Ensuring Efficient Incentive and Disincentive Values for Highway Construction Projects: A Systematic Approach Balancing Road User, Agency and Contractor Acceleration Costs and Savings

Abstract

:1. Introduction

2. Definition of I/D, Guidelines of Use and Current Practices

2.1. I/D Definition

2.2. US Guidelines for Determining I/D Amounts

2.3. I/D’s Performance and Current Practices

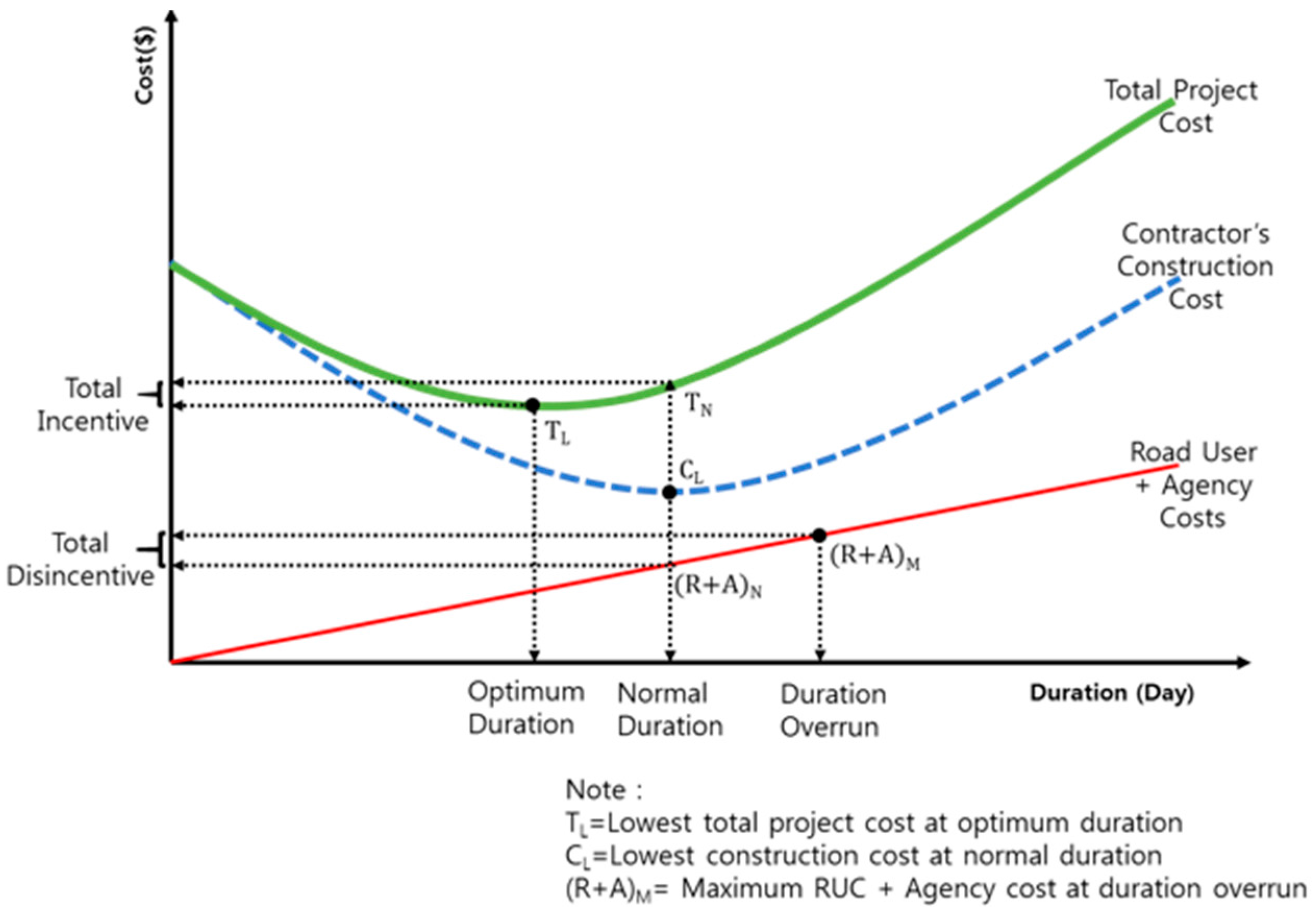

3. Time-Cost Tradeoff Model

- CC = Contractor’s actual project cost

- C0 = Normal construction cost

- D0 = Contract time (specified or proposed)

- D = Actual days used by the contractor

- A = Agency Cost

- CCD = Construction Cost at duration D.

- Total Incentive = TN – TL

- TN = Total Cost at “Normal duration”

- TL = Total Cost at the “Optimum duration”

- Optimal Acceleration Duration = (Normal duration – Optimum duration).

- Total Disincentive = (R + A)M – (R + A)N

- (R + A)M = RUC + Agency costs at “Duration Overrun”

- (R + A)N = RUC + Agency costs at “Normal Duration”

- Delay Duration = Overrun (SHA Specified) – Normal Duration

4. Point of Departure and Contributions to Practice and Theory

5. Research Methods

- (1)

- Performed a literature review related to determining daily I/D dollar amounts and up-to-date information on current practices to set up I/D amounts;

- (2)

- Collected Caltrans I/D project data, including project type and location, construction time and cost information, average daily traffic (ADT), project length, I/D daily dollar amounts and maximum incentive cap amounts;

- (3)

- Collected I/D project data nationwide from 291 sampled projects collected through an FHWA alternative contracting methods cost/benefit investigation;

- (4)

- Performed loosely structured interviews with subject matter experts from eight public/industry agencies and one screen survey with multiple SHA representatives;

- (5)

- Evaluated performance of projects collected in steps 3 and 4 above, specifically the relationship between I/D dollar amount and project time and cost performance;

- (6)

- Evaluated RUC-calculating computer simulation software;

- (7)

- Performed case studies on four Caltrans I/D projects, performing I/D calculations using three different levels of CA4PRS implementations for said calculation; and

- (8)

- Demonstrated tool implementation on one Caltrans project.

5.1. Literature

5.2. Caltrans I/D Project Data Collection

- Most of the projects were 3R projects (resurfacing, rehabilitation and reconstruction) or widening;

- 23, or 54%, of the projects had high traffic volumes;

- Median project length was 3.8 miles;

- Average contract award was approximately $40 million;

- Average duration was 515 working days;

- Average incentive cap was $1.1 million per project, ranging from $15,000 to $5.3 million;

- 22 projects’ incentives were between $100 and $600 k.

5.3. FHWA Nationwide I/D Project Data Collection

5.4. Subject Matter Expert Interviews

5.5. Quantitative Analyses

5.6. Computer Simulation Software for Lane Analysis and Potential Road User Impacts

5.7. Caltrans I/D Implementation Case Studies

5.8. Demonstration of Implementation on a Caltrans Project

6. Optimum ID Process with Step-by-Step Procedure

6.1. Findings from Existing SHA Practices

6.2. Step-by-Step Procedure for Optimum I/D Process

- Traffic Impacts: analyze work zone impacts, check if acceleration through incentive is feasible and estimate RUC.

- Schedule Analysis: Estimate baseline schedule, identify contractor’s major constraints on critical activities, identify contractor resources required for acceleration and calculate maximum schedule compression.

- Cost Estimate: Estimate contractor’s cost for additional resource inputs, agency cost benefits and contractor’s benefits for schedule compression.

- I/D Amount Calculation and Adjustments: calculate minimum daily incentive (contractor cost for acceleration), baseline daily incentive (contractor additional cost, RUC savings, agency cost savings, less contractor’s savings), maximum daily incentive (RUC plus agency cost savings) and incentive cap (incentives * maximum compression). I/Ds amounts within the calculated range

- Schedule Baseline

- ○

- Inputs: closure options, section profile, lane width, curing time and working method

- ○

- Outputs: detailed schedule with construction window types and closures

- Estimate impact of the work zone on the traveling public:

- ○

- Inputs: roadway capacity and traffic information

- ○

- Outputs: work zone user delay costs

- Chose a conversion factor to discount the value of the RUC and agency cost

- ○

- Input: conversion and discount factors

- ○

- Output: I/D dollar amount per closure

- Set up the maximum incentive amount

- ○

- I/D dollar amount per closure and schedule baseline

- ○

- Maximum incentive and number of closures

- CCOptimal = Equation (1) result using the optimal point cost and duration

- CCOptimal = Equation (1) result using the normal point cost and duration

- Optimal Acceleration Duration = (Normal duration − Optimum duration)

- CA = Daily Contractor Acceleration Costs

- Shared Agency Savings (Shared A) =

- CA savings =

- CF = Conversion Factor

- DF = Discount Factor

- CF1 = range of 1 to 3

- CF2 = range of 1 to 2

- DF1 = range of 2 to 3

- DF2 = range of 5 to 10

6.3. Implementation of the Process

- Contractor’s acceleration cost is $9007 per day

- This paper’s incentive amount is $11.488.5 per day

- Shr et al.’s model incentive amount would be $9080 per day

- SHA’s conventional incentive amount would be $5425 per day

6.4. Contractor Acceleration Incorporated with Resource Mobilization

7. Conclusions

8. Limitations and Recommendations for Future Research

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| ADT | Average Daily Traffic |

| CA4PRS | Construction Analysis for Pavement Rehabilitation Strategies |

| CA | Contractor Acceleration Costs |

| CC | Contractor Costs |

| CF | Conversion Factor |

| DF | Discount Factor |

| FHWA | United States’ Federal Highway Agency |

| I/D | Incentive/Disincentive |

| LD | Liquidated Damages |

| RUC | Road User Costs |

| SHA | State Highway Agency |

| TN | Total Cost at Normal Duration |

| TL | Total Cost at Optimum Duration |

References

- Mallela, J.; Sadavisam, S. Work Zone Road User Costs: Concepts and Applications; US Department of Transportation, Federal Highway Administration: Washington, DC, USA, 2011.

- Federal Highway Administration (FHWA). Incentive/Disincentive for Early Contract Completion. In FHWA Technical Advisory T5080.10; Federal Highway Administration (FHWA): Washington, DC, USA, 1989. Available online: http://www.fhwa.dot.gov/construction/contracts/t508010.cfm (accessed on 3 March 2018).

- Herbsman, Z.J.; Tong Chen, W.; Epstein, W.C. Time is money: Innovative contracting methods in highway construction. J. Constr. Eng. Manag. 1995, 121, 273–281. [Google Scholar] [CrossRef]

- Sillars, D.N.; Leray, J.P.A. Incentive/Disincentive Contracting Practices for Transportation Projects; ASCE Press: Washington, DC, USA, 2006. [Google Scholar]

- Sun, C.; Edara, P.; Mackley, A. Refocusing on Liquidated Damages in Incentive/Disincentive Contracts. J. Leg. Aff. Disput. Resolut. Eng. Constr. 2013, 5, 136–141. [Google Scholar] [CrossRef]

- Fick, G.J. Time-Related Incentive and Disincentive Provisions in Highway Construction Contracts; Transportation Research Board: Washington, DC, USA, 2010; Volume 652.

- Gillespie, J. Estimating Road User Costs as a Basis for Incentive/Disincentive Amounts in Highway Construction Contracts; Virginia Transportation Research Council: Charlottesville, VA, USA, 1998.

- Jiang, Y.; Chen, H. The Effects of User Costs at Highway Work Zones on the Incentive and Disincentive Values of Highway Construction Projects. In Proceedings of the 18th CIB World Building Congress, Salford Quays, UK, 10–13 May 2010. [Google Scholar]

- Yimin, Z.; Irtishad, A. Developing a Realistic-Prototyping RUC Evaluation Tool for FDOT; US Department of Transportation: Washington, DC, USA, 2008.

- Shr, J.-F.; Chen, W.T. Setting maximum incentive for incentive/disincentive contracts for highway projects. J. Constr. Eng. Manag. 2004, 130, 84–93. [Google Scholar] [CrossRef]

- Sillars, D.N. Establishing Guidelines for Incentive/Disincentive Contracting at ODOT; Oregon State Library: Salem, OR, USA, 2007.

- Shr, J.-F.; Thompson, B.; Russell, J.; Ran, B.; Tserng, H. Determining minimum contract time for highway projects. Transp. Res. Rec. J. Transp. Res. Board 2000, 1712, 196–201. [Google Scholar] [CrossRef]

- American Association of State Highway and Transportation Officials (AASHTO). Primer on Contracting for the Twenty-First Century; Report; Contract Administration Section of the AASHTO Subcommittee on Construction: Washington, DC, USA, 15 June 2006. [Google Scholar]

- Ellis, R.D., Jr.; Pyeon, J.-H.; Herbsman, Z.J.; Minchin, E.; Molenaar, K. Evaluation of Alternative Contracting Techniques on FDOT Construction Projects; Department of Civil and Coastal Engineering, University of Florida: Gainesville, FL, USA, 2007. [Google Scholar]

- Florida Department of Transportation (FDOT). Alternative Contracting Methods; Office of Inspector General Audit Report 04B-0001: Tallahassee, FL, USA, 2000.

- Shr, J.F.; Chen, W.T. Functional Model of Cost and Time for Highway Construction Projects. J. Mar. Sci. Technol. 2006, 14, 127–138. [Google Scholar]

- Cusack, M.M. Construction Management—The Way Forward, Investment, Procurement and Performance in Construction; E & FN Spon: London, UK, 1991. [Google Scholar]

- Shen, L.; Drew, D.; Zhang, Z. Optimal bid model for price-time biparameter construction contracts. J. Constr. Eng. Manag. 1999, 125, 204–209. [Google Scholar] [CrossRef]

- Pyeon, J.H.; Lee, E.B. Systematic Procedures to Determine Incentive/Disincentive Dollar Amounts for Highway Transportation Construction Projects; Mineta Transportation Institute Research Report 11-22; SJSU Research Foundation: San Jose, CA, USA, June 2012. [Google Scholar]

- Federal Highway Administration. Quantification of Cost, Benefits and Risk Associated with Alternative Contracting Methods and Accelerated Performance Specifications. Federal Highway Administration Project, Contract No. DTFH61-11-D-00009, 2013–2016. Available online: https://www.fbo.gov/index?s=opportunity&mode=form&id=a4c450b35ead6e702cd29cf108be1826&tab=core&_cview=1 (accessed on 3 March 2018).

- Collura, J.; Heaslip, K.; Knodler, M.; Ni, D.; Louisell, W.C.; Berthaume, A.; Khanta, R.; Moriarty, K.; Wu, F. Evaluation and Implementation of Traffic Simulation Models for Work Zones. 2010. Available online: http://www.ct.gov/dot/LIB/dot/documents/dresearch/NETCR80_05-8.pdf (accessed on 3 March 2018).

- Lee, E.B.; Ibbs, C.W. A Computer Simulation Model: Construction Analysis for Highway Rehabilitation Strategies (CA4PRS). JCEM 2005, 131, 449–458. [Google Scholar]

- Federal Highway Administration (FHWA). Construction Analysis for Pavement Rehabilitation Strategies (CA4PRS). Available online: https://www.fhwa.dot.gov/research/deployment/ca4prs.cfm (accessed on 8 March 2017).

- Transportation Research Board, National Research Counsel. Highway Capacity Manual (HCM) 2000; Transportation Research Board, National Research Counsel: Washington, DC, USA, 2000.

- Lee, E.-B.; Thomas, D.K.; Bloomberg, L. Planning urban-highway reconstruction with traffic demand affected by construction schedule. J. Transp. Eng. 2005, 11, 752–761. [Google Scholar] [CrossRef]

- Taylor, T.R.; Brockman, M.; Zhai, D.; Goodrum, P.M.; Sturgill, R. Accuracy analysis of selected tools for estimating contract time on highway construction projects. In Proceedings of the Construction Research Congress 2012: Construction Challenges in a Flat World, West Lafayette, IN, USA, 21–23 May 2012; pp. 217–225. [Google Scholar]

- Fekpe, E.; Gopalakrishna, D.; Middleton, D. Highway Performance Monitoring System Traffic Data for High-Volume Routes: Best Practices and Guidelines; Federal Highway Administration: Washington, DC, USA, 2004.

- California Department of Transportation (Caltrans). Memorandum: Delegation of Authority for Use of A + B Bidding and Incentive/Disincentive Provisions. Available online: http://www.dot.ca.gov/hq/oppd/design/m061200.pdf (accessed on 12 March 2017).

- Shuka, A. An Exploration of the Relationship between Construction Cost and Duration in Highway Projects. Master’s Thesis, University of Colorado at Boulder, Boulder, CO, USA, 1 January 2017. [Google Scholar]

| Project | CA4PRS Stage Used | Project Characteristics (PC), Incentive (I), Disincentive (D), Earned (E) | |

|---|---|---|---|

| I-10 Pomona | Schedule Analysis (1) | PC: | Long-life concrete rehabilitation project; 240,000 ADT, 9% trucks |

| I: | $600 per lane-m replaced >2000 lane-meters during closures $500,000 Maximum | ||

| D: | $250 per lane-m replaced <2000 lane-meters during closures $10,000 per 10-min of lanes still closed on Monday morning | ||

| E: | The contractor was awarded $500,000 | ||

| I-710 Long Beach | Schedule Analysis | PC: | Long-life concrete rehabilitation project; 164,000 ADT, 13% trucks |

| I: | $100,000 per weekend closure <10 weekend closures $500,000 Maximum | ||

| D: | $100,000 per weekend closure >10 weekend closures | ||

| E: | The contractor was awarded $200,000 (8 weekend closures) | ||

| I-15 Devore | Traffic Analysis (2) | PC: | 4.5 km truck lanes rebuild; peak 5500 vehicles/h and 110,000 ADT |

| I: | $300,000 if closure was completed faster than 111 h per unit $75,000 per day completed faster than 19 days | ||

| D: | Uncapped $ if closure was completed slower than 111 h per unit $75,000 per day completed slower than 19 days | ||

| E: | N/A | ||

| I-80 Sacramento * | Schedule, Traffic, Cost Analysis (3) | PC: | 8.6 miles Rehab with widening; 140,000 ADT and estimated 200,000 ADT by 2030 with 10% trucks |

| I: | $100,000 per reduced weekend closure $400,000 Maximum | ||

| D: | $100,000 per increased weekend closure | ||

| E: | N/A | ||

| I/D Valuation Component | No. | Percentage |

|---|---|---|

| Road User 1 | 28 | 42% |

| SHA 1 | 9 | 14% |

| Contractor 1 | 1 | 2% |

| Project Acceleration 1 | 7 | 11% |

| Some Combination of Above | 9 | 14% |

| Only SHA Policy | 12 | 18% |

| None of the above | 1 | 2% |

| Step | Resultant | |

|---|---|---|

| Step 1: Closure Scheme | CA4PRS Output: | 8-night time closures 1 lane will always be open 2 lanes closed for construction |

| Step 2: Daily RUC | CA4PRS Output: | $10,850/day |

| Step 3: Daily Agency | CA4PRS Output: | $7309/day |

| Step 4: Contractor Cost | CA4PRS Output: | C0 = $30 Million (Normal Construction Cost) |

| Time-Cost Curve: | See above Figure 4. | |

| Step 5: Cost at Normal and Optimal Durations | CA4PRS Output: | D0 = 300 days (Normal Construction Duration) |

| Time-Cost Curve: | TN = $35,447,906 (Total Cost at Normal Dur., 300 days) TL = $34,916,974 (Total Cost at Optimal Dur., 242 days) | |

| Step 6: Total Incentive | Time-Cost Curve: | Total incentive (TN – TL) = $530,932 Maximum Acceleration (300 – 242) = 58 days |

| Step 7: Daily Incentive | SHA Practice: | |

| Time-Cost Curve: | /day | |

| Step 7: Contractor Acc. | SHA Practice: | Not Taken into Consideration |

| Time-Cost Curve: | ||

| Step 8: Adjust Incentive | SHA Practice: | Use Step 7 finding of $5425/day |

| Equation (7): | ||

| Step 9: Max Incentive | SHA Practice (5%): | $1,500,000 |

| Step 6: | $530,932 | |

| Step 10: Disincentive | SHA Practice: | |

| Equation (5): | $18,159/day | |

| Step 11: Chose Date | Start Date + 300 working days | |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lee, E.-B.; Alleman, D. Ensuring Efficient Incentive and Disincentive Values for Highway Construction Projects: A Systematic Approach Balancing Road User, Agency and Contractor Acceleration Costs and Savings. Sustainability 2018, 10, 701. https://doi.org/10.3390/su10030701

Lee E-B, Alleman D. Ensuring Efficient Incentive and Disincentive Values for Highway Construction Projects: A Systematic Approach Balancing Road User, Agency and Contractor Acceleration Costs and Savings. Sustainability. 2018; 10(3):701. https://doi.org/10.3390/su10030701

Chicago/Turabian StyleLee, Eul-Bum, and Douglas Alleman. 2018. "Ensuring Efficient Incentive and Disincentive Values for Highway Construction Projects: A Systematic Approach Balancing Road User, Agency and Contractor Acceleration Costs and Savings" Sustainability 10, no. 3: 701. https://doi.org/10.3390/su10030701