New Algorithm for Evaluating the Green Supply Chain Performance in an Uncertain Environment

Abstract

:1. Introduction

2. Indicator Systems and Methods of GSC Performance Evaluation

3. Nature-Inspired Algorithms and Their Applications to GSC Performance Evaluation

3.1. Nature-Inspired Algorithms

3.2. Applications of Nature-Inspired Algorithms to GSC Performance Evaluation

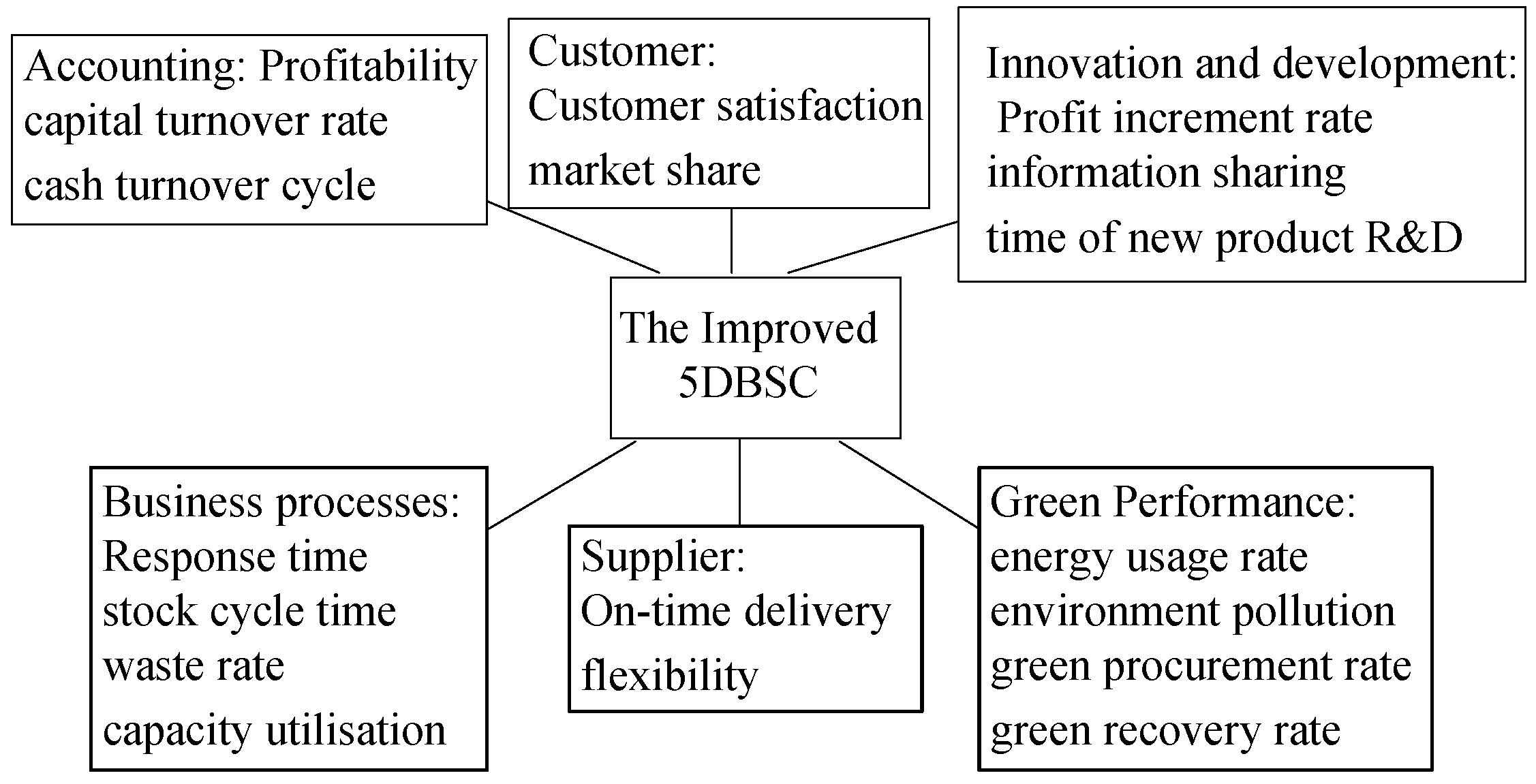

4. Improved 5DBSC

5. Related Algorithms of the RS-GA-LMBP Neural Network Algorithm

5.1. RS Theory

5.2. GA

5.3. LMBP Neural Network Algorithm

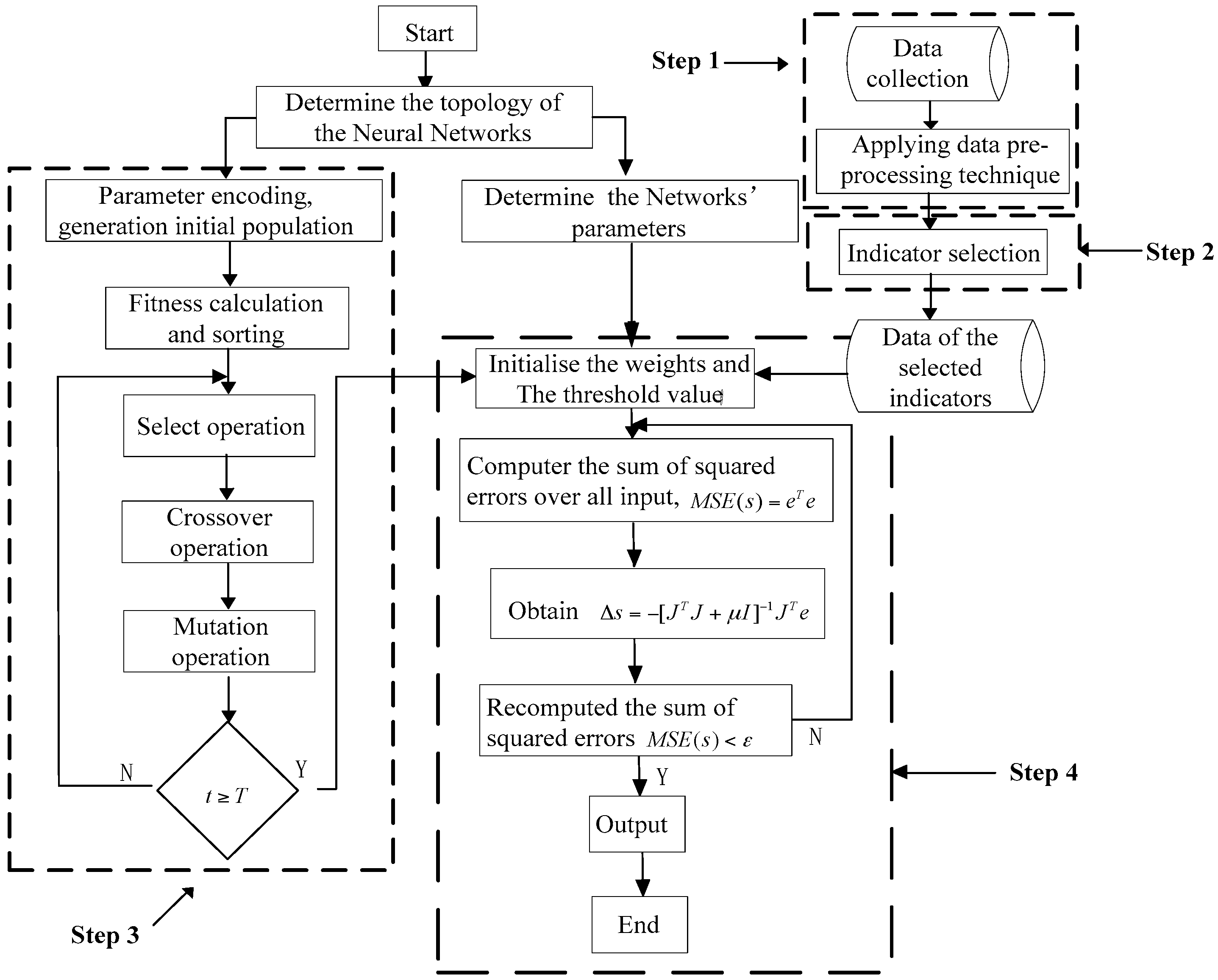

6. Model of the RS-GA-LMBP Neural Network Algorithm

7. Case Study

7.1. Data Preparation

7.2. Selection Indicators

7.3. Chromosomal Gene Coding

7.4. Fitness Formula

7.5. Acquisition of the Hidden Layer Nodes

7.6. Application Process of the GA-LMBP Neural Network Algorithm

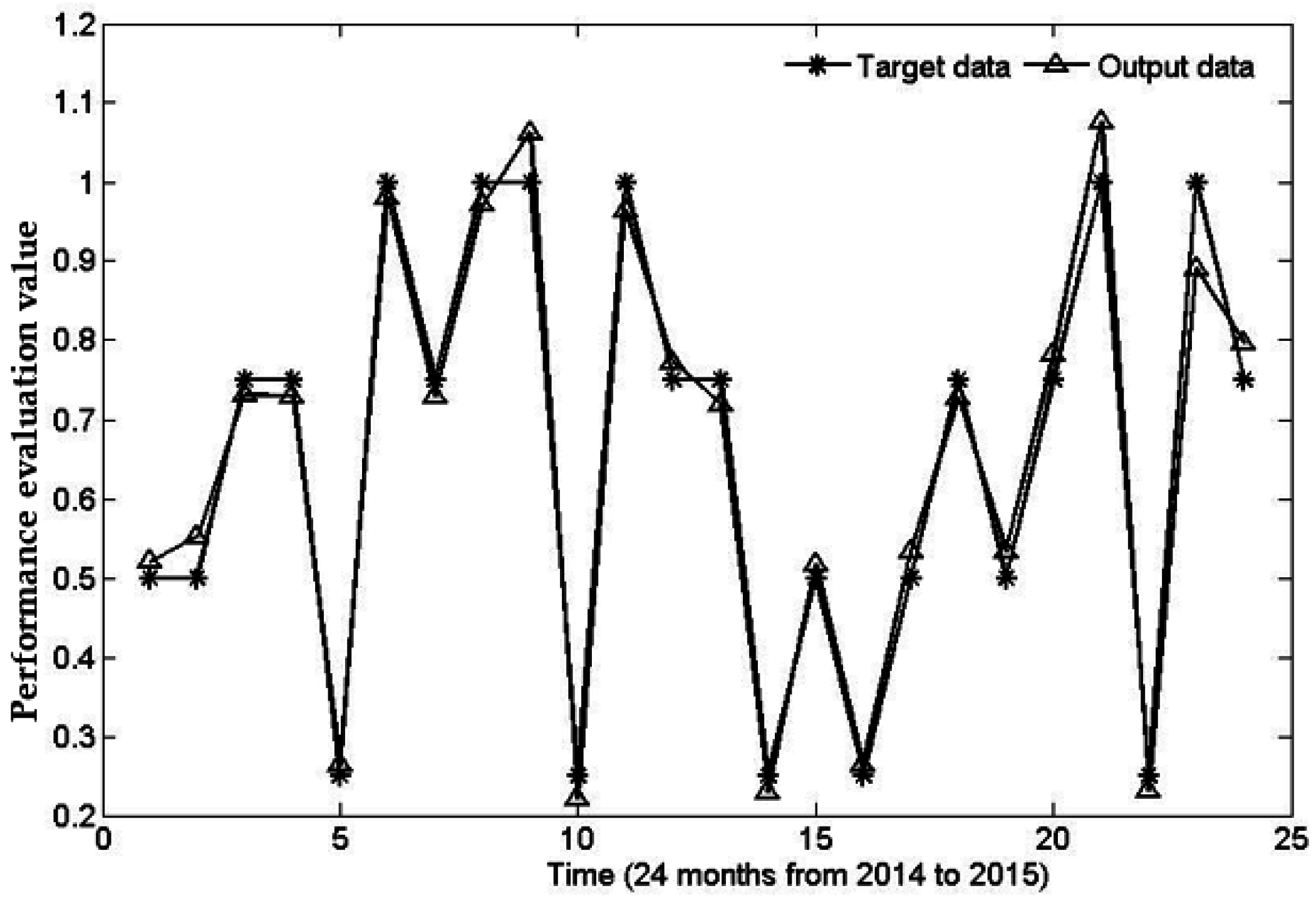

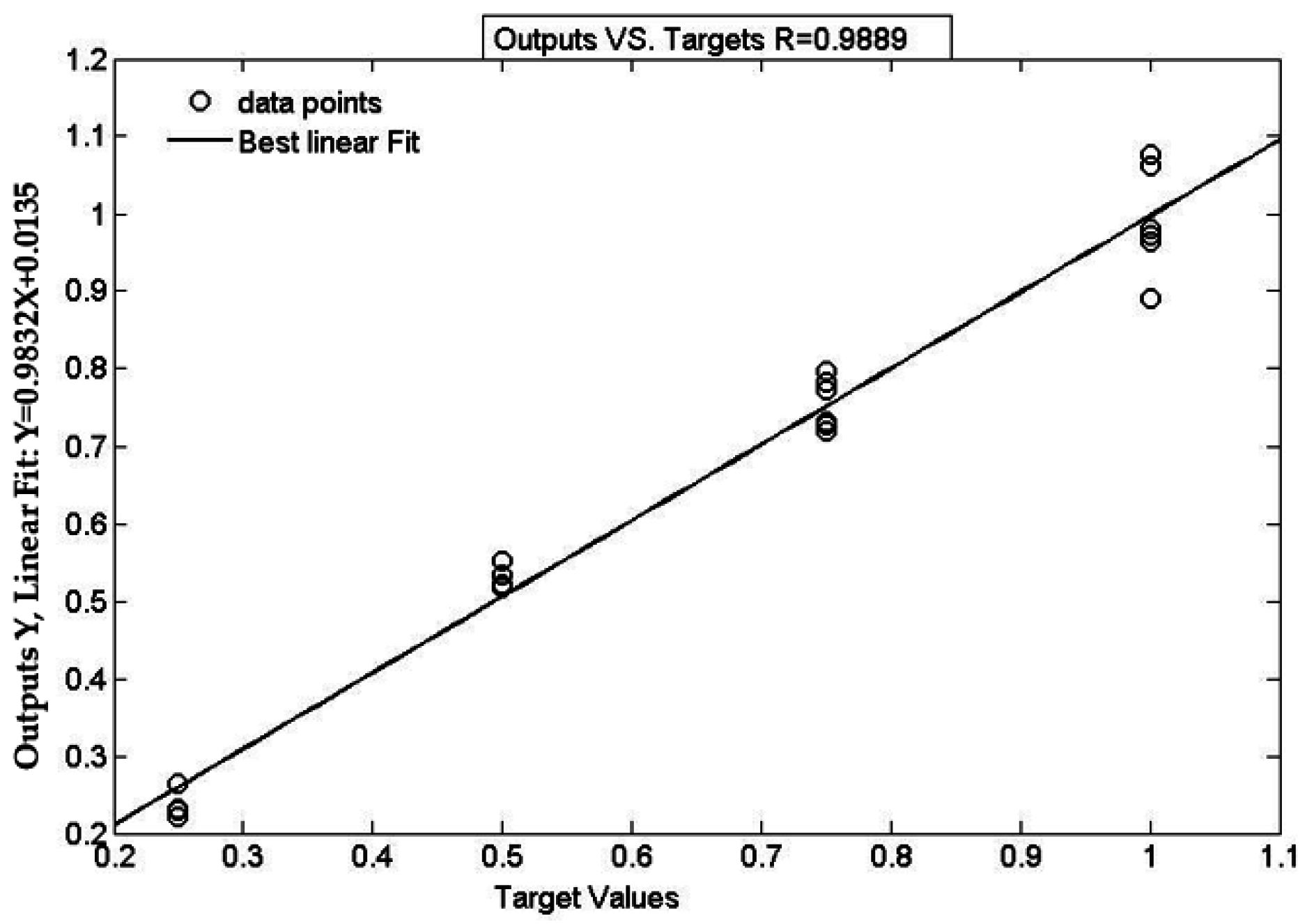

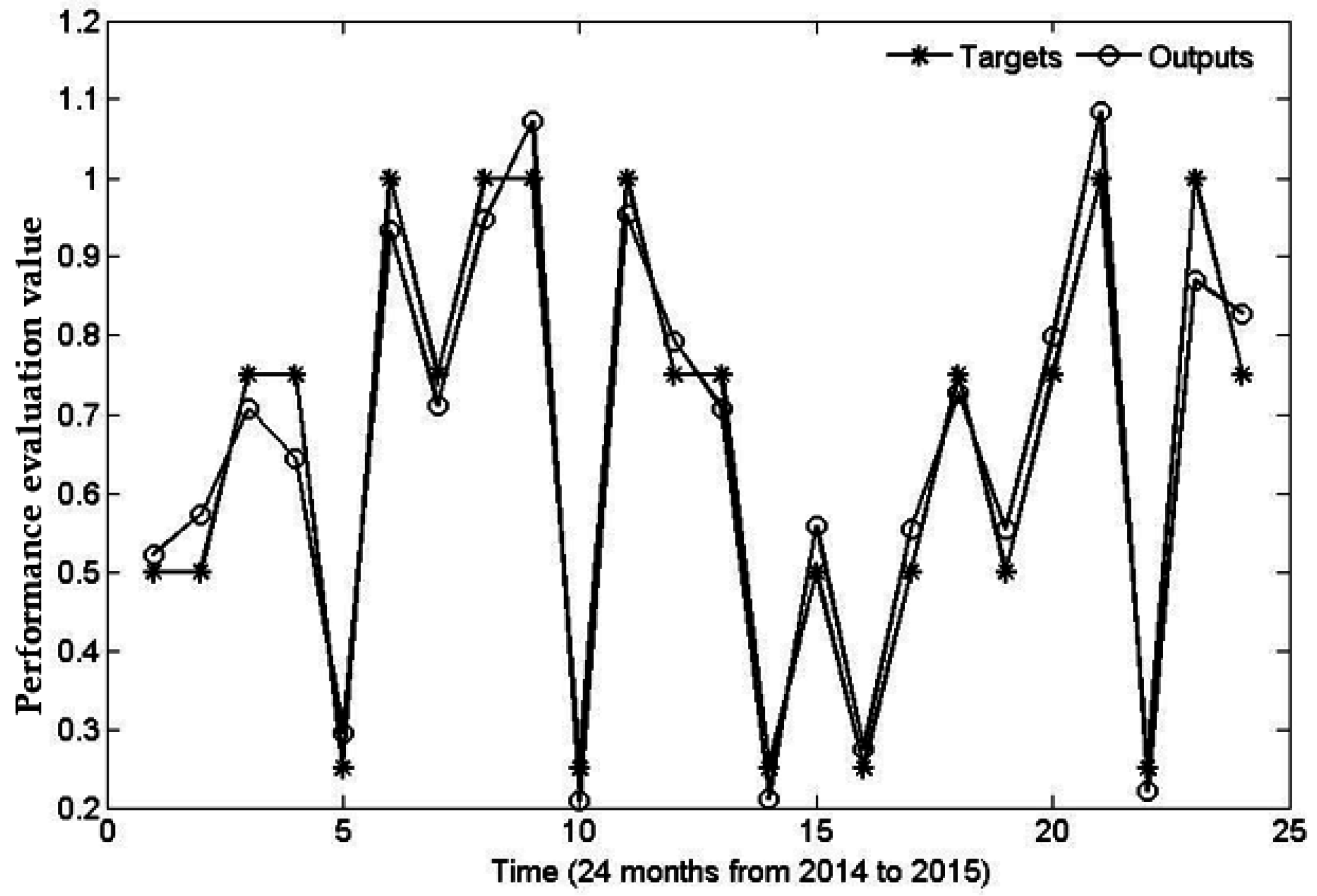

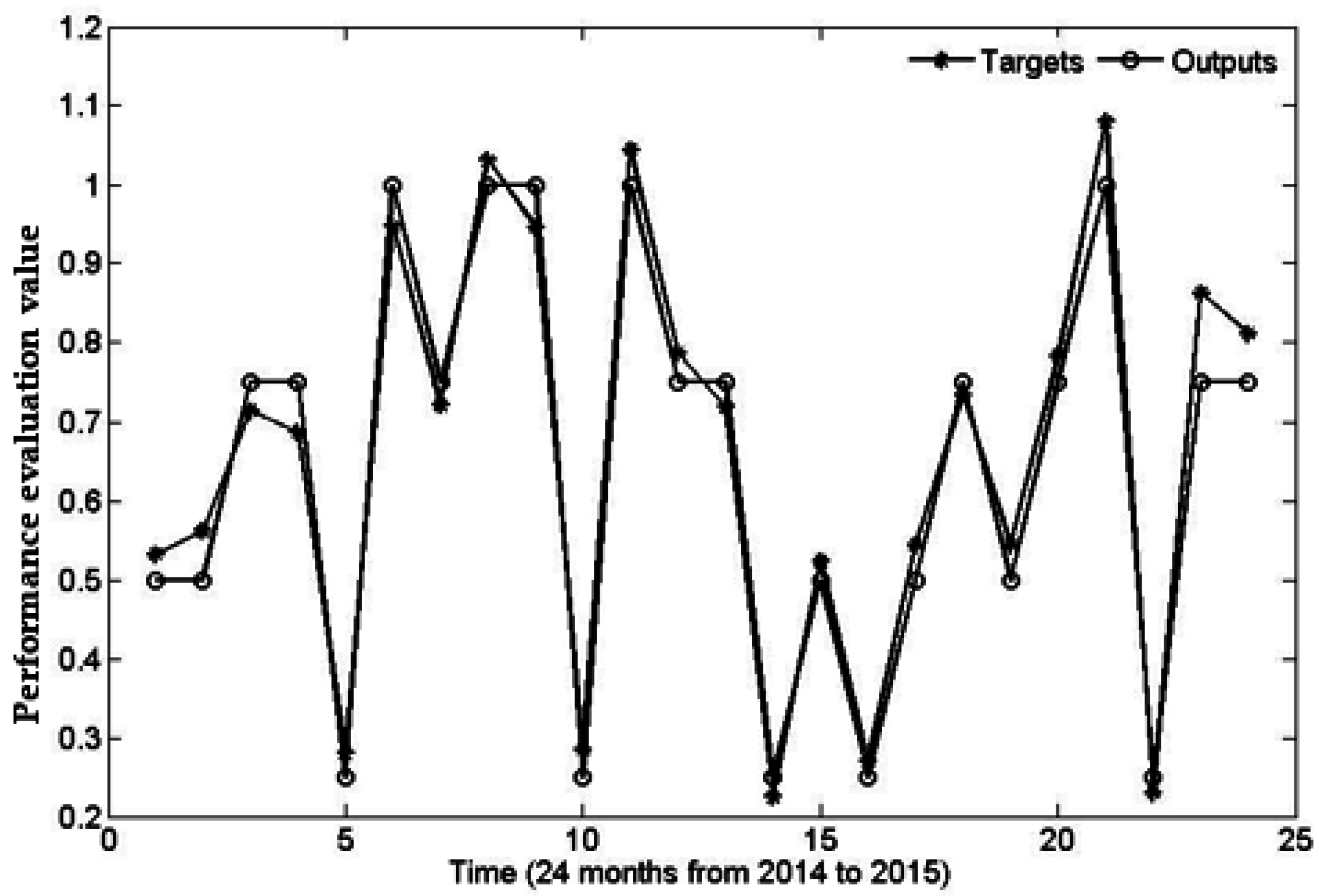

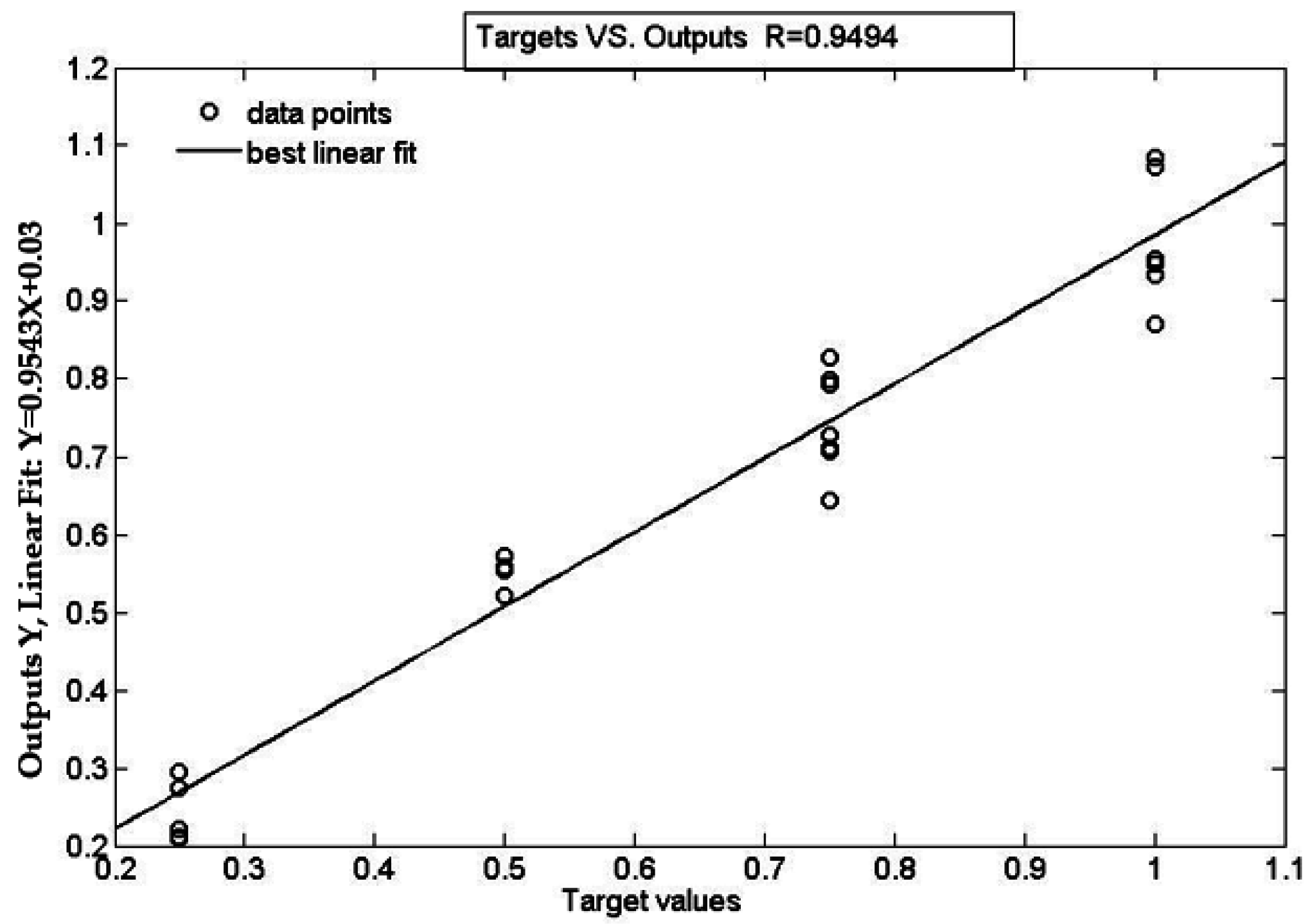

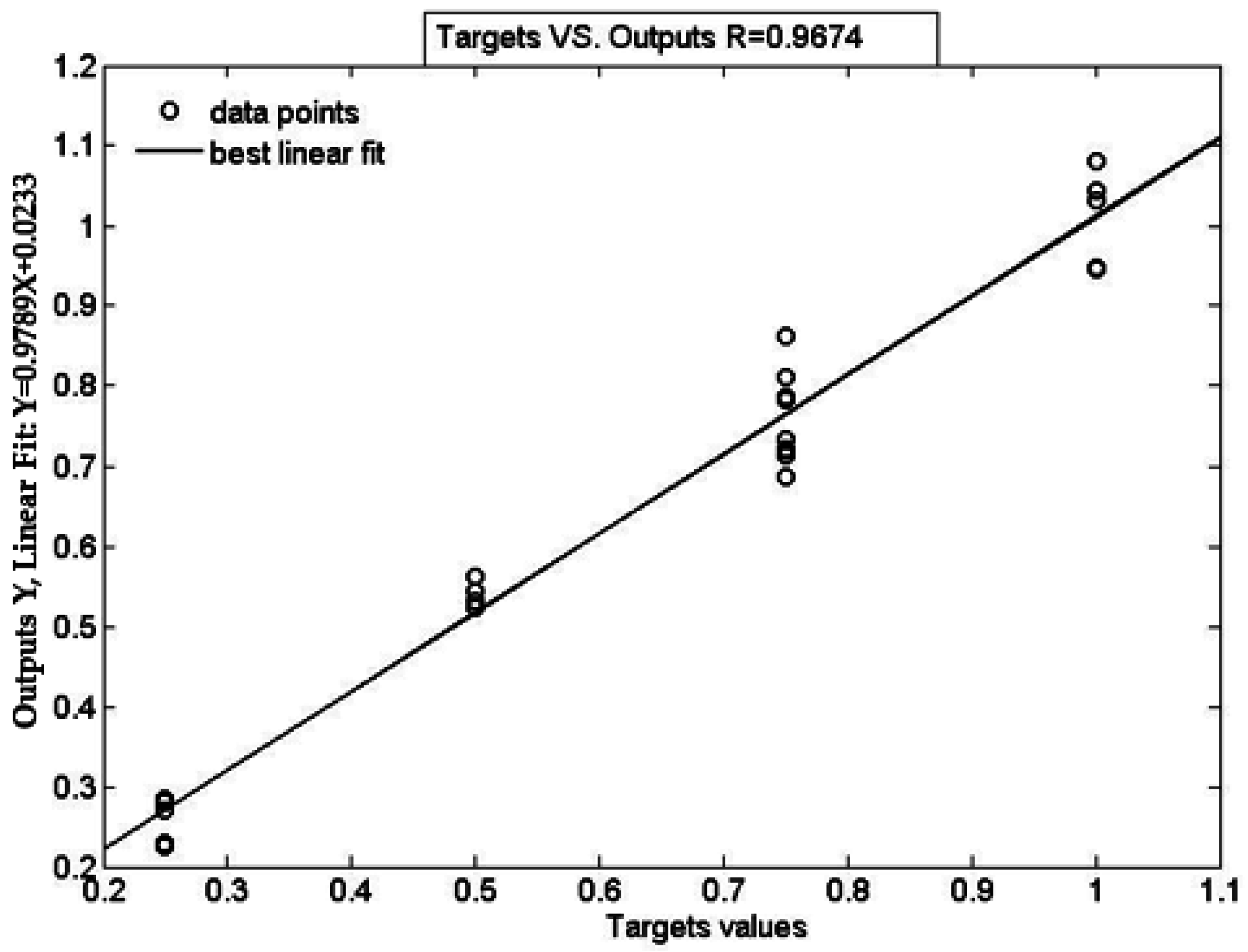

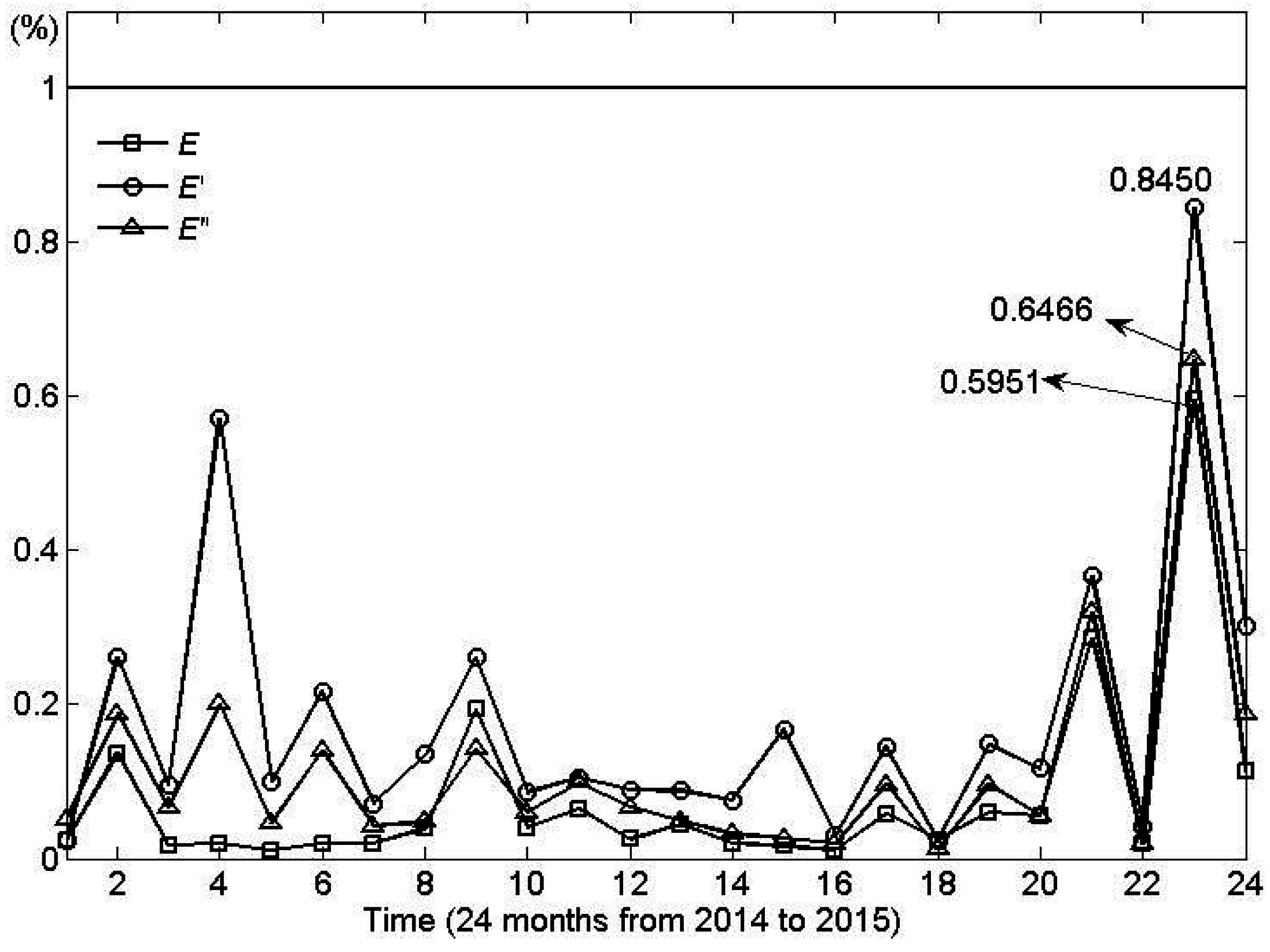

7.7. Results Analysis and Discussion

8. Conclusions

- (1)

- An improved 5DBSC for GSC performance evaluation was proposed. Based on the applications and shortcomings of the 5DBSC and the requirements of the IOS 14000 Environment Management Standard, the 5DBSC for GSC performance evaluation was improved. Its main contribution is that the measurement method of the “environmental pollution” indicator contained in the green performance was improved. The “environmental pollution” indicator was revised to measure the total emissions of “three wastes”. The modified indicator was more easily measured and more practical.

- (2)

- A new algorithm was proposed for GSC performance evaluation. According to the applications and shortcomings of RS theory, GA, the LMBP neural network algorithm, and the GA-LMBP neural network algorithm for evaluating supply chain performance, a RS-GA-LMBP neural network algorithm was proposed and developed. The algorithm of the proposed model was presented. Then, from the aspect of a theoretical analysis and a literature review, it was demonstrated that the proposed algorithm could be used in an uncertain environment and could help eliminate redundant indicators. This algorithm has a high convergence speed and a more accurate prediction ability.

- (3)

- From a practical perspective, the effectiveness of the proposed algorithm was confirmed. A case study was conducted, and the practical values of 18 indicators from 2014 to 2015 were collected from automotive company F. According to the analysis, the results show that the proposed model is effective, valid, and reliable. This model has a faster convergence speed than BP and LMBP neural network algorithms.

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

| 2014 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | |

| C1 | 0.75 | 1 | 0.75 | 1 | 0.75 | 1 | 1 | 0.75 | 0.75 | 1 | 0.75 | 0.75 |

| C2 | 0.82 | 0.7 | 0.81 | 0.71 | 0.6 | 0.8 | 0.76 | 0.83 | 0.81 | 0.65 | 0.76 | 0.72 |

| F2 | 0.24 | 0.26 | 0.34 | 0.26 | 0.22 | 0.29 | 0.29 | 0.29 | 0.33 | 0.23 | 0.27 | 0.29 |

| F3 | 0.8 | 0.8 | 0.6 | 0.6 | 0.8 | 0.6 | 0.8 | 0.6 | 0.6 | 0.6 | 0.4 | 0.6 |

| P1 | 0.6 | 0.1 | 0.7 | 0.5 | 0.2 | 0.5 | 0.2 | 0.3 | 0 | 0.6 | 0.7 | 0.3 |

| P2 | 0.25 | 0.27 | 0.31 | 0.25 | 0.14 | 0.32 | 0.23 | 0.31 | 0.27 | 0.13 | 0.32 | 0.23 |

| P3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| P4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| D1 | 0.15 | 0.16 | 0.67 | 0.12 | −0.32 | 0.49 | 0.08 | 0.5 | 0.09 | −0.16 | 0.5 | 0.07 |

| D2 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1 | 0.75 | 1 | 1 | 0.5 | 1 | 0.75 |

| D3 | 0.75 | 0.91 | 0.67 | 0.75 | 0.36 | 0.75 | 0.75 | 0.75 | 0.91 | 0.25 | 0.67 | 0.75 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 0.75 | 0.75 | 0.5 | 1 | 1 | 1 | 0.75 | 1 | 1 | 0.75 | 0.75 | 0.75 |

| E1 | 0.7 | 0.76 | 0.84 | 0.85 | 0.6 | 0.9 | 0.86 | 0.91 | 0.9 | 0.54 | 0.9 | 0.81 |

| E2 | 0.33 | 1 | 0.33 | 0.33 | 1 | 0 | 0.33 | 0 | 0 | 1 | 0 | 0.33 |

| E3 | 0.79 | 0.79 | 0.93 | 0.77 | 0.81 | 0.84 | 0.91 | 0.87 | 0.8 | 0.43 | 0.85 | 0.84 |

| E4 | 0.63 | 0.65 | 0.81 | 0.87 | 0.45 | 0.85 | 0.72 | 0.88 | 0.82 | 0.72 | 0.88 | 0.75 |

| Performance | 0.5 | 0.5 | 0.75 | 0.75 | 0.25 | 1 | 0.75 | 1 | 1 | 0.25 | 1 | 0.75 |

| 2015 | ||||||||||||

| C1 | 0.75 | 1 | 1 | 0.75 | 1 | 1 | 0.75 | 1 | 1 | 1 | 1 | 0.75 |

| C2 | 0.8 | 0.6 | 0.77 | 0.59 | 0.65 | 0.82 | 0.7 | 0.7 | 0.82 | 0.54 | 0.81 | 0.72 |

| F2 | 0.33 | 0.22 | 0.26 | 0.22 | 0.25 | 0.31 | 0.25 | 0.28 | 0.32 | 0.23 | 0.29 | 0.3 |

| F3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| P1 | 0.7 | 0.3 | 0.5 | 0.3 | 0.5 | 0.6 | 0.5 | 0.5 | 0.5 | 0.4 | 0.7 | 0.5 |

| P2 | 0.3 | 0.15 | 0.25 | 0.1 | 0.15 | 0.3 | 0.25 | 0.25 | 0.25 | 0.1 | 0.3 | 0.2 |

| P3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| P4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| D1 | 0.66 | −0.32 | 0 | −0.28 | −0.16 | −0.08 | 0.16 | 0.14 | 0.1 | −0.17 | 0.49 | 0.09 |

| D2 | 0.75 | 1 | 0.75 | 1 | 1 | 1 | 0.75 | 0.75 | 1 | 0.75 | 1 | 1 |

| D3 | 0.75 | 0.25 | 0.08 | 0.08 | 0.08 | 0.58 | 0.75 | 0.67 | 0.75 | 0.08 | 0.75 | 0.67 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 0.75 | 1 | 0.5 | 1 | 1 | 0.75 | 0.75 | 1 | 1 | 0.75 | 1 | 1 |

| E1 | 0.85 | 0.53 | 0.72 | 0.53 | 0.7 | 0.84 | 0.74 | 0.86 | 0.93 | 0.57 | 0.93 | 0.83 |

| E2 | 0.33 | 1 | 0.33 | 1 | 0.67 | 0.33 | 0.67 | 0.33 | 0 | 1 | 0 | 0.33 |

| E3 | 0.95 | 0.83 | 0.52 | 0.63 | 0.67 | 0.34 | 0.84 | 0.76 | 0.83 | 0.47 | 0.83 | 0.93 |

| E4 | 0.85 | 0.43 | 0.62 | 0.83 | 0.77 | 0.74 | 0.64 | 0.86 | 0.89 | 0.77 | 0.86 | 0.73 |

| Performance | 0.75 | 0.25 | 0.5 | 0.25 | 0.5 | 0.75 | 0.5 | 0.75 | 1 | 0.25 | 1 | 0.75 |

References

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Weng, H.-H.R.; Chen, J.-S.; Chen, P.-C. Effects of green innovation on environmental and corporate performance: A stakehold perspect. Sustainability 2015, 7, 4997–5026. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Mohapatra, P.; Kumar, V.; Dey, P.K.; Brady, M.; Tiwari, M.K.; Nudurupati, S.S. Green supply chain performance measurement using fuzzy ANP-based balanced scorecard: A collaborative decision-making approach. Prod. Plan. Control 2014, 25, 698–714. [Google Scholar] [CrossRef]

- Hervani, A.A.; Helms, M.M.; Sarkis, J. Performance measurement for green supply chain management. Benchmarking 2005, 12, 330–353. [Google Scholar] [CrossRef]

- Shen, L.; Olfat, L.; Govindan, K.; Khodaverdi, R.; Diabat, A. A fuzzy multi criteria approach for evaluating green supplier’s performance in green supply chain with linguistic preferences. Resour. Conserv. Recycl. 2013, 74, 170–179. [Google Scholar] [CrossRef]

- Uygun, Ö.; Dede, A. Performance evaluation of green supply chain management using integrated fuzzy multi-criteria decision making techniques. Comput. Ind. Eng. 2016, in press. [Google Scholar] [CrossRef]

- Richardson, P. Fitness for the Future: Applying Biomimetics to Business Strategy. Ph.D. Thesis, Bath University, Bath, UK, 2010. [Google Scholar]

- Li, Y. Application of GA and SVM to the performance evaluation of supply chain. Comput. Eng. Appl. 2010, 46, 246–248. [Google Scholar]

- Fan, X.; Zhang, S.; Wang, L.; Yang, Y.; Hapeshi, K. An evaluation model of supply chain performances using 5DBSC and LMBP neural network algorithm. J. Bionic Eng. 2013, 10, 383–395. [Google Scholar] [CrossRef]

- Xi, Y.F.; Wang, C.; Nie, X.X. Study of the evaluation methods of supply chain performances using fuzzy neural network. Inf. J. 2007, 9, 77–79. [Google Scholar]

- Seeley, T.D. The Wisdom of the Hive: The Social Physiology of Honey Bee Colonies; Harvard University Press: Cambridge, UK, 1996. [Google Scholar]

- Martens, D.; De Backer, M.; Haesen, R.; Vanthienen, J.; Snoeck, M.; Baesens, B. Classification with ant colony optimization. IEEE Trans. Evol. Comput. 2007, 11, 651–665. [Google Scholar] [CrossRef]

- Gabbert, P.; Brown, D.E.; Huntley, C.L.; Markowicz, B.P.; Sappington, D.E. A system for learning routes and schedules with genetic algorithms. In Proceedings of the Fourth International Conference on Genetic Algorithms (ICGA’91), Santt Diego, CA, USA, 13–16 July 1991; pp. 430–436.

- Huang, H.X. Modeling and prediction of water-assisted injection molding based on GA-LMBP inverse neural network. J. South China Univ. Technol. Nat. Sci. Ed. 2007, 35, 23–27. [Google Scholar]

- Wu, X.; Xie, L.; Ge, M. Analog circuit fault diagnosis method based on GA-LMBP. Mod. Electron. Tech. 2010, 4, 177–189. [Google Scholar]

- Li, X.; Yu, J.; Jia, Z.; Song, J. Harmful algal blooms prediction with machine learning models in Tolo Harbour. In Proceedings of the 2014 International Conference on IEEE Smart Computing (SMARTCOMP), Hong Kong, China, 3–5 November 2014; pp. 245–250.

- Xue, Y. Research on Evaluation and Analysis of Passenger Comfort in Relation to Vibration in Railway Vehiele; Beijing Jiaotong University: Beijing, China, 2011. [Google Scholar]

- Zhu, Q.; Sarkis, J. Relationships between operational practices and performance among early adopters of green supply chain management practices in Chinese manufacturing enterprises. J. Oper. Manag. 2004, 22, 265–289. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiu, A.S.F. Evaluating firm’s green supply chain management in linguistic preferences. J. Clean. Prod. 2013, 40, 22–31. [Google Scholar] [CrossRef]

- Tseng, M.L.; Chiang, J.H.; Lan, L.W. Selection of optimal supplier in supply chain management strategy with analytic network process and choquet integral. Comput. Ind. Eng. 2009, 57, 330–340. [Google Scholar] [CrossRef]

- Sarkis, J. A strategic decision framework for green supply chain management. J. Clean. Prod. 2003, 11, 397–409. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Geng, Y. Green supply chain management in china: Pressures, practices and performance. Int. J. Oper. Prod. Manag. 2005, 25, 449–468. [Google Scholar] [CrossRef]

- Diabat, A.; Govindan, K. An analysis of the drivers affecting the implementation of green supply chain management. Resour. Conserv. Recycl. 2011, 55, 659–667. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lin, Y.H.; Tan, K.; Chen, R.H.; Chen, Y.H. Using TODIM to evaluate green supply chain practices under uncertainty. Appl. Math. Model. 2014, 38, 2983–2995. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring supply chain performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Farris, P.W.; Bendle, N.T.; Pfeifer, P.E.; Reibstein, D.J. Marketing Metrics: The Definitive Guide to Measuring Marketing Performance; Pearson Education: Upper Saddle River, NJ, USA, 2010. [Google Scholar]

- Stewart, G. Supply-chain operations reference model (SCOR): The first cross-industry framework for integrated supply-chain management. Logist. Inf. Manag. 1997, 10, 62–67. [Google Scholar] [CrossRef]

- Yi, K.G. KPI assessment: Study of implication, workflow and counter measures. Technol. Econ. 2005, 24, 48–49. [Google Scholar]

- Gecevska, V.; Chiabert, P.; Anisic, Z.; Lombardi, F. Product lifecycle management through innovative and competitive business environment. J. Ind. Eng. Manag. 2010, 3, 323–336. [Google Scholar] [CrossRef]

- Alemanni, M.; Alessia, G.; Tornincasa, S.; Vezzetti, E. Key performance indicators for PLM benefits evaluation: The Alcatel Alenia Space case study. Comput. Ind. 2008, 59, 833–841. [Google Scholar] [CrossRef]

- Kaplan, R.S.; Norton, D.P. The balanced scorecard: Measures that drive performance. Harv. Bus. Rev. 1992, 70, 71–79. [Google Scholar] [PubMed]

- Wong, W.P. A review on benchmarking of supply chain performance measures. Benchmarking 2008, 15, 25–51. [Google Scholar] [CrossRef]

- Akkermans, H.; Orschot, K.V. Developing a balanced scorecard with system dynamics. In Proceedings of the 20th International System Dynamics Conference, Palermo, Italy, 28 July–1 August 2002.

- Zheng, P. Study of Methods for Evaluating the Performance of Dynamic Supply Chains. Ph.D. Thesis, Hunan University, Changsha, China, 2008. [Google Scholar]

- Kurnia, S.; Shokravi, S. A step towards developing a sustainability performance measure within industrial networks. Sustainability 2014, 6, 2201–2222. [Google Scholar]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Duarte, S.; Cruz-Machado, V.A. Lean and green supply chain performance: A balanced scorecard perspective. In Proceedings of the Eighth International Conference on Management Science and Engineering Management; Springer: Heidelberg, Germany, 2014. [Google Scholar]

- Shao, K.; Yang, J. Study on the performance evaluation of green supply chain Based on the balance scorecard and fuzzy theory. In Proceedings of the 2nd IEEE International Conference on Information Management and Engineering (ICIME), Chengdu, China, 16–18 April 2010; pp. 242–246.

- Chen, W.W.; Zhang, Y.N.; Ouyang, H.X. Green building supply chain performance evaluation based on improved BSC method. J. Eng. Manag. 2014, 28, 201403007. [Google Scholar]

- Fukushima, K. Neocognitron: A self-organizing neural network model for a mechanism of pattern recognition unaffected by shift in position. Biol. Cybern. 1980, 36, 193–202. [Google Scholar] [CrossRef] [PubMed]

- Hinton, G.E.; Osindero, S.; Teh, Y. A fast learning algorithm for deep belief nets. Neural Comput. 2006, 18, 1527–1554. [Google Scholar] [CrossRef] [PubMed]

- Mcculloch, W.; Pitts, W. A logical calculus of the ideas immanent in nervous activity. Bull. Math. Biophys. 1943, 5, 115–133. [Google Scholar] [CrossRef]

- Zhang, F.M.; Cao, Q.K.; Fang, Q.Y. A comparative inquiry into supply chain performance appraisal based on support vector machine and neural network. In Proceedings of the 2008 International Conference on Management Science & Engineering, Long Beach, CA, USA, 10–12 September 2008; pp. 370–377.

- Bocharnikov, Y.V.; Tobias, A.M.; Roberts, C. Reduction of train and net energy consumption using genetic algorithms for Trajectory Optimisation. In Proceedings of the IET Conference on Railway Traction Systems, Birmingham, UK, 13–15 April 2010; pp. 1–5.

- Cha, S.H.; Tappert, C.C. A genetic algorithm for constructing compact binary decision trees. J. Pattern Recognit. Res. 2009, 4, 1–13. [Google Scholar] [CrossRef]

- Shi, C.D.; Chen, J.H. Study of supply chain performance prediction based on rough sets and BP neural network. Comput. Eng. Appl. 2006, 43, 203–205. [Google Scholar]

- Zheng, P.; Lai, K.K. A rough set approach on supply chain dynamic performance measurement. In Kes International Conference on Agent and Multi-Agent Systems: Technologies and Applications; Springer: Heidelberg, Germany, 2008; Volume 4953, pp. 312–322. [Google Scholar]

- Huang, J.Y.H.J.Z. BP network and its application in SCM performance evaluation. Shanghai Manag. Sci. 2006, 6, 57–75. [Google Scholar]

- Pawlak, Z. Rough set. Int. J. Comput. Inf. Sci. 1982, 11, 341–356. [Google Scholar] [CrossRef]

- Xu, J.; Li, B.; Wu, D. Rough data envelopment analysis and its application to supply chain performance evaluation. Int. J. Prod. Econ. 2009, 122, 628–638. [Google Scholar] [CrossRef]

- Dong, X.U.; Chen, C.X.; Wang, H.H. Research on heart disease diagnosis basd on RS-LMBP neural network. Comput. Simul. 2011, 28, 236–239. [Google Scholar]

- Øhrn, A.; Komorowski, J. Rosetta—A rough set toolkit for analysis of data. In Proceedings of the Third International Joint Conference on Information Sciences, Durham, NC, USA, 1–5 March 1997; pp. 403–407.

- Øhrn, A.; Komorowski, J.; Skowron, A.; Synak, P. The Design and Implementation of a Knowledge Discovery Toolkit Based on Rough Sets—The ROSETTA System. Available online: https://www.researchgate.net/publication/2806936_The_Design_and_Implementation_of_a_Knowledge_Discovery_Toolkit_Based_on_Rough_Sets_-_The_ROSETTA_System (accessed on 28 May 2016).

- The ROSETTA WWW Homepage. Available online: http://www.idi.ntnu.no/~aleks/ROSETTA/ (accessed on 28 May 2016).

| Evaluation Dimensions | KPIs | Index Description |

|---|---|---|

| Accounting | Profitability (F1) | Profit level of a SC |

| Capital turnover rate (F2) | Management efficiency of the net capital of a SC | |

| Cash turnover time (F3) | Cash flow payback period | |

| Customer | Customer satisfaction (C1) | Customers’ awareness and acceptability |

| Market share (C2) | Size of the customer community | |

| Business processes | SCRT (Supply chain response time) (P1) | Required time from all enterprises on the chain finding the changes of the market requirements to absorbing these changes and adjusting their plans to meet these changes |

| Stock turnover rate (P2) | Amount of cash in the stock account | |

| Waste rate (P3) | The quality control and production technology | |

| Capacity utilization (P4) | Facility application level | |

| Innovation and development | Profit increment rate (D1) | Development capability of an enterprise |

| Information sharing (D2) | Level of the information integration Dependent on the partners strategic relationships | |

| Period of a new product R&D (D3) | How fast a chain responds to market changes Different for each product and enterprise, so it is difficult to determine its value | |

| Suppliers | On-time delivery rate (S1) | Delivery capability of a supplier |

| Flexibility (S2) | SC’s capability of dealing with the special business environment and meeting the customers’ special requirements or unexpected requirements | |

| Green Performance | Energy usage rate (E1) | Rate of energy consumption |

| Environment pollution (E2) | Total emissions of “three wastes” | |

| Green procurement rate (E3) | The proportion of Green Materials contained in raw materials | |

| Green recovery rate (E4) | The proportion of the Recyclable wastes Value accounting for the product total value | |

| Evaluation dimensions | Measurement method | Property |

| Accounting | Net profit/total income (%) | Quantitative |

| Total sales/total value of net assets | Quantitative | |

| Inventory days of supply + Receivables age − Payables age | Quantitative | |

| Customer | Fuzzy evaluation | Quantitative |

| Product sales/Total sales of industry | Quantitative | |

| Business processes | The time required to meet the sudden demand | Quantitative |

| Cost of sales/The average occupancy amount of inventory | Quantitative | |

| Number of the defective products/Total production | Quantitative | |

| Fuzzy evaluation | Quantitative | |

| Innovation and development | This period/profit of Previous period | Quantitative |

| Fuzzy evaluation | Quantitative | |

| Statistical mean | Quantitative | |

| Suppliers | Punctual delivery times/Total delivery times | Quantitative |

| Fuzzy evaluation | Quantitative | |

| Green Performance | The energy amount contained in the product/Total energy consumption | Quantitative |

| Liquid wastes emissions + Gas wastes emissions + Solid wastes emissions | Quantitative | |

| Number of green materials/total raw material | Quantitative | |

| Recyclable wastes Value/product production gross | Quantitative |

| 2014 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | |

| C1 | 3 | 4 | 3 | 4 | 3 | 4 | 4 | 3 | 3 | 4 | 3 | 3 |

| C2 | 1.40% | 1.39% | 1.61% | 1.41% | 1.19% | 1.59% | 1.52% | 1.65% | 1.62% | 1.30% | 1.52% | 1.43% |

| F1 | 0.425 | 0.437 | 0.53 | 0.461 | 0.42 | 0.51 | 0.457 | 0.53 | 0.51 | 0.41 | 0.54 | 0.47 |

| F2 | 0.239 | 0.263 | 0.34 | 0.264 | 0.22 | 0.29 | 0.285 | 0.291 | 0.334 | 0.231 | 0.272 | 0.287 |

| F3 | 110 | 110 | 120 | 120 | 110 | 120 | 110 | 120 | 130 | 120 | 130 | 120 |

| P1 | 89 | 94 | 88 | 90 | 93 | 90 | 94 | 92 | 95 | 89 | 88 | 92 |

| P2 | 0.25 | 0.27 | 0.31 | 0.25 | 0.14 | 0.32 | 0.23 | 0.31 | 0.27 | 0.13 | 0.32 | 0.23 |

| P3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| P4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| D1 | 0.147 | 0.161 | 0.67 | 0.124 | −0.315 | 0.49 | 0.079 | 0.5 | 0.091 | −0.161 | 0.5 | 0.07 |

| D2 | 3 | 3 | 3 | 3 | 3 | 4 | 3 | 4 | 4 | 2 | 4 | 3 |

| D3 | 120 | 110 | 130 | 120 | 170 | 120 | 120 | 120 | 110 | 180 | 130 | 120 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 3 | 3 | 2 | 4 | 4 | 4 | 3 | 4 | 4 | 3 | 3 | 3 |

| E1 | 0.7 | 0.76 | 0.84 | 0.85 | 0.6 | 0.9 | 0.86 | 0.91 | 0.9 | 0.54 | 0.9 | 0.81 |

| E2 | 3 | 1 | 3 | 3 | 1 | 4 | 3 | 4 | 4 | 1 | 4 | 3 |

| E3 | 0.79 | 0.79 | 0.93 | 0.77 | 0.81 | 0.84 | 0.91 | 0.87 | 0.8 | 0.43 | 0.85 | 0.84 |

| E4 | 0.63 | 0.65 | 0.81 | 0.87 | 0.45 | 0.85 | 0.72 | 0.88 | 0.82 | 0.72 | 0.88 | 0.75 |

| Performance | M | M | G | G | P | E | G | E | E | P | E | G |

| 2015 | ||||||||||||

| C1 | 3 | 4 | 4 | 3 | 4 | 4 | 3 | 4 | 4 | 4 | 4 | 3 |

| C2 | 1.59% | 1.20% | 1.54% | 1.18% | 1.29% | 1.64% | 1.40% | 1.39% | 1.64% | 1.29% | 1.62% | 1.44% |

| F1 | 0.52 | 0.419 | 0.444 | 0.414 | 0.561 | 0.507 | 0.426 | 0.459 | 0.509 | 0.426 | 0.5 | 0.468 |

| F2 | 0.328 | 0.215 | 0.263 | 0.216 | 0.248 | 0.31 | 0.247 | 0.275 | 0.322 | 0.225 | 0.289 | 0.295 |

| F3 | 130 | 120 | 120 | 120 | 120 | 120 | 110 | 110 | 120 | 130 | 120 | 110 |

| P1 | 88 | 92 | 90 | 92 | 90 | 89 | 90 | 90 | 90 | 91 | 88 | 90 |

| P2 | 0.3 | 0.15 | 0.25 | 0.1 | 0.15 | 0.3 | 0.25 | 0.25 | 0.25 | 0.1 | 0.3 | 0.2 |

| P3 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| P4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 | 4 |

| D1 | 0.66 | −0.324 | 0 | −0.281 | −0.16 | −0.069 | 0.157 | 0.136 | 0.095 | −0.171 | 0.489 | 0.088 |

| D2 | 3 | 4 | 3 | 4 | 4 | 4 | 3 | 3 | 4 | 3 | 4 | 4 |

| D3 | 120 | 180 | 200 | 200 | 200 | 140 | 120 | 130 | 120 | 200 | 120 | 130 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 3 | 4 | 2 | 4 | 4 | 3 | 3 | 4 | 4 | 3 | 4 | 4 |

| E1 | 0.85 | 0.53 | 0.72 | 0.53 | 0.7 | 0.84 | 0.74 | 0.86 | 0.93 | 0.57 | 0.93 | 0.83 |

| E2 | 3 | 1 | 3 | 1 | 2 | 3 | 2 | 3 | 4 | 1 | 4 | 3 |

| E3 | 0.95 | 0.83 | 0.52 | 0.63 | 0.67 | 0.34 | 0.84 | 0.76 | 0.83 | 0.47 | 0.83 | 0.93 |

| E4 | 0.85 | 0.43 | 0.62 | 0.83 | 0.77 | 0.74 | 0.64 | 0.86 | 0.89 | 0.77 | 0.86 | 0.73 |

| Performance | G | P | M | P | M | G | M | G | E | P | E | G |

| C2 | F1 | F2 | F3 | P1 | P2 | P3 | D1 | D3 | S1 |

|---|---|---|---|---|---|---|---|---|---|

| (0, 2%) | (0, 1) | (0, 1) | (100, 150) | (85, 95) | (0, 1) | (0, 1) | (0, 1) | (100, 210) | (0, 1) |

| 2014 | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Jan. | Feb. | Mar. | Apr. | May | Jun. | Jul. | Aug. | Sep. | Oct. | Nov. | Dec. | |

| C1 | 0.75 | 1 | 0.75 | 1 | 0.75 | 1 | 1 | 0.75 | 0.75 | 1 | 0.75 | 0.75 |

| C2 | 0.82 | 0.7 | 0.81 | 0.71 | 0.6 | 0.8 | 0.76 | 0.83 | 0.81 | 0.65 | 0.76 | 0.72 |

| F1 | 0.43 | 0.44 | 0.53 | 0.46 | 0.42 | 0.51 | 0.46 | 0.53 | 0.51 | 0.41 | 0.54 | 0.47 |

| F2 | 0.24 | 0.26 | 0.34 | 0.26 | 0.22 | 0.29 | 0.29 | 0.29 | 0.33 | 0.23 | 0.27 | 0.29 |

| F3 | 0.8 | 0.8 | 0.6 | 0.6 | 0.8 | 0.6 | 0.8 | 0.6 | 0.6 | 0.6 | 0.4 | 0.6 |

| P1 | 0.6 | 0.1 | 0.7 | 0.5 | 0.2 | 0.5 | 0.2 | 0.3 | 0 | 0.6 | 0.7 | 0.3 |

| P2 | 0.25 | 0.27 | 0.31 | 0.25 | 0.14 | 0.32 | 0.23 | 0.31 | 0.27 | 0.13 | 0.32 | 0.23 |

| P3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| P4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| D1 | 0.15 | 0.16 | 0.67 | 0.12 | −0.32 | 0.49 | 0.08 | 0.5 | 0.09 | −0.16 | 0.5 | 0.07 |

| D2 | 0.75 | 0.75 | 0.75 | 0.75 | 0.75 | 1 | 0.75 | 1 | 1 | 0.5 | 1 | 0.75 |

| D3 | 0.75 | 0.91 | 0.67 | 0.75 | 0.36 | 0.75 | 0.75 | 0.75 | 0.91 | 0.25 | 0.67 | 0.75 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 0.75 | 0.75 | 0.5 | 1 | 1 | 1 | 0.75 | 1 | 1 | 0.75 | 0.75 | 0.75 |

| E1 | 0.7 | 0.76 | 0.84 | 0.85 | 0.6 | 0.9 | 0.86 | 0.91 | 0.9 | 0.54 | 0.9 | 0.81 |

| E2 | 0.33 | 1 | 0.33 | 0.33 | 1 | 0 | 0.33 | 0 | 0 | 1 | 0 | 0.33 |

| E3 | 0.79 | 0.79 | 0.93 | 0.77 | 0.81 | 0.84 | 0.91 | 0.87 | 0.8 | 0.43 | 0.85 | 0.84 |

| E4 | 0.63 | 0.65 | 0.81 | 0.87 | 0.45 | 0.85 | 0.72 | 0.88 | 0.82 | 0.72 | 0.88 | 0.75 |

| Performance | 0.5 | 0.5 | 0.75 | 0.75 | 0.25 | 1 | 0.75 | 1 | 1 | 0.25 | 1 | 0.75 |

| 2015 | ||||||||||||

| C1 | 0.75 | 1 | 1 | 0.75 | 1 | 1 | 0.75 | 1 | 1 | 1 | 1 | 0.75 |

| C2 | 0.8 | 0.6 | 0.77 | 0.59 | 0.65 | 0.82 | 0.7 | 0.7 | 0.82 | 0.54 | 0.81 | 0.72 |

| F1 | 0.52 | 0.42 | 0.42 | 0.42 | 0.56 | 0.51 | 0.43 | 0.46 | 0.51 | 0.43 | 0.5 | 0.47 |

| F2 | 0.33 | 0.22 | 0.26 | 0.22 | 0.25 | 0.31 | 0.25 | 0.28 | 0.32 | 0.23 | 0.29 | 0.3 |

| F3 | 0.4 | 0.6 | 0.6 | 0.6 | 0.6 | 0.6 | 0.8 | 0.8 | 0.6 | 0.4 | 0.6 | 0.8 |

| P1 | 0.7 | 0.3 | 0.5 | 0.3 | 0.5 | 0.6 | 0.5 | 0.5 | 0.5 | 0.4 | 0.7 | 0.5 |

| P2 | 0.3 | 0.15 | 0.25 | 0.1 | 0.15 | 0.3 | 0.25 | 0.25 | 0.25 | 0.1 | 0.3 | 0.2 |

| P3 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| P4 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| D1 | 0.66 | −0.32 | 0 | −0.28 | −0.16 | −0.08 | 0.16 | 0.14 | 0.1 | −0.17 | 0.49 | 0.09 |

| D2 | 0.75 | 1 | 0.75 | 1 | 1 | 1 | 0.75 | 0.75 | 1 | 0.75 | 1 | 1 |

| D3 | 0.75 | 0.25 | 0.08 | 0.08 | 0.08 | 0.58 | 0.75 | 0.67 | 0.75 | 0.08 | 0.75 | 0.67 |

| S1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 | 1 |

| S2 | 0.75 | 1 | 0.5 | 1 | 1 | 0.75 | 0.75 | 1 | 1 | 0.75 | 1 | 1 |

| E1 | 0.85 | 0.53 | 0.72 | 0.53 | 0.7 | 0.84 | 0.74 | 0.86 | 0.93 | 0.57 | 0.93 | 0.83 |

| E2 | 0.33 | 1 | 0.33 | 1 | 0.67 | 0.33 | 0.67 | 0.33 | 0 | 1 | 0 | 0.33 |

| E3 | 0.95 | 0.83 | 0.52 | 0.63 | 0.67 | 0.34 | 0.84 | 0.76 | 0.83 | 0.47 | 0.83 | 0.93 |

| E4 | 0.85 | 0.43 | 0.62 | 0.83 | 0.77 | 0.74 | 0.64 | 0.86 | 0.89 | 0.77 | 0.86 | 0.73 |

| Performance | 0.75 | 0.25 | 0.5 | 0.25 | 0.5 | 0.75 | 0.5 | 0.75 | 1 | 0.25 | 1 | 0.75 |

| Methods | BP Neural Network Algorithm | LMBP Neural Network Algorithm | RS-GA-LMBP Neural Network Algorithm |

|---|---|---|---|

| Standard MSE | 0.01 | 0.01 | 0.01 |

| Iteration number | 20 | 9 | 4 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, P.; Yi, S. New Algorithm for Evaluating the Green Supply Chain Performance in an Uncertain Environment. Sustainability 2016, 8, 960. https://doi.org/10.3390/su8100960

Liu P, Yi S. New Algorithm for Evaluating the Green Supply Chain Performance in an Uncertain Environment. Sustainability. 2016; 8(10):960. https://doi.org/10.3390/su8100960

Chicago/Turabian StyleLiu, Pan, and Shuping Yi. 2016. "New Algorithm for Evaluating the Green Supply Chain Performance in an Uncertain Environment" Sustainability 8, no. 10: 960. https://doi.org/10.3390/su8100960