A Supernetwork-Based Model for Design Processes of Complex Mechanical Products

Abstract

:1. Introduction

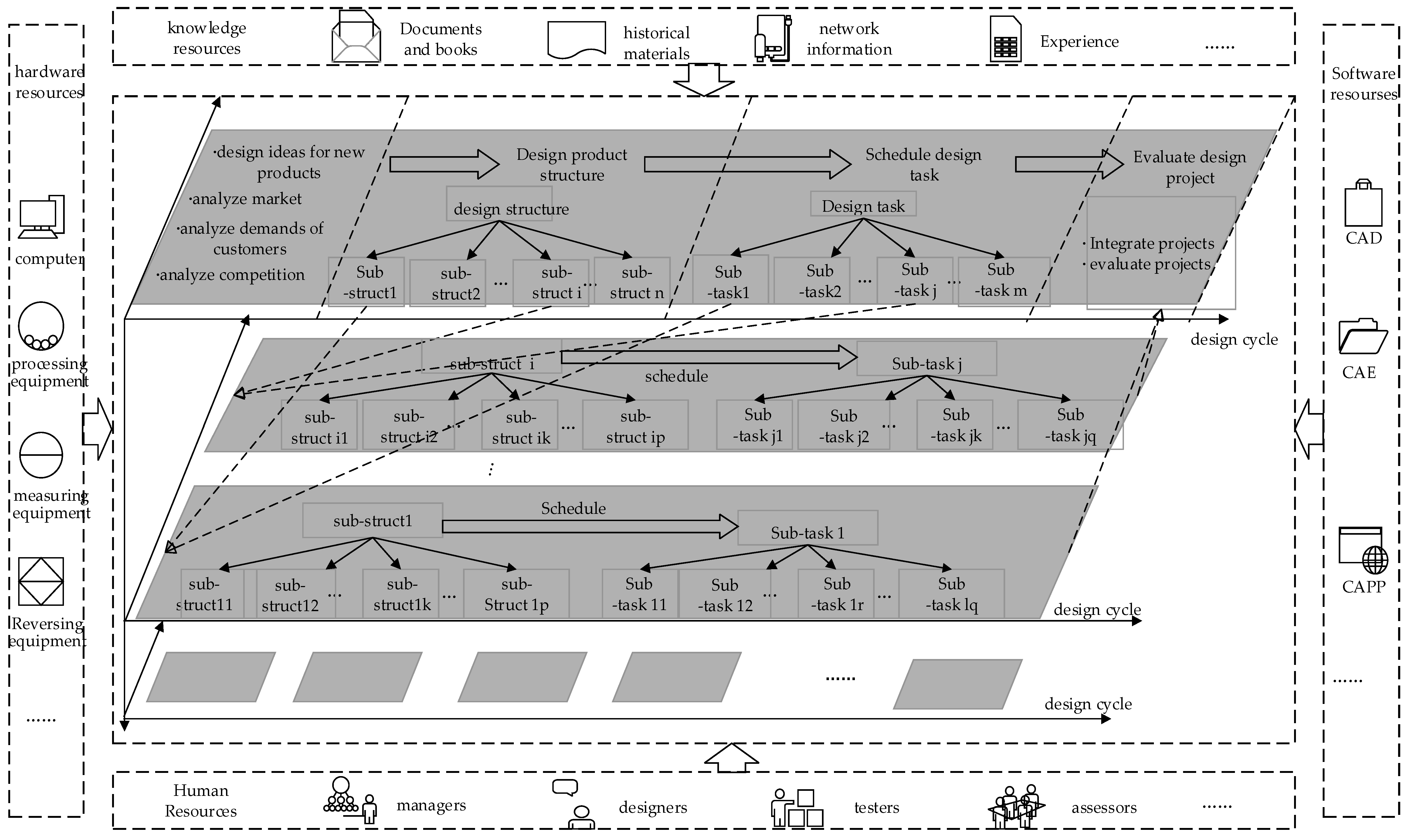

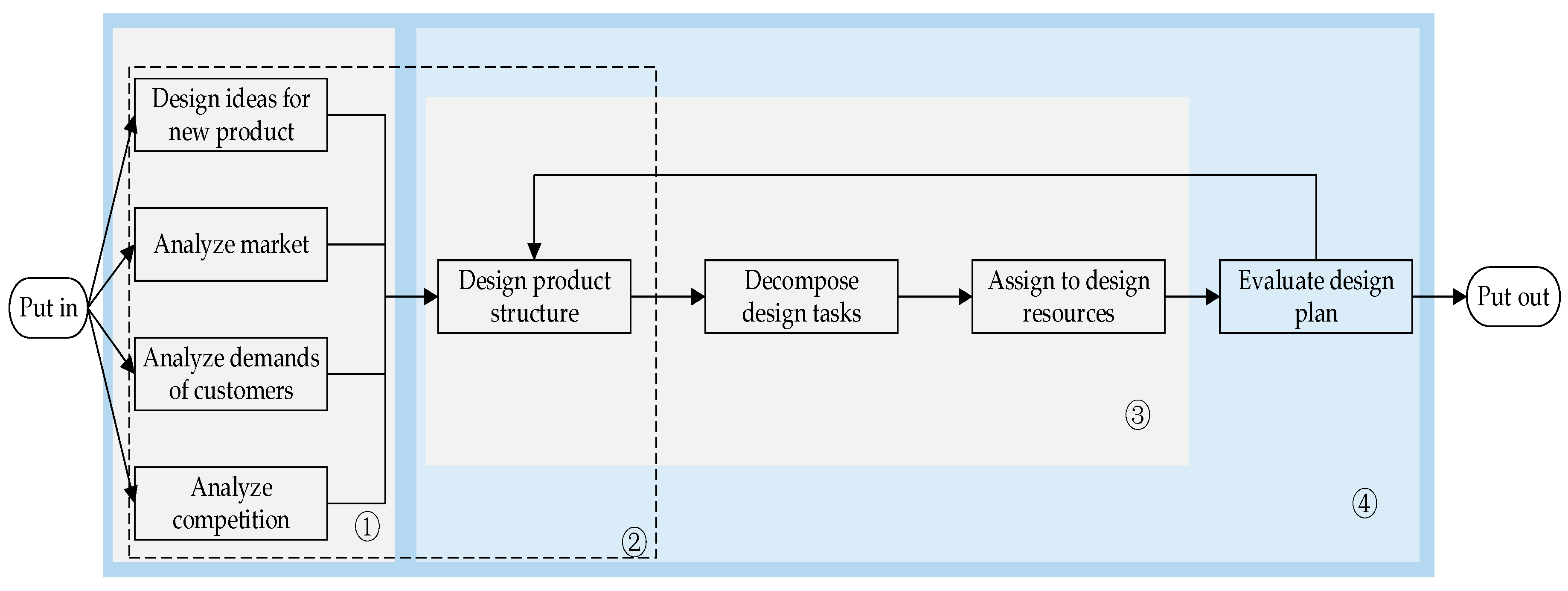

2. Identify the Key Elements and Analyze Their Relationships in the Design Processes of Complex Mechanical Products

2.1. Identify Key Elements in the Design Processes of Complex Mechanical Products

- (1)

- Design structures not only determine the functions of complex mechanical products, but also influence the decomposition of design tasks. Therefore, the design structures are key elements in the design processes of complex mechanical products.

- (2)

- Design tasks are necessary activities to achieve design structures and functions of complex mechanical products. In turn, complex product design is a process of completing a series of design tasks. Therefore, design tasks are key elements in the design processes of complex mechanical products.

- (3)

- Without knowledge, hardware, software, and human resources, design activities could not be carried out. Therefore, design resources are key elements in the design processes of complex mechanical products.

2.2. Analyze the Relationships between Design Structures of Complex Mechanical Products

- (1)

- The containment relationship is longitudinal. It means a component is composed of parts. When a component needs to be adjusted, relevant parts should also be changed.

- (2)

- The associational relationship is horizontal. When there is a change in any one part, other associational parts will be impacted.

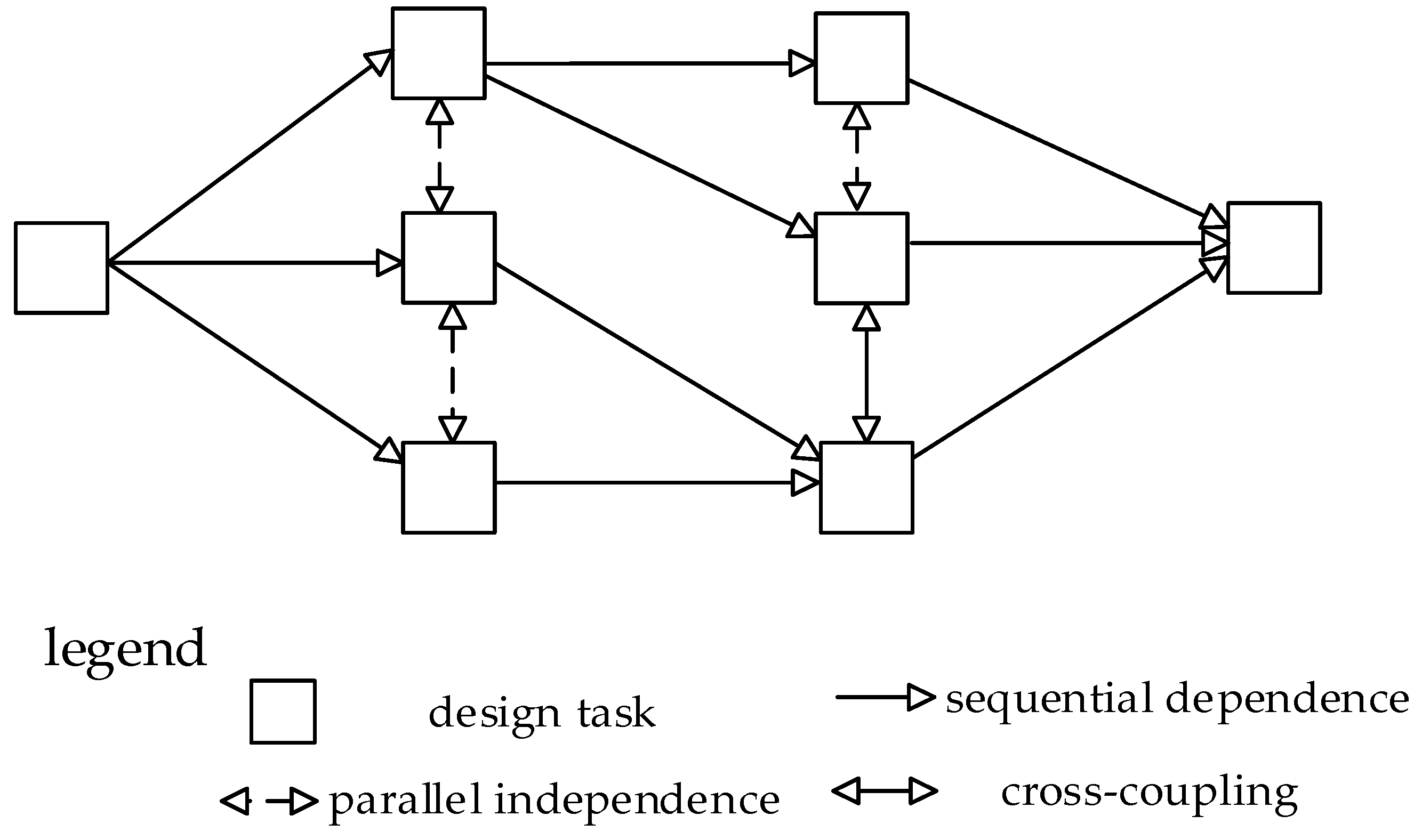

2.3. Analyze the Relationships between Design Tasks of Complex Mechanical Products

- (1)

- Sequential dependence. If the execution of a task requires outputs from an upstream task as its inputs, but the execution of the upstream task does not require outputs from it as input, the relationship between the two tasks is sequential dependence.

- (2)

- Parallel independence. The task will not be affected by other tasks of same granularity. That is, there is no information interaction between them.

- (3)

- Cross-coupling. The relationship between the two tasks is bidirectional. The execution of a task requires outputs from an upstream task as its inputs, while the execution of the upstream task requires outputs from the one downstream as input. The relationship between the two tasks is cross-coupling.

2.4. Analyze the Relationships between Design Resources of Complex Mechanical Products

- (1)

- Cooperative relationship. Managers, designers, testers, and assessors cooperate with each other to complete design tasks.

- (2)

- Matching relationship. Different actors use different knowledge, hardware, and software resources in their fields to complete design tasks.

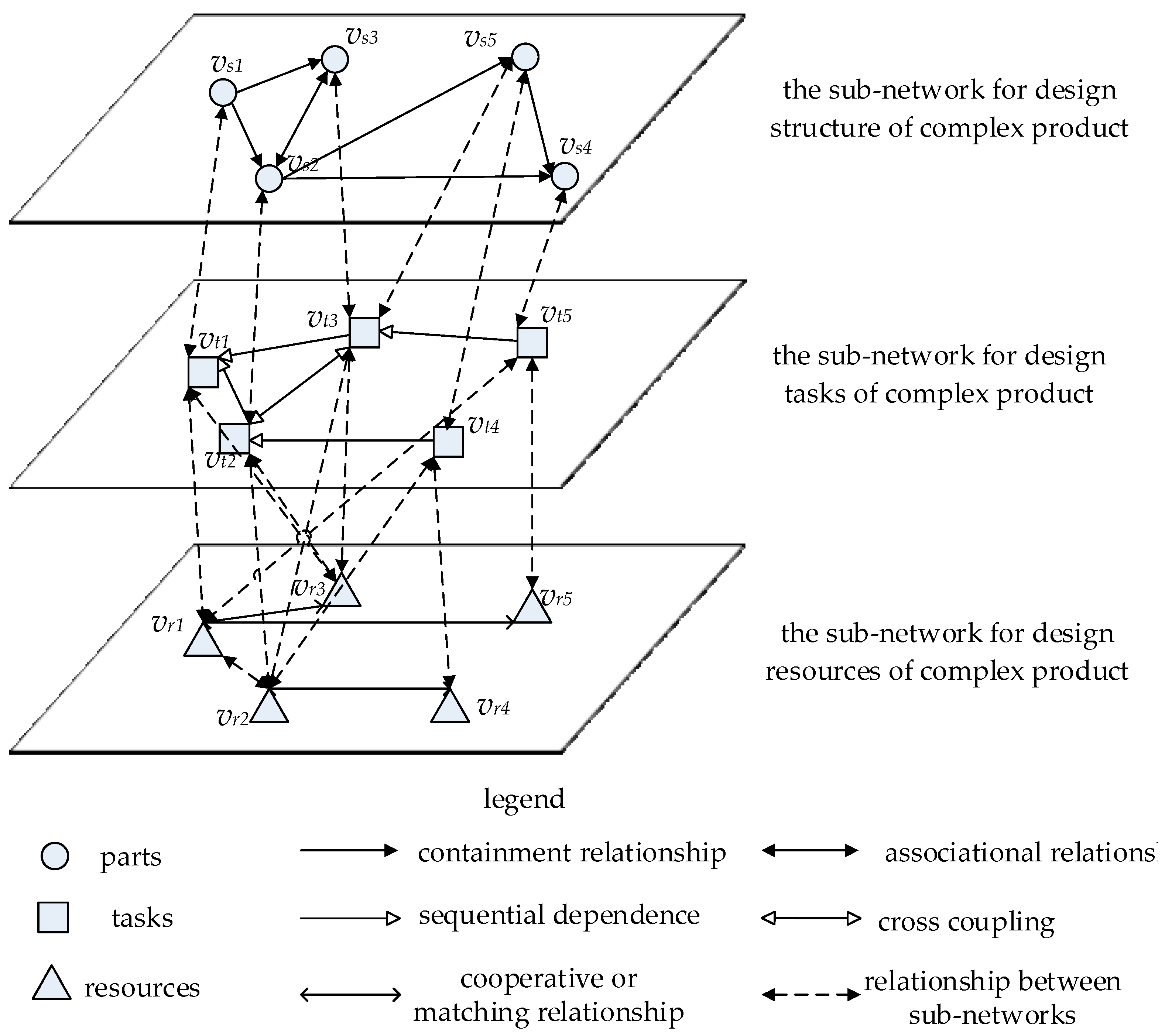

3. Supernetwork-Based Model for Design Processes of Complex Mechanical Products

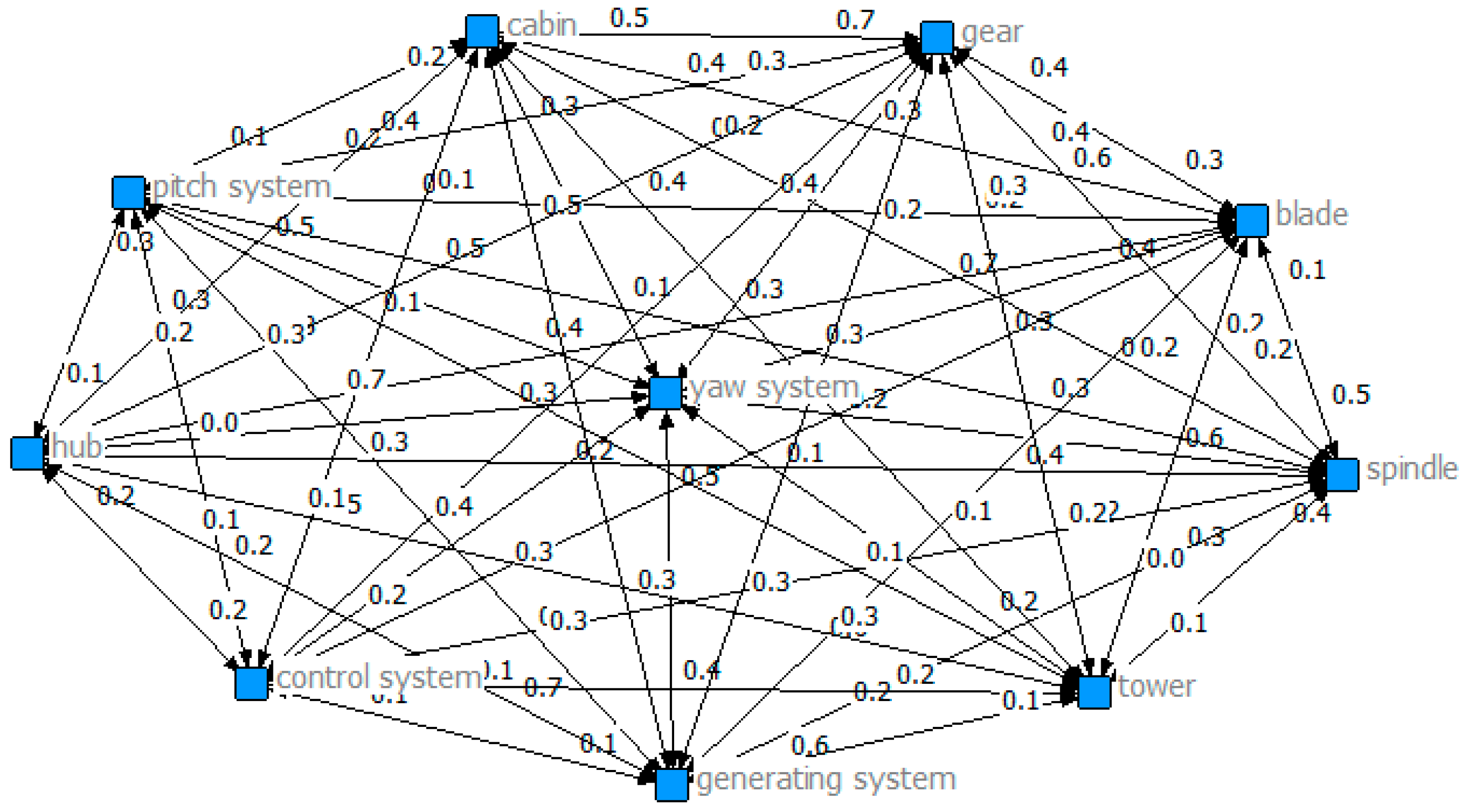

3.1. Sub-Network for Design Structure of Complex Mechanical Products

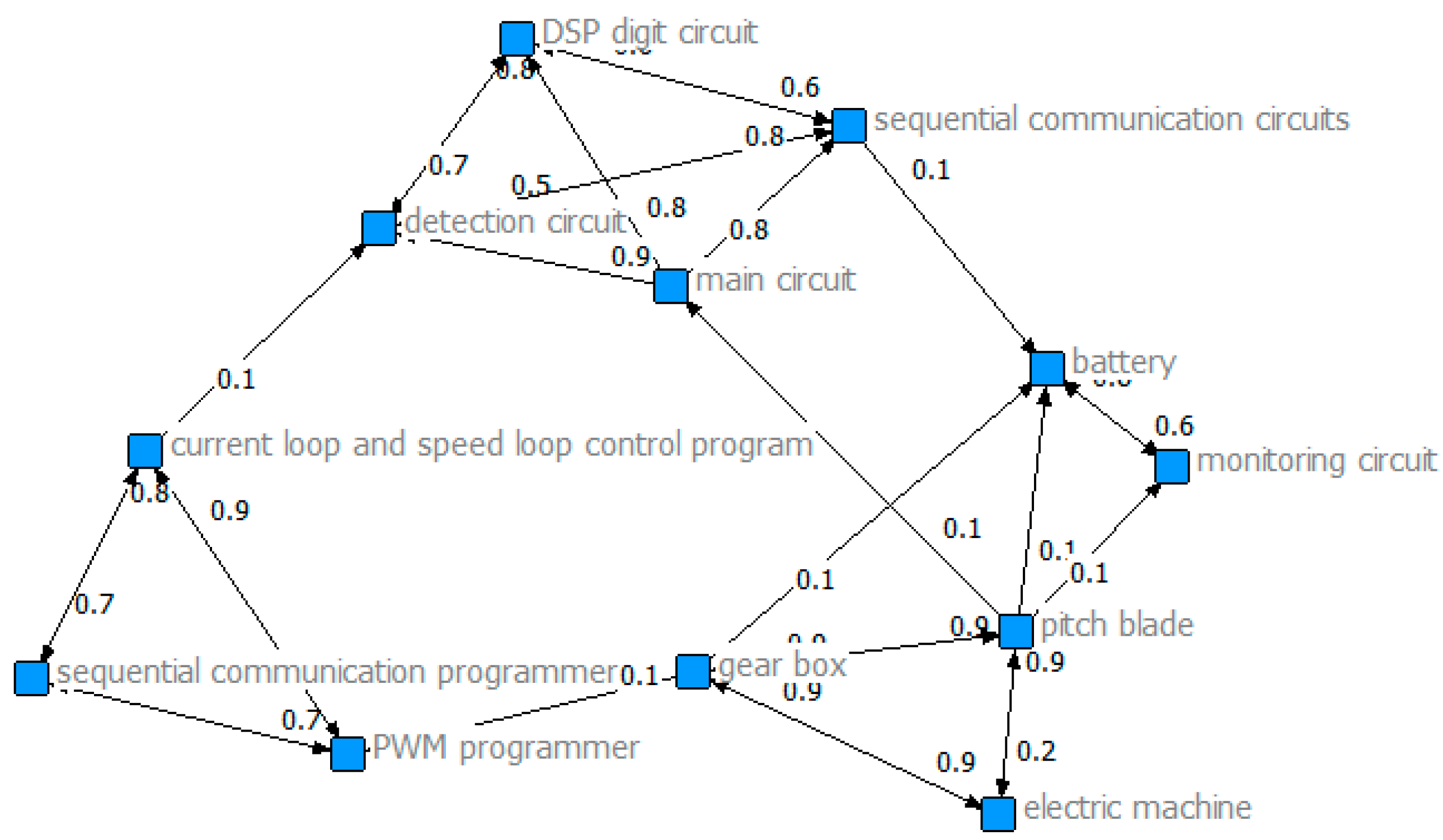

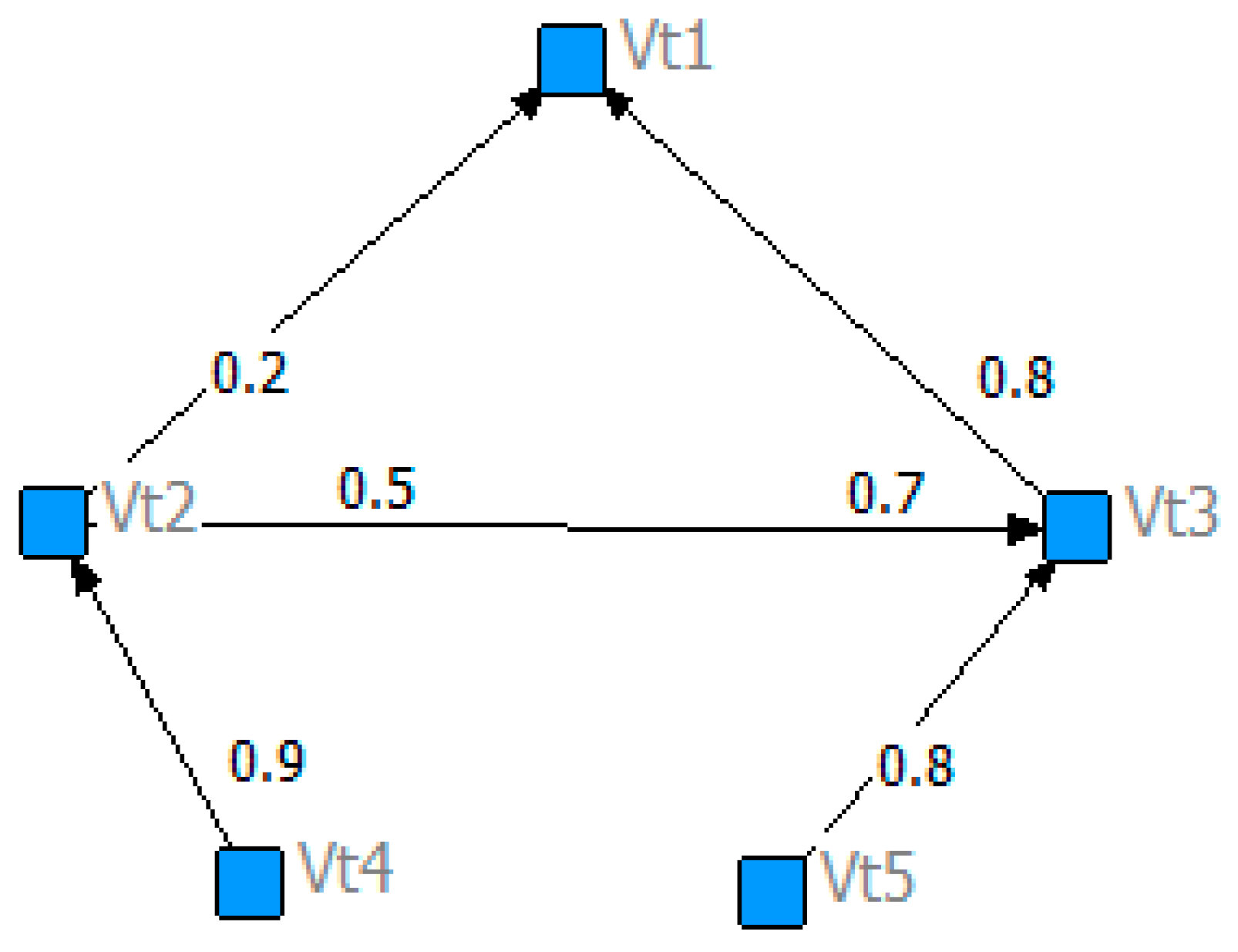

3.2. Sub-Network for Design Tasks of Complex Mechanical Products

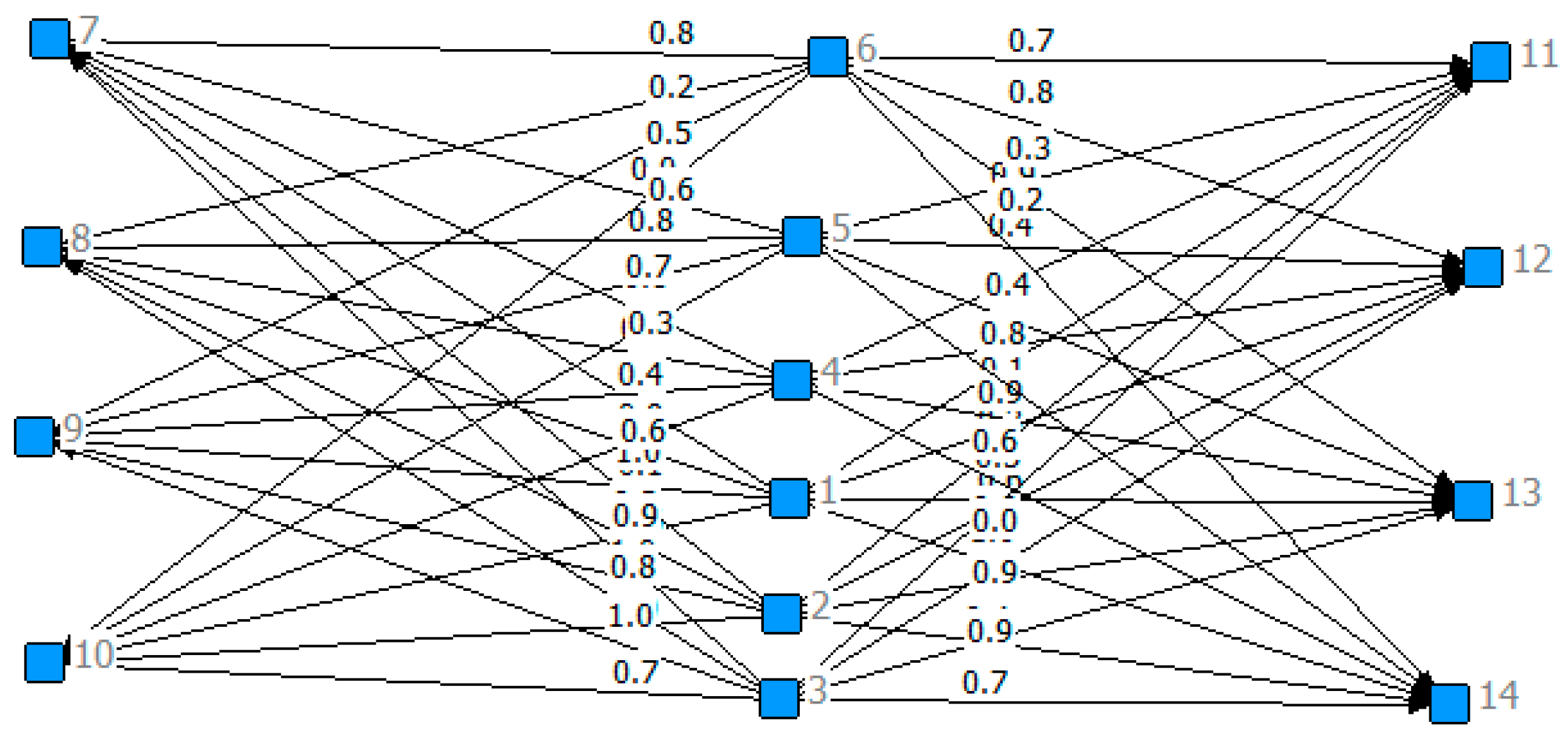

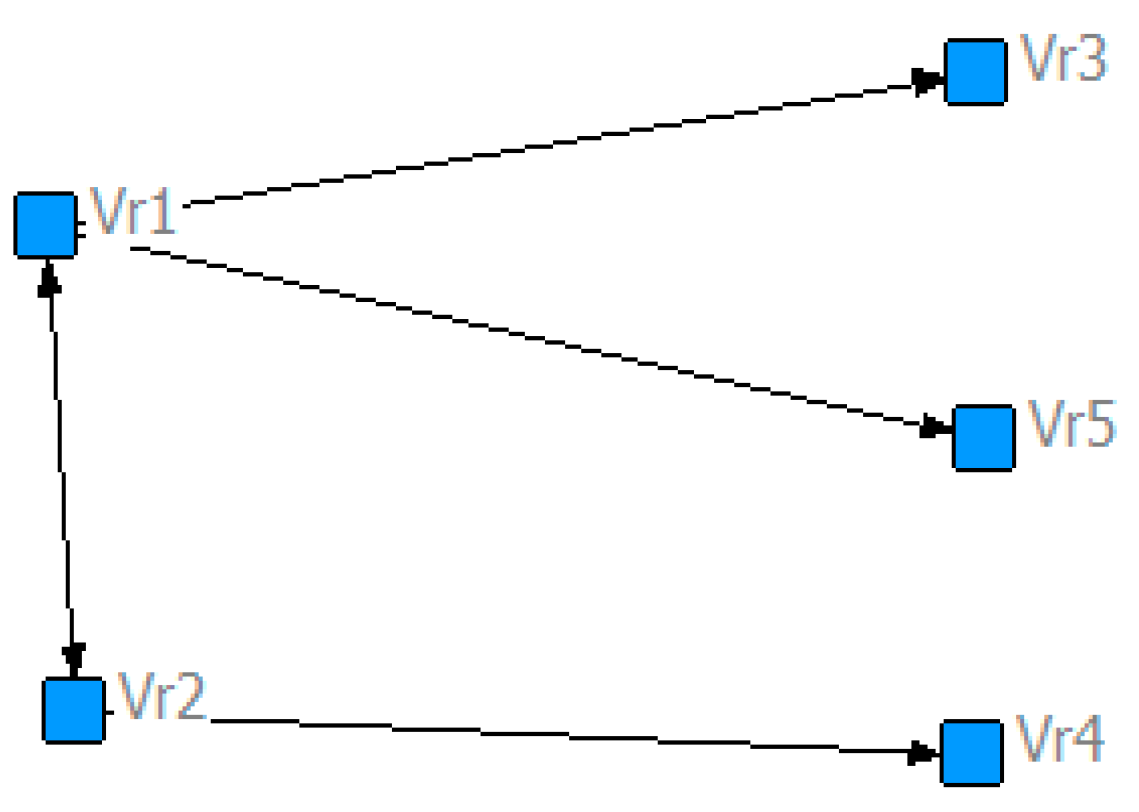

3.3. Sub-Network for Design Resources of Complex Mechanical Products

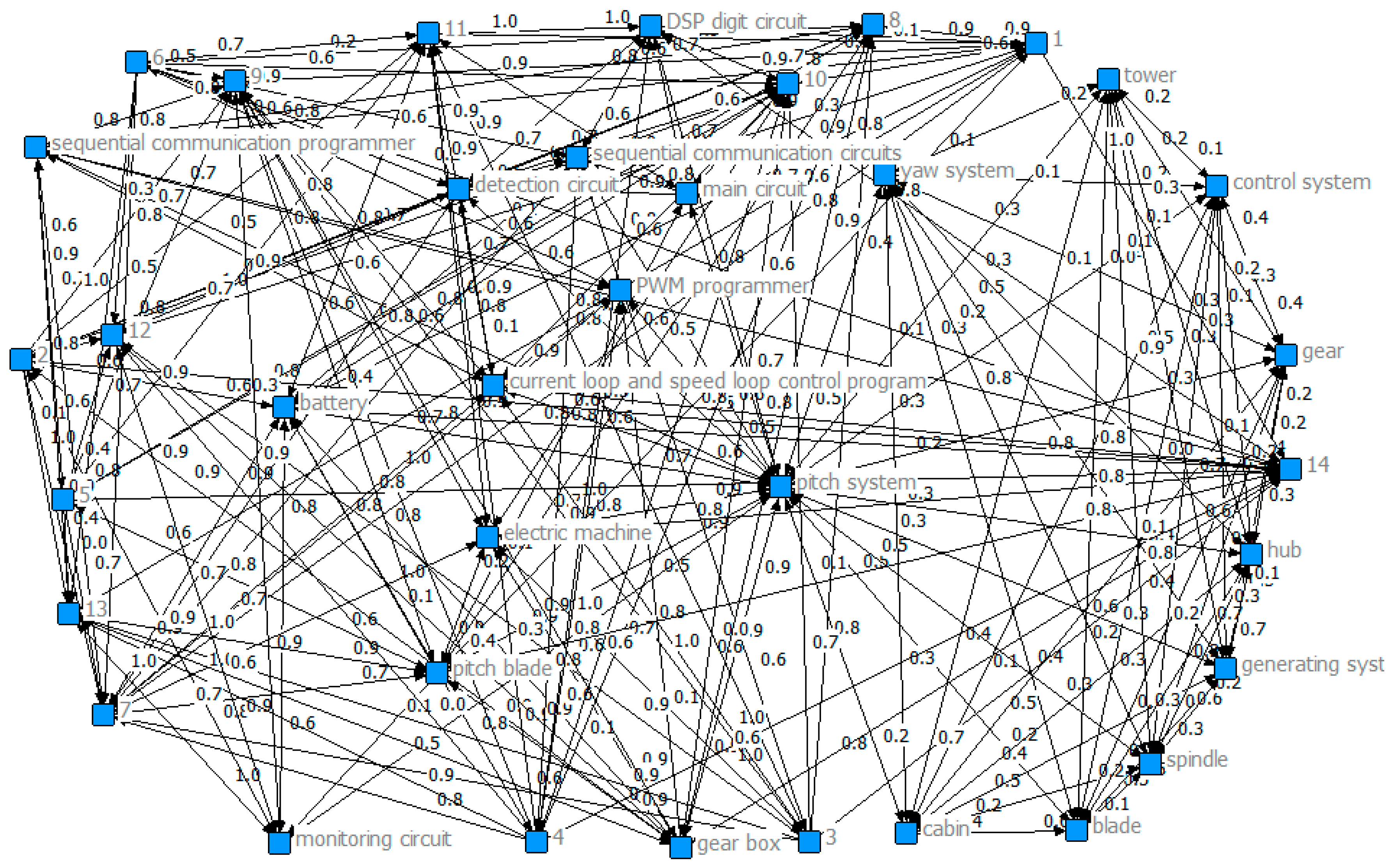

3.4. Supernetwork-Based Model for the Design Processes of Complex Mechanical Products

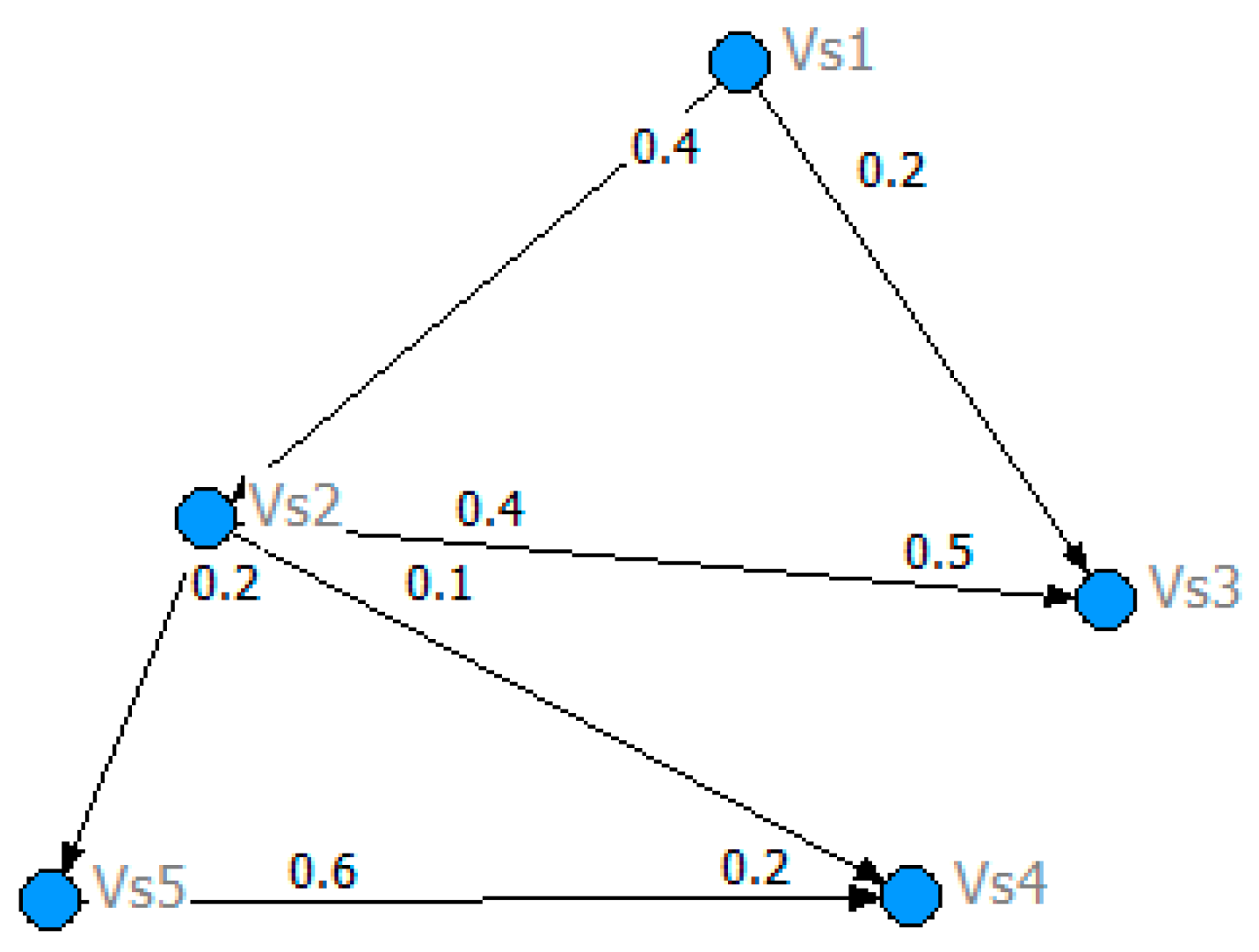

3.5. Compute Edge Weights in Supernetwork-Based Model for Design Processes of Complex Mechanical Products

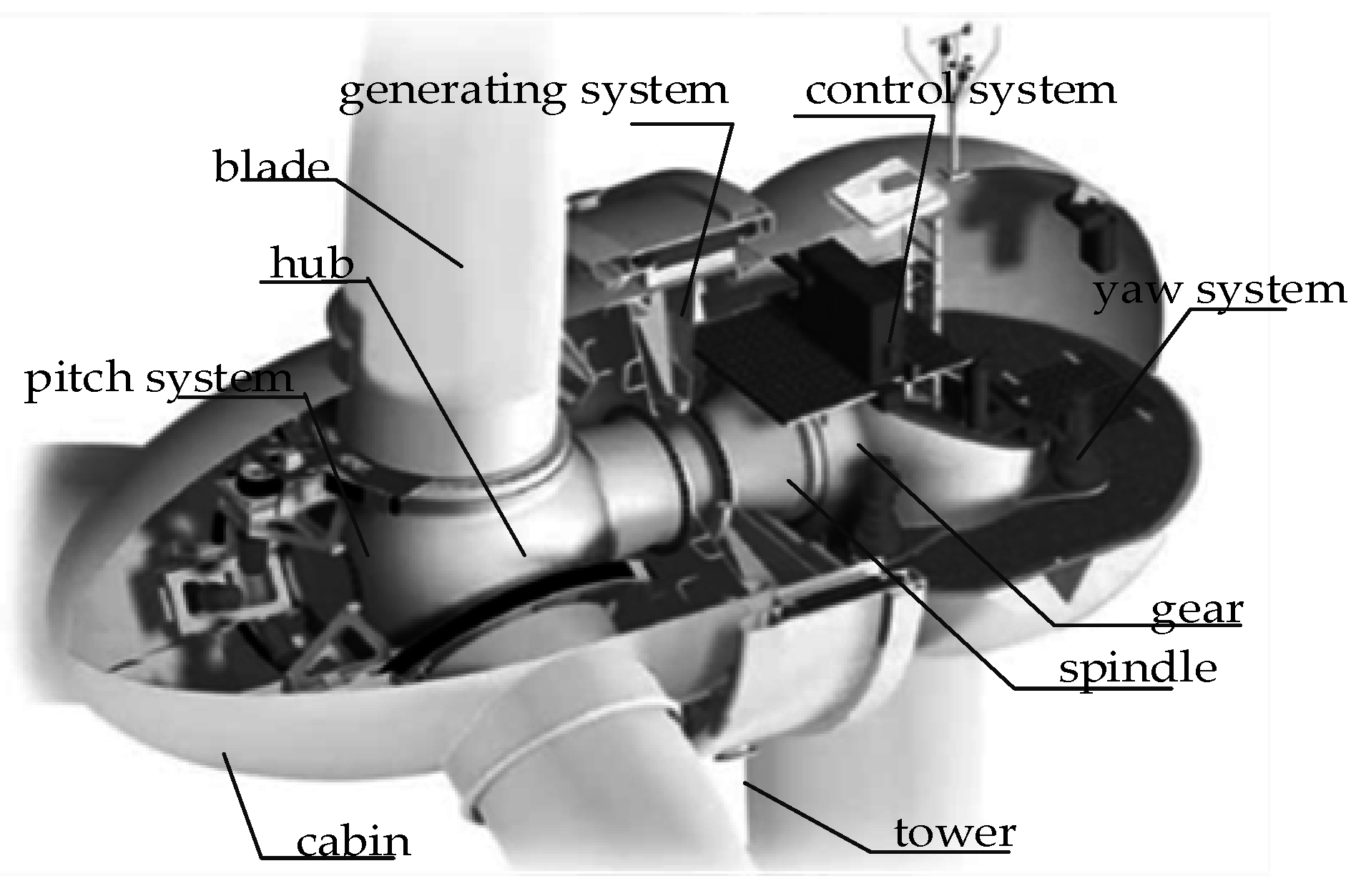

4. Case Study

4.1. Example of the Model Application

4.2. Comparison Analysis

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| Blade | Yaw System | Pitch System | Cabin | Spindle | Gear | Control System | Generating System | Hub | Tower | |

|---|---|---|---|---|---|---|---|---|---|---|

| blade | gravity, lateral force, torque | relative velocity | load | load | torque | torque | rotational inertia | torque | air load, radius | |

| yaw system | rotation angle | torque | lateral forces | fit, axial force | load | torque | yaw angle | torque | torque | |

| pitch system | blade azimuth | load | load | torque | torque | load | load | load | gravity | |

| cabin | gravity, load | gravity, horizontal and vertical distance | yaw angle | axial thrust | load | load | area coefficient, height | area coefficient, height | gravity, resistance | |

| spindle | load | fit, axial force | torque | axial thrust | torque, fit | friction | impulse load | axial force, fit | bending moment | |

| gear | torque, drive ratio | load | torque | load | torque, fit | torque, load | torque, drive ratio | load | gravity | |

| control system | torque | torque | load | load | friction | torque, load | load | load | gravity | |

| generating system | angular speed | extreme angle | load, power | gravity, type | impulse load | angular speed | load | power, pitch angle | gravity | |

| hub | radius | torque | load | diameter | torque, bending moment | load | load, weight | load | load | |

| tower | load | bending moment, thrust | thrust | thrust | bending moment | thrust | load | load | load |

| Pitch Blade | Electric Machine | Gear Box | Main Circuit | DSP Digit Circuit | Detection Circuit | Sequential Communication Circuits | Battery | Monitoring Circuit | PWM Programmer | Sequential Communication Programmer | Current Loop and Speed Loop Control Program | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | |

| 1 | 0.89 | 0.89 | 0.05 | 0.03 | 0.02 | 0.04 | 0.06 | 0.10 | 0.01 | 0.02 | 0.04 | |

| 2 | 0.20 | 0.90 | 0.01 | 0.01 | 0.02 | 0.02 | 0.01 | 0.01 | 0 | 0 | 0.01 | |

| 3 | 0.88 | 0.92 | 0.01 | 0.03 | 0.01 | 0.01 | 0.05 | 0.01 | 0.05 | 0.01 | 0.02 | |

| 4 | 0.03 | 0 | 0.03 | 0.75 | 0.86 | 0.84 | 0.01 | 0.01 | 0.02 | 0.03 | 0.01 | |

| 5 | 0.01 | 0.02 | 0.01 | 0.01 | 0.78 | 0.64 | 0.02 | 0.03 | 0.01 | 0.02 | 0.01 | |

| 6 | 0.02 | 0.01 | 0.03 | 0.02 | 0.65 | 0.45 | 0.01 | 0.02 | 0.02 | 0.01 | 0.03 | |

| 7 | 0.01 | 0.03 | 0.02 | 0.02 | 0.59 | 0.83 | 0.05 | 0.03 | 0.01 | 0.02 | 0.01 | |

| 8 | 0 | 0.01 | 0.03 | 0.01 | 0.01 | 0.03 | 0.02 | 0.76 | 0.02 | 0.01 | 0.02 | |

| 9 | 0.04 | 0.02 | 0.01 | 0.02 | 0.04 | 0.01 | 0.02 | 0.55 | 0.01 | 0.02 | 0.01 | |

| 10 | 0.02 | 0 | 0.01 | 0.01 | 0.01 | 0.03 | 0.02 | 0.02 | 0.01 | 0.66 | 0.73 | |

| 11 | 0.03 | 0.01 | 0.02 | 0.02 | 0.01 | 0.02 | 0.02 | 0.01 | 0.02 | 0.74 | 0.68 | |

| 12 | 0.02 | 0.01 | 0.02 | 0.01 | 0.01 | 0.05 | 0.01 | 0.01 | 0.03 | 0.87 | 0.79 |

| 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | |

|---|---|---|---|---|---|---|---|---|

| 1 | 0.82 | 0.91 | 0.13 | 0.63 | 0.10 | 0.28 | 0.55 | 0.96 |

| 2 | 0.97 | 0.16 | 0.97 | 0.96 | 0.49 | 0.80 | 0.14 | 0.42 |

| 3 | 0.92 | 0.80 | 0.96 | 0.66 | 0.04 | 0.85 | 0.93 | 0.69 |

| 4 | 0.76 | 0.74 | 0.39 | 0.65 | 0.27 | 0.03 | 0.87 | 0.64 |

| 5 | 0.03 | 0.82 | 0.70 | 0.32 | 0.95 | 0.43 | 0.38 | 0.77 |

| 6 | 0.80 | 0.19 | 0.49 | 0.65 | 0.71 | 0.75 | 0.28 | 0.24 |

| Pitch Blade | Electric Machine | Gear Box | Main Circuit | DSP Digit Circuit | Detection Circuit | |

|---|---|---|---|---|---|---|

| Pitch system | 0.88 | 0.90 | 0.93 | 0.76 | 0.72 | 0.59 |

| sequential dependence interface circuits | battery | monitoring circuit | PWM programmer | sequential dependence communication programmer | current loop and speed loop control program | |

| pitch system | 0.56 | 0.69 | 0.52 | 0.49 | 0.46 | 0.55 |

| Pitch Blade | Electric Machine | Gear Box | Main Circuit | DSP Digit Circuit | Detection Circuit | Sequential Dependence Interface Circuits | Battery | Monitoring Circuit | PWM Programmer | Sequential Dependence Communication Programmer | Current Loop and Speed Loop Control Program | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 0.79 | 0.90 | 0.79 | 0.79 | ||||||||

| 2 | 0.90 | 0.82 | 0.64 | 0.84 | ||||||||

| 3 | 1.00 | 0.63 | 1.00 | |||||||||

| 4 | 0.78 | 0.78 | 0.81 | 0.59 | ||||||||

| 5 | 0.60 | 0.60 | ||||||||||

| 6 | 0.65 | 0.93 | 0.60 | |||||||||

| 7 | 0.65 | 0.96 | 0.73 | 0.78 | 0.94 | 0.71 | 0.65 | 0.96 | ||||

| 8 | 0.69 | 0.87 | 0.65 | 0.69 | ||||||||

| 9 | 0.75 | 0.77 | 0.58 | 0.92 | 0.75 | 0.77 | ||||||

| 10 | 0.82 | 0.55 | 0.90 | 0.94 | 0.55 | 0.62 | 0.82 | |||||

| 11 | 0.87 | 0.94 | 0.96 | 0.59 | 0.87 | |||||||

| 12 | 0.85 | 0.74 | 0.90 | |||||||||

| 13 | 0.91 | 0.62 | 0.98 | 0.91 | ||||||||

| 14 | 0.79 | 0.83 | 0.80 | 0.90 | 0.79 | 0.79 | 0.83 |

| Blade | Yaw System | Pitch System | Cabin | Spindle | Gear | Control System | Generating System | Hub | Tower | |

|---|---|---|---|---|---|---|---|---|---|---|

| blade | 0.45 | 0.11 | 0.43 | 0.85 | 0.42 | 0.78 | 0.23 | 0.55 | 0.93 | |

| yaw system | 0.79 | 0.96 | 1.00 | 0.62 | 0.05 | 0.39 | 0.35 | 0.30 | 1.00 | |

| pitch system | 0.31 | 0.23 | 0.18 | 0.35 | 0.90 | 0.24 | 0.82 | 0.74 | 0.49 | |

| cabin | 0.53 | 0.91 | 0.77 | 0.51 | 0.94 | 0.40 | 0.02 | 0.19 | 0.44 | |

| spindle | 0.17 | 0.15 | 0.82 | 0.15 | 0.49 | 0.10 | 0.04 | 0.69 | 0.45 | |

| gear | 0.60 | 0.83 | 0.87 | 0.14 | 0.08 | 0.13 | 1.00 | 0.18 | 0.31 | |

| control system | 0.26 | 0.54 | 0.08 | 0.87 | 0.24 | 0.34 | 0.65 | 0.37 | 0.51 | |

| generating system | 0.65 | 1.00 | 0.40 | 0.58 | 0.12 | 0.90 | 1.00 | 0.63 | 0.51 | |

| hub | 0.69 | 0.08 | 0.26 | 0.55 | 0.18 | 0.37 | 0.58 | 0.65 | 0.82 | |

| tower | 0.75 | 0.44 | 0.80 | 1.00 | 0.24 | 0.11 | 0.06 | 0.45 | 0.08 |

References

- Holdren, J.P.; Power, T.; Tassey, G.; Ratcliff, A.; Christodoulou, L. A National Strategic Plan for Advanced Manufacturing; US National Science and Technology Council: Washington, DC, USA, 2012.

- Wahlster, W. SemProM; Springer: Berlin/Heidelberg, Germany, 2013. [Google Scholar]

- Deng, Q.; Liu, X.; Liao, H. Identifying Critical Factors in the Eco-Efficiency of Remanufacturing Based on the Fuzzy DEMATEL Method. Sustainability 2015, 7, 15527–15547. [Google Scholar] [CrossRef]

- Fernandes, J.; Henriques, E.; Silva, A.; Moss, M.A. A method for imprecision management in complex product development. Res. Eng. Des. 2014, 25, 309–324. [Google Scholar] [CrossRef]

- Rosen, M.A.; Kishawy, H.A. Sustainable manufacturing and design: Concepts, practices and needs. Sustainability 2012, 4, 154–174. [Google Scholar] [CrossRef]

- Gokpinar, B.; Hopp, W.J.; Iravani, S.M. The impact of misalignment of organizational structure and product architecture on quality in complex product development. Manag. Sci. 2010, 56, 468–484. [Google Scholar] [CrossRef]

- Gokpinar, B.; Hopp, W.; Iravani, S.M. The impact of product architecture and organization structure on efficiency and quality of complex product development. Unpublished work. 2007. [Google Scholar]

- Browning, T.R.; Ramasesh, R.V. A Survey of Activity Network-Based Process Models for Managing Product Development Projects. Prod. Oper. Manag. 2007, 16, 217–240. [Google Scholar] [CrossRef]

- Zhou, J.; Xiao, F.; Tang, H.; Tang, W. Research on process model and framework of collaborative design for complex product based on meta-synthesis. J. Graph. 2013, 34, 72–78. [Google Scholar]

- Zhou, J. Key Problems of Complex Product Collaborative Design Based on Meta-Synthesis; Nanjing University of Science and Technology: Nanjing, China, 2012. [Google Scholar]

- Van Der Aalst, W.M.; Ter Hofstede, A.H. Verification of workflow task structures: A petri-net-baset approach. Inf. Syst. 2000, 25, 43–69. [Google Scholar] [CrossRef]

- Jia, L.; Tan, R.; Zhang, H.; Liu, W. Product modeling and timing improvement method based on petri nets. Comput. Integr. Manuf. Syst. 2016, 22, 630–638. [Google Scholar]

- Cao, Y.Y.; Qin, X.S.; Wang, W. General Petri net model of product development ProA. Comput. Integr. Manuf. Syst. 2009, 15, 2328–2334. [Google Scholar]

- Liu, H.Q.; Qi, G.N.; Zhang, T.H.; Ji, Y.J. Research on multi-disciplinary process modeling of conceptual design for complex product. J. Zhejiang Univ. Eng. Sci. 2009, 43, 517–522. [Google Scholar]

- Hu, Z.Y.; Yi, G.D.; Zhang, S.Y. Hierarchical evolutionary approach for design structure matrix oriented to complex electromechanical system modeling. Comput. Integr. Manuf. Syst. 2013, 10, 2385–2393. [Google Scholar]

- Song, X.; Wang, L.; Liu, J.Q. Planning methods for complex product design based on QFD and DSM. Mach. Des. Manuf. 2012, 1, 242–234. [Google Scholar]

- Sun, Y.; Zhang, X.; Ning, R.; Wang, T. Research on development process of complex product based on multi-level design structure matrix. J. Mech. Eng. 2011, 47, 166–175. [Google Scholar] [CrossRef]

- Zhu, D.; Guo, W.; Ma, R. Automation of modeling and integrated design optimization of complex product. J. Tianjin Univ. 2010, 43, 452–466. [Google Scholar]

- Browning, T.R. Applying the design structure matrix to system decomposition and integration problems: A review and new directions. IEEE Trans. Eng. Manag. 2001, 48, 292–306. [Google Scholar] [CrossRef]

- Browning, T.R. Process integration using the design structure matrix. Syst. Eng. 2002, 5, 180–193. [Google Scholar] [CrossRef]

- Chen, L.; Ding, Z.; Li, S. A formal two-phase method for decomposition of complex design problems. J. Mech. Des. 2005, 127, 184–195. [Google Scholar] [CrossRef]

- Chen, L.; Macwan, A.; Li, S. Model-based rapid redesign using decomposition patterns. J. Mech. Des. 2007, 129, 283–294. [Google Scholar] [CrossRef]

- Bartolomei, J.E.; Hastings, D.E.; de Neufville, R.; Rhodes, D.H. Engineering Systems Multiple-Domain Matrix: An organizing framework for modeling large-scale complex systems. Syst. Eng. 2012, 15, 41–61. [Google Scholar] [CrossRef]

- Carley, K.M.; Reminga, J. Ora: Organization Risk Analyzer; Center for Computational Analysis of Social and Organizational Systems: Pittsburgh, PA, USA, 2004. [Google Scholar]

- Wang, Z.; Wang, Z. Elementary study of supernetworks. Chin. J. Manag. 2008, 5, 1–8. [Google Scholar] [CrossRef] [PubMed]

- Zhong-tuo, W.A. Reflection on supernetwork. J. Univ. Shanghai Sci. Technol. 2011, 33, 229–237. [Google Scholar]

- Wang, Z.; Wang, Z. Supernetwork Theory and its Application; China Science Publishing & Media Ltd.: Bejing, China, 2008. (In Chinese) [Google Scholar]

- Nagurney, A.; Dong, J. Supernetworks: Decision-Making for the Information Age; Edward Elgar Publishing Incorporated: Cheltenham, UK, 2002. [Google Scholar]

- Yamada, T.; Imai, K.; Nakamura, T.; Taniguchi, E. A supply chain-transport supernetwork equilibrium model with the behaviour of freight carriers. Trans. Res. Part E Logist. Trans. Rev. 2011, 47, 887–907. [Google Scholar] [CrossRef]

- Nagurney, A. Supernetworks: An Introduction to the Concept and Its Applications with a Specific Focus on Knowledge Supernetworks; University of Massachusetts Amherst: Amherst, MA, USA, 2005. [Google Scholar]

- Cruz, J.M.; Nagurney, A.; Wakolbinger, T. Financial engineering of the integration of global supply chain networks and social networks with risk management. Nav. Res. Logist. 2006, 53, 674–696. [Google Scholar] [CrossRef]

- Wakolbinger, T.; Nagurney, A. Dynamic supernetworks for the integration of social networks and supply chains with electronic commerce: Modeling and analysis of buyer–seller relationships with computations. Netnomics 2004, 6, 153–185. [Google Scholar] [CrossRef]

- Hu, C.L.; Rong, Z.J.; Chen, K.S.; Dan, B.B. Research on process model of product design based on path searching. Comput. Integr. Manuf. Syst. 2013, 19, 293–299. [Google Scholar]

- Ma, M.; Wang, C.; Zhang, J.; Huang, Z. Multidisciplinary design optimization for complex product review. Chin. J. Mech. Eng. 2008, 44, 15–26. [Google Scholar] [CrossRef]

- An, Y.; Li, R. Modeling & analysis of collaborative design based on process control Petri nets. Comput. Integr. Manuf. Syst. 2006, 12, 1352–1358. [Google Scholar]

- Wang, Y.; Duan, G.J. Complex product design process model based on generalized characters evolution. Comput. Integr. Manuf. Syst. 2011, 12, 2562–2572. [Google Scholar]

- Otto, K.N.; Wood, K.L. Product Design; Tsinghua University Press: Beijing, China, 2001. (In Chinese) [Google Scholar]

- Deng, J.Z. Essential design theory and technology for product development. China Mech. Eng. 2000, 11, 139–143. [Google Scholar]

- Kong, J.; Zhang, Y.; Wang, H.; Chen, S. Study on integration of distributed PM and workflow in collaborative product development environment. China Mech. Eng. 2003, 14, 1122–1125. [Google Scholar]

- Cao, J.; Zhang, S.; Hu, J. Research on concurrent engineering oriented integrated product development process management system. China Mech. Eng. 2002, 13, 80–83. [Google Scholar]

- Chen, S.; Lin, Li. Decomposition of interdependent task group for concurrent engineering. Comput. Ind. Eng. 2003, 44, 435–459. [Google Scholar] [CrossRef]

- Stone, P.; Veloso, M. Task decomposition, dynamic role assignment, and low-bandwidth communication for real-time strategic teamwork. Artif. Intell. 1999, 110, 241–273. [Google Scholar] [CrossRef]

- Orsv, Ä.K. Some principles for libraries of task decomposition methods. Int. J. Hum. Comput. Stud. 1998, 49, 417–435. [Google Scholar] [CrossRef]

- Bian, Y.; Guo, K. The identification of system key elements. J. Syst. Sci. 2013, 21, 22–27. [Google Scholar]

- Yang, F.; Tang, X. Propagation of engineering change based on characteristic linkage perspective. J. Beijing Univ. Aeronaut. Astronaut. 2012, 38, 1–8. [Google Scholar]

- Yang, F.; Tang, X.; Duan, G. Searching model of change propagation paths for mechanical product based on characteristic linkage network. J. Mech. Eng. 2011, 47, 97–106. [Google Scholar] [CrossRef]

- Pang, H.; Fang, Z. Task decomposition strategy and granularity design in networked collaborative environment. Comput. Integr. Manuf. Syst. 2008, 3, 425–430. [Google Scholar]

- Bao, B.; Yang, Y.; Li, F.; Xue, C. Decomposition model in product customization collaborative development task. Comput. Integr. Manuf. Syst. 2014, 20, 1537–1545. [Google Scholar]

- Sim, S.K.; Duffy, A.H.B. Towards an ontology of generic engineering design activities. Res. Eng. Des. 2003, 14, 200–223. [Google Scholar] [CrossRef]

- McMahon, C. Design informatics: Supporting engineering design processes with information technology. J. Indian Inst. Sci. 2016, 95, 365–378. [Google Scholar]

- Chen, G. Optimize the Product Development Process based on Design Structure Matrix; Huazhong University of Science and Technology: Wuhan, China, 2009. [Google Scholar]

- Meng, X. Key Technology for Product Collaborative Design of Machine Tool Supporting Environment; Dongnan University: Nanjing, China, 2005. [Google Scholar]

- Feng, Z. Study on Modeling, Simulation and Optimization of the Product Designing Process; Dalin University of Technology: Dalian, China, 2008. [Google Scholar]

- Pengbiao, N. Research on Optimizing the Allocation of Aeronautic Complex Product Collaborative Design Resources; Nanchang Hangkong University: Nanchang, China, 2013. [Google Scholar]

- Zhangyin, G. Research on Model Control and Management for Computer Supporting Collaborative Design Process of Mechanical Products; Taiyuan University of Science and Technology: Taiyuan, China, 2011. [Google Scholar]

- Schwartz, D.R. Database support for conflict detection in a computer-supported cooperative work environment. In Proceedings of the International Database Engineering and Applications Symposium, Montreal, QC, Candada, 25–27 August 1997; pp. 240–249.

- Egyed, A.; Grunbacher, P. Identifying requirements conflicts and cooperation: How quality attributes and automated traceability can help. IEEE Softw. 2004, 21, 50–58. [Google Scholar] [CrossRef]

- Fu, G. A fuzzy optimization method for multicriteria decision making: An application to reservoir flood control operation. Expert Syst. Appl. 2008, 34, 145–149. [Google Scholar] [CrossRef]

- Herrera, F.; Herrera-Viedma, E. Choice functions and mechanisms for linguistic preference relations. Eur. J. Oper. Res. 2000, 120, 144–161. [Google Scholar] [CrossRef]

- Kao, C.; Lin, P.H. Qualitative factors in data envelopment analysis: A fuzzy number approach. Eur. J. Oper. Res. 2011, 211, 586–593. [Google Scholar] [CrossRef]

- Herrera, F.; Herrera-Viedma, E.; Martı́nez, L. A fusion approach for managing multi-granularity linguistic term sets in decision making. Fuzzy Sets Syst. 2000, 114, 43–58. [Google Scholar] [CrossRef]

- Opricovic, S.; Tzeng, G.H. Defuzzification within a multicriteria decision model. Int. J. Uncertain. Fuzziness Knowl. Based Syst. 2003, 11, 635–652. [Google Scholar] [CrossRef]

- Osborne, S.M. Product Development Cycle Time Characterization through Modeling of Process Iteration; Massachusetts Institute of Technology: Cambridge, MA, USA, 1993. [Google Scholar]

- Cheng, H.; Chu, X. A network-based assessment approach for change impacts on complex product. J. Intell. Manuf. 2012, 23, 1419–1431. [Google Scholar] [CrossRef]

- Yu, G. Change Response and Key Technologies for Customer Requirements in Customized Complex Product Design; Chongqing University: Chongqing, China, 2015. [Google Scholar]

- Zhao, D.E. Load Simulation in Offshore Wind Turbine System and Design Optimization of Hub; Harbin Institute of Technology: Harbin, China, 2010. [Google Scholar]

- Han, D. Structural Analysis and Study on Wind Turbine Main Shaft; Chongqing University: Chongqing, China, 2009. [Google Scholar]

- Xu, Z. The Study on Yaw Control System of Wind Turbin; Dalian University of Tehchnology: Dalian, China, 2010. [Google Scholar]

- Shen, X. Wind Turbine Global Design Technology and Design Software Development; Shantou University: Shantou, China, 2005. [Google Scholar]

- Novák, V. A comprehensive theory of trichotomous evaluative linguistic expressions. Fuzzy Sets Syst. 2008, 159, 2939–2969. [Google Scholar] [CrossRef]

- Lee, Y.S.; Cheng, M.W. Intelligent control battery equalization for series connected lithium-ion battery strings. IEEE Trans. Ind. Electron. 2005, 52, 1297–1307. [Google Scholar] [CrossRef]

- Berenji, H.R. Fuzzy Logic Controllers/An Introduction to Fuzzy Logic Applications in Intelligent Systems; Springer: New York, NY, USA, 1992; pp. 69–96. [Google Scholar]

- Logambigai, R.; Kannan, A. Fuzzy logic based unequal clustering for wireless sensor networks. Wirel. Netw. 2016, 22, 945–957. [Google Scholar] [CrossRef]

- Martin, M.V.; Ishii, K. Design for variety: Developing standardized and modularized product platform architectures. Res. Eng. Des. 2002, 13, 213–235. [Google Scholar]

- Zhang, X. Process Modeling of Customer Collaborative Product Innovation and Its Key Technologies; Chongqing University: Chongqing, China, 2015. [Google Scholar]

| 0 | 0.4 | 0.2 | 0 | 0 | |

| 0 | 0 | 0.4 | 0.1 | 0.2 | |

| 0 | 0 | 0.5 | 0 | 0 | |

| 0 | 0 | 0 | 0 | 0.2 | |

| 0 | 0 | 0 | 0.6 | 0 |

| 0 | 0 | 0 | 0 | ||

| 0.2 | 0 | 0.5 | 0 | ||

| 0.8 | 0.7 | 0 | 0 | ||

| 0 | 0.9 | 0 | 0 | ||

| 0 | 0 | 0.8 | 0 |

| 0.9 | 0.8 | 0 | 0.9 | ||

| 0.9 | 0 | 0.9 | 0 |

| 1 | 0 | 0 | 0 | 0 | |

| 0 | 1 | 0 | 0 | 0 | |

| 0 | 0 | 1 | 0 | 0.9 | |

| 0 | 0 | 0 | 0 | 0.8 | |

| 0 | 0 | 0.9 | 0.8 | 0 |

| 0.9 | 0 | 0.1 | 0 | 0.6 | |

| 0 | 0.9 | 0.4 | 0.5 | 0 | |

| 0.8 | 0.1 | 0.6 | 0 | 0 | |

| 0 | 1 | 0 | 0.9 | 0 | |

| 1 | 0 | 0 | 0 | 0.9 |

| Linguistic Variables | |||

|---|---|---|---|

| most insignificant relationship | 0 | 0 | 0.1667 |

| more insignificant relationship | 0 | 0.1667 | 0.3333 |

| insignificant relationship | 0.1667 | 0.3333 | 0.5 |

| general relationship | 0.3333 | 0.5 | 0.6667 |

| significant relationship | 0.5 | 0.6667 | 0.8333 |

| more significant relationship | 0.6667 | 0.8333 | 1 |

| most significant relationship | 0.8333 | 1 | 1 |

| Linguistic Variables | |||

|---|---|---|---|

| insignificant relationship | 0 | 0 | 0.25 |

| insignificant relationship | 0 | 0.25 | 0.5 |

| general relationship | 0.25 | 0.5 | 0.75 |

| significant relationship | 0.5 | 0.75 | 1 |

| more significant relationship | 0.75 | 1 | 1 |

| Blade | Yaw System | Pitch System | Cabin | Spindle | Gear | Control System | Generating System | Hub | Tower | |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | |

| 1 | 0.36 | 0.22 | 0.58 | 0.14 | 0.29 | 0.31 | 0.46 | 0.72 | 0.19 | |

| 2 | 0.31 | 0.41 | 0.07 | 0.17 | 0.31 | 0.22 | 0.48 | 0.29 | 0.1 | |

| 3 | 0.46 | 0.5 | 0.12 | 0.53 | 0.19 | 0.29 | 0.26 | 0.34 | 0.12 | |

| 4 | 0.36 | 0.29 | 0.15 | 0.21 | 0.5 | 0.07 | 0.46 | 0.38 | 0.43 | |

| 5 | 0.46 | 0.58 | 0.31 | 0.19 | 0.17 | 0.17 | 0.26 | 0.38 | 0.38 | |

| 6 | 0.36 | 0.26 | 0.34 | 0.7 | 0.36 | 0.43 | 0.17 | 0.22 | 0.26 | |

| 7 | 0.34 | 0.24 | 0.22 | 0.46 | 0.26 | 0.36 | 0.07 | 0.17 | 0.12 | |

| 8 | 0.6 | 0.43 | 0.26 | 0.34 | 0.19 | 0.26 | 0.07 | 0.72 | 0.58 | |

| 9 | 0.67 | 0.04 | 0.06 | 0.19 | 0.31 | 0.26 | 0.22 | 0.09 | 0.07 | |

| 10 | 0.03 | 0.22 | 0.14 | 0.07 | 0.14 | 0.19 | 0.22 | 0.11 | 0.34 |

| No. | Parts | No. | Parts | ||||

|---|---|---|---|---|---|---|---|

| 1 | blade | 3.73 | 0.57 | 6 | gear | 3.1 | 0.59 |

| 2 | yaw system | 2.36 | 0.69 | 7 | control system | 2.24 | 0.70 |

| 3 | pitch system | 2.81 | 0.63 | 8 | generating system | 3.45 | 0.54 |

| 4 | cabin | 2.85 | 0.62 | 9 | hub | 1.91 | 0.75 |

| 5 | spindle | 2.9 | 0.62 | 10 | tower | 1.46 | 0.81 |

| No. | Parts | No. | Parts | ||||

|---|---|---|---|---|---|---|---|

| 1 | blade | 4.75 | 0.91 | 6 | gear | 4.13 | 0.92 |

| 2 | yaw system | 5.47 | 0.90 | 7 | control system | 3.86 | 0.93 |

| 3 | pitch system | 4.27 | 0.92 | 8 | generating system | 5.79 | 0.89 |

| 4 | cabin | 4.72 | 0.91 | 9 | hub | 4.17 | 0.92 |

| 5 | spindle | 3.04 | 0.94 | 10 | tower | 3.93 | 0.93 |

| No. | Parts | ||

|---|---|---|---|

| 1 | blade | 0.47 | 0.72 |

| 2 | yaw system | 0.54 | 0.79 |

| 3 | pitch system | 0.48 | 0.73 |

| 4 | cabin | 0.53 | 0.76 |

| 5 | spindle | 0.50 | 0.75 |

| 6 | gear | 0.56 | 0.84 |

| 7 | control system | 0.54 | 0.81 |

| 8 | generating system | 0.51 | 0.75 |

| 9 | hub | 0.49 | 0.74 |

| 10 | tower | 0.48 | 0.73 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, Y.-J.; Yang, Y.; Zhang, N.; Jiao, Y. A Supernetwork-Based Model for Design Processes of Complex Mechanical Products. Sustainability 2016, 8, 992. https://doi.org/10.3390/su8100992

Zheng Y-J, Yang Y, Zhang N, Jiao Y. A Supernetwork-Based Model for Design Processes of Complex Mechanical Products. Sustainability. 2016; 8(10):992. https://doi.org/10.3390/su8100992

Chicago/Turabian StyleZheng, Yu-Jie, Yu Yang, Na Zhang, and Yao Jiao. 2016. "A Supernetwork-Based Model for Design Processes of Complex Mechanical Products" Sustainability 8, no. 10: 992. https://doi.org/10.3390/su8100992