1. Introduction

The retrofitting of existing office buildings is becoming increasingly important due to required energy savings and the fact that people in industrial societies spend 90% of their time indoors [

1,

2,

3], so that they require improved thermal comfort. For this reason, effective retrofitting concepts, which should include newly developed or modified and upgraded technologies, as well as new design concepts, need to be developed and their validity confirmed [

4,

5,

6]. It should be mentioned that these technologies should also be considered from the seismic engineering point of view, since certain elements could influence the dynamic stability of a structure [

7,

8]. The specific properties and energy efficiency of such new technologies, as well as their design concepts, can be evaluated by the performance of different kinds of tests, especially when such measurements are combined with real case demonstrations [

9,

10,

11,

12,

13]. On the other hand, modeling by means of various mathematical tools, too, is a powerful method for the evaluation of the overall impact of such technologies on thermal comfort and energy utilization [

14,

15,

16]. Thus the most efficient method is surely to combine both approaches together, since in this way successive improvements in technologies and design are possible.

Large surface radiant bodies are one of the promising future technologies for the provision of heating and cooling energy in buildings. This particular technology makes efficient use of the principle of the small temperature differences between a large radiant surface and its surroundings [

17]. Large surface radiant systems can be built into nearby structure, or suspended from it. The most widely known and commonly used form of built-in systems is the floor heating system. Built-in systems can be installed into the floor, ceiling, or wall structure, and possess the additional function of activating the thermal mass (so-called thermally activated building systems). Suspended systems are usually fixed onto the ceiling as a suspended ceiling in the form of gypsum plasterboard elements with embedded capillary tubes or tubes covered with metal sheets.

The energy utilization of radiant ceiling and wall surfaces, as well as thermal comfort, has been an important topic in many studies that have been described in literature. Most of the studies are mainly based on small-scale experiments or on numerical models, and have focused on specific questions concerning these systems. As shown in the study by Miriel

et al. [

12], radiant ceiling panels can be efficiently used for heating and cooling in buildings with good thermal insulation and low cooling loads. Compared to conventional air-conditioning systems, such systems can create a more comfortable environment with less energy utilization [

11], and can also cope with complex user behavior as long as good solar protection is provided and correctly implemented [

13]. In these cases, mechanical ventilation of the treated indoor environment also needs to be carefully considered: when no additional air treatment for increasing convection is provided, the system may be able to prevent possible overheating only to a limited extent [

12]. Better results can be achieved by integrating suitable mechanical ventilation systems, which can increase the convective heat transfer and improve the time response of the radiant system [

18]. In this way, the needed size of the radiant surfaces can be reduced [

18].

As shown in the study by Rahimi

et al. [

19], in large surface radiant systems the main mechanism for transferring heat from the warm surface of a ceiling to another surface is radiation. However, in typical offices the transitional period between winter and summer is the most sensitive to user interference [

20]. In many research studies [

17,

21,

22] it has been mentioned that determining the proper heat transfer coefficient and the cooling capacity of the cooled ceiling systems is of crucial importance, especially in connection with solar gains. The surface temperatures in the room and the air velocity are the two main factors, which influence the actual cooling performance of ceiling radiant cooling panels [

23]. In fact, both factors can have a considerable influence on the efficiency of radiant ceiling systems in both the heating and the cooling mode, so that the latter must be evaluated together with the nearby indoor environment, and not as separate heating, ventilation and air conditioning (HVAC) equipment [

10,

24,

25].

The dynamic simulation program TRNSYS [

26] is commonly used for modeling and analyzing larger models, e.g., when the energy performance and thermal comfort of buildings are studied [

14,

15]. However, the TRNSYS simulation program is also used for dynamic simulations of buildings or parts of buildings that are equipped with radiant systems [

12,

13,

18,

27]. By performing TRNSYS computer simulations of a typical office floor equipped with a radiant cooling system, it has been found that occupant behavior can have an important influence on the cooling demand and thermal comfort [

13]. Similar conclusions have been drawn in the case of investigations into the possible impact of occupant behavior on building performance and thermal sensation in the case of conventionally heated buildings: compared to the design strategy used in the model, the measured energy demand can be twice as high, and the thermal comfort lower [

28]. Additionally, it has been found not only that very good thermal insulation is needed, but also that an adequate thermal mass has to be foreseen in the case of buildings with large radiant surfaces [

29]. By means of simulations, which were consequently calibrated using measured

in situ data, Tian

et al. [

30] demonstrated that limitations of measured data can significantly contribute to observed discrepancies between measured and simulated results [

30].

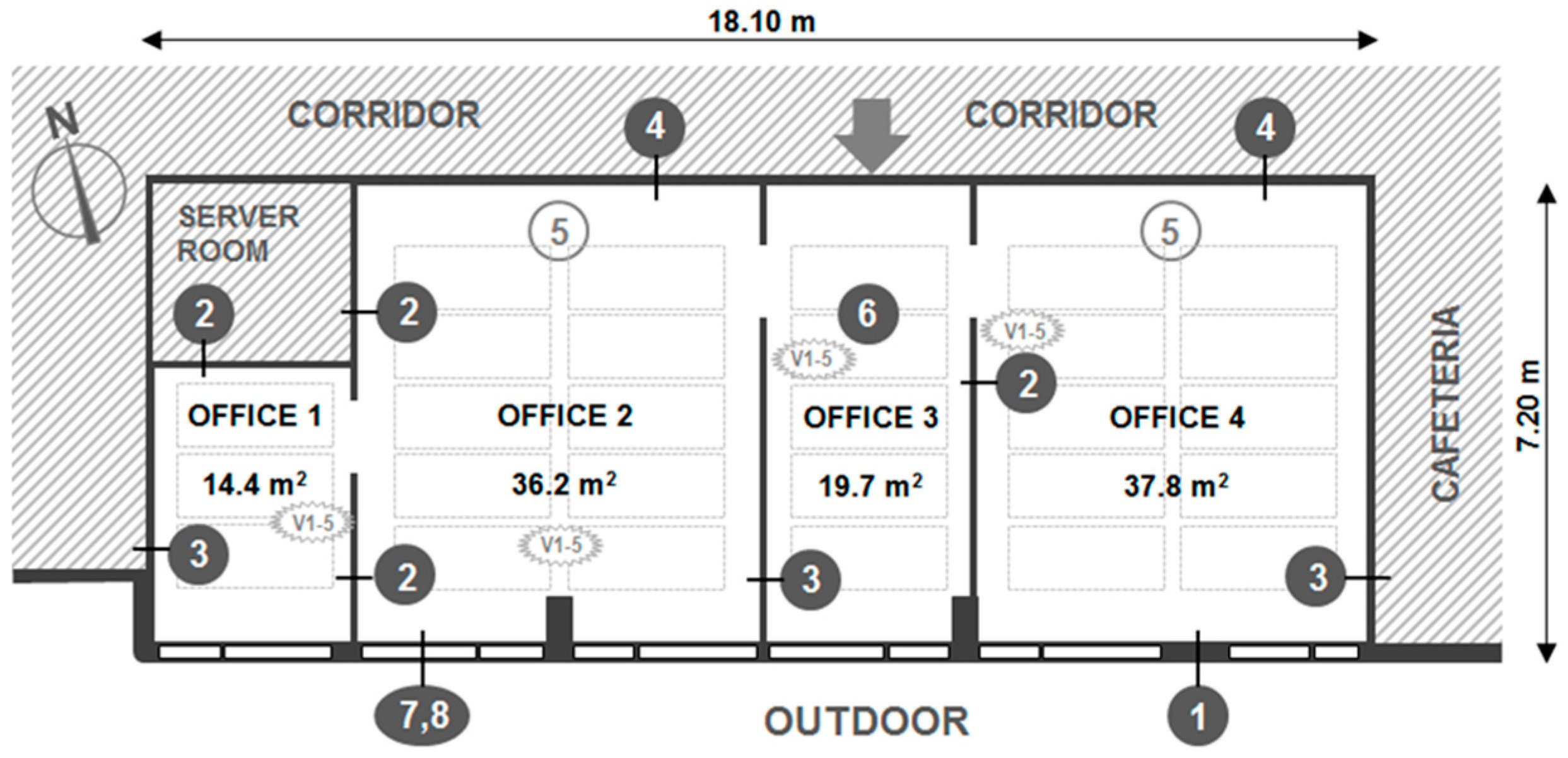

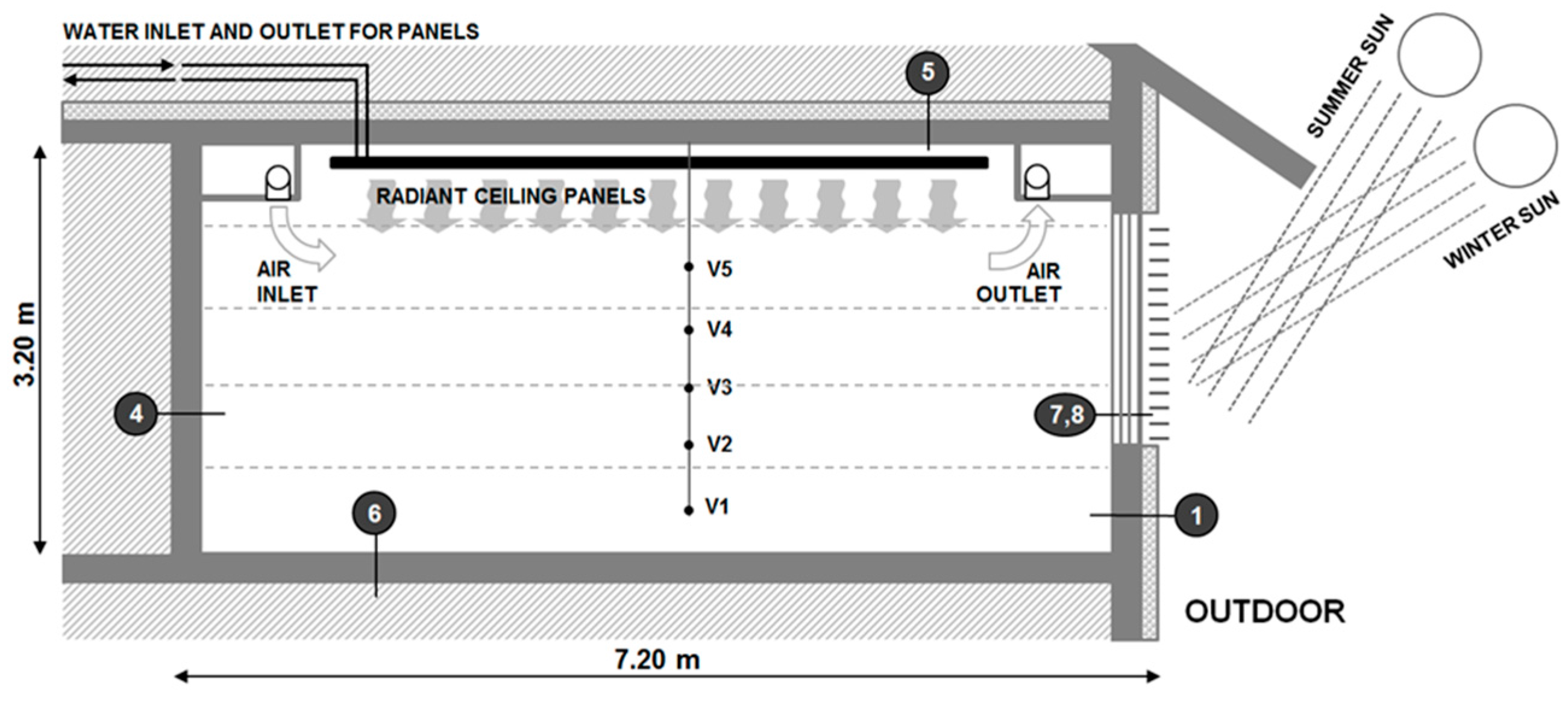

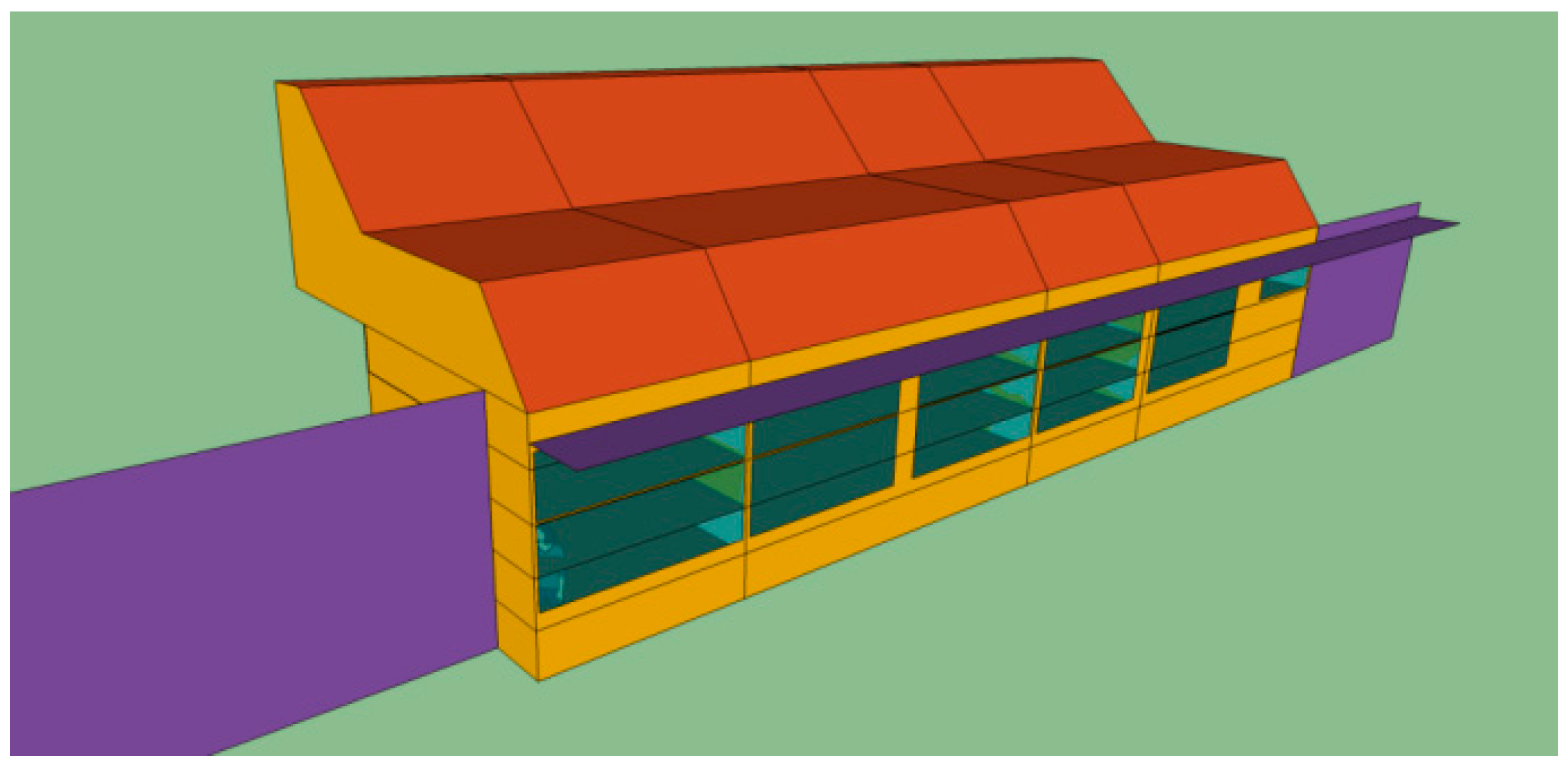

The purpose of the present study was to evaluate different retrofitting concepts for existing office buildings with the focus on the transparent part of the building envelope. The retrofitting concepts included different façade characteristics (glazing size, glazing types), shading strategies, and window opening strategies, combined with the radiant ceiling system. In order to perform sufficiently accurate analyses and evaluations of the proposed concepts, a comprehensive TRNSYS simulation model based on the actual technical performances of the retrofitted offices was defined. These retrofitted offices were pilot demonstrators in the EU project COST EFFECTIVE (Resource- and Cost-Effective Integration of Renewables in Existing High-Rise Buildings, 7FP, 2008-2012) [

31]. After the TRNSYS model had been defined, specific data were added to the model. The model was then validated by means of a comparison with actual data that had been obtained in retrofitted pilot offices equipped with radiant heating/cooling ceiling system [

9,

32,

33]. Furthermore, based on the variations of the model and the performed analyses, as well as on a comparison of the results, the goal was to determine valid concepts and to check the impacts of different parameters on the results obtained in the simulations.

It should be noted, however, that the study was limited to modeling and simulations of energy use and to an indoor environment only. Thus, evaluated quantities were the energy utilization for heating and cooling of the offices and the indoor air temperatures. Consequently, modeling of the energy supply equipment and equipment for the everyday operation of the investigated offices, as well as the use of primary energy, and evaluation of the various control strategies, were not considered within the scope of this study.

5. Conclusions

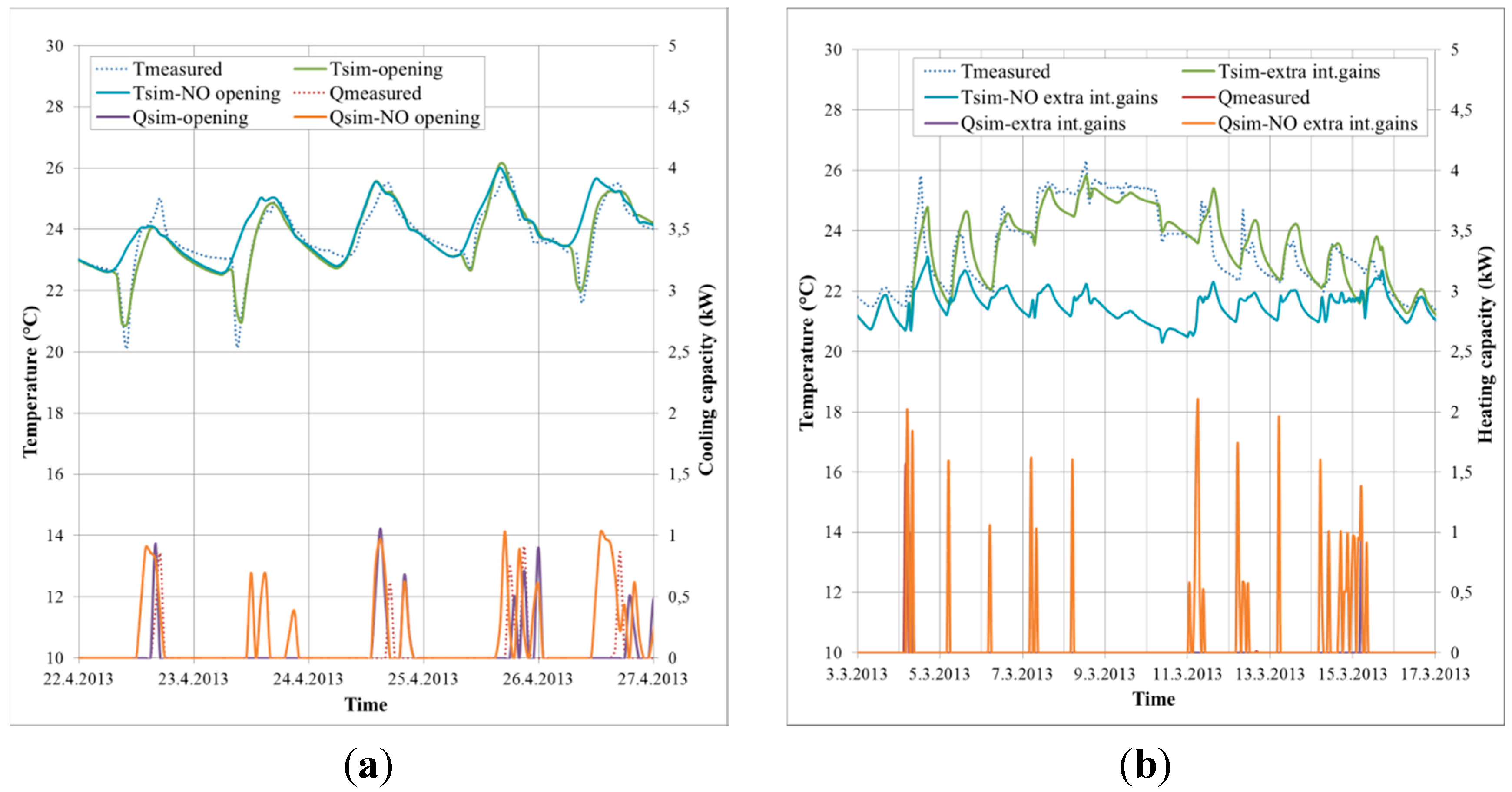

In this study, a detailed TRNSYS model for the simulation of the energy utilization of offices and an indoor environment was defined. The model was verified by comparisons with measurements obtained in the real case pilot offices over the period of one year. An extensive range of simulations using this model was also performed in order to evaluate the different retrofitting concepts, focusing on the transparent part of the building envelope, which have been proposed for office buildings with installed radiant ceiling systems.

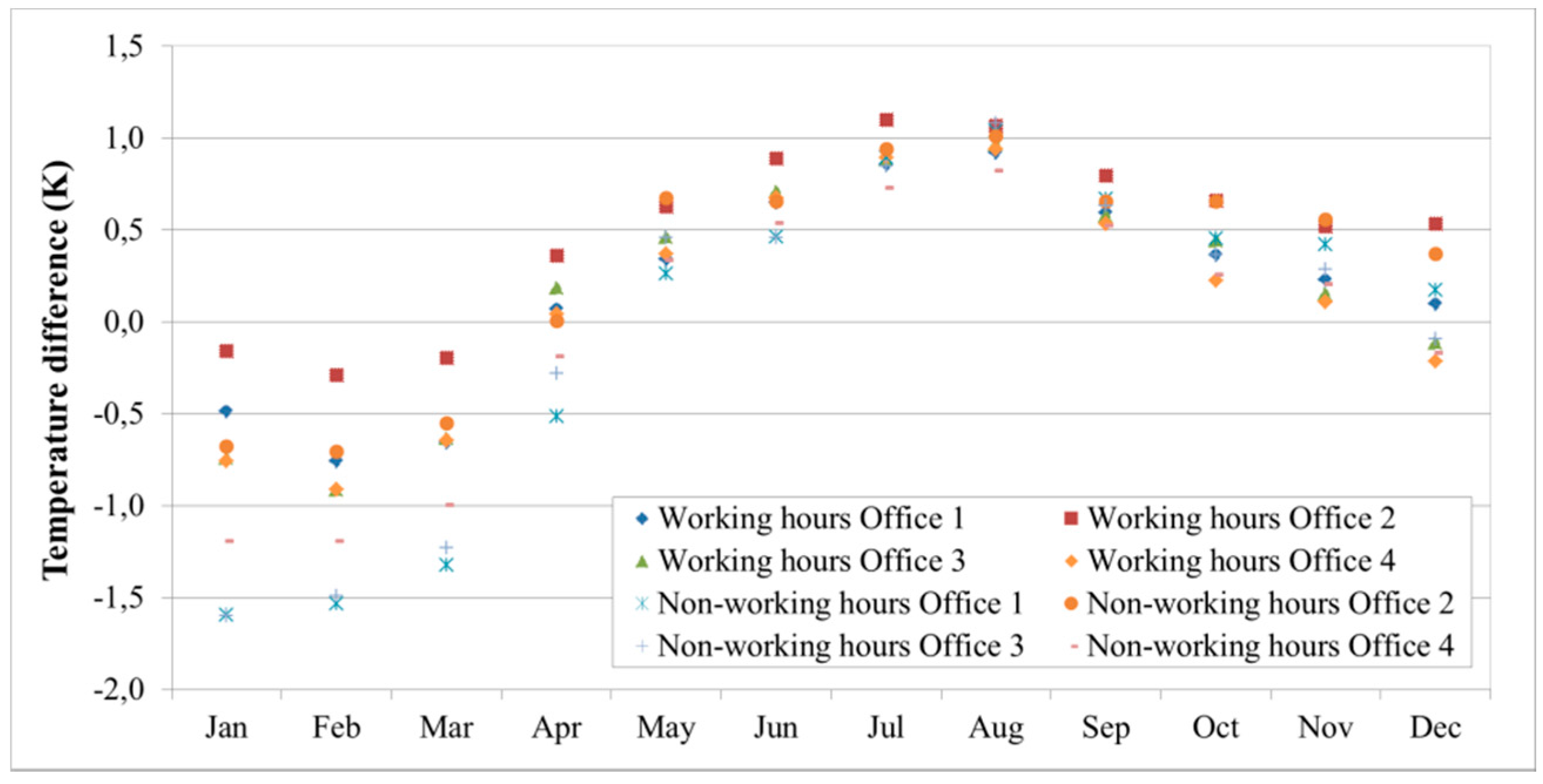

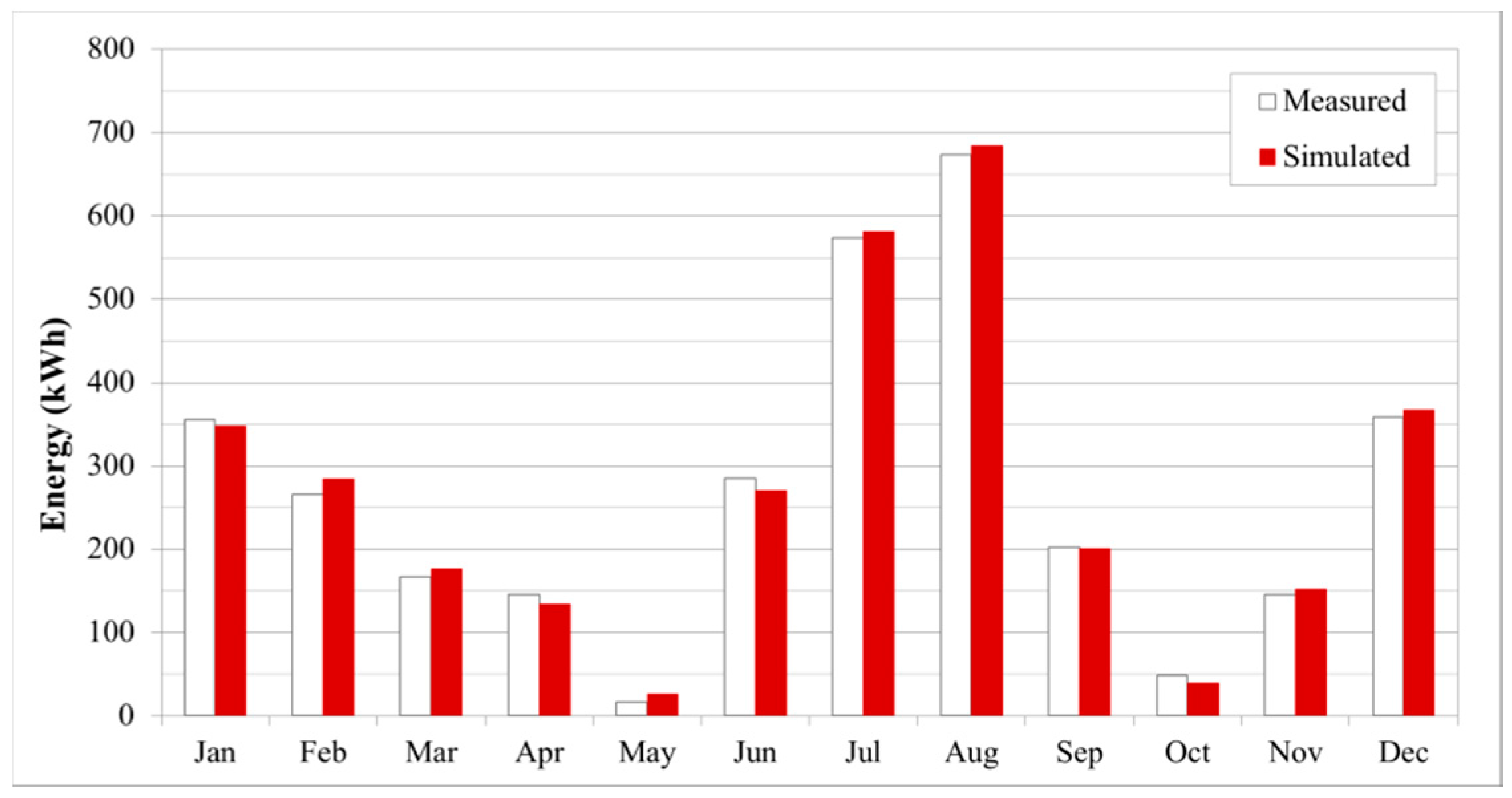

It was found that the model defined by the use of TRNSYS simulated the actual situation in the pilot offices well. Comparisons between the simulated air temperatures that were generated by the model and the air temperatures that were measured by means of temperature sensors clearly showed good correlation in both the heating and the cooling season. The average RMSE of the simulated temperature values was ±0.45 K in the heating season and ±0.58 K in the cooling season. The final MBE percentage for the simulated yearly energy from the panels was −0.8%. This means that the simulated energy was only 0.8% higher than the measured energy. Based on excellent correlation between the measured and the simulated heating and cooling energy, it can be confirmed that the model based on the use of radiant ceiling panels was indeed very accurate.

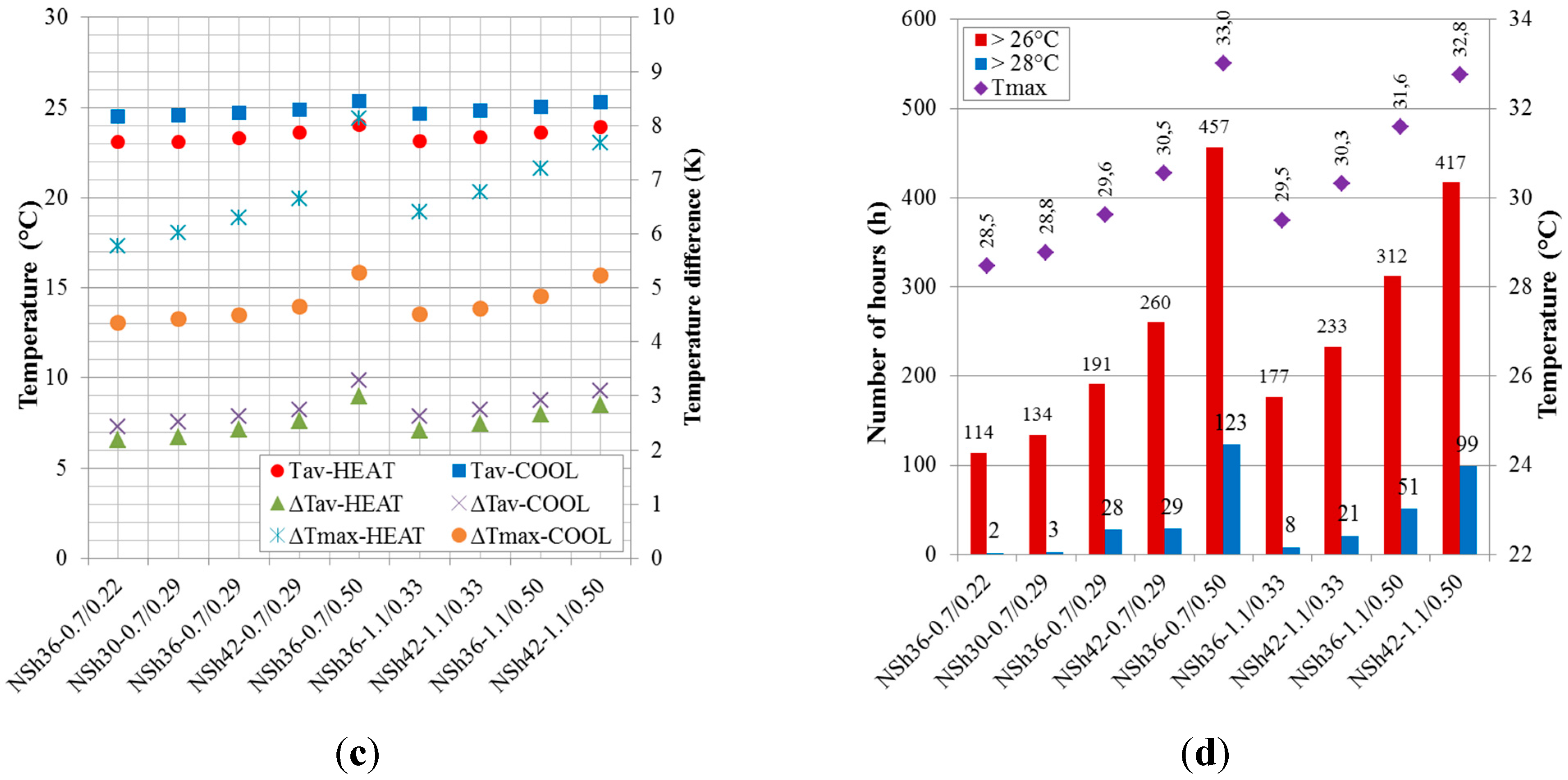

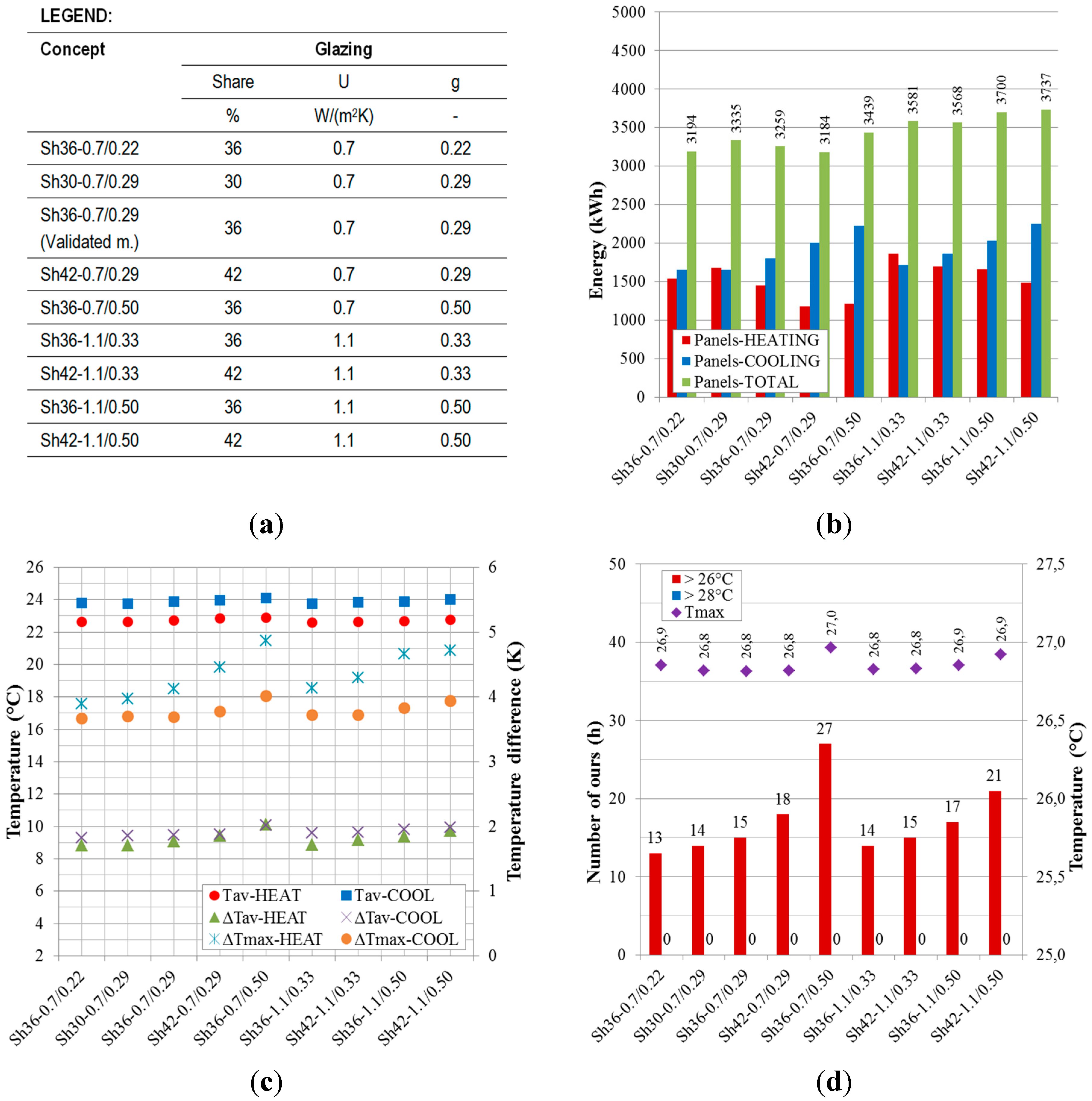

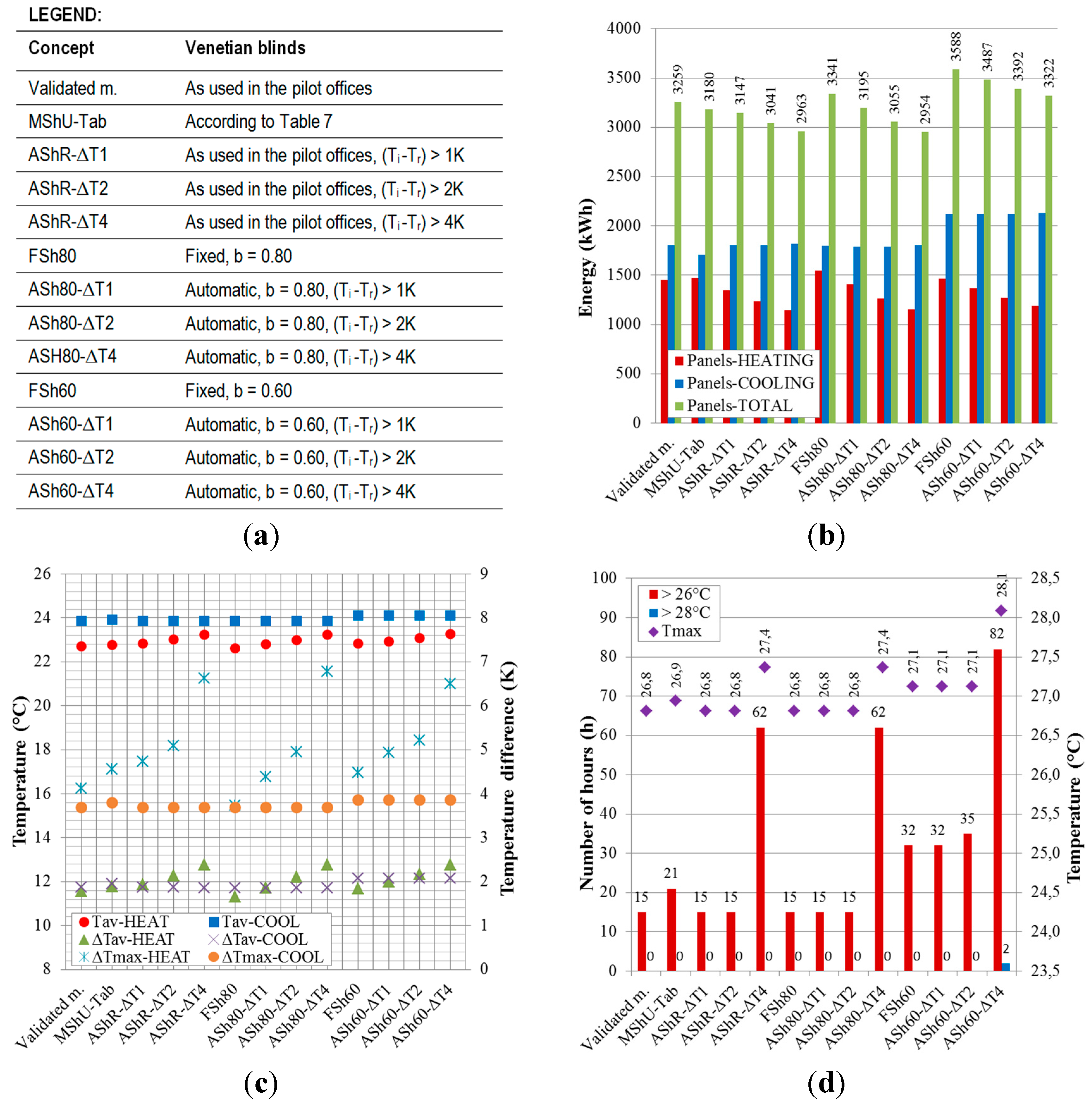

The validated model was then used for the evaluation of different retrofitting concepts for building envelopes. The results of these simulations clearly showed that, without effective shading devices (e.g., venetian blinds), the concepts with radiant ceiling panels cannot, in the case of offices, guarantee thermal comfort in the cooling season. It was therefore concluded that, for concepts of this kind, the use of adjustable shading devices is absolutely necessary, irrespective of any shading provided by a roof. Additionally, it was established that adequate thermal comfort can only be achieved if the façades provide effective shading in combination with glazing with a g-value close to 0.33 or lower. It was also concluded that the use of shading devices with a shading coefficient of less than 0.80 in the cooling season is not to be recommended. In the case of automatic shading, the criterion of 1 K for the difference between the indoor air temperature and the temperature at the room regulator proved to be the most suitable for efficient regulation, which is needed for adequate thermal comfort.

The performed simulations showed that, in terms of the heating and cooling energy use and comfortable indoor air temperatures, the optimal proportion of glazing was roughly 36% of the entire façade. Reduction of this ratio resulted in higher energy utilization for heating and cooling. In the case when the ratio was increased, higher deviations occurred in the average air temperatures, and there was also a significant increase in the air temperature fluctuations. A smaller proportion of glazing of the façade, together with lower g-values and higher shading coefficients of the glazing, would guarantee better thermal comfort in the offices. On the other hand, it is well-known that this would almost certainly reduce the penetration of daylight into such rooms. Further analysis is needed in order to be able to define the optimal combinations between the energy utilization for heating and cooling, appropriate indoor thermal conditions, and sufficient daylight illumination.

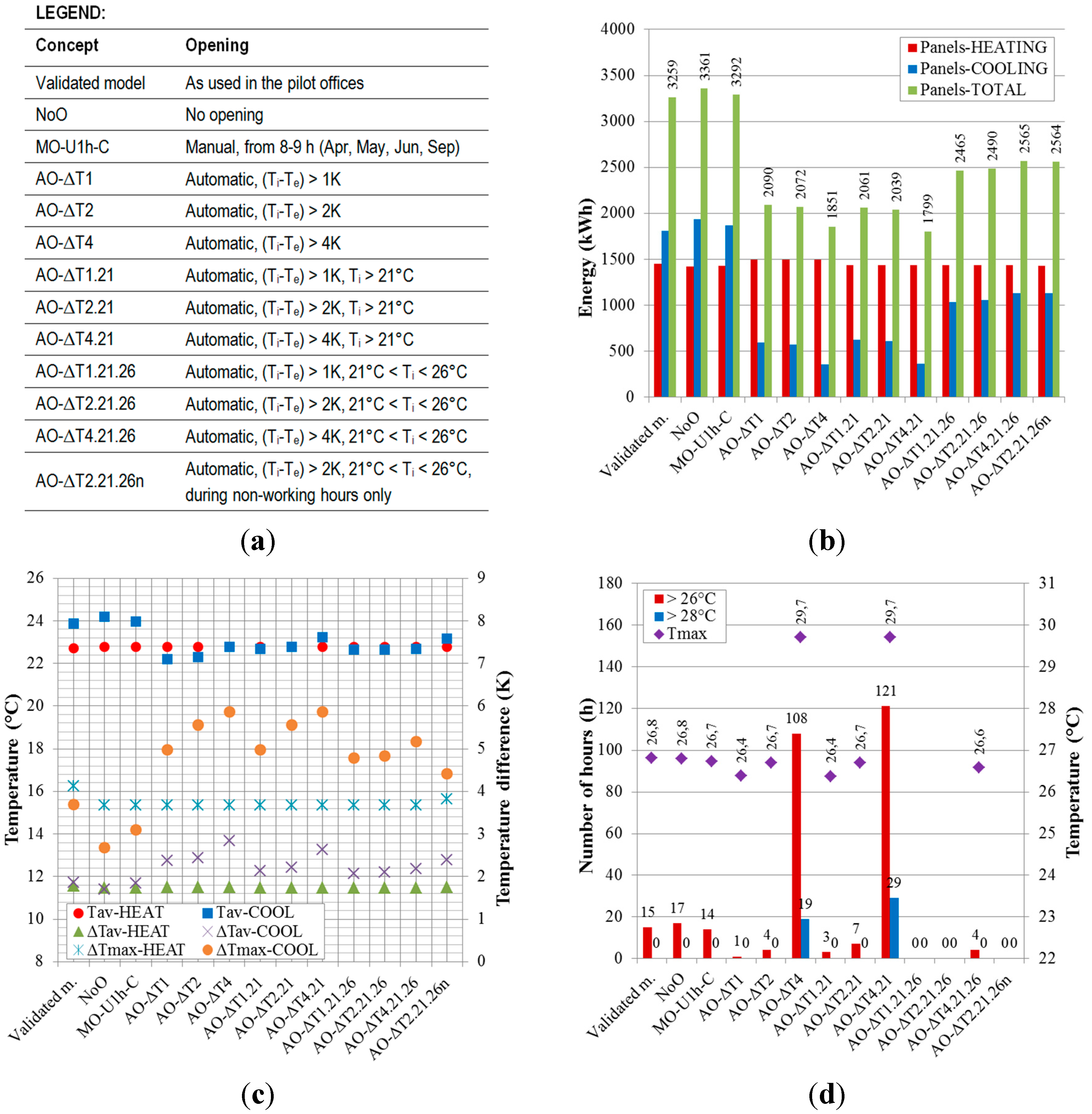

The results of the present study confirmed the validity of the hypothesis that strategies for window opening in the cooling period can considerably influence building performance in the case of the proposed retrofitting concepts. Actually, a decrease in the average air temperatures, in combination with an increase in indoor air temperature fluctuations, was detected. The analysis also revealed that these temperature fluctuations can be partly minimized when the following temperature conditions for opening the window are used: an indoor air temperature 2 K higher than the outdoor temperature, and an indoor air temperature between 21 °C and 26 °C, and opening during non-working hours only. It was also established that strategies for window opening, using such reasonable parameters, can considerably reduce the energy utilization needed for cooling.

The results of the study have also clearly showed that a comprehensive TRNSYS model can reliably evaluate various retrofitting concepts of building envelopes for offices. Dynamic simulations have reflected the indoor environment of the retrofitted offices, and have made it possible to determine the benefits and limitations of individual design concepts. It is expected that, with certain modifications, this model could be effectively applied for the evaluations of concepts that could be used in other climatic environments.