Soft Asphalt and Double Otta Seal—Self-Healing Sustainable Techniques for Low-Volume Gravel Road Rehabilitation

Abstract

:1. Introduction

2. Test Road Sections

2.1. Soft Asphalt

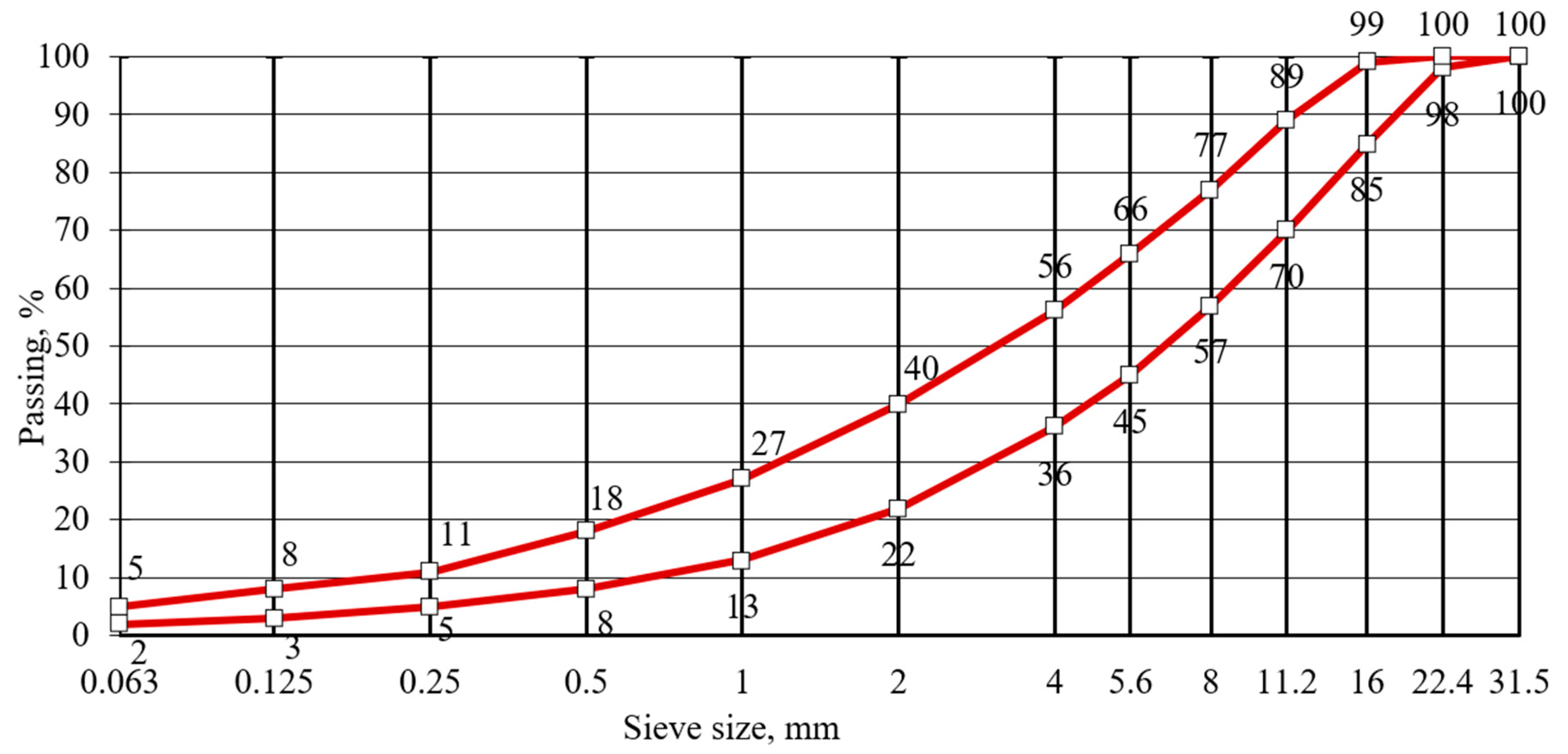

2.2. Double Otta Seal

3. Research Methodology

4. Results and Discussion

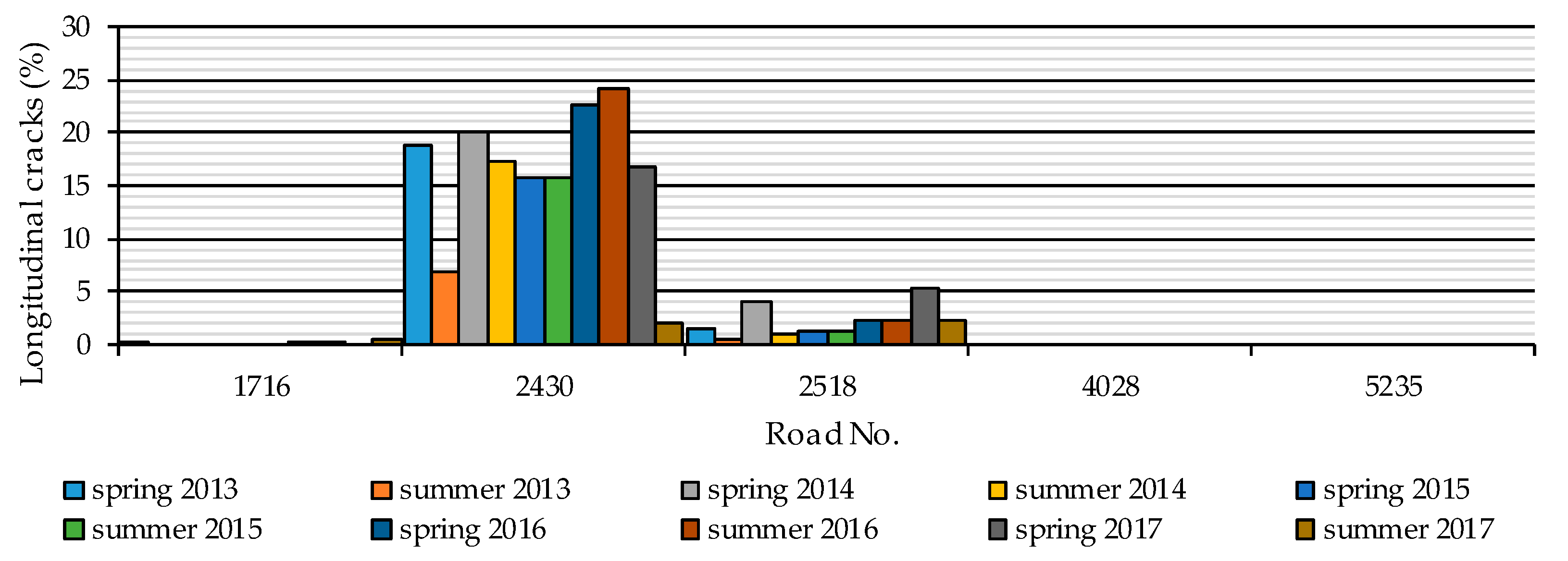

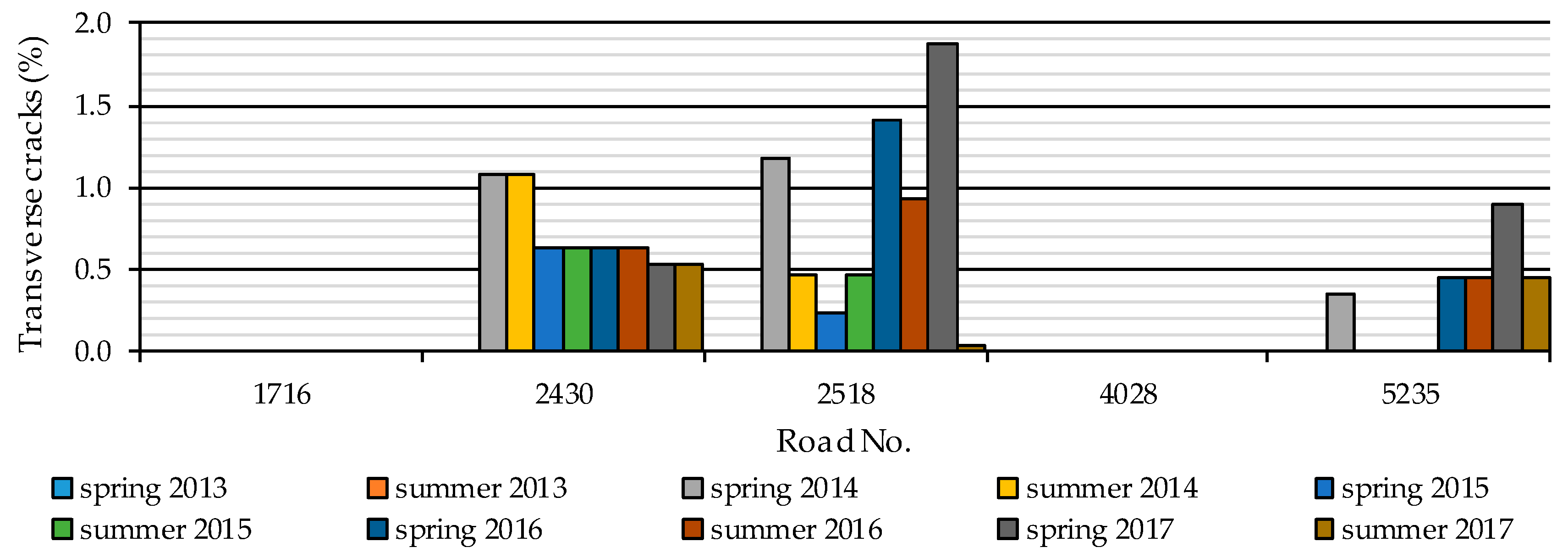

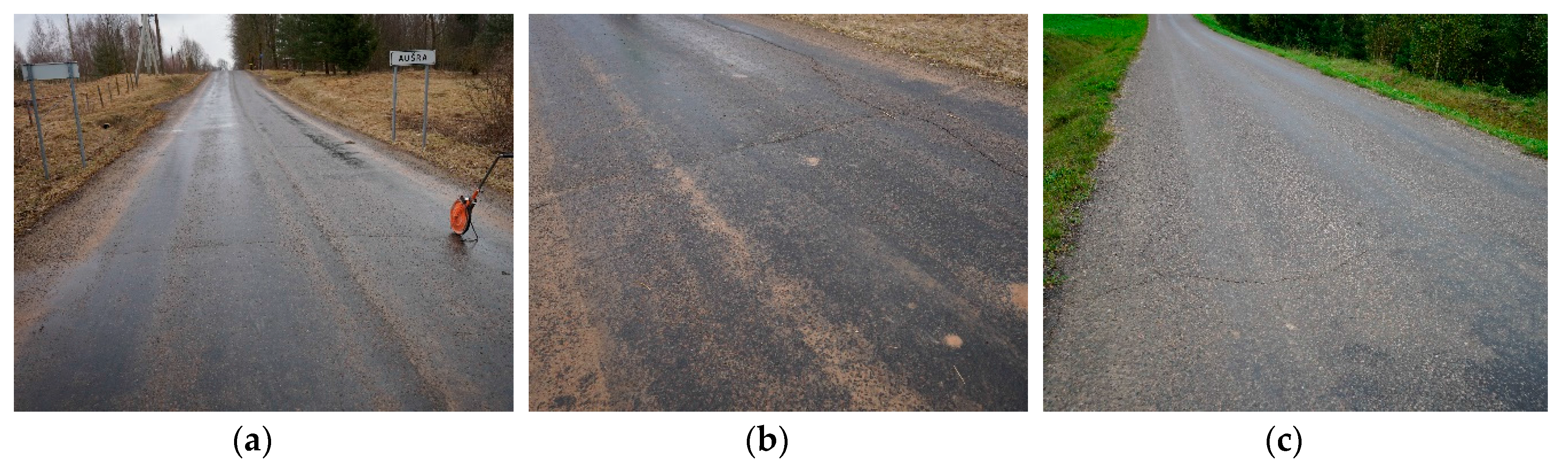

4.1. Soft Asphalt

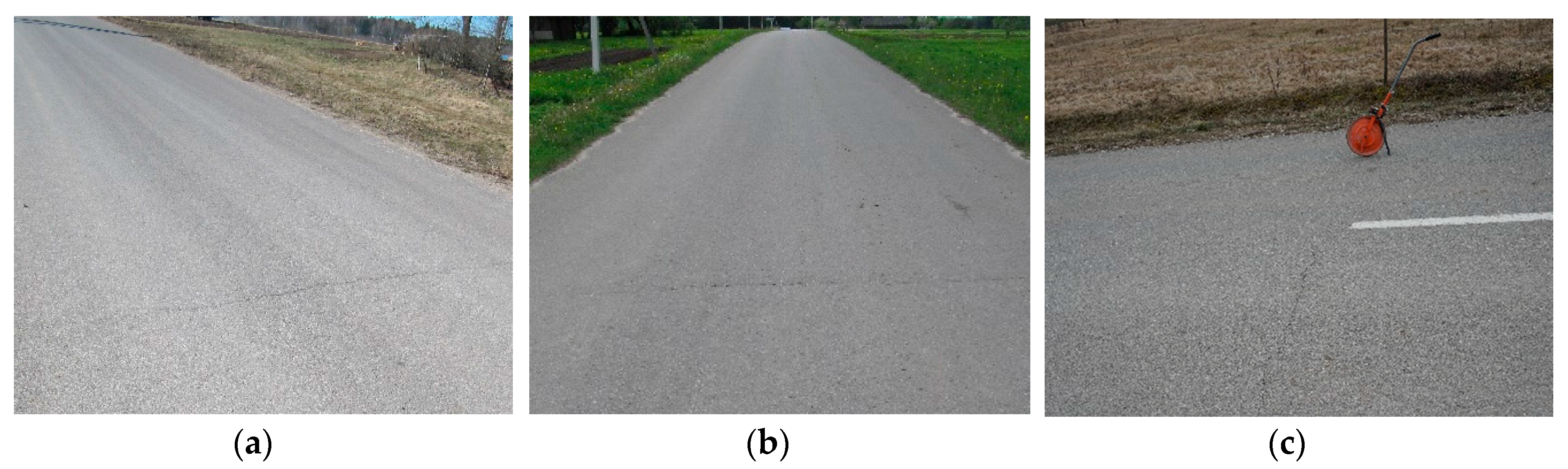

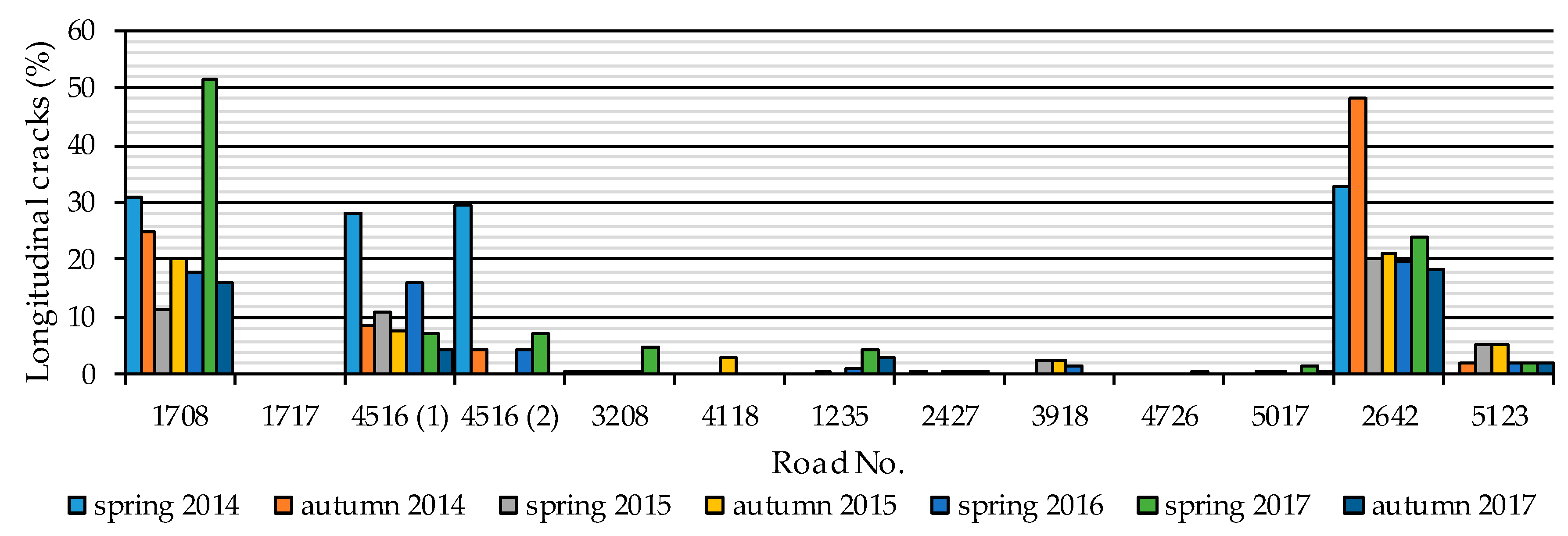

4.2. Double Otta Seal

4.3. Life Cycle Cost

5. Conclusions

- Longitudinal cracking was 10 to 25 times more severe than transverse cracking, depending on the technology (soft asphalt or double Otta Seal) and existing pavement structure composition. An adequate frost resistance of the whole pavement structure and bearing capacity of the base and subgrade (especially during the spring thaw), were vital for satisfactory pavement performance.

- Both technologies were able to self-heal during spring–summer. The healing effect was more than 13% and 19% on roads with soft asphalt and double Otta Seal, respectively. In addition, on some roads, all cracks observed in spring self-healed during summer.

- Three of five roads with soft asphalt (Nos. 1716, 4028, and 5235) and six of 13 roads with double Otta Seal (Nos. 1717, 4118, 2427, 3918, 4726, and 5017) were resistant to both longitudinal and transverse cracking (the average of cracking was less than 1%) independent of both AADT and ESALs. This might be related to the existing pavement structure composition and thickness, since during the design process, neither structure composition nor thickness were considered. Further evaluation and analysis of these factors will be conducted in future research.

Author Contributions

Conflicts of Interest

References

- Jones, T.E. Dust Emission from Unpaved Roads in Kenya; Laboratory Report 1110; Transport and Road Research Laboratory: Crowthome, UK, 1984. [Google Scholar]

- Edvardsson, K. Gravel Roads and Dust Suppression. Road Mater. Pavement 2009, 10, 439–469. [Google Scholar] [CrossRef]

- Behnood, A.; Roshandeh, A.M.; Mannering, F.L. Latent class analysis of the effects of age, gender, and alcohol consumption on driver-injury severities. Anal. Methods Accid. Res. 2014, 3–4, 56–91. [Google Scholar] [CrossRef]

- Monlux, S.; Mitchell, M. Chloride Stabilization of Unpaved Road Aggregate Surfacing. Transp. Res. Rec. J. Transp. Res. Board 2007, 1989, 50–58. [Google Scholar] [CrossRef]

- Addo, J.Q.; Sanders, T.G. Effectiveness and Environmental Impact of Road Dust Suppressants; Mountain-Plains Consortium; U.S. Department of Commerce: Ft. Collins, CO, USA, 1995.

- Thompson, R.J.; Visser, A.T. Selection, performance and economic evaluation of dust palliatives on surface mine haul roads. J. S. Afr. Inst. Min. Metal. 2007, 107, 435–450. [Google Scholar]

- Gottschalk, K. Road Dust: A Survey of Particle Size, Elemental Composition, Human Respiratory Deposition and Clearance Mechanisms; Unpublished Independent Study; Colorado State University: Ft Collins, CO, USA, 1994. [Google Scholar]

- Donaldson, K.; Gilmour, M.I.; MacNee, W. Asthma and PM10. Respir. Res. 2000, 1, 12–15. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Hoover, J.M. Surface Improvement and Dust Palliation of Unpaved Secondary Roads and Streets; Report ISU-ERI-AMES-72316; Engineering Research Institute, Iowa State University: Ames, IA, USA, 1973. [Google Scholar]

- Sanders, T.G.; Addo, J.; Ariniello, J.; Heiden, W. Relative Effectiveness of Road Dust Suppressants. J. Transp. Eng. 1997, 123, 393–397. [Google Scholar] [CrossRef]

- Golden, B. Impact of magnesium chloride dust control product on the environment. In Proceedings of the Transportation Association of Canada Annual Conference, Winnipeg, MB, Canada, 15–16 September 1991; pp. 1–6. [Google Scholar]

- Vorobjovas, V. Assurance of the Function of Low-Volume Roads for the Improvement of Driving Conditions. Balt. J. Road Bridge Eng. 2011, 6, 67–75. [Google Scholar] [CrossRef]

- Roads and Traffic Research Society and Asphalt Roads Working Group. Supplementary Technical Contract Specifications and Guidelines for the Construction of Carriageway Surfacing from Asphalt ZTV Asphalt—StB 2000; Road and Transportation Research Association: Cologne, Germany, 2000.

- Silfwerbrand, J. Swedish Design of Industrial Concrete Pavements. In Proceedings of the 7th International Conference on Concrete Pavements, Orlando, FL, USA, 9–13 September 2001; p. 16. [Google Scholar]

- Swedish National Road Administration. General Technical Construction Specifications for Roads; Chapter 1, Common Prerequisites; Chapter 3, Pavement Design; Chapter 6, Bitumen-Bound Layers; Swedish National Road Administration: Solna, Sweden, 1996. [Google Scholar]

- Joshi, S.G.; Jha, A.K. Otta Seal Experience in Nepal. In Proceedings of the Transportation Research Board 92nd Annual Meeting, Transportation Research Board of the National Academies, Washington, DC, USA, 13–17 January 2013. [Google Scholar]

- Overby, C.; Pinard, M. Development of an Economic and Practical Alternative to Traditional Bituminous Surface Treatments. Transp. Res. Rec. J. Transp. Res. Board 2007, 1989, 226–233. [Google Scholar] [CrossRef]

- Pinard, M.; Obika, B.; Motswagole, K. Developments in Innovative Low-Volume Road Technology in Botswana. Transp. Res. Rec. J. Transp. Res. Board 1999, 1652, 68–75. [Google Scholar] [CrossRef]

- Oloo, S.; Lindsay, R.; Mothilal, S. Otta Seals and Gravseals as Low-Cost Surfacing Alternatives for Low-Volume Roads: Experiences in South Africa. Transp. Res. Rec. J. Transp. Res. Board 2003, 1819, 338–342. [Google Scholar] [CrossRef]

- Johnson, G. Minnesota’s Experience with Thin Bituminous Treatments for Low-Volume Roads. Transp. Res. Rec. J. Transp. Res. Board 2003, 1819, 333–337. [Google Scholar] [CrossRef]

- Waters, J.C. Long-Term Dust Suppression Using the Otta Seal Technique; New Zealand Transport Agency: Wellington, New Zealand, 2009.

- Overby, C.; Pinard, M.I. The Otta Seal Surfacing: A practical and Economic Alternative to Traditional Bituminous Surface Treatments. Transp. Res. Rec. J. Transp. Res. Board 2013, 2349, 136–144. [Google Scholar] [CrossRef]

- Vaitkus, A.; Vorobjovas, V.; Tuminienė, F.; Gražulytė, J. Performance of Soft Asphalt and Double Otta Seal within First Three Years. Adv. Mater. Sci. Eng. 2016, 1–12. [Google Scholar] [CrossRef]

- Perveneckas, Z.; Vaitkus, A.; Vorobjovas, V. Soft Asphalt Pavements—Solution for Low Traffic Volume Roads in Lithuania. In Proceedings of the 28th International Baltic Road Conference, Vilnius, Lithuania, 26–28 August 2013. [Google Scholar]

- Vorobjovas, V.; Andriejauskas, T.; Perveneckas, Z. Selection of Soft Asphalt Pavements for Low-volume roads in Lithuania. In Proceedings of the 9th International Conference on Environmental Engineering, Vilnius, Lithuania, 22–24 May 2014. [Google Scholar]

- Gražulytė, J.; Žilionienė, D.; Tuminienė, F. Otta Seal—The New Way to Solve Problems of Maintenance of Gravel Roads in Lithuania. In Proceedings of the 9th International Conference on Environmental Engineering, Vilnius, Lithuania, 22–24 May 2014. [Google Scholar]

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Vaitkus, A.; Vorobjovas, V.; Tuminienė, F.; Gražulytė, J.; Čygas, D. Soft Asphalt and Double Otta Seal—Self-Healing Sustainable Techniques for Low-Volume Gravel Road Rehabilitation. Sustainability 2018, 10, 198. https://doi.org/10.3390/su10010198

Vaitkus A, Vorobjovas V, Tuminienė F, Gražulytė J, Čygas D. Soft Asphalt and Double Otta Seal—Self-Healing Sustainable Techniques for Low-Volume Gravel Road Rehabilitation. Sustainability. 2018; 10(1):198. https://doi.org/10.3390/su10010198

Chicago/Turabian StyleVaitkus, Audrius, Viktoras Vorobjovas, Faustina Tuminienė, Judita Gražulytė, and Donatas Čygas. 2018. "Soft Asphalt and Double Otta Seal—Self-Healing Sustainable Techniques for Low-Volume Gravel Road Rehabilitation" Sustainability 10, no. 1: 198. https://doi.org/10.3390/su10010198