1. Introduction

Agricultural production systems are open, thermodynamic, and comprehensive life systems. They are a combination of ecological and economic systems, associated with transmission, transformation, and circulation processes, and flows of material cash and energy. The differences in energy consumption and efficiency of agricultural production are caused by a variety of factors, such as crop growth, soil type, field farming methods, organic manure and fertilizers, plant protection measures, production levels, etc. [

1].

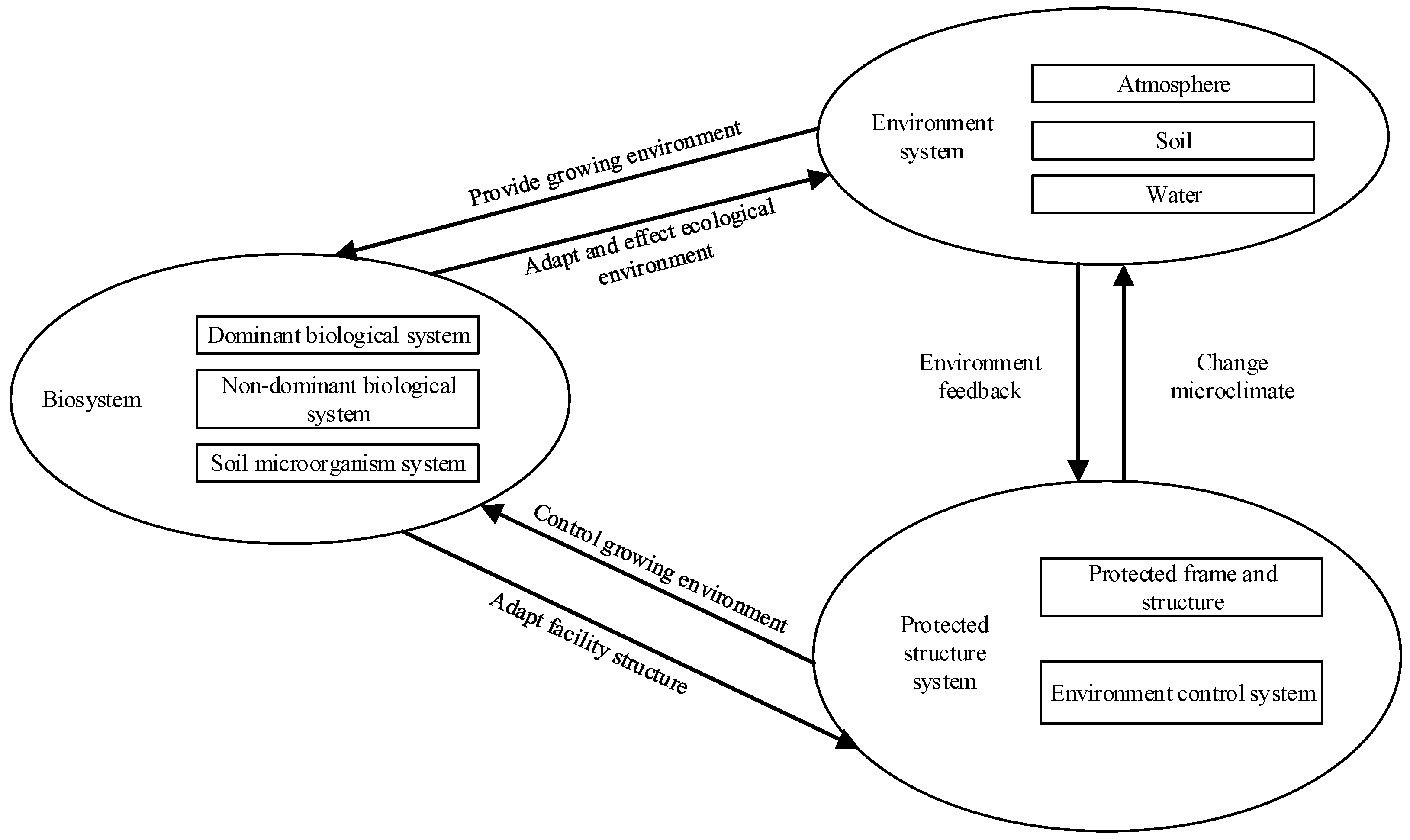

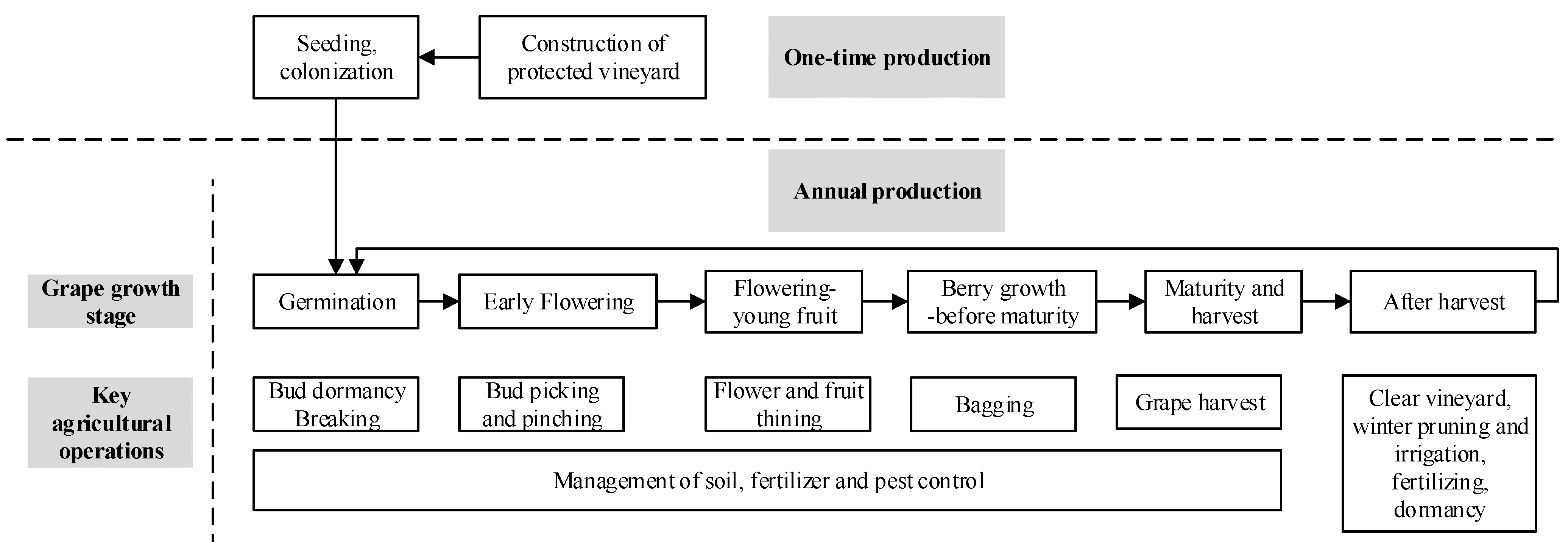

Protected grape cultivation provides relatively controllable and suitable temperature, humidity, and other environmental conditions for grape production. With the adoption of modern agricultural engineering technology, protected grape cultivation breaks the seasonal and regional restrictions of grape production and significantly improves the adaptability of grape production. Consequently, protected grape cultivation has been rapidly developing in China. The protected grape production system is a special agricultural system composed of natural and socio-economic production systems. The system maintains itself through exchanging matter and energy with the outside environment, so it has poor self-adjusting ability and feedback mechanisms for maintaining ecological balance—the success of the system strongly depends on human management activities. The system can be divided into three subsystems: biological, environment, and protected structure system. There are relationships between subsystems, such as control, dependency, and feedback as displayed in

Figure 1.

According to different classification criteria, protected grape cultivation can be classified into different sub-patterns in China.

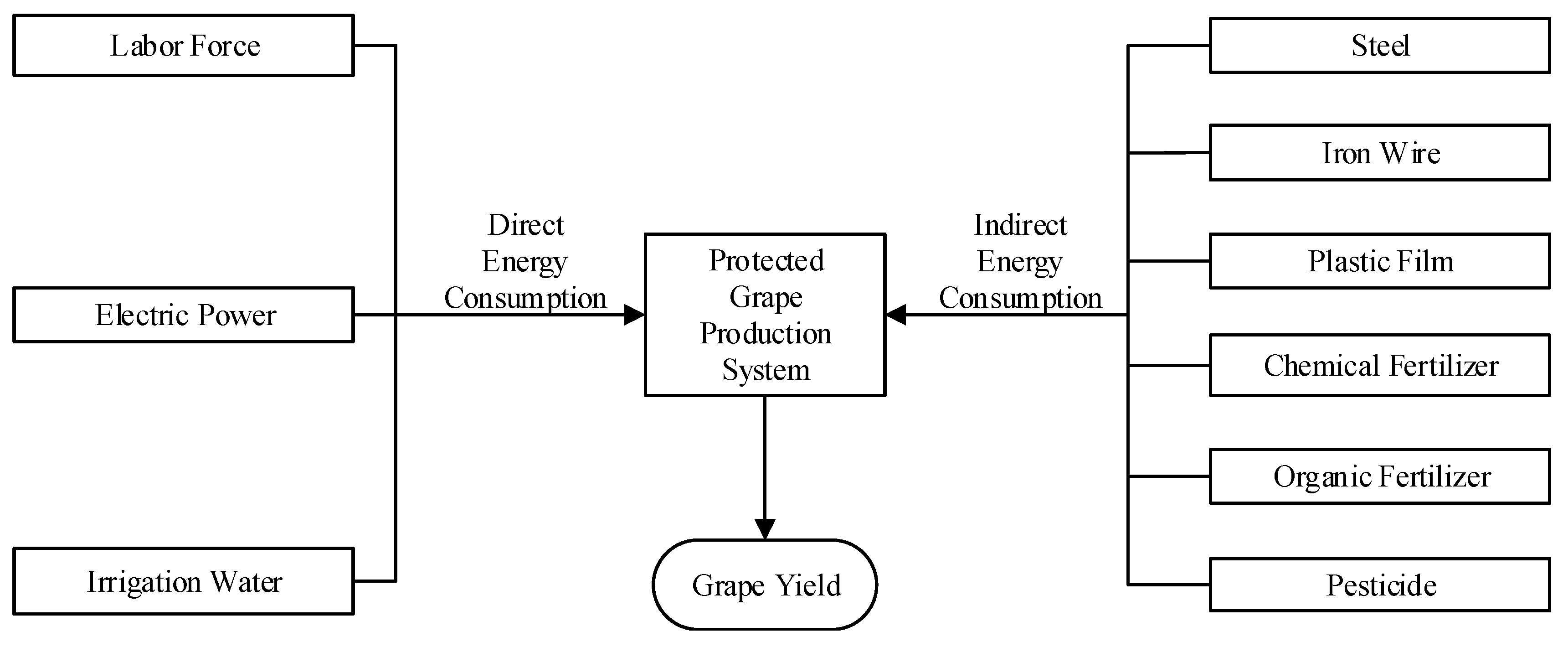

Table 1 lists the main classifications of protected cultivation and the descriptions. The greenhouse structure, agricultural operations, cost of investment, and energy consumption are different for each sub-pattern, so analysing and comparing the energy consumption of each protected viticulture mode are meaningful for adjusting the energy input structure and optimizing energy consumption. Agricultural production uses large quantities of energy, both directly and indirectly, in the form of machinery, diesel fuels, seeds, fertilizer, manure, chemicals, electricity, and water for irrigation. For protected grapes, the high levels of energy can protect grapes away natural disaster, plant diseases, and insect pests. It is commonly thought that protected agriculture is a highly intensive mode of agricultural production with greater economic benefits, supporting the development of protected grape cultivation by vine growers. However, high output may arise from the considerable consumption of financial resources, manpower, energy, and other resources, which lead to increasing economic and environmental pressure. As the world is facing a resource shortage crisis and energy is becoming increasingly expensive, production processes that consume high levels of energy are obviously not sustainable. As a developing country, per capita resources in China are scarce, and the gap in energy consumption continues to widen [

2]. Therefore, in the future, Chinese agricultural production must be sustainable, environmentally friendly, and characterized by high efficiency, resource conservation, energy saving, and low emissions.

Furthermore, China has a vast territory, and there are significant differences in resource availability, production level, and labor quality in each production region. Producers in some regions adopted protected grape cultivation without considering the local or their own situation, which has led to various problems including high investments and lower production efficiency. The low efficiency of energy and resources has caused a serious waste, which is undoubtedly aggravating the environmental cost of production systems, resulting in apparent or potential environmental damage and ecological pollution, finally affecting the sustainable development of production systems. Therefore, efficient utilization of energy is one of the core components of sustainable agricultural production, and the effectiveness of energy utilization is recognized as an important index of production efficiency and environmental impact assessment of the production system. It is therefore urgent and necessary to optimize the energy consumption of protected grape production from the perspective of spatial variation.

In recent years, scholars have conducted many studies on energy consumption in agricultural production. The research object involved planting systems [

4,

5,

6], livestock breeding systems [

7,

8,

9], and aquaculture systems [

10,

11].

Ozkan et al. analysed the energy use patterns and the cost of production in greenhouse and open-field grape production in Turkey, and found that the production cost of greenhouse production was more profitable than open-field production due to higher prices for greenhouse grapes [

12]. Hamedani et al. examined the energy use patterns and the relationship between energy input and yield for grape production in Hamadan Province in Iran and found that direct energy and non-renewable energy use were rather high [

13]. Khoshroo et al. found the association of energy efficiency and performance that explained farmers’ specific characteristics [

14]. In addition, some researchers studied other protected crops or fields. Salehi et al. examined the energy balance between the input and the output for button mushroom production in the Isfahan province of Iran [

15]. Xue et al. researched total energy consumption efficiency in the construction industry in China [

16].

Most existing studies focused on the energy consumption of macro-industries, whereas there is a lack of the research on micro-agricultural production systems. As a result, the research on energy consumption by the protected grape production system is lacking, and in these studies, they ignored the energy consumption distinction between different protected cultivation modes and different regions [

4,

17,

18]. Many factors lead to differences in the energy consumption of agricultural production systems. Therefore, it is necessary to study the spatial differences in energy consumption. However, analysis of geographical spatial differences based on production systems is relatively rare. Geographic information system (GIS) tools have a powerful role in spatial analysis. Therefore, based on the analysis of energy consumption, this study explored GIS-based spatial variation in protected grape cultivation.

This paper aimed to investigate energy consumption features of protected grape production; we also focused on the differences in energy consumption and its spatial characteristics between different production modes to improve the level of sustainable development by adjusting energy input structure and choosing more sustainable production modes and production areas.

The rest of the paper is organized as follows:

Section 2 outlines protected grape cultivation systems, a spatial variation analysis model, and data collection and analysis. Energy consumption quantity, energy consumption structure, and spatial variation of energy consumption are discussed, taking data from 2011 to 2013 as an example, in

Section 3. Conclusions are provided in the last section.

4. Conclusions

The main objectives of this study were to examine energy consumption and develop a function relationship in different protected cultivation modes and regions for protected grape cultivation in China. Based on the present study, the following conclusions were drawn:

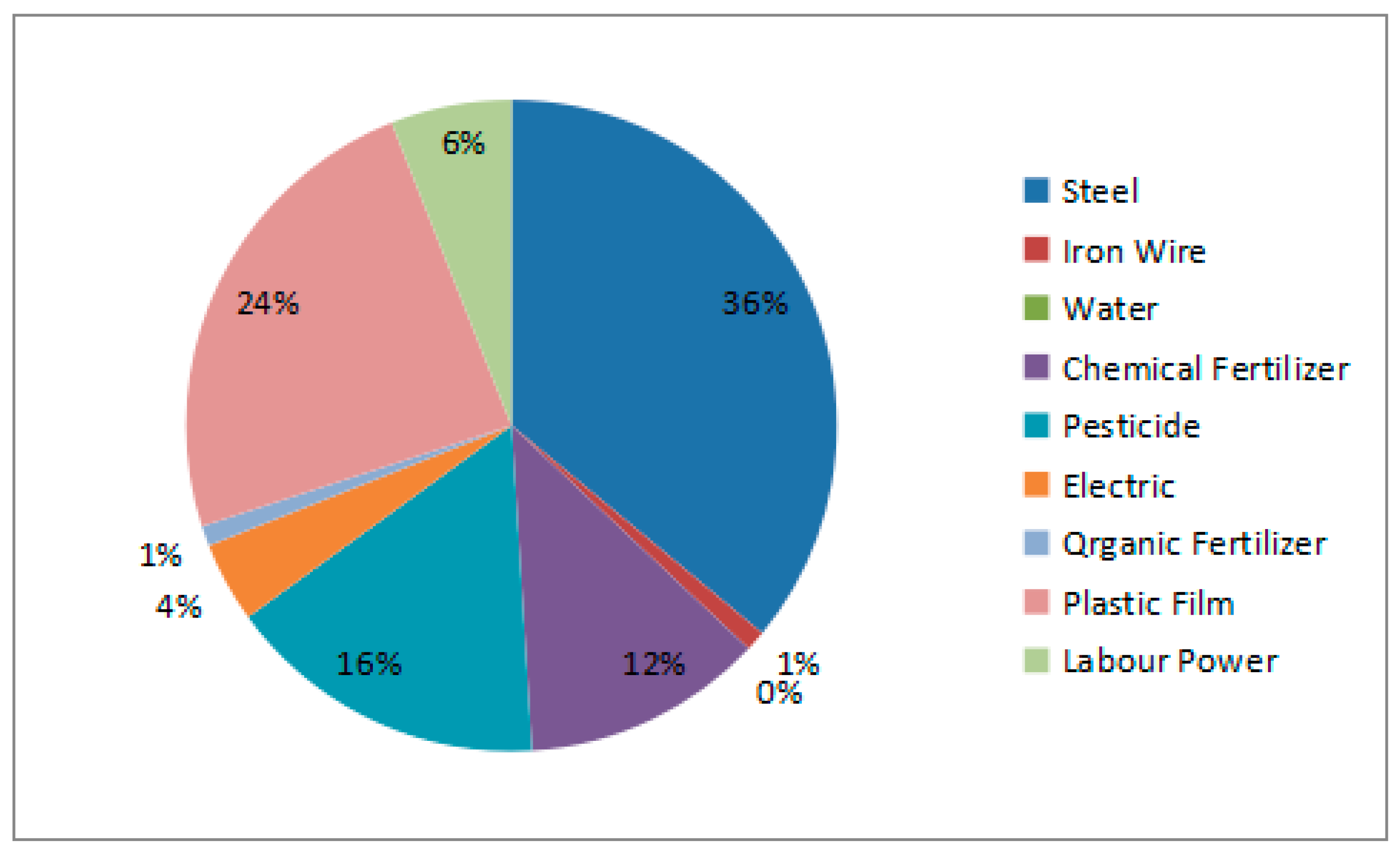

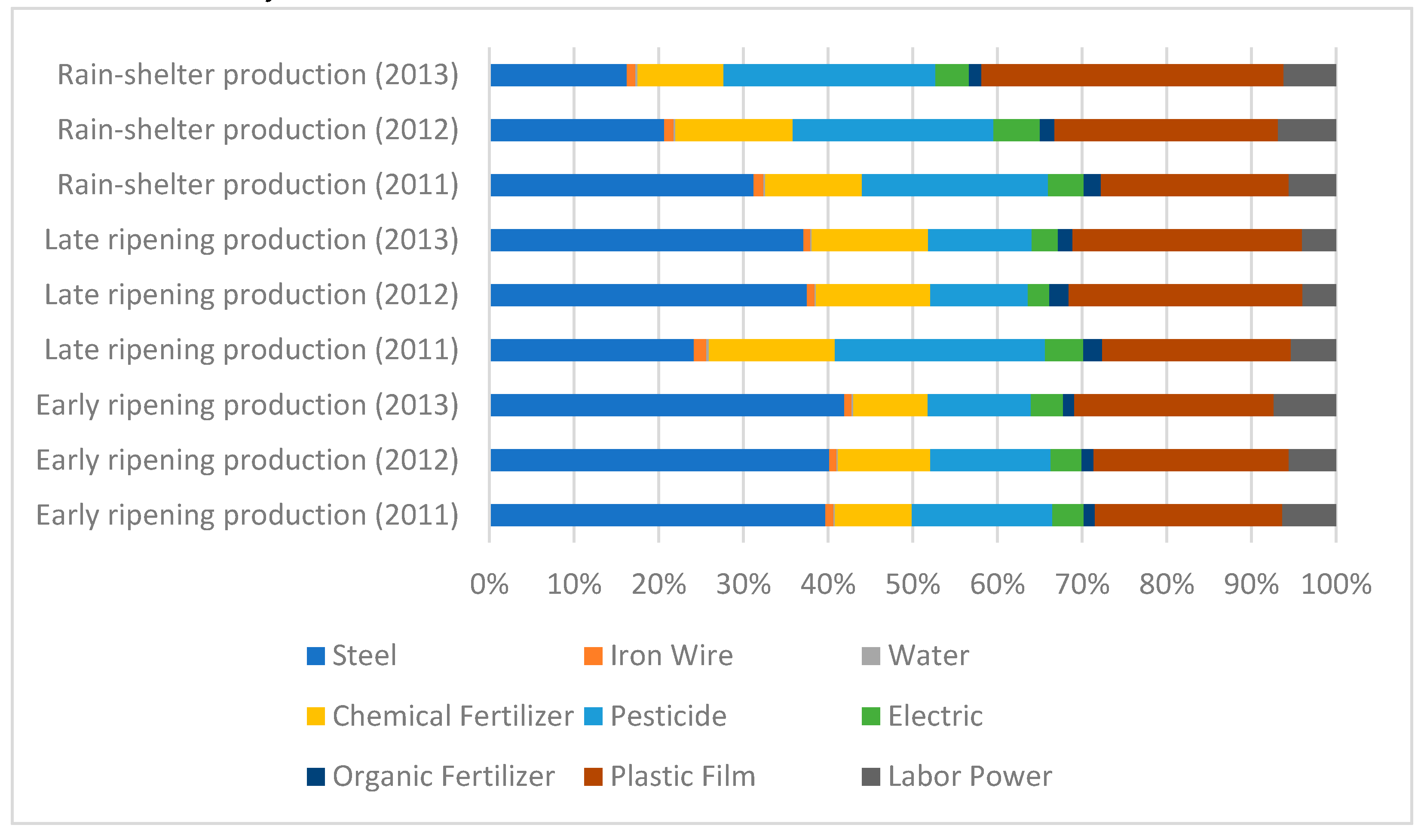

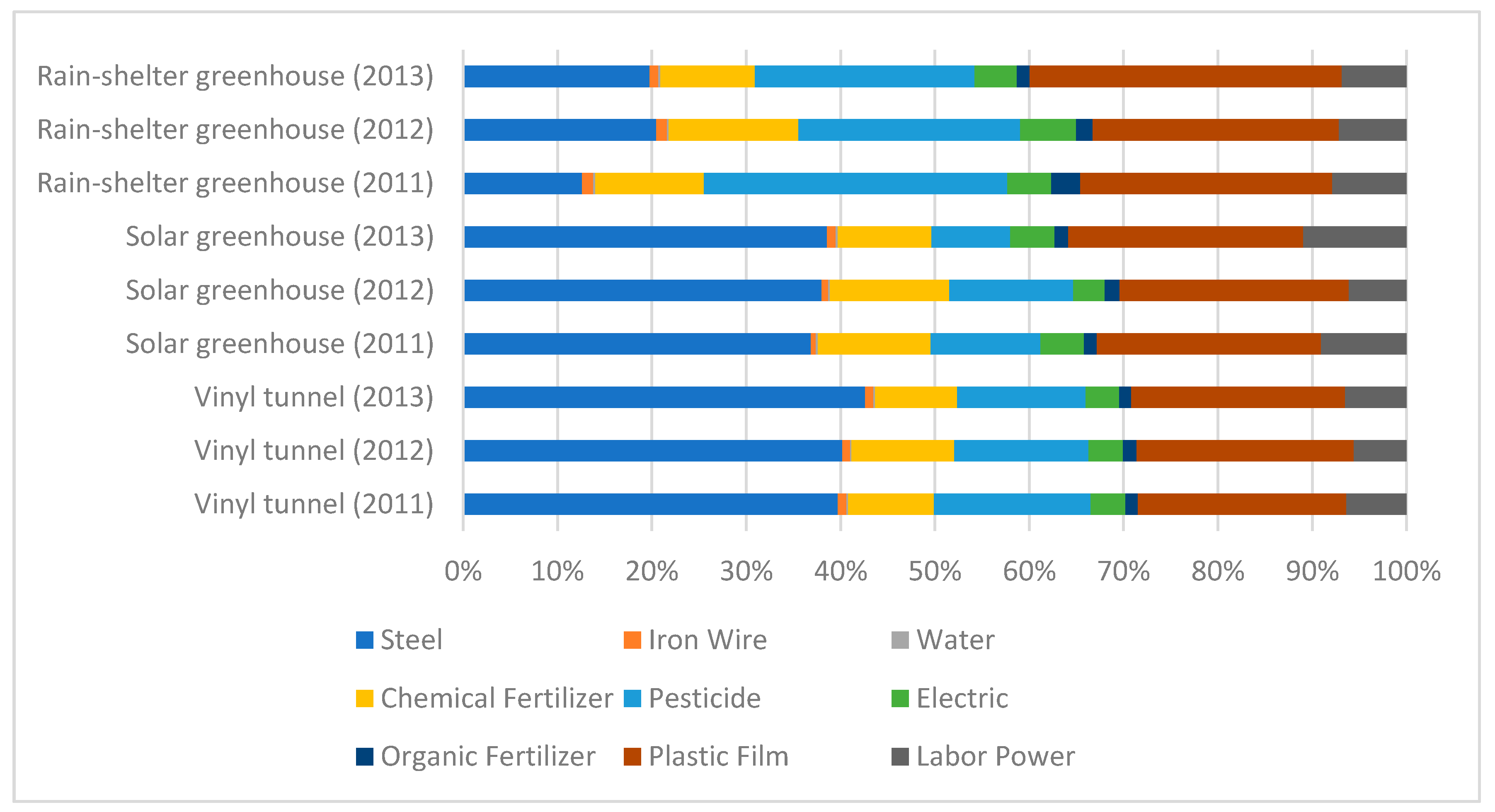

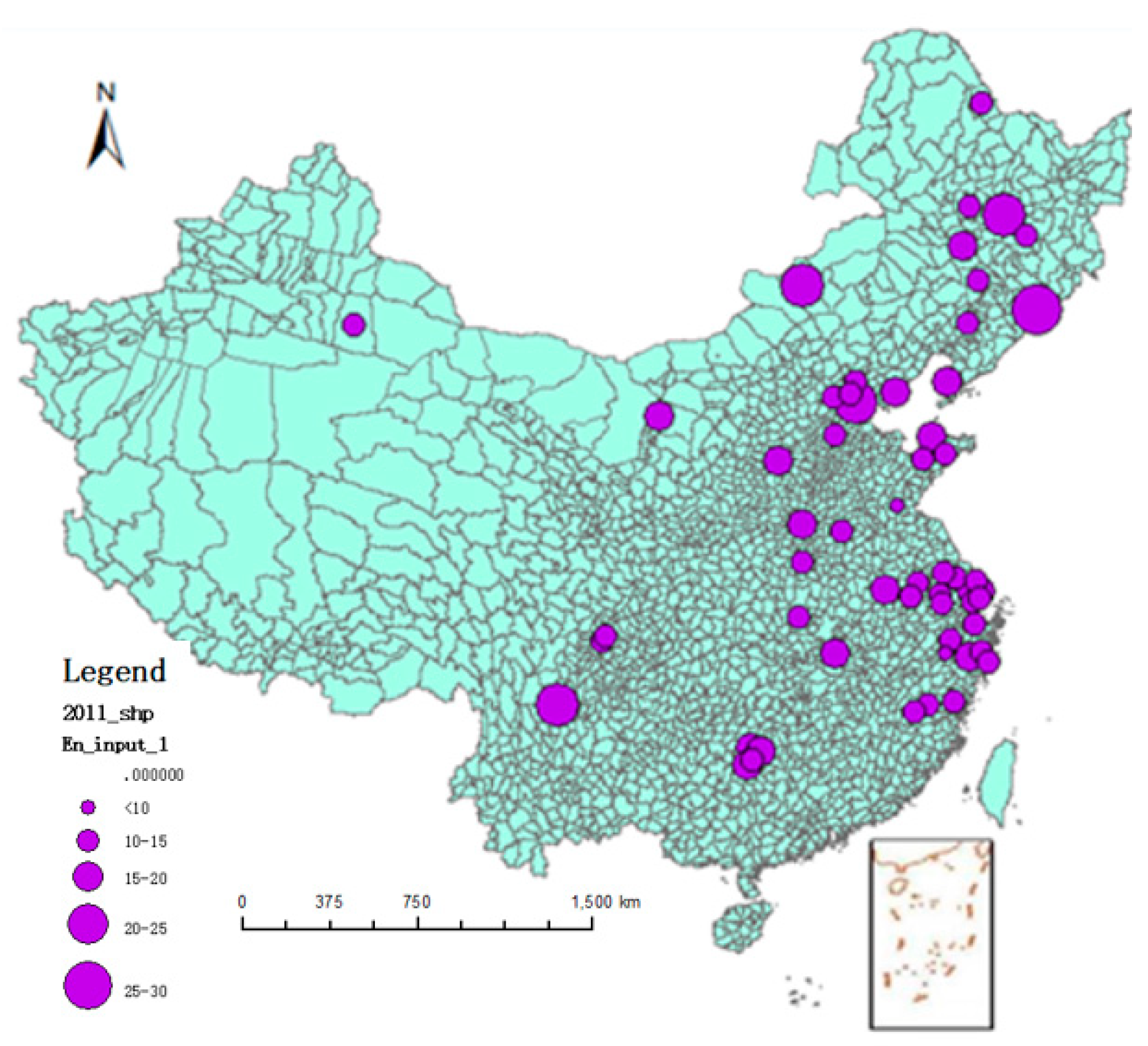

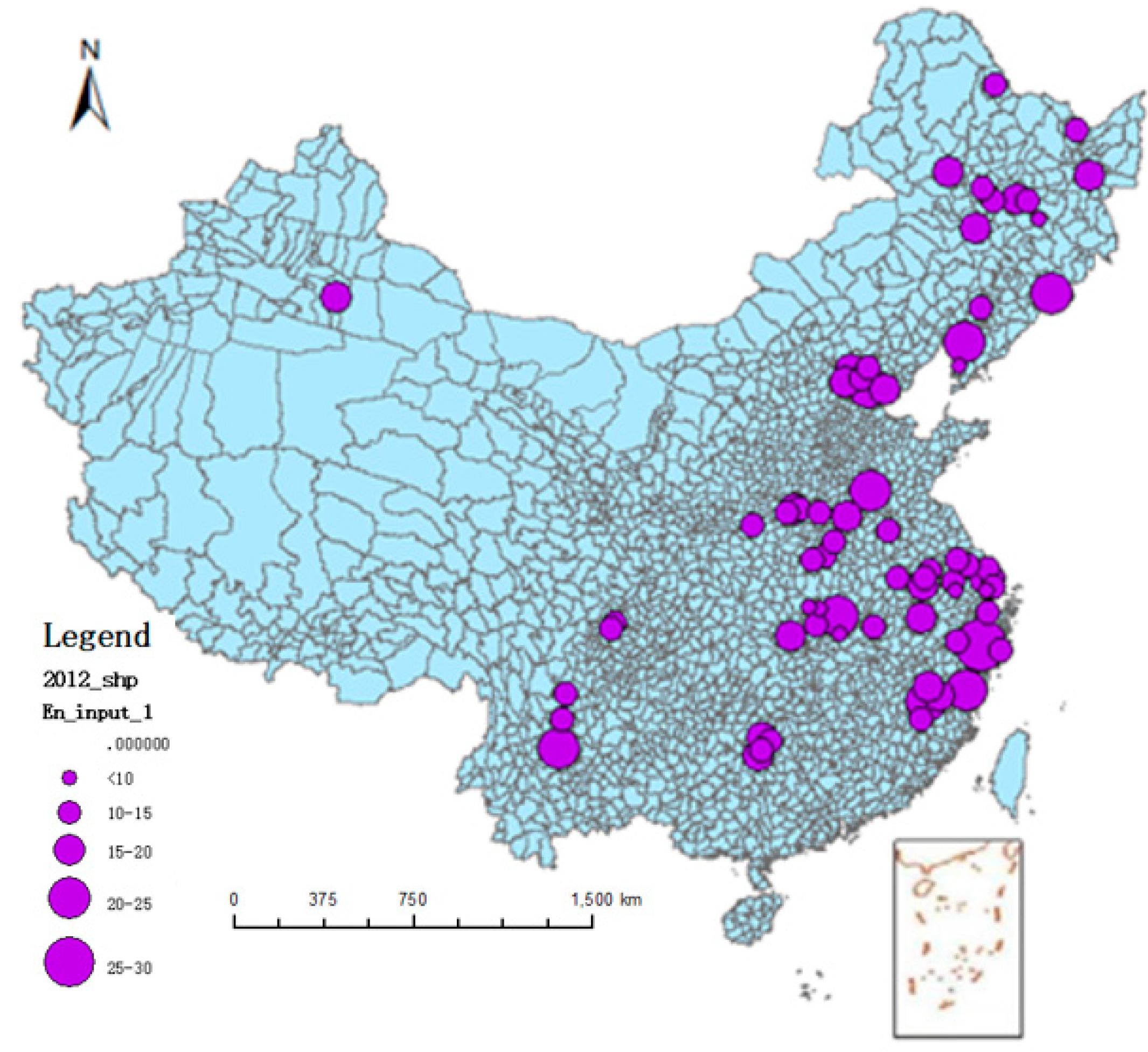

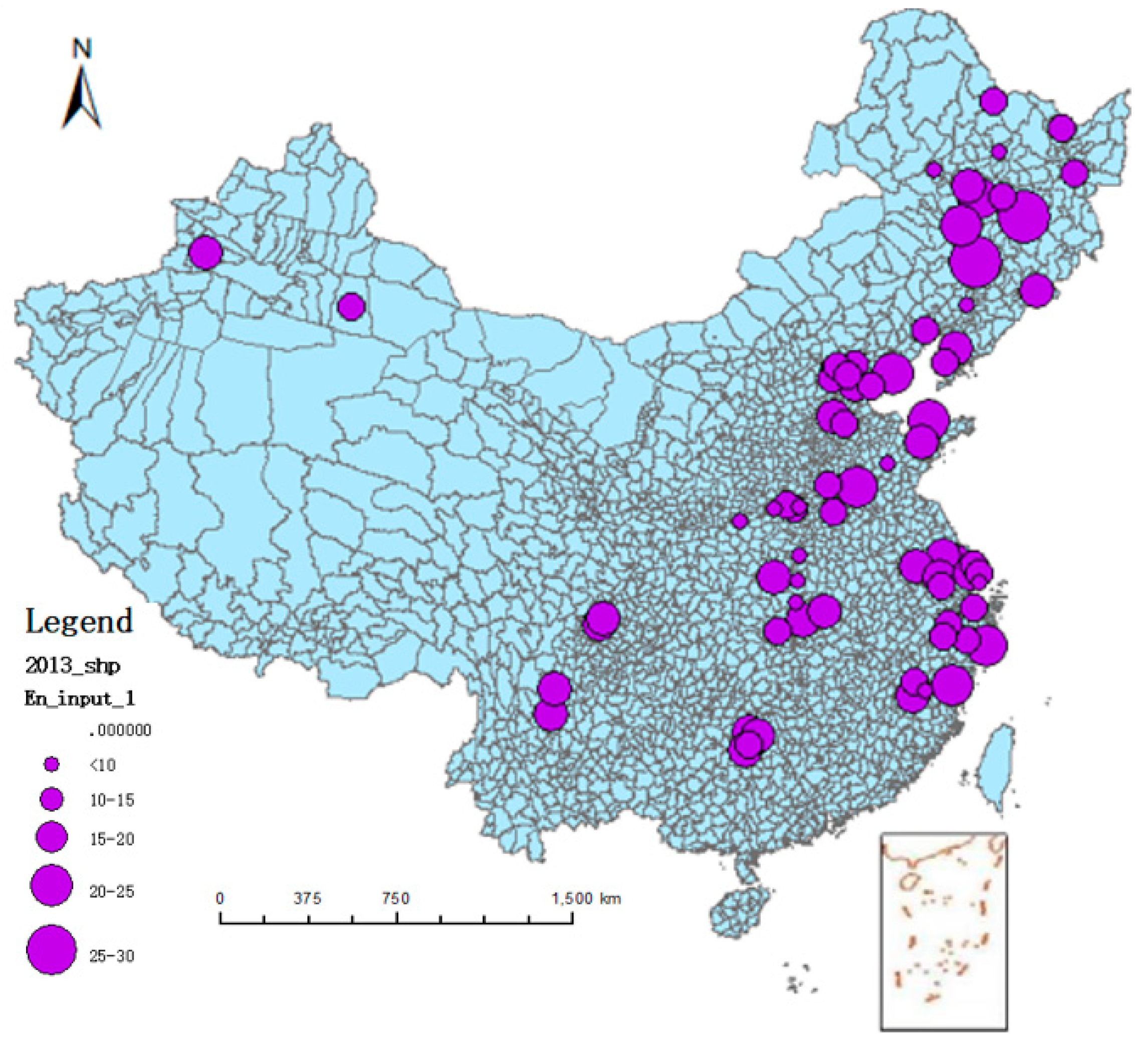

(1) The kinds of energy consumed were steel, iron wire, water, chemical fertilizer, pesticide, electric power, organic fertilizer, plastic film, and labor power. The average total energy input and output of protected grape cultivation were calculated as 21.1 and 4.9 MJm−2 in 2011, 21.2 and 5.3 MJm−2 in 2012, and 22.3 and 5.2 MJm−2 in 2013, respectively.

(2) The data for the three years showed that the main energy consumption was due to steel, plastic film, and pesticides. Furthermore, the analysis of the total investment ratio and total energy input ratio showed that early ripening production and late ripening production consumed more energy than rain-shelter production.

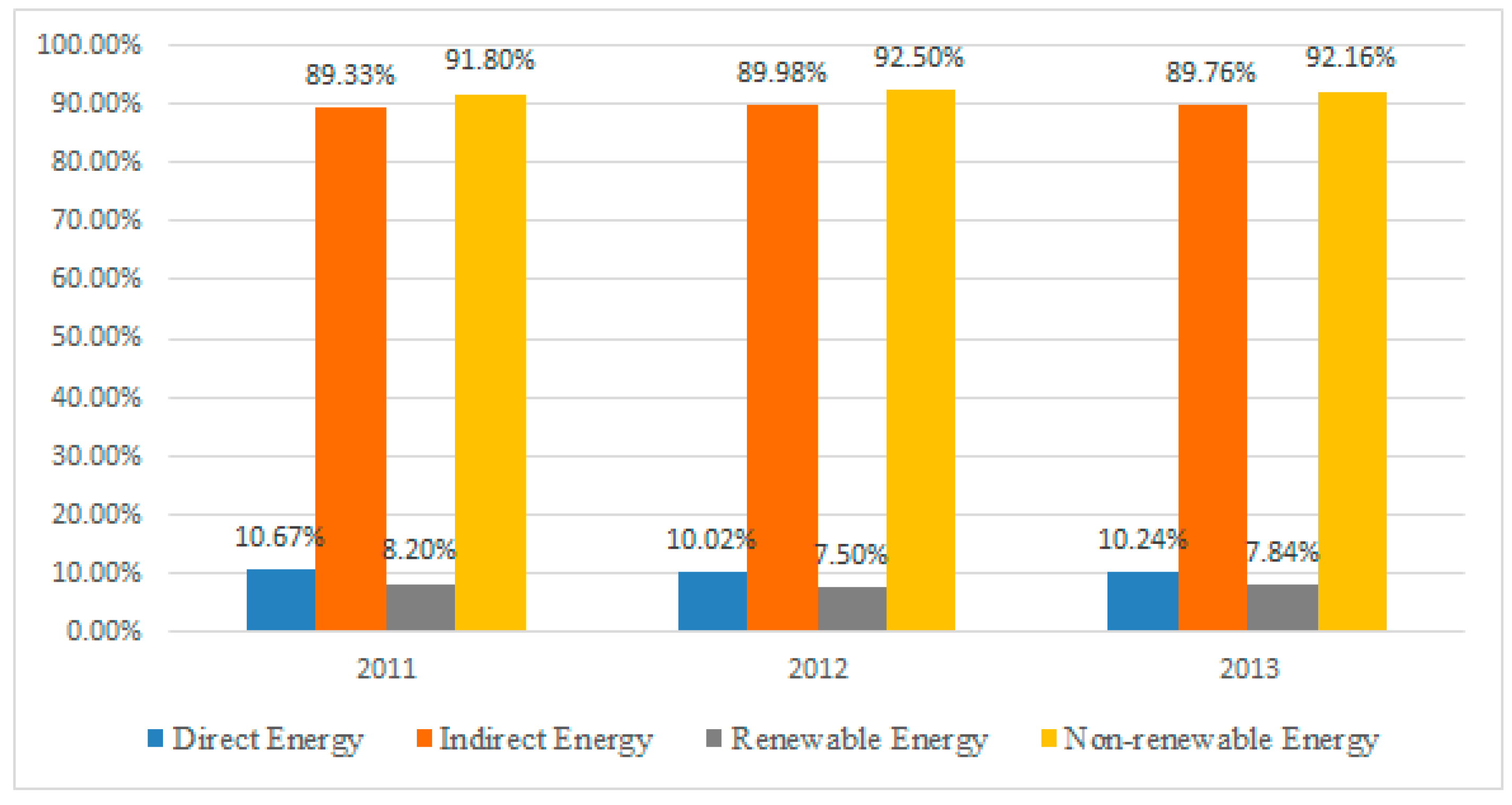

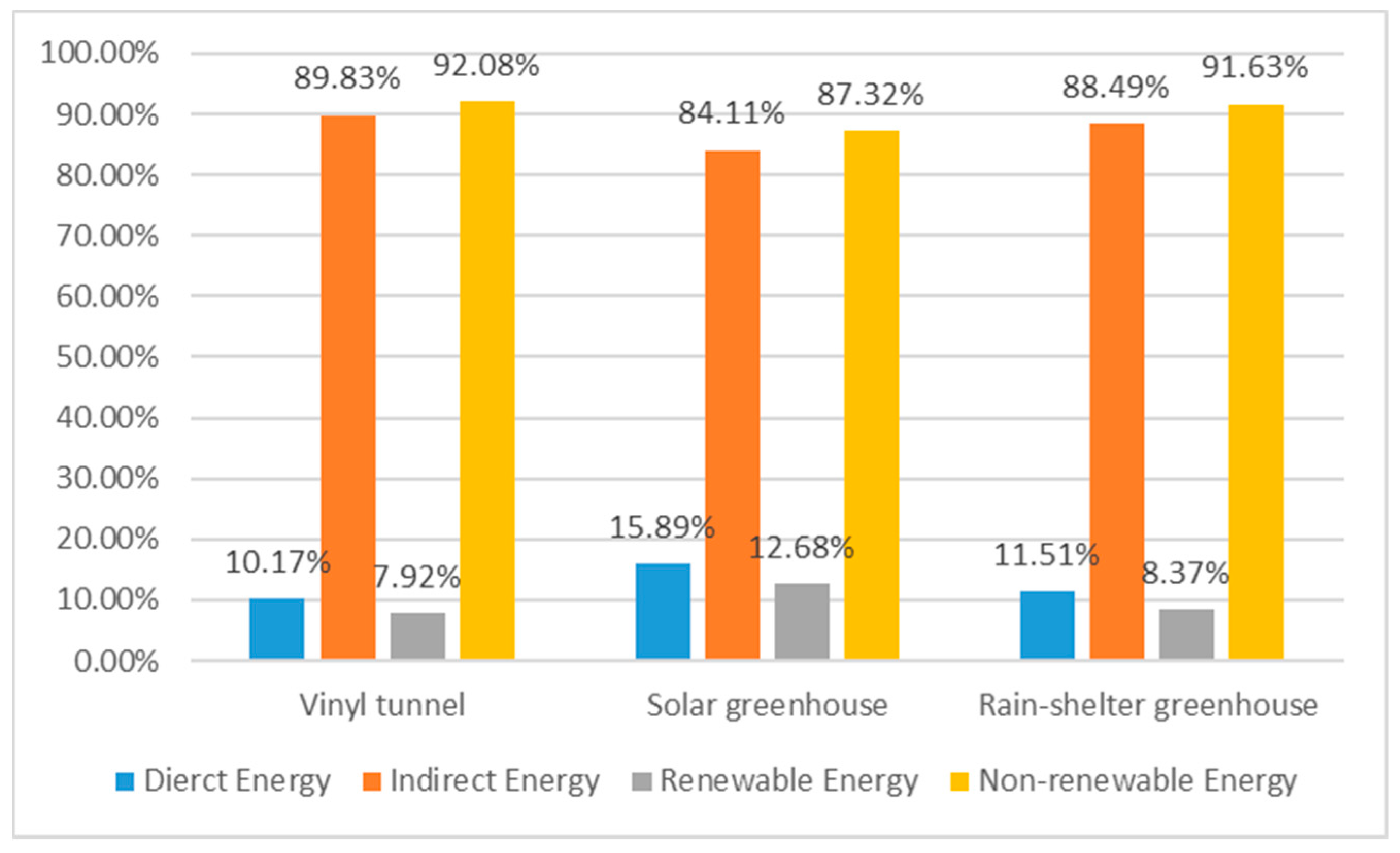

(3) In the protected grape cultivation production system, the share of indirect and non-renewable energies was higher than direct and renewable energy. Indirect and non-renewable energy input accounted for 90% of total energy consumption.

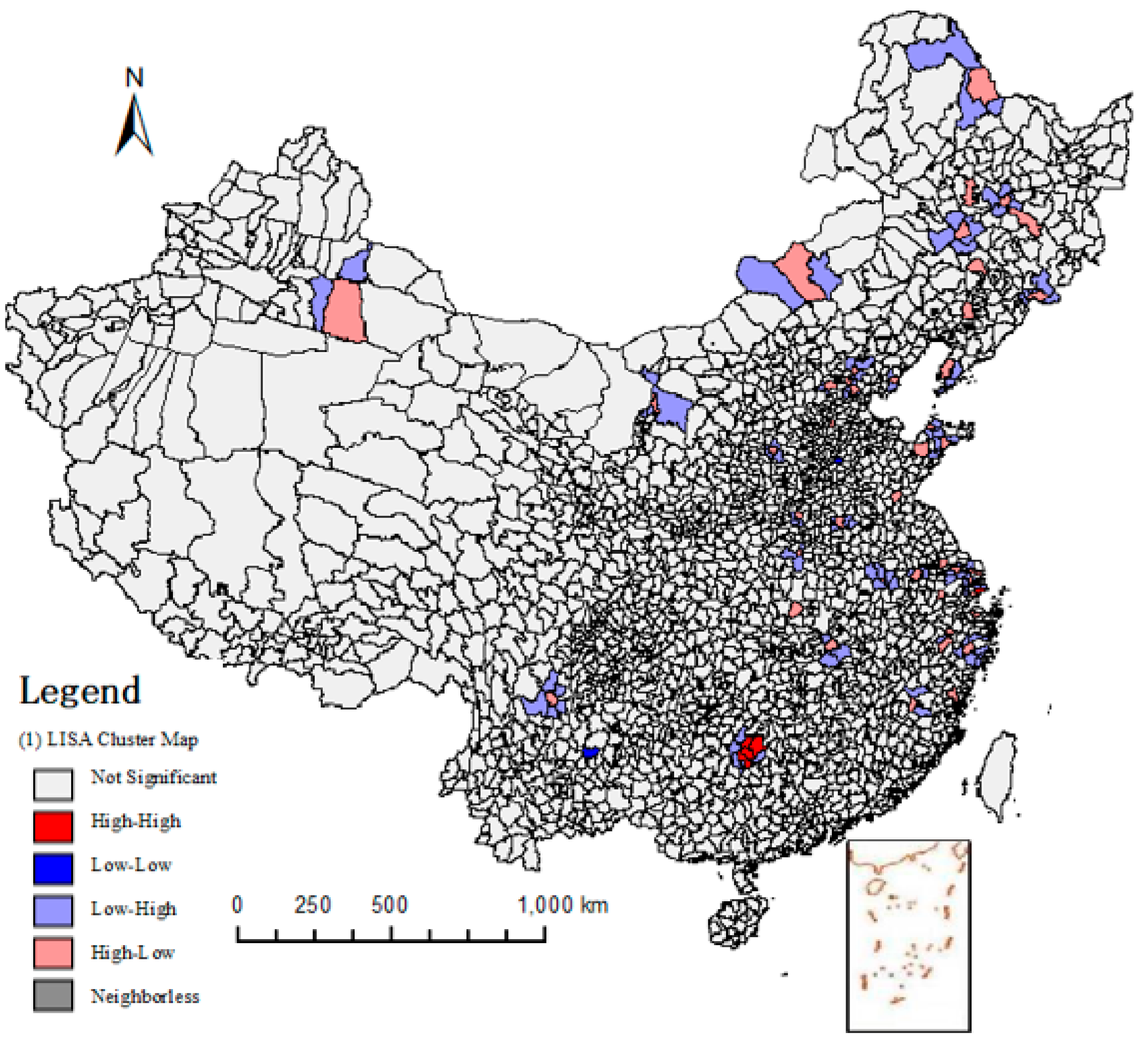

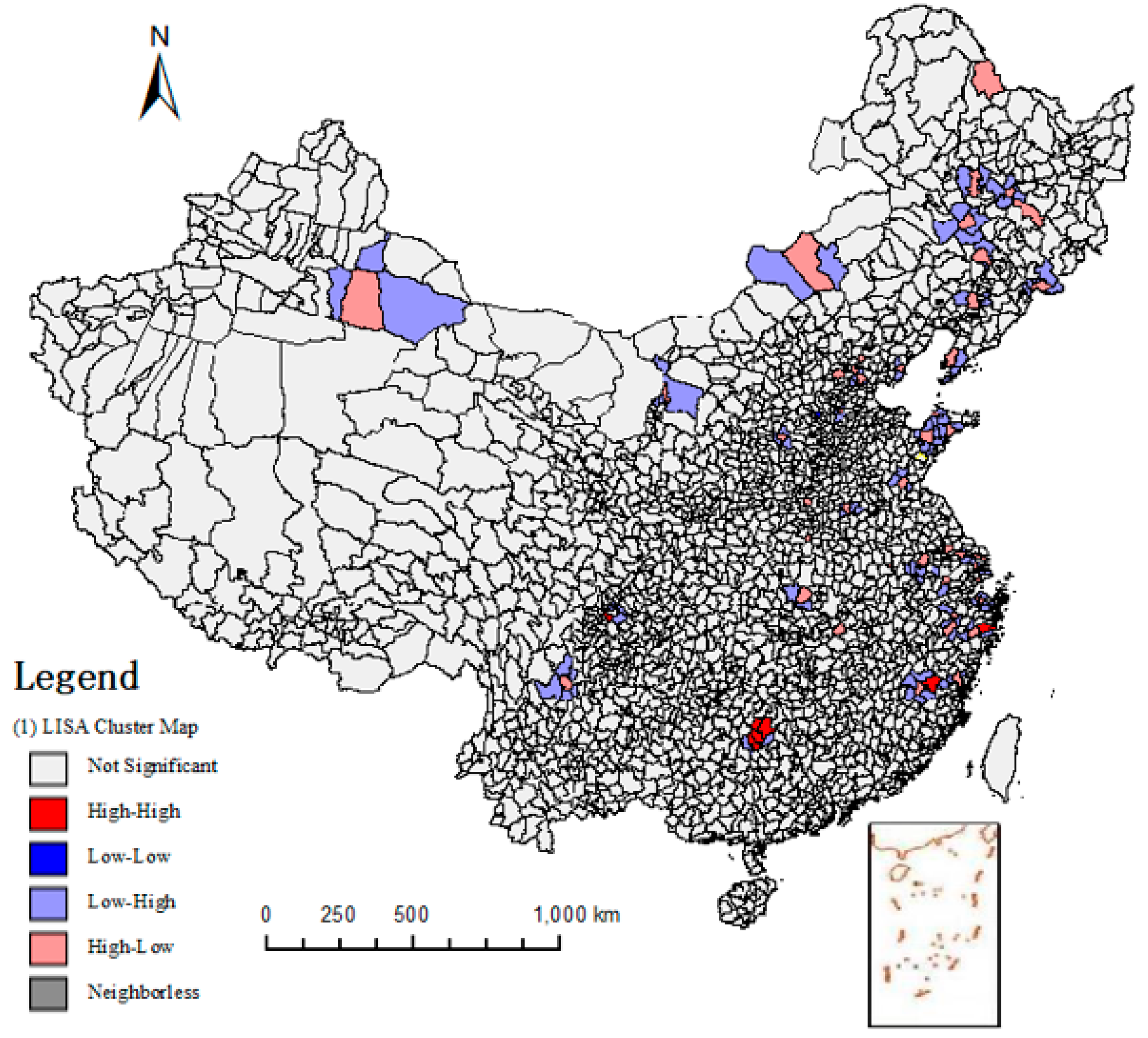

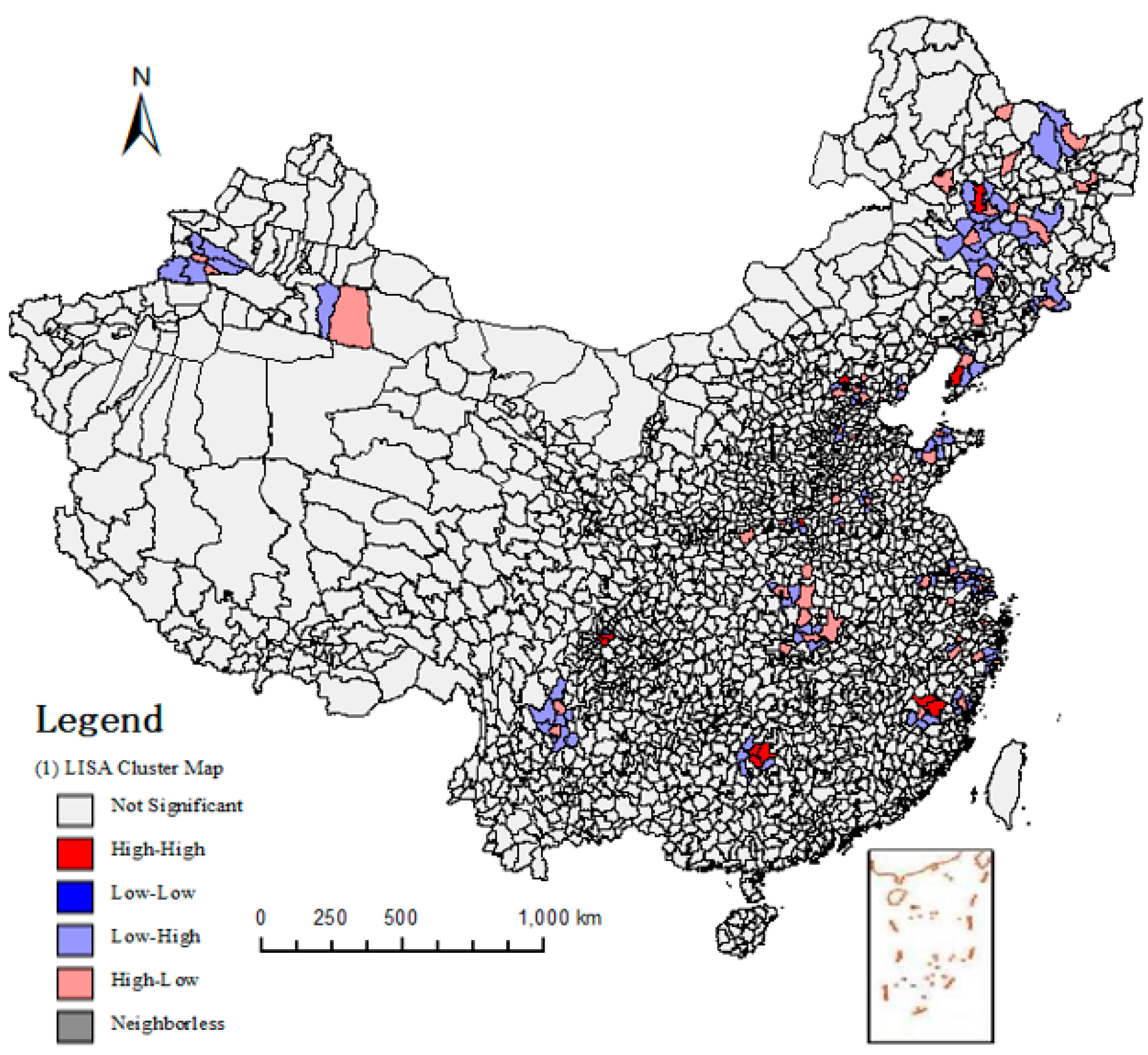

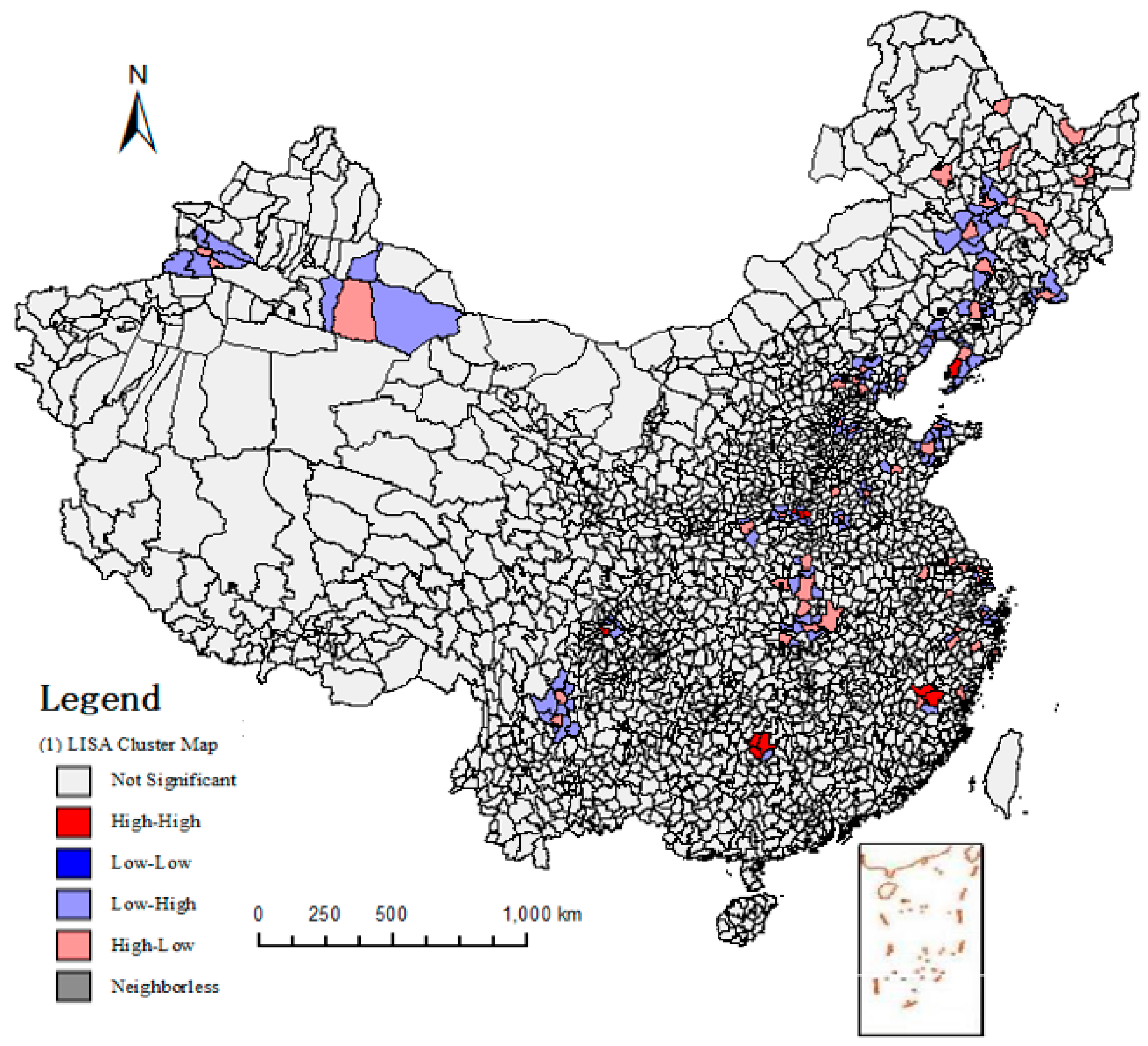

(4) Spatial analysis showed that the values of Moran’s I were all positive for the three years, and the significance of p test values and Z values both passed the significance test. Thus protected grape energy input and energy output were positively spatially autocorrelated.