Towards Drylands Biorefineries: Valorisation of Forage Opuntia for the Production of Edible Coatings

Abstract

:1. Introduction

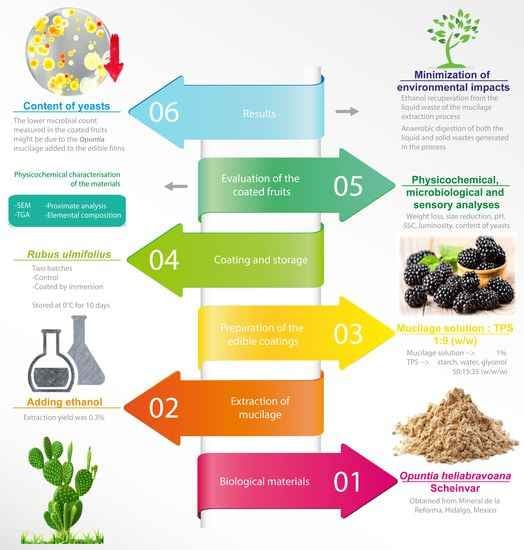

2. Materials and Methods

2.1. Biological Materials

2.2. Extraction of Opuntia Mucilage

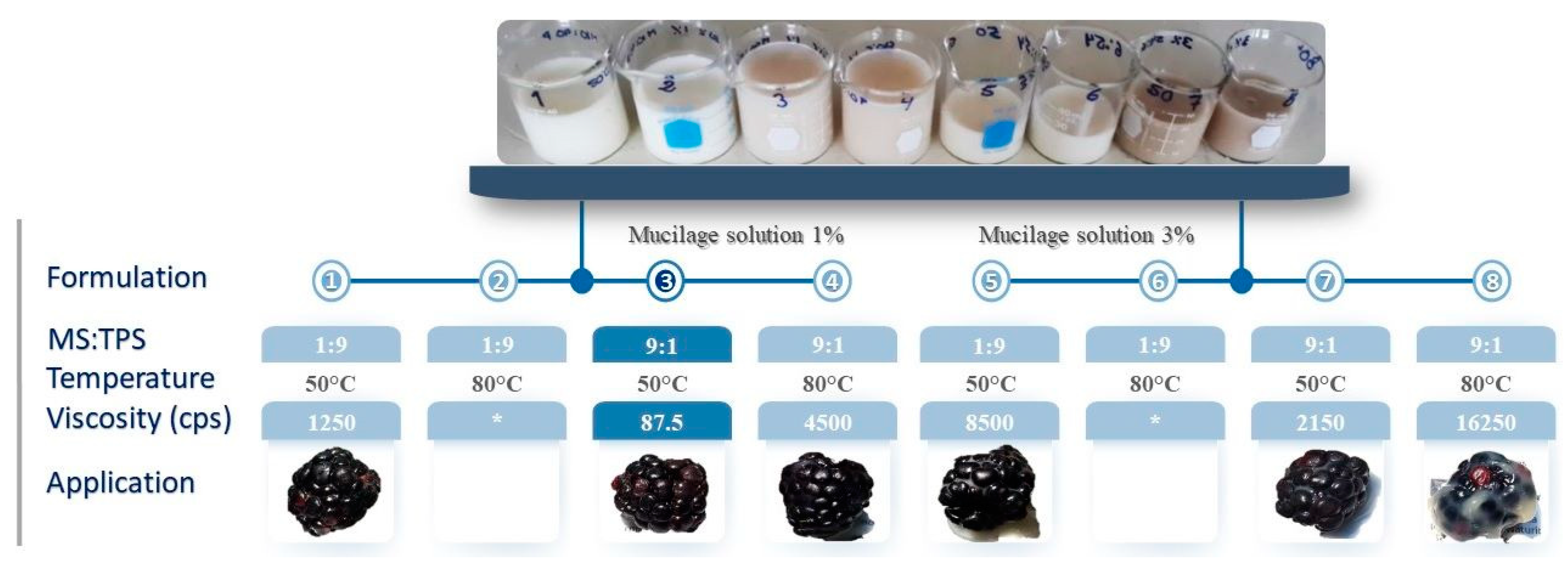

2.3. Preparation of the Edible Coatings

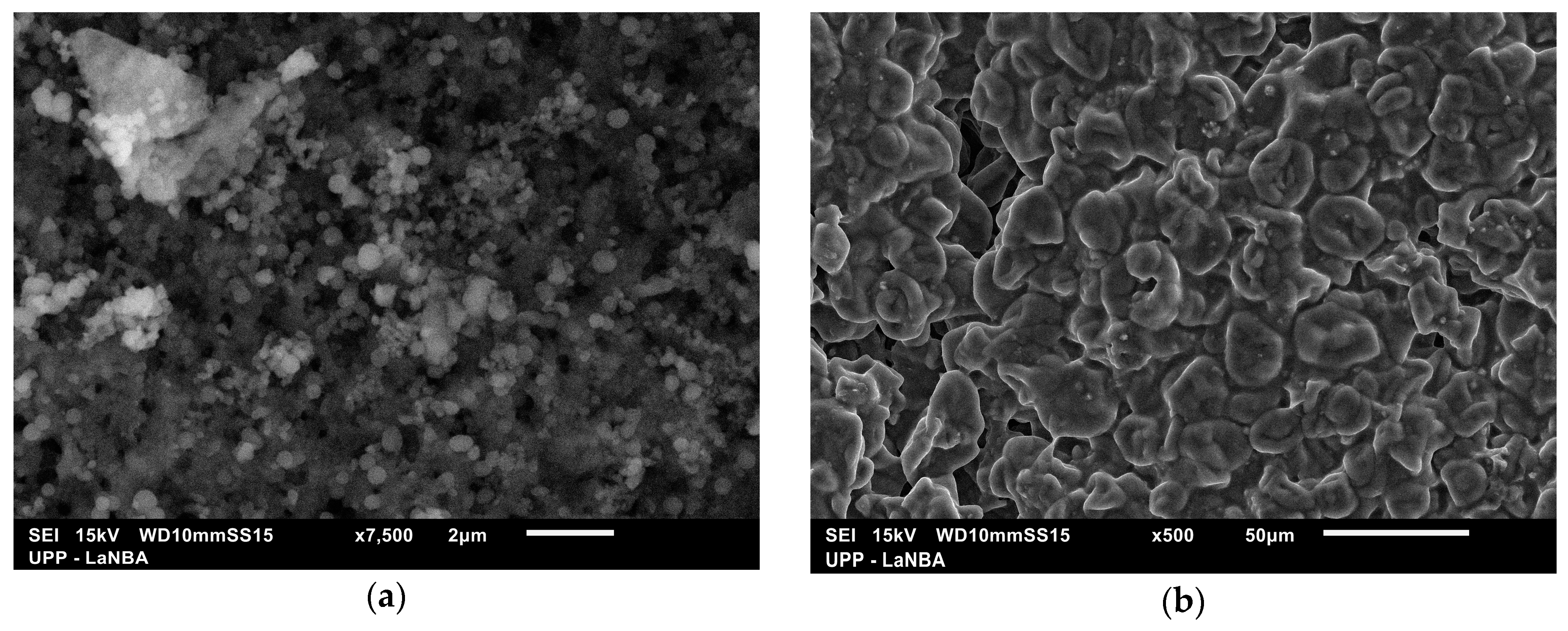

2.4. Physicochemical Characterisation of the Materials

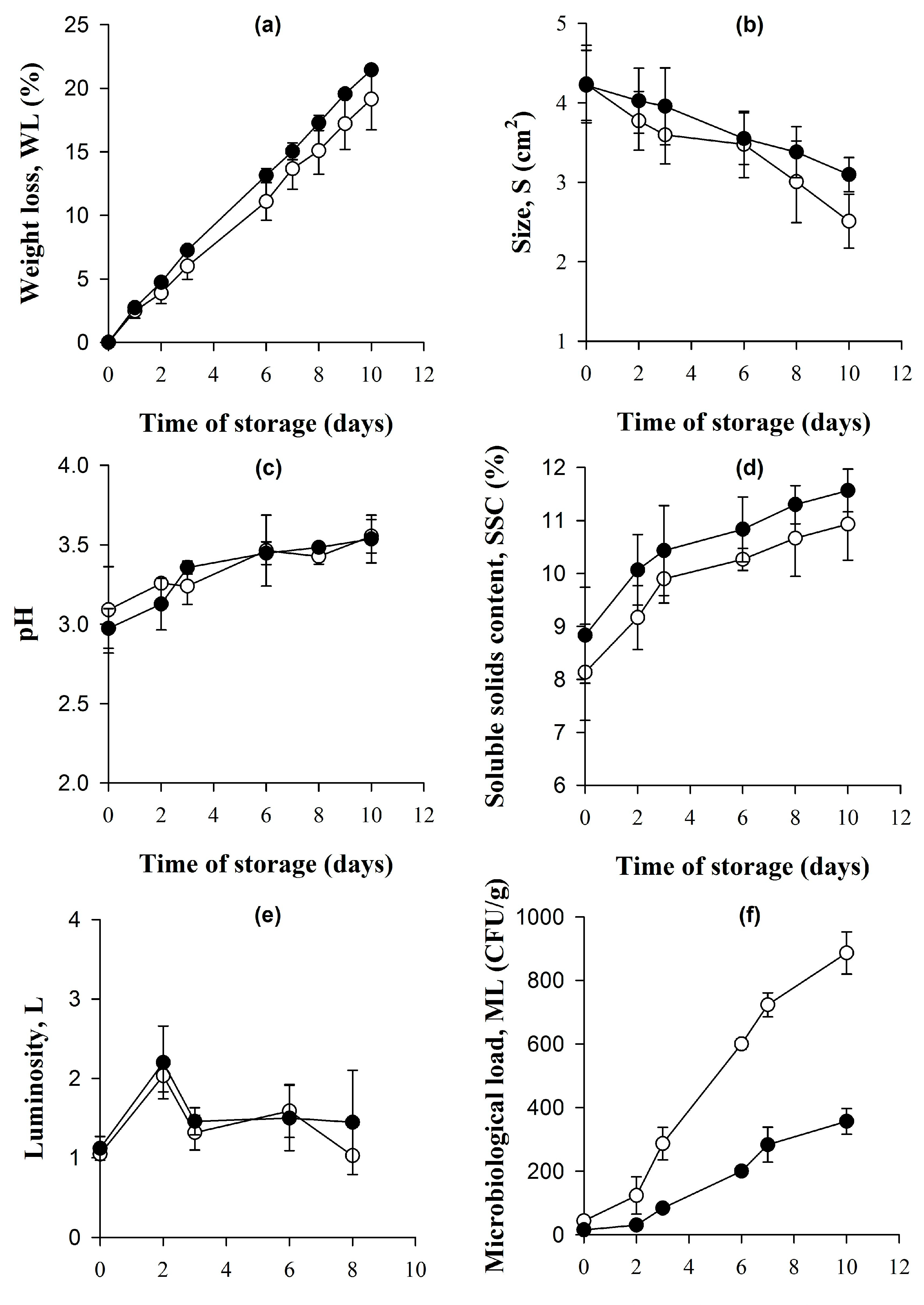

2.5. Physicochemical and Microbiological Evaluation of the Coated Fruits

2.6. Sensory Evaluation of the Coated Fruits

2.7. Statistical Analyses

2.8. Analysis of the Environmental Impact of the Valorisation of Forage Opuntia

3. Results and Discussion

3.1. Mucilage Extraction

3.2. Preparation of the Edible Coatings

3.3. Physicochemical Characterisation of the Mucilage and the Edible Coating

3.4. Physicochemical and Microbiological Evaluation of the Coated Fruits

3.5. Results of the Multivariate Analysis of the Characteristics of the Coated Fruits

3.6. Results of the LSD Statistical Analysis of the Sensory Evaluation of the Coated Fruits

3.7. Environmental and Social Impacts of the Proposed Edible Coatings

4. Conclusions

Author Contributions

Acknowledgments

Conflicts of Interest

References

- Bastidas-Oyanedel, J.R.; Fang, C.; Almardeai, S.; Javid, U.; Yousuf, A.; Schmidt, J.E. Waste biorefinery in arid/semi-arid regions. Bioresour. Technol. 2016, 215, 21–28. [Google Scholar] [CrossRef] [PubMed]

- Soberón, J.; Golubov, J.; Sarukhan, J. The importance of Opuntia in Mexico and routes of invasion and impact of Cactoblastis cactorum (Lepidoptera: Pyralidae). Fla. Entomol. 2001, 84, 486–492. [Google Scholar] [CrossRef]

- Jigar, E.; Sulaiman, H.; Asfaw, A.; Bairu, A. Study on renewable biogas energy production from cladodes of Opuntia ficus-indica. ISABB J. Food Agric. Sci. 2011, 1, 44–48. [Google Scholar]

- Nascimento-Santos, T.; Dutra, E.D.; Prado, A.G.; Leite, F.C.B.; Souza, R.D.F.R.; Santos, D.C.; Abreu, C.A.M.; Simões, D.A.; Morais, M.A., Jr.; Menezes, R.S.C. Potential for biofuels from the biomass of prickly pear cladodes: Challenges for bioethanol and biogas production in dry areas. Biomass Bioenergy 2016, 85, 215–222. [Google Scholar] [CrossRef]

- Owen, N.A.; Griffiths, H. Marginal land bioethanol yield potential of four crassulacean acid metabolism candidates (Agave fourcroydes, Agave salmiana, Agave tequilana and Opuntia ficus-indica) in Australia. GCB Bioenergy 2014, 6, 687–703. [Google Scholar] [CrossRef]

- Ciriminna, R.; Delisi, R.; Albanese, L.; Meneguzzo, F.; Pagliaro, M. Opuntia ficus-indica seed oil: Biorefinery and bioeconomy aspects. Eur. J. Lipid Sci. Technol. 2017, 118, 1700013. [Google Scholar] [CrossRef]

- Beltrán-Hernández, R.I.; Vázquez-Rodríguez, G.A.; Juárez-Santillán, L.F.; Martínez-Ugalde, I.; Coronel-Olivares, C.; Lucho-Constantino, C.A. Cadmium removal from aqueous systems using Opuntia albicarpa L. Scheinvar as biosorbent. BioMed Res. Int. 2015, 2015, 832571. [Google Scholar] [CrossRef] [PubMed]

- Sáenz, C.; Sepúlveda, E.; Matsuhiro, B. Opuntia spp. mucilage’s: A functional component with industrial perspectives. J. Arid Environ. 2004, 57, 275–290. [Google Scholar] [CrossRef]

- Espino-Díaz, M.; Ornelas-Paz, J.J.; Martínez-Téllez, M.A.; Santillán, C.; Barbosa-Cánovas, G.V.; Zamudio-Flores, P.B.; Olivas, G.I. Development and characterization of edible films based on mucilage of Opuntia ficus-indica (L). J. Food Sci. 2010, 75, E347–E352. [Google Scholar] [CrossRef] [PubMed]

- Ruíz, H. Aplicación de las Películas Comestibles a Base de Quitosano y Mucílago de Nopal en Fresa (Fragaria ananassa) en Refrigeración. Master’s Thesis, Universidad de las Américas Puebla, Cholula, Mexico, 2009. (In Spanish). [Google Scholar]

- Pavlath, A.E.; Orts, W. Edible films and coatings: Why, what, and how? In Edible Films and Coatings for Food Applications; Embuscado, M.E., Huber, K.C., Eds.; Springer: New York, NY, USA, 2009; pp. 1–23. ISBN 978-0-387-92823-4. [Google Scholar]

- Otoni, C.G.; Avena-Bustillos, R.J.; Azeredo, H.; Lorevice, M.V.; Moura, M.R.; Mattoso, L.H.; McHugh, T.H. Recent Advances on Edible Films Based on Fruits and Vegetables—A Review. Compr. Rev. Food Sci. Food Saf. 2017, 16, 1151–1169. [Google Scholar] [CrossRef]

- Food and Agriculture Organization (FAO). Losses and Food Waste in Latin America and the Caribbean; Food and Agriculture Organization: Santiago, Chile, 2015; Available online: http://www.fao.org/3/I4655S.pdf (accessed on 5 November 2017).

- Mikkonen, K.S.; Tenkanen, M. Sustainable food-packaging materials based on future biorefinery products: Xylans and mannans. Trends Food Sci. Technol. 2012, 28, 90–102. [Google Scholar] [CrossRef]

- Scheinvar, L.; Gallegos-Vázquez, C.; Olalde-Parra, G.; Sánchez-Cordero, V.; Linaje, M.; Gaytán, A.; Matías-Hernández, H.; Mena-Mendieta, M.; Rivera-Fuentes, B.R. Estado del Conocimiento de las Especies del nopal (Opuntia spp.) Productoras de Xoconostles Silvestres y Cultivadas. Informe Final; Comisión Nacional para el Conocimiento y Uso de la Biodiversidad; Instituto de Biología, Universidad Nacional Autónoma de México: Mexico City, Mexico, 2011. (In Spanish) [Google Scholar]

- Sepúlveda, E.; Sáenz, C.; Aliaga, E.; Aceituno, C. Extraction and characterization of mucilage in Opuntia spp. J. Arid Environ. 2007, 68, 534–545. [Google Scholar] [CrossRef]

- Schlemmer, D.; Oliveira, E.R.; Aráujo-Sales, J. Polystyrene/thermoplastic starch blends with different plasticizers. J. Therm. Anal. Calorim. 2007, 87, 635–638. [Google Scholar] [CrossRef]

- Association of Official Analytical Chemists (AOAC). Official Methods of Analysis of the AOAC, 20th ed.; Association of Official Analytical Chemists: Gaithersburg, MD, USA, 2016. [Google Scholar]

- Bradford, M.M. A rapid and sensitive method for the quantitation of microgram quantities of protein utilizing the principle of protein-dye binding. Anal. Biochem. 1976, 72, 248–254. [Google Scholar] [CrossRef]

- Greenfield, H.; Southgate, D.A. Food Composition Data: Production, Management, and Use; Food and Agriculture Organization: Rome, Italy, 2003. [Google Scholar]

- Secretaría de Salud (SSA) NOM-111-SSA1-1994. Standard Method for the Count of Yeasts and Molds in Food; Secretaría de Salud: Mexico City, Mexico, 1994. (In Spanish) [Google Scholar]

- Lucho-Constantino, C.A.; Poggi-Varaldo, H.; Beltrán-Hernández, R.I.; Prieto-García, F.; Alvarez-Suárez, M.A. multivariate analysis of the accumulation and fractionation of selected cations and heavy metals in agricultural soils in Hidalgo State, Mexico irrigated with raw wastewater. Environ. Int. 2005, 31, 313–323. [Google Scholar] [CrossRef] [PubMed]

- WARM: Waste Reduction Model Version 14. Available online: https://www.epa.gov/warm/versions-waste-reduction-model-warm#WARM (accessed on 25 October 2017).

- United States Environmental Protection Agency (USEPA). Solid Waste Management and Greenhouse Gases: A Life-Cycle Assessment of Emissions and Sinks, 3rd ed.; United States Environmental Protection Agency: Washington, DC, USA, 2006. [Google Scholar]

- Greenhouse Gas Equivalencies Calculator. Available online: https://www.epa.gov/energy/greenhouse-gas-equivalencies-calculator (accessed on 3 November 2017).

- Ornelas-Núñez, H. Mejoramiento del Método de Extracción del Mucilago de Nopal Opuntia ficus-indica y Evaluación de sus Propiedades de Viscosidad. Undergraduate Thesis, Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Mexico, 2011. (In Spanish). [Google Scholar]

- Rodríguez-González, S. Efecto de la incorporación de mucílago de nopal sobre las propiedades sensoriales y texturales de una pasta a base de huitlacoche Ustilago maydis. Undergraduate Thesis, Universidad Michoacana de San Nicolás de Hidalgo, Morelia, Mexico, 2010. (In Spanish). [Google Scholar]

- Rodríguez-González, S.; Martínez-Flores, H.E.; Chávez-Moreno, C.K.; Macías-Rodríguez, L.; Zavala-Mendoza, E.; Garnica-Romo, M.G.; Chacón-García, L. Extraction and characterization of mucilage from wild species of Opuntia. J. Food Process Eng. 2014, 37, 285–292. [Google Scholar] [CrossRef]

- Trachtenberg, S.; Mayer, A. Biophysical properties of Opuntia ficus-indica mucilage. Phytochemistry 1982, 21, 2835–2844. [Google Scholar] [CrossRef]

- Pérez-Gallardo, A.; García-Almendárez, B.; Barbosa-Cánovas, G.; Pimentel-González, D.; Reyes-González, L.R.; Regalado, C. Effect of starch-beeswax coatings on quality parameters of blackberries (Rubus spp.). J. Food Sci. Technol. 2015, 52, 5601–5610. [Google Scholar] [CrossRef] [PubMed]

- Meneghel, R.F.A.; Benassi, M.T.; Yamashita, F. Revestimento comestível de alginato de sódio para frutos de amora-preta (Rubus ulmifolius). Semin. Ciênc. Agrárias 2008, 29, 609–618. [Google Scholar] [CrossRef]

- Oliveira, D.M.; Kwiatkowski, A.; Rosa, C.I.L.F.; Clemente, E. Refrigeration and edible coatings in blackberry (Rubus spp.) conservation. J. Food Sci. Technol. 2014, 51, 2120–2126. [Google Scholar] [CrossRef] [PubMed]

- Baldwin, E.; Nisperos-Carriedo, M.; Baker, R. Use of edible coatings to preserve quality of lightly (and slightly) processed products. Crit. Rev. Food Sci. Nutr. 1995, 35, 509–524. [Google Scholar] [CrossRef] [PubMed]

- Ulloa, J.A. Frutas Autoestabilizadas en el Envase: La Tecnología de Obstáculos; Universidad Autónoma de Nayarit: Tepic, Mexico, 2007. (In Spanish) [Google Scholar]

- Food and Agriculture Organization (FAO). Manual de Manejo Postcosecha de Frutas Tropicales (Papaya, Piña, Plátano, Cítricos); FAO: Rome, Italy, 2000; Available online: http://www.fao.org/3/a-ac304s.pdf (accessed on 5 November 2017).

- Tosun, I.; Ustun, N.S.; Tekguler, B. Physical and chemical changes during ripening of blackberry fruits. Sci. Agric. 2008, 65, 87–90. [Google Scholar] [CrossRef]

- Dechaine, J.M.; Burger, J.C.; Burke, J.M. Ecological patterns and genetic analysis of post-dispersal seed predation in sunflower (Helianthus annuus) crop-wild hybrids. Mol. Ecol. 2010, 19, 3477–3488. [Google Scholar] [CrossRef] [PubMed]

- Joo, M.; Lewandowski, N.; Auras, R.; Harte, J.; Almenar, E. Comparative shelf life study of blackberry fruit in bio-based and petroleum-based containers under retail storage conditions. Food Chem. 2011, 126, 1734–1740. [Google Scholar] [CrossRef] [PubMed]

- Ortiz-Rodríguez, R.; Aguilar-Barrera, J.L.; Valdéz-Alarcón, J.J.; Val-Arreola, D.; Esquivel-Córdoba, J.; Martínez-Flores, H.E.; Pérez-Sánchez, R.E. Efecto de la adición de mucílago de Opuntia ficus-indica y Opuntia atropes a la leche cruda sobre bacterias mesófilas aerobias y coliformes totales. Nova Sci. 2016, 8, 106–122. (In Spanish) [Google Scholar]

- Food Wastage Footprint—Impacts on Natural Resources. Available online: http://www.fao.org/fileadmin/templates/nr/sustainability_pathways/docs/FAO_FWF_ES_Presentation_2_Sept_2013_ES_web.pdf (accessed on 5 November 2017).

- Vilariño, M.V.; Franco, C.D.; Quarrington, C. Food loss and waste reduction as an integral part of a circular economy. Front. Environ. Sci. 2017, 5, 21. [Google Scholar] [CrossRef]

| Material | Proximate Analysis | Elemental Analysis | ||||||

|---|---|---|---|---|---|---|---|---|

| Moisture | Ash 1 | Protein 1 | Dietary Fibre 1 | Nitrogen-Free Extract (NFE) 1 | C | N | H | |

| Mucilage | 7.75 ± 1.15 | 13.14 ± 1.58 | 1.11 ± 0.01 | 55.92 ± 1.76 | 22.08 | 36.91 | <1.0 | 6.00 |

| Edible coating | 93.82 ± 1.69 | 1.21 ± 0.11 | <0.01 ± 0.003 | 0.24 ± 0.04 | 4.73 | 37.66 | <1.0 | 7.65 |

| Attribute | Days (D) | Treatment (T) | Mean | Standard Error | Significance (T) | |

|---|---|---|---|---|---|---|

| Uncoated | Coated | |||||

| Brightness | 0 | 4.03 | 3.50 | 3.77 | 0.27 | s |

| 6 | 4.17 | 2.70 | 3.43 | 0.73 | s | |

| Mean | 4.10 | 3.10 | ||||

| Standard error | 0.07 | 0.40 | ||||

| Significance (D) | ns | s | ||||

| Colour | 0 | 4.07 | 3.90 | 3.98 | 0.83 | ns |

| 6 | 4.13 | 3.00 | 3.57 | 0.57 | s | |

| Mean | 4.10 | 3.45 | ||||

| Standard error | 0.03 | 0.45 | ||||

| Significance (D) | ns | s | ||||

| Flavour | 0 | 3.53 | 3.67 | 3.60 | 0.70 | ns |

| 6 | 3.40 | 3.37 | 3.38 | 0.02 | ns | |

| Mean | 3.47 | 3.52 | ||||

| Standard error | 0.07 | 0.15 | ||||

| Significance (D) | ns | s | ||||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Nájera-García, A.I.; López-Hernández, R.E.; Lucho-Constantino, C.A.; Vázquez-Rodríguez, G.A. Towards Drylands Biorefineries: Valorisation of Forage Opuntia for the Production of Edible Coatings. Sustainability 2018, 10, 1878. https://doi.org/10.3390/su10061878

Nájera-García AI, López-Hernández RE, Lucho-Constantino CA, Vázquez-Rodríguez GA. Towards Drylands Biorefineries: Valorisation of Forage Opuntia for the Production of Edible Coatings. Sustainability. 2018; 10(6):1878. https://doi.org/10.3390/su10061878

Chicago/Turabian StyleNájera-García, Alba Iris, Raúl Eduardo López-Hernández, Carlos Alexander Lucho-Constantino, and Gabriela A. Vázquez-Rodríguez. 2018. "Towards Drylands Biorefineries: Valorisation of Forage Opuntia for the Production of Edible Coatings" Sustainability 10, no. 6: 1878. https://doi.org/10.3390/su10061878