Identifying Critical Factors in the Eco-Efficiency of Remanufacturing Based on the Fuzzy DEMATEL Method

Abstract

:1. Introduction

2. Literature Review

2.1. Factors Influencing Remanufacturing

2.2. Evaluation on the Eco-Efficiency of Remanufacturing

2.3. The Application of DEMATEL Method in Identifying Important Factors

2.4. Gap Analysis and Research Highlights

3. Factors regarding the Eco-Efficiency of Remanufacturing

| Dimensions | Factors | Dimensions | Factors | |

|---|---|---|---|---|

| Internal factors | F1. Quantity of cores [9,10] | External factors | F10. Design for remanufacturing [16,21,30] | |

| F2. Quality of cores [8,16] | F11. OEMs information sharing [8,16,33] | |||

| F3. Recycling system [9,23] | F12. Policy guidance [8,10,19,21,34,35,36] | |||

| F4. Information system [9,16,22] | F13. Laws and regulations system [15,19,21,33] | |||

| F5. Quality management [10,28] | F14. Standards of remanufacturing industry [9,37] | |||

| F6. Pollution control [28] | F15. Social awareness of recycling and remanufacturing [8,21,22] | |||

| F7. Remanufacturing equipment [9,21] | ||||

| F8. Key remanufacturing technology [2,8,37] | ||||

| F9. Remanufacturing technology R&D [10,38] | ||||

| Economic benefits | G1. Cost saving [23,28,38,39] | Environmental benefits | G5. Emission reduction [14,15,25,26] | |

| G2. Remanufacturing profits [26,28] | G6. Compliance rate of waste discharge [40] | |||

| G3. Market occupancy [15,19,26] | G7. Recycle and reuse rate of end-of-life products [23,39] | |||

| G4. Green image of corporation [14,28] | G8. Resources conservation [15,27,38] | |||

| G9. Resource efficiency [28,38,40] | ||||

3.1. Factors Affecting the Eco-Efficiency of Remanufacturing

3.1.1. Internal Factors

3.1.2. External Factors

3.2. Indicators on Eco-Efficiency of Remanufacturing

3.2.1. Economic Benefits

3.2.2. Environmental Benefits

4. Application of the Fuzzy DEMATEL Method in the Eco-Efficiency of Remanufacturing

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 0 | 0 | 3 | 2 | 3 | 2 | 3 | 2 | 2 | 0 | 0 | 3 | 2 | 0 | 2 | 4 | 3 | 2 | 1 | 2 | 0 | 0 | 3 | 3 |

| F2 | 0 | 0 | 1 | 1 | 3 | 0 | 0 | 3 | 0 | 3 | 0 | 2 | 0 | 0 | 0 | 3 | 4 | 1 | 0 | 3 | 1 | 3 | 3 | 0 |

| F3 | 4 | 3 | 0 | 3 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 4 | 3 | 0 | 3 | 0 | 0 | 2 | 1 | 1 |

| F4 | 3 | 2 | 4 | 0 | 3 | 2 | 0 | 3 | 2 | 0 | 2 | 2 | 3 | 1 | 0 | 3 | 3 | 2 | 0 | 3 | 2 | 3 | 3 | 2 |

| F5 | 0 | 0 | 0 | 3 | 0 | 3 | 0 | 2 | 1 | 2 | 2 | 1 | 2 | 4 | 4 | 4 | 4 | 3 | 4 | 3 | 2 | 2 | 2 | 2 |

| F6 | 0 | 0 | 0 | 0 | 2 | 0 | 2 | 2 | 2 | 3 | 2 | 2 | 3 | 3 | 0 | 2 | 2 | 0 | 4 | 4 | 3 | 0 | 3 | 2 |

| F7 | 0 | 0 | 0 | 0 | 2 | 1 | 0 | 2 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 3 | 1 | 0 | 0 | 2 | 1 | 2 | 1 | 3 |

| F8 | 0 | 2 | 3 | 2 | 4 | 3 | 3 | 0 | 3 | 3 | 2 | 3 | 2 | 3 | 0 | 4 | 3 | 3 | 2 | 3 | 2 | 4 | 3 | 3 |

| F9 | 0 | 1 | 0 | 0 | 0 | 0 | 2 | 4 | 0 | 2 | 0 | 2 | 0 | 0 | 0 | 3 | 1 | 1 | 2 | 2 | 1 | 3 | 3 | 3 |

| F10 | 0 | 4 | 0 | 2 | 3 | 3 | 0 | 2 | 2 | 0 | 3 | 3 | 2 | 3 | 0 | 4 | 1 | 1 | 3 | 3 | 1 | 4 | 3 | 2 |

| F11 | 0 | 3 | 0 | 4 | 4 | 4 | 0 | 3 | 3 | 4 | 0 | 3 | 4 | 2 | 2 | 3 | 2 | 0 | 2 | 3 | 1 | 3 | 3 | 2 |

| F12 | 4 | 3 | 2 | 3 | 2 | 2 | 3 | 4 | 3 | 3 | 3 | 0 | 3 | 3 | 4 | 4 | 2 | 3 | 3 | 3 | 2 | 3 | 3 | 1 |

| F13 | 3 | 1 | 2 | 0 | 3 | 3 | 0 | 1 | 0 | 4 | 4 | 3 | 0 | 4 | 3 | 2 | 0 | 1 | 2 | 4 | 3 | 4 | 2 | 0 |

| F14 | 0 | 0 | 0 | 0 | 4 | 3 | 1 | 4 | 4 | 2 | 3 | 3 | 2 | 0 | 1 | 2 | 1 | 2 | 3 | 4 | 1 | 2 | 3 | 2 |

| F15 | 4 | 3 | 2 | 2 | 4 | 0 | 0 | 2 | 2 | 3 | 3 | 3 | 2 | 2 | 0 | 3 | 1 | 3 | 3 | 2 | 1 | 1 | 2 | 2 |

| G1 | 2 | 2 | 2 | 2 | 0 | 0 | 1 | 2 | 2 | 2 | 1 | 0 | 0 | 0 | 0 | 0 | 4 | 3 | 3 | 1 | 0 | 3 | 3 | 2 |

| G2 | 1 | 1 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 3 | 0 | 2 | 0 | 0 | 0 | 2 | 0 | 2 |

| G3 | 0 | 0 | 0 | 1 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 1 | 0 | 3 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| G4 | 3 | 2 | 0 | 0 | 3 | 3 | 0 | 1 | 2 | 2 | 1 | 0 | 0 | 0 | 1 | 3 | 3 | 3 | 0 | 3 | 3 | 1 | 2 | 1 |

| G5 | 0 | 0 | 0 | 0 | 1 | 3 | 1 | 2 | 2 | 1 | 0 | 0 | 2 | 1 | 0 | 2 | 1 | 0 | 4 | 0 | 4 | 0 | 3 | 0 |

| G6 | 0 | 0 | 0 | 0 | 1 | 2 | 1 | 0 | 2 | 0 | 0 | 1 | 2 | 0 | 2 | 2 | 1 | 2 | 4 | 3 | 0 | 0 | 0 | 0 |

| G7 | 0 | 1 | 0 | 2 | 2 | 0 | 2 | 2 | 3 | 2 | 2 | 2 | 0 | 1 | 0 | 4 | 3 | 2 | 3 | 3 | 1 | 0 | 4 | 2 |

| G8 | 0 | 0 | 0 | 0 | 2 | 0 | 1 | 2 | 1 | 2 | 2 | 1 | 0 | 0 | 0 | 4 | 3 | 3 | 3 | 4 | 2 | 0 | 0 | 2 |

| G9 | 0 | 0 | 0 | 0 | 2 | 0 | 2 | 2 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 3 | 3 | 0 | 3 | 3 | 1 | 0 | 4 | 0 |

| Linguistic Evaluation | Influencing Numbers | Triangular Fuzzy Numbers |

|---|---|---|

| Very high influence | 4 | (0.7,0.9,1.0) |

| High influence | 3 | (0.5,0.7,0.9) |

| Low influence | 2 | (0.3,0.5,0.7) |

| Very low influence | 1 | (0.1,0.3,0.5) |

| No influence | 0 | (0,0.1,0.3) |

| F1 | F2 | F3 | F4 | F5 | F6 | F7 | F8 | F9 | F10 | F11 | F12 | F13 | F14 | F15 | G1 | G2 | G3 | G4 | G5 | G6 | G7 | G8 | G9 | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| F1 | 0.0462 | 0.0479 | 0.0756 | 0.0699 | 0.1010 | 0.0748 | 0.0803 | 0.0849 | 0.0794 | 0.0569 | 0.0497 | 0.0912 | 0.0698 | 0.0474 | 0.0635 | 0.1297 | 0.1066 | 0.0814 | 0.0824 | 0.0958 | 0.0525 | 0.0609 | 0.1060 | 0.0919 |

| F2 | 0.0370 | 0.0418 | 0.0445 | 0.0519 | 0.0915 | 0.0463 | 0.0385 | 0.0875 | 0.0499 | 0.0836 | 0.0434 | 0.0712 | 0.0412 | 0.0416 | 0.0348 | 0.1073 | 0.1062 | 0.0619 | 0.0622 | 0.0972 | 0.0552 | 0.0875 | 0.0957 | 0.0485 |

| F3 | 0.0826 | 0.0736 | 0.0346 | 0.0730 | 0.0539 | 0.0415 | 0.0590 | 0.0503 | 0.0460 | 0.0444 | 0.0384 | 0.0676 | 0.0373 | 0.0352 | 0.0324 | 0.1122 | 0.0933 | 0.0479 | 0.0881 | 0.0578 | 0.0405 | 0.0711 | 0.0677 | 0.0561 |

| F4 | 0.0829 | 0.0742 | 0.0890 | 0.0527 | 0.1081 | 0.0813 | 0.0504 | 0.1029 | 0.0857 | 0.0636 | 0.0765 | 0.0862 | 0.0873 | 0.0622 | 0.0453 | 0.1284 | 0.1140 | 0.0865 | 0.0804 | 0.1163 | 0.0798 | 0.1013 | 0.1140 | 0.0841 |

| F5 | 0.0503 | 0.0543 | 0.0443 | 0.0863 | 0.0783 | 0.0964 | 0.0483 | 0.0930 | 0.0773 | 0.0882 | 0.0802 | 0.0755 | 0.0777 | 0.0984 | 0.0898 | 0.1386 | 0.1239 | 0.1016 | 0.1270 | 0.1194 | 0.0824 | 0.0901 | 0.1039 | 0.0855 |

| F6 | 0.0433 | 0.0478 | 0.0381 | 0.0455 | 0.0910 | 0.0578 | 0.0666 | 0.0859 | 0.0822 | 0.0937 | 0.0737 | 0.0793 | 0.0839 | 0.0834 | 0.0420 | 0.1071 | 0.0914 | 0.0588 | 0.1191 | 0.1219 | 0.0899 | 0.0614 | 0.1070 | 0.0785 |

| F7 | 0.0294 | 0.0321 | 0.0276 | 0.0325 | 0.0667 | 0.0465 | 0.0321 | 0.0649 | 0.0505 | 0.0389 | 0.0337 | 0.0477 | 0.0326 | 0.0326 | 0.0281 | 0.0907 | 0.0587 | 0.0400 | 0.0498 | 0.0723 | 0.0464 | 0.0631 | 0.0595 | 0.0735 |

| F8 | 0.0541 | 0.0822 | 0.0822 | 0.0815 | 0.1297 | 0.1025 | 0.0905 | 0.0804 | 0.1084 | 0.1073 | 0.0854 | 0.1067 | 0.0824 | 0.0942 | 0.0507 | 0.1527 | 0.1253 | 0.1078 | 0.1155 | 0.1302 | 0.0888 | 0.1222 | 0.1268 | 0.1058 |

| F9 | 0.0355 | 0.0504 | 0.0332 | 0.0390 | 0.0558 | 0.0442 | 0.0613 | 0.0967 | 0.0493 | 0.0701 | 0.0413 | 0.0687 | 0.0386 | 0.0387 | 0.0326 | 0.1047 | 0.0698 | 0.0595 | 0.0822 | 0.0843 | 0.0542 | 0.0851 | 0.0951 | 0.0820 |

| F10 | 0.0487 | 0.0990 | 0.0442 | 0.0761 | 0.1127 | 0.0974 | 0.0504 | 0.0965 | 0.0905 | 0.0688 | 0.0928 | 0.0996 | 0.0780 | 0.0896 | 0.0465 | 0.1415 | 0.0927 | 0.0774 | 0.1183 | 0.1228 | 0.0718 | 0.1150 | 0.1197 | 0.0860 |

| F11 | 0.0544 | 0.0948 | 0.0495 | 0.1029 | 0.1307 | 0.1137 | 0.0546 | 0.1152 | 0.1082 | 0.1197 | 0.0653 | 0.1070 | 0.1064 | 0.0847 | 0.0730 | 0.1416 | 0.1109 | 0.0736 | 0.1143 | 0.1315 | 0.0781 | 0.1129 | 0.1276 | 0.0926 |

| F12 | 0.1049 | 0.1008 | 0.0776 | 0.0995 | 0.1185 | 0.0975 | 0.0951 | 0.1323 | 0.1155 | 0.1151 | 0.1037 | 0.0812 | 0.1012 | 0.0994 | 0.0996 | 0.1629 | 0.1209 | 0.1156 | 0.1338 | 0.1390 | 0.0943 | 0.1195 | 0.1355 | 0.0889 |

| F13 | 0.0850 | 0.0666 | 0.0670 | 0.0565 | 0.1148 | 0.1003 | 0.0514 | 0.0842 | 0.0704 | 0.1135 | 0.1048 | 0.1026 | 0.0590 | 0.1019 | 0.0834 | 0.1211 | 0.0812 | 0.0779 | 0.1097 | 0.1334 | 0.0961 | 0.1140 | 0.1075 | 0.0648 |

| F14 | 0.0468 | 0.0527 | 0.0421 | 0.0521 | 0.1199 | 0.0967 | 0.0599 | 0.1154 | 0.1106 | 0.0889 | 0.0909 | 0.0977 | 0.0770 | 0.0548 | 0.0561 | 0.1163 | 0.0883 | 0.0872 | 0.1169 | 0.1293 | 0.0708 | 0.0899 | 0.1158 | 0.0851 |

| F15 | 0.0960 | 0.0907 | 0.0689 | 0.0787 | 0.1241 | 0.0640 | 0.0508 | 0.0958 | 0.0896 | 0.1016 | 0.0922 | 0.1017 | 0.0787 | 0.0774 | 0.0485 | 0.1330 | 0.0938 | 0.1026 | 0.1174 | 0.1090 | 0.0701 | 0.0814 | 0.1067 | 0.0870 |

| G1 | 0.0607 | 0.0648 | 0.0574 | 0.0635 | 0.0596 | 0.0455 | 0.0496 | 0.0762 | 0.0723 | 0.0710 | 0.0522 | 0.0507 | 0.0400 | 0.0390 | 0.0338 | 0.0744 | 0.1084 | 0.0859 | 0.0948 | 0.0739 | 0.0448 | 0.0874 | 0.0969 | 0.0724 |

| G2 | 0.0382 | 0.0400 | 0.0258 | 0.0308 | 0.0626 | 0.0320 | 0.0287 | 0.0384 | 0.0358 | 0.0351 | 0.0308 | 0.0570 | 0.0294 | 0.0294 | 0.0269 | 0.0844 | 0.0445 | 0.0591 | 0.0434 | 0.0440 | 0.0314 | 0.0593 | 0.0439 | 0.0570 |

| G3 | 0.0265 | 0.0274 | 0.0234 | 0.0374 | 0.0591 | 0.0299 | 0.0249 | 0.0338 | 0.0314 | 0.0313 | 0.0283 | 0.0541 | 0.0276 | 0.0274 | 0.0352 | 0.0446 | 0.0726 | 0.0330 | 0.0478 | 0.0389 | 0.0290 | 0.0333 | 0.0374 | 0.0310 |

| G4 | 0.0727 | 0.0646 | 0.0354 | 0.0426 | 0.0952 | 0.0835 | 0.0406 | 0.0663 | 0.0746 | 0.0740 | 0.0541 | 0.0521 | 0.0442 | 0.0427 | 0.0477 | 0.1102 | 0.0997 | 0.0880 | 0.0662 | 0.1014 | 0.0823 | 0.0634 | 0.0870 | 0.0614 |

| G5 | 0.0343 | 0.0367 | 0.0305 | 0.0347 | 0.0623 | 0.0783 | 0.0454 | 0.0701 | 0.0681 | 0.0561 | 0.0396 | 0.0440 | 0.0603 | 0.0477 | 0.0325 | 0.0867 | 0.0641 | 0.0465 | 0.1019 | 0.0595 | 0.0880 | 0.0464 | 0.0892 | 0.0439 |

| G6 | 0.0338 | 0.0347 | 0.0288 | 0.0330 | 0.0580 | 0.0621 | 0.0421 | 0.0443 | 0.0638 | 0.0422 | 0.0361 | 0.0506 | 0.0574 | 0.0347 | 0.0531 | 0.0803 | 0.0595 | 0.0645 | 0.0964 | 0.0870 | 0.0397 | 0.0425 | 0.0505 | 0.0396 |

| G7 | 0.0421 | 0.0572 | 0.0381 | 0.0679 | 0.0879 | 0.0529 | 0.0656 | 0.0845 | 0.0917 | 0.0784 | 0.0703 | 0.0770 | 0.0462 | 0.0552 | 0.0390 | 0.1273 | 0.1047 | 0.0805 | 0.1045 | 0.1071 | 0.0619 | 0.0598 | 0.1152 | 0.0782 |

| G8 | 0.0362 | 0.0405 | 0.0325 | 0.0395 | 0.0781 | 0.0464 | 0.0470 | 0.0735 | 0.0590 | 0.0697 | 0.0627 | 0.0566 | 0.0402 | 0.0392 | 0.0344 | 0.1135 | 0.0941 | 0.0839 | 0.0950 | 0.1052 | 0.0669 | 0.0504 | 0.0590 | 0.0690 |

| G9 | 0.0321 | 0.0346 | 0.0290 | 0.0336 | 0.0707 | 0.0398 | 0.0557 | 0.0678 | 0.0648 | 0.0419 | 0.0357 | 0.0402 | 0.0342 | 0.0337 | 0.0297 | 0.0961 | 0.0870 | 0.0445 | 0.0873 | 0.0884 | 0.0502 | 0.0439 | 0.0963 | 0.0424 |

| Factors | R | D | R + D | R − D |

|---|---|---|---|---|

| F1: Quantity of cores | 1.8456 | 1.2737 | 3.1193 | 0.5719 |

| F2: Quality of cores | 1.5265 | 1.4094 | 2.9359 | 0.1171 |

| F3: Recycling system | 1.4046 | 1.1192 | 2.5238 | 0.2854 |

| F4: Information system | 2.0532 | 1.3810 | 3.4341 | 0.6722 |

| F5: Quality management | 2.1106 | 2.1303 | 4.2409 | −0.0197 |

| F6: Pollution control | 1.8494 | 1.6310 | 3.4804 | 0.2183 |

| F7: Remanufacturing equipment | 1.1502 | 1.2888 | 2.4390 | −0.1386 |

| F8: Key remanufacturing technology | 2.4136 | 1.9408 | 4.3544 | 0.4728 |

| F9: Remanufacturing technology R&D | 1.4722 | 1.7752 | 3.2474 | −0.3030 |

| F10: DFR | 2.1360 | 1.7541 | 3.8901 | 0.3818 |

| F11: OEMs information sharing | 2.3632 | 1.4817 | 3.8450 | 0.8815 |

| F12: Policy guidance | 2.6523 | 1.7662 | 4.4185 | 0.8862 |

| F13: Laws and regulations system | 2.1671 | 1.4306 | 3.5977 | 0.7365 |

| F14: Standards of remanufacturing industry | 2.0612 | 1.3906 | 3.4517 | 0.6706 |

| F15: Social awareness of remanufacturing | 2.1596 | 1.1585 | 3.3181 | 1.0010 |

| G1: Cost saving | 1.5753 | 2.7052 | 4.2804 | −1.1299 |

| G2: Remanufacturing profits | 1.0080 | 2.2118 | 3.2198 | −1.2039 |

| G3: Market occupancy | 0.8652 | 1.7658 | 2.6310 | −0.9006 |

| G4: Green image of corporation | 1.6500 | 2.2545 | 3.9045 | −0.6046 |

| G5: Emission reduction | 1.3667 | 2.3656 | 3.7323 | −0.9990 |

| G6: Compliance rate of waste discharge | 1.2346 | 1.5653 | 2.7999 | −0.3307 |

| G7: The recycle and reuse rate of end-of-life products | 1.7934 | 1.8618 | 3.6552 | −0.0685 |

| G8: Resources conservation | 1.4925 | 2.2638 | 3.7562 | −0.7713 |

| G9: Resource efficiency | 1.2798 | 1.7054 | 2.9852 | −0.4256 |

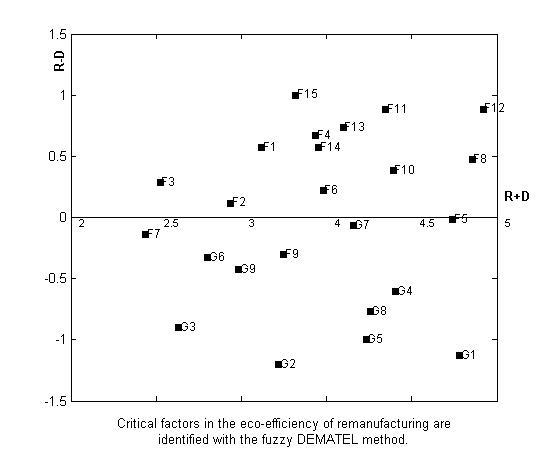

5. Analysis on the Factors Affecting the Eco-Efficiency of Remanufacturing

5.1. Identifying Critical Factors

5.1.1. Cause Cluster

5.1.2. Effect Cluster

5.2. Further Analysis on the Critical Factors

6. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sales of Topten Automobile Enterprises in December 2014. Available online: http://www.caam.org.cn/zhengche/20150112/1705144354.html (accessed on 12 October 2015).

- Xu, B. Remanufacturing engineering and its development in China. China Surf. Eng. 2010, 23, 1–6. (In Chinese) [Google Scholar]

- Analysis of the Annual Sample Survey on Automotive Parts Remanufacturing Industry in 2013. Available online: http://www.remanchina.org/info/173.jspx (accessed on 11 November 2015).

- Notice on the Issuance of “China Manufacturing 2025” by the State Council of China. Available online: http://www.gov.cn/zhengce/content/2015-05/19/content_9784.htm (accessed on 11 November 2015).

- Xu, B.; Liu, S.; Shi, P. Study on the contribution of engine remanufacturing to the recycle economy. China Surf. Eng. 2005, 18, 1–7. (In Chinese) [Google Scholar]

- Kerr, W.; Ryan, C. Eco-efficiency gains from remanufacturing: A case study of photocopier remanufacturing at Fuji Xerox Australia. J. Clean. Prod. 2001, 9, 75–81. [Google Scholar] [CrossRef]

- Quariguasi-Frota-Neto, J.; Bloemhof, J. An Analysis of the Eco-Efficiency of Remanufactured Personal Computers and Mobile Phones. Prod. Oper. Manag. 2012, 21, 101–114. [Google Scholar] [CrossRef]

- Zhang, T.; Chu, J.; Wang, X.; Liu, X.; Cui, P. Development pattern and enhancing system of automotive components remanufacturing industry in China. Resour. Conserv. Recycl. 2011, 55, 613–622. [Google Scholar] [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing internal barriers for automotive parts remanufacturers in China using grey-DEMATEL approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Zhu, Q.; Sarkis, J.; Lai, K. Supply chain-based barriers for truck-engine remanufacturing in China. Transp. Res. Part E 2014, 68, 103–117. [Google Scholar] [CrossRef]

- Wu, W.W. Choosing knowledge management strategies by using a combined ANP and DEMATEL approach. Expert Syst. Appl. 2008, 35, 828–835. [Google Scholar] [CrossRef]

- Yang, J.L.; Tzeng, G.H. An integrated MCDM technique combined with DEMATEL for a novel cluster-weighted with ANP method. Expert Syst. Appl. 2011, 38, 1417–1424. [Google Scholar] [CrossRef]

- Zhou, Q.; Huang, W.; Zhang, Y. Identifying critical success factors in emergency management using a fuzzy DEMATEL method. Saf. Sci. 2011, 49, 243–252. [Google Scholar] [CrossRef]

- Govindan, K.; Kannan, D.; Shankar, K.M. Evaluating the drivers of corporate social responsibility in the mining industry with multi-criteria approach: A multi-stakeholder perspective. J. Clean. Prod. 2014, 84, 214–232. [Google Scholar] [CrossRef]

- Lin, R.J. Using fuzzy DEMATEL to evaluate the green supply chain management practices. J. Clean. Prod. 2013, 40, 32–39. [Google Scholar] [CrossRef]

- Wu, H.H.; Chang, S.Y. A case study of using DEMATEL method to identify critical factors in green supply chain management. Appl. Math. Comput. 2015, 256, 394–403. [Google Scholar] [CrossRef]

- Hsu, C.W.; Kuo, T.C.; Chen, S.H.; Hu, A.H. Using DEMATEL to develop a carbon management model of supplier selection in green supply chain management. J. Clean. Prod. 2013, 56, 164–172. [Google Scholar] [CrossRef]

- Lee, W.S.; Huang, Y.H.; Chang, Y.Y.; Cheng, C.-M. Analysis of decision making factors for equity investment by DEMATEL and Analytic Network Process. Expert Syst. Appl. 2011, 38, 8375–8383. [Google Scholar] [CrossRef]

- Wei, S.; Cheng, D.; Sundin, E.; Tang, O. Motives and barriers of the remanufacturing industry in China. J. Clean. Prod. 2015, 94, 340–351. [Google Scholar] [CrossRef]

- Yang, W.; Zeng, Y.; Wu, Y. Research on factors that affect the eco-efficiency of remanufacturing closed-loop supply chain. In Proceedings of the International Conference on Management Science and Engineering, Chengdu, China, 20–21 November 2011; pp. 75–80.

- Abdulrahman, M.D.; Gunasekaran, A.; Subramanian, N. Critical barriers in implementing reverse logistics in the Chinese manufacturing sectors. Int. J. Prod. Econ. 2014, 147, 460–471. [Google Scholar] [CrossRef]

- González-Torre, P.; Alvarez, M.; Sarkis, J.; Adenso-Díaz, B. Barriers to the implementation of environmentally oriented reverse logistics: Evidence from the automotive industry sector. Br. J. Manag. 2010, 21, 889–904. [Google Scholar] [CrossRef]

- Sabharwal, S.; Garg, S. Determining cost effectiveness index of remanufacturing: A graph theoretic approach. Int. J. Prod. Econ. 2013, 144, 521–532. [Google Scholar] [CrossRef]

- Schau, E.M.; Traverso, M.; Lehmann, A.; Finkbeiner, M. Life Cycle Costing in Sustainability Assessment—A Case Study of Remanufactured Alternators. Sustainability 2011, 3, 2268–2288. [Google Scholar] [CrossRef]

- Sundin, E.; Lee, H.M. In what way is remanufacturing good for the environment. In Design for Innovative Value towards a Sustainable Society; Matsumoto, M., Umeda, Y., Eds.; Springer: Berlin, Germany, 2012; pp. 552–557. [Google Scholar]

- Goldey, C.L.; Kuester, E.U.; Mummert, R.; Okrasinski, T.A. Lifecycle assessment of the environmental benefits of remanufactured telecommunications product within a “green” supply chain Sustainable Systems and Technology. In Proceedings of the IEEE International Symposium on Sustainable Systems and Technology, Arlington, VA, USA, 17–19 May 2010; pp. 1–6.

- Du, Y.; Li, C. Implementing energy-saving and environmental-benign paradigm: Machine tool remanufacturing by OEMs in China. J. Clean. Prod. 2014, 66, 272–279. [Google Scholar] [CrossRef]

- Golinska, P.; Kuebler, F. The method for assessment of the sustainability maturity in remanufacturing companies. Procedia CIRP 2014, 15, 201–206. [Google Scholar] [CrossRef]

- Rathore, P.; Kota, S.; Chakrabarti, A. Sustainability through remanufacturing in India: A case study on mobile handsets. J. Clean. Prod. 2011, 19, 1709–1722. [Google Scholar] [CrossRef]

- Falatoonitoosi, E.; Ahmed, S.; Sorooshian, S. A Multicriteria Framework to Evaluate Supplier’s Greenness. Abstr. Appl. Anal. 2014. [Google Scholar] [CrossRef]

- Guo, W.F.; Zhou, J.; Yu, L.-C.; Tsai, S.-B.; Xue, Y.-Z.; Chen, Q.; Guo, J.-J.; Huang, P.-Y.; Wu, C.-H. Evaluating the green corporate social responsibility of manufacturing corporations from a green industry law perspective. Int. J. Prod. Res. 2015, 53, 665–674. [Google Scholar] [CrossRef]

- Chang, B.; Chang, C.W.; Wu, C.H. Fuzzy DEMATEL method for developing supplier selection criteria. Expert Syst. Appl. 2011, 38, 1850–1858. [Google Scholar] [CrossRef]

- Subramoniam, R.; Huisingh, D.; Chinnam, R.B.; Subramoniam, S. Remanufacturing Decision-Making Framework (RDMF): Research validation using the analytical hierarchical process. J. Clean. Prod. 2013, 40, 212–220. [Google Scholar] [CrossRef]

- Liu, B.; Shi, P.; Xu, B.; Huang, T. Subsidy policy of remanufacturing for electromechanical products. China Surf. Eng. 2012, 25, 15–20. (In Chinese) [Google Scholar]

- Chang, X.; Zhong, Y.; Wang, Y.; Chen, Z. Research of low-carbon policy to promote automotive parts remanufacturing in China: A case study of auto engine remanufacturing. Syst. Eng. Theory Pract. 2013, 33, 2811–2821. (In Chinese) [Google Scholar]

- Li, J.; Du, W.; Yang, F.; Hua, G. The Carbon Subsidy Analysis in Remanufacturing Closed-Loop Supply Chain. Sustainability 2014, 3861–3877. [Google Scholar] [CrossRef]

- Xu, B.; Dong, S.; Shi, P. States and prospects of China characterized quality guarantee technology system for remanufactured parts. J. Mech. Eng. 2013, 49, 84–90. (In Chinese) [Google Scholar] [CrossRef]

- Jiang, Z.; Zhang, H.; Sutherland, J.W. Development of multi-criteria decision making model for remanufacturing technology portfolio selection. J. Clean. Prod. 2011, 19, 1939–1945. [Google Scholar] [CrossRef]

- Joung, C.B.; Carrell, J.; Sarkar, P.; Feng, S.C. Categorization of indicators for sustainable manufacturing. Ecol. Indic. 2013, 24, 148–157. [Google Scholar] [CrossRef]

- Tang, F.; Wang, C.; Qiu, C. Empirical research on greenness evaluation of supply chain management based on statistical analysis of enterprises in Anhui province. Sci. Technol. Prog. Policy 2009, 26, 121–128. (In Chinese) [Google Scholar]

- Karsak, E.E.; Tolga, E. Fuzzy multi-criteria decision-making procedure for evaluating advanced manufacturing system investments. Int. J. Product. Econ. 2001, 69, 49–64. [Google Scholar] [CrossRef]

- Zeng, G.H.; Teng, J.Y. Transportation Investment Project Selection with Fuzzy Multi-objectives. Transp. Plan. Technol. 1993, 17, 91–112. [Google Scholar] [CrossRef]

- Yao, J.; Yang, J.; Zhu, S. Quality control in remanufacturing waste product. China Surf. Eng. 2006, 19, 115–117. (In Chinese) [Google Scholar]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Deng, Q.; Liu, X.; Liao, H. Identifying Critical Factors in the Eco-Efficiency of Remanufacturing Based on the Fuzzy DEMATEL Method. Sustainability 2015, 7, 15527-15547. https://doi.org/10.3390/su71115527

Deng Q, Liu X, Liao H. Identifying Critical Factors in the Eco-Efficiency of Remanufacturing Based on the Fuzzy DEMATEL Method. Sustainability. 2015; 7(11):15527-15547. https://doi.org/10.3390/su71115527

Chicago/Turabian StyleDeng, Qianwang, Xiahui Liu, and Haolan Liao. 2015. "Identifying Critical Factors in the Eco-Efficiency of Remanufacturing Based on the Fuzzy DEMATEL Method" Sustainability 7, no. 11: 15527-15547. https://doi.org/10.3390/su71115527