Evaluating the Feasibility of Using Produced Water from Oil and Natural Gas Production to Address Water Scarcity in California’s Central Valley

Abstract

:1. Introduction

2. Materials and Methods

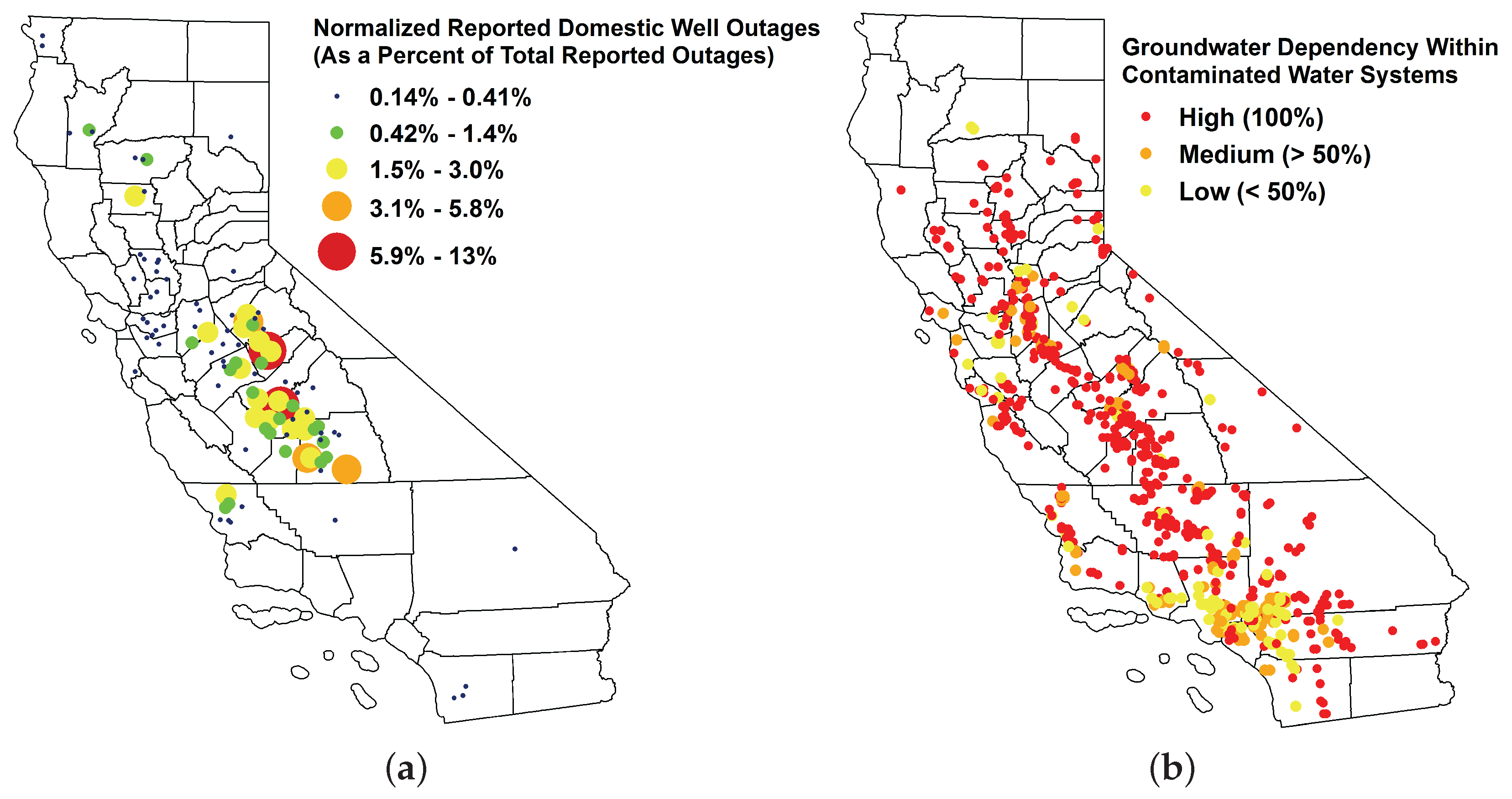

2.1. Domestic Water Shortage Data

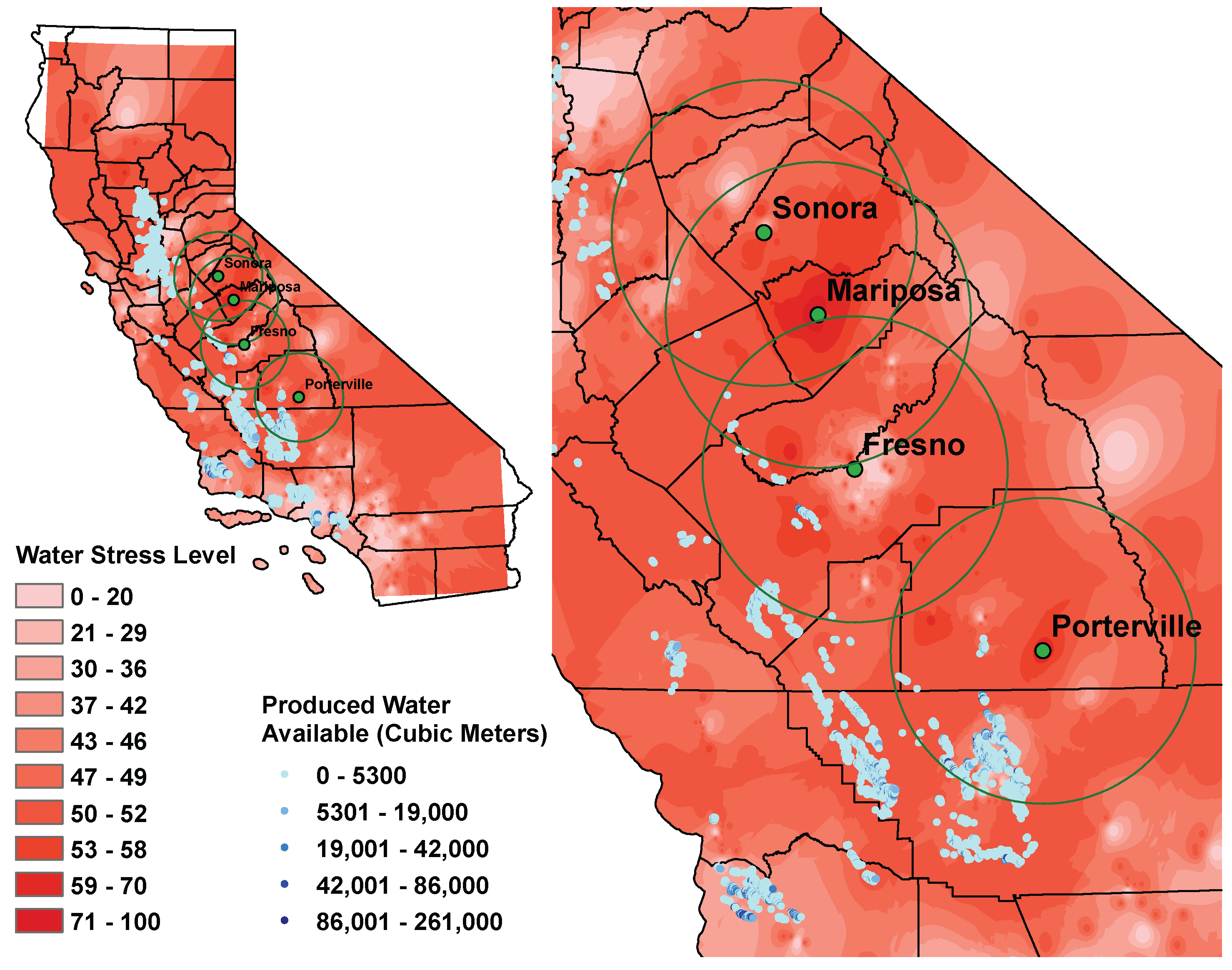

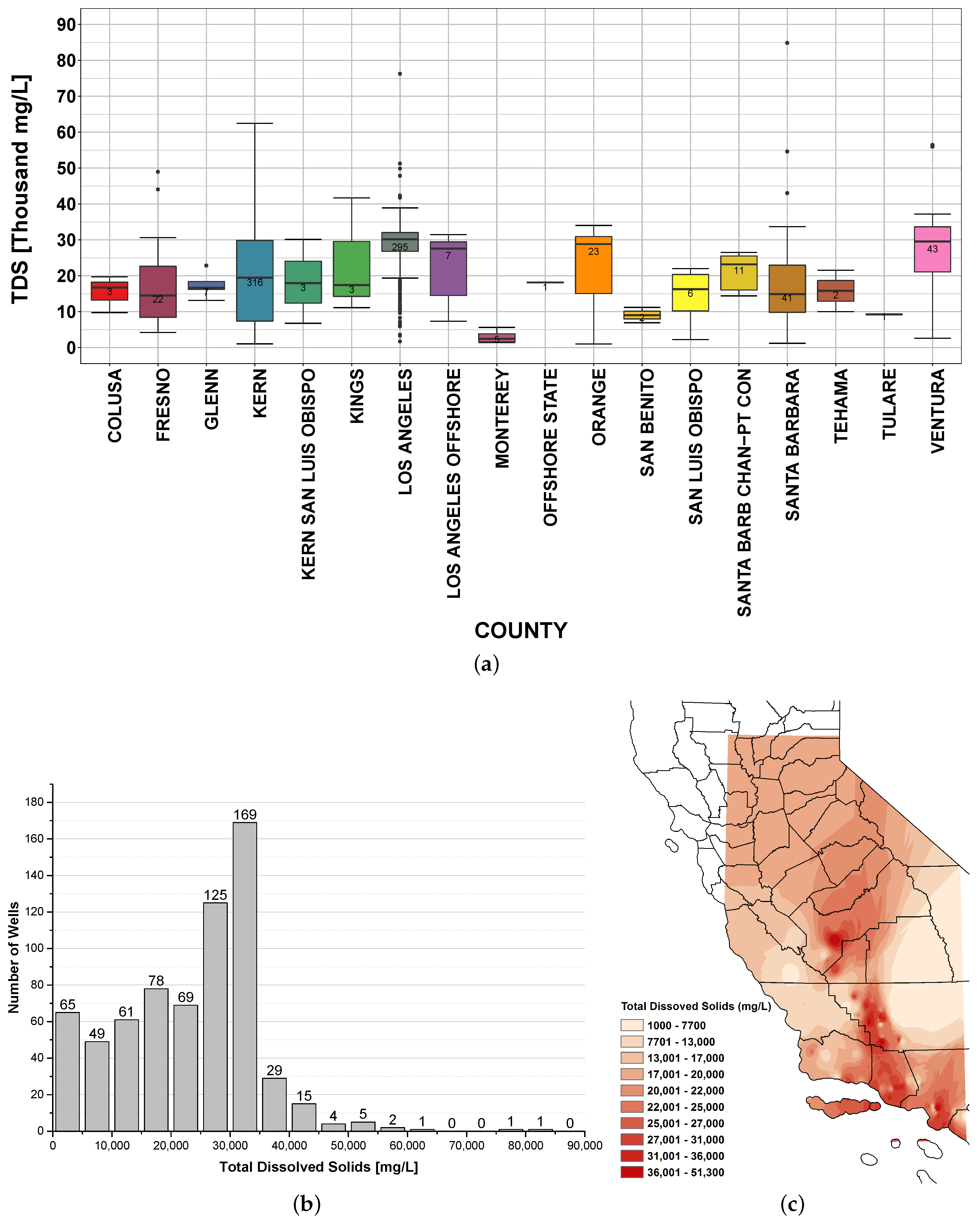

2.2. Oil and Gas Production Produced Water Data

2.3. Techno-Economic Analysis

3. Results

4. Discussion

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| DOGGR | Division of Oil, Gas, and Geothermal Resources |

| EIA | U.S. Energy Information Administration |

| GAMA | Groundwater Ambient Monitoring and Assessment |

| IDW | Inverse Distance Weighting |

| NORM | Naturally Occurring Radioactive Materials |

| OPR | Office of Planning and Research |

| RO | Reverse Osmosis |

| SWRCB | California State Water Resources Control Board |

| TDS | Total Dissolved Solids |

| USGS | United States Geological Survey |

References

- Faunt, C.C.; Sneed, M.; Traum, J.; Brandt, J.T. Water availability and land subsidence in the Central Valley, California, USA. Hydrogeol J. 2015, 24, 675–684. [Google Scholar] [CrossRef]

- Griffin, D.; Anchukaitis, K.J. How unusual is the 2012–2014 California drought? Geophys. Res. Lett. 2014, 41, 9017–9023. [Google Scholar] [CrossRef]

- Fuchs, B. U.S. Drought Monitor—California; National Drought Mitigation Center: Lincoln, NE, USA, 2016. [Google Scholar]

- Steinschneider, S.; Lall, U. El Nino and the U.S. precipitation and floods: What was expected for the January–March 2016 winter hydroclimate that is now unfolding? Water Resour. Res. 2016, 52, 1498–1501. [Google Scholar] [CrossRef]

- Famiglietti, J.S.; Lo, M.; Ho, S.L.; Bethune, J.; Anderson, K.J.; Syed, T.H.; Swenson, S.C.; De Linage, C.R.; Rodell, M. Satellites measure recent rates of groundwater depletion in California’s Central Valley. Geophys. Res. Lett. 2011, 38, 2–5. [Google Scholar] [CrossRef]

- Ritchel, M. California Farmers Dig Deeper for Water, Sipping Their Neighbors Dry; The New York Times: New York, NY, USA, 2015; pp. 1–9. [Google Scholar]

- Household Water Shortage Intake Form Data; Technical Report; California Office of Planning and Research: Sacramento, CA, USA, 2015.

- State Water Resources Control Board. Communities that Rely on a Contaminated Groundwater Source for Drinking Water; State Water Resources Control Board: Sacramento, CA, USA, 2013; p. 178.

- Hanak, E.; Mount, J.; Chappelle, C.; Lund, J.; Medellin-Azuara, J.; Moyle, P.; Seavy, N. What If California’s Drought Continues? Public Policy Institute of California: San Francisco, CA, USA, 2015. [Google Scholar]

- Cooley, C.; Ajami, N. Key Issues for Seawater Desalination in California Cost and Financing. World’s Water 2014, 8, 93–121. [Google Scholar]

- Mccool, B.C.; Rahardianto, A.; Faria, J.; Kovac, K.; Lara, D.; Cohen, Y. Feasibility of reverse osmosis desalination of brackish agricultural drainage water in the San Joaquin Valley. Desalination 2010, 261, 240–250. [Google Scholar] [CrossRef]

- Stein, S.; Russak, A.; Sivan, O.; Yechieli, Y.; Rahav, E.; Oren, Y.; Kasher, R. Saline groundwater from coastal aquifers as a source for desalination. Environ. Sci. Technol. 2016, 50, 1955–1963. [Google Scholar] [CrossRef] [PubMed]

- Stuber, M.D. Optimal design of fossil-solar hybrid thermal desalination for saline agricultural drainage water reuse. Renew. Energy 2016, 89, 552–563. [Google Scholar] [CrossRef]

- Clayton, M.E.; Stillwell, A.S.; Webber, M.E. Implementation of brackish groundwater desalination using wind-generated electricity: A case study of the energy-water nexus in Texas. Sustainability 2014, 6, 758–778. [Google Scholar] [CrossRef]

- Boo, C.; Lee, J.; Elimelech, M. Omniphobic Polyvinylidene Fluoride (PVDF) Membrane for Desalination of Shale Gas Produced Water by Membrane Distillation. Environ. Sci. Technol. 2016, 50, 12275–12282. [Google Scholar] [CrossRef] [PubMed]

- Shaffer, D.L.; Chavez, L.H.A.; Ben-sasson, M.; Castrillo, S.R.; Yip, N.Y.; Elimelech, M. Desalination and Reuse of High-Salinity Shale Gas Produced Water: Drivers, Technologies, and Future Directions. Environ. Sci. Technol. 2013, 47, 9569–9583. [Google Scholar] [CrossRef] [PubMed]

- Guerra, K.; Dahm, K.; Dundorf, S. Oil and Gas Produced Water Management and Beneficial Use in the Western United States; Technical Report 157; Bureau of Reclamation: Denver, CO, USA, 2011.

- Kondash, A.; Vengosh, A. Water Footprint of Hydraulic Fracturing. Environ. Sci. Technol. Lett. 2015, 10, 276–280. [Google Scholar] [CrossRef]

- Oikonomou, P.D.; Kallenberger, J.A.; Waskom, R.M.; Boone, K.K.; Plombon, E.N.; Ryan, J.N. Water acquisition and use during unconventional oil and gas development and the existing data challenges. J. Environ. Manag. 2016, 181, 36–47. [Google Scholar] [CrossRef] [PubMed]

- Tiedeman, K.; Yeh, S.; Scanlon, B.; Teter, J.; Mishra, G.S. Recent Trends in Water Use and Production for California Conventional and Unconventional Oil Production. Environ. Sci. Technol. 2016, 50, 7904–7912. [Google Scholar] [CrossRef] [PubMed]

- Murray, K.E. State-scale perspective on water use and production associated with oil and gas operations, Oklahoma, U.S. Environ. Sci. Technol. 2013, 47, 4918–4925. [Google Scholar] [CrossRef] [PubMed]

- 2014 Preliminary Report of California Oil and Gas Production Statistics; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2015.

- Kuwayama, Y.; Olmstead, S.; Krupnick, A. Water Quality and Quantity Impacts of Hydraulic Fracturing. Curr. Sustain. Renew. Energy Rep. 2015, 2, 17–24. [Google Scholar] [CrossRef]

- Shonkoff, S.B.C.; Stringfellow, W.T.; Domen, J.K. Preliminary Hazard Assessment of Chemical Additives Used in Oil and Gas Fields that Reuse Their Produced Water for Agricultural Irrigation in The San Joaquin Valley of California; Technical Report; PSE Healthy Energy, Inc.: Oakland, CA, USA, 2016. [Google Scholar]

- State Water Resources Control Board. GAMA—Groundwater Ambient Monitoring and Assessment Program; State Water Resources Control Board: Sacramento, CA, USA, 2015.

- Sanders, K.T. The energy trade-offs of adapting to a water-scarce future: Case study of Los Angeles. Int. J. Water Resour. Dev. 2016, 32, 362–378. [Google Scholar] [CrossRef]

- Blondes, M.S.; Gans, K.D.; Thorsden, J.J.; Reidy, M.E.; Thomas, B.; Engle, M.A.; Kharaka, Y.K.; Rowan, E.L. U.S. Geological Survey National Produced Waters Geochemical Database v2.1 (PROVISIONAL). 2015. Available online: http://xxx.lanl.gov/abs/arXiv:1011.1669v3 (accessed on 12 November 2015). [Google Scholar]

- Monthly Production and Injection Databases; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2016.

- Glazer, Y.R.; Kjellsson, J.B.; Sanders, K.T.; Webber, M.E. Potential for Using Energy from Flared Gas for On-Site Hydraulic Fracturing Wastewater Treatment in Texas. Environ. Sci. Technol. Lett. 2014, 1, 300–304. [Google Scholar] [CrossRef]

- Sanders, K.T.; Webber, M.E. Evaluating the energy consumed for water use in the United States. Environ. Res. Lett. 2012. [Google Scholar] [CrossRef]

- Ghaffour, N.; Missimer, T.M.; Amy, G.L. Technical review and evaluation of the economics of water desalination: Current and future challenges for better water supply sustainability. Desalination 2013, 309, 197–207. [Google Scholar] [CrossRef]

- Elimelech, M.; Phillip, W.A. The Future of Seawater and the Environment: Energy, Technology, and the Environment. Science 2011, 333, 712–718. [Google Scholar] [CrossRef] [PubMed]

- Fakhru’l-Razi, A.; Pendashteh, A.; Abdullah, L.C.; Biak, D.R.A.; Madaeni, S.S.; Abidin, Z.Z. Review of technologies for oil and gas produced water treatment. J. Hazard. Mater. 2009, 170, 530–551. [Google Scholar] [CrossRef] [PubMed]

- A Study of NORM Associated with Oil and Gas Production Operations in California; Technical Report; Department of Health Services Radiologic Health Branch and Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 1996.

- U.S. Environmental Protection Agency. TENORM: Oil and Gas Production Wastes; U.S. Environmental Protection Agency: Washington, DC, USA. Available online: https://www.epa.gov/radiation/tenorm-oil-and-gas-production-wastes (accessed on 29 October 2016).

- Kim, Y.M.; Kim, S.J.; Kim, Y.S.; Lee, S.; Kim, I.S.; Kim, J.H. Overview of systems engineering approaches for a large-scale seawater desalination plant with a reverse osmosis network. Desalination 2009, 238, 312–332. [Google Scholar] [CrossRef]

- Voutchkov, N. Considerations for selection of seawater filtration pretreatment system. Desalination 2010, 261, 354–364. [Google Scholar] [CrossRef]

- Arthur, J.D.; Langhus, B.G.; Patel, C. Technical Summary of Oil & Gas Produced Water Treatment Technologies; Technical Report; ALL Consulting: Tulsa, OK, USA, 2005. [Google Scholar]

- Water Report Summary Division of Oil, Gas, and Geothermal Resources Second Quarter 2015; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2015.

- Wiedeman, A. Regulation of Produced Water By the U.S. Environmental Protection Agency. In Produced Water 2: Environmental Issues and Mitigation Technologies; Springer: New York, NY, USA, 1996; pp. 27–41. [Google Scholar]

- Greenlee, L.F.; Lawler, D.F.; Freeman, B.D.; Marrot, B.; Moulin, P. Reverse osmosis desalination: Water sources, technology, and today’s challenges. Water Res. 2009, 43, 2317–2348. [Google Scholar] [CrossRef] [PubMed]

- U.S. Geological Survey. The National Map Elevation; U.S. Geological Survey: Reston, VA, USA, 2015.

- Stillwell, A.S.; King, C.W.; Webber, M.E. Desalination and Long-Haul Water Transfer as a Water Supply for Dallas, Texas: A Case Study of the Energy-Water Nexus in Texas. Texas Water J. 2010, 1, 33–41. [Google Scholar]

- U.S. Energy Information Adminstration. Electric Power Monthly with Data for March 2016; Technical Report; U.S. Energy Information Adminstration: Washington, DC, USA, 2016.

- Sullivan, E.J.; Chu, S.; Stauffer, P.H.; Middleton, R.S.; Pawar, R.J. A method and cost model for treatment of water extracted during geologic CO2 storage. Int. J. Greenh. Gas Control 2013, 12, 372–381. [Google Scholar] [CrossRef]

- California Environmental Protection Agency. November 2015 Water Conservation Report by Supplier; Technical Report; California Environmental Protection Agency: Sacramento, CA, USA, 2015.

- Mezher, T.; Fath, H.; Abbas, Z.; Khaled, A. Techno-economic assessment and environmental impacts of desalination technologies. Desalination 2011, 266, 263–273. [Google Scholar] [CrossRef]

- Benjamin, M. Porterville, Clovis Lead Central San Joaquin Valley in Population Growth in 2015; The Fresno Bee: Fresno, CA, USA, 2016. [Google Scholar]

- Çakmakce, M.; Kayaalp, N.; Koyuncu, I. Desalination of produced water from oil production fields by membrane processes. Desalination 2008, 222, 176–186. [Google Scholar] [CrossRef]

- Sauvet-Goichon, B. Ashkelon desalination plant—A successful challenge. Desalination 2007, 203, 75–81. [Google Scholar] [CrossRef]

- Board of Governors of the Federal Reserve System. Selected Interest Rates (Daily). 2016. Available online: https://www.federalreserve.gov/releases/h15/ (accessed on 29 October 2016). [Google Scholar]

- Avlonitis, S.A.; Kouroumbas, K.; Vlachakis, N. Energy consumption and membrane replacement cost for seawater RO desalination plants. Desalination 2003, 157, 151–158. [Google Scholar] [CrossRef]

- Avlonitis, S.A. Operational water cost and productivity improvements for small-size RO desalination plants. Desalination 2002, 142, 295–304. [Google Scholar] [CrossRef]

- Baldocchi, D. California Drought: Charge True Cost of Agricultural Water; San Francisco Chronicle: San Francisco, CA, USA, 2015. [Google Scholar]

- Vekshin, A. California Water Prices Soar for Farmers as Drought Grows; Bloomberg: New York, NY, USA, 2014. [Google Scholar]

- City of Porterville. Utility Rates & Information; City of Porterville: Porterville, CA, USA, 2015. [Google Scholar]

- Municipal Financial Services. Water Utility Financial Plan and Rates Study; Technical Report; Municipal Financial Services: Fresno, CA, USA, 2015. [Google Scholar]

- International Bottled Water Association. How Much Does Bottled Water Cost? International Bottled Water Association: Alexandria, VA, USA, 2015. [Google Scholar]

- Nestlé Waters North America Inc. ReadyFresh; Nestlé Waters North America Inc.: Stamford, CT, USA, 2016. [Google Scholar]

- Gude, V.G. Energy storage for desalination processes powered by renewable energy and waste heat sources. Appl. Energy 2015, 137, 877–898. [Google Scholar] [CrossRef]

- Investigating a Higher Renewables Portfolio Standard in California; Technical Report; Energy and Environmental Economics, Inc.: San Francisco, CA, USA, 2014.

- Richards, B.S.; Capão, D.P.S.; Früh, W.G.; Schäfer, A.I. Renewable energy powered membrane technology: Impact of solar irradiance fluctuations on performance of a brackish water reverse osmosis system. Sep. Purif. Technol. 2015, 156, 379–390. [Google Scholar] [CrossRef]

- Lai, W.; Ma, Q.; Lu, H.; Weng, S.; Fan, J.; Fang, H. Effects of wind intermittence and fluctuation on reverse osmosis desalination process and solution strategies. Desalination 2016, 395, 17–27. [Google Scholar] [CrossRef]

- SB 1281 Water Report Summary—First Quarter 2015; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2015.

- SB 1281 Water Report Summary—Second Quarter 2015; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2015.

- SB 1281 Water Report Summary—Third Quarter 2015; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2016.

- SB 1281 Water Report Summary—Fourth Quarter 2015; Technical Report; Division of Oil, Gas, and Geothermal Resources: Sacramento, CA, USA, 2016.

| Radius | Produced Water Available (1000 m) | Water After Treatment (1000 m) | Water After Treatment (People-Years) | ||||||||||||

| (miles/km) | Fresno | Mariposa | Sonora | Porterville | Fresno | Mariposa | Sonora | Porterville | Fresno | Mariposa | Sonora | Porterville | |||

| Volumes | 15/24 | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 30/48 | 610 | – | – | 3800 | 310 | – | – | 1900 | 3000 | – | – | 18,000 | |||

| 50/80 | 950 | 0.0042 | 0.0042 | 72,000 | 450 | 0.0020 | 0.0022 | 37,000 | 4500 | 0.019 | 0.021 | 350,000 | |||

| 75/121 | 8700 | 610 | 18 | 120,000 | 4200 | 310 | 8.7 | 64,000 | 41,000 | 3000 | 85 | 600,000 | |||

| 100/161 | 79,000 | 7200 | 640 | 140,000 | 38,000 | 3600 | 330 | 68,000 | 380,000 | 35,000 | 3100 | 650,000 | |||

| Radius | Pumping Cost of Treated Water (1000 USD) | Annualized RO Treatment Costs (1000 USD) | Brine Disposal Costs (1000 USD) | ||||||||||||

| (miles/km) | Fresno | Mariposa | Sonora | Porterville | Fresno | Mariposa | Sonora | Porterville | Fresno | Mariposa | Sonora | Porterville | |||

| Costs | 15/24 | – | – | – | – | – | – | – | – | – | – | – | – | ||

| 30/48 | 0.95–1.3 | – | – | 30–40 | 58 | – | – | 350 | 5.2 | – | – | 32 | |||

| 50/80 | 1.5–2.0 | 0.00029–0.00038 | 0.00028–0.00038 | 600–790 | 88 | 0.0004 | 0.0004 | 6900 | 7.6 | 0.000033 | 0.000036 | 620 | |||

| 75/121 | 15–19 | 45–60 | 1.2–1.5 | 1000–1100 | 810 | 58 | 1.7 | 12,000 | 70 | 5.2 | 0.15 | 1800 | |||

| 100/161 | 140–180 | 520–700 | 43–57 | 1100–1500 | 7300 | 670 | 61 | 13,000 | 630 | 60 | 5.5 | 1100 | |||

| Radius (Miles/km) | Fresno per m | Mariposa per m | Sonora per m | Porterville per m |

|---|---|---|---|---|

| 15/24 | – | – | – | – |

| 30/48 | $0.19 | – | – | $0.21 |

| 50/80 | $0.19 | $0.38 | $0.36 | $0.21 |

| 75/121 | $0.19 | $0.38 | $0.36 | $0.21 |

| 100/161 | $0.19 | $0.38 | $0.36 | $0.21 |

| Agricultural Water (Retail) | $0.014 [54] to $0.89 [55] per m | |||

| California Public Water Supply (Retail) | $0.31 [56] (Porterville) to $0.45 [57] (Fresno) per m | |||

| Bottled Water (Retail) | $320.00 [58] per m | |||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Meng, M.; Chen, M.; Sanders, K.T. Evaluating the Feasibility of Using Produced Water from Oil and Natural Gas Production to Address Water Scarcity in California’s Central Valley. Sustainability 2016, 8, 1318. https://doi.org/10.3390/su8121318

Meng M, Chen M, Sanders KT. Evaluating the Feasibility of Using Produced Water from Oil and Natural Gas Production to Address Water Scarcity in California’s Central Valley. Sustainability. 2016; 8(12):1318. https://doi.org/10.3390/su8121318

Chicago/Turabian StyleMeng, Measrainsey, Mo Chen, and Kelly T. Sanders. 2016. "Evaluating the Feasibility of Using Produced Water from Oil and Natural Gas Production to Address Water Scarcity in California’s Central Valley" Sustainability 8, no. 12: 1318. https://doi.org/10.3390/su8121318