4.1. Data and Analysis Method

To analyze employment and robotization, two sets of data are used. One is the industrial robot data obtained from the Work Environment Assessment Survey. Industrial robots are defined as either stationary or mobile machines that are automatically controlled, reprogrammable, and have manipulator to operate three or more axes. Work Environment Assessment Survey, which is published by the Korea Occupational Safety and Health Agency [

19], regularly assesses the safety risk factors in workplaces across Korea. The risk factors include handling of hazardous chemicals, installment and operation of machinery, equipment, tools, and etc. Collected data are used to create industrial health and safety policies and establish occupational disaster prevention plans. Since the first survey in 1993 and the second survey in 1999, the survey, which concerns all workplaces in the nation, has been conducted every five years. A complete enumeration method is used for manufacturing workplaces with five or more employees, whereas a sample survey method is used for manufacturing workplaces with fewer than five employees and for non-manufacturing workplaces. The 2014 survey population includes a total of 359,745 workplaces, located across the nation, that have workers’ industrial accident compensation insurance as of 1 January 2014. The target sample size is 150,000 workplaces, which is 41.7% of the survey population, of which 126,846 workplaces responded to the survey. The survey uses the 5-digit-Korea standard industrial classification (KSIC) to classify industries. The KSIC of Statistics Korea is a classification system that is based on the UNSD’s ISIC [

22]. For this reason, the survey allows direct identification of the demand for robot in each industry. This study views robotization as an automation by the use of industrial robots, as an infrastructure that can lower human workers’ burden of repetitive tasks and excessive workload. This is different from a typical automated production process that is optimized for mass production, and performs programmed tasks only. In this sense, this study assumes that the number of industrial robots may be used as a reliable indicator of robotization in place of degree of robotization in each industry, therefore implementing the number of robots as a robotization indicator.

For the business level variables, employment type data were collected from the Survey on Labor Conditions by Employment Type published by the Ministry of Employment and Labor [

23]. The survey target includes all industries defined in the KSIC with the exclusion of public administration and defense, activities of households as employers and activities of extraterritorial organizations and bodies. In terms of employment type, a survey of 32,000 sample firms that have one or more workers is conducted once a year. This survey is administered to both firms and individuals; therefore it has the capacity to identify employment type, occupations, working hours, wages and overtime payscale and/or union membership on both business and individual levels. For this study, the data are organized by the unit of business, and variables such as the number of total employees, the number of direct employees, total working hours, total wages, union membership rate, the proportion of production workers, the proportion of simple labor workers, firm size and industry classifications are created. The Survey on Labor Conditions by Employment Type provides only 1-digit-classifications, which is used to link the data with the above mentioned robotization indicator.

Existing studies on the core technologies of the 4th Industrial Revolution conclude that automation such as the use of robot and AI has a negative impact on human employment [

3,

7,

24]. However, employment and robot-based technological advancement can have a negative or a positive relationship. If technological progress can boost productivity, productivity per unit capital can exceed labor productivity which can, in turn, result in labor-substitution [

25]. This means that robotization and employment have a negative relationship. On the other hand, if technological progress improves firms’ competitiveness by lowering prices, demand for goods and services would increase which should lead to employment recovery or increase [

10,

11]. Technological advancement alone would not necessarily reduce the number of jobs, all of the time. It should be noted that the technological advancement and employment can have both negative and positive relationships.

In terms of the relationship between working hours and robotization, reduction of working hours primarily raise labor costs however, the overall effect of working hour reduction would vary depending upon the means and methods by which individual firms attempt to maintain an acceptable level of production output. If firms opt to push for overtime in an effort to sustain the existing productivity level, increased labor cost would result in greater fixed cost. Or, a business might choose to improve productivity by introducing robotization instead of increasing working hours. If the diminution of human working hours is gradual, automation can be gradually introduced as a response [

26]. Currently, Korea is one of the top countries in terms of long work-hour-days and is trying to reduce working hours due to the national social needs for shorter days. During this transitional period in a general effort to reduce working hours and to employ systems for flexible working hours, firms could try to expand robotization to increase productivity.

The higher the labor cost, the more incentives firms have to automate and substitute labor with an alternative production element; and the firms apply automation to increasing productivity and recuperating the labor cost [

27]. For this reason, chances are that firms would opt for robotization to maintain their cost competitiveness. A great number of Korean firms utilize a seniority-based wage system. This wage system is determined by length of employment therefore, companies are bound to face increasing labor costs as their employees’ period of employment increases. This institution of seniority-based wage rate encourages firms to switch to robotization [

28]. On the other hand, robotization can be weak and relatively ineffective in tasks where robots cannot be replaced by experienced hands of by in firms that do work that requires human workers who have cutting-edge expertise and judgement. In fact, highly skilled workers demanding commensurate wages in non-manufacturing industries are still difficult to adequately replaced by robots [

29,

30].

Labor unions’ attitude towards robotization may be discussed from two perspectives. According to the insider-outsider theory, unions are expected to take a positive view on robotization. A labor union is an insider, and as an insider, it is likely to keep the membership small and elite and keep out the outsiders to protect the interests of the members within the members [

31,

32]. Firms of which labor unions have a strong negotiating power hire a substantial share of indirect employees (such as subcontracting). A labor union that views indirect employment as a buffer to support its members’ employment stability, or that prefers outsourcing dirty and dangerous jobs, may condone or even encourage indirect employment [

33,

34,

35]. On the other hand, if a labor union opposes hiring of non-regular employees, the tendency for labor-substitution through robotization may be weakened as well. According to the theory of rights of collective bargaining, labor unions primary aim and objective is to improve their collective bargaining power and an increase in non-regular employment tends to undermine their collective bargaining power. In addition, non-regular employees can fill in for regular employees who belong to the union when the union decides to engage in a collective behavior such as a strike, which also can undermine the union’s effort. Therefore, the greater the union’s bargaining power, the smaller the number of non-regular employment, and vice versa [

36,

37]. Robotization, in this context, can be a substitute to non-regular employment; therefore the probability to introduce robotization would not be high if labor unions are opposed to hiring non-regular employees.

Robotization and the progress of automation technology are closely related to repetitive and simple tasks such as production-line works and simple labor [

38]. Within the German manufacturing industry, 120,000 production jobs decrease due to substitution of automatized machine and it is expected that over 20,000 routine-intensive tasks in the production plan segment will also disappear [

39]. In the US as well, concerns are rising that automation by AI and robotization could take over the simple tasks performed by low-skill and low-wage workers [

40]. In this study, robotization is defined as automation by robots, and an infrastructure that can reduce the burden of repetitive tasks and excessive workload. This is different from characteristics of service robots used to perform tasks outside of manufacturing. Service robots are semi– or fully–automated machines that perform tasks for convenience of families and individuals. In this context, therefore, routine tasks in production-lines or simple manual tasks will be most directly related to the changing employment structure like robotization.

Large corporations have a competitive advantage over small and medium enterprises and small firms owing to the economy of scale. Such advantage proves to be even more beneficial in capital-intensive firms. In fact, robotization requires substantial capital investment and large corporations are clearly better able to access the sort of funding necessary for such an undertaking. Therefore, the opportunities and financial feasibility for robotization could be increased in larger companies that operate in capital-intensive industries where investment in facilities is vital.

Table 5 presents the basic statistics of the business level variables that are used in the analysis. The robotization indicator, which is the dependent variable, is computed by taking logarithm of the number of robots in 2014. The rate of increase in total employment was calculated by subtracting the number of total employees in 2009 from that in 2014, and dividing it with the number of total employees in 2009. Total employment is categorized as direct employment and indirect employment. Direct employment includes part-time, fixed-term, non-fixed term’s contingent and regular employees. Indirect employment includes special types of employment, home-based, temporary agency, contract agency, and on-call employees. As for the increase in direct employment, the difference between the 2014 and 2009 direct employment is obtained and divided by the 2009 direct employment. We use the growth rate of total employment and direct employment after eliminating the outliers. The outliers are unreliable because the standard deviation is above 30 before the rejection of the outliers, we doubt them. The existence of outliers can affect the stability and generalization of our model. To reject the outliers, we use a method devised by a statistician, John Tukey, and introduced by Hamilton [

41]. This solution is used to define numerically what an outlier is and then specify the appropriate selection, i.e., find the inner fences. Thus, by this method, we find the lower and upper inner fences of the variable of interest, and remove the outliers which are the values outside the range between them.

In order to compute total working hours, actual monthly prescribed working hours and actual hours worked overtime in 2014 are combined and then averaged by each business. Then, logarithm is taken to the averages. The total wage is the sum of base pay, normal wage, other allowances and overtime pay of June 2014. Average of total wage of an individual worker is computed by business and logarithm is taken to the averages. For union membership rate, the ratio of employees belonging to a union to total number of employees is calculated by business. In order to compute the proportion of production workers and simple labor workers, we group them according to the Korean Standard Classification of Occupations (KSCO) 1-digit classification codes. We define the production workers as 7-Craft and related trades workers and 8-Plant, machine operators and assemblers; and we define the simple labor workers as 9-Elementary workers as the simple labor workers. The occupations included in 7-Craft and related trades workers are metal core makers, machinery equipment mechanics and fitters, electricians, construction, and mining-related workers. 8-Plant, machine operators and assemblers include chemical, metal, machine production, electrical and electronic driving related machine operating occupations. The simple labor workers include construction and mining, transport, production, cleaning and guard related elementary occupations. The KSCO is based on the International Standard Classification of Occupations (ISCO) adopted by the ILO [

22]. Based on this categorization, the proportion of production workers to total employees is calculated for each business. For the proportion of simple labor workers, the share of workers whose job classifications pertain to simple labor is calculated. Company size is represented in dummy variables that consist of four categories: Companies with fewer than five employees; entities with five-29 employees; with 30–299 employees; and, with 300 or more employees. Industries are categorized into eighteen industries, which are ultimately divided by manufacturing industry and non-manufacturing industry.

In

Table 6, we use the Pearson correlation coefficient to examine how strongly the variables are correlated. The Pearson Correlation Coefficient is a linear correlation coefficient that returns a value of between −1 and +1. The value of −1 means there is a strong negative correlation and +1 means that there is a strong positive correlation [

41]. Pearson correlation coefficients are significant at the 0.05 level in general. The correlation coefficient is 0.537 between the logarithm of total wage and the logarithm of total working hours, which is the largest among all the coefficients. The coefficient between the proportion of the simple labor workers and the proportion of the production workers is −0.193, which is a negligible relationship.

An Ordinary Least Squares (OLS) is performed to analyze the effects of labor variables such as employment, working hours, and wages on robotization, which is a dependent variable. Regression analysis using OLS is useful in examining the average relationship between dependent and independent variables. Based on the variables mentioned above, details of the model are established as described below.

represents company, and represents the year 2014. The dependent variable, , is the robotization indicator, and is , represents the rate of total employment growth between 2009 and 2014. For Models (3) and (4), , which is the rate of direct employment growth instead of , is used. represents total working hours, while represents total wage. is union membership rate, the proportion of production workers, and the proportion of simple labor workers. is a four-category dummy variable representing company size. The firms that hire less than five employees were set as a reference variable, followed by small firms with 5–29 employees, medium-sized business with 30–299 employees, and large firms with 300 or more employees. represents the error term. This model allows identification of the effects of employment, working hours and wage on robotization. In addition, an interaction term of the manufacturing dummy variable and the rate of total employment growth and the rate of direct employment growth is added to the model. This is to investigate the respective effect of employment in manufacturing industry and non-manufacturing industry on robotization.

4.2. Results

Table 7 presents the results of the OLS regression. Models (1) and (2) use the rate of total employment growth as the employment variable, while Models (3) and (4) use the rate of direct employment growth. Both Models (2) and (4) include the interaction term of the employment variables and manufacturing dummy variable. Results of the analysis are as follows. The rate of total employment growth has a positive relationship with robotization. This circumstance may be viewed as the net effect of employment on robotization because the effects of working hours, wages, union membership rate, and company sizes were controlled. In addition to labor cost and the investment cost needed for robotization, firms considering robotization also have to take into account the cost associated with labor-substitution as well as the profitability after the substitution. Facility investment costs or sales figures are not considered in this study as relevant data are unavailable. Instead, this study controls for capacity of job creating parts by including total wage in the model. Therefore, the positive relationship between the rate of total employment growth and robotization indicates that robotization might have a complementary relationship with employment.

To examine total employment and direct employment by industry, the interaction term with the manufacturing dummy variable is incorporated. The rate of total employment growth and the interaction term for manufacturing industry have a positive relationship. The industrial robots currently used in manufacturing sectors typically perform repetitive and simple tasks. This study defines robotization as automation by industrial robots. Therefore, the positive sign of employment in the manufacturing industry indicates that processes which require repetitive and simple labor compared to other jobs can have a collaboration relation with robotization. In the Model (4), the interaction term which the rate of direct employment growth and the manufacturing industry shows a positive sign. Assuming that direct employment offers higher quality labor than would indirect employment, the positive sign of direct employment in manufacturing indicates that highly skilled labor and robotization can have a Possibility of complementary collaboration.

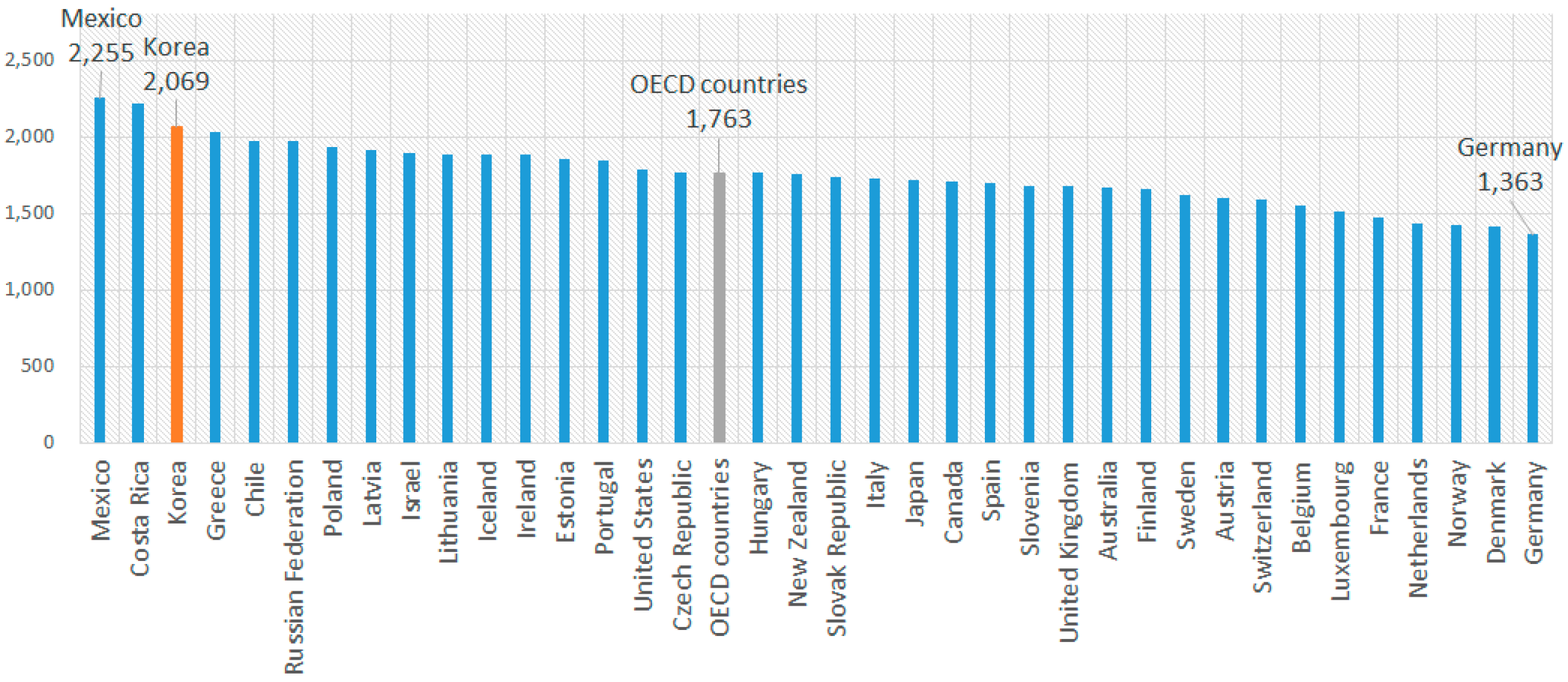

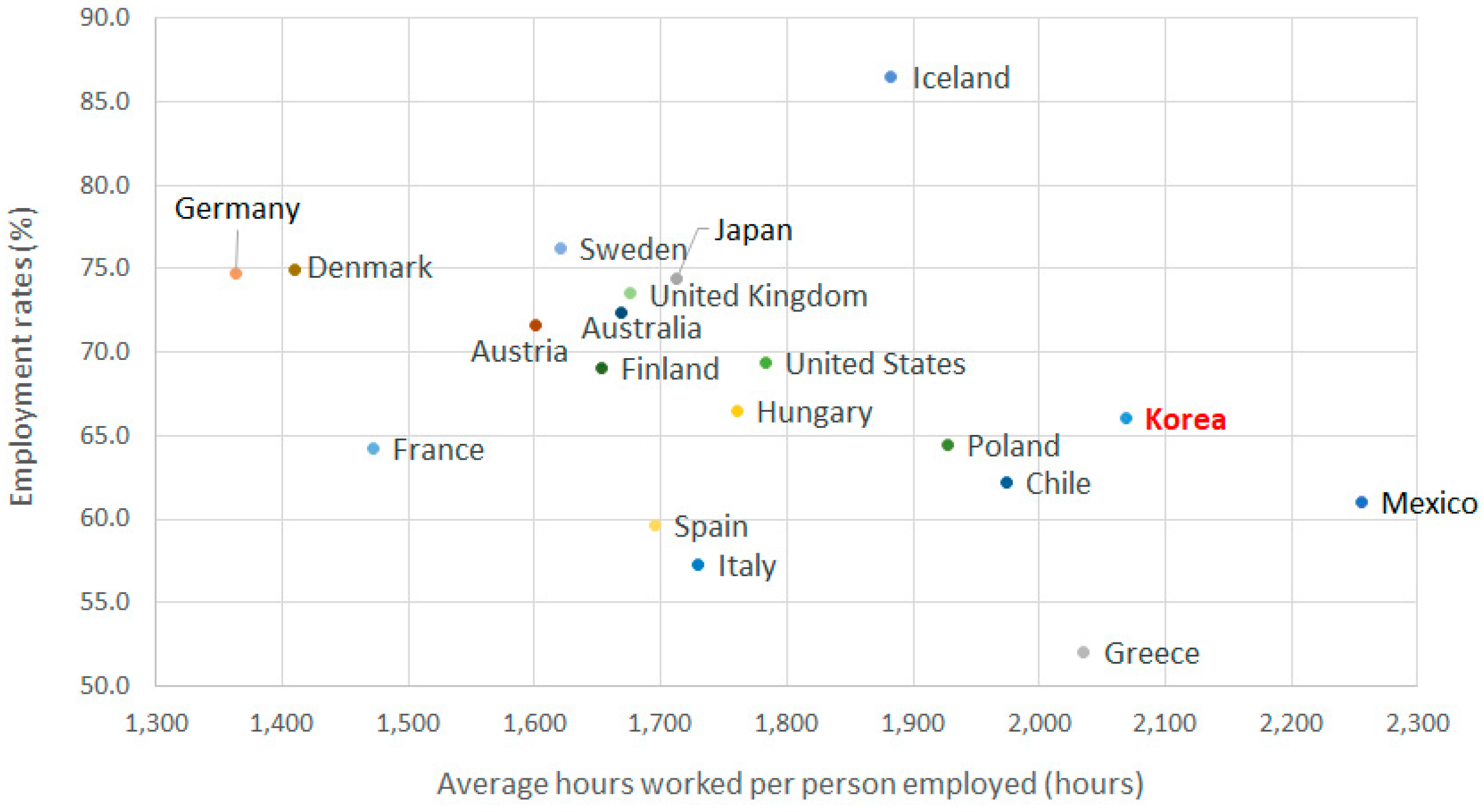

Working hours has a negative relationship with robotization. Korea, which ranks the third place from the top when it comes to the amount of working hours among OECD countries, is taking steps to shorten the long working hours. Firms would be motivated to increase productivity by deploying robots to substitute the overtime labor. Higher wages lead to more robotization. Wages often represent the financial capacity of firms, vis-à-vis the cost of labor. Therefore, if wages gets higher, firms would try to maintain their competitiveness through higher level of robotization.

There is a negative relationship between union membership rate and robotization; higher union membership leads to decreased robotization. Unions may take a hostile stance towards robotization because robotization could be perceived as undermining their organizational and collective clout and threaten the future employment of the membership. The proportions of production workers and simple laborers were positively related with robotization. This suggests that robotization could have a complementary relationship with human workforce in processes that require these types of work, the work that are mainly comprised of highly concentrated, repetitive and simple tasks. Robotization expands as company size grows; medium sized firms with 30–299 employees and large corporations with 300 or more employees deploy more robots in general. This could be attributed to the greater investment capacity among big companies, when compared to the financial resources available to small and medium-sized companies.