1. Introduction

Buildings generate a high amount of impacts throughout their life cycles. The construction of buildings promotes modification of landscape and consumption of natural resources, while during their use phase, there is high utilization of energy and their demolition generates elevated volumes of waste [

1,

2,

3]. Further, the impacts relating to processes for manufacturing and distribution supply chain of products and by-products are part of the life cycle of buildings and are incorporated into the total load of the building. Thereby, the buildings must be assessed in their completeness aiming at improved processes, technologies and management that reduce their environmental load.

The life cycle impacts of buildings can vary radically and these should be studied on a case-by-case basis. Energy consumption in the use phase of buildings [

4] makes this stage the most impactful of the of the building’s life cycle. However, the consumption of oil products, coal, electricity and natural gas in natural resource extraction, the production and assembly of materials, demolition, and transportation of materials and staff add to the energy impacts of buildings [

5].

Therefore, we must pay attention cases where material transport can also be very harmful in terms of use of fossil fuels. The burning of fuel releases toxic gases into the atmosphere, and which are major contributors to global warming.

Life Cycle Assessment (LCA) is a methodology for Environmental Impact Assessment that evaluates and compares environmental load in products and services. LCA studies investigate the mass balance between processes and sub-processes in a fragmented way to ascertain the inputs, outputs and emissions, thus being able to model the system and provide a full overview of the life cycle of services and products.

LCA has been used in the construction sector to assess trends and identify potential environmental impacts [

6,

7], assisting stakeholders in making decisions about planning, design, and management in future ventures [

5,

8,

9].

This article applies LCA thinking to assess the life cycle of two building systems for internal walls, masonry and drywall in a Brazilian construction in order to get an overview of the requirements for the life of the building and the products it generated.

2. Methodology

Internal wall systems are analyzed in a qualitative life cycle inventory based on academic literature and technical reports. Data related to all life cycle phases of the systems are obtained in specific literature and compiled in process-inputs-outputs tables. Based on the locations of potential suppliers, distances travelled for the transportation of materials to the construction site are measured and are modelled in material flow charts.

For the analysis of climate change impacts generated by transport systems, the distances travelled by the materials were estimated and types of vehicles were checked on the basis of academic literature and technical reports. The distances are adopted based on the median of the distances between possible extractive companies, manufacturing, materials distribution, construction and landfill. The calculations are based on data selected in the international EcoInvent database that best represent the characteristics of the case study. The method applied is the IPCC2013 with global warming factor temperature for one hundred years.

2.1. Life Cycle Assessment (LCA)

The LCA methodology is guided by own standards [

10,

11] and is employed to identify environmental impacts throughout the cycle of a system investigated [

12,

13]. This series of standards suggests that LCA studies must include four phases: definition of goal and scope, Life Cycle Inventory (LCI), Life Cycle Impact Assessment (LCIA) and Interpretation. The definition of goal and scope defines parameters and limits for the study, LCI reveals information about input and output of processes, LCIA measures impacts in damage categories and Interpretation is present in all phases and affects the selection of data [

10,

11,

14]. The LCA was adapted to also analyze costs, using the approach Life Cycle Cost (LCC), and the social impacts related to the life cycle, covering the social and socio-economic aspects, were measured using the approach Social Life Cycle Assessment (SLCA) [

15]. Moreover, these approaches were applied along with other methodologies, adapting to the purpose and scope of the studies. Halog and Manik proposed an LCA thinking method merging the approaches LCA, LCC, and SLCA plus dynamic system models for multi-criteria in order to analyze the production chain of biodiesel [

16].

LCA works with different indicators of impacts, which are applicable to achieve different targets, among them, enhance the building sector and its supply chains. Khasreen, Banfill, and Menzies published in 2009 a review about LCA of the building sector elaborated during the 15 years prior, in Europe and United States of America [

17].

Moreover, LCA thinking is a term used by the Society of Environmental Toxicology and Chemistry (SETAC) representing a simple and conceptual process for analyzing the entire life cycle of a product to identify avoidable environmental impacts [

18,

19,

20,

21,

22,

23,

24,

25].

2.2. IPCC2013

The IPCC2013 [

26] is a method created by the Intergovernmental Panel on Climate Change to assess the global warming factors temperature (GWT ) for Carbon Foot printing for 20, 100 and 500 year-term horizons. This method of midpoint is also called “impact- oriented”;

i.e., oriented to impact damage. The IPCC2013 replaces the IPCC in 2007, changing the values for Methane (CH

4) and Nitrous Oxide (N

2O), which are of utmost importance in the industrial sector and agriculture [

27].

2.3. Objective and Scope

This study seeks to evaluate masonry and drywall systems as internal walls through a qualitative Life Cycle Inventory, in order to get an overview of the requirements for the life of buildings and the products it generates. Also, it validates the impacts of climatic change on the transport of materials using a study on Life Cycle Impact Assessment of transportation.

The case study is a dwelling in Rio de Janeiro, Brazil. This evaluation covers the entire life cycle of the building, using a “cradle to grave” approach. This inquiry is theoretical and descriptive giving an overview of these systems’ life cycle.

The study of Life Cycle Impact Assessment seeks to assess environmental impacts of climate change in relation to the transport of materials between locations of the main processes involved in the system life cycle: extraction of natural resources and processing or beneficiation, marketing, construction, demolition, disposal and recycling. The functional unit is the internal partition house walls, which represents 115 m2 of inner walls in length vs. height. The boundary of the study excludes lifecycle refurbishments and possible expansions.

Distances for cement, aggregates and waste for these construction materials presented here are taken from a published paper [

28] where we estimate life cycle impacts relating to masonry in the same region.

In order to minimize uncertainty from lack of data, losses of material during the processes are disregarded. We consider actual material effectively transformed into walls.

3. Inquiry into Systems’ Life Cycle

We have identified the flows and processes specific for each construction system, evaluated each step of the building life cycle, and have commented on the weakness of the construction system aforementioned.

3.1. The Building

The object of this study is the main floor of a single-family home, located in Rio de Janeiro, Brazil. The building is built with reinforced concrete structure, lattice slab (floor and ceiling), pillars and beams cast on site, with vertical enclosure in non-structural masonry (brick and mortar ceramic bored grout). The walls received a covering of mortars made manually as typical in Brazilian small constructions.

3.2. Construction Systems

The combination of reinforced concrete cast on site with enclosure by non-structural masonry brick and mortar is the predominant building system in Brazil, especially in residential dwellings. While a drywall system has been used in the residential sector, there has been yet little uptake of this approach in the industry.

The masonry system applied in small constructions is a handmade process. It affords errors of proportions in the mixture of materials, walls out of plumb and construction problems that will appear in the use phase. Thereby, waste in construction is estimated to represent about 18% of mortar and 21% of ceramic bricks [

29]. The inputs for masonry construction are ceramic brick, sand, cement and lime which are composed of non-renewable materials, that are abundant in Brazil and produced regionally [

30] in medium and small companies located near the construction site.

The processes of preparing primary materials require the combustion of firewood for burning in brick production and are not standardized [

30]. Fossil fuel consumption for transportation tends to be small, due to the short transport distances of transport between extraction/manufacturing, and construction sites. Moreover, emissions of greenhouse gas tend to be high due to losses in production, transport of materials and storage due to lack of proper packaging.

Drywall is a modular and lightweight system that offers fast execution. Otherwise, it requires skilled labor for design, specification and installation, and as such, losses of materials during its assembly represent only 5% of total required material for construction. Drywall system materials are galvanized steel, drywall and mineral wool.

3.3. Masonry System

3.3.1. Pre-Construction Phase

Table 1 describes specific features of this phase and present the production sequence phases allowing a better comprehension of the whole process.

Table 1.

Pre-construction phase of the masonry system. Sources [

30,

31,

32,

33,

34,

35,

36].

Table 1.

Pre-construction phase of the masonry system. Sources [30,31,32,33,34,35,36].

| Main process | Cement production |

| Processes | Limestone and clay extraction of, crushing, mixing with clay, grinding, raw, cooking, grinding cement, packaging cement and trade. |

| Inputs | Limestone, clay, plaster (can be used recycled gypsum), additives, bags and wood pallets, explosives, water, electricity, diesel and woodchips (residual material of the furniture industry). |

| Outputs | Particulates, greenhouse gas (GHG) emissions, and possible contamination water resource. |

| Transport/Distances/Vehicle | From extraction to production/disregarded/truck. |

| From production to market/40 km/truck. |

| From market to construction site/10 km/truck. |

| Notes | Cement industry in Brazil uses filters to collect waste and reuse them in production. The reduction in additives use and in gases emissions contribute to the preservation of natural resources and help to save energy. |

| | Water used in most cement factories (in cooling towers and injection in the mills for cooling the material) is nearly completely reused [

30]. The water waste generation is not significant in cement industry. |

| Main process | Hydrated lime production |

| Processes | Limestone extraction, crushing, grinding and hydration. |

| Inputs | Limestone, clay, explosives and water. |

| Outputs | Particulate and GHG emissions and possible contaminate of water resources. |

| Transport/Distances/Vehicle | From extraction to processing and production/disregarded/truck. |

| From production to market:/40 km/truck. |

| From market to construction site/10 km/truck. |

| Note | Packages are disregarded. |

| Main process | Sand processing |

| Processes | Suction, screening, washing, sorting grading and drying. |

| Inputs | Sand, water, diesel and electricity. |

| Outputs | GHG emissions. |

| Transport/Distances/Vehicle | From extraction to processing/0 km. |

| From processing to construction site/50 km/truck. |

| Note | Packages are disregarded. |

| Main process | Brick production |

| Processes | Clay extraction, preparation of the dough, moulding, drying, baking; palletizing brick and market; |

| Inputs | Soft clay, hard clay, plastic film, diesel, electricity and wood. |

| Outputs | Particulate and GHG emissions, losses of brick and losses of wood. |

| Transport/Distances/Vehicle | From extraction to production/disregarded. |

| From production to market/40 km/truck |

| From market to construction site (or edification in reform)/10 km/truck |

| Notes | Packages are disregarded. Small and medium sized potteries usually carry the bricks directly on trucks without packaging. |

This research highlights the importance of extraction of non-renewable mineral resources for all inputs and the use of firewood for the kilns to produce bricks. The cement industry has shown environmental concern and uses proper tools to minimize environmental impacts in their production. In masonry construction, mortars are produced at the jobsite without following any particular pattern in implementation, and after execution, brick walls are trimmed to make installations, which leads to a high loss rate of materials at the construction site.

3.3.2. Construction

The construction phase comprises assembly of the walls and preparation for the specific coating. Walls in wet areas such as kitchens, bathrooms and the laundry area receive ceramic finishes, while the other rooms are painted.

Table 2 describes specific features of this phase.

Table 2.

Construction phase of the masonry system. Source [

37].

Table 2.

Construction phase of the masonry system. Source [37].

| Main process | Masonry wall construction |

|---|

| Processes | Laying brick with mortar, painting and application of ceramic products. |

| Inputs | Bricks, cement, lime, sand (fine, medium and coarse), water (preparation of the mortar and cleaning tools), diesel, materials for paint finishing: sandpaper, sealer, paint, paint remover, and materials for application of ceramic: adhesive and ceramics. |

| Outputs | Waste of bricks, cement, lime, sand and packaging, waste of painting: sandpaper, sealer, paint, paint remover, packaging, and waste of ceramic application: adhesive, ceramics, packaging, emissions in waste water (cleaning) and particulate. |

| Transport/Distances/Vehicle | Material transport to the building site is considered in the pre-construction phase. |

| Notes | Wall construction is manual. Mixing of materials and assembly occur on site, under the guidance of the architect/builder. |

3.3.3. Maintenance/Reforms/Refurbishment

Table 3 describes specific features of this phase.

Table 3.

Maintenance/Reforms/Refurbishment phase of the masonry system. Source [

37].

Table 3.

Maintenance/Reforms/Refurbishment phase of the masonry system. Source [37].

| Main process | Masonry wall Maintenance/Reforms/Refurbishment |

|---|

| Processes | Partial demolition, laying brick with mortar, paint, ceramic application. |

| Inputs | Bricks, cement, lime, sand, water (preparation of the mortar and cleaning tools), diesel, painting materials: sandpaper, sealer, paint and paint remover.

Ceramic application materials: adhesive and ceramics. |

| Outputs | Waste of bricks, cement, lime, sand and packaging, waste of painting: sandpaper, sealer, paint, paint remover, packaging, waste of application ceramic: adhesive, ceramics, packaging, emissions in waste water (cleaning) and particulate. |

| Transport/Distances/Vehicle: | Material transport to the building site is considered in the pre-construction phase. |

| Notes | Wall construction is manual. The mix of materials and assembly occur on site, under the guidance of the architect/builder. |

The processes of opening gaps in the walls for maintenance, the removal of coatings for the substitution of new materials and demolishing walls during refurbishment generate and emit noise and dust which spreads into the air.

3.3.4. Demolition and Disposal/Recycling (end of life)

In Brazil, construction and demolition waste are not commonly treated and most of this waste is dumped into landfills that does not receive treatment to prevent contamination of the soil, air or groundwater.

Table 4 describes specific features of this phase.

Table 4.

End of life phase of the masonry system. Source: [

37,

38,

39,

40].

Table 4.

End of life phase of the masonry system. Source: [37,38,39,40].

| Main process | Demolition |

| Processes | Manual masonry wall dismantling |

| Inputs | Masonry and diesel |

| Outputs | Debris |

| Transport/Distances/Vehicle | - |

| Note | Manual dismantling without the use of machines. |

| Main process | Disposal in landfill |

| Processes | Displacement |

| Inputs | Debris and diesel. |

| Outputs | Mixed waste and contaminated waste |

| Transport/Distances/Vehicle | From demolition site to landfill/30 km/truck. |

| Note | Landfill unprepared to deal with construction waste. |

| Main process | Recycling |

| Processes | Separation of undesirable materials, crushing, screening and storage. |

| Inputs | Debris and diesel. |

| Outputs | Recycled aggregates and emissions: noise and effluent liquids (cleaning), particulate and GHG. |

| Transport/Distances/Vehicle | From demolition site to recycling area/30 km/truck. |

| Note | The transport from recycling area to next construction is disregarded. |

Recycling of waste from demolition of this type of building is unusual in this region. However, this is a possible solution and it should now be adopted more frequently due to the prior implementation of a new policy on solid waste.

3.4. Drywall System

A Brazilian performance standard, ABNT NBR 15575, suggests a 20-year lifespan [

41] and five-year warranty for interior walls [

42], regardless of the material used. In addition, the literature suggests that there is about 1% to 3% of waste during extraction of raw materials for drywall production, as well as about 5% to 12% of waste in system assembly into construction sites [

43] and a further 10% during manufacturing of steel supporting structures [

29]. Therefore, a building will probably undergo four major renovations, on average, over its lifetime.

3.4.1. Pre-Construction Phase

Only a few multinational companies control the majority of the consumer market of this construction system. They also produce the mineral wool, the paperboard and the additives used in drywall production. They do not disclose details of these processes. This leads to gaps in this research.

Table 5 describes specific features of this phase.

Table 5.

Pre-construction phase of the drywall system. Sources [

43,

44,

45,

46,

47].

Table 5.

Pre-construction phase of the drywall system. Sources [43,44,45,46,47].

| Main process | Plaster production |

| Processes | Gypsum extraction, crushing, grinding, roasting and packaging. |

| Inputs | Gypsum, diesel, electricity and firewood |

| Outputs | Plaster, particulate and GHG emissions. |

| Transport/Distances/Vehicle | From Gypsum extraction to Processing and production of primary products: disregarded. |

| From Processing and production of primary products to Manufacturing plasterboard/2200 km/truck. |

| Note | Plaster is carried by long distance between the pole of Araripe plasterer in North-eastern Brazil and drywall manufacturing plants in the southeast of the country. |

| Main process | Galvanized steel |

| Processes | Extraction of Iron Ore, sinter, pellet, stockpiling, homogenization, reduction, refining, rolling and galvanizing. |

| Inputs | Iron ore, coal, lime, (pellet), pig iron, scrap, zinc, explosives, water, coal or gas, diesel, electricity, gas produced in reduction |

| Outputs | Galvanized steel, Particulate and GHG emissions, with possibility of contamination of water resources. |

| Transport/Distances/Vehicle | From Iron ore extraction to Processing/production of primary products/disregarded/train. |

| From Processing to production of primary products and Manufacturing plasterboard/disregarded/truck. |

| From production to construction site/80 km/truck. |

| Note | One of the few materials that are widely recycled in this country is the material from ferrous metals. Scrap this material is reinserted in the production chain. |

| Main process: | Cardboard and additives |

| Processes: | Importation |

| Inputs: | Cardboard and additives and diesel |

| Outputs: | Cardboard, additives ,GHG emissions |

| Transport/Distances/Vehicle | From extraction of raw materials and Processing and Production of primary products/distances and vehicle not found. |

| From Processing and production of primary products and manufacturing/distances and vehicle not found. |

| From manufacturing and port of Santos seaport, in São Paulo/distance not found/ship. |

| From Santos seaport and construction site/460 km/truck. |

| Note | The products come to Brazil by ship and are transported by truck to the manufacturing plant. |

| Main process | Drywall |

| Processes | Mix of inputs, plaque formation, cutting, drying and packaging. |

| Inputs | Gypsum, cardboard, additives, water, mixer, trainer edge, forming table, guillotine, continuous dryer, palletizer, forklift. Diesel, electricity. |

| Outputs | Drywall, particulate emissions and GHG |

| Transport/Distances/Vehicle | From production to construction site: 80 km—Truck |

| Note | Here the inputs gypsum, additives and cardboard are used for the drywall production. |

3.4.2. Construction

Drywall is a system that requires skilled labor for assembly. Consequently, this results in the shortest execution time and low index of waste.

Table 6 describes specific features of this phase.

Table 6.

Construction phase of the drywall system. Source [

45,

48,

49].

Table 6.

Construction phase of the drywall system. Source [45,48,49].

| Main process | Drywall construction |

|---|

| Processes | Mounting drywall, painting and application of ceramic. |

| Inputs | Drywall, profiles and amounts of galvanized steel, screws, punched paper tape, mineral wool, acoustic tape, drywall mud, water (cleaning tools) and diesel. |

| Painting materials: sandpaper, sealer, paint and paint remover |

| Ceramic materials: adhesive and ceramic. |

| Outputs | Drywall, remains of materials and packaging |

| Paint waste: remnants of sandpaper, sealer, paint, paint remover and packaging. |

| Ceramic waste: remains adhesive, ceramics, packaging. |

| Emissions: water waste (cleaning) and particulate. |

| Transport/Distances/Vehicle | From plasterboard manufacturing to construction/80 km/truck |

| Note | The process of assembly requires skilled labor and requires one quarter of the time of the execution of masonry. |

3.4.3. Maintenance/Reforms/Refurbishment

Like the masonry system, a building using the drywall system will also undergo four major renovations, on average, over its lifetime. Twenty years of useful life and reforms every five years are assumed.

Table 7 describes specific features of this phase.

Table 7.

Maintenance/Reforms/Refurbishment phase of the drywall system. Source [

45,

48,

49].

Table 7.

Maintenance/Reforms/Refurbishment phase of the drywall system. Source [45,48,49].

| Main process | Drywall construction |

|---|

| Processes | Mounting drywall, painting and application of ceramic. |

| Inputs | Drywall, profiles and amounts of galvanized steel, screws, punched paper tape, mineral wool, acoustic tape, drywall mud, water (cleaning tools) and diesel. |

| Painting materials: sandpaper, sealer, paint and paint remover |

| Ceramic materials: adhesive and ceramic. |

| Outputs | Drywall, remains of materials and packaging |

| Paint waste: remnants of sandpaper, sealer, paint, paint remover and packaging. |

| Ceramic waste: remains adhesive, ceramics, packaging. |

| Emissions: water waste (cleaning) and particulate. |

| Transport/Distances/Vehicle | From plasterboard manufacturing to construction/80 km/truck |

| Note | The process of assembly requires skilled labor and requires one quarter of the time of the execution of masonry. |

3.4.4. Demolition and Disposal/Recycling (End of Life)

The Brazilian Drywall Association recommends that waste from the drywall installation and demolition should be sent to special triage and temporary storage areas. After that, the sorted material is sent for production of cement and plaster or to the agro-industry. However, only a small portion of the overall waste is recycled and reused.

Waste gypsum from drywall demolition emits toxic dust. When dumped in landfills, this may pollute the groundwater. Bacterial action can form hydrogen sulphide (H

2S) which poses risks to human health [

46]. To avoid contamination, the drywall companies and the Brazilian Drywall Association suggest that screening and handling represent adequate treatment. At this time, such care is not taken in the Brazilian construction, where the Construction and Demolition Waste (CDW) is mixed and dumped into landfills without proper treatment [

50].

Table 8 describes specific features of this phase system.

Table 8.

End of life phase of the drywall system. Source [

38,

39,

43,

50].

Table 8.

End of life phase of the drywall system. Source [38,39,43,50].

| Main process | Demolition |

| Processes | Dismantling, |

| Inputs | Drywall |

| Outputs | Drywall waste, emissions: noise and effluent liquids (cleaning), particulate, GHG, asbestos present in some drywall muds. |

| Transport/Distances/Vehicle | - |

| Note | The dismantling is done without care to avoid contamination other waste and health impacts of professionals. |

| Main process | Disposal in landfill |

| Processes | Displacement |

| Inputs | Drywall debris and diesel. |

| Outputs | Contaminated mixed waste for recycling steel (scrap) and gypsum product |

| Emissions: noise and effluent liquids (cleaning), particulate, GHG. |

| Transport/Distances/Vehicle | From construction site (or edification in reform) to landfill/30 km/truck. |

| Note | The landfill has no treatment necessary to prevent contamination of soil and air. |

| Main process | Recycling |

| Processes | Disposal at recycling plant |

| Inputs | Drywall debris, diesel |

| Outputs | Recycling steel (scrap), gypsum product, emissions: particulate, GHG. |

| Transport/Distances/Vehicle | From construction site (or edification in reform) to recycling area/30 km/truck. |

| Note | Rest of galvanized steel (scrap) is reused in steel. |

| Recycled lime is Input for use in cement and agriculture. Lime is not the same as gypsum. |

3.4.5. Life Cycle Impacts Analysis of Transports

Analysis of material flows estimates the distance traveled from extractive mines in the country to possible construction materials suppliers, bearing in mind an optimistic logistics scenario in the use of resources. Plaster is gypsum mined in the northeastern region and is transported to the southeast (São Paulo) where the drywall boards are produced and stored. Iron ore is mined and steel is produced by the same company in Minas Gerais. The cardboard is imported and comes from the port of Santos to the construction site. On the other hand, extraction, processing and production of materials for masonry tend to be regionally located and travel short paths. Thus, the survey showed wide discrepancies between the distances traveled for the different drywall materials. These data are the basis for the study of LCIA for the transport of materials. Considering the amount of materials needed for construction and demolition waste generated from the materials, drywall waste travels 3427.8 km while the masonry travels only 246.9 km.

Table 9 shows the distances traveled by the component materials of the systems and their waste.

Table 9.

Distance travelled by material.

Table 9.

Distance travelled by material.

| | | Distances (km) |

| Masonry | Materials | to trade | to site | to landfill |

| Sand | 30.0 | 15.9 | - |

| Hydrated lime | 40.0 | 18.8 | - |

| Cement | 40.0 | 17.0 | - |

| Brick | 40.0 | 34.0 | - |

| Waste | - | - | 11.2 |

| | | Distances (km) |

| Drywall | Materials | to trade | to site | to landfill |

| Cardboard | 460.0 | 392.0 | - |

| Plaster | 2,200.0 | 80.0 | - |

| Steel | 270.0 | 14.6 | - |

| Waste | - | - | 11.2 |

The Brazilian scenario for materials transportation is predominantly highways, which cover a large area [

51]. As there were no distance data for travel by train for the cement or travel by ship for the import of cardboard, these vehicles were excluded.

Table 10.

Vehicle used.

| | Vehicle |

|---|

| Materials | To manufacturing | To Trade | To site | To landfill |

| Sand | Lorry | Lorry | Lorry | - |

| Hydrated lime | Lorry | Lorry | Lorry | - |

| Cement | Train and Lorry | Lorry | Lorry | - |

| Cardboard | Ship + Lorry | Lorry | Lorry | |

| Steel | Lorry | Lorry | Lorry | - |

| Plaster | Lorry | Lorry | Lorry | - |

| Waste | - | - | - | Lorry |

The transportation dataset is prepared for to the EcoInvent database references that best fit the Brazilian scenario.

Table 11 shows selected references, the method used and the values of climate change impacts IPCC2013 for 100 years.

Table 11.

EcoInvent references.

Table 11.

EcoInvent references.

| Dataset Information (LCIA) | | |

|---|

| Reference | Method | Climate Change (kg CO2-Eq) |

|---|

| transport, freight, lorry, unspecified [metric ton × km], RoW | IPCC—GWP 100a | 0.11946 |

| transport, freight, lorry > 32 metric ton, EURO4, RoW | IPCC—GWP 100a | 0.07592 |

The first truck, which is smaller and more polluting, was applied to masonry materials and waste. The second truck with higher capacity to transport bulk material and has better performance was applied to drywall.

The estimated consumption of materials for the construction of masonry walls is 5.6 tons of material [

28] and for drywall walls it is 1.6 tons of material.

Table 9 shows in detail the consumption of the component materials of the systems for 115 m

2 of internal walls.

Table 12.

Material consumption of the systems.

Table 12.

Material consumption of the systems.

| Material consumption in 115 m2 |

|---|

| Masonry | |

| Materials | Weight (kg) |

| Sand | 4376.03 |

| Lime | 2185.69 |

| Cement | 772.21 |

| Hollow brick (9 × 19 × 29 cm) | 5688.57 |

| Total | 5688.57 |

| Note: brick weight 3.10 kg/un | |

| Drywall | |

| Materials | Weight (kg) |

| Cardboard | 34.50 |

| Plaster | 977.50 |

| Steel | 598.00 |

| Mineral wool | 805.00 |

| Total | 1610.00 |

We calculated the transportation impacts related to each system by the sum of the impacts of their related component materials to the market. Where the material impacts are the multiplication of the mass of each material by IPCC 2013 transport factor of transport and the sum of distance traveled to the market. We calculate the waste impact on the landfill by multiplying the waste mass at IPCC 2013 transport factor and the distance to the landfill. The IPCC factor, the demand for transportation of material m and generation of waste w are given, having the following mathematical representation:

The impacts of IPCC factor on climate change on transportation of material

m and waste

w in each system are given by,

where:

Is(factor) = impact of transportation of material m and waste w in each inner wall system s in IPCC factor

Massw,s = mass of materials m in system s

IPCCt = indicator factor for transport t

Dw,l = distance traveled by the waste w between construction and landfill

Dm,m = distance traveled by the materials m between until the market

Dm,c = distance traveled by the materials m between the market and the construction

Table 13.

Climate change results.

Table 13.

Climate change results.

| | Climate change IPCC 2013 (kg CO2-Eq) | |

|---|

| Components of Systems | to de market | to the construction | to the landfill | total |

|---|

| Sand | 15.68 | 8.31 | | 23.99 |

| Lime | 10.44 | 4.91 | | 15.35 |

| Cement | 3.69 | 1.57 | | 5.25 |

| Brick | 27.18 | 23.10 | | 50.29 |

| Material for Masonry | 56.99 | 37.89 | | 94.89 |

| Waste of Masonry | | | 17.35 | 17.35 |

| Cardboard | 0.71 | 0.04 | | 0.75 |

| Plaster | 180.64 | 29.09 | | 209.72 |

| Steel | 20.88 | 17.79 | | 38.68 |

| Material for Drywall | 202.22 | 46.92 | | 249.14 |

| Waste of Drywall | | | 3.22 | 3.22 |

Limitations of this transportation Life Cycle Impact Assessment are the lack of data and, hence, the omission of impacts related to mineral wool transportation, which is a drywall component. Also, impacts of rail and water transportation were not considered.

4. Models and Discussion

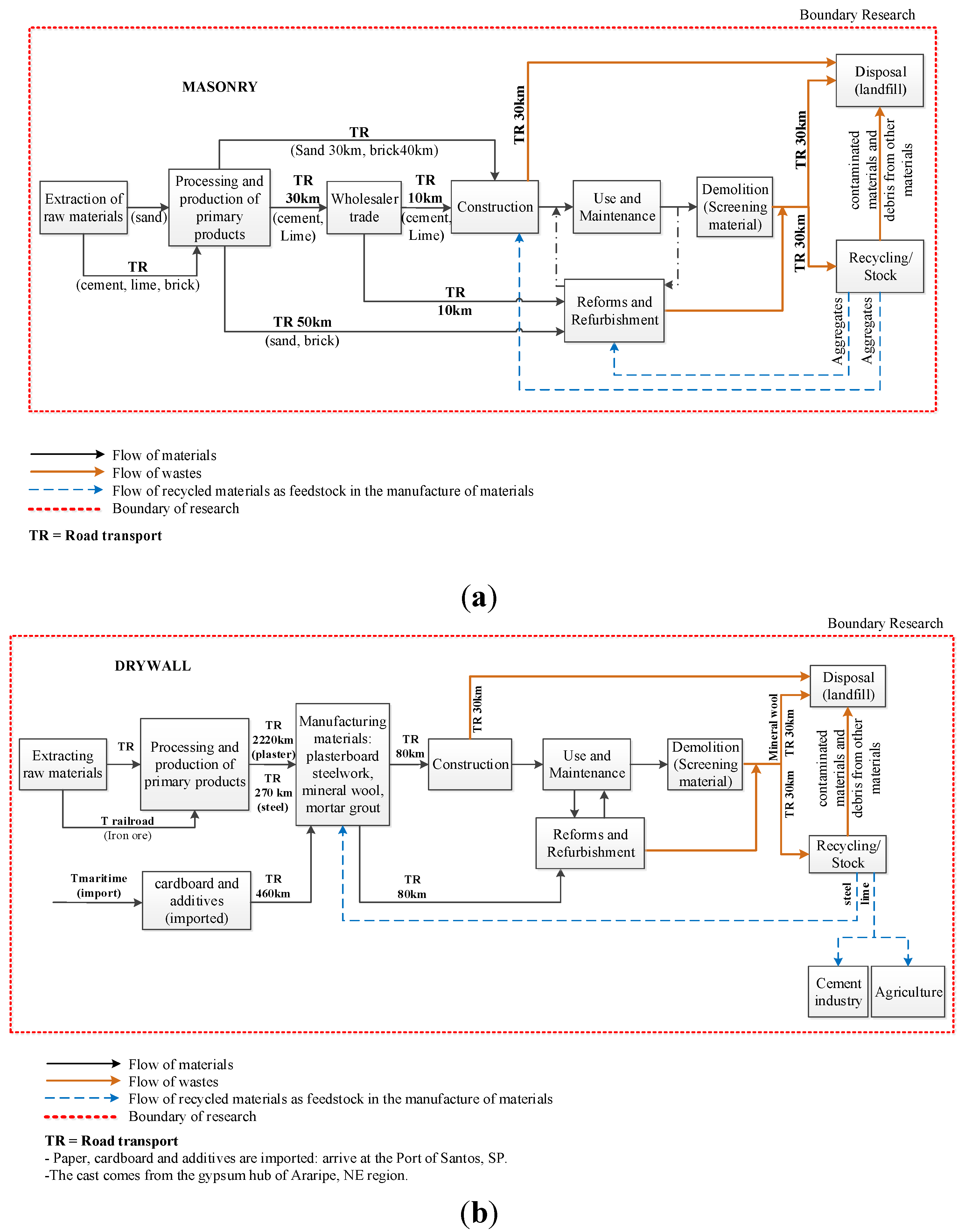

The flowchart in the

Figure 1a shows the main stages of production of masonry products, and identifies flows of materials, waste and recycled materials (as feedstock for the manufacture of materials), as well as kind of vehicle used to transport and the distance travelled, while the flowchart in

Figure 1b provides the input and output flow of the main stages of production of drywall. It identifies materials, waste and recycled materials (as feedstock for the manufacture of materials), the type of vehicles used in transportation and the distances travelled.

Figure 1.

(a) Material flows for masonry inner walls; (b) Material flows for drywall inner walls.

Figure 1.

(a) Material flows for masonry inner walls; (b) Material flows for drywall inner walls.

The flowchart of masonry system (

Figure 1a) shows that the inputs sand and brick are transported from the processing and production plant directly to the construction site by truck, as well as the transport of waste from construction site to landfill or recycling/stock. Thereat, the road transport generates impacts on the surrounding road network by circulating trucks, noise, and dust emissions into the air by wear of the asphalt. If recycled, these materials would have great potential as aggregate for new construction, mainly for pavement. However, even today, in Brazil, most of the residue of masonry construction is still dumped in landfills [

52].

The flowchart of a drywall (

Figure 1b) system shows that the cardboard and additives are imported. These materials arrive at the port of Santos in ships and are transported by truck to drywall manufacturing plants in the Southeast of Brazil. The gypsum is extracted and processed in the plasterer pole of Araripe in Northeastern Brazil and travels a long distance to the drywall manufacturing plants. Among the inputs, only the steel is recycled. Almost all the residue of this material is inserted through the steel industry as an input in production.

During the pre-construction of masonry system, there are high extraction of non-renewable minerals (clay and limestone) and the production of ceramic brick; plaster and lime tend to produce large CO2 emissions. In addition, masonry wall systems exhibit semi-artisanal production and little standardization in the pre-construction phase (extraction, processing and production of primary products), with large loss in production and transportation of products.

In the course of construction of masonry buildings, mortars are produced on site without following testing standards, which results in constructive errors with low-grade buildings. Standardizing the amount of inputs in the mix for sand, cement and lime mortar and the control of constructions by regulatory institutions can minimize these losses.

The use and maintenance phase of masonry building is long and fraught with uncertainty about possible renovations and refurbishments of architectural space and repairs or retrofits of installations. Literature indicates that, in the Brazilian context, there are high rates of exchange and substitution of materials works, which generates large amounts of masonry debris, particulate and noise.

The demolition work of masonry clearly generates large amounts of waste, and without protection, particulates and noise pollute the environment and disrupt workers and residents living around the construction site. In the current Brazilian scenario, the end of the life of masonry building represents a large amount of mixed CDW dumped in landfills, with low rates of waste recycled and reused as flooring. This debris may contain toxic materials that cause air pollution, releasing dust into the air. It may cause river and groundwater pollution by leaching and may cause soil contamination when dumped onto ground not properly protected.

During the pre-construction of drywall systems, the supply chain for the drywall by-products involves large distances travelled by road from the northeast to the southeast of the country (gypsum) and for importation of cardboard and additives from abroad by sea and road. Consequently, high hates of fossil are burned, which releases CO2 to the atmosphere and contributes to climate changes. The use of raw material in the production of gypsum drywall panels without introducing any recycled material relies on extraction of natural resources and contributes to the depletion of this resource.

In the course of the drywall construction phase, as well as during the use and maintenance phase, the assembly is fast and clean with low generation of waste during construction. However, this system requires planning and specialized workers for future modifications. If users and construction workers are not accustomed to this, it represents risks to the environment and human health, as well as financial loss.

At the end of the life of the building, in the current Brazilian scenario, drywall demolition waste is mixed with another CDW and dumped at unprepared landfills. The drywall waste contains toxic materials that may result in air pollution (by dust and H2S which is formed and released into the air), river and groundwater pollution (by leaching), and soil contamination. Already, the steel is recycled almost entirely, reintroducing the scrap material into the manufacturing process of new products.

Impacts of Building Material Transport

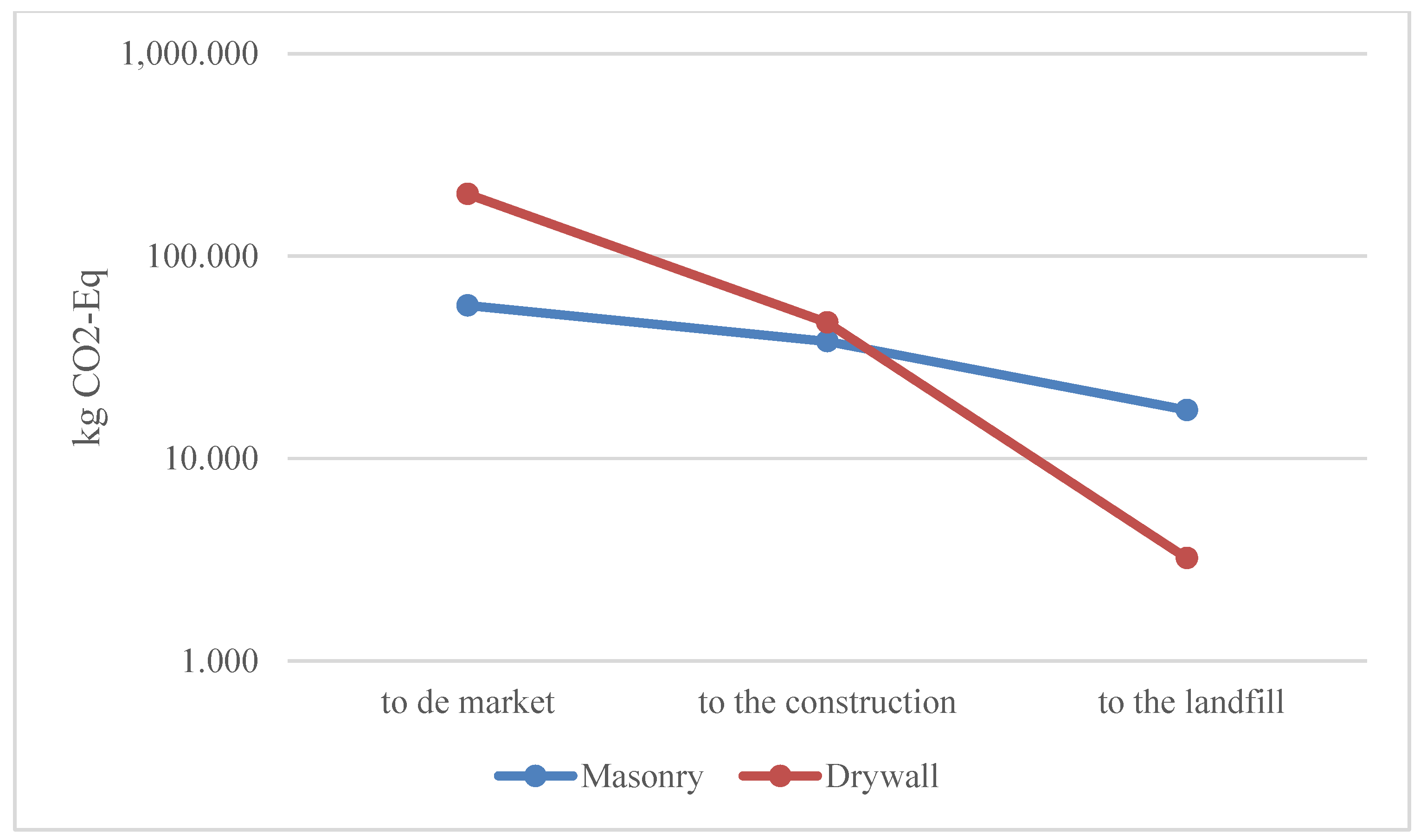

The total results are 112.23 kgCO2-Eq/115 m2 for masonry and 252.36 kgCO2-Eq/115 m2 for drywall, which represents 1.0 kgCO2-Eq/m2 of masonry and 2.2 kgCO2-Eq/m2 of drywall into one square meter of floor built.

The steel is extracted and produced in the same place since the drywall boards are extracted and produced by companies in the same region. Because of differences between extraction and production and the lack of information about distances of vehicles used between some short distances, we disregarded them. Thus, we grouped the transportation results into three categories: to the market, to the construction site, and to the landfill.

Figure 2 is the graph showing the climatic change impacts for masonry and drywall.

Figure 2.

Material flows for masonry inner walls.

Figure 2.

Material flows for masonry inner walls.

Transportation between extraction of natural resources, industry and the distributor market has much greater relevance than transportation to the construction site. Both systems followed the same pattern in the first two categories, differing only in impacts for transportation to the landfill. In this step, the drywall system has the advantage of producing a smaller volume of debris than masonry.

Impact of Material Components

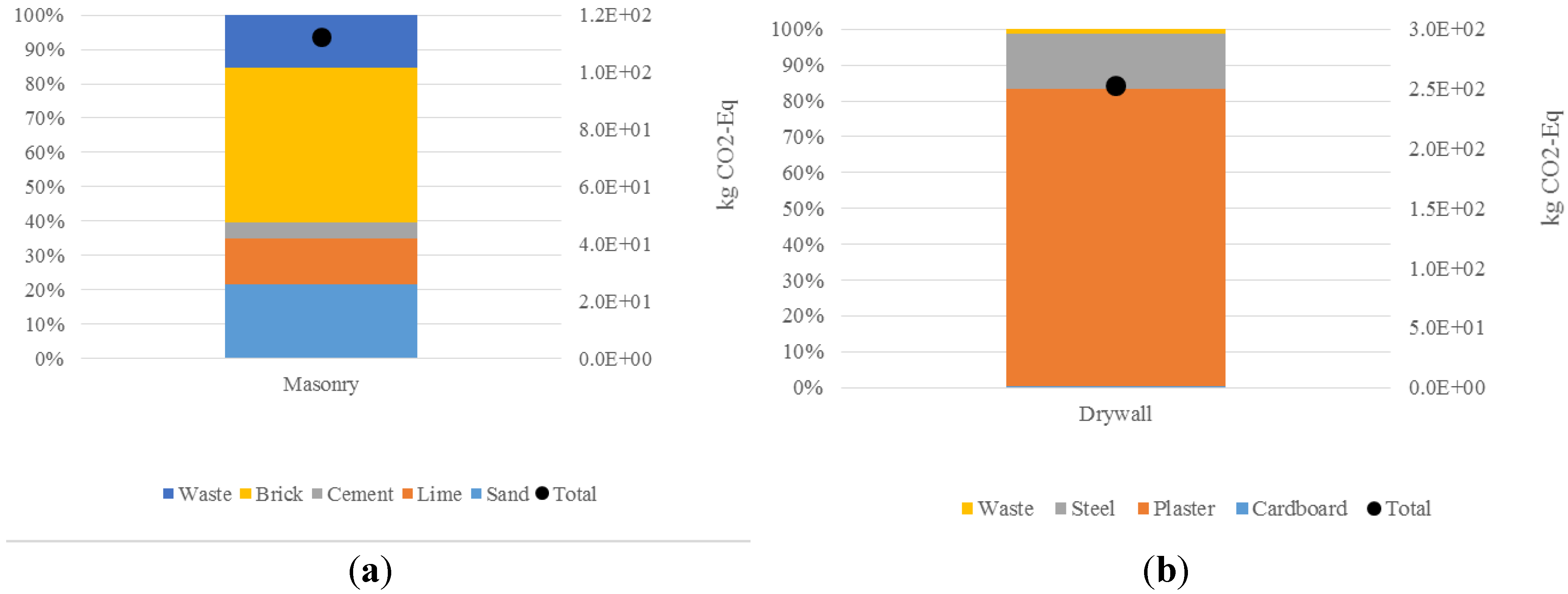

Figure 3a shows the percentage of the component materials and the full impact of climatic changes for the masonry, while

Figure 3b shows the same data for drywall.

Figure 3.

(a) Partial and total impacts of masonry; (b) Partial and total impacts of drywall.

Figure 3.

(a) Partial and total impacts of masonry; (b) Partial and total impacts of drywall.

Among components of masonry materials, brick has the greatest impact, with 50.29 kgCO2-Eq, followed by sand with 23.99 kgCO2-Eq, lime with 15.35 kgCO2-Eq, cement with 5.25 kgCO2-Eq and the residue with 17.35 kgCO2-Eq. Meanwhile, among the drywall components, plaster has 209.72 kgCO2-Eq, followed by steel with 38.68 kgCO2-Eq, cardboard 0.75 kgCO2-Eq, and residue with 3.22 kgCO2-Eq.

Even when not taking into consideration the calculations on impacts of mineral wool on the life cycle of the drywall transportation in Brazil, this system still has more than two times’ higher impact than the masonry, as most of the plaster transportation involves long distances to the end consumer. The impact of residue transportation is lower in drywall, which is a lighter system than the masonry, which produces a large volume of debris.

Therefore, LCIA results demonstrate the discrepancies in kgCO2-Eq emissions of drywall component materials in relation to masonry, thus proving the qualitative analysis of LCI that identified this weakness in drywall systems in the Brazilian scene.

In addition, material transportation affects not only emission of air contaminant gases, it generates noise and dust, as well as requiring maintenance of roads and increasing demand for transportation.

In order to mitigate the weaknesses of both systems and to increase the sustainability in the Brazilian context, we suggest some actions, such as:

Encourage domestic production of cardboard and additives for drywall;

Provide incentives for local companies producing ceramic bricks and hydrated lime to use industry standards and to pursue quality and maturity certifications;

Investment for freight transport less harmful to the environment;

Development of technologies to recycle drywall and masonry waste;

Development, application and oversight of planning to construction and CDW management.

5. Conclusions

This manuscript provides an overview of ceramic brick masonry and drywall systems as internal walls, according to a Life Cycle approach. It identified their processes, inputs and outputs; modeled the systems in terms of materials flows; and prepared a study of life cycle impact assessment for the transport of building materials, also looking at climatic changes.

Since drywall has recent application in residential buildings in the Brazilian context, we must evaluate this system and compare it with typical systems in Brazil, such as masonry.

The results highlight the greatest weakness of both construction systems for walls and suggestions for mitigation are put forward. The life cycle of masonry is shown to have a higher consumption of non-renewable resources and loss of materials due to lack of compliance during production of materials and construction and demolition stages. On the other hand, the drywall system has a dispersed supply chain dispersed with the use of imported materials and the requirement for material transport over long distances. In Brazil, this system is still not culturally accepted, and due to lack of understanding and poor design for loading, customers and construction workers do not use it efficiently, generating losses and contamination.

Therefore, both systems have weak points with room for improvement in terms of infrastructure, planning, and management. Thereby, while the production of by-products in the supply chain of masonry must be improved, the drywall supply chain must adjust its geographical and cultural aspects to minimize environmental impacts over its lifecycle, especially in terms of long distance material transportation.

The improvement of the weaknesses in the life cycle of both systems can reduce environmental load and, hence, sustainability. Therefore, this manuscript achieves its objective giving an overview of both systems in the Brazilian scenario. It can also assist in improving decision-making on technical choices in architectural planning, which can minimize the environmental loads of future ventures.