Potential and Realized Absorptive Capacity as Complementary Drivers of Green Product and Process Innovation Performance

Abstract

:1. Introduction

2. Conceptual Framework and Hypotheses

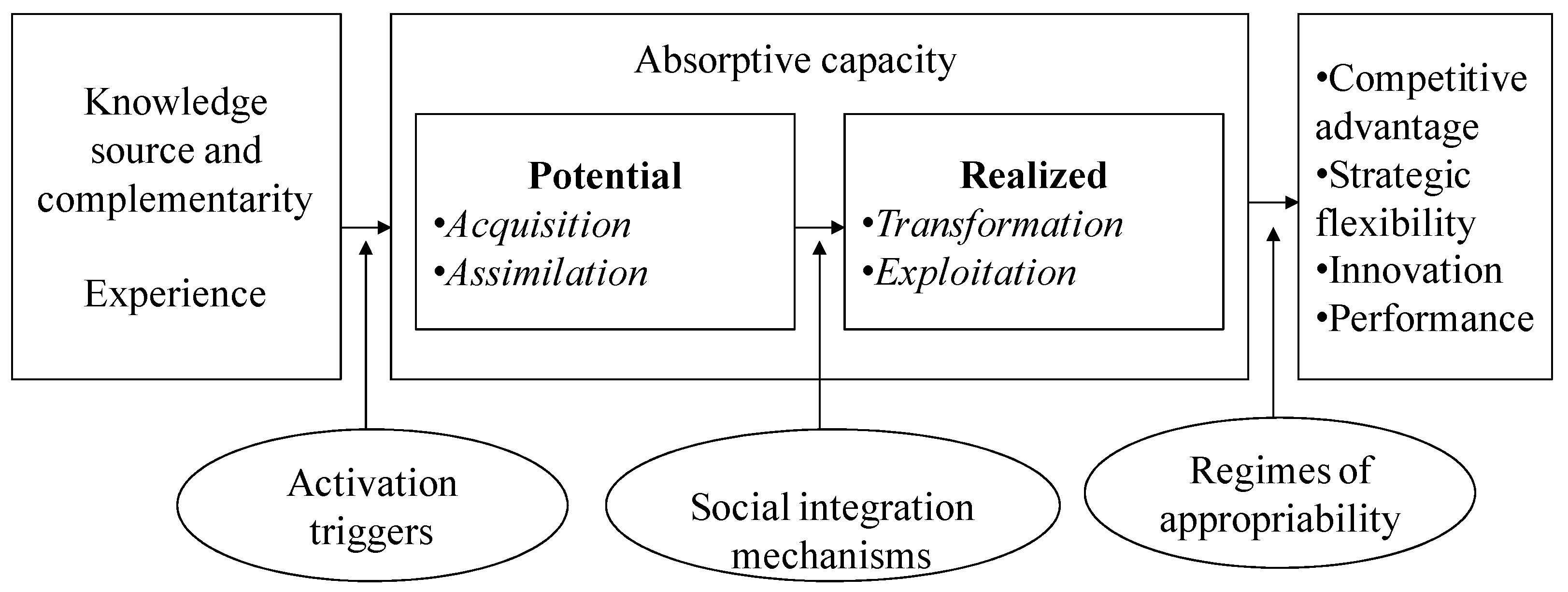

2.1. Absorptive Capacity

2.2. Green Innovation Performance

2.3. The Effects of Absorptive Capacity on the Firm’s Green Product and Process Innovation Performance

2.4. The Mediating Role of Realized in the Potential Absorptive Capacity-Green Innovation Performance Link

3. Method

3.1. Sample and Measures

3.2. Measures

3.3. Data Analysis

4. Results

4.1. Evaluation of Global Model Fit

4.2. Measurement Model

4.3. Structural Model

4.4. Additional Interaction Analysis

5. Discussion

5.1. Theoretical Contribution

5.2. Managerial Implications

5.3. Limitations and Future Research

Acknowledgments

Author Contributions

Conflicts of Interest

Appendix A

- Absorptive CapacityPotential absorptive capacity (PACAP) (1 = completely disagree and 7 = completely agree)In my organization:

- We have frequent interactions with top management to acquire new knowledge.

- Employees regularly visit other units or project teams.

- We collect information through informal means (e.g., lunches with colleagues, friends, and chats with partners).

- Members do not visit other units or project teams (reverse).

- We periodically organize special meetings with clients, suppliers, or third parties to acquire new knowledge.

- Members meet regularly with external professionals, such as advisers, managers, or consultants.

- We are slow to recognize shifts in our market (competitors, laws, demographic changes, etc.) (reverse).

- New opportunities to serve our clients are quickly understood.

- We quickly analyze and interpret changing client demands.

Realized absorptive capacity (RACAP) (1 = completely disagree and 7 = completely agree)In my organization:- We regularly consider the consequences of changing market demands, in terms of new ways to provide services.

- Employees record and store newly acquired knowledge for future reference.

- We quickly recognize the usefulness of new external knowledge for existing knowledge.

- Employees hardly share practical experiences (reverse).

- We laboriously grasp opportunities for our unit from new external knowledge (reverse).

- We periodically meet to discuss the consequences of market trends and new service development.

- It is clearly known how activities within our unit should be performed.

- Clients’ complaints fall on deaf ears in our unit (reverse).

- We have a clear division of roles and responsibilities.

- We constantly consider how to better exploit knowledge.

- We have difficulty implementing new services (reverse).

- Employees have a common language regarding our services.

- Green product innovation performance (GIPr) (1 = high disagreement and 7 = high agreement)

- My company chooses the materials of the product that produce the least amount of pollution for conducting product development or design.

- My company chooses the materials of their products that consume the least amount of energy and resources for conducting product development or design.

- My company uses the least amount of materials to comprise their products for conducting the product development or design.

- My company circumspectly evaluates whether their products are easy to recycle, reuse, and decompose when conducting the product development or design.

- Green process innovation performance (GIPc) (1 = high disagreement and 7 = high agreement)

- The manufacturing process of the company effectively reduces the emission of hazardous substances or wastes.

- The manufacturing process of my company effectively recycles wastes and emission that can be treated and re-used.

- The manufacturing process of my company effectively reduces the consumption of water, electricity, coal, or oil.

- The manufacturing process of my company effectively reduces the use of raw materials.

References

- Leal-Millán, A.; Peris-Ortiz, M.; Leal-Rodríguez, A.L. The Route Towards Sustainable Innovation and Entrepreneurship: An Overview. In Sustainability in Innovation and Entrepreneurship; Springer: Cham, Switzerland, 2017; pp. 1–9. [Google Scholar]

- Albort-Morant, G.; Leal-Millán, A.; Cepeda-Carrión, G. The antecedents of green innovation performance: A model of learning and capabilities. J. Bus. Res. 2016, 69, 4912–4917. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Henseler, J.; Leal-Millán, A.; Cepeda-Carrión, G. Mapping the Field: A Bibliometric Analysis of Green Innovation. Sustainability 2017, 9, 1011. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Ariza-Montes, A.J.; Morales-Fernández, E.; Albort-Morant, G. Green innovation, indeed a cornerstone in linking market requests and business performance. Evidence from the Spanish automotive components industry. Technol. Forecast. Soc. Chang. 2017. [Google Scholar] [CrossRef]

- Chen, Y.S.; Chang, C.H.; Lin, Y.H. The Determinants of green radical and incremental innovation performance: Green shared vision, green absorptive capacity, and green organizational ambidexterity. Sustainability 2014, 6, 7787–7806. [Google Scholar] [CrossRef]

- Buhl, A.; Blazejewski, S.; Dittmer, F. The More, the Merrier: Why and How Employee-Driven Eco-Innovation Enhances Environmental and Competitive Advantage. Sustainability 2016, 8, 946. [Google Scholar] [CrossRef]

- Lai, S.B.; Wen, C.T.; Chen, Y.S. The exploration of the relationship between the environmental pressure and the corporate competitive advantage. In Proceedings of the 2003 CSMOT Academic Conference, National Chiao Tung University, Hsin-Chu, Taiwan, 22 September 2003. [Google Scholar]

- Chen, Y.S.; Lai, S.B.; Wen, C.T. The influence of green innovation performance on corporate advantage in Taiwan. J. Bus. Ethics 2006, 67, 331–339. [Google Scholar] [CrossRef]

- Fosfuri, A.; Tribó, J.A. Exploring the antecedents of potential absorptive capacity and its impact on innovation performance. Omega 2008, 36, 173–187. [Google Scholar] [CrossRef] [Green Version]

- Tsai, W. Knowledge transfer in intraorganizational networks: Effects of network position and absorptive capacity on business unit innovation and performance. Acad. Manag. J. 2001, 44, 996–1004. [Google Scholar] [CrossRef]

- Delmas, M.; Hoffmann, V.H.; Kuss, M. Under the tip of the iceberg: Absorptive capacity, environmental strategy, and competitive advantage. Bus. Soc. 2011, 50, 116–154. [Google Scholar] [CrossRef]

- Cohen, W.M.; Levinthal, D.A. Absorptive capacity: A new perspective on learning and innovation. Adm. Sci. Q. 1990, 35, 128–152. [Google Scholar] [CrossRef]

- Hashim, R.; Bock, A.J.; Cooper, S. The Relationship between Absorptive Capacity and Green Innovation. World Academy of Science, Engineering and Technology. Int. J. Ind. Manuf. Eng. 2015, 9, 1065–1072. [Google Scholar]

- Zahra, S.A.; George, G. Absorptive capacity: A review, reconceptualization, and extension. Acad. Manag. Rev. 2002, 27, 185–203. [Google Scholar]

- Lane, P.J.; Koka, B.R.; Pathak, S. The reification of absorptive capacity: A critical review and rejuvenation of the construct. Acad. Manag. Rev. 2006, 31, 833–863. [Google Scholar] [CrossRef]

- Setia, P.; Patel, P.C. How information systems help create OM capabilities: Consequents and antecedents of operational absorptive capacity. J. Oper. Manag. 2013, 31, 409–431. [Google Scholar] [CrossRef]

- Auguste, M.S.C.; Jashapara, A.; Bernroider, E. Exploring the Perceived Influence of New Knowledge on Absorptive Capacity in a Public Sector Organisation; José-Rodrigo Córdoba School of Management, Royal Holloway University of London: London, UK, 2010; p. 6. [Google Scholar]

- Noblet, J.P.; Simon, E.; Parent, R. Absorptive capacity: A proposed operationalization. Knowl. Manag. Res. Pract. 2011, 9, 367–377. [Google Scholar] [CrossRef] [Green Version]

- Mariano, S.; Walter, C. The construct of absorptive capacity in knowledge management and intellectual capital research: Content and text analyses. J. Knowl. Manag. 2015, 19, 372–400. [Google Scholar] [CrossRef]

- Bhupendra, K.V.; Sangle, S. What drives successful implementation of pollution prevention and cleaner technology strategy? The role of innovative capability. J. Environ. Manag. 2015, 155, 184–192. [Google Scholar] [CrossRef] [PubMed]

- Gabler, C.B.; Richey, R.G., Jr.; Rapp, A. Developing an eco-capability through environmental orientation and organizational innovativeness. Ind. Mark. Manag. 2015, 45, 151–161. [Google Scholar] [CrossRef]

- Castiaux, A. Developing dynamic capabilities to meet sustainable development challenges. Int. J. Innov. Manag. 2012, 16, 1240013. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sinkovics, R.R. The use of partial least squares path modeling in international marketing. In New Challenges to International Marketing; Emerald Group Publishing Limited: Bingley, UK, 2009; pp. 277–319. [Google Scholar]

- Kim, L. The dynamics of Samsung’s technological learning in semiconductors. Calif. Manag. Rev. 1997, 39, 86–100. [Google Scholar] [CrossRef]

- Kim, L. Imitation to Innovation: The Dynamics of Korea’s Technological Learning; Harvard Business Press: Boston, MA, USA, 1997. [Google Scholar]

- Schiederig, T.; Tietze, F.; Herstatt, C. Green innovation in technology and innovation management—An exploratory literature review. R D Manag. 2012, 42, 180–192. [Google Scholar] [CrossRef]

- Fussler, C.; James, P. A Breakthrough Discipline for Innovation and Sustainability; Pitman Publishing: London, UK, 1996. [Google Scholar]

- Halila, F.; Rundquist, J. The development and market success of eco-innovations: A comparative study of eco-innovations and “other” innovations in Sweden. Eur. J. Innov. Manag. 2011, 14, 278–302. [Google Scholar] [CrossRef]

- Damanpour, F. Organizational innovation: A meta-analysis of effects of determinants and moderators. Acad. Manag. J. 1991, 34, 555–590. [Google Scholar] [CrossRef]

- Porter, M.E. The competitive advantage of nations. Harv. Bus. Rev. 1990, 68, 73–93. [Google Scholar]

- OECD, E. Oslo Manual: Guidelines for Collecting and Interpreting Innovation Data; OECD: Paris, France, 2005. [Google Scholar]

- Kemp, R.; Pearson, P. Final Report MEI Project about Measuring Eco-Innovation; Community Research and Development Information Service: Maastricht, The Netherlands, 2008. [Google Scholar]

- Hart, S.L. A natural-resource-based view of the firm. Acad. Manag. Rev. 1995, 20, 986–1014. [Google Scholar]

- Porter, M.E.; Van der Linde, C. Toward a new conception of the environment-competitiveness relationship. J. Eco. Perspect. 1995, 9, 97–118. [Google Scholar] [CrossRef]

- Chang, C.H. The influence of corporate environmental ethics on competitive advantage: The mediation role of green innovation. J. Bus. Ethics 2011, 104, 361–370. [Google Scholar] [CrossRef]

- Leal-Millán, A.; Roldán, J.L.; Leal-Rodríguez, A.L.; Ortega-Gutiérrez, J. IT and relationship learning in networks as drivers of green innovation and customer capital: Evidence from the automobile sector. J. Knowl. Manag. 2016, 20, 444–464. [Google Scholar] [CrossRef]

- Klassen, R.D.; Whybark, D.C. The impact of environmental technologies on manufacturing performance. Acad. Manag. J. 1999, 42, 599–615. [Google Scholar] [CrossRef]

- Tseng, M.L.; Huang, F.H.; Chiu, A.S. Performance drivers of green innovation under incomplete information. Procedia Soc. Behav. Sci. 2012, 40, 234–250. [Google Scholar] [CrossRef]

- Chen, Y.S. The driver of green innovation and green image–green core competence. J. Bus. Ethics 2008, 81, 531–543. [Google Scholar] [CrossRef]

- Fiol, C.M. Squeezing harder doesn’t always work: Continuing the search for consistency in innovation research. Acad. Manag. Rev. 1996, 21, 1012–1021. [Google Scholar] [CrossRef]

- Lane, P.J.; Lubatkin, M. Relative absorptive capacity and interorganizational learning. Strateg. Manag. J. 1998, 19, 461–477. [Google Scholar] [CrossRef]

- Cepeda-Carrión, G.; Gabriel Cegarra-Navarro, J.; Leal-Millán, A.G. Finding the hospital-in-the-home units’ innovativeness. Manag. Decis. 2012, 50, 1596–1617. [Google Scholar] [CrossRef]

- Barney, J. Firm resources and sustained competitive advantage. J. Manag. 1991, 17, 99–120. [Google Scholar] [CrossRef]

- Beckenbach, F.; Daskalakis, M. Invention and Innovation as Creative Problem-Solving Activities; Springer: New York, NY, USA, 2013; pp. 1118–1131. [Google Scholar]

- Nonaka, I.; Takeuchi, H. The Knowledge-Creating Company: How Japanese Companies Create the Dynamics of Innovation; Oxford University Press: Oxford, UK, 1995. [Google Scholar]

- Van Den Bosch, F.A.; Van Wijk, R.; Volberda, H.W. Absorptive capacity: Antecedents, models and outcomes. In Handbook of Organizational Learning and Knowledge Management; Blackwell: Hoboken, NJ, USA, 2003. [Google Scholar]

- Lichtenthaler, U. Absorptive capacity, environmental turbulence, and the complementarity of organizational learning processes. Acad. Manag. J. 2009, 52, 822–846. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Roldán, J.L.; Ariza-Montes, J.A.; Leal-Millán, A. From potential absorptive capacity to innovation outcomes in project teams: The conditional mediating role of the realized absorptive capacity in a relational learning context. Int. J. Proj. Manag. 2014, 32, 894–907. [Google Scholar] [CrossRef]

- Gluch, P.; Gustafsson, M.; Thuvander, L. An absorptive capacity model for green innovation and performance in the construction industry. Constr. Manag. Econ. 2009, 27, 451–464. [Google Scholar] [CrossRef]

- Chen, Y.S.; Lin, Y.H.; Lin, C.Y.; Chang, C.W. Enhancing green absorptive capacity, green dynamic capacities and green service innovation to improve firm performance: An analysis of structural equation modeling (SEM). Sustainability 2015, 7, 15674–15692. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Roldán, J.L.; Leal, A.G.; Ortega-Gutiérrez, J. Knowledge management, relational learning, and the effectiveness of innovation outcomes. Serv. Ind. J. 2013, 33, 1294–1311. [Google Scholar] [CrossRef]

- Leal-Rodríguez, A.L.; Ariza-Montes, J.A.; Roldán, J.L.; Leal-Millán, A.G. Absorptive capacity, innovation and cultural barriers: A conditional mediation model. J. Bus. Res. 2014, 67, 763–768. [Google Scholar] [CrossRef]

- Limaj, E.; Bernroider, E.W. The roles of absorptive capacity and cultural balance for exploratory and exploitative innovation in SMEs. J. Bus. Res. 2017, in press. [Google Scholar] [CrossRef]

- Bower, J.L.; Christensen, C.M. Disruptive technologies: Catching the wave. Harv. Bus. Rev. 1995, 73, 43–53. [Google Scholar]

- Ali, M.; Ali, I.; Al-Maimani, K.A.; Park, K. The effect of organizational structure on absorptive capacity in single and dual learning modes. J. Innov. Knowl. 2017, in press. [Google Scholar] [CrossRef]

- Lee, C.Y.; Wu, F.C. Factors affecting knowledge transfer and absorptive capacity in multinational corporations. J. Int. Manag. Stud. 2010, 5, 118–126. [Google Scholar]

- Yu, Y.; Dong, X.Y.; Shen, K.N.; Khalifa, M.; Hao, J.X. Strategies, Technologies, and Organizational Learning for Developing Organizational Innovativeness in Emerging Economies. J. Bus. Res. 2013, 66, 2507–2514. [Google Scholar] [CrossRef]

- Sernauto. Annual Memory 2016. 2016. Available online: http://www.sernauto.es/images/memorias_sernauto/2016/ (accessed on 18 April 2016).

- Gerrard, J.; Kandlikar, M. Is European end-of-life vehicle legislation living up to expectations? Assessing the impact of the ELV Directive on ‘green’innovation and vehicle recovery. J. Clean. Prod. 2007, 15, 17–27. [Google Scholar] [CrossRef]

- Jansen, J.J.; Van Den Bosch, F.A.; Volberda, H.W. Managing potential and realized absorptive capacity: How do organizational antecedents matter? Acad. Manag. J. 2005, 48, 999–1015. [Google Scholar] [CrossRef]

- Rigdon, E.E. Choosing PLS path modeling as analytical method in European management research: A realist perspective. Eur. Manag. J. 2016, 34, 598–605. [Google Scholar] [CrossRef]

- Henseler, J.; Dijkstra, T.K. ADANCO 2.0. Composite Modeling, Kleve. 2015. Available online: www.compositemodeling.com (accessed on 14 December 2015).

- Henseler, J.; Hubona, G.; Ray, P.A. Using PLS path modeling in new technology research: Updated guidelines. Ind. Manag. Data Syst. 2016, 116, 2–20. [Google Scholar] [CrossRef]

- Henseler, J. Adanco 2.0.1. User Manual; Composite Modeling GmbH & Co.: KG, Kleve, Germany, 2017. [Google Scholar]

- Hu, L.T.; Bentler, P.M. Fit indices in covariance structure modeling: Sensitivity to underparameterized model misspecification. Psychol. Methods 1998, 3, 424–453. [Google Scholar] [CrossRef]

- Henseler, J.; Ringle, C.M.; Sarstedt, M. A new criterion for assessing discriminant validity in variance-based structural equation modeling. J. Acad. Mark. Sci. 2015, 43, 115–135. [Google Scholar] [CrossRef]

- Hair, J., Jr.; Sarstedt, M.; Hopkins, L.; Kuppelwieser, V. Partial least squares structural equation modeling (PLS-SEM) An emerging tool in business research. Eur. Bus. Rev. 2014, 26, 106–121. [Google Scholar] [CrossRef]

- Chin, W.W. How to write up and report PLS analyses. In Handbook of Partial Least Squares; Springer: Berlin/Heidelberg, Germany, 2010; pp. 655–690. [Google Scholar]

- Nitzl, C.; Roldán, J.L.; Cepeda-Carrión, G. Mediation Analysis in Partial Least Squares Path Modeling: Helping Researchers Discuss More Sophisticated Models. Ind. Manag. Data Syst. 2016, 116, 1849–1864. [Google Scholar] [CrossRef]

- Henseler, J. Partial least squares path modeling: Quo vadis? Qual. Quant. 2018. [Google Scholar] [CrossRef]

- Todorova, G.; Durisin, B. Absorptive capacity: Valuing a reconceptualization. Acad. Manag. Rev. 2007, 32, 774–786. [Google Scholar] [CrossRef]

- Fassott, G.; Henseler, J.; Coelho, P.S. Testing moderating effects in PLS path models with composite variables. Ind. Manag. Data Syst. 2016, 116, 1887–1900. [Google Scholar] [CrossRef]

- Henseler, J.; Fassott, G. Testing Moderating Effects in PLS Path Models: An Illustration of Available Procedures. In Handbook of Partial Least Squares; Springer: Berlin/Heidelberg, Germany, 2010; pp. 713–735. [Google Scholar]

- Leal-Rodríguez, A.L.; Albort-Morant, G. Capacidad de absorción del conocimiento y resultados de la innovación: Un estudio empírico en empresas españolas del sector de la automoción. Universitas: Gestão e TI. 2015, 5. [Google Scholar] [CrossRef]

- Martelo-Landroguez, S.; Albort-Morant, G.; Leal-Rodríguez, A.L.; Ribeiro-Soriano, B. The Effect of Absorptive Capacity on Green Customer Capital under an Organizational Unlearning Context. Sustainability 2018, 10, 265. [Google Scholar] [CrossRef]

- Albort-Morant, G.; Leal-RodrÞguez, A.L.; De Marchi, V. Absorptive Capacity and Relationship Learning Mechanisms as Complementary Drivers of Green Innovation Performance. J. Knowl. Manag. 2018, 22, 432–452. [Google Scholar]

- Srivastava, S.K. Green supply-chain management: A state-of-the-art literature review. Int. J. Manag. Rev. 2007, 9, 53–80. [Google Scholar] [CrossRef]

| Value | HI95 | HI99 | |

|---|---|---|---|

| SRMR | 0.059 | 0.056 | 0.063 |

| dULS | 1.516 | 1.364 | 1.730 |

| dG | 1.858 | 2.168 | 2.636 |

| Construct/Indicator | Outer Loadings | Rho (Pa) | Cronbach’s Alpha(α) | AVE |

|---|---|---|---|---|

| Potential Absorptive capacity (PACAP) | 0.9588 | 0.9490 | 0.7571 | |

| We have frequent interactions with top management to acquire new knowledge | 0.9842 | |||

| Employees regularly visit other units or project teams | 0.8580 | |||

| We collect information through informal means | 0.6071 | |||

| Members do not visit other units or project teams (R) | 0.8678 | |||

| We periodically organize special meetings with clients, suppliers, or third parties to acquire new knowledge | 0.9144 | |||

| Members meet regularly with external professionals, such as advisers, managers, or consultants | 0.9380 | |||

| Realized Absorptive capacity (RACAP) | 0.9630 | 0.9575 | 0.7183 | |

| We regularly consider the consequences of changing market demands, in terms of new ways to provide service | 0.9349 | |||

| We quickly recognize the usefulness of new external knowledge for existing knowledge | 0.8045 | |||

| Employees hardly share practical experiences (R) | 0.9010 | |||

| We laboriously grasp opportunities for our unit from new external knowledge (R) | 0.7441 | |||

| We periodically meet to discuss the consequences of market trends and new service development | 0.9872 | |||

| It is clearly known how activities within our unit should be performed | 0.8984 | |||

| We have a clear division of roles and responsibilities | 0.6750 | |||

| We constantly consider how to better exploit knowledge | 0.8422 | |||

| We have difficulties implementing new services (R) | 0.7947 | |||

| Green Product Innovation Performance (GIPr) | 0.9364 | 0.9289 | 0.8174 | |

| My company chooses the materials of their products that produce the least amount of pollution for conducting product development or design | 0.9868 | |||

| My company chooses the materials of their products that consume the least amount of energy and resources for conducting product development or design | 0.8794 | |||

| My company uses the least amount of materials to comprise their products when conducting product development or design | 0.8398 | |||

| Green Process Innovation Performance (GIPc) | 0.9284 | 0.9250 | 0.7546 | |

| The manufacturing process of the company effectively reduces the emission of hazardous substances or wastes | 0.9313 | |||

| The manufacturing process of my company effectively recycles wastes and emission that can be treated and re-used | 0.8040 | |||

| The manufacturing process of my company effectively reduces the consumption of water, electricity, coal, or oil | 0.9159 | |||

| The manufacturing process of my company effectively reduces the use of raw materials | 0.8159 | |||

| Heterotrait-Monotrait Ratio (HTMT) | ||||

|---|---|---|---|---|

| GIPr | GIPc | PACAP | RACAP | |

| GIPr | ||||

| GIPc | 1.0028 | |||

| PACAP | 0.1905 | 0.2125 | ||

| RACAP | 0.4418 | 0.5123 | 0.2691 | |

| Direct Effects on Endogenous Constructs | Path Coefficient | t-Value | p-Value | 95% BCCI | Support |

| RACAP → GIP Product (R2 = 0.2389) | 0.4703 *** | 5.7430 | 0.0000 | [0.3199; 0.6392] | Yes |

| RACAP → GIP Process (R2 = 0.1791)) | 0.3972 *** | 4.5240 | 0.0000 | [0.2344; 0.5720] | Yes |

| PACAP → RACAP (R2 = 0.0727) | 0.2697 ** | 2.3727 | 0.0089 | [0.0664; 0.5005] | Yes |

| Indirect Effects on Endogenous Constructs | Path Coefficient | t-Value | p-Value | 95% BCCI | Support |

| PACAP → GIP Product (R2 = 0.2389) | 0.1268 * | 2.0550 | 0.0201 | [0.0295; 0.2675] | Yes |

| PACAP → GIP Process (R2 = 0.1791) | 0.1071 * | 1.8419 | 0.0329 | [0.0231; 0.2431] | Yes |

| Direct Effects on Endogenous Constructs | Path Coefficient | t-Value | p-Value | 95% BCCI |

| RACAP → GIPr (R2 = 0.2316) | 0.4934 | 6.8486 | 0.0000 | [0.3600; 0.6369] |

| RACAP → GIPc (R2 = 0.1767) | 0.4275 | 5.3323 | 0.0000 | [0.2665; 0.5853] |

| Interaction Effects | Path Coefficient | t-Value | p-Value | 95% BCCI |

| PACAP × RACAP → GIPr (R2 = 0.2316) | 0.0902 | 1.2111 | 0.2261 | [−0.0588; 0.2380] |

| PACAP × RACAP → GIPc (R2 = 0.1767) | 0.1273 | 1.5506 | 0.1213 | [−0.0450; 0.2806] |

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Albort-Morant, G.; Henseler, J.; Cepeda-Carrión, G.; Leal-Rodríguez, A.L. Potential and Realized Absorptive Capacity as Complementary Drivers of Green Product and Process Innovation Performance. Sustainability 2018, 10, 381. https://doi.org/10.3390/su10020381

Albort-Morant G, Henseler J, Cepeda-Carrión G, Leal-Rodríguez AL. Potential and Realized Absorptive Capacity as Complementary Drivers of Green Product and Process Innovation Performance. Sustainability. 2018; 10(2):381. https://doi.org/10.3390/su10020381

Chicago/Turabian StyleAlbort-Morant, Gema, Jörg Henseler, Gabriel Cepeda-Carrión, and Antonio L. Leal-Rodríguez. 2018. "Potential and Realized Absorptive Capacity as Complementary Drivers of Green Product and Process Innovation Performance" Sustainability 10, no. 2: 381. https://doi.org/10.3390/su10020381