4.07 | 3.20 | 4.15 | 4.07 | 3.35 | 4.11 | 3.10 | 4.12 |

| Heavy metals in the effluent | ||||||||||

| Cd (mg) | 0.14 | 0.14 | 0.14 | 0.15 | 0.14 | 0.14 | 0.15 | 0.14 | 0.14 | 0.14 |

| Cr (mg) | 13.9 | 13.9 | 13.9 | 15.1 | 14.3 | 13.9 | 14.7 | 14.1 | 14.1 | 14.1 |

| Cu (mg) | 13.9 | 13.9 | 13.9 | 15.1 | 14.3 | 13.9 | 14.7 | 14.1 | 14.1 | 14.1 |

| Hg (mg) | 0.14 | 0.14 | 0.14 | 0.15 | 0.14 | 0.14 | 0.15 | 0.14 | 0.14 | 0.14 |

| Ni (mg) | 4.18 | 4.18 | 4.18 | 4.52 | 4.28 | 4.18 | 4.41 | 4.23 | 4.21 | 4.23 |

| Pb (mg) | 10.5 | 10.5 | 10.5 | 11.3 | 10.7 | 10.5 | 11.0 | 10.6 | 10.5 | 10.6 |

| Zn (mg) | 34.9 | 34.9 | 34.8 | 37.7 | 35.7 | 34.9 | 36.8 | 35.3 | 35.1 | 35.3 |

| Emissions to air | ||||||||||

| CH (g) | 0.62 | 0.62 | 0.62 | 0.72 | 0.60 | 0.62 | 0.71 | 0.61 | 0.74 | 0.61 |

| NO (g) | 0.06 | 0.06 | 0.06 | 0.07 | 0.06 | 0.06 | 0.07 | 0.06 | 0.07 | 0.06 |

| NH (g) | 1.21 | 1.21 | 1.21 | 1.42 | 1.19 | 1.21 | 1.39 | 1.20 | 1.45 | 1.20 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meneses, M.; Concepción, H.; Vilanova, R. Joint Environmental and Economical Analysis of Wastewater Treatment Plants Control Strategies: A Benchmark Scenario Analysis. Sustainability 2016, 8, 360. https://doi.org/10.3390/su8040360

Meneses M, Concepción H, Vilanova R. Joint Environmental and Economical Analysis of Wastewater Treatment Plants Control Strategies: A Benchmark Scenario Analysis. Sustainability. 2016; 8(4):360. https://doi.org/10.3390/su8040360

Chicago/Turabian StyleMeneses, Montse, Henry Concepción, and Ramon Vilanova. 2016. "Joint Environmental and Economical Analysis of Wastewater Treatment Plants Control Strategies: A Benchmark Scenario Analysis" Sustainability 8, no. 4: 360. https://doi.org/10.3390/su8040360