Effects of Environment in the Microstructure and Properties of Sustainable Mortars with Fly Ash and Slag after a 5-Year Exposure Period

Abstract

:1. Introduction

2. Materials and Methods

2.1. Sample Preparation

2.2. Environmental Conditions

2.3. Mercury Intrusion Porosimetry

2.4. Capillary Absorption Test

2.5. Forced Migration Test

2.6. Mechanical Strength Test

3. Results and Discussion

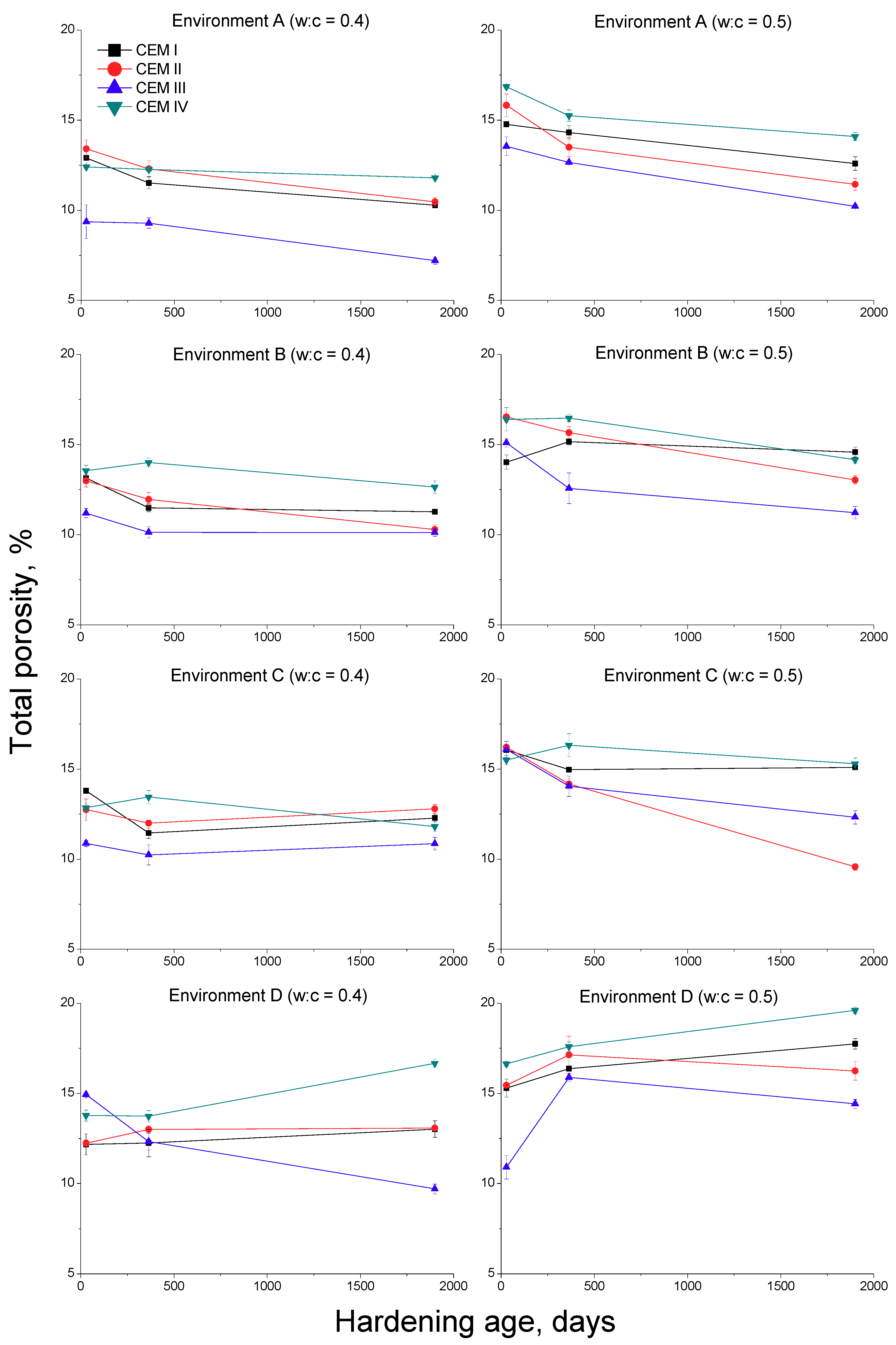

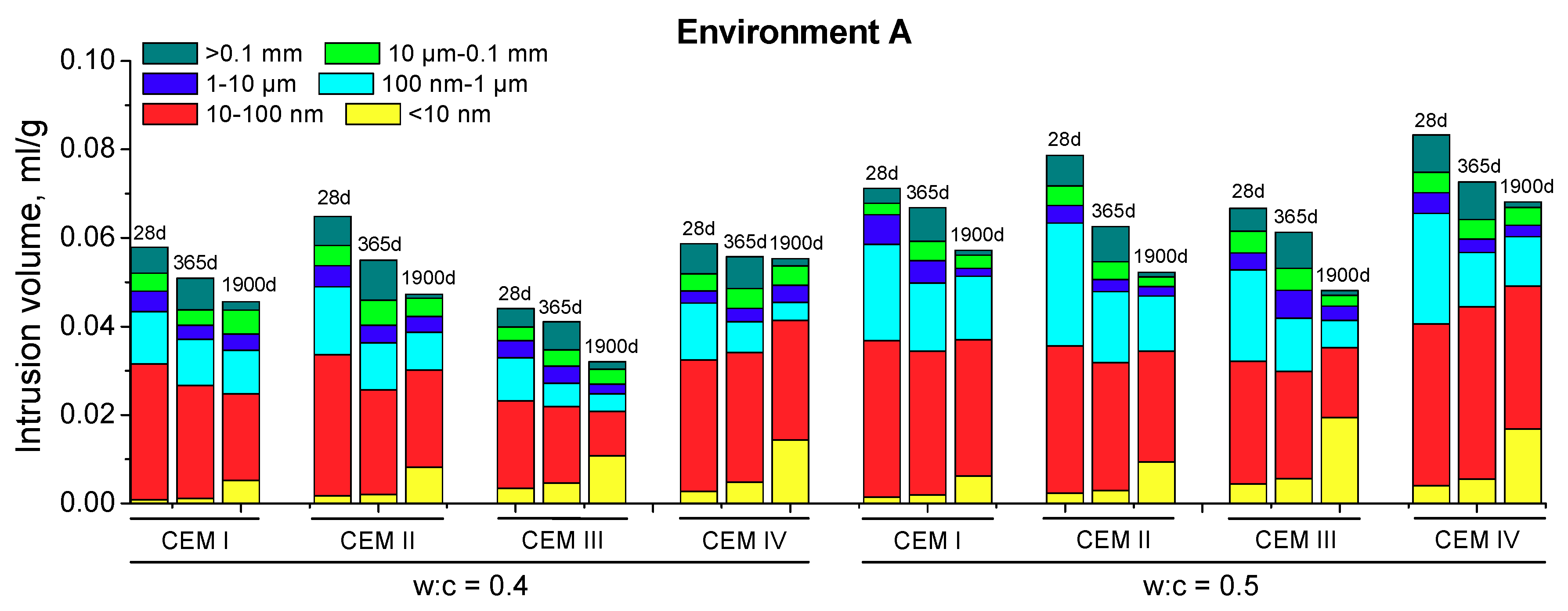

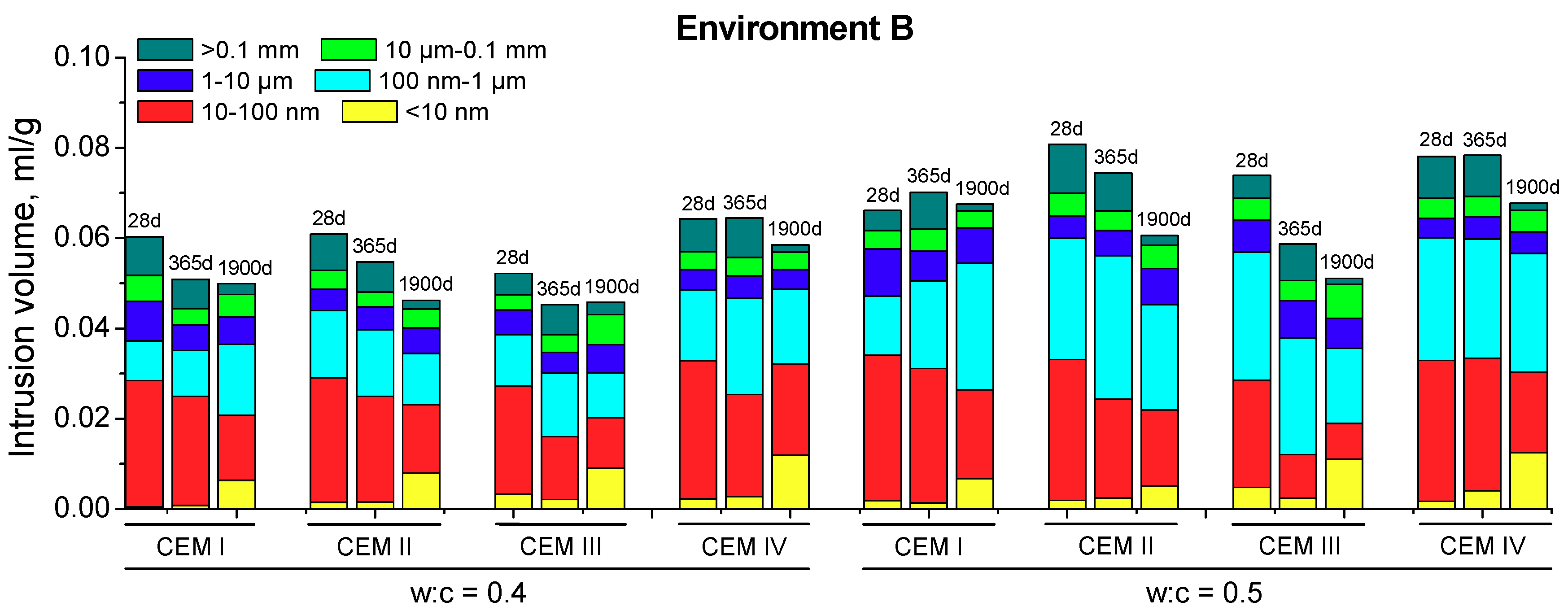

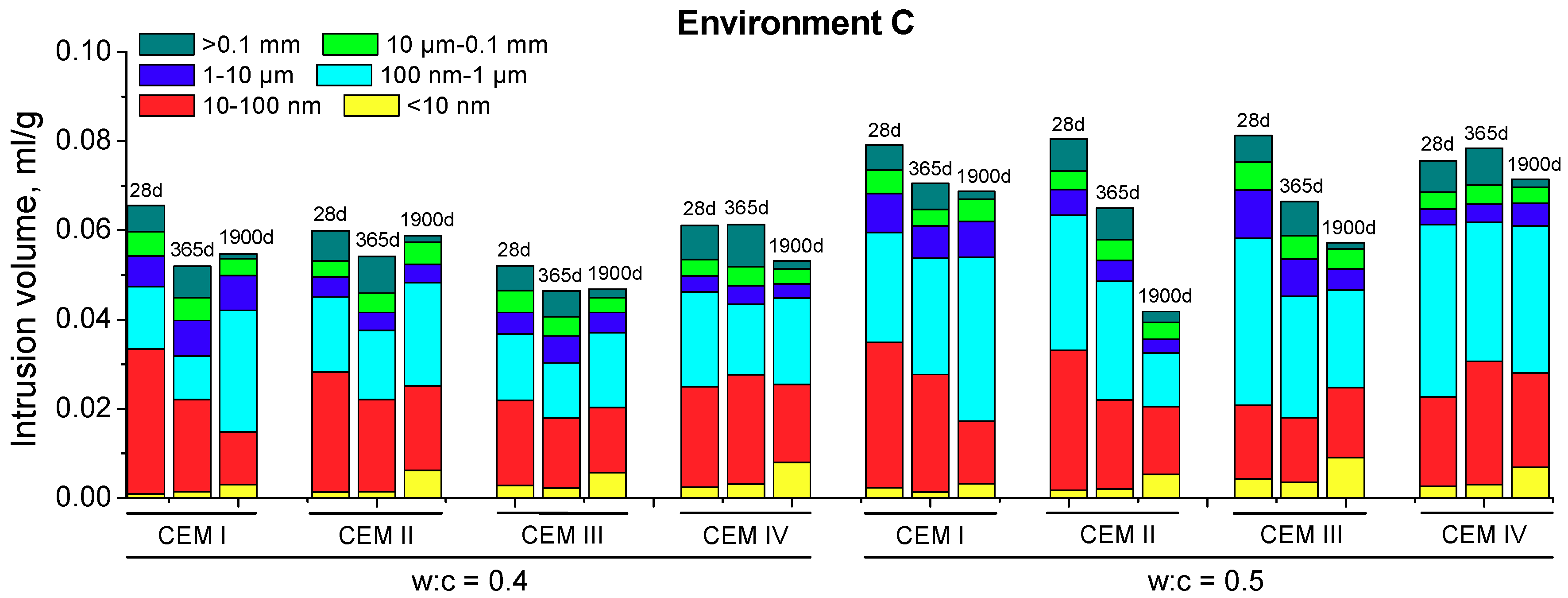

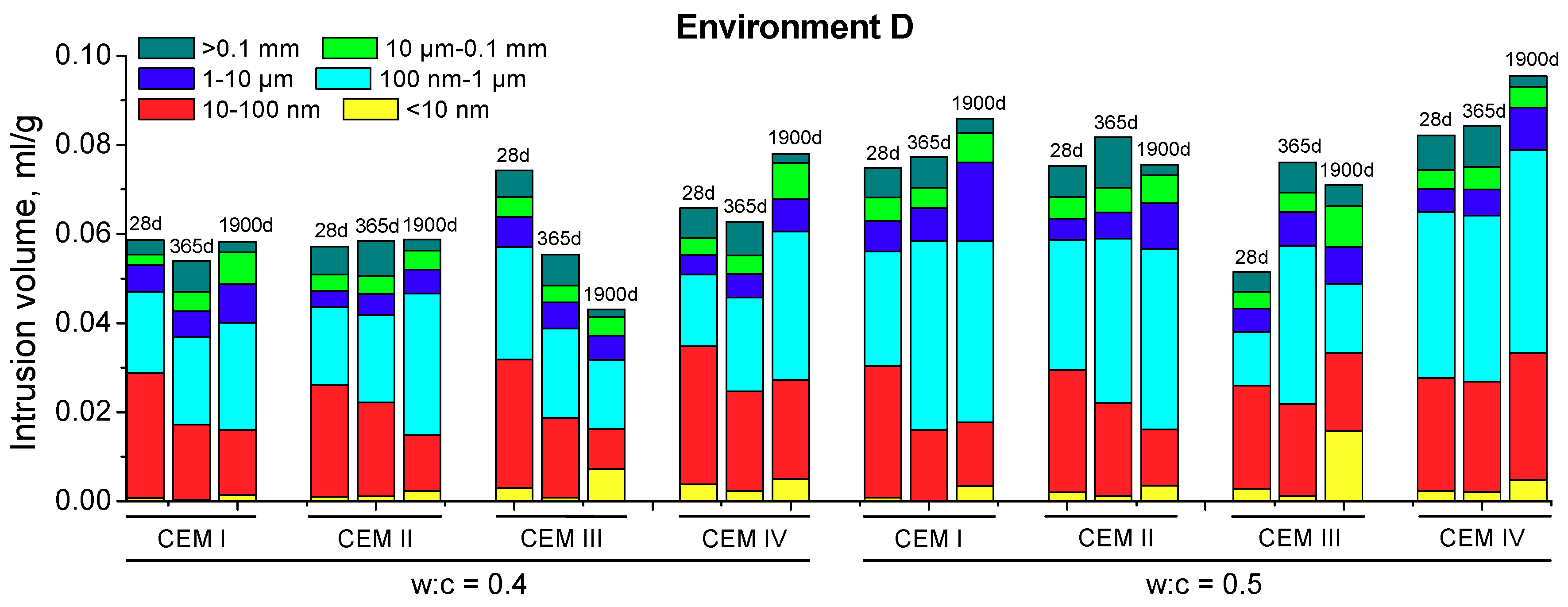

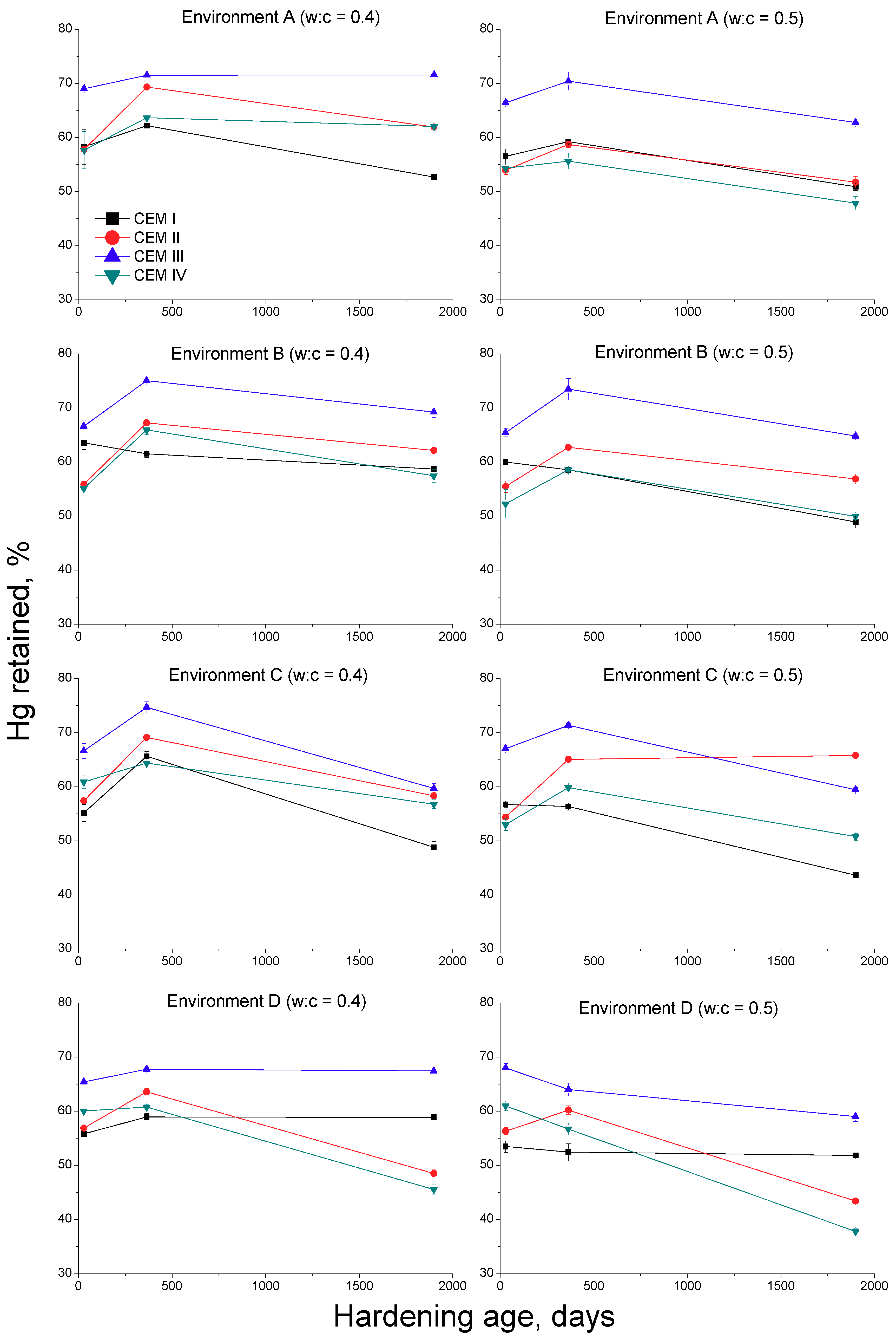

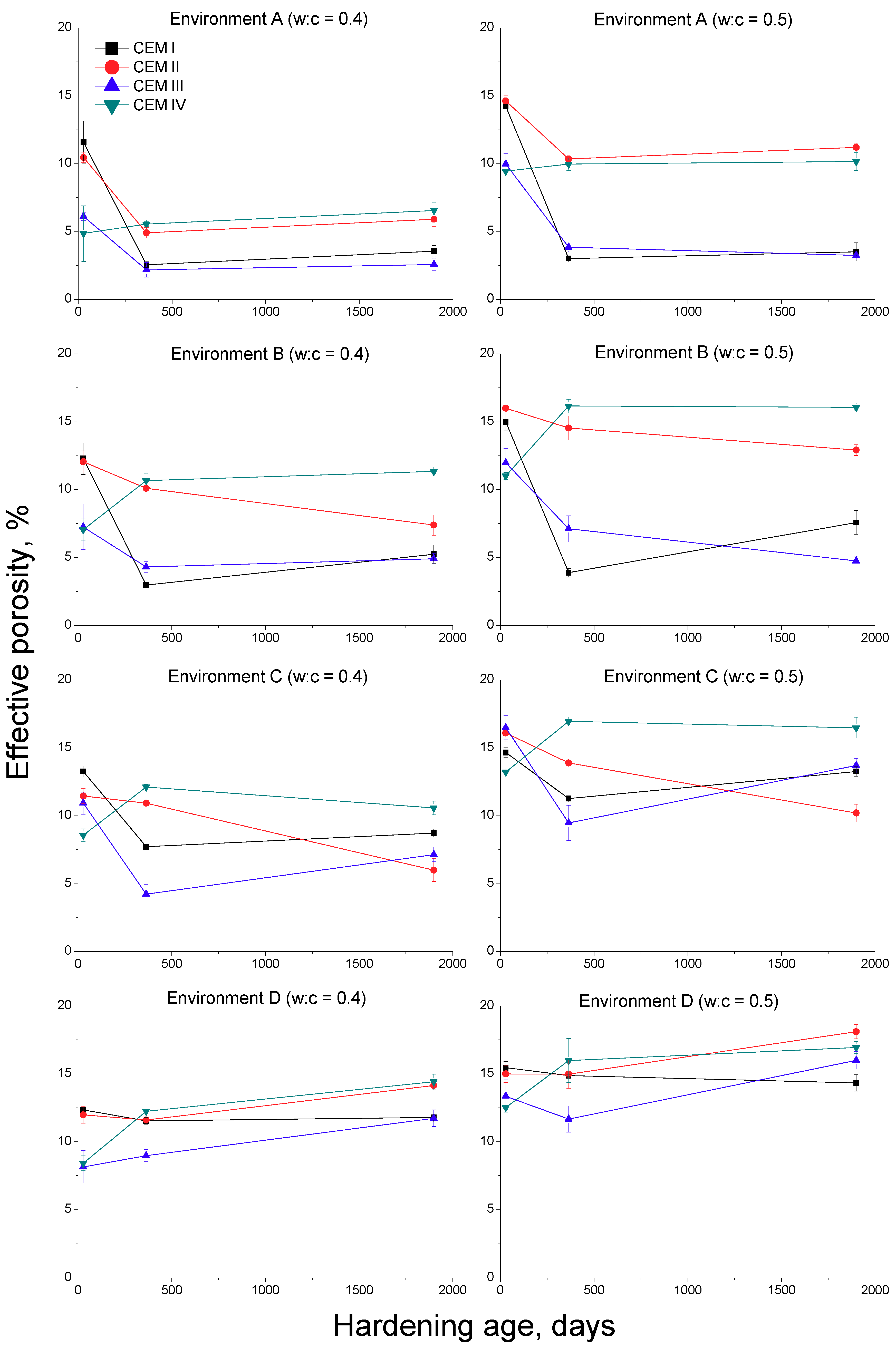

3.1. Mercury Intrusion Porosimetry

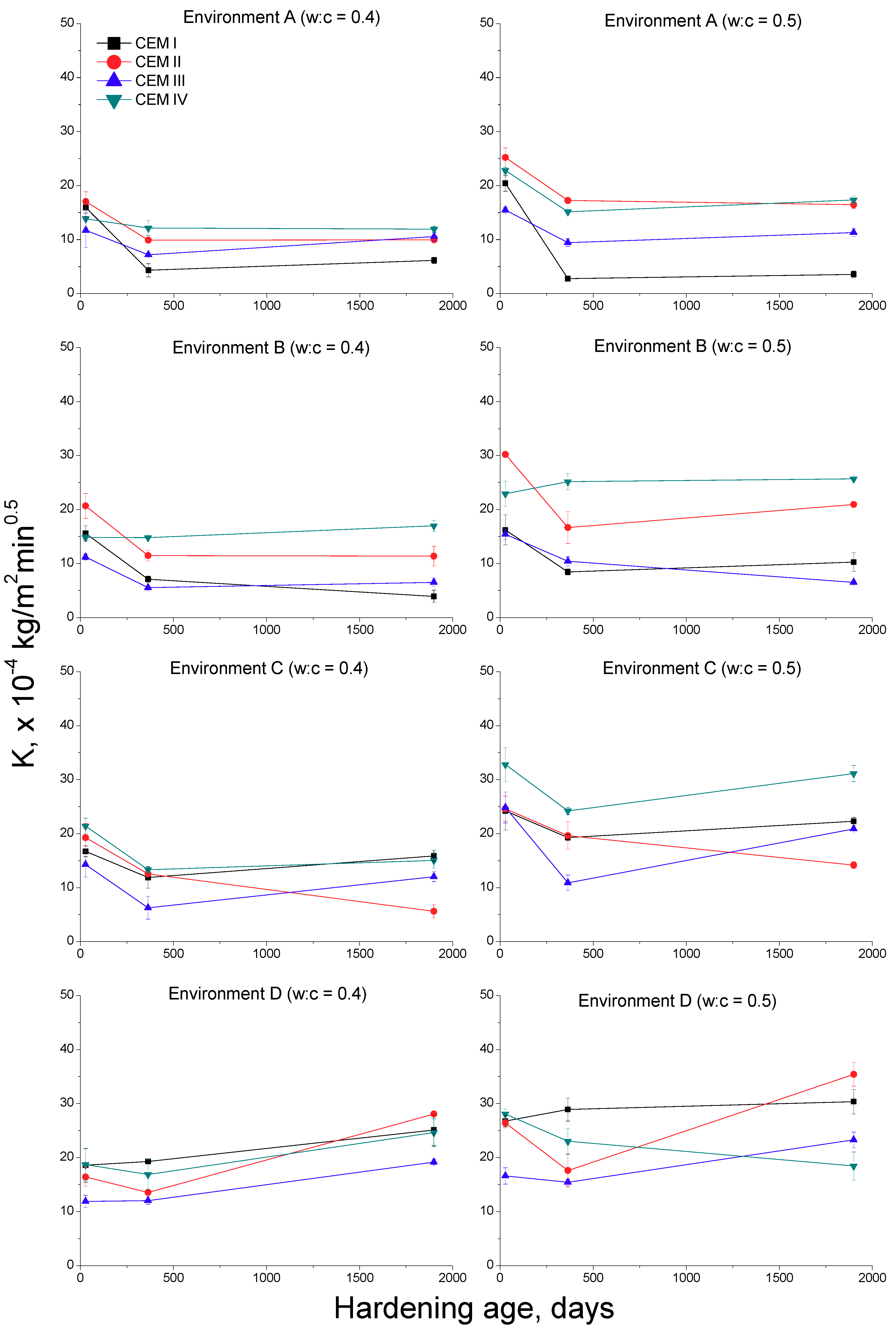

3.2. Capillary Absorption Results

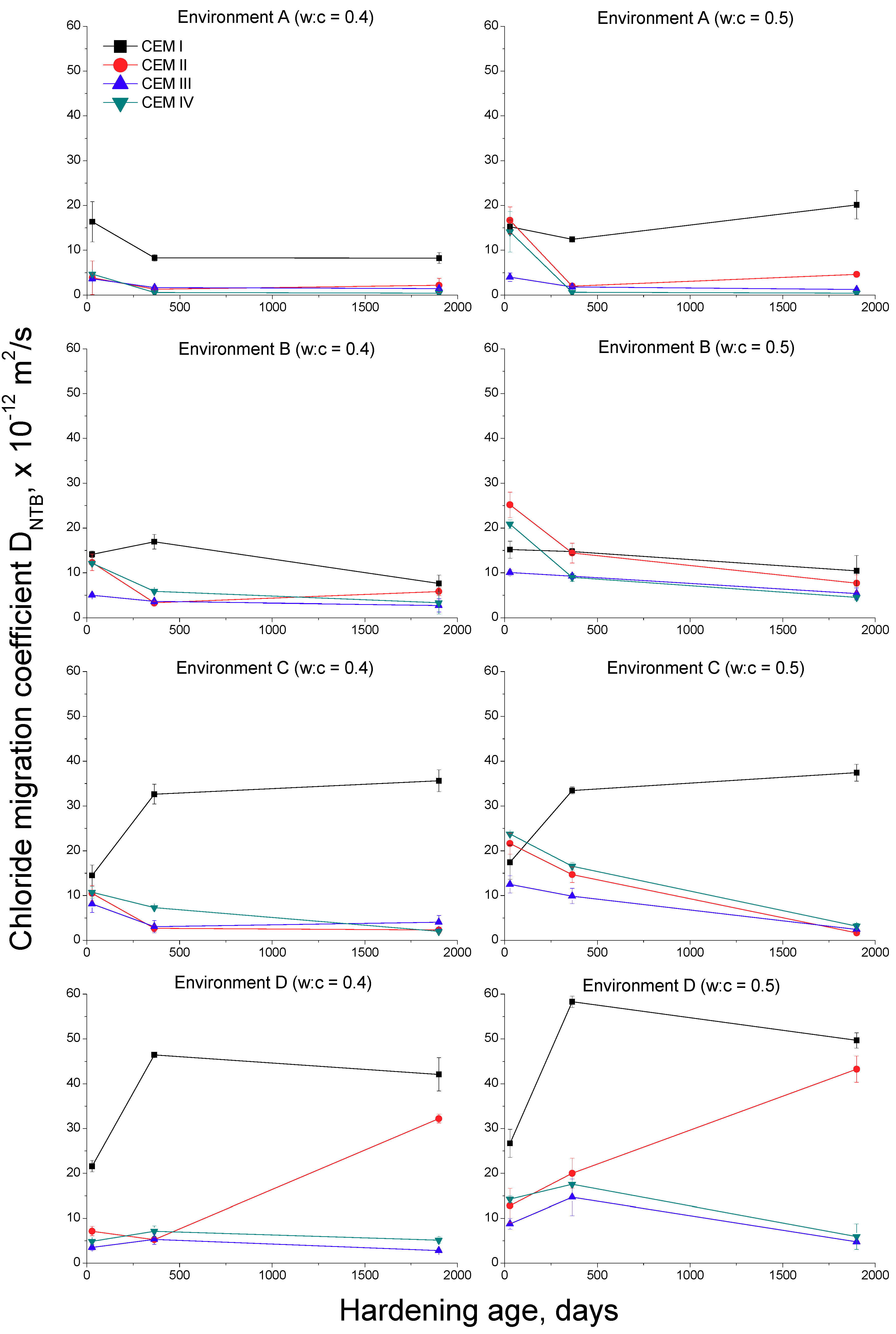

3.3. Forced Chloride Migration Results

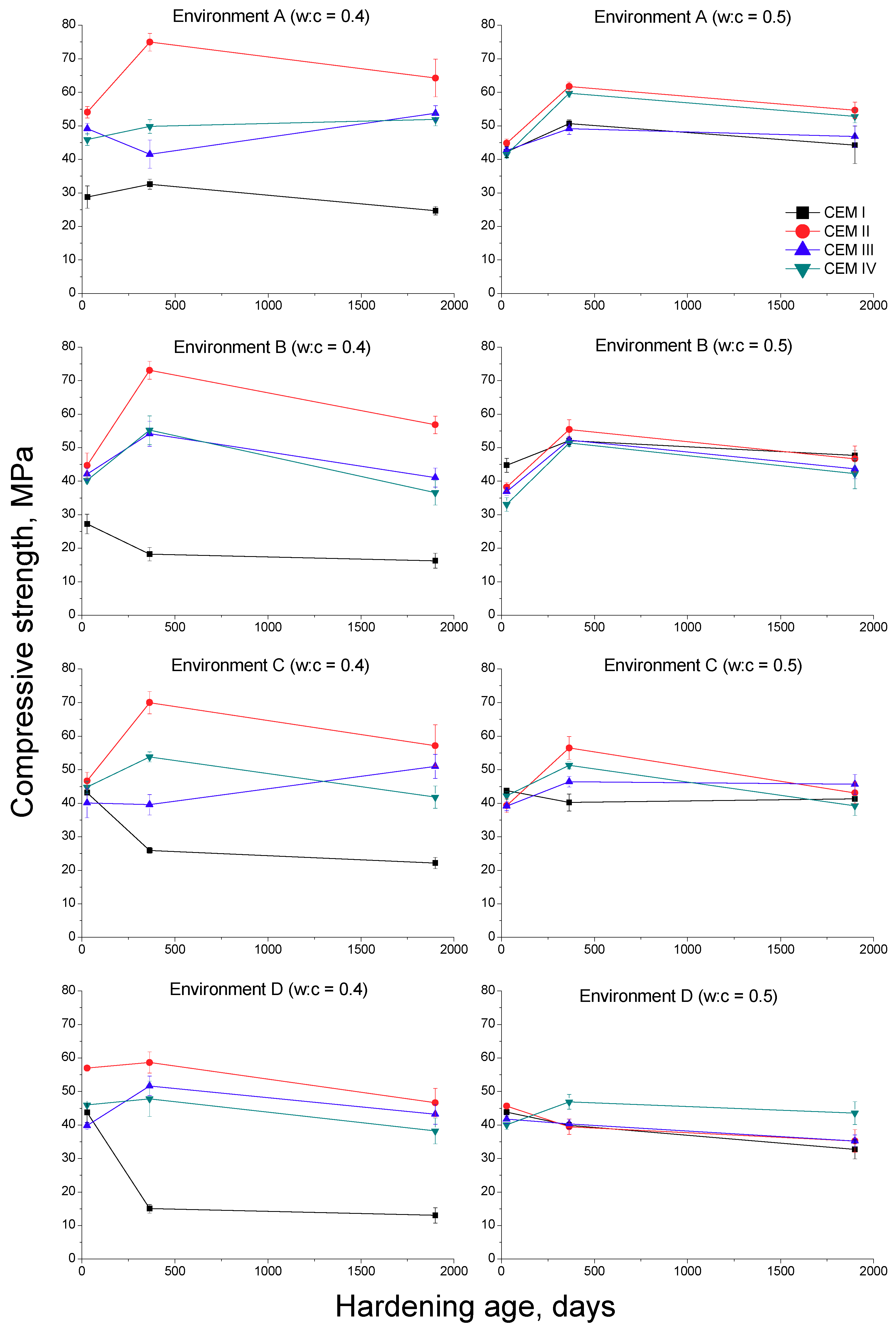

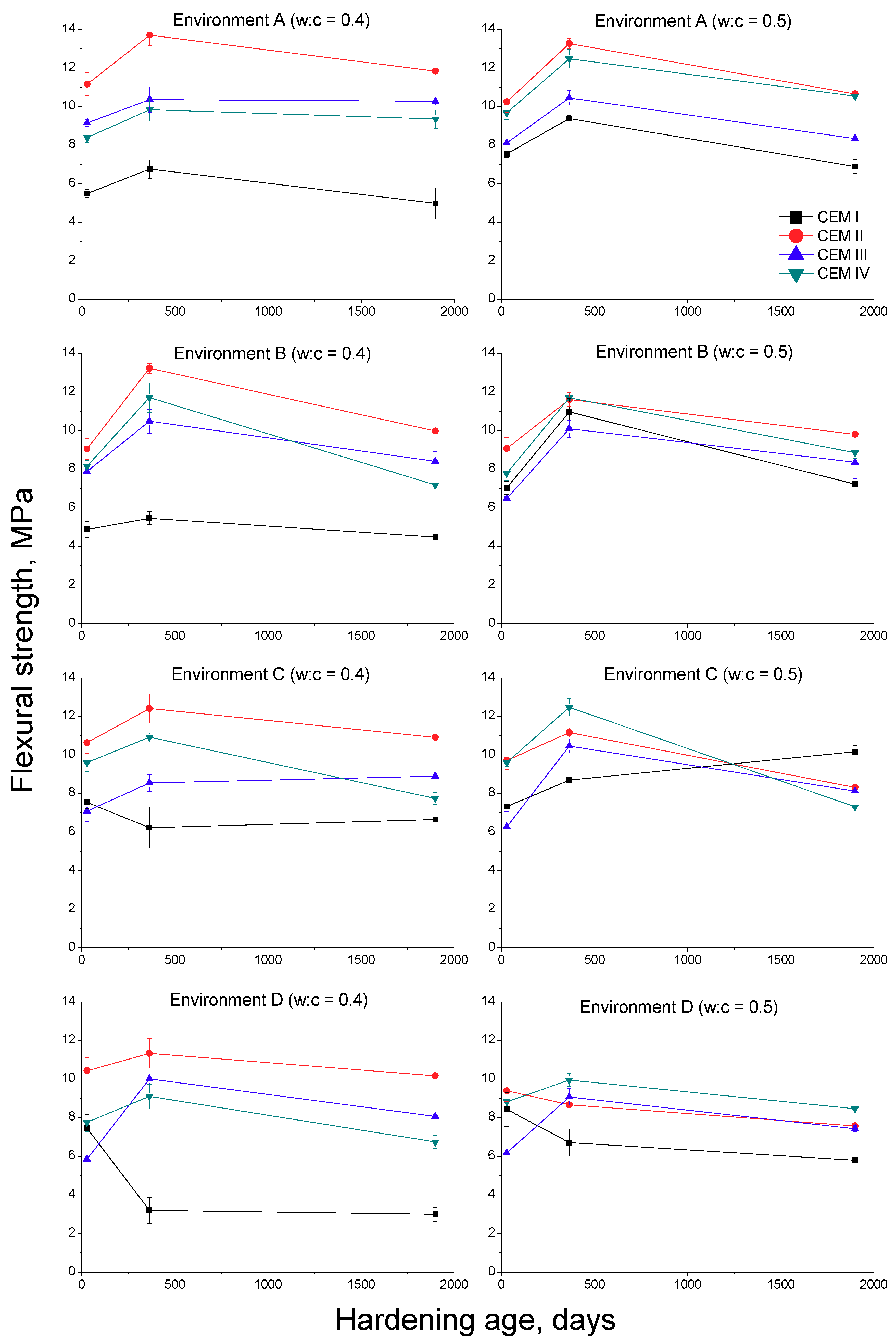

3.4. Mechanical Strength Results

4. Conclusions

- (1)

- An environment with high relative humidity would produce a more refined microstructure and would improve the mechanical performance and the durability-related properties of fly ash, slag and OPC mortars in the very long-term (5-years period approximately).

- (2)

- The environmental temperature has an influence in the development of pore structure and service properties of fly ash, slag and OPC mortars. A high temperature would accelerate the pore network refinement and the improvement of properties in the short-term, while a lower environmental temperature would slow down them. This is due to the effects of the temperature in the progress of clinker and slag hydration and fly ash pozzolanic reactions.

- (3)

- A low environmental relative humidity would entail a reduction of pore network refinement in the very long-term for all the studied mortars.

- (4)

- Generally, the pore structure of fly ash and slag cement mortars was more refined for all the analysed environments than that observed for CEM I ones. This may be due to the additional solid phases formed as products of fly ash pozzolanic reactions, as well as slag hydration.

- (5)

- The effective porosity and the capillary suction coefficient for all the studied mortars in the very long-term were hardly influenced by the environmental conditions.

- (6)

- The mortars prepared using sustainable cements with slag and fly ash generally showed in the very long-term similar or lower values of both effective porosity and capillary suction coefficient, as compared to OPC mortars, when they are exposed to low relative humidity environments.

- (7)

- The lowest non-steady state chloride migration coefficients were observed for the mortars made with fly ash and slag cements, regardless of the environmental condition. This may be related to the pore structure refinement provided by fly ash and slag compared to clinker and by the greater binding capacity of cements with those additions.

- (8)

- The CEM I mortars exposed to the environments with 40% and 65% relative humidity showed an important increase of the non-steady state chloride migration coefficient in the long-term. This was also noted for CEM II mortars but only for 40% relative humidity condition. Then, it seems that an environment with low relative humidity would have deleterious effects in the long-term resistance against chloride ingress of mortars in which the abovementioned cement types were used.

- (9)

- After a 5-years exposure period, the mortars prepared using sustainable slag and fly ash cements overall showed similar or higher compressive and flexural strengths compared to CEM I ones.

- (10)

- The mechanical strengths of all the studied mortars in the very long-term were slightly affected by the environmental conditions.

- (11)

- In view of the results obtained, mortars made with sustainable commercial cements with ground granulated blast-furnace slag and fly ash, exposed to non-optimum environments, show a good performance in the very long-term (after a 5-years hardening period) with respect to their microstructure, mechanical and durability-related properties, being similar or even better compared to OPC mortars.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Ponikiewski, T.; Gołaszewski, J. The effect of high-calcium fly ash on selected properties of self-compacting concrete. Arch. Civ. Mech. Eng. 2014, 14, 455–465. [Google Scholar] [CrossRef]

- Glinicki, M.; Jóźwiak-Niedźwiedzka, D.; Gibas, K.; Dąbrowski, M. Influence of Blended Cements with Calcareous Fly Ash on Chloride Ion Migration and Carbonation Resistance of Concrete for Durable Structures. Materials 2016, 9, 18. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Sánchez, I. Microstructural Effects of Sulphate Attack in Sustainable Grouts for Micropiles. Materials 2016, 9, 905. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M.A. Long-Term Behaviour of Fly Ash and Slag Cement Grouts for Micropiles Exposed to a Sulphate Aggressive Medium. Materials 2017, 10, 598. [Google Scholar] [CrossRef] [PubMed]

- Williams, M.; Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Non-Destructive Study of the Microstructural Effects of Sodium and Magnesium Sulphate Attack on Mortars Containing Silica Fume Using Impedance Spectroscopy. Appl. Sci. 2017, 7, 648. [Google Scholar] [CrossRef]

- Ortega, J.M.; Esteban, M.D.; Rodríguez, R.R.; Pastor, J.L.; Ibanco, F.J.; Sánchez, I.; Climent, M.A. Influence of Silica Fume Addition in the Long-Term Performance of Sustainable Cement Grouts for Micropiles Exposed to a Sulphate Aggressive Medium. Materials 2017, 10, 890. [Google Scholar] [CrossRef] [PubMed]

- Bijen, J. Benefits of slag and fly ash. Constr. Build. Mater. 1996, 10, 309–314. [Google Scholar] [CrossRef]

- Wedding, P.; Manmohan, D.; Mehta, P. Influence of Pozzolanic, Slag and Chemical Admixtures on Pore Size Distribution and Permeability of Hardened Cement Pastes. Cem. Concr. Aggreg. 1981, 3, 63–67. [Google Scholar] [CrossRef]

- Papadakis, V.G. Effect of fly ash on Portland cement systems. Cem. Concr. Res. 1999, 29, 1727–1736. [Google Scholar] [CrossRef]

- Leng, F.; Feng, N.; Lu, X. An experimental study on the properties of resistance to diffusion of chloride ions of fly ash and blast furnace slag concrete. Cem. Concr. Res. 2000, 30, 989–992. [Google Scholar] [CrossRef]

- Nochaiya, T.; Wongkeo, W.; Chaipanich, A. Utilization of fly ash with silica fume and properties of Portland cement–fly ash–silica fume concrete. Fuel 2010, 89, 768–774. [Google Scholar] [CrossRef]

- Geiseler, J.; Kollo, H.; Lang, E. Influence of blast furnace cements on durability of concrete structures. ACI Mater. J. 1995, 92, 252–257. [Google Scholar]

- Thomas, M.D.A.; Scott, A.; Bremner, T.; Bilodeau, A.; Day, D. Performance of slag concrete in marine environment. ACI Mater. J. 2008, 105, 628–634. [Google Scholar]

- Ortega, J.M.; Albaladejo, A.; Pastor, J.L.; Sánchez, I.; Climent, M.A. Influence of using slag cement on the microstructure and durability related properties of cement grouts for micropiles. Constr. Build. Mater. 2013, 38, 84–93. [Google Scholar] [CrossRef]

- Pastor, J.L.; Ortega, J.M.; Flor, M.; López, M.P.; Sánchez, I.; Climent, M.A. Microstructure and durability of fly ash cement grouts for micropiles. Constr. Build. Mater. 2016, 117, 47–57. [Google Scholar] [CrossRef]

- Jain, J.A.; Neithalath, N. Chloride transport in fly ash and glass powder modified concretes—Influence of test methods on microstructure. Cem. Concr. Compos. 2010, 32, 148–156. [Google Scholar] [CrossRef]

- Kamali, M.; Ghahremaninezhad, A. An investigation into the hydration and microstructure of cement pastes modified with glass powders. Constr. Build. Mater. 2016, 112, 915–924. [Google Scholar] [CrossRef]

- Ortega, J.M.; Pastor, J.L.; Albaladejo, A.; Sánchez, I.; Climent, M.A. Durability and compressive strength of blast furnace slag-based cement grout for special geotechnical applications. Mater. Constr. 2014, 64. [Google Scholar] [CrossRef] [Green Version]

- Scott, A.N.; Thomas, M.D.A.; Bremner, T.W. Marine performance of concrete containing fly ash and slag. In Proceedings of the Annual Conference—Canadian Society for Civil Engineering, St. Johns, NL, Canada, 30 May 2009; Volume 3, pp. 1559–1568. [Google Scholar]

- Shattaf, N.R.; Alshamsi, A.M.; Swamy, R.N. Curing/environment effect on pore structure of blended cement concrete. J. Mater. Civ. Eng. 2001, 13, 380–388. [Google Scholar] [CrossRef]

- Pasupathy, K.; Berndt, M.; Castel, A.; Sanjayan, J.; Pathmanathan, R. Carbonation of a blended slag-fly ash geopolymer concrete in field conditions after 8 years. Constr. Build. Mater. 2016, 125, 661–669. [Google Scholar] [CrossRef]

- Polder, R.B.; De Rooij, M.R. Durability of marine concrete structures—Field investigations and modelling. Heron 2005, 50, 133–154. [Google Scholar]

- Thomas, M.D.A.; Matthews, J. Performance of pfa concrete in a marine environment—10-year results. Cem. Concr. Compos. 2004, 26, 5–20. [Google Scholar] [CrossRef]

- Chalee, W.; Jaturapitakkul, C.; Chindaprasirt, P. Predicting the chloride penetration of fly ash concrete in seawater. Mar. Struct. 2009, 22, 341–353. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Cabeza, M.; Climent, M.A. Short-Term Behavior of Slag Concretes Exposed to a Real In Situ Mediterranean Climate Environment. Materials 2017, 10, 915. [Google Scholar] [CrossRef] [PubMed]

- Ortega, J.M.; Esteban, M.D.; Sánchez, I.; Climent, M.A. Performance of sustainable fly ash and slag cement mortars exposed to simulated and real in situ Mediterranean conditions along 90 warm season days. Materials 2017, 10, 1254. [Google Scholar] [CrossRef] [PubMed]

- Chalee, W.; Ausapanit, P.; Jaturapitakkul, C. Utilization of fly ash concrete in marine environment for long term design life analysis. Mater. Des. 2010, 31, 1242–1249. [Google Scholar] [CrossRef]

- Ganjian, E.; Pouya, H.S. The effect of Persian Gulf tidal zone exposure on durability of mixes containing silica fume and blast furnace slag. Constr. Build. Mater. 2009, 23, 644–652. [Google Scholar] [CrossRef]

- Detwiler, R.J.; Kjellsen, K.O.; Gjorv, O.E. Resistance to chloride intrusion of concrete cured at different temperatures. ACI Mater. J. 1991, 88, 19–24. [Google Scholar]

- Çakır, Ö.; Aköz, F. Effect of curing conditions on the mortars with and without GGBFS. Constr. Build. Mater. 2008, 22, 308–314. [Google Scholar] [CrossRef]

- Ramezanianpour, A.A.; Malhotra, V.M. Effect of curing on the compressive strength, resistance to chloride-ion penetration and porosity of concretes incorporating slag, fly ash or silica fume. Cem. Concr. Compos. 1995, 17, 125–133. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Durability related transport properties of OPC and slag cement mortars hardened under different environmental conditions. Constr. Build. Mater. 2012, 27, 176–183. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions in the microstructure development of OPC and slag cement mortars. Arch. Civ. Mech. Eng. 2015, 15, 569–583. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Antón, C.; De Vera, G.; Climent, M.A. Influence of environment on durability of fly ash cement mortars. ACI Mater. J. 2012, 109, 647–656. [Google Scholar]

- Maltais, Y.; Marchand, J. Influence of curing temperature on cement hydration and mechanical strength development of fly ash mortars. Cem. Concr. Res. 1997, 27, 1009–1020. [Google Scholar] [CrossRef]

- Hanehara, S.; Tomosawa, F.; Kobayakawa, M.; Hwang, K. Effects of water/powder ratio, mixing ratio of fly ash and curing temperature on pozzolanic reaction of fly ash in cement paste. Cem. Concr. Res. 2001, 31, 31–39. [Google Scholar] [CrossRef]

- Climent, M.A.; Ortega, J.M.; Sánchez, I. Cement mortars with fly ash and slag—Study of their microstructure and resistance to salt ingress in different environmental conditions. In Concrete Repair, Rehabilitation and Retrofitting III, Proceedings of the 3rd International Conference on Concrete Repair, Rehabilitation and Retrofitting (ICCRRR 2012), Cape Town, South Africa, 3–5 September 2012; Taylor & Francis Group: London, UK, 2012; pp. 345–350. [Google Scholar]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Impedance spectroscopy study of the effect of environmental conditions on the microstructure development of sustainable fly ash cement mortars. Materials 2017, 10, 1130. [Google Scholar] [CrossRef] [PubMed]

- European Committee for Standardization. EN 1992-1-1 Eurocode 2: Design of Concrete Structures—Part 1-1: General Rules and Rules for Buildings; Committee European Normalization (CEN): Brussels, Belgium, 2004. [Google Scholar]

- Asociación Española de Normalización y Certificación (AENOR). UNE-EN 197-1:2011. Composición, Especificaciones y Criterios de Conformidad de Los Cementos Comunes; AENOR: Madrid, Spain, 2011; p. 30. (In Spanish) [Google Scholar]

- Asociación Española de Normalización y Certificación (AENOR). UNE-EN 196-1:2005. Métodos de Ensayo de Cementos. Parte 1: Determinación de Resistencias Mecánicas; AENOR: Madrid, Spain, 2005; p. 36. (In Spanish) [Google Scholar]

- Deutsches Institut für Normung, e.V. Deutsche Norm DIN 50008 Part 1; DIN: Berlin, Germany, 1981. (In German) [Google Scholar]

- Asociación Española de Normalización y Certificación (AENOR). UNE 83982:2008. Durabilidad del Hormigón. Métodos de Ensayo. Determinación de La Absorción de Agua Por Capilaridad del Hormigón Endurecido. Método Fagerlund; AENOR: Madrid, Spain, 2008; p. 8. (In Spanish) [Google Scholar]

- Ortega, J.M.; Sánchez, I.; Climent, M.Á. Influence of different curing conditions on the pore structure and the early age properties of mortars with fly ash and blast-furnace slag. Mater. Constr. 2013, 63. [Google Scholar] [CrossRef]

- Ortega, J.M.; Sánchez, I.; Climent, M.A. Influence of environmental conditions on durability of slag cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 277–287. [Google Scholar]

- RILEM TC 116-PCD. A. Preconditioning of concrete test specimens for the measurement of gas permeability and capillary absorption of water. Mater. Struct. 1999, 32, 174–179. Available online: https://link.springer.com/article/10.1007%2FBF02481510 (accessed on 28 February 2018).

- Nordtest. NT Build 492. Concrete, Mortar and Cement-Based Repair Materials: Chloride Migration Coefficient from Non-Steady-State Migration Experiments; Nordtest Espoo: Greater Helsinki, Finland, 1999; p. 8. [Google Scholar]

- Ortega, J.M.; Ferrandiz, V.; Antón, C.; Climent, M.A.; Sánchez, I. Influence of curing conditions on the mechanical properties and durability of cement mortars. In Materials Characterisation IV: Computational Methods and Experiments; Mammoli, A.A., Brebbia, C.A., Eds.; WIT Press: Southampton, UK, 2009; pp. 381–392. [Google Scholar] [CrossRef]

- Escalante-García, J.I.; Sharp, J.H. Effect of temperature on the hydration of the main clinker phases in Portland cements: Part II, blended cements. Cem. Concr. Res. 1998, 28, 1259–1274. [Google Scholar] [CrossRef]

- Sánchez, I.; Albertos, T.S.; Ortega, J.M.; Climent, M.A. Influence of environmental conditions on durability properties of fly ash cement mortars. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancona, Italy, 28–30 June 2010; pp. 655–666. [Google Scholar]

- Kanna, V.; Olson, R.A.; Jennings, H.M. Effect of shrinkage and moisture content on the physical characteristics of blended cement mortars. Cem. Concr. Res. 1998, 28, 1467–1477. [Google Scholar] [CrossRef]

- Cabeza, M.; Merino, P.; Miranda, A.; Nóvoa, X.R.; Sanchez, I. Impedance spectroscopy study of hardened Portland cement paste. Cem. Concr. Res. 2002, 32, 881–891. [Google Scholar] [CrossRef]

- Demirboğa, R. Thermal conductivity and compressive strength of concrete incorporation with mineral admixtures. Build. Environ. 2007, 42, 2467–2471. [Google Scholar] [CrossRef]

- Malhotra, V.M.; Mehta, P.K. High-Performance, High-Volume Fly ash Concrete: Materials, Mixture Proportioning, Properties, construction Practice and Case Histories; Suppementary Cementing Materials for Sustainable Development, Inc.: Ottawa, ON, Canada, 2002. [Google Scholar]

- Comisión Permanente del Hormigón. Instrucción De Hormigón Estructural EHE-08; Ministerio de Fomento: Madrid, Spain, 2008. (In Spanish)

- Thomas, M.D.A.; Bremner, T.; Scott, A.C.N. Actual and modeled performance in a tidal zone. Concrete mixtures with supplementary cementitious materials evaluated after 25-year exposure at Treat Island. Concr. Int. 2011, 33, 23–28. [Google Scholar]

| Component | CEM I | CEM II | CEM III | CEM IV | ||||

|---|---|---|---|---|---|---|---|---|

| UNE-EN 197-1 [40] | Manufacturer Data 1 | UNE-EN 197-1 [40] | Manufacturer Data 1 | UNE-EN 197-1 [40] | Manufacturer Data 1 | UNE-EN 197-1 [40] | Manufacturer Data 1 | |

| Portland cement clinker | 95–100% | 95% | 65–79% | 75% | 20–34% | 31% | 45–64% | 50% |

| Limestone | - | 5% | - | - | - | - | - | - |

| Blast-furnace slag | - | - | - | - | 66–80% | 69% | - | - |

| Fly ash | - | - | 21–35% | 25% | - | - | 36–55% | 50% |

| Environment | Temperature | Relative Humidity | Represented Climate |

|---|---|---|---|

| Environment A | 20 °C | 100% | Optimum condition |

| Environment B | 15 °C | 85% | Atlantic climate |

| Environment C | 20 °C | 65% | Mediterranean climate |

| Environment D | 30 °C | 40% | Extreme condition |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ortega, J.M.; Tremiño, R.M.; Sánchez, I.; Climent, M.Á. Effects of Environment in the Microstructure and Properties of Sustainable Mortars with Fly Ash and Slag after a 5-Year Exposure Period. Sustainability 2018, 10, 663. https://doi.org/10.3390/su10030663

Ortega JM, Tremiño RM, Sánchez I, Climent MÁ. Effects of Environment in the Microstructure and Properties of Sustainable Mortars with Fly Ash and Slag after a 5-Year Exposure Period. Sustainability. 2018; 10(3):663. https://doi.org/10.3390/su10030663

Chicago/Turabian StyleOrtega, José Marcos, Rosa María Tremiño, Isidro Sánchez, and Miguel Ángel Climent. 2018. "Effects of Environment in the Microstructure and Properties of Sustainable Mortars with Fly Ash and Slag after a 5-Year Exposure Period" Sustainability 10, no. 3: 663. https://doi.org/10.3390/su10030663