Sustainability in the Minerals Industry: Seeking a Consensus on Its Meaning

Abstract

:1. Introduction

- RQ 1: How has sustainability been conceptualized and approached in general, and in the minerals industry context?

- RQ 2: Which are the sustainability challenges for the minerals industry from a more comprehensive perspective, considering each of the dimensions of sustainability and their interactions (trade-offs and synergies), as well as the different spatial and temporal domains?

2. Methods

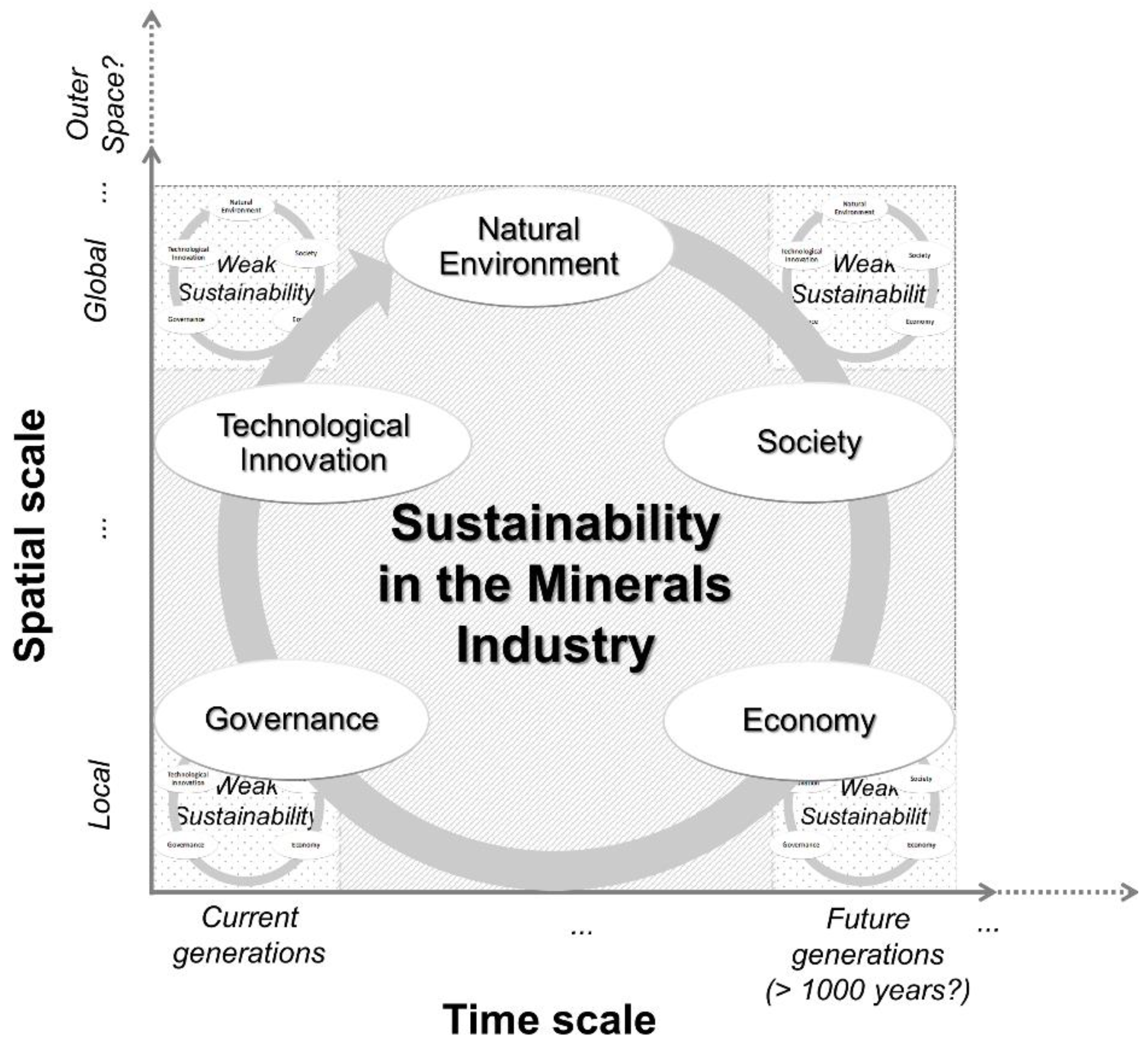

3. The Sustainable Development Paradigm

4. Conceptualizing Sustainability

5. Overview of Sustainability in the Minerals Industry

5.1. Introduction

5.2. Sustainability Frameworks in the Minerals Industry Context

6. Sustainability Challenges and Opportunities for the Minerals Industry: A Complex Multi-Dimensional and Multi-Scale Network of Interactions

6.1. Introduction

- Society (community, workers, NGOs, etc.);

- Economic System (or Economy);

- Natural Environment (Ecosphere = Geosphere + Biosphere);

- Technology (Artificial Environment, Artefacts or Technosphere); and

- Governance (including both public/political and private/corporate leadership).

6.2. Natural Environment Preservation

6.2.1. Resource Availability and Criticality

- absolute, related to the geological aspects;

- temporary, when the supply is smaller than the demand; and

- structural, when some metals are coproduced (“companion metals”) along the production chain of other metals (“carrier metals”) and their supply do not necessarily respond to market demand.

6.2.2. Resource Use Efficiency and Secondary Resources

6.3. Human and Social Well-Being

6.4. Economic Prosperity

6.4.1. Mining, Economic Growth and Well-Being

6.4.2. Development of Primary and Secondary Resources

6.4.3. Operating (Eco)-Efficiently

6.4.4. The True Value of the Resource in the Market

6.4.5. Sustainable Consumption and Production

6.5. Public and Private Institutional Leadership

- Choice of the minerals that must be prioritized in terms of reduction of extraction rate;

- Definition of sustainable extraction rates, introducing the reduction necessary in the exploitation of each mineral resource and the period within which those reductions are to be achieved; and

- Allocation of an exploitation limit for priority resources between producing countries—as well as those potential producers—of these minerals.

6.6. Sustainability-Driven Technological Innovation

7. Concluding Remarks

- Proactive management and continuous engagement with the different stakeholders throughout the life cycle of both mining projects and products based on mineral resources, which requires attention on proper management of primary and secondary (recycled) resources;

- Sustainability dimensions beyond the Triple Bottom Line, giving greater emphasis to institutional leadership and sustainability-driven technological innovation;

- Multiple spatial and geographical scales of mining activities from local to global contexts; and

- Intra- and intergenerational equity, aiming at the sustainability of mineral resources in a long-term horizon.

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Dubiński, J. Sustainable Development of Mining Mineral Resources. J. Sustain. Min. 2013, 12, 1–6. [Google Scholar] [CrossRef]

- Azapagic, A. Developing a framework for sustainable development indicators for the mining and minerals industry. J. Clean. Prod. 2004, 12, 639–662. [Google Scholar] [CrossRef]

- Pokhrel, L.R.; Dubey, B. Global scenarios of metal mining, environmental repercussions, public policies, and sustainability: A review. Crit. Rev. Environ. Sci. Technol. 2013, 43, 2352–2388. [Google Scholar] [CrossRef]

- Ali, S.H.; Giurco, D.; Arndt, N.; Nickless, E.; Brown, G.; Demetriades, A.; Durrheim, R.; Enriquez, M.A.; Kinnaird, J.; Littleboy, A.; et al. Mineral supply for sustainable development requires resource governance. Nature 2017, 543, 367–372. [Google Scholar] [CrossRef] [PubMed]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W. The Limits to Growth. A Report for the Club of Rome’s Project on the Predicament of Mankind; Universe Books: New York, NY, USA, 1972; ISBN 0876631650. [Google Scholar]

- Birat, J.P.L. Environmental metallurgy: Continuity or new discipline? Steel Res. Int. 2014, 85, 1240–1256. [Google Scholar] [CrossRef]

- Petrie, J. New Models of Sustainability for the Resources Sector: A Focus on Minerals and Metals. Process Saf. Environ. Prot. 2007, 85, 88–98. [Google Scholar] [CrossRef]

- Giurco, D.; Cooper, C. Mining and sustainability: Asking the right questions. Miner. Eng. 2012, 29, 3–12. [Google Scholar] [CrossRef]

- Worrall, R.; Neil, D.; Brereton, D.; Mulligan, D. Towards a sustainability criteria and indicators framework for legacy mine land. J. Clean. Prod. 2009, 17, 1426–1434. [Google Scholar] [CrossRef]

- Moran, C.J.; Kunz, N.C. Sustainability as it pertains to minerals and energy supply and demand: A new interpretative perspective for assessing progress. J. Clean. Prod. 2014, 84, 16–26. [Google Scholar] [CrossRef]

- Basu, A.J.; Kumar, U. Innovation and technology driven sustainability performance management framework (ITSPM) for the mining and minerals sector. Int. J. Surf. Min. Reclam. Environ. 2004, 18, 135–149. [Google Scholar] [CrossRef]

- Fitzpatrick, P.; Fonseca, A.; McAllister, M.L. From the Whitehorse Mining Initiative towards Sustainable Mining: Lessons learned. J. Clean. Prod. 2011, 19, 376–384. [Google Scholar] [CrossRef]

- Moran, C.J.; Lodhia, S.; Kunz, N.C.; Huisingh, D. Sustainability in mining, minerals and energy: New processes, pathways and human interactions for a cautiously optimistic future. J. Clean. Prod. 2014, 84, 1–15. [Google Scholar] [CrossRef]

- Cowell, S.J.; Wehrmeyer, W.; Argust, P.W.; Robertson, J.G.S. Sustainability and the primary extraction industries: Theories and practice. Resour. Policy 1999, 25, 277–286. [Google Scholar] [CrossRef]

- Rosen, M.A. Sustainability: A Crucial Quest for Humanity—Welcome to a New Open Access Journal for a Growing Multidisciplinary Community. Sustainability 2009, 1, 1–4. [Google Scholar] [CrossRef]

- Kuhlman, T.; Farrington, J. What is Sustainability? Sustainability 2010, 2, 3436–3448. [Google Scholar] [CrossRef]

- Laurence, D. Establishing a sustainable mining operation: An overview. J. Clean. Prod. 2011, 19, 278–284. [Google Scholar] [CrossRef]

- Jovane, F.; Yoshikawa, H.; Alting, L.; Boër, C.R.; Westkamper, E.; Williams, D.; Tseng, M.; Seliger, G.; Paci, A.M. The incoming global technological and industrial revolution towards competitive sustainable manufacturing. CIRP Ann. Manuf. Technol. 2008, 57, 641–659. [Google Scholar] [CrossRef]

- Wennersten, R.; Qie, S. United Nations Sustainable Development Goals for 2030 and Resource Use. In Handbook of Sustainability Science and Research; World Sustainability Series; Leal Filho, W., Ed.; Springer: Cham, Switzerland, 2018; pp. 317–339. ISBN 9783319630076. [Google Scholar]

- Hilson, G. Barriers to implementing cleaner technologies and Cleaner Production (CP) practices in the mining industry: A case study of the Americas. Miner. Eng. 2000, 13, 699–717. [Google Scholar] [CrossRef]

- Brundtland, G.H. Report of the World Commission on Environment and Development: Our Common Future. United Nations, 1987. Available online: http://www.un-documents.net/our-common-future.pdf (accessed on 9 October 2017).

- Canuel, E. Sustainable development, natural resource extraction, and the Artic: The road ahead. Alsk. Law Rev. 2016, 33, 31–63. [Google Scholar]

- Elkington, J. Cannibals with Forks. The Triple Bottom Line of 21st Century Business; Capstone Publishing Limited: Oxford, UK, 1997; ISBN 190096127X. [Google Scholar]

- United Nations (UN). The Millennium Development Goals Report 2006; United Nations (UN): New York, NY, USA, 2006. [Google Scholar]

- United Nations (UN). Transforming Our World: The 2030 Agenda for Sustainable Development; A/RES/70/1; United Nations (UN): New York, NY, USA, 2015. [Google Scholar]

- Glavič, P.; Lukman, R. Review of sustainability terms and their definitions. J. Clean. Prod. 2007, 15, 1875–1885. [Google Scholar] [CrossRef]

- Robèrt, K.-H. Tools and concepts for sustainable development, how do they relate to a general framework for sustainable development, and to each other? J. Clean. Prod. 2000, 8, 243–254. [Google Scholar] [CrossRef]

- Heijungs, R.; Huppes, G.; Guinée, J.B. Life cycle assessment and sustainability analysis of products, materials and technologies. Toward a scientific framework for sustainability life cycle analysis. Polym. Degrad. Stab. 2010, 95, 422–428. [Google Scholar] [CrossRef]

- Villeneuve, C.; Tremblay, D.; Riffon, O.; Lanmafankpotin, G.Y.; Bouchard, S. A Systemic Tool and Process for Sustainability Assessment. Sustainability 2017, 9, 1909. [Google Scholar] [CrossRef]

- Bendell, J.; Kearins, K. The Political Bottom Line: The Emerging Dimension to Corporate Responsibility for Sustainable Development. Bus. Strategy Environ. 2005, 14, 372–383. [Google Scholar] [CrossRef]

- Karlsson, S.; Dahl, A.L.; Biggs, R.; ten Brink, B.J.E.; Gutiérrez-Espeleta, E.; Hasan, M.N.H.; Laumann, G.; Moldan, B.; Singh, A.; Spangenberg, J.H.; et al. Meeting Conceptual Challenges. In Sustainablity Indicators: A Scientific Assessment; Scope Series; Hák, T., Moldan, B., Dahl, A.L., Eds.; Island Press: Washington, DC, USA, 2007; pp. 27–48. ISBN 9781597261302. [Google Scholar]

- John, L.; Narayanamurthy, G. Converging sustainability definitions: Industry independent dimensions. World J. Sci. Technol. Sustain. Dev. 2015, 12, 206–232. [Google Scholar] [CrossRef]

- Lozano, R. Envisioning sustainability three-dimensionally. J. Clean. Prod. 2008, 16, 1838–1846. [Google Scholar] [CrossRef]

- Washington, H. Demystifying Sustainability: Towards Real Solutions; Routledge: London, UK, 2015; ISBN 9781138812680. [Google Scholar]

- Bebbington, A. Capitals and Capabilities: A Framework for Analyzing Peasant Viability, Rural Livelihoods and Poverty. World Dev. 1999, 27, 2021–2044. [Google Scholar] [CrossRef]

- Parkin, S.; Sommer, F.; Uren, S. Sustainable development: Understanding the concept and practical challenge. Proc. ICE Eng. Sustain. 2003, 156, 19–26. [Google Scholar] [CrossRef]

- Porritt, J. Capitalism as If the World Matters; Earthscan: London, UK, 2007; ISBN 9781844071937. [Google Scholar]

- Parkin, S. The Positive Deviant—Sustainability Leadership in a Perverse World; Earthscan: London, UK, 2010; ISBN 9781849711180. [Google Scholar]

- Hector, D.C.; Christensen, C.B.; Petrie, J. Sustainability and Sustainable Development: Philosophical Distinctions and Practical Implications. Environ. Values 2014, 23, 7–28. [Google Scholar] [CrossRef]

- Sikdar, S.K. Sustainability and recycle-reuse in process systems. Clean Technol. Environ. Policy 2007, 9, 167–174. [Google Scholar] [CrossRef]

- McLellan, B.C.; Corder, G.D.; Giurco, D.; Green, S. Incorporating sustainable development in the design of mineral processing operations—Review and analysis of current approaches. J. Clean. Prod. 2009, 17, 1414–1425. [Google Scholar] [CrossRef] [Green Version]

- Durucan, S.; Korre, A.; Munoz-Melendez, G. Mining life cycle modelling: A cradle-to-gate approach to environmental management in the minerals industry. J. Clean. Prod. 2006, 14, 1057–1070. [Google Scholar] [CrossRef]

- Hilson, G.; Murck, B. Sustainable development in the mining industry: Clarifying the corporate perspective. Resour. Policy 2000, 26, 227–238. [Google Scholar] [CrossRef]

- Bond, C.J. Positive peace and sustainability in the mining context: Beyond the triple bottom line. J. Clean. Prod. 2014, 84, 164–173. [Google Scholar] [CrossRef]

- Pimentel, B.S.; Gonzalez, E.S.; Barbosa, G.N.O. Decision-support models for sustainable mining networks: Fundamentals and challenges. J. Clean. Prod. 2016, 112, 2145–2157. [Google Scholar] [CrossRef]

- Espinoza, R.D.; Morris, J.W.F. Towards sustainable mining (part II): Accounting for mine reclamation and post reclamation care liabilities. Resour. Policy 2017, 52, 29–38. [Google Scholar] [CrossRef]

- Kogel, J.E. Sustainable development and the minerals industry. In Engineering Solutions for Sustainability: Materials and Resources II; The Minerals, Metals & Materials Series; Fergus, J.W., Mishra, B., Anderson, D., Sarver, E.A., Neelameggham, N.R., Eds.; Springer: Cham, Switzerland, 2015; pp. 25–34. ISBN 9783319481388. [Google Scholar]

- Fleury, A.M.; Davies, B. Sustainable supply chains-minerals and sustainable development, going beyond the mine. Resour. Policy 2012, 37, 175–178. [Google Scholar] [CrossRef]

- MMSD Project. Breaking New Ground; MMSD Project: London, UK, 2002. [Google Scholar]

- Fox, S.J. SPACE: The race for mineral rights “The sky is no longer the limit” Lessons from earth! Resour. Policy 2016, 49, 165–178. [Google Scholar] [CrossRef]

- Odell, S.D.; Bebbington, A.; Frey, K.E. Mining and climate change: A review and framework for analysis. Extr. Ind. Soc. 2018, 5, 201–214. [Google Scholar] [CrossRef]

- Sharma, V. Mining and Climate Change. In Mining in the Asia-Pacific, The Political Economy of the Asia Pacific; O’Callaghan, T., Graetz, G., Eds.; Springer: Cham, Switzerland, 2017; pp. 301–320. ISBN 9783319613956. [Google Scholar]

- Batterham, R.J. The mine of the future—Even more sustainable. Miner. Eng. 2017, 107, 2–7. [Google Scholar] [CrossRef]

- Batterham, R. Lessons in Sustainability from the Mining Industry. Procedia Eng. 2014, 83, 8–15. [Google Scholar] [CrossRef]

- Prno, J. An analysis of factors leading to the establishment of a social licence to operate in the mining industry. Resour. Policy 2013, 38, 577–590. [Google Scholar] [CrossRef]

- Franks, D.M.; Cohen, T. Social Licence in Design: Constructive technology assessment within a mineral research and development institution. Technol. Forecast. Soc. Chang. 2012, 79, 1229–1240. [Google Scholar] [CrossRef]

- Giurco, D.; McLellan, B.; Franks, D.M.; Nansai, K.; Prior, T. Responsible mineral and energy futures: Views at the nexus. J. Clean. Prod. 2014, 84, 322–338. [Google Scholar] [CrossRef] [Green Version]

- Han Onn, A.; Woodley, A. A discourse analysis on how the sustainability agenda is defined within the mining industry. J. Clean. Prod. 2014, 84, 116–127. [Google Scholar] [CrossRef] [Green Version]

- Hinton, J.J.; Veiga, M.M.; Veiga, A.T.C. Clean artisanal gold mining: A utopian approach? J. Clean. Prod. 2003, 11, 99–115. [Google Scholar] [CrossRef]

- Geenen, S. Underground dreams. Uncertainty, risk and anticipation in the gold production network. Geoforum 2018, 91, 30–38. [Google Scholar] [CrossRef]

- Hodges, C.A. Mineral Resources, Environmental Issues, and Land Use. Science 1995, 268, 1305–1312. [Google Scholar] [CrossRef] [PubMed]

- United Nations (UN). Berlin II: Guidelines for Mining and Sustainable Development; United Nations (UN): New York, NY, USA, 2002. [Google Scholar]

- Bastida, A.E. Integrating Sustainability into Legal Frameworks for Mining in Some Selected Latin American Countries; Report Commissioned by the MMSD Project of IIED; International Institute for Environment and Development: London, UK; World Business Council for Sustainable Development: Geneva, Switzerland, 2002. [Google Scholar]

- Fonseca, A.; McAllister, M.L.; Fitzpatrick, P. Measuring what? A comparative anatomy of five mining sustainability frameworks. Miner. Eng. 2013, 46–47, 180–186. [Google Scholar] [CrossRef]

- Whitmore, A. The emperors new clothes: Sustainable mining? J. Clean. Prod. 2006, 14, 309–314. [Google Scholar] [CrossRef]

- Levesque, M.; Millar, D.; Paraszczak, J. Energy and mining—The home truths. J. Clean. Prod. 2014, 84, 233–255. [Google Scholar] [CrossRef]

- International Council on Mining and Metals (ICMM). Sustainable Development Framework: ICMM Principles; International Council on Mining and Metals (ICMM): London, UK, 2015. [Google Scholar]

- SDIMI.org. Available online: http://www.sdimi.org (accessed on 7 September 2017).

- Petrie, J.; Cohen, B.; Stewart, M. Decision support frameworks and metrics for sustainable development of minerals and metals. Clean Technol. Environ. Policy 2007, 9, 133–145. [Google Scholar] [CrossRef]

- Tverdak-Slattery, G. ICMM Represents Mining at Rio+20—The mining industry demonstrates its commitment to sustainability. Eng. Min. J. 2012, 213, 108–114. [Google Scholar]

- Bastida, A.E. From extractive to transformative industries: Paths for linkages and diversification for resource-driven development. Miner. Econ. 2014, 27, 73–87. [Google Scholar] [CrossRef] [Green Version]

- Ferring, D.; Hausermann, H.; Effah, E. Site specific: Heterogeneity of small-scale gold mining in Ghana. Extr. Ind. Soc. 2016, 3, 171–184. [Google Scholar] [CrossRef]

- Gibb, H.; O’Leary, K.G. Mercury Exposure and Health Impacts among Individuals in the Artisanal and Small-Scale Gold Mining Community: A Comprehensive Review. Environ. Health Perspect. 2014, 122, 667–672. [Google Scholar] [CrossRef] [PubMed]

- Hilson, G.; Hilson, A.; Maconachie, R.; McQuilken, J.; Goumandakoye, H. Artisanal and small-scale mining (ASM) in sub-Saharan Africa: Re-conceptualizing formalization and “illegal” activity. Geoforum 2017, 83, 80–90. [Google Scholar] [CrossRef]

- Geenen, S. A dangerous bet: The challenges of formalizing artisanal mining in the Democratic Republic of Congo. Resour. Policy 2012, 37, 322–330. [Google Scholar] [CrossRef]

- Childs, J. A new means of governing artisanal and small-scale mining? Fairtrade gold and development in Tanzania. Resour. Policy 2014, 40, 128–136. [Google Scholar] [CrossRef]

- Fisher, E. Solidarities at a distance: Extending Fairtrade gold to east Africa. Extr. Ind. Soc. 2018, 5, 81–90. [Google Scholar] [CrossRef]

- Hilson, G.; Gillani, A.; Kutaula, S. Towards Sustainable Pro-Poor Development? A Critical Assessment of Fair Trade Gold. J. Clean. Prod. 2018, 186, 894–904. [Google Scholar] [CrossRef]

- Schoenberger, E. Environmentally sustainable mining: The case of tailings storage facilities. Resour. Policy 2016, 49, 119–128. [Google Scholar] [CrossRef]

- Horsley, J.; Prout, S.; Tonts, M.; Ali, S.H. Sustainable livelihoods and indicators for regional development in mining economies. Extr. Ind. Soc. 2015, 2, 368–380. [Google Scholar] [CrossRef]

- Corder, G.D.; Keith, A.; Dyer, L. A Capitals Based Approach—Leading Innovation in Planning for Life-of-Mine Sustainability. In Proceedings of the Life-of-Mine 2014, Brisbane, QLD, Australia, 16–18 July 2014; pp. 499–511. [Google Scholar]

- Tuazon, D.; Corder, G.D.; Powell, M.; Ziemski, M. A practical and rigorous approach for integrating sustainability principles into decision-making processes at minerals processing operations. In Proceedings of the Life-of-Mine 2012, Brisbane, QLD, Australia, 10–12 July 2012; pp. 233–241. [Google Scholar]

- Corder, G.D.; McLellan, B.C.; Bangerter, P.J.; van Beers, D.; Green, S.R. Engineering-in sustainability through the application of SUSOP®. Chem. Eng. Res. Des. 2012, 90, 98–109. [Google Scholar] [CrossRef]

- Rabiee, F. Delivering Solutions for Sustainable Mining in Solomon Iron Ore Project through SUSOP®. Master’s Thesis, Uppsala University, Uppsala, Sweden, 2014. [Google Scholar]

- Caron, J.; Durand, S.; Asselin, H. Principles and criteria of sustainable development for the mineral exploration industry. J. Clean. Prod. 2016, 119, 215–222. [Google Scholar] [CrossRef]

- Eggert, R.G. Economic Perspectives on Sustainability, Mineral Development, and Metal Life Cycles. In Metal Sustainability: Global Challenges, Consequences, and Prospects; Izatt, R.M., Ed.; John Wiley & Sons, Ltd.: Hoboken, NJ, USA, 2016; pp. 467–484. ISBN 9781119009115. [Google Scholar]

- Bian, Z.; Inyang, H.I.; Daniels, J.L.; Otto, F.; Struthers, S. Environmental issues from coal mining and their solutions. Min. Sci. Technol. 2010, 20, 215–223. [Google Scholar] [CrossRef]

- Edraki, M.; Baumgartl, T.; Manlapig, E.; Bradshaw, D.; Franks, D.M.; Moran, C.J. Designing mine tailings for better environmental, social and economic outcomes: A review of alternative approaches. J. Clean. Prod. 2014, 84, 411–420. [Google Scholar] [CrossRef]

- Ihle, C.F.; Kracht, W. The relevance of water recirculation in large scale mineral processing plants with a remote water supply. J. Clean. Prod. 2018, 177, 34–51. [Google Scholar] [CrossRef]

- Lèbre, É.; Corder, G. Integrating Industrial Ecology Thinking into the Management of Mining Waste. Resources 2015, 4, 765–786. [Google Scholar] [CrossRef] [Green Version]

- De Villiers, J.P.R. How to Sustain Mineral Resources: Beneficiation and Mineral Engineering Opportunities. Elements 2017, 13, 307–312. [Google Scholar] [CrossRef]

- Northey, S.A.; Mudd, G.M.; Werner, T.T.; Jowitt, S.M.; Haque, N.; Yellishetty, M.; Weng, Z. The exposure of global base metal resources to water criticality, scarcity and climate change. Glob. Environ. Chang. 2017, 44, 109–124. [Google Scholar] [CrossRef]

- Asif, Z.; Chen, Z. Environmental management in North American mining sector. Environ. Sci. Pollut. Res. 2016, 23, 167–179. [Google Scholar] [CrossRef] [PubMed]

- Hirons, M.; Hilson, G.; Asase, A.; Hodson, M.E. Mining in a changing climate: What scope for forestry-based legacies? J. Clean. Prod. 2014, 84, 430–438. [Google Scholar] [CrossRef]

- Calvo, G.; Mudd, G.; Valero, A.; Valero, A. Decreasing Ore Grades in Global Metallic Mining: A Theoretical Issue or a Global Reality? Resources 2016, 5, 36. [Google Scholar] [CrossRef]

- Bazilian, M.; Rogner, H.; Howells, M.; Hermann, S.; Arent, D.; Gielen, D.; Steduto, P.; Mueller, A.; Komor, P.; Tol, R.S.J.; et al. Considering the energy, water and food nexus: Towards an integrated modelling approach. Energy Policy 2011, 39, 7896–7906. [Google Scholar] [CrossRef]

- Dai, J.; Wu, S.; Han, G.; Weinberg, J.; Xie, X.; Wu, X.; Song, X.; Jia, B.; Xue, W.; Yang, Q. Water-energy nexus: A review of methods and tools for macro-assessment. Appl. Energy 2018, 210, 393–408. [Google Scholar] [CrossRef]

- Endo, A.; Tsurita, I.; Burnett, K.; Orencio, P.M. A review of the current state of research on the water, energy, and food nexus. J. Hydrol. Reg. Stud. 2017, 11, 20–30. [Google Scholar] [CrossRef]

- Garcia, D.J.; You, F. The water-energy-food nexus and process systems engineering: A new focus. Comput. Chem. Eng. 2016, 91, 49–67. [Google Scholar] [CrossRef]

- Hamiche, A.M.; Stambouli, A.B.; Flazi, S. A review of the water-energy nexus. Renew. Sustain. Energy Rev. 2016, 65, 319–331. [Google Scholar] [CrossRef]

- Ringler, C.; Bhaduri, A.; Lawford, R. The nexus across water, energy, land and food (WELF): Potential for improved resource use efficiency? Curr. Opin. Environ. Sustain. 2013, 5, 617–624. [Google Scholar] [CrossRef]

- Sanders, K.T.; Masri, S.F. The energy-water agriculture nexus: The past, present and future of holistic resource management via remote sensing technologies. J. Clean. Prod. 2016, 117, 73–88. [Google Scholar] [CrossRef]

- Tan, C.; Zhi, Q. The Energy-Water nexus: A literature Review of the Dependence of Energy on Water. Energy Procedia 2016, 88, 277–284. [Google Scholar] [CrossRef]

- Tokimatsu, K.; Wachtmeister, H.; McLellan, B.; Davidsson, S.; Murakami, S.; Höök, M.; Yasuoka, R.; Nishio, M. Energy modeling approach to the global energy-mineral nexus: A first look at metal requirements and the 2 °C target. Appl. Energy 2017, 207, 494–509. [Google Scholar] [CrossRef]

- Zhang, X.; Vesselinov, V.V. Energy-water nexus: Balancing the tradeoffs between two-level decision makers. Appl. Energy 2016, 183, 77–87. [Google Scholar] [CrossRef]

- Brown, J.H.; Burger, J.R.; Burnside, W.R.; Chang, M.; Davidson, A.D.; Fristoe, T.S.; Hamilton, M.J.; Hammond, S.T.; Kodric-Brown, A.; Mercado-Silva, N.; et al. Macroecology meets macroeconomics: Resource scarcity and global sustainability. Ecol. Eng. 2014, 65, 24–32. [Google Scholar] [CrossRef] [PubMed]

- U.S. National Research Council. Minerals, Critical Minerals, and the U.S. Economy; The National Academies Press: Washington, DC, USA, 2008; ISBN 9780309112826. [Google Scholar]

- Graedel, T.E.; Harper, E.M.; Nassar, N.T.; Nuss, P.; Reck, B.K. Criticality of metals and metalloids. Proc. Natl. Acad. Sci. USA 2015, 112, 4257–4262. [Google Scholar] [CrossRef] [PubMed]

- Tilton, J.E.; Crowson, P.C.F.; DeYoung, J.H.; Eggert, R.G.; Ericsson, M.; Guzmán, J.I.; Humphreys, D.; Lagos, G.; Maxwell, P.; Radetzki, M.; et al. Public policy and future mineral supplies. Resour. Policy 2018. [Google Scholar] [CrossRef]

- Tilton, J.E. Exhaustible resources and sustainable development: Two different paradigms. Resour. Policy 1996, 22, 91–97. [Google Scholar] [CrossRef]

- Tilton, J.E. Depletion and the Long-Run Availability of Mineral Commodities; Report Commissioned by the MMSD Project of IIED; International Institute for Environment and Development: London, UK; World Business Council for Sustainable Development: Geneva, Switzerland, 2001. [Google Scholar]

- Henckens, M.L.C.M.; Driessen, P.P.J.; Ryngaert, C.; Worrell, E. The set-up of an international agreement on the conservation and sustainable use of geologically scarce mineral resources. Resour. Policy 2016, 49, 92–101. [Google Scholar] [CrossRef]

- Prior, T.; Giurco, D.; Mudd, G.; Mason, L.; Behrisch, J. Resource depletion, peak minerals and the implications for sustainable resource management. Glob. Environ. Chang. 2012, 22, 577–587. [Google Scholar] [CrossRef]

- Graetz, G. Uranium mining and First Peoples: The nuclear renaissance confronts historical legacies. J. Clean. Prod. 2014, 84, 339–347. [Google Scholar] [CrossRef]

- Habib, K.; Hamelin, L.; Wenzel, H. A dynamic perspective of the geopolitical supply risk of metals. J. Clean. Prod. 2016, 133, 850–858. [Google Scholar] [CrossRef]

- Henckens, M.L.C.M.; Driessen, P.P.J.; Worrell, E. Metal scarcity and sustainability, analyzing the necessity to reduce the extraction of scarce metals. Resour. Conserv. Recycl. 2014, 93, 1–8. [Google Scholar] [CrossRef]

- Atherton, J. Declaration by the Metals Industry on Recycling Principles. Int. J. Life Cycle Assess. 2007, 12, 59–60. [Google Scholar] [CrossRef]

- Espi, J.A.; Moreno, S.A. The scarcity-abundance relationship of mineral resources introducing some sustaintable aspects. Dyna 2010, 77, 21–29. [Google Scholar]

- Mishra, D.P.; Sugla, M.; Singha, P. Productivity Improvement in Underground Coal Mines—A Case Study. J. Sustain. Min. 2013, 12, 48–53. [Google Scholar] [CrossRef]

- Pease, J.; Walters, S.; Keeney, L.; Shapland, G. A Step Change in Mining Productivity: Time to Deliver the Promise. In Sustainability in the Mineral and Energy Sectors; Devasahayam, S., Dowling, K., Mahapatra, M.K., Eds.; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA, 2017; pp. 27–34. ISBN 9781498733021. [Google Scholar]

- Espinoza, R.D.; Rojo, J. Towards sustainable mining (Part I): Valuing investment opportunities in the mining sector. Resour. Policy 2017, 52, 7–18. [Google Scholar] [CrossRef]

- Runge, I.C. Mining Economics and Strategy; Society for Mining, Metallurgy and Exploration, Inc.: Englewood, CO, USA, 1998; ISBN 0873351657. [Google Scholar]

- World Bank. Atlas of Sustainable Development Goals 2017: From World Development Indicators; World Bank: Washington, DC, USA, 2017. [Google Scholar]

- Fisher, E.; Mwaipopo, R.; Mutagwaba, W.; Nyange, D.; Yaron, G. “The ladder that sends us to wealth”: Artisanal mining and poverty reduction in Tanzania. Resour. Policy 2009, 34, 32–38. [Google Scholar] [CrossRef]

- Siegel, S.; Veiga, M.M. Artisanal and small-scale mining as an extralegal economy: De Soto and the redefinition of “formalization”. Resour. Policy 2009, 34, 51–56. [Google Scholar] [CrossRef]

- Hilson, G.; Yakovleva, N.; Banchirigah, S.M. “To move or not to move”: Reflections on the resettlement of artisanal miners in the Western Region of Ghana. Afr. Aff. (Lond). 2007, 106, 413–436. [Google Scholar] [CrossRef]

- Lehner, T. Plenary lecture on the wise production and use of metals. Miner. Eng. 2007, 20, 822–829. [Google Scholar] [CrossRef]

- Achzet, B.; Helbig, C. How to evaluate raw material supply risks—An overview. Resour. Policy 2013, 38, 435–447. [Google Scholar] [CrossRef]

- Henderson, J.; Dicken, P.; Hess, M.; Coe, N.; Wai-Chung Yeung, H. Global production networks and the analysis of economic development. Rev. Int. Polit. Econ. 2002, 9, 436–464. [Google Scholar] [CrossRef]

- Perez, C. Technological revolutions and techno-economic paradigms. Camb. J. Econ. 2010, 34, 185–202. [Google Scholar] [CrossRef]

- Morone, P. The times they are a-changing: Making the transition toward a sustainable economy. Biofuels Bioprod. Biorefin. 2016, 10, 369–377. [Google Scholar] [CrossRef]

- Perez, C. Technological Revolutions and Financial Capital: The Dynamics of Bubbles and Golden Ages; Edward Elgar Publishing: Cheltenham, UK, 2002; ISBN 1840649224. [Google Scholar]

- Bartos, P.J. Is mining a high-tech industry? Investigations into innovation and productivity advance. Resour. Policy 2007, 32, 149–158. [Google Scholar] [CrossRef]

- Bearman, R.A. Step change in the context of comminution. Miner. Eng. 2013, 43–44, 2–11. [Google Scholar] [CrossRef]

- Lynch, A.J.; Rowland, C.A. The History of Grinding; Society for Mining, Metallurgy and Exploration, Inc.: Littleton, CO, USA, 2005; ISBN 0873352386. [Google Scholar]

- MacHunter, R.M.G.; Pax, R.A. Whole plant process modelling incorporating an estimate on the impact of uncertainties in equipment and orebody composition on separation performance. In The 6th International Heavy Minerals Conference “Back to Basics”; The Southern African Institute of Mining and Metallurgy: Johannesburg, South Africa, 2007; pp. 15–20. [Google Scholar]

- Napier-Munn, T. Is progress in energy-efficient comminution doomed? Miner. Eng. 2015, 73, 1–6. [Google Scholar] [CrossRef]

- Powell, M.S.; Bye, A.R. Beyond Mine-to-Mill—Circuit Design for Energy Efficient Resource Utilisation. In Proceedings of the 10th Mill Operators’ Conference, Adelaide, Australia, 12–14 October 2009; pp. 357–364. [Google Scholar]

- Norgate, T.; Haque, N. The greenhouse gas impact of IPCC and ore-sorting technologies. Miner. Eng. 2013, 42, 13–21. [Google Scholar] [CrossRef]

- Musa, F.; Morrison, R. A more sustainable approach to assessing comminution efficiency. Miner. Eng. 2009, 22, 593–601. [Google Scholar] [CrossRef]

- Daniel, M.J. Energy Use in Comminution in a Global Context. In Sustainability in the Mineral and Energy Sectors; Devasahayam, S., Dowling, K., Mahapatra, M.K., Eds.; CRC Press—Taylor & Francis Group: Boca Raton, FL, USA, 2017; pp. 51–72. ISBN 9781498733021. [Google Scholar]

- Lieberwirth, H. Securing resources for growth—challenges and opportunities for comminution in mineral processing. In Proceedings of the Conference in Minerals Engineering—Konferens i Mineralteknik, Luleå, Sweden, 7–8 February 2017. [Google Scholar]

- Yahyaei, M.; Hilden, M.; Shi, F.; Liu, L.X.; Ballantyne, G.; Palaniandy, S. Comminution. In Production, Handling and Characterization of Particulate Materials; Merkus, H.G., Meesters, G.M.H., Eds.; Springer: Cham, Switzerland, 2016; Volume 25, pp. 157–199. ISBN 9783319209487. [Google Scholar]

- Bouffard, S.C. Benefits of process control systems in mineral processing grinding circuits. Miner. Eng. 2015, 79, 139–142. [Google Scholar] [CrossRef]

| Sustainability/ SD Approach | Main Foundations | Sustainability Dimensions 1 | Concerned with Secondary Resources? | Spatial/ Geographic Domain | Temporal and “Life Cycle” Domains | |

|---|---|---|---|---|---|---|

| Dimensions | Hierarchy in Bottom Lines? | |||||

| Sustainability and SD in the primary extraction [14] | Brundtland Definition, TBL, TNS, LCT | 1, 2, 3 (5 as subdimension and weakly addressed) | No | Yes | Local to global (unit process, mine site, company, nation, world) | Present to future generations; project (rehabilitation)/product life cycle |

| MMSD Project SD Principles [49] | Brundtland Definition, TBL, LCT | 1, 2, 3, 4 (5 as subdimension) | Yes (Strong Sust.) | Yes | Local to global (mine site, region, nation) | Present to future generations; project/product life cycle |

| ICMM SD Principles [67] | MMSD Proj., TBL, GRI, LCT | 1, 2, 3, 4 | No | Yes | Local (mine site, company) | Project/product life cycle |

| MAC-TSM [12,64] | Brundtland Definition, GRI | 1, 2, 3 (specific issues of each dimension) | No | Yes (tailings management) | Local to national (mine site, company, Canada) | Present to future generations |

| SD indicators for minerals industry [2] | Brundtland Definition, TBL, MMSD Proj, GRI, LCT | 1, 2, 3 | No | Yes | Local (large-scale mining companies) | Present to future generations; project/product life cycle |

| ITSPM [11] | Brundtland Definition, TBL, MMSD Proj. | 1, 2, 3, 4, 5 | Yes | No | Local (company, mining project) | Present to future generations; project life cycle (design) |

| Sustainability criteria and indicators for legacy mine land [9] | Brundtland Definition, TBL, MMSD Proj., ICMM-GRI, others | 1, 2, 3, 4 | No | Yes (land rehabilitation) | Local and regional (state) | Present to future generations; project life cycle (restoration and monitoring) |

| SUSOP® [41,83] | FCM, TBL, HAZOP, ICMM Principles, LCT | 1, 2, 3 (4 and 5 partially addressed) | No | Yes | Local (company, mining project) | Project life cycle (planning, design, operation); product life cycle |

| Sustainable mining practices [17] | TBL | 1, 2, 3, 5 (5 not explicit and weakly addressed) | No | No | Local (company, mine site) | Project life cycle (operation) |

| Mineral Resources Landscape [8] | FCM, LCT, PESTEL analysis | 1, 2, 3, 4, 5 | No | Yes | Local to global (mine site, nation, world) | Product life cycle |

| Progress of minerals and energy industries towards SD [10] | Brundtland Definition, FCM, LCT | 1, 2, 3, 4, 5 (dimensions not formally stated; 5 weakly addressed) | No | Yes | Local to global (unit process, company, region, nation, world) | Present to future generations; project/product life cycle |

| SD principles for mineral exploration [85] | SD guidelines, expert consultation and consensus | 1, 2, 3, 4, 5 (5 weakly addressed) | No | Yes (efficient resource use for waste management) | Local (mine site, company) | Project life cycle (exploration, rehabilitation), product life cycle |

| Tool for SD assessment in a mining project [29] | Brundtland Definition, UN SDGs, ISO 26000, others | 1, 2, 3, 4 (Ethical and Cultural pillars also added) | No | Yes (land rehabilitation, reuse, recycling) | Local to national | Present to future generations; project life cycle |

| 20th Century | Emerging Technologies (21st Century) |

|---|---|

Comminution and classification equipment

| Process innovations

|

Grade control

| Location and mapping of resources

|

Surface mining

| Recovery from end of life goods

|

Underground mining

| New extraction methods

|

Production programming

| Increase in productivity, scale and safety in extraction

|

Other innovations

|

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Segura-Salazar, J.; Tavares, L.M. Sustainability in the Minerals Industry: Seeking a Consensus on Its Meaning. Sustainability 2018, 10, 1429. https://doi.org/10.3390/su10051429

Segura-Salazar J, Tavares LM. Sustainability in the Minerals Industry: Seeking a Consensus on Its Meaning. Sustainability. 2018; 10(5):1429. https://doi.org/10.3390/su10051429

Chicago/Turabian StyleSegura-Salazar, Juliana, and Luís Marcelo Tavares. 2018. "Sustainability in the Minerals Industry: Seeking a Consensus on Its Meaning" Sustainability 10, no. 5: 1429. https://doi.org/10.3390/su10051429