Abstract

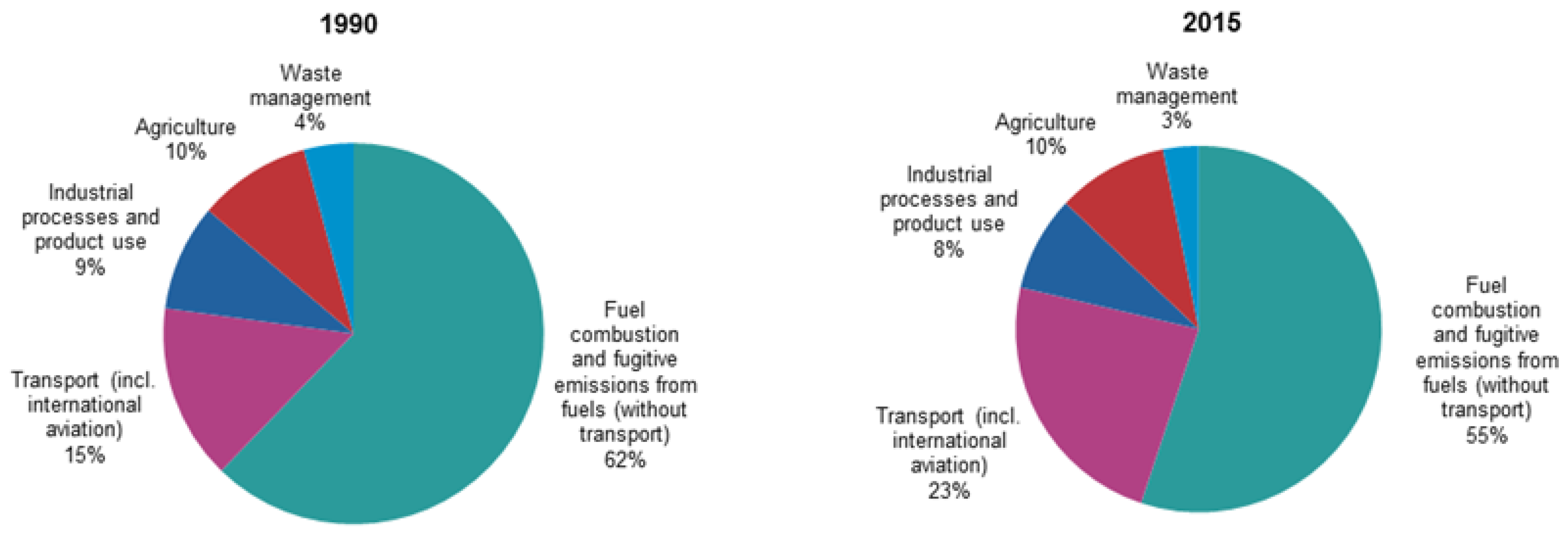

:1. Introduction

2. Method and Data

2.1. Efficiency Measurement

2.2. Sustainability Data

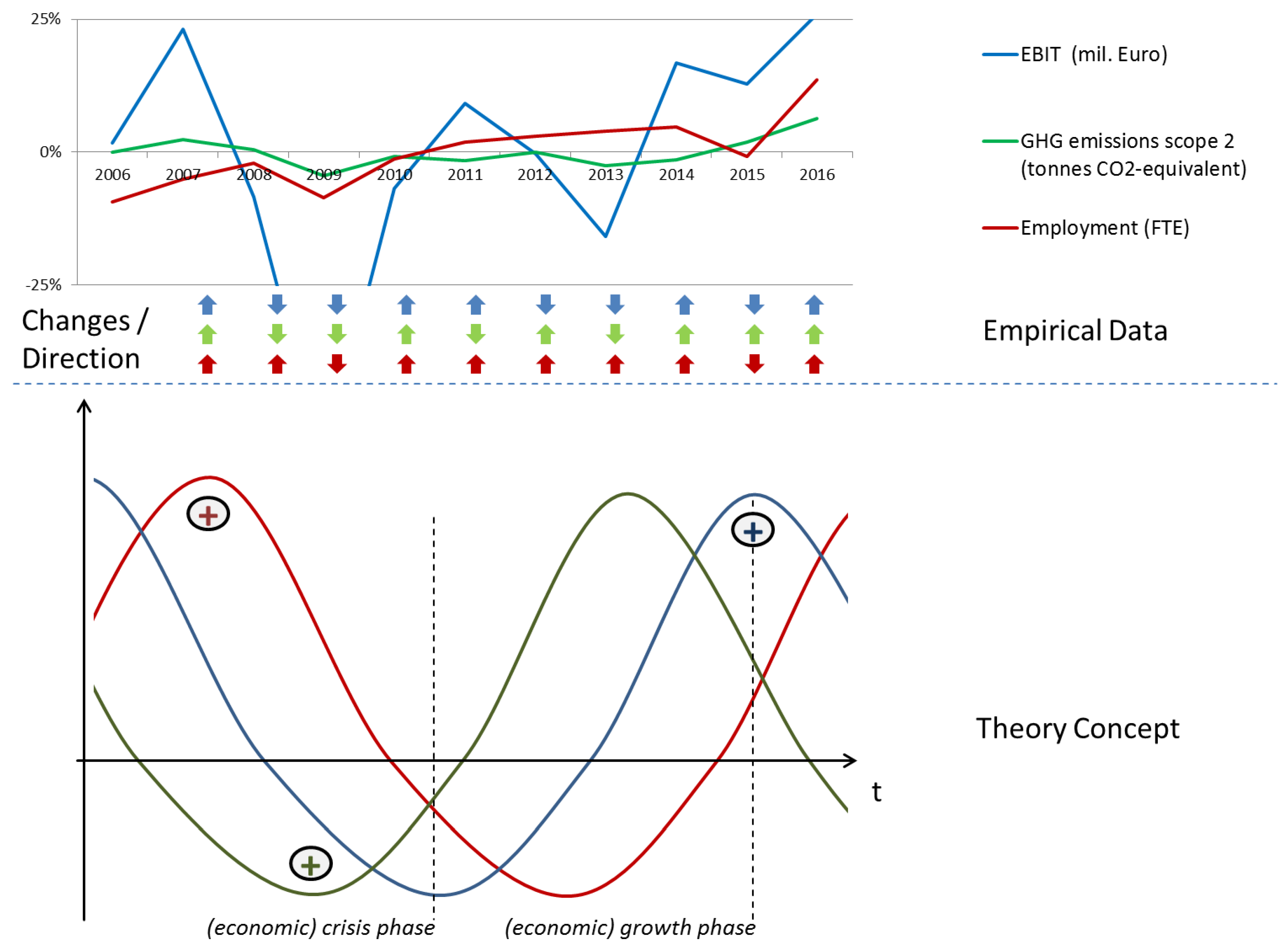

3. Results

4. Discussion

5. Simulation

- Objective function variables (five output parameters presented here, right side in Figure 5),

- Transport market spot prices as input variable (start value),

- Business cycle efficiency shift node (cycle variable with a TBL-specific time lag or off-shift between +1 and −1 one years; business cycle length of 8 years altogether),

- LSP efficiency level as starting input variable,

- Technical efficiency node (non-linear advance, probability function ranging from −5 to +10% per annum),

- LSP R&D volume as input variable for efficiency frontier shift,

- Frontier efficiency shift node (gradual advance, probability function in the range of 0 to 5% increase per annum).

6. Conclusions

Conflicts of Interest

References

- Eurostat. Greenhouse Gas Emissions–Analysis per Source Sector. Eurostat LuxembourgEurostat. 2017. Available online: http://ec.europa.eu/eurostat/statistics-explained/index.php/File:Greenhouse_gas_emissions,analysis_by_source_sector,_EU-28,_1990_and_2015_(percentage_of_total)_new.png (accessed on 30 November 2017).

- Vachon, S.; Klassen, R.D. Extending green practices across the supply chain: The impact of upstream and downstream integration. Int. J. Oper. Prod. Manag. 2006, 26, 795–821. [Google Scholar] [CrossRef]

- Halldórsson, A.; Kovács, G. The sustainable agenda and energy efficiency: Logistics solutions and supply chains in times of climate change. Int. J. Phys. Distrib. Logist. Manag. 2010, 40, 5–13. [Google Scholar] [CrossRef]

- McKinnon, A.; Browne, M.; Whiteing, A.; Piecyk, M. Green Logistics: Improving the Environmental Sustainability of Logistics; Kogan Page: London, UK, 2015; ISBN 978-0749456788. [Google Scholar]

- Mejías, A.M.; Paz, E.; Pardo, J.E. Efficiency and sustainability through the best practices in the Logistics Social Responsibility framework. Int. J. Phys. Distrib. Logist. Manag. 2016, 36, 164–199. [Google Scholar] [CrossRef]

- Golinska-Dawson, P.; Kolinski, A. Efficiency in Sustainable Supply Chain; Springer: Cham, Switzerland, 2017; ISBN 978-3319464503. [Google Scholar]

- Sudarto, S.; Takahashi, K.; Morikawa, K. Efficient flexible long-term capacity planning for optimal sustainability dimensions performance of reverse logistics social responsibility: A system dynamics approach. Int. J. Prod. Econ. 2016, 184, 179–192. [Google Scholar] [CrossRef]

- Ma, K.; Wang, L.; Chen, Y. A collaborative cloud service platform for realizing sustainable make-to-order apparel supply chain. Sustainability 2018, 10, 11. [Google Scholar] [CrossRef]

- Tang, A.K.Y.; Lai, K.-H.; Cheng, T.C.E. A Multi-research-method approach to studying environmental sustainability in retail operations. Int. J. Prod. Econ. 2016, 171, 394–404. [Google Scholar] [CrossRef]

- Lucato, W.C.; da Silva Santo, J.C.; Pacchini, A.P.T. Measuring the sustainability of manufacturing process: A conceptual framework. Sustainability 2018, 10, 81. [Google Scholar] [CrossRef]

- Dijkema, G.P.J.; Ferra, P.; Herder, P.M.; Heitor, M. Trends and opportunities framing innovation for sustainability in the learning society. Technol. Forecast. Soc. Chang. 2006, 73, 215–227. [Google Scholar] [CrossRef]

- Heiskala, M.; Jokinen, J.-P.; Tinnilä, M. Crowdsensing-based transportation services–An analysis from business model and sustainability viewpoints. Res. Transp. Bus. Manag. 2016, 18, 38–48. [Google Scholar] [CrossRef]

- Rimos, S.; Hoadley, A.F.A.; Brennan, D.J. Environmental consequence analysis for resource depletion. Proc. Saf. Environ. Prot. 2014, 9, 849–861. [Google Scholar] [CrossRef]

- Kuhn, M.A.; Kuhn, P.; Villeval, M.C. Decision-Environment Effects on Intertemporal Financial Choices: How Relevant are Resource-Depletion Models? J. Econ. Behav. Organ. 2017, 137, 72–89. [Google Scholar] [CrossRef]

- Mahoney, L.S.; Thorne, L.; Cecil, L.; LaGore, W. A research note on standalone corporate social responsibility reports: Signaling or greenwashing? Crit. Perspect. Account. 2013, 24, 350–359. [Google Scholar] [CrossRef]

- Siano, A.; Vollero, A.; Conte, F.; Amabile, S. ‘More than words’: Expanding the taxonomy of greenwashing after the Volkswagen scandal. J. Bus. Res. 2017, 71, 27–37. [Google Scholar] [CrossRef]

- Brix-Asala, C.; Hahn, R.; Seuring, S. Reverse logistics and informal valorisation at the Base of the Pyramid: A case study on sustainability synergies and trade-offs. Eur. Manag. J. 2016, 34, 414–423. [Google Scholar] [CrossRef]

- Davarzani, H.; Fahimnia, B.; Bell, M.; Sarkis, J. Greening ports and maritime logistics: A review. Transp. Res. Part D 2016, 48, 473–487. [Google Scholar] [CrossRef]

- Osorio-Tejada, J.L.; Llera-Sastresa, E.; Scarpellini, S. A multi-criteria sustainability assessment for biodiesel and liquefied natural gas as alternative fuels in transport systems. J. Natl. Gas Sci. Eng. 2017, 42, 169–186. [Google Scholar] [CrossRef]

- Armeanu, D.S.; Vintila, G.; Gherghina, S.C. Empirical study towards the drivers of sustainable aconomic growth in EU-28 countries. Sustainability 2018, 10, 4. [Google Scholar] [CrossRef]

- United Nations Framework Convention on Climate Change (UNFCCC). United Nations Framework Convention on Climate Change; Climate Change Secretariat: Bonn, Germany, 1992. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Kyoto Protocol; Climate Change Secretariat: Bonn, Germany, 1998. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Copenhagen Accord 2009; Climate Change Secretariat: Bonn, Germany, 2009. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Doha Amendment to the Kyoto Protocol 2012; Climate Change Secretariat: Bonn, Germany, 2012. [Google Scholar]

- United Nations Framework Convention on Climate Change (UNFCCC). Paris Agreement 2015; Climate Change Secretariat: Bonn, Germany, 2015. [Google Scholar]

- Brundtlandt, G.M. Our Common Future; World Commission on Environment and Development: New York, NY, USA, 1988. [Google Scholar]

- Holden, E.; Linnerud, K.; Banister, D. Sustainable development: Our Common Future revisited. Glob. Environ. Chang. 2014, 26, 130–139. [Google Scholar] [CrossRef]

- Sneddon, C.; Howarth, R.B.; Norgaard, R.B. Sustainable development in a post-Brundtland world. Ecol. Econom. 2006, 57, 253–268. [Google Scholar] [CrossRef]

- Von Carlowitz, H.-C. Sylvicultura Oeconomica; J.F. Braun: Leipzig, Germany, 1713. [Google Scholar]

- Meadows, D.H.; Meadows, D.L.; Randers, J.; Behrens, W.W. The Limits to Growth; Universe Books: New York, NY, USA, 1972; ISBN 978-1849775861. [Google Scholar]

- Vermeulen, W.J.V.; Witjes, S. On addressing the dual and embedded nature of business and the route towards corporate sustainability. J. Clean. Prod. 2016, 112, 2822–2832. [Google Scholar] [CrossRef]

- Brockhaus, S.; Fawcett, S.E.; Knemeyer, A.M.; Fawcett, A.M. Motivations for environmental and social consciousness: Reevaluating the sustainability-based view. J. Clean. Prod. 2017, 143, 933–947. [Google Scholar] [CrossRef]

- McManners, P.J. Developing policy integrating sustainability: A case study into aviation. Environ. Sci. Policy 2016, 57, 86–92. [Google Scholar] [CrossRef]

- Chang, R.-D.; Zuo, J.; Zhao, Z.-Y.; Zillante, G.; Gan, X.-L.; Soebarto, V. Evolving theories of sustainability and firms: History, future directions and implications for renewable energy research. Renew. Sustain. Energy Rev. 2017, 72, 48–56. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Trans. Res. Part D Trans. Environ. 2017, 53, 454–470. [Google Scholar] [CrossRef]

- Schrettle, S.; Hinz, A.; Scherrer-Rathje, M.; Friedli, T. Turning sustainability into action: Explaining firms’ sustainability efforts and their impact on firm performance. Int. J. Prod. Econ. 2014, 147, 73–84. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a literature review to a conceptual framework for sustainable supply chain management. J Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Fahimnia, B.; Jabbarzadeh, A. Marrying supply chain sustainability and resilience: A match made in heaven. Trans. Res. Part E 2016, 91, 306–324. [Google Scholar] [CrossRef]

- Kaur, H.; Singh, S.P. Heuristic modeling for sustainable procurement and logistics in a supply chain using big data. Comput. Oper. Res. 2017. [Google Scholar] [CrossRef]

- Suzuki, Y.; Lu, S.-H. Economies of product diversity in collaborative logistics. J. Bus. Logist. 2017, 38, 115–129. [Google Scholar] [CrossRef]

- Evangelista, P.; Colicchia, C.; Creazza, A. Is environmental sustainability a strategic priority for logistics service providers? J. Environ. Manag. 2017, 198, 353–362. [Google Scholar] [CrossRef] [PubMed]

- Colicchia, C.; Marchet, G.; Melacini, M.; Perotti, S. Building environmental sustainability: Empirical evidence from Logistics Service Providers. J Clean. Prod. 2013, 59, 197–209. [Google Scholar] [CrossRef]

- Sim, J.; Sim, J. Air emission and environmental impact assessment of Korean automotive logistics. J. Clean. Prod. 2017, 159, 130–140. [Google Scholar] [CrossRef]

- European Environmental Agency (EEA). Greenhouse Gas Emissions from Transport; EEA: Copenhagen, Denmark, 2017; Available online: https://www.eea.europa.eu/data-and-maps/indicators/transport-emissions-of-greenhouse-gases/transport-emissions-of-greenhouse-gases-10 (accessed on 30 January 2018).

- Levallois, C. Can de-growth be considered a policy option? A historical note on Nicholas Georgescu-Roegen and the Club of Rome. Ecol. Econ. 2010, 69, 2271–2278. [Google Scholar] [CrossRef]

- European Commission. Roadmap to a Single European Transport Area–Towards a Competitive and Resource Efficient Transport System; European Commission: Brussels, Germany, 2011; COM(2011)144 final. [Google Scholar]

- Du, T. Performance measurement of healthcare service and association discussion between quality and efficiency: Evidence from 31 provinces of mainland china. Sustainability 2018, 10, 74. [Google Scholar] [CrossRef]

- Mohanty, M.; Shankar, R. Modelling uncertainty in sustainable integrated logistics using Fuzzy-TISM. Transp. Res. Part D 2017, 53, 471–491. [Google Scholar] [CrossRef]

- Marshall, D.; McCarthy, L.; McGrath, P.; Claudy, M. Going above and beyond: How sustainability culture and entrepreneurial orientation drive social sustainability supply chain practice adoption. Supply Chain Manag. Int. J. 2015, 20, 434–454. [Google Scholar] [CrossRef]

- Deutsche Bahn. 2016 Integrated Report-Quality That Persuades! Deutsche Bahn AG: Berlin, Germany, 2017. [Google Scholar]

- Deutsche Post DHL. Smart Logistics–2015 Annual Report; Deutsche Post AG: Bonn, Germany, 2016. [Google Scholar]

- Gammelgaard, B.; Andersen, C.B.G.; Aastrup, J. Value co-creation in the interface between city logistics provider and in-store processes. Trans. Res. Proc. 2016, 12, 787–799. [Google Scholar] [CrossRef]

- Oltean-Dumbrava, C.; Watts, G.; Miah, A. Towards a more sustainable surface transport infrastructure: A case study of applying multi criteria analysis techniques to assess the sustainability of transport noise reducing devices. J. Clean. Prod. 2016, 112, 2922–2934. [Google Scholar] [CrossRef]

- Postorino, M.N.; Mantecchini, L. A transport carbon footprint methodology to assess airport carbon emissions. J. Air Trans. Manag. 2014, 37, 76–86. [Google Scholar] [CrossRef]

- Gupta, M.D. Carbon footprint from road transport use in Kolkata city. Trans. Res. Part D 2014, 32, 397–410. [Google Scholar] [CrossRef]

- Jevons, W.S. The Coal Question: An Inquiry Concerning the Progress of the Nation, and the Probable Exhaustion of Our Coal Mines; Macmillan: London, UK, 1865. [Google Scholar]

- Alcott, B. Jevons’ paradox. Ecol. Econ. 2005, 54, 9–21. [Google Scholar] [CrossRef]

- Higgins, C.; Coffey, B. Improving how sustainability reports drive change: A critical discourse analysis. J. Clean. Prod. 2016, 136, 18–29. [Google Scholar] [CrossRef]

- Domingues, A.R.; Lozano, R.; Ceulemanns, K.; Ramos, T.B. Sustainability reporting in public sector organisations: Exploring the relation between the reporting process and organisational change management for sustainability. J. Environ. Manag. 2017, 192, 292–301. [Google Scholar] [CrossRef] [PubMed]

- Eroglu, C.; Kurt, A.C.; Elwakil, O.S. Stock market reaction to quality, safety, and sustainability awards in logistics. J. Bus. Logist. 2016, 37, 329–345. [Google Scholar] [CrossRef]

- Ha, H.K.; Kaneko, S.; Yamamoto, M.; Yoshida, Y.; Zhang, A. On the discrepancy in the social efficiency measures between parametric and non-parametric production technology identification. J. Air Trans. Manag. 2017, 58, 9–14. [Google Scholar] [CrossRef]

- Toma, P.; Miglietta, P.P.; Zurlini, G.; Valente, D.; Petrosillo, I. A non-parametric bootstrap data envelopment analysis approach for environmental policy planning and management of agricultural efficiency in EU countries. Ecol. Indic. 2017, 83, 132–143. [Google Scholar] [CrossRef]

- Chen, C.-M. A critique of non-parametric efficiency analysis in energy economics studies. Energy Econ. 2013, 28, 146–152. [Google Scholar] [CrossRef]

- Koopmans, T.C. Analysis of Production as an Efficient Combination of Activities. In Activity Analysis of Production and Allocation, Proceedings of a Conference; Koopmans, T.C., Ed.; Wiley: New York, NY, USA, 1951; pp. 33–97. [Google Scholar]

- Debreu, G. The Coefficient of Resource Utilization. Econometrica 1951, 19, 273–292. [Google Scholar] [CrossRef]

- Farrell, M.J. The Measurement of Productive Efficiency. J. R. Stat. Soc. Ser. A (Gen.) 1957, 120, 253–290. [Google Scholar] [CrossRef]

- Diewert, W.E. Functional Forms for Profit and Transformation Functions. J. Econ. Theory 1973, 6, 284–316. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E.L. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Karsak, E.E.; Karadayi, M.A. Imprecise DEA framework for evaluating health care performance of districts. Kybernetes 2017, 46. [Google Scholar] [CrossRef]

- Shwartz, M.; Burgess, J.F.; Zhu, J. A DEA based composite measure of quality and its associated data uncertainty interval for health care provider profiling and pay-for-performance. Eur. J. Oper. Res. 2016, 253, 489–502. [Google Scholar] [CrossRef]

- Hollingsworth, B. Non-Parametric and Parametric Applications Measuring Efficiency in Health Care. Health Care Manag. Sci. 2003, 6, 203–218. [Google Scholar] [CrossRef] [PubMed]

- Bolli, T.; Olivares, M.; Bonaccorsi, A.; Daraio, C.; Aracil, A.D.; Lepori, B. The differential effects of competitive funding on the production frontier and the efficiency of universities. Econ. Educ. Rev. 2016, 52, 91–104. [Google Scholar] [CrossRef]

- Bessent, A.M.; Bessent, E.W.; Charnes, A.; Cooper, W.W.; Thorogood, N. Evaluation of educational program proposals by means of DEA. Educ. Adm. Q. 1983, 19, 82–107. [Google Scholar] [CrossRef]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some models for estimating technical and scale inefficiencies in data envelopment analysis. Manag. Sci. 1984, 30, 1078–1092. [Google Scholar] [CrossRef]

- Malmquist, S. Index numbers and indifference surfaces. Trab. Estad. Investig. Oper. 1953, 42, 209–242. [Google Scholar] [CrossRef]

- Caves, D.W.; Christensen, L.R.; Diewert, W. The Economic Theory of Index Numbers and the Measurement of Input, Output, and Productivity. Econometrica 1982, 50, 1393–1414. [Google Scholar] [CrossRef]

- Grifell-Tatje, E.; Lovell, C.A.K.; Pastor, J.T. A quasi-Malmquist productivity index. J. Product. Anal. 1998, 10, 7–20. [Google Scholar] [CrossRef]

- Thanassoulis, E.; Shiraz, R.K.; Maniadakis, N. A cost Malmquist productivity index capturing group performance. Eur. J. Oper. Res. 2015, 241, 796–805. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Yang, G. A framework for measuring global Malmquist-Luenberger productivity index with CO2 emissions on Chinese manufacturing industries. Energy 2016, 115, 840–856. [Google Scholar] [CrossRef]

- Sueyoshi, T.; Goto, M. DEA environmental assessment in time horizon: Radial approach for Malmquist index measurement on petroleum companies. Energy Econ. 2015, 51, 329–345. [Google Scholar] [CrossRef]

- Chang, D.-S.; Kuo, L.R.; Chen, Y. Industrial changes in corporate sustainability performance–an empirical overview using data envelopment analysis. J Clean. Prod. 2013, 56, 147–155. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W. Preface to topics in data envelopment analysis. Ann. Oper. Res. 1985, 2, 59–94. [Google Scholar] [CrossRef]

- Färe, R.; Grosskopf, S.; Lovell, C.A.K.; Pasurka, C. Multilateral productivity comparisons when some outputs are undesirable. Rev. Econ. Stat. 1989, 71, 90–98. [Google Scholar] [CrossRef]

- Guo, X.; Lu, C.-C.; Lee, J.-H.; Chiu, Y.-H. Applying the dynamic DEA model to evaluate the energy efficiency of OECD countries and China. Energy 2017, 134, 392–399. [Google Scholar] [CrossRef]

- Khushalani, J.; Ozcan, Y.A. Are hospitals producing quality care efficiently? An analysis using Dynamic Network Data Envelopment Analysis (DEA). Socio-Econ. Plan. Sci. 2017, 60, 15–23. [Google Scholar] [CrossRef]

- Vlontzos, G.; Pardalos, P.M. Assess and prognosticate green house gas emissions from agricultural production of EU countries, by implementing, DEA Window analysis and artificial neural networks. Renew. Sustain. Energy Rev. 2017, 76, 155–162. [Google Scholar] [CrossRef]

- Halkos, G.E.; Tzeremes, N.G. Exploring the existence of Kuznets curve in countries’ environmental efficiency using DEA window analysis. Ecol. Econ. 2009, 68, 2168–2176. [Google Scholar] [CrossRef] [Green Version]

- Sueyoshi, T.; Goto, M.; Sugiyama, M. DEA window analysis for environmental assessment in a dynamic time shift: Performance assessment of U.S. coal-fired power plants. Energy Econ. 2013, 40, 845–857. [Google Scholar] [CrossRef]

- Kazley, A.S.; Ozcan, Y.A. Electronic medical record use and efficiency: A DEA and windows analysis of hospitals. Socio-Econ. Plan. Sci. 2009, 43, 209–216. [Google Scholar] [CrossRef]

- Pulina, M.; Detotto, C.; Paba, A. An investigation into the relationship between size and efficiency of the Italian hospitality sector: A window DEA approach. Eur. J. Oper. Res. 2010, 204, 613–620. [Google Scholar] [CrossRef]

- La Poste. 2016 CSR Report; Le Groupe La Poste: Paris, France, 2017. [Google Scholar]

- Elkington, J. Cannibals with Forks–The Triple Bottom Line of 21st Century Business; Capstone: Oxford, UK, 1997; ISBN 978-1841120843. [Google Scholar]

- Formentini, M.; Taticchi, P. Corporate sustainability approaches and governance mechanisms in sustainable supply chain management. J. Clean. Prod. 2016, 112, 1920–1933. [Google Scholar] [CrossRef] [Green Version]

- Akhtar, P.; Tse, Y.K.; Khan, Z.; Rao-Nicholson, R. Data-driven and adaptive leadership contributing to sustainability: Global agri-food supply chains connected with emerging markets. Int. J. Prod. Econ. 2015, 181, 392–401. [Google Scholar] [CrossRef]

- Hansen, T.; Coenen, L. The geography of sustainability transitions: Review, synthesis and reflections on an emergent research field. Environ. Innov. Soc. Trans. 2015, 17, 92–109. [Google Scholar] [CrossRef]

- Luthra, S.; Garg, D.; Haleem, A. An analysis of interactions among critical success factors to implement green supply chain management towards sustainability: An Indian perspective. Resour. Policy 2015, 46, 37–50. [Google Scholar] [CrossRef]

- Lehtonen, M. The environmental-social interface of sustainable development: Capabilities, social capital, institutions. Ecol. Econ. 2004, 49, 199–214. [Google Scholar] [CrossRef]

- Grund, C. Gender pay gaps among highly educated professionals—Compensation components do matter. Lab. Econ. 2015, 34, 118–126. [Google Scholar] [CrossRef]

- Buchanan, T. The Influence of Gender Role Attitudes on Perceptions of Women’s Work Performance and the Importance of Fair Pay. Sociol. Spectr. 2014, 34, 203–221. [Google Scholar] [CrossRef]

- Al-Shaer, H.; Zaman, M. Board gender diversity and sustainability reporting quality. J. Contemp. Account. Econ. 2016, 12, 210–222. [Google Scholar] [CrossRef]

- Perryman, A.A.; Fernando, G.D.; Tripathy, A. Do gender differences persist? An examination of gender diversity on firm performance, risk, and executive compensation. J. Bus. Res. 2016, 69, 579–586. [Google Scholar] [CrossRef]

- Wang, Z.; He, W. CO2 emissions efficiency and marginal abatement costs of the regional transportation sectors in China. Trans. Res. Part D 2017, 50, 83–97. [Google Scholar] [CrossRef]

- Voytenko, Y.; McCormick, K.; Evans, J.; Schliwa, G. Urban living labs for sustainability and low carbon cities in Europe: Towards a research agenda. J Clean. Prod. 2016, 123, 45–54. [Google Scholar] [CrossRef]

- Alibeyg, A.; Contreras, I.; Fernández, E. Hub network design problems with profits. Trans. Res. Part E 2016, 96, 40–59. [Google Scholar] [CrossRef]

- Li, Y.; Chen, H.; Prins, C. Adaptive large neighborhood search for the pickup and delivery problem with time windows, profits, and reserved requests. Eur. J. Oper. Res. 2016, 252, 27–38. [Google Scholar] [CrossRef]

- OECD. OECD Data–Exchange Rates. Available online: https://data.oecd.org/conversion/exchange-rates.htm (accessed on 30 November 2017).

- Klumpp, M. Do forwarders improve sustainability efficiency? Evidence from a European DEA Malmquist Index Calculation. Sustainability 2017, 9, 842. [Google Scholar] [CrossRef]

- Deutsche Bahn. 2015 Integrated Report—More Quality, More Customers, More Success; Deutsche Bahn AG: Berlin, Germany, 2016. [Google Scholar]

- Deutsche Bahn. 2014 Integrated Report—Integrated Thinking. Sustainable Action. Long-Term Success; Deutsche Bahn AG: Berlin, Germany, 2015. [Google Scholar]

- Deutsche Bahn. 2013 Integrated Report—DB2020: Our Compass, Even in Challenging Times; Deutsche Bahn AG: Berlin, Germany, 2014. [Google Scholar]

- Deutsche Bahn. Our Future: Sustainably Successful—Deutsche Bahn 2012 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2013. [Google Scholar]

- Deutsche Bahn. DB Mobility Logistics—2011 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2012. [Google Scholar]

- Deutsche Bahn. 2010 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2011. [Google Scholar]

- Deutsche Bahn. 2009 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2010. [Google Scholar]

- Deutsche Bahn. 2008 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2009. [Google Scholar]

- Deutsche Bahn. 2007 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2008. [Google Scholar]

- Deutsche Bahn. 2006 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2007. [Google Scholar]

- Deutsche Post DHL. 2016 Annual Report—Constantly Reinventing the Future of Logistics; Deutsche Bahn AG: Berlin, Germany, 2017. [Google Scholar]

- Deutsche Post DHL. When You Think of Logistics—2014 Annual Report; Deutsche Bahn AG: Berlin, Germany, 2015. [Google Scholar]

- Deutsche Post DHL. Tailor Made—2013 Annual Report; Deutsche Post AG: Bonn, Germany, 2014. [Google Scholar]

- Deutsche Post DHL. Pioneering Future Markets—2012 Annual Report; Deutsche Post AG: Bonn, Germany, 2013. [Google Scholar]

- Deutsche Post DHL. Simply Grow—2011 Annual Report; Deutsche Post AG: Bonn, Germany, 2012. [Google Scholar]

- Deutsche Post DHL. Being Your Choice—2010 Annual Report; Deutsche Post AG: Bonn, Germany, 2011. [Google Scholar]

- Deutsche Post DHL. Showing Respect, Delivering Results—2009 Annual Report; Deutsche Post AG: Bonn, Germany, 2010. [Google Scholar]

- Deutsche Post DHL. Delivering on the Future—2008 Annual Report; Deutsche Post AG: Bonn, Germany, 2009. [Google Scholar]

- Deutsche Post DHL. Roadmap to Value—2007 Annual Report; Deutsche Post AG: Bonn, Germany, 2008. [Google Scholar]

- Deutsche Post DHL. Building on Our Strategic Strengths—2006 Annual Report; Deutsche Post AG: Bonn, Germany, 2007. [Google Scholar]

- DSV. 2016 Annual Report; DSV A/S: Hedehusene, Denmark, 2017. [Google Scholar]

- DSV. 2015 Annual Report; DSV A/S: Hedehusene, Denmark, 2016. [Google Scholar]

- DSV. 2014 Annual Report; DSV A/S: Hedehusene, Denmark, 2015. [Google Scholar]

- DSV. 2013 Annual Report; DSV A/S: Hedehusene, Denmark, 2014. [Google Scholar]

- DSV. 2012 Annual Report; DSV A/S: Hedehusene, Denmark, 2013. [Google Scholar]

- DSV. 2011 Annual Report; DSV A/S: Hedehusene, Denmark, 2012. [Google Scholar]

- DSV. 2010 Annual Report; DSV A/S: Hedehusene, Denmark, 2011. [Google Scholar]

- DSV. 2009 Annual Report; DSV A/S: Hedehusene, Denmark, 2010. [Google Scholar]

- DSV. 2008 Annual Report; DSV A/S: Hedehusene, Denmark, 2009. [Google Scholar]

- DSV. 2007 Annual Report; DSV A/S: Hedehusene, Denmark, 2008. [Google Scholar]

- DSV. 2006 Annual Report; DSV A/S: Hedehusene, Denmark, 2007. [Google Scholar]

- Kuehne + Nagel. Annual Report 2016; Kuehne + Nagel: Schindellegi, Switzerland, 2017. [Google Scholar]

- Kuehne + Nagel. Annual Report 2015—Tradition and Innovation; Kuehne + Nagel: Schindellegi, Switzerland, 2016. [Google Scholar]

- Kuehne + Nagel. Annual Report 2014—Global. Customer-Oriented. Innovative; Kuehne + Nagel: Schindellegi, Switzerland, 2015. [Google Scholar]

- Kuehne + Nagel. Annual Report 2013—Continuity and Further Development; Kuehne + Nagel: Schindellegi, Switzerland, 2014. [Google Scholar]

- Kuehne + Nagel. Annual Report 2012—People. Network. Objectives; Kuehne + Nagel: Schindellegi, Switzerland, 2013. [Google Scholar]

- Kuehne + Nagel. Annual Report 2011—Network and Product Portfolio–Kühne + Nagel Accelerates Expansion; Kuehne + Nagel: Schindellegi, Switzerland, 2012. [Google Scholar]

- Kuehne + Nagel. Annual Report 2010; Kuehne + Nagel: Schindellegi, Switzerland, 2011. [Google Scholar]

- Kuehne + Nagel. Annual Report 2009; Kuehne + Nagel: Schindellegi, Switzerland, 2010. [Google Scholar]

- Kuehne + Nagel. Annual Report 2008; Kuehne + Nagel: Schindellegi, Switzerland, 2009. [Google Scholar]

- Kuehne + Nagel. Annual Report 2007; Kuehne + Nagel: Schindellegi, Switzerland, 2008. [Google Scholar]

- Kuehne + Nagel. Annual Report 2006; Kuehne + Nagel: Schindellegi, Switzerland, 2007. [Google Scholar]

- La Poste. Registration Document 2016; Le Groupe La Poste: Paris, France, 2017. [Google Scholar]

- La Poste. Registration Document 2015; Le Groupe La Poste: Paris, France, 2016. [Google Scholar]

- La Poste. Registration Document 2014; Le Groupe La Poste: Paris, France, 2015. [Google Scholar]

- La Poste. Registration Document 2013; Le Groupe La Poste: Paris, France, 2014. [Google Scholar]

- La Poste. Registration Document 2012; Le Groupe La Poste: Paris, France, 2013. [Google Scholar]

- La Poste. Registration Document 2011; Le Groupe La Poste: Paris, France, 2012. [Google Scholar]

- La Poste. Registration Document 2010; Le Groupe La Poste: Paris, France, 2011. [Google Scholar]

- La Poste. Registration Document 2009; Le Groupe La Poste: Paris, France, 2010. [Google Scholar]

- La Poste. Registration Document 2008; Le Groupe La Poste: Paris, France, 2009. [Google Scholar]

- La Poste. Registration Document 2007; Le Groupe La Poste: Paris, France, 2008. [Google Scholar]

- La Poste. Registration Document 2006; Le Groupe La Poste: Paris, France, 2007. [Google Scholar]

- Panalpina. 2016 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2017. [Google Scholar]

- Panalpina. 2015 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2016. [Google Scholar]

- Panalpina. 2014 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2015. [Google Scholar]

- Panalpina. 2013 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2014. [Google Scholar]

- Panalpina. 2012 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2013. [Google Scholar]

- Panalpina. 2011 Annual Report; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2012. [Google Scholar]

- Panalpina. 2010 Annual Report—A Passion for Solutions; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2011. [Google Scholar]

- Panalpina. 2009 Annual Report—A Passion for Solutions; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2010. [Google Scholar]

- Panalpina. 2008 Annual Report—A Passion for Solutions; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2009. [Google Scholar]

- Panalpina. 2007 Annual Report—A Passion for Solutions; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2008. [Google Scholar]

- Panalpina. 2006 Annual Report—A Passion for Solutions; Panalpina World Transport (Holding) Ltd.: Basel, Switzerland, 2007. [Google Scholar]

- SNCF. 2016 Annual Report; SNCF: Saint-Denis, France, 2017. [Google Scholar]

- SNCF. 2015 Annual Report; SNCF: Saint-Denis, France, 2016. [Google Scholar]

- SNCF. 2014 Annual Report; SNCF: Saint-Denis, France, 2015. [Google Scholar]

- SNCF. 2013 Annual report; SNCF: Saint-Denis, France, 2014. [Google Scholar]

- SNCF. 2012 Annual Report; SNCF: Saint-Denis, France, 2013. [Google Scholar]

- SNCF. 2011 Annual Report; SNCF: Saint-Denis, France, 2012. [Google Scholar]

- SNCF. 2010 Annual Report; SNCF: Saint-Denis, France, 2011. [Google Scholar]

- SNCF. 2009 Annual Report; SNCF: Saint-Denis, France, 2010. [Google Scholar]

- SNCF. 2008 Annual Report; SNCF: Saint-Denis, France, 2009. [Google Scholar]

- SNCF. 2007 Annual Report; SNCF: Saint-Denis, France, 2008. [Google Scholar]

- SNCF. 2006 Annual Report; SNCF: Saint-Denis, France, 2007. [Google Scholar]

- Cooper, W.W.; Lawrence, M.S.; Tone, K. Data Envelopment Analysis—A Comprehensive Text with Models, Applications, References and DEA-Solver Software; Springer: New York, NY, USA, 2007; ISBN 978-0-387-45283-8. [Google Scholar]

- Cook, W.D.; Zhu, J. Classifying inputs and outputs in data envelopment analysis. Eur. J. Oper. Res. 2007, 180, 692–699. [Google Scholar] [CrossRef]

- Feng, C.; Chu, F.; Ding, J.; Bi, G.; Liang, L. Carbon Emissions Abatement (CEA) allocation and compensation schemes based on DEA. Omega 2015, 53, 78–89. [Google Scholar] [CrossRef]

- Jain, R.K.; Natarajan, R. A DEA study of airlines in India. Asia Pac. Manag. Rev. 2015, 20, 285–292. [Google Scholar] [CrossRef]

- Sorrell, S. Jevons’ Paradox revisited: The evidence for backfire from improved energy efficiency. Energy Policy 2009, 37, 1456–1469. [Google Scholar] [CrossRef]

- Wang, Z.; Lu, M. An empirical study of direct rebound effect for road freight transport in China. Appl. Energy 2014, 133, 274–281. [Google Scholar] [CrossRef]

- Winebrake, J.J.; Green, E.H.; Comer, B.; Corbett, J.J.; Froman, S. Estimating the direct rebound effect for on-road freight transportation. Energy Policy 2012, 48, 252–259. [Google Scholar] [CrossRef]

- Matos, F.J.F.; Silva, F.J.F. The rebound effect on road freight transport: Empirical evidence from Portugal. Energy Policy 2011, 39, 2833–2841. [Google Scholar] [CrossRef]

- Mentzer, J.T. Rigor versus relevance: Why would we choose only one? J. Supply Chain Manag. 2008, 44, 72–77. [Google Scholar] [CrossRef]

- Wieland, A.; Handfield, R.B.; Durach, C.F. Mapping the landscape of future research themes in supply chain management. J. Bus. Logist. 2016, 37, 205–212. [Google Scholar] [CrossRef]

- Iacovidou, E.; Busch, J.; Hahladakis, J.N.; Baxter, H.; Ng, K.S.; Herberg, B.M.J. A Parameter Selection Framework for Sustainability Assessment. Sustainability 2017, 9, 1497. [Google Scholar] [CrossRef]

- Fawcett, S.E.; Waller, M.A. Supply chain game changers–Mega, nano, and virtual trends–and forces that impede supply chain design (i.e., building a winning team). J. Bus. Logist. 2014, 35, 157–164. [Google Scholar] [CrossRef]

- Brockhaus, S.; Kersten, W.; Knemeyer, A.M. Where do we go from here? Progressing sustainability implementation efforts across supply chains. J. Bus. Logist. 2013, 34, 167–182. [Google Scholar] [CrossRef]

- Turki, S.; Didukh, S.; Sauvey, C.; Rezg, N. Optimization and Analysis of a Manufacturing–Remanufacturing–Transport–Warehousing System within a Closed-Loop Supply Chain. Sustainability 2017, 9, 561. [Google Scholar] [CrossRef]

- Carter, C.R.; Easton, P.L. Sustainable supply chain management: Evolution and future directions. Int. J. Phys. Distrib. Logist. Manag. 2011, 41, 46–62. [Google Scholar] [CrossRef]

- García-Arca, J.; González-Portela Garrido, A.T.; Prado-Prado, J.C. Sustainable Packaging Logistics—The link between Sustainability and Competitiveness in Supply Chains. Sustainability 2017, 9, 1098. [Google Scholar] [CrossRef]

- Carter, C.R.; Rogers, D.S. A framework of sustainable supply chain management: Moving toward new theory. Int. J. Phys. Distrib. Logist. Manag. 2008, 38, 360–387. [Google Scholar] [CrossRef]

- Andersen, M.; Skjoett-Larsen, T. Corporate social responsibility in global supply chains. Supply Chain Manag. Int. J. 2009, 14, 77–87. [Google Scholar] [CrossRef]

- Drucker, P. The New Realities; Transaction: Piscataway, NJ, USA, 1989; ISBN 978-0765805331. [Google Scholar]

| Economic Sector | Relative Change 2015 on 1990 |

|---|---|

| Waste | −30.05% |

| Manufacturing Industries and Construction | −4.49% |

| Energy | +4.15% |

| Energy Industries | +5.04% |

| Agriculture | +5.45% |

| Industrial Processes and Product Use | +10.44% |

| Transport | +16.15% |

| 2016 | Assets (mil. Euro) | Revenue (mil. Euro) | EBIT (mil. Euro) | Dividend Volume (mil. Euro) | GHG Emissions Scope 2 (mil. tonnes CO2) | Employment (FTE) | Women in Management (%) |

|---|---|---|---|---|---|---|---|

| DB Schenker | 56,623 | 40,576 | 1946 | 850 | 21,190,000 | 306,368 | 18.7 |

| DHL | 34,738 | 57,334 | 3491 | 1271 | 6,050,000 | 459,262 | 21.1 |

| DSV | 5420 | 9097 | 337 | 44 | 5,128,395 | 44,779 | - |

| Kühne + Nagel | 5810 | 18,341 | 843 | 604 | 190,833 | 85,887 | - |

| La Poste | 20,197 | 23,294 | 1142 | 174 | 1,729,769 | 197,398 | 31.7 |

| Panalpina | 1511 | 4768 | 75 | 59 | 44,722 | 14,572 | 19.0 |

| SNCF | 37,921 | 30,517 | 878 | 126 | 1,277,220 | 193,817 | 21.5 |

| 2006–2016 | Assets (mil. Euro) | Revenue (mil. Euro) | EBIT (mil. Euro) | Dividend Volume (mil. Euro) | GHG Emissions Scope 2 (mil. Tonnes CO2) | Employment (FTE) | Women in Management (%) |

|---|---|---|---|---|---|---|---|

| Min | 1243.02 | 3942.79 | 0 | 0 | 38,200.00 | 13,773.00 | 10.00 |

| Max | 56,623.00 | 60,545.00 | 3491.00 | 1271.00 | 23,400,000.00 | 463,350.00 | 31.70 |

| Arith. Mean | 22,178.36 | 23,814.67 | 973.29 | 293.17 | 4,945,874.49 | 185,674.29 | 16.80 |

| Median | 15,327.00 | 21,341.00 | 757.00 | 171.00 | 1,415,459.92 | 201,339.00 | 18.00 |

| Std. Dev. | 19,328.88 | 16,575.13 | 895.25 | 324.92 | 7,334,053.70 | 147,641.59 | 5.95 |

| Correl. Assets | 1.00 | 0.78 | 0.72 | 0.47 | 0.69 | 0.74 | 0.28 |

| Correl. Revenue | 1.00 | 0.82 | 0.84 | 0.47 | 0.95 | 0.22 | |

| Correl. EBIT | 1.00 | 0.72 | 0.65 | 0.76 | 0.13 | ||

| Correl. Dividend | 1.00 | 0.36 | 0.73 | −0.03 | |||

| Correl. GHG | 1.00 | 0.40 | −0.16 | ||||

| Correl. Employment | 1.00 | 0.38 | |||||

| Correl. Women in M. | 1.00 | ||||||

| Constant Returns to Scale (CRS) | Variable Returns to Scale (VRS) | |

|---|---|---|

| 0% Weighting | (A) | (B) |

| Arithmetic Mean | 97.90% | 99.65% |

| Median | 100.00% | 100.00% |

| Minimum | 63.90% | 82.40% |

| Standard Deviation | 5.99% | 2.12% |

| Share Efficient Units (once) | 100.00% | 100.00% |

| Share Efficient Units (every year) | 42.86% | 71.43% |

| 10% Weighting | (C) | (D) |

| Arithmetic Mean | 85.36% | 98.44% |

| Median | 90.50% | 100.00% |

| Minimum | 43.30% | 62.70% |

| Standard Deviation | 15.83% | 5.74% |

| Share Efficient Units (once) | 57.14% | 100.00% |

| Share Efficient Units (every year) | 28.57% | 57.14% |

| Year | LSP | Malmquist Index | Catch-Up | Frontier Shift | Efficiency Score | Scale |

|---|---|---|---|---|---|---|

| 2006 | DB | 100.00% | Constant | |||

| 2007 | DB | 1.0642 | 1 | 1.0642 | 100.00% | Constant |

| 2008 | DB | 0.9245 | 1 | 0.9245 | 100.00% | Constant |

| 2009 | DB | 0.9058 | 1 | 0.9058 | 100.00% | Constant |

| 2010 | DB | 1.1045 | 1 | 1.1045 | 100.00% | Constant |

| 2011 | DB | 1.1349 | 1 | 1.1349 | 100.00% | Constant |

| 2012 | DB | 1.0925 | 1 | 1.0925 | 100.00% | Constant |

| 2013 | DB | 0.8929 | 0.9352 | 0.9548 | 93.50% | Decreasing returns |

| 2014 | DB | 0.9384 | 0.9288 | 1.0103 | 86.90% | Decreasing returns |

| 2015 | DB | 0.9216 | 1.0171 | 0.9061 | 88.40% | Decreasing returns |

| 2016 | DB | 1.0964 | 0.9594 | 1.1428 | 84.80% | Decreasing returns |

| 2006 | DHL | 100.00% | Constant | |||

| 2007 | DHL | 1.0228 | 1 | 1.0228 | 100.00% | Constant |

| 2008 | DHL | 0.6888 | 1 | 0.6888 | 100.00% | Constant |

| 2009 | DHL | 1.0465 | 1 | 1.0465 | 100.00% | Constant |

| 2010 | DHL | 1.4049 | 1 | 1.4049 | 100.00% | Constant |

| 2011 | DHL | 1.16 | 1 | 1.16 | 100.00% | Constant |

| 2012 | DHL | 1.0725 | 1 | 1.0725 | 100.00% | Constant |

| 2013 | DHL | 1.0597 | 1 | 1.0597 | 100.00% | Constant |

| 2014 | DHL | 1.0239 | 1 | 1.0239 | 100.00% | Constant |

| 2015 | DHL | 0.9236 | 1 | 0.9236 | 100.00% | Constant |

| 2016 | DHL | 1.2122 | 1 | 1.2122 | 100.00% | Constant |

| 2006 | DSV | 100.00% | Constant | |||

| 2007 | DSV | 1.029 | 1 | 1.029 | 100.00% | Constant |

| 2008 | DSV | 0.9377 | 1 | 0.9377 | 100.00% | Constant |

| 2009 | DSV | 0.529 | 0.6271 | 0.8437 | 62.70% | Increasing returns |

| 2010 | DSV | 1.6438 | 1.5947 | 1.0308 | 100.00% | Constant |

| 2011 | DSV | 0.9654 | 0.9026 | 1.0696 | 90.30% | Increasing returns |

| 2012 | DSV | 1.0144 | 1.1079 | 0.9156 | 100.00% | Constant |

| 2013 | DSV | 1.0186 | 1 | 1.0186 | 100.00% | Constant |

| 2014 | DSV | 0.9487 | 0.9944 | 0.954 | 99.40% | Increasing returns |

| 2015 | DSV | 1.0627 | 1.0056 | 1.0568 | 100.00% | Constant |

| 2016 | DSV | 0.8064 | 0.7444 | 1.0832 | 74.40% | Increasing returns |

| 2006 | KUEHNE | 100.00% | Constant | |||

| 2007 | KUEHNE | 1.155 | 1 | 1.155 | 100.00% | Constant |

| 2008 | KUEHNE | 1.7006 | 1 | 1.7006 | 100.00% | Constant |

| 2009 | KUEHNE | 0.738 | 1 | 0.738 | 100.00% | Constant |

| 2010 | KUEHNE | 1.0783 | 1 | 1.0783 | 100.00% | Constant |

| 2011 | KUEHNE | 1.2722 | 1 | 1.2722 | 100.00% | Constant |

| 2012 | KUEHNE | 1.0567 | 1 | 1.0567 | 100.00% | Constant |

| 2013 | KUEHNE | 1.0243 | 1 | 1.0243 | 100.00% | Constant |

| 2014 | KUEHNE | 1.2351 | 1 | 1.2351 | 100.00% | Constant |

| 2015 | KUEHNE | 1.1518 | 1 | 1.1518 | 100.00% | Constant |

| 2016 | KUEHNE | 0.9393 | 1 | 0.9393 | 100.00% | Constant |

| 2006 | La Poste | 100.00% | Constant | |||

| 2007 | La Poste | 1.0634 | 1 | 1.0634 | 100.00% | Constant |

| 2008 | La Poste | 1.0069 | 1 | 1.0069 | 100.00% | Constant |

| 2009 | La Poste | 0.9493 | 1 | 0.9493 | 100.00% | Constant |

| 2010 | La Poste | 0.9683 | 1 | 0.9683 | 100.00% | Constant |

| 2011 | La Poste | 0.9715 | 1 | 0.9715 | 100.00% | Constant |

| 2012 | La Poste | 1.0107 | 1 | 1.0107 | 100.00% | Constant |

| 2013 | La Poste | 1.0764 | 1 | 1.0764 | 100.00% | Constant |

| 2014 | La Poste | 1.0736 | 1 | 1.0736 | 100.00% | Constant |

| 2015 | La Poste | 0.7933 | 1 | 0.7933 | 100.00% | Constant |

| 2016 | La Poste | 1.001 | 1 | 1.001 | 100.00% | Constant |

| 2006 | PANALPINA | 100.00% | Constant | |||

| 2007 | PANALPINA | 1.1658 | 1 | 1.1658 | 100.00% | Constant |

| 2008 | PANALPINA | 1 | 1 | 1 | 100.00% | Constant |

| 2009 | PANALPINA | 0.5305 | 1 | 0.5305 | 100.00% | Constant |

| 2010 | PANALPINA | 0.9968 | 1 | 0.9968 | 100.00% | Constant |

| 2011 | PANALPINA | 2.6185 | 1 | 2.6185 | 100.00% | Constant |

| 2012 | PANALPINA | 1 | 1 | 1 | 100.00% | Constant |

| 2013 | PANALPINA | 1 | 1 | 1 | 100.00% | Constant |

| 2014 | PANALPINA | 1 | 1 | 1 | 100.00% | Constant |

| 2015 | PANALPINA | 1 | 1 | 1 | 100.00% | Constant |

| 2016 | PANALPINA | 0.9533 | 1 | 0.9533 | 100.00% | Constant |

| 2006 | SNCF | 100.00% | Constant | |||

| 2007 | SNCF | 1.1725 | 1 | 1.1725 | 100.00% | Constant |

| 2008 | SNCF | 0.9461 | 1 | 0.9461 | 100.00% | Constant |

| 2009 | SNCF | 0.8843 | 1 | 0.8843 | 100.00% | Constant |

| 2010 | SNCF | 1.3105 | 1 | 1.3105 | 100.00% | Constant |

| 2011 | SNCF | 0.7844 | 0.9962 | 0.7874 | 99.60% | Decreasing returns |

| 2012 | SNCF | 1.1592 | 1.0038 | 1.1548 | 100.00% | Constant |

| 2013 | SNCF | 0.9408 | 1 | 0.9408 | 100.00% | Constant |

| 2014 | SNCF | 1.0957 | 1 | 1.0957 | 100.00% | Constant |

| 2015 | SNCF | 0.7838 | 1 | 0.7838 | 100.00% | Constant |

| 2016 | SNCF | 0.984 | 1 | 0.984 | 100.00% | Constant |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Klumpp, M. How to Achieve Supply Chain Sustainability Efficiently? Taming the Triple Bottom Line Split Business Cycle. Sustainability 2018, 10, 397. https://doi.org/10.3390/su10020397

Klumpp M. How to Achieve Supply Chain Sustainability Efficiently? Taming the Triple Bottom Line Split Business Cycle. Sustainability. 2018; 10(2):397. https://doi.org/10.3390/su10020397

Chicago/Turabian StyleKlumpp, Matthias. 2018. "How to Achieve Supply Chain Sustainability Efficiently? Taming the Triple Bottom Line Split Business Cycle" Sustainability 10, no. 2: 397. https://doi.org/10.3390/su10020397