The Effect of the Invasive Plant Species Lupinus polyphyllus Lindl. on Energy Recovery Parameters of Semi-Natural Grassland Biomass

Abstract

:1. Introduction

- (i)

- The nutrient and mineral composition of the silage,

- (ii)

- The mass flows of elements into the press fluid of the IFBB system,

- (iii)

- The concentration of minerals in the press cake,

- (iv)

- The energetic parameters for anaerobic digestion and combustion.

2. Materials and Methods

2.1. Site Characterisation and Harvest of Sample Biomass

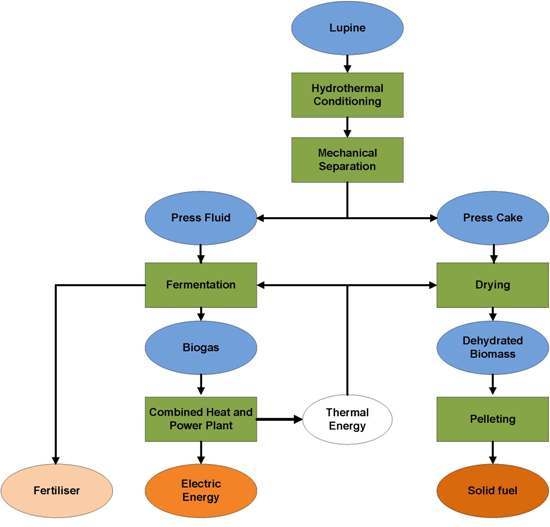

2.2. Processing of the Biomass

2.2.1. Ensiling and Preparation of a Mixture Series

2.2.2. Hydrothermal Conditioning and Mechanical Separation

2.3. Chemical Analysis and Calculation of Mass Flows

- MF_XPC: Mass flow of a specific element X into the press cake,

- MPC: Weight of the press cake in kg,

- XPC: Concentration of a specific element X in the press cake in g∙kg−1,

- MSil: Weight of the silage in kg,

- XSil: Concentration of a specific element X in the silage in g∙kg−1,

- MF_XPF: Mass flow of a specific element X into the press fluid.

2.4. Determination of Biogas Production from Silage and Press Fluid

- DMSILcorr: DM of silage after correction,

- DMSil: DM of silage obtained by oven drying,

- pH: pH value of the silage,

- OA: sum of concentration of organic acids not including lactic acid,

- LA: concentration of lactic acid,

- A: Sum of concentration of alcohols,

- DMPFcorr: DM of press fluid after correction,

- DMPF: DM of press fluid obtained by oven drying,

- pH: pH value of the press fluid,

- OA: sum of concentration of organic acids not including lactic acid,

- LA: concentration of lactic acid,

- A: Sum of concentration of alcohols.

2.5. Calculation of Higher Heating Value and Theoretical Gross Energy Yields

2.6. Statistical Analysis

3. Results

3.1. Chemical Composition of the Silage and Press Cake

3.2. Mass Flows into Press Liquid

3.3. Energetic Parameters

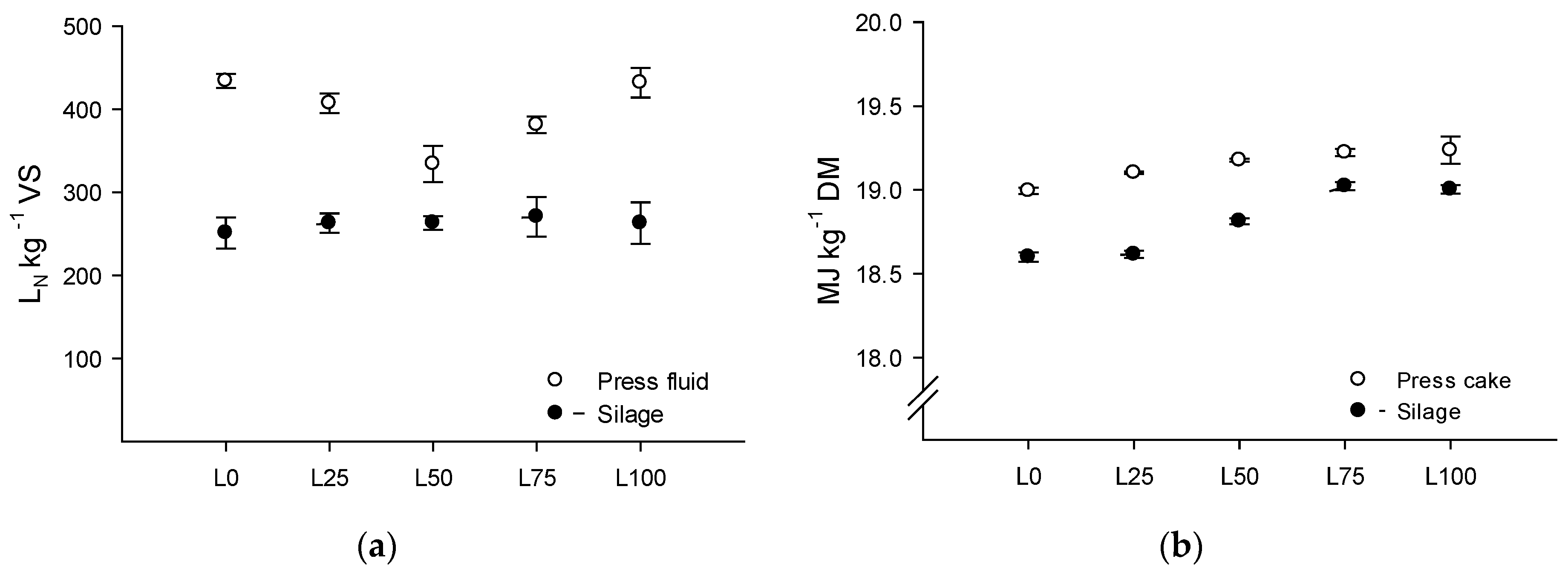

3.3.1. Anaerobic Digestion

3.3.2. Heating Values

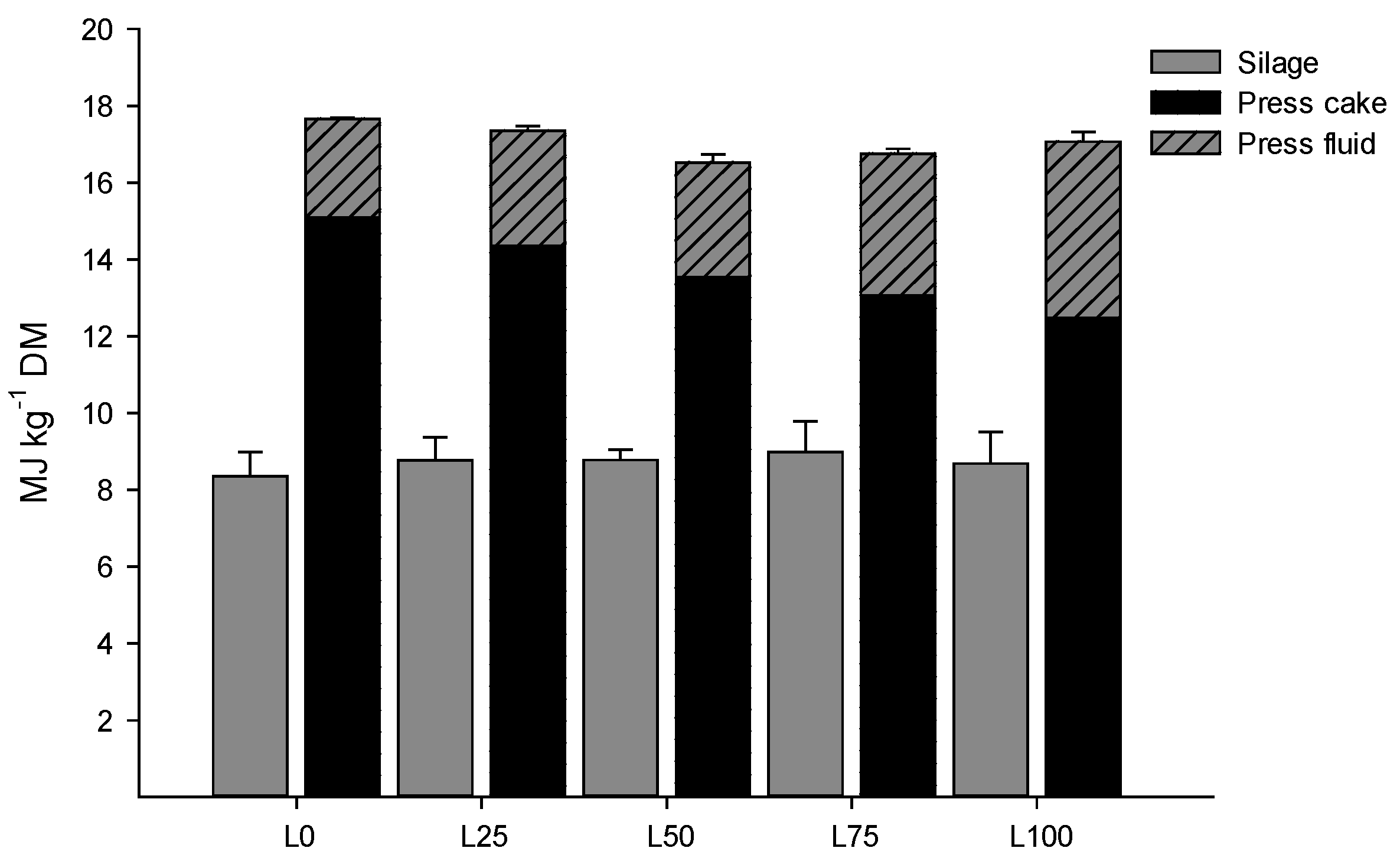

3.3.3. Calculated Gross Energy Yields

4. Discussion

4.1. Chemical Composition of Silage and Press Cake

4.2. Mass Flows into Press Liquid

4.3. Energetic Parameters

4.3.1. Anaerobic Digestion

4.3.2. Heating Value

4.3.3. Calculated Gross Energy Yield

5. Conclusions

- (i)

- There was an effect of lupine on nutrient and mineral composition of the silage, with higher concentrations of total ash, N, Ca and Mg, but also significantly lower DM, S, K, Cl and P concentrations compared to semi-natural grassland silage.

- (ii)

- There was an effect of lupine on the mass flow of elements into press fluid after washing and mechanical dehydration, with higher mass flows of N, K, Mg, Ca and P for lupine material.

- (iii)

- There was an effect of lupine on the concentration of minerals in the press cake. The press cakes from biomass containing lupine showed significantly higher concentrations of N, Mg and Ca and significantly lower concentrations of K, Cl, and P compared to semi-natural grassland biomass without lupine.

- (iv)

- There was no effect of lupine on methane yields and degree of degradation of silages. However, methane yields of press fluids from the 50% mixture of lupine and grassland biomass showed significantly lower methane yields and degrees of degradation in anaerobic digestion. Within the IFBB system, increased lupine content led to higher gross energy yields from PF, but lower gross energy yields from PC. In total, the gross energy yields were best for the lupine-free semi-natural grassland biomass and worst for the 50% mixture, but differences were only marginal.

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| A | Alcohol |

| HHV | Higher heating value |

| IFBB | Integrated generation of solid fuel and biogas from biomass |

| LA | Lactic acid |

| LHV | Lower heating value |

| L0 | Biomass sample containing 0% lupine and 100% semi-natural grassland biomass |

| L25 | Biomass sample containing 25% lupine and 75% semi-natural grassland biomass |

| L50 | Biomass sample containing 50% lupine and 50% semi-natural grassland biomass |

| L75 | Biomass sample containing 75% lupine and 25% semi-natural grassland biomass |

| L100 | Biomass sample containing 100% lupine and 0% semi-natural grassland biomass |

| OA | Organic acids |

| PF | Press fluid |

| PC | Press cake |

| VS | Volatile solids |

| XA | Ash |

Appendix A

| DM | Ash | N | S | K | Mg | Ca | Cl | P | ||

|---|---|---|---|---|---|---|---|---|---|---|

| % FM | % DM | % DM | % DM | % DM | % DM | % DM | % DM | % DM | ||

| L100 | Silage | 15.82 | 8.98 | 2.43 | 0.10 | 0.95 | 0.58 | 2.14 | 0.12 | 0.17 |

| Silage | 15.61 | 9.31 | 2.36 | 0.10 | 0.91 | 0.56 | 1.95 | 0.11 | 0.16 | |

| Silage | 15.58 | 8.92 | 2.38 | 0.10 | 0.92 | 0.54 | 1.85 | 0.11 | 0.16 | |

| L75 | Silage | 19.71 | 8.44 | 1.93 | 0.11 | 1.21 | 0.41 | 1.33 | 0.40 | 0.18 |

| Silage | 19.95 | 8.35 | 1.98 | 0.11 | 1.22 | 0.42 | 1.37 | 0.39 | 0.18 | |

| Silage | 17.92 | 8.53 | 2.02 | 0.11 | 1.25 | 0.45 | 1.40 | 0.40 | 0.19 | |

| L50 | Silage | 23.22 | 8.12 | 1.74 | 0.12 | 1.54 | 0.37 | 1.10 | 0.61 | 0.21 |

| Silage | 23.41 | 8.17 | 1.72 | 0.11 | 1.47 | 0.36 | 1.08 | 0.59 | 0.20 | |

| Silage | 23.87 | 8.11 | 1.72 | 0.12 | 1.51 | 0.37 | 1.09 | 0.62 | 0.21 | |

| L25 | Silage | 26.90 | 8.17 | 1.57 | 0.13 | 1.70 | 0.31 | 0.80 | 0.77 | 0.22 |

| Silage | 25.95 | 8.23 | 1.58 | 0.12 | 1.74 | 0.33 | 0.84 | 0.77 | 0.22 | |

| Silage | 25.37 | 8.06 | 1.57 | 0.12 | 1.70 | 0.33 | 0.88 | 0.74 | 0.22 | |

| L0 | Silage | 30.50 | 8.23 | 1.45 | 0.14 | 1.88 | 0.28 | 0.66 | 0.90 | 0.24 |

| Silage | 31.31 | 8.25 | 1.45 | 0.14 | 1.89 | 0.29 | 0.69 | 0.91 | 0.23 | |

| Silage | 29.92 | 8.44 | 1.47 | 0.12 | 1.87 | 0.28 | 0.62 | 0.90 | 0.23 | |

| L100 | PC | 44.47 | 6.07 | 1.50 | 0.07 | 0.09 | 0.15 | 1.07 | 0.01 | 0.03 |

| PC | 43.56 | 4.68 | 1.57 | 0.06 | 0.09 | 0.15 | 1.01 | 0.01 | 0.03 | |

| PC | 45.38 | 4.59 | 1.59 | 0.07 | 0.09 | 0.15 | 1.07 | 0.01 | 0.03 | |

| L75 | PC | 44.19 | 4.57 | 1.32 | 0.08 | 0.14 | 0.13 | 0.83 | 0.03 | 0.04 |

| PC | 44.92 | 4.59 | 1.29 | 0.09 | 0.14 | 0.14 | 0.89 | 0.02 | 0.04 | |

| PC | 45.85 | 4.49 | 1.29 | 0.07 | 0.14 | 0.13 | 0.85 | 0.02 | 0.04 | |

| L50 | PC | 42.20 | 4.73 | 1.19 | 0.07 | 0.20 | 0.12 | 0.69 | 0.05 | 0.05 |

| PC | 48.60 | 4.71 | 1.28 | 0.08 | 0.19 | 0.12 | 0.74 | 0.04 | 0.05 | |

| PC | 43.54 | 4.81 | 1.26 | 0.08 | 0.20 | 0.12 | 0.73 | 0.04 | 0.05 | |

| L25 | PC | 48.17 | 4.69 | 1.07 | 0.07 | 0.22 | 0.11 | 0.62 | 0.04 | 0.05 |

| PC | 44.31 | 4.80 | 1.11 | 0.07 | 0.24 | 0.11 | 0.58 | 0.05 | 0.05 | |

| PC | 46.41 | 4.81 | 1.10 | 0.08 | 0.23 | 0.12 | 0.64 | 0.05 | 0.05 | |

| L0 | PC | 45.31 | 5.26 | 1.07 | 0.08 | 0.31 | 0.12 | 0.56 | 0.07 | 0.06 |

| PC | 44.37 | 5.12 | 1.06 | 0.08 | 0.32 | 0.12 | 0.56 | 0.07 | 0.06 | |

| PC | 45.39 | 4.97 | 1.01 | 0.08 | 0.32 | 0.12 | 0.55 | 0.07 | 0.06 |

References

- Poschlod, P.; Bakker, J.P.; Kahmen, S. Changing land use and its impact on biodiversity. Basic Appl. Ecol. 2005, 6, 93–98. [Google Scholar] [CrossRef]

- Ostermann, O.P. The need for management of nature conservation sites designated under Natura 2000. J. Appl. Ecol. 1998, 35, 968–973. [Google Scholar] [CrossRef]

- Lambdon, P.W.; Pysek, P.; Basnou, C.; Hejda, M.; Arianatsou, M.; Essl, F.; Jarosik, V.; Pergl, J.; Winter, M.; Anastasiu, P.; et al. Alien flora of Europe: Species diversity temporal trends, geographical patterns and research needs. Preslia 2008, 80, 101–149. [Google Scholar]

- Lapin, K.; Bernhardt, K.G.; Lichtenwöhrer, P.; Roithmayr, S. Welchen Einfluss haben invasive Pflanzenarten auf die Phytodiversität von renaturierten Flusslandschaften? Gesunde Pflanz. 2015, 67, 75–82. (In German) [Google Scholar] [CrossRef]

- Otte, A.; Maul, P. Verbreitungsschwerpunkte und strukturelle Einnischung der Stauden-Lupine (Lupinus polyphyllus Lindl.) in Bergwiesen der Rhön. Tuexenia 2005, 25, 151–182. (In German) [Google Scholar]

- Jaquemyn, H.; Brys, R.; Hermy, M. Short-term effects of different management regimes on the response of calcareous grassland vegetation to increased nitrogen. Biol. Conserv. 2003, 111, 137–147. [Google Scholar] [CrossRef]

- Zechmeister, H.G.; Schmitzberger, I.; Steurer, B.; Peterseil, J.; Wrbka, T. The influence of land-use practices and economics on plant species richness in meadows. Biol. Conserv. 2003, 114, 165–177. [Google Scholar] [CrossRef]

- Veen, G.; Schmidt, C.; Witte, L.; Wray, V.; Czygan, F.C. Lupin alkaloids from Lupinus polyphyllus. Phytochemistry 1992, 31, 4343–4345. [Google Scholar] [CrossRef]

- Wachendorf, M.; Richter, F.; Fricke, T.; Graß, R.; Neff, R. Utilization of semi-natural grassland through integrated generation of solid fuel and biogas from biomass. I. Effects of hydrothermal conditioning and mechanical dehydration on mass flows of organic and mineral plant compounds, and nutrient balances. Grass Forage Sci. 2009, 64, 132–143. [Google Scholar] [CrossRef]

- Hensgen, F.; Bühle, L.; Donnison, I.; Fraser, M.; Vale, J.; Corton, J.; Heinsoo, K.; Melts, I.; Wachendorf, M. Mineral concentrations in solid fuels from European semi-natural grasslands after hydrothermal conditioning and subsequent mechanical dehydration. Bioresour. Technol. 2012, 118, 332–342. [Google Scholar] [CrossRef] [PubMed]

- Hensgen, F.; Bühle, L.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Energetic conversion of European semi-natural grassland silages through the integrated generation of solid fuel and biogas from biomass: Energy yields and the fate of organic compounds. Bioresour. Technol. 2014, 154, 192–200. [Google Scholar] [CrossRef] [PubMed]

- Hensgen, F.; Bühle, L.; Wachendorf, M. The effect of harvest, mulching and low-dose fertilization of liquid digestate on above ground biomass yield and diversity of lower mountain semi-natural grasslands. Agric. Ecosyst. Environ. 2016, 216, 283–292. [Google Scholar] [CrossRef]

- Verein Deutscher Ingenieure. VDI 4630. Vergärung organischer Stoffe (Fermentation of Organic Materials); Verein Deutscher Ingenieure (German Association of Engineers): Düsseldorf, Germany. (In German)

- Porter, M.G.; Murray, R.S. The volatility of components of grass silage on oven drying and the inter-relationship between dry-matter content estimated by different analytical methods. Grass Forage Sci. 2001, 65, 405–411. [Google Scholar] [CrossRef]

- Friedl, A.; Padouvas, E.; Rotter, H.; Varmuza, K. Prediction of heating values of biomass fuel from elemental composition. Anal. Chim. Acta 2005, 544, 191–198. [Google Scholar] [CrossRef]

- R Development Core Team. R: A Language and Environment for Statistical Computing; R Foundation for Statistical Computing: Vienna, Austria, 2011. [Google Scholar]

- Schmider, E.; Ziegler, M.; Danay, E.; Beyer, L.; Bühner, M. Is it really robust? Reinvestigating the robustness of ANOVA against violations of the normal distribution assumption. Methodology 2010, 6, 147–151. [Google Scholar] [CrossRef]

- Richter, F.; Fricke, T.; Wachendorf, M. Influence of sward maturity and pre-conditioning temperature on the energy production from grass silage through integrated generation of solid fuel and biogas from biomass (IFBB): 1. The fate of mineral compounds. Bioresour. Technol. 2011, 102, 4855–4865. [Google Scholar] [CrossRef] [PubMed]

- Tonn, B.; Thumm, U.; Claupein, W. Semi-natural grassland biomass for combustion: Influence of botanical composition, harvest date and site conditions on fuel composition. Grass Forage Sci. 2012, 65, 383–397. [Google Scholar] [CrossRef]

- Ruano-Ramos, A.; Garcia-Ciudad, A.; Garcia-Criado, B. Near infrared spectroscopy prediction of mineral content in botanical fractions from semi-arid grasslands. Anim. Feed Sci. Technol. 1999, 77, 331–343. [Google Scholar] [CrossRef]

- Ruano-Ramos, A.; Garcia-Ciudad, A.; Garcia-Criado, B. Determination of nitrogen and ash contents in total herbage and botanical components of grassland systems with near infra-red spectroscopy. J. Sci. Food Agric. 1999, 79, 137–143. [Google Scholar] [CrossRef]

- Obernberger, I.; Brunner, T.; Bärnthaler, G. Chemical properties of solid biofuels—Significance and impact. Biomass Bioenergy 2006, 30, 973–982. [Google Scholar] [CrossRef]

- Nussbaumer, T. Combustion on co-combustion of biomass: Fundamentals, technologies, and primary measures for emission reduction. Energy Fuels 2003, 17, 1510–1521. [Google Scholar] [CrossRef]

- Salzmann, R.; Nussbaumer, T. Fuel staging for NOx reduction in biomass combustion: Experiments and modelling. Energy Fuels 2001, 15, 575–582. [Google Scholar] [CrossRef]

- Piepenschneider, M.; Bühle, L.; Hensgen, F.; Wachendorf, M. Energy recovery from grass of urban roadside verges by anaerobic digestion and combustion after pre-processing. Biomass Bioenergy 2016, 85, 278–287. [Google Scholar] [CrossRef]

- Richter, F.; Fricke, T.; Wachendorf, M. Influence of sward maturity and pre-conditioning temperature on the energy production from grass silage through integrated generation of solid fuel and biogas from biomass (IFBB): 2. Properties of energy carriers and energy yield. Bioresour. Technol. 2011, 102, 4866–4875. [Google Scholar] [CrossRef] [PubMed]

- De la Vega, R.; Gutierrez, M.P.; Sanz, C.; Calvo, R.; Robredo, L.M.; de la Cuadra, C.; Muzquiz, M. Bactericide-like effect of Lupinus alkaloids. Ind. Crops Prod. 1996, 5, 141–148. [Google Scholar] [CrossRef]

- Bühle, L.; Reulein, J.; Stülpnagel, R.; Zerr, W.; Wachendorf, M. Methane yields and digestion dynamics of press fluids from mechanically dehydrated maize silages using different types of digesters. Bioenergy Res. 2012, 5, 294–305. [Google Scholar] [CrossRef]

- Hensgen, F.; Richter, F.; Wachendorf, M. Integrated generation of solid fuel and biogas from green cut material from landscape conservation and private households. Bioresour. Technol. 2011, 102, 10441–10450. [Google Scholar] [CrossRef] [PubMed]

- Piepenschneider, M.; Nurmatov, N.; Bühle, L.; Hensgen, F.; Wachendorf, M. Chemical properties and ash slagging characteristics of solid fuels from urban leaf litter. Waste Biomass Valor. 2016, 7, 625–633. [Google Scholar] [CrossRef]

- Richter, F.; Fricke, T.; Wachendorf, M. Utilization of semi-natural grassland through integrated generation of solid fuel and biogas from biomass. III. Effects of hydrothermal conditioning and mechanical dehydration on solid fuel properties and on energy and greenhouse gas balances. Grass Forage Sci. 2010, 65, 185–199. [Google Scholar] [CrossRef]

- Khalsa, J.H.A.; Döhling, F.; Berger, F. Foliage and grass as fuel pellets-small scale combustion of washed and mechanically leached biomass. Energies 2016, 9, 361. [Google Scholar] [CrossRef]

- Hartmann, H. Brennstoffzusammensetzung und -eigenschaften (Composition and characteristics of fuels). In Energie aus Biomasse: Grundlagen, Techniken und Verfahren, 2nd ed.; Kaltschmitt, M., Hartmann, H., Eds.; Springer: Berlin, Germany, 2009. (In German) [Google Scholar]

- Bühle, L.; Hensgen, F.; Donnison, I.; Heinsoo, K.; Wachendorf, M. Life cycle assessment of the integrated generation of solid fuel and biogas from biomass (IFBB) in comparison to different energy recovery, animal-based and non-refining management systems. Bioresour. Technol. 2012, 111, 230–239. [Google Scholar] [CrossRef] [PubMed]

| Silage | Press Cake | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| p | L0 | L25 | L50 | L75 | L100 | p | L0 | L25 | L50 | L75 | L100 | |

| DM | <0.001 | a | b | c | d | e | 0.78 | n.s. | n.s. | n.s. | n.s. | n.s. |

| Ash | <0.001 | b | b | b | b | a | 0.34 | n.s. | n.s. | n.s. | n.s. | n.s. |

| N | <0.001 | e | d | c | b | a | <0.001 | c | c | b | b | a |

| S | <0.001 | a | ab | b | cb | c | 0.08 | n.s. | n.s. | n.s. | n.s. | n.s. |

| K | <0.001 | a | b | c | d | e | <0.001 | a | b | c | d | e |

| Mg | <0.001 | e | d | c | b | a | <0.001 | cd | d | c | b | a |

| Ca | <0.001 | d | d | c | b | a | <0.001 | d | d | c | b | a |

| Cl | <0.001 | a | b | c | d | e | <0.001 | a | b | b | c | d |

| P | <0.001 | a | b | c | d | e | <0.001 | a | b | b | c | d |

| L0 | L25 | L50 | L75 | L100 | |

|---|---|---|---|---|---|

| DM | 15.6 ± 1.5 | 25.9 ± 5.5 | 25.4 ± 4.5 | 25.4 ± 4.3 | 31.5 ± 3.2 |

| Ash | 48.0 ± 1.2 | 56.6 ± 3.4 | 56.5 ± 2.3 | 59.8 ± 1.9 | 61.2 ± 4.9 |

| N | 39.5 ± 1.2 b | 48.4 ± 4.2 ab | 46.2 ± 4.4 ab | 51.1 ± 2.0 ab | 55.5 ± 2.1 a |

| S | 47.8 ± 2.2 | 55.9 ± 4.3 | 49.4 ± 5.9 | 45.2 ± 2.7 | 52.7 ± 4.9 |

| K | 85.9 ± 0.3 c | 90.0 ± 0.8 b | 90.5 ± 0.5 b | 91.6 ± 0.3 ab | 93.3 ± 0.4 a |

| Mg | 63.6 ± 1.1 c | 73.8 ± 1.5 b | 75.0 ± 1.7 b | 76.9 ± 0.9 ab | 81.4 ± 1.2 a |

| Ca | 28.2 ± 3.5 c | 45.7 ± 2.2 b | 50.6 ± 3.8 ab | 53.3 ± 2.2 ab | 63.5 ± 2.9 a |

| Cl | 93.3 ± 0.1 | 95.3 ± 0.6 | 94.5 ± 0.3 | 95.4 ± 0.2 | 94.9 ± 1.0 |

| P | 78.9 ± 0.4 b | 83.7 ± 1.6 ab | 82.2 ± 1.3 ab | 83.1 ± 0.7 ab | 86.2 ± 1.0 a |

| Silage | Press Fluid | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| p | L0 | L25 | L50 | L75 | L100 | p | L0 | L25 | L50 | L75 | L100 | |

| CH4 yield | 0.97 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.004 | a | a | b | ab | a |

| Degree of degradation | 0.85 | n.s. | n.s. | n.s. | n.s. | n.s. | 0.006 | a | a | b | ab | a |

| Press Cake | ||||||||||||

| HHV | <0.001 | b | b | a | a | a | 0.009 | b | ab | ab | a | a |

| p | L0 | L25 | L50 | L75 | L100 | |

|---|---|---|---|---|---|---|

| AD | 0.971 | n.s. | n.s. | n.s. | n.s. | n.s. |

| IFBB PF | <0.001 | c | c | c | b | a |

| IFBB PC | <0.001 | a | ab | b | bc | c |

| IFBB PC + PF | 0.005 | a | ab | c | bc | abc |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hensgen, F.; Wachendorf, M. The Effect of the Invasive Plant Species Lupinus polyphyllus Lindl. on Energy Recovery Parameters of Semi-Natural Grassland Biomass. Sustainability 2016, 8, 998. https://doi.org/10.3390/su8100998

Hensgen F, Wachendorf M. The Effect of the Invasive Plant Species Lupinus polyphyllus Lindl. on Energy Recovery Parameters of Semi-Natural Grassland Biomass. Sustainability. 2016; 8(10):998. https://doi.org/10.3390/su8100998

Chicago/Turabian StyleHensgen, Frank, and Michael Wachendorf. 2016. "The Effect of the Invasive Plant Species Lupinus polyphyllus Lindl. on Energy Recovery Parameters of Semi-Natural Grassland Biomass" Sustainability 8, no. 10: 998. https://doi.org/10.3390/su8100998