1. Introduction

Supply chain management (SCM) is a process that controls, coordinates, and integrates the logistics and the flow of information and capital from original suppliers through a series of intermediaries to end customers in a timely manner to improve the performance of all parties involved [

1,

2,

3]. There is a consensus that the successful SCM leads to a range of benefits, including reduced costs and reduced rate of occupying funds, increased market shares and sales, on-time in-full (OTIF) deliveries, and solid customer relations [

4,

5]. However, despite the growing interest among practitioners and researchers in improving firm performance through SCM, there is enough evidence to suggest that achieving SCM success may not be as effective in most cases as we assumed [

6,

7,

8]. For example, Stank, Keller & Daugherty [

9] found no sufficient evidence to support a significant positive relationship between SCM and firms’ performance, and some researchers even found a negative relationship between SCM and performance [

10,

11,

12]. More seriously, the failure of SCM would incur actual negative impacts on the operational continuity and sometimes even threaten the very survival of the firms involved in the supply chain. Quoting the data from Sáenz & Revilla [

13], on average, the percentage of global companies reporting a loss of revenue due to a supply chain failure increased from 28% in 2011 to 42% in 2013. Therefore, how to mitigate and eliminate the negative impacts of supply chain failures in today’s constantly evolving and fiercely competitive business environment and how to achieve ideal cooperation, collaboration, and integration between members in a supply chain to build supply chain resilience [

14,

15] become the first and foremost precondition to its success [

16,

17].

Essentially, SCM is the management or governance of inter-organizational relationships. It is widely acknowledged that without appropriate governance mechanisms, supply chain collaboration is always short-lived and doomed to failure [

18,

19,

20]. Unfortunately, although literature studied supply chain governance from many different perspectives, there are still considerable gaps in the supply chain governance literature [

21,

22]. This paper argues that, first, the current focuses of the supply chain governance literature usually concentrate on specific issues or from the perspectives of single or bilateral parties in supply chain. Very little effort has been made in the existing SCM literature to construct a holistic governance model from the perspective of the whole supply chain. Second, the understanding of “sustainable SCM” in the literature still remains in the arena of natural-social-economic sustainable development (the contextual sustainability), rather than the sustainable development of the supply chain itself (the internal sustainability). Third, although researchers have proposed a few theories or models on supply chain governance, these models usually fall short of proposing systematic and concrete mechanisms for supply chain managers to implement, which largely inhibits their practical applications.

It is these research gaps that shape the main focus and contributions of this paper. To address these gaps, this paper focuses on the research question: how to design a governance model with high adaptability and resilience against uncertainties for the whole supply chain to obtain and sustain an ideal collaboration with improved performance. We will propose a Sustainable Collaborative Governance Framework, detailing the adaptive decision-making and action mechanisms throughout supply chain lifecycle that will enable the whole supply chain proactively and resiliently respond to uncertainties or perturbations without undergoing significant changes to its normal operations. The proposed framework extends the research on “sustainable SCM” from the natural–social–economic sustainable development to a focus on the internal capability of a supply chain to develop itself sustainably. Our research elucidates the characteristics of supply chains’ internal sustainability as dynamic, elastic, holistic, uncertainty-handling and future-oriented, and provides a clear classification scheme reflecting the sustainable lifecycle of a supply chain. The Framework proposes a series of systematic sustainable mechanisms and a functional governance structure of the whole supply chain. We believe the proposed framework provides a concrete tool for supply chain managers to implement appropriate governance structure and different sustainable mechanisms based on different situations with improved adaptability and responsiveness in handling today’s changing business environment.

This paper is structured as follows: we will first analyze current supply chain governance literature that has been mainly focusing on specific issues or from the perspectives of single or bilateral parties in supply chain. We then theorize a Sustainable Collaborative Governance Framework as a holistic governance model depicting the highly adaptable and sustainable interactions between supply chain members across the lifecycle of a supply chain in a dynamic and uncertain environment. We end the paper with a delineation of the contributions of the proposed framework and practical managerial applications built upon from this framework.

2. Governance and Collaborative Governance in Supply Chain

As a widely used concept in many fields, governance can be generally described as a series of regulation and coordination of activities through a variety of formal and/or informal mechanisms based on a specific purpose [

23,

24,

25]. Governance mechanisms may include policies, guidelines, rules, laws, norms, standards, monitoring and verification procedures, financial and other incentives, and the exercise of authority [

26,

27]. For SCM, proper governance mechanisms are critical to the success of the supply chain and have attracted growing academic attention in recent years [

28]. Although significant progress has been made toward understanding supply chain governance, the current focuses of the supply chain governance literature usually concentrate on specific issues or from the perspectives of single or bilateral parties in supply chain. Very little effort has been made in the existing SCM literature to construct a holistic governance model from the perspective of the whole supply chain. For example:

From buyers’ perspectives, Claycomb & Frankwick [

29] studied the governance on buyer–seller relations. By dividing the relationships into four phases of relationship development, they argued that joint problem solving will increase buyer’s uncertainty while conflict resolution decrease buyer’s uncertainty, and buyers should seek suppliers with strong positive reputations. Stanko, Bonner & Calantone [

30] also argued from buyers’ perspective that buyers should engage more in informal interpersonal activities, such as golf, fishing, billiards, dinner and drinks, which contributes to establishing a common understanding, shared values, and emotional ties that in turn improve the collaboration. Similarly, from manufacturer’s perspectives, Vázquez-Casielles, Iglesias & Varela-Neira [

31] studied the role of governance and information sharing based on manufacturer–distributor relationship. They argued that manufacturers should focus on distributors’ willingness to share strategic information with them that contributes to achieving a more effective manufacturer–distributor relationship beyond the contractual market negotiation.

All these researches have concentrated on either a single firm’s perspective or a particular party’s perspective. Despite the escalating importance of SCM and the positive impact it can have on performance, there is a clear tendency that the governance in supply chain is often implemented by a single member mainly based on their arm-length contract. Few companies and practitioners are actually engaged in collaborative governance efforts that promote extensive cooperation or collaboration between members [

32].

Theoretically, a supply chain is not just a “supply” chain, but also a collaboration chain. Supply chain collaboration implies that the interdependent yet autonomous firms are working jointly to achieve overall performance collaboratively [

16,

33]. Collaborative governance contributes to achieve successful collaboration by emphasizing governance through relational means in addition to governance through traditional means (e.g., arm-length contract) [

34,

35]. The current literature on collaborative governance in supply chain extends the governance as implemented by a single member to the bilateral collaborative governance (typically buyer–seller collaborative governance). These dyadic studies made a promising progress towards a more holistic understanding of supply chain governance. For example, based on buyer–seller collaborative governance, Cai, Yang & Hu [

36] examined the effects of four governance mechanisms: legal contract, joint problem solving, joint planning and collaborative communication, on the buyer–seller collaborative relationships. Empirical results showed that the four governance mechanisms, driven by inter-firm dependence, have distinct effects on supplier’s performance and buyer’s commitment. Similarly, by focusing on a good buyer–supplier strategic relationship, Tanskanen & Aminoff [

37] studied the governance mechanisms on how to enhance buyer and supplier attractiveness in order to get the other party to put more effort on the relationship. The results showed that the economic and behavior-based attractiveness existed strongly in the buyer-supplier relationship, while the resource and bridging-based attractiveness are important when the aim is to leverage the buyer-supplier relationship in developing and expanding businesses outside the dyad.

Another stream of research in collaborative governance in supply chain paid attention to the specific issues such as contract, conflict, power and trust. Ellegaard & Andersen [

38] investigated conflicts in buyer–seller collaborations due to conflicting goals. By focusing on the evolution of conflicts, they suggested a preventive mechanism where efforts should be aimed at avoiding conflict escalation into the severe domain, together with joint and interactive resolution tactics such as problem solving, compromising, consensus or activation of commitments necessary for the conflict resolution. Celuch, Bantham & Kasouf [

39] studied the role of trust in buyer–seller conflict management by highlighting the crucial importance of trust in the process of conflict resolution and advancing some useful tactics on how to maintain successful collaborative business relationships. Similarly, Liu et al., [

40] discussed the justice issue in buyer–seller collaborative governance by exploring the role of mutual perceptions of distributive, procedural, interpersonal and informational justice in achieving profitable and stable performance through coupling behaviors of the dyad.

Even though the current literature still fall short of proposing a holistic framework on collaborative governance of a whole supply chain, it should be noted that some recent researches have begun to investigate the specific issues in the whole supply chain, such as measurement and performance [

5], inventory [

41], information distortion [

42], risk mitigation [

43,

44]. However, the complexity of managing modern supply chain requires more researches on the holistic framework of the supply chain cooperation and collaboration, rather than solving some specific issues embedded in the whole supply chain. In this paper, we will focus on the collaborative governance of the whole supply chain by proposing adaptive processes and structures of decision-making and management that engage supply chain members to work collaboratively across their boundaries in order to carry out a common strategic purpose that could not otherwise be accomplished by any single member.

In addition, the understanding of “sustainable SCM” in the literature still remains in the arena of natural-social-economic sustainable development (the contextual sustainability), rather than the sustainable development of the supply chain itself (the internal sustainability). As an important business concern, sustainability in the context of supply chain has attracted significant attention in the past decade [

45,

46,

47]. However, the understanding of “sustainable SCM” in the extant literature usually focuses on how supply chain could contribute to the sustainable development of natural-social-economic environment throughout its lifecycles (so called “Green Supply Chain”) [

48,

49]. For example, Gimenez & Sierra [

48] defined “sustainable SCM” as ‘‘the management of material, information and capital flows as well as cooperation among parties in supply chain while taking goals from all three dimensions of sustainable development, i.e., economic, environmental and social, into account’’. De Brito & Van der Laan [

49] also defined “sustainable SCM” as the strategic, transparent integration and achievement of the supply chain’s social, environmental, and economic goals in its business processes for improving the long-term economic performance. What is missing in this understanding is how a supply chain could develop itself sustainably. In today’s complex and uncertain business environment, the capability of a supply chain to develop itself sustainably with improved performance, resilience and competitiveness should be highlighted as well.

Furthermore, some researchers have proposed a few frameworks or models from dynamic or evolutionary perspectives, such as Contingency Framework, Three-stage process model, SCMM [

50,

51,

52,

53,

54]. Undoubtedly, these frameworks or models made significant contributions to improve the supply chain’s operation in some specific context. For example, Contingency Framework describes supply chain networks as open organizations in an ever-changing environment, and decision-makers must design supply chain networks to be dynamic and flexible through the implementation of the right contingent strategic response in a collaborative manner. Although decision-makers enhanced their contingent response abilities by identifying the environmental driving forces and internal resisting force, the framework did not sketch in detail the strategic development process nor provide specific mechanisms for the governance of the contingent network. In contrast, both Three-stage process model [

54] and SCMM [

50,

51,

52] detailed the development process of the supply chain. The Three Stage process model divided the supply chain development process into unfreeze, transformational, and steady states, which largely adopted Kurt Lewin’s three stage change model [

55], while SCMM categorized the supply chain into four phases: the autonomous phase, the serial dependence phase, the reciprocal dependence phase, and the mutual dependence phase. Although both Three-stage process model and SCMM model mapped the development of a supply chain, they ignored the rapid market evolution and high uncertain business environments from a long term perspective and failed to propose systematic and concrete mechanisms for supply chain managers to implement, which largely inhibited their practical applications.

Acknowledging the contributions made by the existing literature and aiming to address the weaknesses of the literature identified above, this paper will propose a Sustainable Collaborative Governance Framework with adaptive decision-making and action mechanisms throughout the supply chain lifecycle that will enable the whole supply chain proactively respond to uncertainties or perturbations without undergoing significant changes to firms’ normal operations.

3. Sustainable Collaborative Governance in Supply Chain

Undoubtedly, theorizing and practicing collaborative governance are not an easy task [

56,

57]. Though the literature has done extensive work from many different perspectives, there is still a pressing call for an effective program to support a continuous and successful collaboration in the highly uncertain business environment. The Sustainable Collaborative Governance Framework we propose will hopefully address this call. In the following sections, we will first define the concept of “sustainable collaborative governance”, and then we will delineate the scope and the characteristics of the framework, as well as the specific dynamics and mechanisms of the sustainable collaborative governance.

3.1. “Sustainability” and Sustainable Collaborative Governance

Sustainable development of a supply chain entails a high degree of adaptability, responsiveness, and resilience in handling the complexities and uncertainties of today’s business environment. Sustainable governance will act as an effective strategy to deal with challenges and improve competitiveness and the financial performance of a supply chain. The sustainable collaborative governance in supply chain, based on this understanding, could be defined as an adaptive decision-making and action mechanism in a changing business environment guiding the evolution of a supply chain throughout its lifecycle. It enables the collaboration of the whole supply chain to proactively respond to unanticipated or unpredictable incidents, events or perturbations without undergoing significant changes to their normal operations. It could also guide the whole supply chain to evolve from a lower level of sustainable development to a higher level associated with revenue increase, cost reduction, risk reduction, and increased competitiveness.

3.2. Sustainable Collaborative Governance Framework

The theoretical foundation for our conceptualization of the Sustainable Collaborative Governance Framework is the Network theory and Resource-based view on governance [

58,

59,

60]. In essence, the supply chain could be viewed as a single unified entity that creates and delivers values to the end consumer, rather than as a set of fragmented parts, each performing its own function [

3,

61]. In the network context, a supply chain’s value-creating capability stems from the advantage that utilizes the resources of the entire network effectively and efficiently. And this capability also contributes to foster new and inimitable value-creating resources in a virtuous cycle, making supply chain a constantly evolving network with the aim of achieving sustainable competitive advantage. Furthermore, in today’s global environment, global dynamic capability of SCM, characterized by timely response, rapid and flexible strategies, and coordinating mechanisms to effectively re-deploy internal and relational resources [

62], is necessary for the development of global management capabilities and difficult-to-imitate combinations of organizational, functional and technological skills to gain and sustain competitive advantage [

63]. This capability could facilitate the customization of SCM strategies via adaptation, integration and reconfiguration of both internal and relational resources to match the opportunities in the global and local market [

64,

65].

Built upon this theoretical foundation, our theorizing of Sustainable Collaborative Governance Framework starts from a recognition of the previous classification schemes researchers have developed on the lifecycle of a supply chain [

50,

51,

52,

53]. Especially, Tuckman’s process model on small group development [

53] provided some insightful observations on the development of a network of agents in a group setting that will go through “storming”, “norming”, and “performing” stages. Researchers have noted that a systematic framework is needed [

66,

67] to guide a supply chain to proactively and resiliently respond to perturbations and evolve from a lower level of sustainable development to a higher level, where different stages of development could be characterized. We theorized and developed a new integrative classification scheme detailing the evolution of a supply chain in different phases of sustainable development (

Table 1).

Reflecting the sustainable lifecycle of a supply chain, this classification scheme provides us a clear path for a supply chain to evolve from an unsustainable state to a sustainable one that is positively associated with its performance and competitiveness. The four different phases in the classification scheme situate a supply chain in terms of its sustainable development and the implementation of best governance practices.

The first phase in the evolution of a supply chain is disorderly development. In this phase, the firm’s internal integration has not been achieved yet and it does not have a clear strategic goal and stable business partners. Firms are still in the process of establishing their core competitive advantages with the focus on their internal functional integration and their independent operations. As the lowest level, there is no supply chain integration in this phase, and the supply chain cooperation is temporary, unstable, and non-strategic.

The second phase in the evolution of a supply chain is contractual integration. In this phase, the firm’s internal functional integration has been achieved successfully and its core competitive advantage is established which makes it possible to build a stable supply chain with others. Firms begin to cultivate stable business partnership consciously by establishing contractual relations, although each firm is still mainly interested in its own objectives and interests instead of focusing on the shared objectives and substantial collaboration, leading to minimum supply chain integration. At this phase, the governance mechanisms of a supply chain are mainly implemented by a single member independently, and the supply chain cooperation is based on arm’s length contracts that are relatively stable but without overall strategic goals for the whole supply chain. As a significant turning point of the “breakthrough” phase, contractual integration marks a beginning of a possible collaborative relationship.

The third phase is bilateral integration. In this phase, the neighboring partners in a supply chain achieve bilateral integration on the basis of mutual understanding of each other’s capabilities to achieve their mutual strategic missions. The supply chain collaboration is not just contractual, but more strategic with focus on win-win potentials of both parties. Therefore, a long-term and stable partnership between the neighboring partners was established with bilateral strategic goals of collaboration built upon each other’s complementary competitive advantages. The governance mechanisms in this phase are often implemented as bilateral collaborative governance between neighboring partners which mainly focus on fostering, promoting and extending their collaboration as their mutual objectives.

The last phase is the holistic integration. It is an ideal and desired phase of a supply chain. In this phase, an intimate, long-term and strategic partnership is firmly established and formalized by maximizing mutual interests that benefit the whole supply chain. Every partner in the supply chain is strategically benefited from the advanced management practices and innovative technology introduced and adopted in a timely manner to enhance the competitiveness of the whole supply chain. Furthermore, continuous improvements are made jointly by each partner learning from the feedback of the performance measurement of the whole supply chain. The governance of the whole supply chain is sustainable with dynamic, elastic, holistic, uncertainty-handling and future-oriented characteristics.

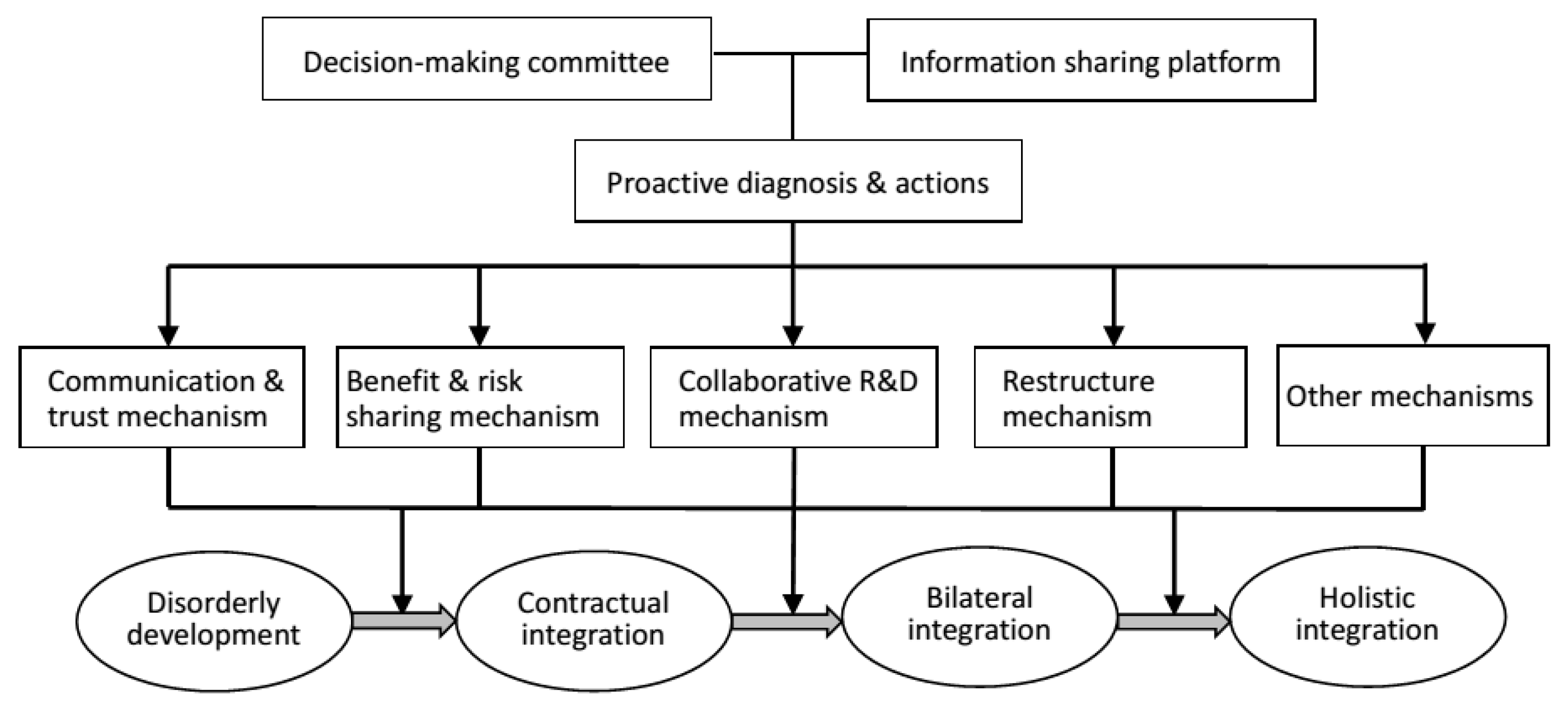

The four phases of a supply chain evolution in this classification scheme detail a sustainable development of a supply chain, which laid the foundation for the Sustainable Collaborative Governance Framework (

Figure 1). The framework aims to direct a supply chain evolving from a lower sustainable level to a higher one throughout the supply chain lifecycle.

As

Figure 1 shows, the Sustainable Collaborative Governance Framework enables supply chain managers make comprehensive diagnosis and actions in its evolution process to promote harmonious collaboration that positively contributes to its synergistic growth. Specifically, the framework provides us a clear roadmap of the evolutionary process of a supply chain lifecycle from the lowest phase of disorderly development to the ideal holistic integration phase. Based on the framework, supply chain managers could continuously implement necessary actions to ensure and promote the whole supply chain development in a positive direction associated with improved performance and competitiveness. Through some necessary sustainable mechanisms (such as communication and trust, benefit and risk sharing, collaborative R&D, restructure, etc.), the framework enables supply chain managers continuously reexamine and adjust the supply chain strategy to ensure it is still appropriate based on the situational circumstances. These sustainable mechanisms contribute to improved forecasting, production scheduling and inventory planning, etc., to respond swiftly to uncertainties and to govern the supply chain more sustainably and more effectively, through an overarching governance structure of decision-making committee and information sharing platform. Thus, the framework shows a high degree of collaborative adaptability and resilience to cope with today’s constantly changing business environment and competitive landscape. Moreover, as a sustainable holistic collaborative governance framework throughout the lifecycle of a supply chain, a high degree of proactive responsiveness, rather than passively responding to the changing business environment, is called upon for supply chain managers to proactively respond to the possible changes and uncertainties.

Moreover, the framework provides an evolutionary path and a governance structure for supply chain managers to lead the supply chain towards a more sustainable state based on different situations and following different mechanisms. For firms whose internal integration has not been achieved yet and who do not have a clear strategic goal and stable business partners, the evolution of a supply chain is from the disorderly development phase to the contractual integration phase, involving accelerating firms’ internal functional integration and strengthening communication and trust in order to stabilize and extend their business as the top priority. For firms who have established stable supply chain partners based on contractual relations, the evolution of the supply chain is from contractual integration phase to bilateral integration phase where benefit and risk sharing, conflict resolution, and collaborative R&D will play a greater role in achieving their mutual strategic missions of win-win integration. Furthermore, besides all of the mechanisms mentioned above, the evolution from bilateral integration phase to holistic integration phase will also entail that supply chain managers need to adopt any necessary mechanisms, including restructuring the supply chain situationally and dynamically, to benefit the whole supply chain.

The Sustainable Collaborative Governance Framework emphasizes a governance structure for decision-makers to proactively diagnose and act through sustainable mechanisms as the pivotal factor to the positive evolution of a supply chain.

3.3. Sustainable Governance and Mechanisms

To guide a supply chain to move positively from a lower phase to a higher one under the Sustainable Collaborative Governance Framework, we propose a governance structure and a series of sustainable mechanisms to be implemented situationally.

Governance of a supply chain requires a governing structure. In our framework, we propose a decision-making committee and an information sharing platform as the governing structure of a sustainable supply chain. Some researchers emphasized the pivotal role of a decision-making committee in SCM which functions as the nerve center for the whole supply chain [

68,

69,

70]. Therefore, the decision-making committee is also named as “steering committee” [

71,

72]. Although Stadtler [

68] argues that the most powerful partner of a supply chain will be the decision-maker for the whole supply chain that will lead to difficulties in the governance of the supply chain, this paper proposes a different perspective. In our framework, the decision-making committee is established upon the consensus of all partners in the supply chain aiming at a win-win strategic planning. This consensus among supply chain partners is the result of negotiations between partners based upon rational tradeoff leading to a consent on the pattern of power distribution in decisions pertinent to the interests of the whole supply chain. Thus, the decision-making committee acquires its legitimacy and decision power from all partners who choose to stay in the supply chain. An effective decision-making committee will be empowered by the whole supply chain to serve as the mind for this complex federation of organizations to handle the myriad activities and multiple objectives of the supply chain. In general, the decision-making committee will serve several different functions to SCM, namely, governance, coordination and administration, market analysis, imposing discipline for violations, etc. The decision-making committee therefore affords the supply chain decision-makers with the knowledge and skills to make meaningful and acceptable decisions in order to move the supply chain to a higher phase and effectively overcome the challenges of the changing environment.

Information sharing platform is considered as an essential component of a supply chain architecture which contributes to a better collaboration and integration [

73,

74,

75]. An efficient and effective information sharing platform should be structured to enable the whole supply chain to share essential market and operational information, improve productivity, and reduce transaction cost and time-to-market. As a centralized information platform, partners of the supply chain will continuously update operational data required by the decision-making committee, monitor the critical situation as reflected by the updated data, and coordinate the daily operational schedule based on the information in the platform.

In fact, what the information sharing platform shared is not just information, but also knowledge. According to Resource-based view, knowledge is also a resource. Increasingly, a key goal in SCM is to acquire and disseminate knowledge in ways that lead to effective decision making [

76,

77]. And in today’s global environment, research confirms that knowledge value is increased when globally diverse supply chain partners share knowledge [

78]. Converting knowledge resources into value requires a proper governance framework because knowledge is only valuable when it is in use [

79,

80]. Thus, the information sharing platform serves as the governance framework and performs four functions: facilitating daily operations, monitoring critical information, triggering responses, and managing knowledge. Specifically, it enables partners of the supply chain to optimize their daily operations with an increased return to be shared among them thus further consolidating partnerships and moving the supply chain in a positive direction. The information sharing platform also dynamically monitors critical information or key indicators in the supply chain, and if necessary, triggers appropriate responses to deal with potential crisis. And most importantly, this information sharing platform codifies knowledge acquired from the collaborative governance of the supply chain, shares the knowledge in the network, and routinizes the acquired knowledge to increase the network capabilities to handle disturbances.

The Sustainable Collaborative Governance Framework also identifies a series of mechanisms for decision-makers to proactively diagnose and act. Among many, four major mechanisms are proposed: communication and trust mechanism, benefit and risk sharing mechanism, collaborative R&D mechanism, and restructure mechanism.

Communication and trust mechanism: Effective cross-functional communication contributes to mutual understanding and trust, and having been widely considered as an important driver for culture, identity, image and reputation of a supply chain [

36,

39,

81]. Two patterns of communication could be used: formal and informal communication. Formal communication involves specific structural formats for engagement, such as cross-functional teams, co-location, regularly scheduled meetings and conferences, or matrix-style reporting structures, which will result in greater boundary-spanning activities for the whole supply chain. Informal communication, viewed as “socialization tactics” in a non-workplace environment, focuses on mutual understanding and awareness by interpersonal relationship-building activities. Compared with formal communication, informal communication often plays a more significant role in creating and maintaining trust, contributing to reduced conflicts and leading to a more coherent collaboration of the supply chain.

Benefit and risk sharing mechanism: Supply chain tends to increase in complexity. The involvement of numerous partners in a network of relationships causes risks and vulnerability for everyone [

82]. Thus, how to reduce the risk of disruption as much as possible becomes a major concern in SCM. Benefit and risk sharing is considered one of the effective programs to handle this challenge [

83,

84]. For a trust-based complex federation of organizations, a benefit and risk sharing mechanism is significant to supply chain continuity. Though the benefit and risk sharing varies based on the type of collaboration, they are often shared with formal agreements such as obligating contracts, price concession and profit sharing schemes, property rights sharing, or ownership control, all providing an incentive for partners to further their collaboration.

Collaborative R&D mechanism: Supply chain is also a collaboration chain and an innovation chain. From the Resource-based view, the focus of SCM research in recent years has shifted from the narrow operating efficiency considerations to the effective resources or capabilities development that emphasizes collaborative R&D and innovation [

85,

86]. Collaborative R&D and innovation reflects the characteristics of win-win cooperation in SCM which contributes to maximizing their mutual interests that benefit the whole supply chain [

87]. Greater supply chain collaboration has important strategic significance to the boundary-spanning of a supply chain because they need to utilize the resources and knowledge of their partners to enhance innovation capacity that could not be accomplished solely by themselves. Built upon the communication and trust mechanism and the benefit and risk sharing mechanism, it is possible for the collaborative R&D of the supply chain to be launched successfully in a format of a series of detailed arrangements, such as clear divisions of labor, intellectual and intangible property ownership, cost-sharing, and opportunism prevention.

Restructure mechanism: From a strategic perspective, a supply chain is structured and established based comparative advantage with focus on win-win potentials. Today’s tremendously changing and competitive environment imposes a significant challenge for SCM. If the existing supply chain structure could not meet their strategic goals and respond to dynamic and unpredictable changes after the necessary adjustment and maintenance procedure, the supply chain should be restructured to adapt to such changes [

88,

89]. As an uncertainty handling mechanism, options for restructuring include re-enacted strategic objectives (e.g., Blue Ocean Strategy), technology acquisition, partner update, and others.

In addition to the four major mechanisms to ensure sustainable evolution of a supply chain, decision-makers could use other mechanisms such as moral hazard prevention and punishment, joint investment, cultural identity, information confidentiality and disclosure, etc. to proactively diagnose and act in developing a supply chain sustainably. In fact, drawing from the relationship marketing literature [

90,

91], a supply chain could be considered as relationships in networks in which partners interact through an interaction process to create value for each other collaboratively [

92]. In the process of collaboration, the idea of relationship development is necessary, and managing sustainably the development and maintenance of these collaborative relationships will require many mutually complementary mechanisms such as the ones mentioned above and possibly honesty, benevolence, reliability, commitment and diligence [

93,

94]. It should be noted that the use of these mechanisms and detailed implementation of these mechanisms should depend on the specific situation of a supply chain and the different characteristics of each phase.

3.4. Characteristics of the Framework

The Sustainable Collaborative Governance Framework aims to realize a continuously successful collaboration and the sustainable improvement of performance and competitiveness of a supply chain. The framework has five distinctive characteristics.

The first characteristic of the Framework is

dynamic. The dynamic nature reflects the essence of an open system that fast changes in internal and external environments force a system to handle varieties in a dynamic way [

95]. The initial chosen set of strategies, policies and practices are no guarantee for future survival without mechanisms for dynamic adjustments and might eventually lead to stagnation and decay [

96]. Our framework proposed a dynamic monitor-trigger-react governance structure to handle disturbances from internal or external environment of the supply chain through the information sharing platform aiming to prevent the supply chain from moving in the negative direction. Further, the framework proposed mechanisms to proactively handle potential disturbances by continuously scanning environment and conduct collaborative R&D and innovation. In general, the mechanisms proposed in the framework should be implemented dynamically based on different situations in a supply chain lifecycle to ensure continuous adjustments along the positive direction of the supply chain evolving through different phases.

The second characteristic of the framework is

elastic. As mentioned above, the business environment of a supply chain has gone through an unbelievable transformation in recent decades in which only a small number of supply chains survived [

13]. Therefore, supply chains require an elastic governance structure with high degree of fault-tolerance and adaptability capable to respond to the unpredictable scenarios [

19]. Our framework empowers supply chain managers to implement collaborative governance effectively by flexible combinations of sustainable governance mechanisms deemed to be appropriate to respond to different situations. Furthermore, this framework affords a high degree of fault-tolerance and could be used in implementing process control against the potential mistakes made by the decision-makers. Decision-makers could dynamically monitor critical information or key indicators in the supply chain and if necessary, trigger appropriate responses to proactively correct the wrong decision and prevent the supply chain from moving in the negative direction.

The third characteristic of the framework is

holistic. As mentioned above, firms have abandoned the antagonistic approach of doing business and have chosen a more integrative management style which focused on collaboration along the supply chain as a whole in order to sustain their competitive position [

97]. However, collaborating activities in a supply chain is often faced with conflicts between individual member’s interests and the holistic interests of the supply chain [

38]. The framework provides a guidance to coordinate the different individual interests effectively by decision-making committee working through mechanisms such as benefits and risk sharing and communication and trust. As showed in

Figure 1, the framework encompasses a holistic picture of the supply chain lifecycle and divides them into four phases with the aims of improving supply chain overall performance and competitiveness. As we see in the framework, there are different governance needs in each of the phases, and the holistic perspective will offer decision-making committee a method for describing and analyzing problems from such holistic perspective, rather than fall into the trap of focusing on one particular phase losing the sight of the overall supply chain lifecycle movement.

The fourth characteristic of the framework is

uncertainty-handling. There are many sorts of uncertainties associated with doing business on a daily basis which will have various effects on a supply chain [

98]. The traditional governance models that focused on certain and specific problems could not cope with this situation [

99]. The Sustainable Collaborative Governance Framework presented in this paper is developed as an open framework capable of handling diverse uncertainties by incorporating more governance structure and more variety-handling mechanisms. As a strategic framework, it enables the supply chain managers a strategic thinking in proactive diagnosis and novel adoption of pertinent precautionary measures according to the various uncertain events at their early phases. In this way, the negative impacts of the uncertain events would be minimized as far as possible, which guarantees the supply chain collaboration moved forwards in the positive direction.

The fifth characteristic of the framework is

future-oriented. As a collaboration chain, a win-win collaboration is a supply chain’s ultimate strategic goal [

4]. A desired win-win situation can enlarge the joint benefits and reward each partner a share of greater gain that could not be generated by each member on its own [

100]. Future-orientation is the cornerstone of the continuous win-win collaboration. In

Figure 1, the supply chain collaboration is depicted as an evolution from the current state to an ideal future state. The current state could be disorderly development, contractual integration, or bilateral integration, all moving towards a future ideal state of the holistic integration. The governance mechanisms are also future oriented. For example, both supply chain members’ interests and whole system’s interests were guarded through benefit and risk sharing and communication and trust mechanisms. Further, the sustainable evolution of the supply chain is strengthened by the collaborative R&D and restructuring mechanisms that utilize and update each member’s competitive advantages to develop technologies and processes conducive to the sustainable evolution of the whole supply chain.

In summary, the Sustainable Collaborative Governance Framework enables SCM not only to maintain, but also to improve their performance and competitiveness under the changing business environment. We argue that studying SCM through the lens of this framework has the potential to provide useful insights into the governance of a supply chain throughout its lifecycle.

4. Conclusions

The research question we set out in this paper is how to design an appropriate governance framework to guide the whole supply chain to collaborate sustainably in the volatile and uncertain environment. We focused our attention on an effective governance framework to improve the sustainability of a supply chain throughout its lifecycle, and proposed a Sustainable Collaborative Governance Framework with a classification scheme detailing the evolution of a supply chain in different phases of sustainable development. This Framework, covering all possible operating states of a supply chain from disorderly development up to ideal holistic integration and enumerating four major governance mechanisms, provides us a clear roadmap for a supply chain to evolve from an unsustainable state to a sustainable one that is positively associated with its performance and competitiveness. As such, the four different phases in the classification scheme situate a supply chain in terms of its sustainable development and the implementation of best governance practices. This framework, with the classification scheme and its adaptive decision-making and action mechanisms throughout supply chain lifecycle, will enable the whole supply chain proactively and resiliently respond to uncertainties or perturbations without undergoing significant changes to firms’ normal operations.

Comparing to the prior frameworks or models, the Sustainable Collaborative Governance Framework proposed in this paper contributes to the SCM literature in the following ways:

First, this study adds to the existing body of knowledge on “sustainable SCM”. To our best knowledge, although literature has many studies on the sustainable supply chain, very few researches have focused on the sustainable development of the internal lifecycle of a supply chain and proposed an effective program in managing such development. Our study extends the research on “sustainable SCM” from traditional natural-social-economic perspective to managerial perspective that focuses on the capability of a supply chain to develop itself sustainably in today’s complex and uncertain business environment.

Second, our research extends and re-defines the nature and connotation of “sustainable SCM” by clearly elucidating its characteristics as dynamic, elastic, holistic, uncertainty-handling and future-oriented. Today’s increasing changing and complex business environment requires a supply chain network possess the necessary capabilities (the requisite variety) to cope with uncertainties, imposing significant challenges to traditional SCM. The framework provides a clear roadmap of the evolutionary process of a supply chain lifecycle and details a governance structure and a series of sustainable mechanisms that embody the above characteristics to enable the supply chain to move positively from a lower phase to a higher one under the scenario of rapid market evolution and high uncertain business environments.

Third, the framework proposed in this paper provides a clear classification scheme reflecting the sustainable lifecycle of a supply chain, a series of systematic sustainable mechanisms, and a functional governance structure that could implement the sustainable mechanisms situationally. To our best knowledge, this is the first study in the field of sustainable SCM research proposing a framework with more specific implementation mechanisms which showed a high adaptability against uncertainties to ensure the whole supply chain to obtain and sustain an ideal collaboration with improved performance and competitiveness. We believe that our framework makes an important contribution to the study of the sustainable supply chain and we call on future research in refining the framework further, empirically examining it, and operationalizing the framework for the implementation by supply chain managers.

In addition to theoretical contributions, the framework has substantial managerial significance to practitioners. First, the framework provides additional insights into the area of supply chain governance when managerial decisions are especially important to maintain and improve competitiveness and financial performance from a long-term strategic perspective. Second, it enables supply chain managers make comprehensive diagnosis and actions in its evolution process to promote harmonious collaboration that positively contributes to its synergistic growth. Third, through the necessary sustainable mechanisms, the framework enables supply chain managers continuously reexamine and adjust the supply chain strategy to ensure it is still appropriate based on the situational circumstances. Based on the framework, supply chain managers could continuously implement necessary actions to ensure and promote the whole supply chain development in a positive direction and with a high degree of adaptability and responsiveness in handling changing business environment.

In today’s volatile and complex business environment, it is more and more difficult for supply chain managers to make decisions effectively, thereby both researchers and practitioners have an increased interest to investigate how to design an appropriate governance framework to guide the supply chain to collaborate successfully under such environment. This paper theorizes and proposes a framework on the sustainable evolution of a supply chain with specific governance mechanisms that are highly adaptable to proactively respond to uncertainties or perturbations without undergoing significant changes to firms’ normal operations, which contributes to the comprehensive understanding and practice of the sustainable SCM.

”: Operational mechanism; “

”: Operational mechanism; “  ”: Evolutionary progression of a supply chain.

”: Evolutionary progression of a supply chain.

”: Operational mechanism; “

”: Operational mechanism; “  ”: Evolutionary progression of a supply chain.

”: Evolutionary progression of a supply chain.

”: an unstable business partnership. 4. “

”: an unstable business partnership. 4. “  ”: a stable and win-win business partnership. 5. “

”: a stable and win-win business partnership. 5. “  ”: the governance scope. 6. * Although a supply chain is a network in general, at this point, we simplified it as a chain in this table.

”: the governance scope. 6. * Although a supply chain is a network in general, at this point, we simplified it as a chain in this table.