How Do Technological Skills Improve Reverse Logistics? The Moderating Role of Top Management Support in Information Technology Use and Innovativeness

Abstract

:1. Introduction

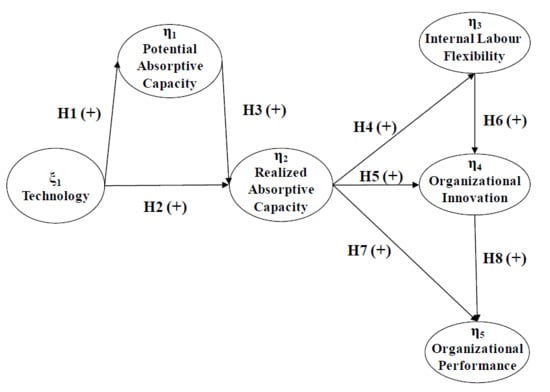

2. Hypotheses

2.1. Technological Skills and RL

2.2. The Moderating Role of TMS for IT Use in the Relationship between Technological Skills and RL

2.3. The Moderating Role of Organizational Innovativeness in the Relationship between Technological Skills and RL

3. Methodology

3.1. Sample

3.2. Variables

4. Results

5. Discussion and Conclusions

5.1. Implications for Researchers

5.2. Implications for Managers

5.3. Limitations and Future Research

Author Contributions

Funding

Conflicts of Interest

Appendix A

- Top Management Support for IT.Indicate the degree to which you agree or disagree with the following statements about top management support.

- Top management cultivates technology project champions.

- Top management ensures adequate funding of technology research and development.

- Top management restructures work processes to leverage technology opportunities in the organization.

- Top management facilitates technology transfer throughout the organization.

- Technological Skills.Indicate the extent to which you agree or disagree with the following statements in relation to the units’ technical skills. Answers may refer to a department or the person in charge of technology.

- Unit skills in the object-oriented languages and systems for customer-server application development are excellent.

- Item measures for IT department technical skills in business application software performance are very superior to those of the closest competitors.

- Item measures for IT department technical skills in communication services efficiency are very superior to those of the closest competitors.

- Information systems unit skills in fourth-generation programming languages areas are excellent.

- Organizational Innovativeness.Where applicable, indicate the extent of changes that have taken place in your company over the past three years.

- Your company’s spending on new product/process development activities.

- Number of new products/processes added and introduced by your company.

- Your adoption of technologies developed by other companies or industries.

- Top management emphasis on R&D, technological leadership and innovation rather than marketing.

- Reverse Logistics.Please indicate your degree of agreement or disagreement with the following statements related to the characteristics of your company. Reverse logistics processes are important or might be important for my company because:

- They involve cost reduction.

- They improve service quality.

- They result in better prices.

- They improve the return policy (returned material).

- They improve product variety.

- They improvedelivery speed (time).

- Organizational PerformanceRelative to your main competitors, what is your firm’s performance in the last three years in the following areas?

- Organizational performance measured by return on assets (economic profitability or ROA)

- Organizational performance measured by return on equity (financial profitability or ROE)

- Organizational performance measured by return on sales (percentage of profits over billing volume)

- Recovery of investments

- Organization’s market share in its main products and markets

- Growth of sales in its main products and markets

References

- Wisner, J.D.; Tan, K.C.; Leong, G.K. Principles of Supply Chain Management: A Balanced Approach, 2nd ed.; South-Western, Cengage Learning: Mason, OH, USA, 2008. [Google Scholar]

- Rogers, D.S.; Tibben-Lembke, R.S. Going Backwards: Reverse Logistics Trends and Practices; Reverse Logistics Executive Council: Pittsburgh, PA, USA, 1999. [Google Scholar]

- Wernerfelt, B. A Resource-based view of the firm. Strateg. Manag. J. 1984, 5, 171–180. [Google Scholar] [CrossRef]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar] [CrossRef]

- Mihi Ramírez, A. Un Análisis Causal de la Relación Entre la Creación del Conocimiento y la Logística Inversa; Universidad de Granada: Granada, Spain, 2010; Available online: http://hdl.handle.net/10481/4935 (accessed on 10 December 2018).

- Lee, C.K.M.; Lam, J.S.L. Managing reverse logistics to enhance sustainability of industrial marketing. Ind. Mark. Manag. 2012, 41, 589–598. [Google Scholar] [CrossRef]

- Faisal, M.N. Sustainable Supply chains: A study of interaction among the enablers. Bus. Process Manag. J. 2010, 16, 508–529. [Google Scholar] [CrossRef]

- Jayaraman, V.; Ross, A.; Agarwal, A. Role of information technology and collaboration in reverse logistics supply chain. Int. J. Logist. Res. Appl. 2008, 11, 409–425. [Google Scholar] [CrossRef]

- Beske, P.; Seuring, S. Putting sustainability into supply chain management. Supply Chain Manag. Int. J. 2014, 19, 322–331. [Google Scholar] [CrossRef]

- Dubey, R.; Gunasekaran, A.; Childe, S.J.; Wamba, S.F.; Papadopoulos, T. The impact of Big Data on world-class sustainable manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 631–645. [Google Scholar] [CrossRef]

- Ferreira, M.A.; Jabbour, C.J.C.; de Sousa Jabbour, A.B.L. Maturity levels of material cycles and waste management in a context of green supply chain management: An innovative framework and its application to Brazilian cases. J. Mater. Cycles Waste Manag. 2015, 19, 516–525. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective. Resour. Policy 2015, 46, 37–50. [Google Scholar] [CrossRef]

- Walker, H.; Jones, N. Sustainable supply chain management across the UK private sector. Supply Chain Manag. Int. J. 2012, 1, 15–28. [Google Scholar] [CrossRef]

- Hazen, B.T.; Cegielski, C.G.; Hanna, J.B. Diffusion of green supply chain management: Examining perceived quality of green reverse logistics. Int. J. Logist. Manag. 2011, 22, 373–389. [Google Scholar] [CrossRef]

- Prakash, C.; Barua, M.K. Integration of AHP-TOPSIS method for prioritizing the solutions of reverse logistics adoption to overcome its barriers under fuzzy environment. J. Manuf. Syst. 2015, 37, 599–615. [Google Scholar] [CrossRef]

- Ravi, V.; Shankar, R. Analysis of interactions among the barriers of reverse logistics. Technol. Forecast. Soc. Chang. 2005, 72, 1011–1029. [Google Scholar] [CrossRef]

- Mai, E.; Chen, H.; Anselmi, K. The role of returns management orientation, internal collaboration and information support in reverse logistics. J. Transp. Manag. 2012, 23, 45–59. [Google Scholar]

- Myerson, P.A. Supply Chain and Logistics Management Made Easy: Methods and Applications for Planning, Operations, Integration, Control and Improvement, and Network Design; FT Press: Upper Saddle River, NJ, USA, 2015. [Google Scholar]

- Sharma, S.K.; Panda, B.N.; Mahapatra, S.S.; Sahu, S. Analysis of barriers for reverse logistics: An Indian perspective. Int. J. Model. Optim. 2011, 1, 101–106. [Google Scholar] [CrossRef]

- Srivastava, S.K. Reverse Supply Chains: Issues and Analysis; CRC Press Inc.: Boca Raton, FL, USA, 2013. [Google Scholar]

- Barney, J.B. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Grant, R.M. Toward a knowledge based theory of the firm. Strateg. Manag. J. 1996, 17, 109–122. [Google Scholar] [CrossRef]

- Ansari, Z.N.; Kant, R. A state-of-art literature review reflecting 15 years of focus on sustainable supply chain management. J. Clean. Prod. 2017, 142, 2524–2543. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Myers, M.B.; Richey, R.G. Information support for reverse logistics: The influence of relationship commitment. J. Bus. Logist. 2002, 23, 85–106. [Google Scholar] [CrossRef]

- Daugherty, P.J.; Richey, R.G.; Genchev, S.E.; Chen, H. Reverse logistics: Superior performance through focused resource commitments to information technology. Transp. Res. Part E Logist. Transp. Rev. 2005, 41, 77–92. [Google Scholar] [CrossRef]

- Christopher, M. Logistics and Supply Chain Management, 4th ed.; Henry Ling: Dorchester, UK, 2011. [Google Scholar]

- Wade, M.; Hulland, J. The resource-based view and information systems research: Review, extension, and suggestions for future research. MIS Q. 2004, 28, 107–142. [Google Scholar] [CrossRef]

- Benavides Velasco, C.A.; Quintana Garcia, C. Proceso y sistemas organizativos para la gestión del conocimiento: El papel de la calidad total. Bol. ICE Econ. 2005, 2838, 37–52. [Google Scholar]

- Ho, G.T.S.; Choy, K.L.; Lam, C.H.Y.; Wong, D.W.C. Factors affecting implementation of reverse logistics: A survey among Hong Kong businesses. Meas. Bus. Excell. 2012, 16, 29–46. [Google Scholar] [CrossRef]

- Richey, R.G.; Genchev, S.E.; Daugherty, P.J. The role of resource commitment and innovation in reverse logistics performance. Int. J. Phys. Distrib. Logist. Manag. 2005, 35, 233–257. [Google Scholar] [CrossRef]

- Huscroft, J.R.; Hazen, B.T.; Hall, D.J.; Skipper, J.B.; Hanna, J.B. Reverse logistics: Past research, current management issues, and future directions. Int. J. Logist. Manag. 2013, 24, 304–327. [Google Scholar] [CrossRef]

- McCracken, M.; Wallace, M. Towards a redefinition of strategic HRD. J. Eur. Ind. Train. 2000, 24, 281–290. [Google Scholar] [CrossRef]

- Christmann, P. Effects of “best practices” of environmental management on cost advantage: The role of complementary assets. Acad. Manag. J. 2000, 43, 663–680. [Google Scholar]

- Huang, Y.C.; Yang, M.L. Reverse logistics innovation, institutional pressures and performance. Manag. Res. Rev. 2014, 37, 615–641. [Google Scholar] [CrossRef]

- Martin-de Castro, G.; Delgado-Verde, M.; Navas-López, J.E.; Cruz-González, J. The moderating role of innovation culture in the relationship between knowledge assets and product innovation. Technol. Forecast. Soc. Chang. 2013, 80, 351–363. [Google Scholar] [CrossRef]

- Sarkis, J.; Helms, M.M.; Hervani, A.A. Reverse Logistics and Social Sustainability. Corp. Soc. Responsib. Environ. Manag. 2010, 17, 337–354. [Google Scholar] [CrossRef]

- Mata, F.J.; Fuerst, W.L.; Barney, J.B. Information technology and sustained competitive advantage: A resource based analysis. MIS Q. 1995, 19, 487–505. [Google Scholar] [CrossRef]

- García-Sánchez, E.; García-Morales, V.J.; Bolívar-Ramos, M.T. The influence of top management support for ICTs on organisational performance through knowledge acquisition, transfer, and utilisation. Rev. Manag. Sci. 2017, 11, 19–51. [Google Scholar] [CrossRef]

- Morgan, T.R.; Glenn Richey, R., Jr.; Autry, H.W. Developing a reverse logistics competency: The influence of collaboration and information technology. Int. J. Phys. Distrib. Logist. Manag. 2016, 46, 293–315. [Google Scholar] [CrossRef]

- Civi, E. Knowledge management as a competitive asset: A review. Mark. Intel. Plan. 2000, 18, 166–174. [Google Scholar] [CrossRef]

- Anderson, J.C.; Narus, J.A. A model of the distributor’s perspective of distributor-manufacturer working relationship. J. Mark. 1984, 48, 62–74. [Google Scholar] [CrossRef]

- Aitken, J.; Harrison, A. Supply governance structures for reverse logistics systems. Int. J. Oper. Prod. Manag. 2013, 33, 745–764. [Google Scholar] [CrossRef]

- Gu, Q.; Jiang, W.; Wang, G.G. Effects of external and internal sources on innovation performance in Chinese high-tech SMEs: A resource-based perspective. J. Eng. Technol. Manag. 2016, 40, 76–86. [Google Scholar] [CrossRef]

- Bowersox, D.J.; Close, D.J.; Stank, T.P. How to master cross-enterprise collaboration. Supply Chain Manag. Rev. 2003, 7, 18–27. [Google Scholar]

- Lewis, I.; Talalayevsky, A. Logistics and information technology: A coordination perspective. J. Bus. Logist. 1997, 18, 141–157. [Google Scholar]

- Rajeswari, K.S.; Anantharaman, R.N. Development of a scale to measure stress among software professionals: A factor analytic study. In Proceedings of the ACM SIGCPR Conference, Philadelphia, PA, USA, 10–12 April 2003; pp. 34–43. [Google Scholar]

- Agrawal, S.; Singh, R.K.; Murtaza, Q. A literature review and perspectives in reverse logistics. Resour. Conserv. Recycl. 2015, 97, 76–92. [Google Scholar] [CrossRef]

- Wittstruck, D.; Teuteberg, F. Understanding the success factors of sustainable supply chain management: Empirical evidence from the electrics and electronics industry. Corp. Soc. Responsib. Environ. Manag. 2012, 19, 141–158. [Google Scholar] [CrossRef]

- Grant, R.M. The Resource-Based Theory of Competitive Advantage: Implications for Strategy Formulation. Calif. Manag. Rev. 1991, 33, 114–135. [Google Scholar] [CrossRef]

- Tsai, W.C.; Tang, L.L. A model of the adoption of radio frequency identification technology: The case of logistics service firms. J. Eng. Technol. Manag. 2012, 29, 131–151. [Google Scholar] [CrossRef]

- Ngai, E.W.T.; Chau, D.C.K.; Poon, J.K.L.; Chan, A.Y.M.; Chan, B.C.M.; Wu, W.W.S. Implementing an RFID-based manufacturing process management system: Lessons learned and success factors. J. Eng. Technol. Manag. 2012, 29, 112–130. [Google Scholar] [CrossRef]

- Porter, M.E. The five competitive forces that shape strategy. Special Issue on HBS Centennial. Harv. Bus. Rev. 2008, 86, 78–93. [Google Scholar]

- Byrd, A.; Davidson, N. Examining possible antecedents of IT impact on the supply chain and its effect on firm performance. Inf. Manag. 2003, 41, 243–255. [Google Scholar] [CrossRef]

- Ravichandran, T.; Liu, Y. Environmental determinism and strategic choice: Exploring the determinants of information technology investment strategy. Decis. Sci. 2011, 42, 537–574. [Google Scholar] [CrossRef]

- Lee, J.; Park, S.; Baker, R. The moderating role of top management support on employees’ attitudes in response to human resource development efforts. J. Manag. Organ. 2018, 24, 369–387. [Google Scholar] [CrossRef]

- Rogers, E. Diffusion of Innovations, 5th ed.; Free Press: New York, NY, USA, 2003. [Google Scholar]

- Pesämaa, O. Personnel and action control in gazelle companies in Sweden. J. Manag. Control 2017, 28, 107–132. [Google Scholar] [CrossRef]

- Frohman, A. Building a culture for innovation. Res. Technol. Manag. 1998, 41, 9–12. [Google Scholar] [CrossRef]

- Pérez, D.; Dressler, M. Tecnologías de la información para la gestión del conocimiento. Intang. Cap. 2007, 15, 31–59. [Google Scholar]

- Amadeus. 2009. Available online: http://amadeus.bvdep.com/ip/ (accessed on 6 April 2010).

- Baer, M.; Frese, M. Innovation is not enough: Climate for initiative and psychological safety, process innovations, and firm performance. J. Organ. Behav. 2003, 24, 45–68. [Google Scholar] [CrossRef]

- Westphal, J.D.; Fredickson, J.W. Who directs strategic change? Director experience, the selection of new CEOs, and change in corporate strategy. Strateg. Manag. J. 2001, 22, 1113–1137. [Google Scholar] [CrossRef]

- Mihi-Ramirez, A. Product return and logistics knowledge: Influence on performance of the firm. Transp. Res. Part E Logist. Transp. Rev. 2012, 48, 1137–1151. [Google Scholar] [CrossRef]

- Armstrong, J.S.; Overton, T.S. Estimating nonresponse bias in mail surveys. J. Mark. Res. 1977, 14, 396–403. [Google Scholar] [CrossRef]

- Konrad, A.M.; Linnehan, F. Formalized HRM structures: Coordinating equal employment opportunity or concealing organizational practice? Acad. Manag. J. 1995, 38, 787–820. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; Organ, D.W. Self-reports in organization research: Problems and prospects. J. Manag. 1986, 12, 531–544. [Google Scholar]

- Ray, G.; Muhanna, W.A.; Barney, J.B. Information technology and the performance of the customer service process: A resource-based analysis. MIS Q. 2005, 29, 625–652. [Google Scholar] [CrossRef]

- Zahra, S.A. Environment, corporate entrepreneurship, and financial performance: A taxonomic approach. J. Bus. Ventur. 1993, 8, 319–340. [Google Scholar] [CrossRef]

- Murray, J.; Kotabe, M. Sourcing strategies of U.S. service companies: A modified transaction-cost analysis. Strateg. Manag. J. 1999, 20, 791–809. [Google Scholar] [CrossRef]

- Choi, J.; Kim, B.; Liu, X.; Simunic, D. Audit pricing, legal liability regimes, and Big 4 premiums: Theory and cross-country evidence. Contemp. Account. Res. 2008, 25, 1–49. [Google Scholar] [CrossRef]

- Douglas, T.J.; Judge, W.Q. Total quality management implementation and competitive advantage: The role of structural control and exploration. Acad. Manag. J. 2001, 44, 158–169. [Google Scholar]

- Homburg, C.; Workman, J.P., Jr.; Krohmer, H. Marketing’s influence within the firm. J. Mark. 1999, 63, 1–17. [Google Scholar] [CrossRef]

- Venkatraman, N.; Ramanujam, V. Measurement of business performance in strategy research: A comparison of approaches. Acad. Manag. Rev. 1986, 11, 801–814. [Google Scholar] [CrossRef]

- Cohen, J.; Cohen, P. Applied Multiple Regression/Correlation Analysis for the Behavioural Sciences, 2nd ed.; Laurence Erlbaum: Hillsdale, NJ, USA, 1983. [Google Scholar]

- Venkatraman, N. Strategic orientation of business enterprises: The construct, dimensionality and measurement. Manag. Sci. 1989, 35, 942–962. [Google Scholar] [CrossRef]

- Hair, J.F.; Black, W.C.; Babin, B.J.; Anderson, R.E. Multivariate Data Analysis; Prentice Hall: Upper Saddle River, NJ, USA, 2009. [Google Scholar]

- Lambert, D.M. An Executive Summary of Supply Chain Management: Process, Partnerships, Performance; The Hartley Press, Inc.: Jacksonville, FL, USA, 2008. [Google Scholar]

- Rogers, P.; de Silva, R.; Bhatia, R. Water is an economic good: How to use prices to promote equity, efficiency and sustainability. Water Policy 2002, 4, 1–17. [Google Scholar] [CrossRef]

- Mason, S. Backward progress. IIE Solut. 2002, 34, 42–46. [Google Scholar]

- Tibben-Lembke, R. Life after death: Reverse logistics and the product life cycle. Int. J. Phys. Distrib. Logist. Manag. 2002, 32, 223–244. [Google Scholar] [CrossRef]

- Liang, H.; Saraf, N.; Hu, Q.; Xue, Y. Assimilation of enterprise systems: The effect of institutional pressures and the mediating role of top management. MIS Q. 2007, 31, 59–87. [Google Scholar] [CrossRef]

- Sharma, S. Managerial interpretations and organizational context as predictors of corporate choice of environmental strategy. Acad. Manag. J. 2000, 43, 681–697. [Google Scholar]

- Stundza, T. Supply Chain Innovation Is Important, Purchasing. 2009. Available online: http://www.purchasing.com/article/354518Supply_chain_innovation_is_important.php (accessed on 10 December 2018).

- Acs, Z.; Plummer, L. Penetrating the knowledge filter in regional economies. Ann. Reg. Sci. 2005, 39, 439–456. [Google Scholar] [CrossRef]

- Ajamieh, A.; Benitez, J.; Braojos, J.; Gelhard, C. IT infrastructure and competitive aggressiveness in explaining and predicting performance. J. Bus. Res. 2016, 69, 4667–4674. [Google Scholar] [CrossRef]

- Podsakoff, P.M.; MacKenzie, S.B.; Lee, J.Y.; Podsakoff, N.P. Common method biases in behavioral research: A critical review of the literature and recommended remedies. J. Appl. Psychol. 2003, 88, 879–903. [Google Scholar] [CrossRef] [PubMed]

| Sectors | High-tech manufacturing firms (pharmaceutical industry, hardware and other computer science equipment, automotive industry, space and aeronautics products). |

| Geographical location | Europe (Austria, Belgium, Denmark, France, Germany, Italy, Poland, Spain, The Netherlands, United Kingdom) |

| Methodology | Structured questionnaire |

| Universe of population | 5441 firms |

| Sample (response) size | 160 firms (17.7%) |

| Sample error | 7.7% |

| Confidence level | 95%, p − q = 0.50; Z = 1.96 |

| Period of data collection | From May 2010 to September 2010 |

| Variable | Operationalization | Confirmatory Factor Analysis (CFA)/Reliability |

|---|---|---|

| Technological skills | Technical information technology (IT) skills refer to general, explicit skills (e.g., programming) possessed by the firm’s IT staff that are needed to develop IT applications; and encompass both firm-specific techniques and scientific understanding (Ray et al., 2005) [67]. | Confirmatory factor analysis: χ22 = 1.26, NFI = 0.99, NNFI = 0.99, GFI = 0.99, CFI= 0.99 Reliability: α = 0.849. |

| Organizational innovativeness | The ability of the organization to adapt or execute new ideas, processes or products satisfactorily, emphasizing creating new business through market developments or by undertaking product, process, technological and administrative innovations (Zahra, 1993) [68]. | Confirmatory factor analysis: χ22 = 4.30, NFI = 0.98, NNFI = 0.97, GFI = 0.99, CFI = 0.99 Reliability: α = 0.792. |

| Top management support for IT | Top management support (TMS) for IT reflects the importance that the top management executives place on IT, the level of funding for IT and the facilitation of technology transfer throughout the firm (Byrd and Davidson, 2003) [53]. | Confirmatory factor analysis: χ22 = 1.19, NFI = 0.99, NNFI = 0.99, GFI = 0.99, CFI = 0.99 Reliability: α = 0.80 |

| Reverse logistics | Implementation and control of the flow of raw material, inventory in process, finished products and information from point of consumption to point of origin, to be done as efficiently and economically as possible in order to recover its value (Rogers and Tibben-Lembke, 1999) [2]. | Confirmatory factor analysis: χ22 = 1.21, NFI = 0.99, NNFI = 0.97, GFI = 0.98, CFI = 0.99 Reliability: α = 0.812 |

| Organizational Performance | Market performance consisted of two composite measures of strategic market performance and financial market performance, using managers’ subjective perceptions to measure beneficial outcomes for firms and others objective data, such as return on assets (ROA) (Homburg et al., 1999; Murray and Kotabe, 1999; Venkatraman and Ramanujam, 1986) [72,69,73]. | Confirmatory factor analysis: χ22 = 24.60, NFI = 0.94, NNFI = 0.94, GFI = 0.98, CFI = 0.96 Reliability: α = 0.816 |

| Mean | Standard Deviation | Reverse Logistics | Firm Size | Sector 1 | Sector 2 | Sector 3 | Performance | Technological Skills | Top Management Support for IT | |

|---|---|---|---|---|---|---|---|---|---|---|

| Reverse logistics | 0.00 | 1.00 | 1.00 | |||||||

| Firm size | 3.81 | 1.76 | 0.27 *** | 1.00 | ||||||

| Sector 1 | 0.26 | 0.57 | 0.19 ** | 0.01 | 1.00 | |||||

| Sector 2 | 0.23 | 0.55 | −0.10 † | −0.25 ** | 0.32 *** | 1.00 | ||||

| Sector 3 | 0.32 | 0.59 | −0.07 | 0.04 | 0.22 | 0.26 | 1.00 | |||

| Performance | 0.00 | 1.00 | 0.18 ** | 0.22 ** | 0.03 | 0.09 | 0.06 | 1.00 | ||

| Technological skills | 0.00 | 1.00 | 0.27 *** | 0.11 † | 0.02 | 0.14 * | 0.11 * | 0.28 *** | 1.00 | |

| Top management support for IT | 0.00 | 1.00 | 0.35 *** | 0.18 ** | 0.09 | 0.08 | 0.09 | 0.41 *** | 0.65 *** | 1.00 |

| Innovativeness | 0.00 | 1.00 | 0.35 *** | 0.18 ** | 0.17 * | 0.11 † | 0.15 * | 0.32 *** | 0.42 *** | 0.57 *** |

| Model 1 | Model 2 | Model 3 | Model 4 | |

|---|---|---|---|---|

| Constant | −0.47 * (0.19) | −0.34 ** (0.2) | −0.32 † (0.18) | −0.36 * (0.18) |

| Firm size | 0.12 ** (0.04) | 0.09 * (0.04) | 0.18 * (0.09) | 0.09 * (0.04) |

| Sector 1 | 0.43 ** (0.14) | 0.39 * (0.14) | 0.33 (0.13) | 0.36 ** (0.13) |

| Sector 2 | −0.19 (0.15) | −0.28 * (0.06) | −0.34 * (0.14) | −0.26 (0.15) |

| Sector 3 | −0.19 (0.13) | −0.17 (0.13) | −0.21 (0.12) | −0.22 (0.13) |

| Performance | −0.19 * (0.13) | 0.03 (0.07) | 0.07 (0.07) | 0.04 (0.08) |

| Technological skills | 0.17 ** (0.08) | 0.29 *** (0.08) | 0.13 * (0.09) | |

| Top management support for IT | 0.32 ** (0.11) | 0.32 ** (0.11) | ||

| Innovativeness | 0.22 ** (0.08) | 0.26 ** (0.08) | ||

| TMS X technological skills | 0.11 ** (0.05) | |||

| Innovativeness X technological skills | 0.21 *** (0.05) | |||

| R2 | 0.15 | 0.25 | 0.31 | 0.26 |

| R2adjusted | 0.12 | 0.21 | 0.28 | 0.25 |

| F change | 5.34 ** | 9.28 ** | 15.92 *** | 4.93 ** |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

García-Sánchez, E.; Guerrero-Villegas, J.; Aguilera-Caracuel, J. How Do Technological Skills Improve Reverse Logistics? The Moderating Role of Top Management Support in Information Technology Use and Innovativeness. Sustainability 2019, 11, 58. https://doi.org/10.3390/su11010058

García-Sánchez E, Guerrero-Villegas J, Aguilera-Caracuel J. How Do Technological Skills Improve Reverse Logistics? The Moderating Role of Top Management Support in Information Technology Use and Innovativeness. Sustainability. 2019; 11(1):58. https://doi.org/10.3390/su11010058

Chicago/Turabian StyleGarcía-Sánchez, Encarnación, Jaime Guerrero-Villegas, and Javier Aguilera-Caracuel. 2019. "How Do Technological Skills Improve Reverse Logistics? The Moderating Role of Top Management Support in Information Technology Use and Innovativeness" Sustainability 11, no. 1: 58. https://doi.org/10.3390/su11010058