1. Introduction

Access to modern and reliable energy services is not explicitly included in the Millennium Development Goals list. However, it is recognized that energy access is a key component for the achievement of most Millennium Development Goals (MDG). International cooperation programmes are ever more focusing on energy strategies to be implemented by NGOs as a means to empower local communities in their effort to reach education, water sanitation, environmental, poverty and hunger targets.

In this paper we present a case study, typical in the Sub-Saharan area of Africa. The case study regards the implementation of the domestic biogas programme within a more comprehensive energy project named Best Ray project—Bringing Energy Services to Tanzanian Rural Areas. Best Ray is a European Commission funded project (2008–2011), which aims to provide energy services to poor non-served rural communities living in the Arumeru District of Northern Tanzania by means of appropriate and renewable technologies. Particular attention was paid to biogas technologies. During its implementation the project joined the Tanzanian Domestic Biogas Programme (TDBP) [

1,

2] an ambitious national programme designed to disseminate in Tanzania 12,000 small domestic biogas installation by 2013. Best Ray’s direct contribution was limited to 25 installations.

2. Background on Best Ray Project

The objective of the Best Ray project was to empower rural communities by providing them with modern and renewable energy technologies, and to integrate principles of sustainable development into local energy policy and programs [

3,

4]. The project was run in the Oldonyosambu and Ngarenanyuki wards, in the Arusha district. The two wards (scattered villages) are populated by Masai and Meru tribes, respectively. The former rely mostly on pastoral, and the latter, on agricultural activities.

When considering the energy issues in rural African areas, one possible approach is to try to emulate typical European energy supply systems on a smaller scale. For example, in many cases, a small hydraulic turbine is installed to provide electricity for a small grid that supplies one or more villages. In other cases, a diesel generator does this. In that case, however there is a risk that an important project component, sustainability, is not adequately considered.

In order to select the most appropriate technologies and implementation strategies, an in-depth analysis of the local situation has been carried out. A number of workshops were organised while the project proposal was being prepared, which involved local stakeholders. This strategy has an essential role in cooperation activities, and represents one of the most important items to be developed [

5]. The results of the workshops were included in the proposal.

In principle, the districts are the administrative level responsible for the development of renewable energy source plans. But they lack expertise and funding. The local population is generally unaware of the different options, and is more likely to buy low quality devices, like photovoltaic panels, which soon break.

The main energy needs that were identified concern residential uses: food preparation, lighting, and powering a radio. Existing economic activities are mainly commercial, where the need for electricity is limited to lighting and charging mobile phones. Only a few manufacturing activities use electricity: grinding corn (with one diesel mill installed in every village) and a welding business.

The main energy source in the rural area is wood, which is used in the preparation of food, either directly, or through the production of charcoal. There is widespread awareness that the unsustainable use of wood is causing environmental and health problems.

In the project area, the environmental impact of using wood for energy purposes however, may be considered to be very limited compared to the impact of the agricultural and pastoral activities. In the Masai area, the environmental impact due to energy use is almost negligible, given the very low population density. Wood harvesting in Masai communities takes an average of 6 hours per week; women go into the bush twice a week. In the Meru area, most of the productive land is used for agricultural purposes. Only marginal areas are exploited for energy use. Here, wood is a scarce resource and is imported from surrounding areas, especially for institutions (such as primary and secondary schools).

In contrast, the health impact is evident. Wood is used in open fires inside the houses (bomas). Uncontrolled wood combustion is energetically inefficient and produces a lot of smoke, which causes coughing, spasms, and in some cases, severe bronchitis. In rural areas, it is not easy to treat these conditions easily.

Afforestation is one possible strategy to solve some of these problems, although over a long time-scale. Afforestation must compete with cattle grazing and agricultural land use in the two wards. Lines of Jatropha plants are used as a fence, but the seeds are not collected for energy purposes.

Light is provided by kerosene lamps (kibatari). Kerosene is bought weekly at the marketplace when there is enough money to do so. Kerosene is sold in larger towns at the price of about €0.40 per liter. The price may reach as much as € 0.50–€ 0.60, when it is resold in rural areas. The monthly cost of kerosene for lighting may be estimated at € 2 per household in the Masai area.

The project proposal was developed in order to allow the sustainability of the activities after the end of the project. By sustainability, we mean:

environmental sustainability: reducing the use of fossil fuels, and promoting the sustainable use of renewable sources;

social sustainability: involving communities and local institutions in the project activities, and promoting participation in the decision process;

economic sustainability: generating income, by developing activities based on the actual market demand for energy technologies.

3. Project Technologies and Results

During project activities, some 50 photovoltaic systems were installed in main institutional buildings (power range between 40 and 960 W) and another 100 systems (10–300 W) were installed in private households and shops by local cooperatives. All schools have been provided with energy efficient stoves with a minimum capacity of 0.5 L per student according to national standard. This is to say that a school with 1000 students was provided with an energy efficient stove that was able to cook at least 500 L of food. Stoves have been oversized to take into account population growth dynamics. In addition some 200 energy efficient stoves have been built by local women’s cooperatives, in private houses. Two small hydro plants were installed, the first (500 W) based on a Banki turbine, entirely built locally at the Arusha Technical College, and the second, (3.2 kW) which was imported. Finally, as explained below, the project has also involved domestic biogas plants.

All installations have been carried out by local staff, who had previously received technical training.

All activities and experiences were collected in two public places named Community Energy Resource Centres (CERCs). The project has built two CERCs in the villages where the weekly markets are hosted. The CERCs are run by cooperatives, formed by villagers chosen by the local community assembly. The CERCs host a number of renewable technologies which are displayed to raise people’s awareness and expectations. The CERC can be defined as a shop where energy and energy-related equipment and expertise are collected and made available to the local population.

For all of the people concerned, the CERCs can provide energy technologies, consulting, and in some cases, rebates and special offers financed by the project.

In the process developed to choose the proper technologies to be included in the CERCs, the concept of appropriate technology was kept in mind (as defined by Hazeltine & Bull, 1999, cited in Wicklein & Kachmar, 2001) [

6,

7]. In this approach, the appropriate technologies should, as far as possible:

aid humankind at the grassroots level;

provide employment for the average citizen;

be sustainable/durable over time;

use locally available resources;

promote self-reliance;

encourage self-supporting processes;

be low cost;

limit cultural damage;

limit environmental damage.

The process of selection is not easy, and can only be achieved by means of in-depth participation of the local community, especially of the women, as already mentioned.

A number of women’s cooperatives have been formed that deal with a number of issues, such as the collection of jatropha seedlings, the preparation of soap (using jatropha oil), the drying of fruit and vegetables and the construction of improved stoves. All of these cooperatives are active economic players, and can make their products available to the population through the CERCs.

4. Best Ray and the Biogas Programme

Biogas plants convert animal manure and human excrement into valuable amounts of combustible methane gas, which can be used in simple gas stoves for cooking, or in lamps for lighting.

Originally Best Ray project was designed to build big biogas systems in three local secondary schools. The schools hosted some 600–1000 students, boarding day and night. Most secondary schools, with students whose ages ranged from 12 to 18 years, are boarding in rural areas given the long distances to be covered from villages to schools in absence of transport infrastructures.

The project idea was to collect human excrement by connecting the biogas tank with the school toilets and to use the gas produced in the school kitchen. The target was to:

a) improve sanitation issue in the school and sterilize human waste through their digestion in the biogas plant;

b) supply the school with a renewable and reliable source of energy to cook food and reduce the high cost of wood purchase.

In the initial phases of the project, the Best Ray team run a feasibility study before installing the planned biogas plants to supply energy for the kitchens in three secondary schools. The assessment found out that:

a) the biogas production from the toilets would satisfy from 9 to 19% of the secondary schools’ energy requirements. To replace the consumption of wood completely, between 25 and 108 cows would be needed in the three schools. The introduction of cattle into the school is not feasible in the short term, and goes beyond the project’s goals.

b) critical issues regarding the management of the plants emerged. It was not clear who would be responsible for proper management of the plant (and of cattle husbandry). The turnover of personnel in the secondary school is unpredictable and occurs often. The training of local personnel during project implementation, therefore, would not have been enough to guarantee management of the plan in the coming years. Moreover during school holiday the waste supply is interrupted for nearly one month;

c) any problem that would arise and harm the functioning of the infrastructure would have raised a critical health issue. With an unclear long term management plan, potential health risks would have overcome energy benefits. In any case, sludge obtained from human manure may have a residual pathogen load, and must, therefore, be treated properly before being utilised in farming.

Considering the limited positive impact of biogas production on wood consumption and the significant risks associated with the construction and management of the plant, it was suggested to give up the project of biogas plants in schools (also considering the educational approach, following the main rules regarding health and environmental problems and risk communications [

8]).

Meanwhile the experiences gained in the domestic biogas program by other NGOs operating in Tanzania, were showing much greater potential for the spread of small-scale biogas plants. To make a biogas plan sustainable in the medium to long term, it is necessary that the same person manages, owns and reaps the benefits of the installation. This can only be achieved at the domestic level.

To solve the school problems it was better to deal the two issues separately. The sanitation problem of the toilets was overcome by the construction of septic tanks and the energy supply cost was cut thanks to the introduction of energy efficient stoves. The costs of sanitation infrastructure were bore by the District, whereas Best Ray project activities covered the costs for new kitchens and improved energy efficient stoves. The project budget was hence modified and the resources originally set aside for the construction of large biogas in secondary schools, were directed to:

Within the new strategy Best Ray joint the Tanzanian Domestic Biogas Programme, which was implemented locally by Camartec (a Tanzanian government-controlled organisation, under the Ministry of Industries located in Arusha) and the Dutch development organisation, Stichting Nederlandse Vrijwilligers (SNV).

In the last two decades, SNV has developed a strategy to increase the use of simple biogas production technologies, in several countries, such as Vietnam, Bangladesh, Cambodia, Laos, Nepal, Benin, Burkina Faso, Cameroon, Senegal, Rwanda, Ethiopia, Kenya and Uganda. The SNV approach uses a so-called “multi-stakeholder sector development” approach, building on organizational and institutional skills that are already available in the country. SNV also establishes and optimizes cooperation between the various players that need to be involved. For instance, where “operation & maintenance” of a biogas plant will be carried out by the households, other tasks should be undertaken by multiple stakeholders. The programme will be considered successful when a commercial viable biogas sector has been developed, with companies acting as suppliers to address an active demand from households that are willing to invest.

In Tanzania, biogas technology was initially introduced by the Small Industries Development Organisation (SIDO) in 1975. Camartec and the German cooperation organization Gesellschaft für Technische Zusammenarbeit (GTZ) carried this work forward in the 1980s–1990s by developing, promoting and providing training in the biogas sector. During those years, interested parties built around 6000 biogas digesters.

The Tanzania Biogas Stakeholders Group, organised by SNV, opted for a modified Camartec design, in four different sizes, to respond to the energy needs of individual households and the availability of animal dung.

In 2008, SNV estimated that the technical potential for domestic biogas in Tanzania is around 165,000 households. The Tanzanian Domestic Biogas Programme (TDBP) aims to support the construction of 12,000 new biogas plants nationwide, and to keep at least 95% of the constructed biogas plants in continued operation. A major challenge is the relatively high initial investment involved in building a biogas plant.

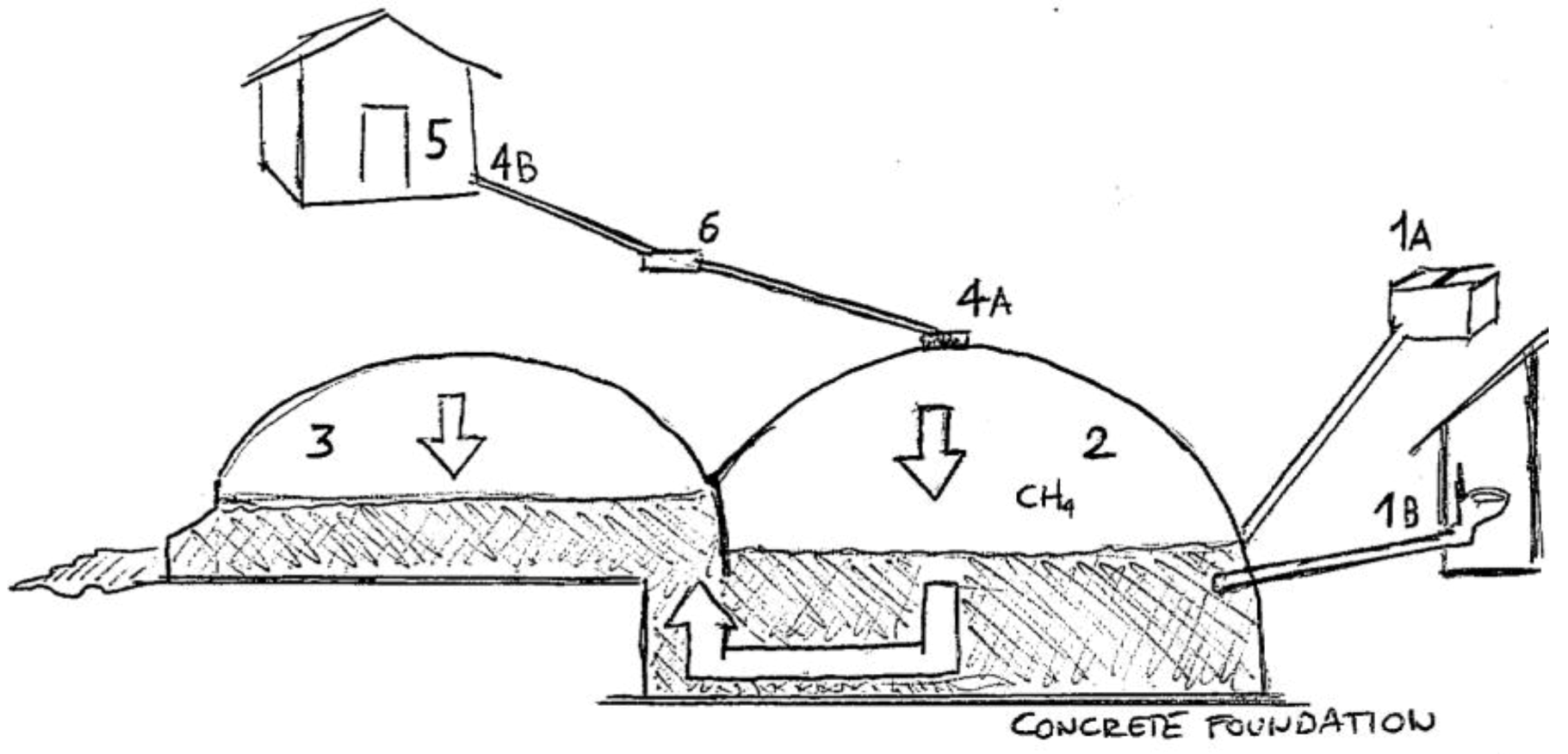

Figure 1.

Modified Camartec Biogas plant

Figure 1.

Modified Camartec Biogas plant

In

Figure 1 a basic sketch of a biogas plant Camartec design is given. The plant consists in the following parts:

1A and 1B are the inlets. A small concrete basin is built to mix cow dung with water with a 1 : 1 ratio and the basin is connected to the digester with a PVC pipe. Human toilets can also be connected;

the digester (2) has the shape of a dome. The gas is produced by the fermentation of excrements. The gas accumulates in the top part of the dome. The gas pressure pushes the exhausted sludge into the top chamber (3). The function of the top chamber is to provide enough pressure for the gas to reach the kitchen and to complete the digestion of the excrements in case the retention time into the digester has not been respected;

on the top of the digester, through a valve (4A), a pipe leads the gas to the kitchen were the gas is burnt in a special burner (5). An additional valve (4B) is installed before the burner for security purposes;

on the lowest point of the pipe network a water trap (6) is positioned in order to collect the condensing water that accumulating may obstruct the pipe and reduce gas flow. A valve let discharge the water on occurrence;

the residue of the anaerobic digestion process (bio-slurry) can be easily collected and used as an organic fertiliser to increase agricultural productivity (7).

A minimum of 20 kg of manure is required, on a daily basis, to feed the plant. Farmers should keep a minimum of two sedentary cows to generate sufficient gas to meet their daily basic cooking and lighting needs.

Table 1 shows design parameters for different digester sizes.

Table 1.

Plant volume and expected daily biogas production production (warm climate) [

9].

Table 1.

Plant volume and expected daily biogas production production (warm climate) [9].

| Parameter | Unit | 3 m3 tank | 4.5 m3 tank | 6.7 m3 tank | 10 m3 tank |

|---|

| Plant volume | dm3 | 3900 | 5850 | 8775 | 13,163 |

| Gas storage volume | dm3 | 900 | 1350 | 2025 | 3038 |

| Digester volume | dm3 | 3000 | 4500 | 6750 | 10,125 |

| Min feeding | kg d-1 | 25 | 38 | 56 | 84 |

| Max feeding | kg d-1 | 38 | 56 | 84 | 127 |

| Min daily gas production | kg d-1 | 1.00 | 1.50 | 2.25 | 3.38 |

| Max daily gas production | kg d-1 | 1.50 | 2.25 | 3.38 | 5.06 |

Normally biogas plants can also be attached to the toilet. With this approach, biogas use has a number of positive advantages, not only with respect to energy issues (reducing the cost of fuel for cooking and lighting) but also to gender issues (reducing the time women need to cook, reducing workload in the collection of wood and the cleaning of pots), to sanitation and health matters (biogas is both smokeless and soot-less, reducing respiratory and eye problems; the toilet attachment improves hygiene and reduces odours), to agricultural needs (reducing the use of chemical fertilisers, improving crop yields and supporting animal husbandry), and environmental issues (improving soil fertility and plant nutrition, reducing deforestation and greenhouse gas emissions).

Particular attention must be paid to the min-max retention time of cattle dung in the digesters. Appropriate training should be given to end users in order to calibrate the dung input with the necessary retention time. The ratio between cattle dung and water to feed the plant is 1 : 1. Other design parameters are shown in

Table 2

Table 2.

Biogas plant design parameters [

9].

Table 2.

Biogas plant design parameters [9].

| Parameter | Unit | Quantity |

|---|

| Dung/water ratio (volume) | | 1.00 |

| Specific gas production | m3 kg-1 | 0.040 |

| Minimum daily gas production | m3 d-1 | 1.00 |

| Maximum retention time | days | 60 |

| Minimum retention time | days | 40 |

| Gas storage volume | % of max dgp | 60% |

The two CERCs were asked to select local masons (fundi) to undergo two-week training on the Camartec premises. Four masons were identified, two of whom had proven experience in building construction, and the remaining two had a more vague profile. Manual and basic mathematical skills were necessary to complete a small biogas installation. Before being accredited as biogas masons, the participants had to build two biogas plants, contributing to some 40% of the final expenses

In Best Ray project area, each 6 m

3 digester can cost around 1.4–1.5 million Tanzanian shillings (TZS, equivalent to some 700–800 Euro).

Table 3 shows costs breakdown. Technical supervision was then provided. The final price of the biogas installation is strongly influenced by transportation costs. Most remote areas face higher transportation costs. The price of bricks is another element that can vary considerably locally. Bricks are normally produced were clay soil is available.

Table 3.

Cost breakdown for a 6 m3 biogas digester.

Table 3.

Cost breakdown for a 6 m3 biogas digester.

| Material | Quantity | Unit price (TZS) | Total |

|---|

| Sand | 1 trip | 120,000 + transp | 120,000 + transp |

| Aggregate | 1 trip (+ other materials) | 120,000 + transp | 120,000 + transp |

| Cement | 15 bags | 13,500 | 202,500 |

| Bricks | 850 pc | 180 | 153,000 |

| Lime | 4 bags (25 kg) | 8500 | 34,000 |

| Water-proof cement | 4 bags (4 kg) | 3500 | 14,000 |

| Chicken wire | 1 roll (35 m) | 45,000 | 45,000 |

| Wire mesh (mviringo) | 1 pc | 12,000 | 12,000 |

| Round bars | 1 pc | 11,000 | 11,000 |

| PVC pipes | 1 pc (6 m) | 14,000 | 14,000 |

| Transport-bricks | 3 trip | 130,000 | 390,000 |

| Valve | 1 pc | 8000 | 8000 |

| Socket | 10 pc | 500 | 5000 |

| Nipple | 5 pc | 500 | 2500 |

| Elbow | 5 pc | 500 | 2500 |

| Thread seal | 5 pc | 500 | 2500 |

| Union | 1 pc | 700 | 700 |

| Nails | 1 kg | 1500 | 1500 |

| Brush | 1 pc | 5000 | 5000 |

| Reducing bush | 1 pc | 800 | 800 |

| Manpower (aggregated) | | | 400,000 |

| Total | | | 1,544,000 |

Once the technical ability of the masons had been established, the CERC started promoting small biogas installations in the local community. An initial incentive of 80% of the final cost was granted for the first four installations. The beneficiaries were selected by the local community, through the CERC. The incentive was subsequently reduced, to reach a long-term incentive of approximately TZS 300,000, which will be given by Camartec-SNV, until 2013. Support can currently be obtained from the CERC in the project area. Camartec has run periodical check-ups of Best Ray installations, in order to improve the technical performances of the masons.

5. Lessons Learned Through a Monitoring Mission One Year After the End of the Project

During the project’s 18 months of activity, 25 biogas digesters have been built (

Figure 2); most of them have a capacity of 6 m

3, only a few tanks, of 9 m

3.

Figure 2.

Construction phase.

Figure 2.

Construction phase.

The cost of transporting materials, sand, bricks and aggregate, accounted for approximately 25% of the final cost. Biogas plants were generally appreciated by final costumers; cooking and food preparation times (the time to have a hot flame, especially in the early morning) were appreciated much more than other considerations concerning the environment and health, or the time spent collecting wood. Most end users were using the biogas waste as a fertilizer in their fields and orchards. The humid content of the waste was also appreciated in areas were irrigation is not possible.

A variation in biogas productivity was found between installations in the northern area of the project (Oldonyosambu Ward) and the southern area (Ngarenanyuki), the former getting much drier during dry season then the latter. The reduced productivity in Oldonyosambu Ward was most probably caused by the poor seasonal diet of cows.

A 6 m3 tank can supply 1 m3 of gas per day. This is a good amount for a rural family, but it may not be sufficient for all cooking activities. Therefore, biogas does not entirely replace the traditional cooking methods. Wood fires are still maintained to cook traditional food. Women interviewed have said that they did not want to waste the biogas on cooking beans, as biogas is very helpful in the early morning to prepare breakfast. According to local knowledge it is better not to soak dry beans before cooking as the saponin content may be washed away. The intestine may develop ulcers on diets highly reliant on beans and saponin is believed to be an effective protection. Dry beans need only a few hours of cooking before they are edible.

Particular conditions must be assured in order to successfully introduce the domestic biogas technology. One of the most challenging one is assuring the permanent presence of at least two cows. The “permanent” condition is not always possible. During the dry season, if there is not a reliable source of water in the neighborhood, cows have to be moved somewhere else, in order to survive [

10]. In that case the biogas tank will dry up and it has to be emptied and cleaned before being started again. Cleaning a biogas tank is a nasty and dangerous job.

Once these conditions are met, the technology proves to be effective.

Assessments have been carried out during project activities and one year after the project completion. All biogas installations are still working after 2–3 years from installation in August 2012. Some technical intervention was needed in a few cases. In five cases the water trap was omitted and it was necessary to install one in order to remove the condensing water from the pipes. In three cases the internal waterproof cement lay had to be reinforced as the mason had not followed technical specification of the project and the tank was leaking. By interviewing the final beneficiaries, it was possible to identify the reasons why the biogas was particularly appreciated (in order of importance):

time saving compared to traditional fire. More importance is given to reduced cooking time rather than saving time to collect wood. Switching on the gas fire is much quicker than setting wood fire, especially in the early morning when some food has to be ready before youths go to school. Rarely biogas has become a complete substitute of wood stove. Most beneficiaries were still using a wood fire (mostly in energy efficient stoves provided by the project) to cook food. They were using biogas for selected cooking activities: breakfast, tea and other recipes that need a short time to be ready (i.e. less than 1 hour);

the quality of the flame and its calorific value;

the possibility to regulate flame output with precision;

the digestion of cow dung and the possibility to use sludge as manure: cow dung could not be directly used in the field. It needs to be digested first. The biogas tank perfectly fits into the management of rural dwelling as it provides a place where cow dung can be disposed before being used. The management of the biogas system does not take additional time, compared to the traditional cleaning and disposing of cow dung operations;

reduced smoke: note, however, that all biogas beneficiaries already had a kitchen area separated by the house. The smoke impact on human health was therefore already limited.

6. Conclusions

The Tanzania Biogas experience was successful in obtaining several objectives, providing low cost combustible for domestic purposes, lowering the impact on the environment, relieving women from part of their daily work and reducing health risks. It has been a relevant income generating activity for the masons involved into the construction.

The link between sanitation and energy, though, it is not always possible. Trying to achieve results at any cost may jeopardize the sustainability of the infrastructure. The Best Ray project was designed with the idea of a cutting-edge strategy to solve sanitation and energy problems in secondary schools by introducing biogas systems. The field works proved that it was better to downscale the target, to achieve the two targets separately and to direct the economic resources to the domestic sector.

Training activities were long but good technical levels were achieved. Through incentives, the technology managed to penetrate the market and 25 tanks were built. Nonetheless, the technology is expensive for a rural area. The local cost of transport and bricks represent a significant economic barrier. The presence of a national program was very helpful both for the Best Ray project management that found local resources to implement an important part of its project strategy once the original target proved to be unachievable, and for the final beneficiaries that were participating to a wider program nationwide.

All systems, with minor interventions, are still working after 2–3 years from construction. Customers are generally satisfied. Final beneficiaries in fact pointed out technology characteristics that were not really identifiable before by those who wrote the project (such as time saving in the early morning and fire regulation). The project was, however, stressing the health advantage by reducing smoke content into houses. This proved not to be a relevant issue in the opinion of the final beneficiaries.

Biogas technology is an efficient way to tackle sanitation and energy problems at the same time. A reliable management strategy though must be elaborated prior to introducing those technologies in public institutions where the benefit of the system management (i.e., the gas) is not directly used by the people taking care of the installation.