Energy Efficiency of Intensive Rice Production in Japan: An Application of Data Envelopment Analysis

Abstract

:1. Introduction

2. Materials and Methods

2.1. Data Collection

2.2. Selection of DEA Input and Output Variables

2.3. DEA Methodology

3. Results

3.1. Descriptive Statistics of the Collected Data

3.2. Energy Consumption

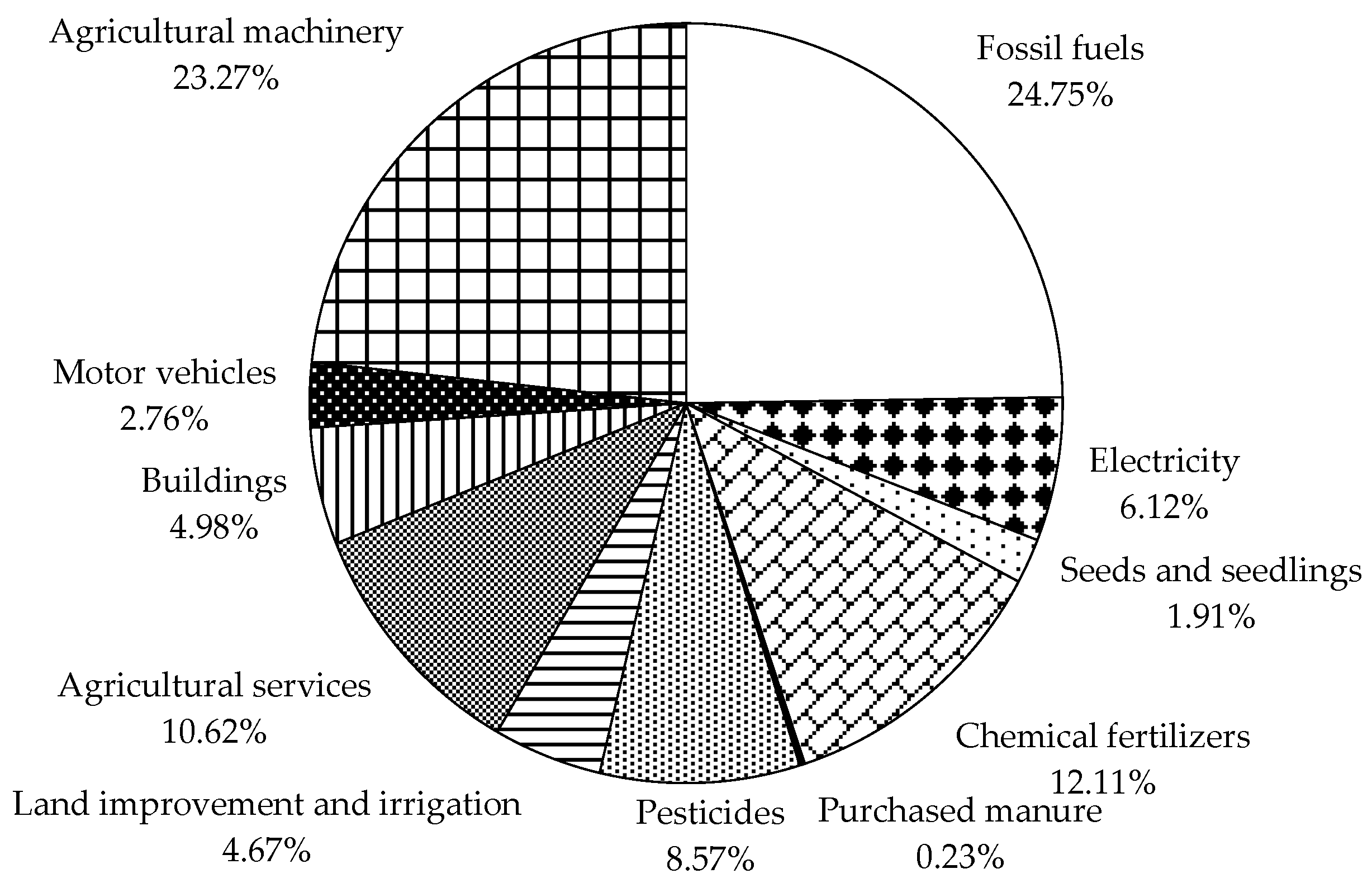

3.3. DEA-Based Energy Efficiency Scores and Operational Targets

4. Discussion

4.1. Findings and Implications

4.2. Lack of Discrimination Power for the <0.5 ha Range

5. Conclusions

Acknowledgments

Conflicts of Interest

References

- Pimentel, D.; Hurd, L.E.; Bellotti, A.C.; Forster, M.J.; Oka, I.N.; Sholes, O.D.; Whitman, R.J. Food production and the energy crisis. Science 1973, 182, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Faidley, L.W. Energy and agriculture. In Energy in Farm Production; Fluck, R.C., Ed.; Elsevier: Amsterdam, The Netherlands, 1992; pp. 1–12. [Google Scholar]

- Food and Agriculture Organization of the United Nations (FAO). FAO Statistical Yearbook 2014: Asia and the Pacific. Food and Agriculture; FAO Regional Office for Asia and the Pacific: Bangkok, Thailand, 2014. [Google Scholar]

- Organisation for Economic Co-operation and Development (OECD). Evaluation of Agricultural Policy Reforms in Japan; OECD Publishing: Paris, France, 2009. [Google Scholar]

- Barker, R.; Herdt, R.W. The Rice Economy of Asia; Resources for the Future: Washington, DC, USA, 1985. [Google Scholar]

- Ministry of Agriculture, Forestry and Fisheries of Japan (MAFF). Statistics on Cultivated Land and Planted Area (2011). Available online: http://www.e-stat.go.jp/SG1/estat/List.do?lid=000001087149 (accessed on 6 September 2016). (In Japanese)

- Ministry of Agriculture, Forestry and Fisheries of Japan (MAFF). Production Cost of Rice, Wheat, and Barley (2005–2011). Available online: http://www.maff.go.jp/j/tokei/kouhyou/noukei/seisanhi_nousan/ (accessed on 2 September 2015). (In Japanese)

- AghaAlikhani, M.; Kazemi-Poshtmasari, H.; Habibzadeh, F. Energy use pattern in rice production: A case study from Mazandaran province, Iran. Energy Convers. Manag. 2013, 69, 157–162. [Google Scholar] [CrossRef]

- Chauhan, N.S.; Mohapatra, P.K.J.; Pandey, K.P. Improving energy productivity in paddy production through benchmarking: An application of data envelopment analysis. Energy Convers. Manag. 2006, 47, 1063–1085. [Google Scholar] [CrossRef]

- Eskandari, H.; Attar, S. Energy comparison of two rice cultivation systems. Renew. Sustain. Energy Rev. 2015, 42, 666–671. [Google Scholar] [CrossRef]

- Hafeez, M.; Bundschuh, J.; Mushtaq, S. Exploring synergies and tradeoffs: Energy, water, and economic implications of water reuse in rice-based irrigation systems. Appl. Energy 2014, 114, 889–900. [Google Scholar] [CrossRef] [Green Version]

- Kazemi, H.; Kamkar, B.; Lakzaei, S.; Badsar, M.; Shahbyki, M. Energy flow analysis for rice production in different geographical regions of Iran. Energy 2015, 84, 390–396. [Google Scholar] [CrossRef]

- Mandal, S.; Roy, S.; Das, A.; Ramkrushna, G.I.; Lal, R.; Verma, B.C.; Kumar, A.; Singh, R.K.; Layek, J. Energy efficiency and economics of rice cultivation systems under subtropical Eastern Himalaya. Energy Sustain. Dev. 2015, 28, 115–121. [Google Scholar] [CrossRef]

- Mushtaq, S.; Maraseni, T.N.; Maroulis, J.; Hafeez, M. Energy and water tradeoffs in enhancing food security: A selective international assessment. Energy Policy 2009, 37, 3635–3644. [Google Scholar] [CrossRef] [Green Version]

- Nabavi-Pelesaraei, A.; Abdi, R.; Rafiee, S.; Taromi, K. Applying data envelopment analysis approach to improve energy efficiency and reduce greenhouse gas emission of rice production. Eng. Agric. Environ. Food 2014, 7, 155–162. [Google Scholar] [CrossRef]

- Rahman, S.; Barmon, B.K. Exploring the potential to improve energy saving and energy efficiency using fertilizer deep placement strategy in modern rice production in Bangladesh. Energy Effic. 2015, 8, 1241–1250. [Google Scholar] [CrossRef]

- Nassiri, S.M.; Singh, S. Study on energy use efficiency for paddy crop using data envelopment analysis (DEA) technique. Appl. Energy 2009, 86, 1320–1325. [Google Scholar] [CrossRef]

- Pishgar-Komleh, S.H.; Sefeedpari, P.; Rafiee, S. Energy and economic analysis of rice production under different farm levels in Guilan province of Iran. Energy 2011, 36, 5824–5831. [Google Scholar] [CrossRef]

- Soni, P.; Soe, M.N. Energy balance and energy economic analyses of rice production systems in Ayeyarwaddy Region of Myanmar. Energy Effic. 2016, 9, 223–237. [Google Scholar] [CrossRef]

- Cooper, W.W.; Seiford, L.M.; Tone, K. Data Envelopment Analysis: A Comprehensive Text with Models, Applications, References and DEA-Solver Software, 2nd ed.; Springer: New York, NY, USA, 2007. [Google Scholar]

- Cooper, W.W.; Seiford, L.M.; Zhu, J. Data envelopment analysis: History, models, and interpretations. In Handbook on Data Envelopment Analysis, 2nd ed.; Cooper, W.W., Seiford, L.M., Zhu, J., Eds.; Springer: New York, NY, USA, 2011; pp. 1–39. [Google Scholar]

- Cooper, W.W.; Ruiz, J.L.; Sirvent, I. Choices and uses of DEA weights. In Handbook on Data Envelopment Analysis, 2nd ed.; Cooper, W.W., Seiford, L.M., Zhu, J., Eds.; Springer: New York, NY, USA, 2011; pp. 93–126. [Google Scholar]

- Dyson, R.G.; Allen, R.; Camanho, A.S.; Podinovski, V.V.; Sarrico, C.S.; Shale, E.A. Pitfalls and protocols in DEA. Eur. J. Oper. Res. 2001, 132, 245–259. [Google Scholar] [CrossRef]

- Podinovski, V.V.; Thanassoulis, E. Improving discrimination in data envelopment analysis: Some practical suggestions. J. Prod. Anal. 2007, 28, 117–126. [Google Scholar] [CrossRef]

- Raynolds, M.; Fraser, R.; Checkel, D. The relative mass-energy-economic (RMEE) method for system boundary selection. Part 1: A means to systematically and quantitatively select LCA boundaries. Int. J. Life Cycle Assess. 2000, 5, 37–46. [Google Scholar] [CrossRef]

- Greenhouse Gas Inventory Office of Japan (GIO) (Ed.) National Greenhouse Gas Inventory Report of Japan (2015); National Institute for Environmental Studies: Tsukuba, Japan, 2015.

- International Energy Agency (IEA). Energy Statistics Manual; IEA Publications: Paris, France, 2005. [Google Scholar]

- Nansai, K.; Kondo, Y.; Kagawa, S.; Suh, S.; Nakajima, K.; Inaba, R.; Tohno, S. Estimates of embodied global energy and air-emission intensities of Japanese products for building a Japanese input–output life cycle assessment database with a global system boundary. Environ. Sci. Technol. 2012, 46, 9146–9154. [Google Scholar] [CrossRef] [PubMed]

- Guinée, J.B. (Ed.) Handbook on Life Cycle Assessment: Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Tone, K. Slacks-based measure of efficiency. In Handbook on Data Envelopment Analysis, 2nd ed.; Cooper, W.W., Seiford, L.M., Zhu, J., Eds.; Springer: New York, NY, USA, 2011; pp. 195–209. [Google Scholar]

- Galanopoulos, K.; Aggelopoulos, S.; Kamenidou, I.; Mattas, K. Assessing the effects of managerial and production practices on the efficiency of commercial pig farming. Agric. Syst. 2006, 88, 125–141. [Google Scholar] [CrossRef]

- Ministry of Agriculture, Forestry and Fisheries of Japan (MAFF). Summary of Farming Income Stabilization Measures in 2016. Available online: http://www.maff.go.jp/j/kobetu_ninaite/keiei/pdf/28pamph_all.pdf (accessed on 31 October 2016). (In Japanese)

- Lozano, S.; Iribarren, D.; Moreira, M.T.; Feijoo, G. The link between operational efficiency and environmental impacts: A joint application of life cycle assessment and data envelopment analysis. Sci. Total Environ. 2009, 407, 1744–1754. [Google Scholar] [CrossRef] [PubMed]

- SaiTech. User’s Guide to DEA-Solver-PRO (Professional Version 10.0); SaiTech: Holmdel, NJ, USA, 2013. [Google Scholar]

- Ministry of Agriculture, Forestry and Fisheries of Japan (MAFF). Statistics on Commodity Prices in Agriculture (2011). Available online: http://www.e-stat.go.jp/SG1/estat/List.do?lid=000001102155 (accessed on 5 October 2015). (In Japanese)

- Duffy, M. Economies of size in production agriculture. J. Hunger Environ. Nutr. 2009, 4, 375–392. [Google Scholar] [CrossRef] [PubMed]

| Coefficient | |

|---|---|

| Fossil fuels (GJ/L) 1 | |

| Heavy oil | 0.0371 |

| Diesel oil | 0.0359 |

| Kerosene | 0.0349 |

| Gasoline | 0.0329 |

| Motor oil | 0.0382 |

| Premixed fuel | 0.0331 |

| Production costs (GJ/million yen) 2 | |

| Fossil fuels | 81.6 |

| Electricity | 472.6 |

| Seeds and seedlings | 29.2 |

| Chemical fertilizers | 79.0 |

| Purchased manure | 35.3 |

| Pesticides | 65.3 |

| Land improvement and irrigation 3 | 47.3 |

| Agricultural services 3 | 47.3 |

| Buildings | 46.3 |

| Motor vehicles | 42.3 |

| Agricultural machinery | 51.2 |

| Rice Farming Scale (ha Per Farm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| <0.5 | 0.5 to <1 | 1 to <2 | 2 to <3 | 3 to <5 | 5 to <7 | 7 to <10 | 10 to <15 | ≥15 | |

| Fossil fuels (L/ha) 2 | |||||||||

| Heavy oil | 0 | 0.1 | 0 | 0 | 0 | 0.1 | 0 | 0 | 0 |

| (0) | (0.4) | (0) | (0) | (0) | (0.4) | (0) | (0) | (0) | |

| Diesel oil | 111.4 | 116.4 | 116.7 | 119.4 | 120.1 | 121.2 | 136.0 | 153.9 | 152.8 |

| (11.6) | (7.9) | (1.6) | (8.7) | (7.8) | (2.4) | (6.2) | (11.4) | (9.2) | |

| Kerosene | 34.4 | 43.4 | 73.4 | 79.9 | 88.4 | 98.2 | 108.9 | 109.8 | 103.4 |

| (4.8) | (2.9) | (5.2) | (6.8) | (9.7) | (4.8) | (5.0) | (16.2) | (9.0) | |

| Gasoline | 94.2 | 88.2 | 75.6 | 72.2 | 67.0 | 59.4 | 60.1 | 64.7 | 44.5 |

| (5.0) | (4.0) | (4.5) | (7.2) | (2.9) | (7.6) | (3.2) | (5.5) | (10.2) | |

| Motor oil | 5.0 | 3.6 | 3.5 | 3.4 | 2.5 | 3.1 | 2.5 | 3.2 | 1.8 |

| (1.2) | (0.7) | (0.5) | (0.5) | (0.5) | (0.7) | (0.5) | (0.5) | (0.4) | |

| Premixed fuel | 19.4 | 15.1 | 8.9 | 4.6 | 4.3 | 2.9 | 2.9 | 2.5 | 0.8 |

| (1.6) | (1.4) | (1.3) | (1.1) | (0.8) | (0.6) | (1.1) | (1.1) | (0.7) | |

| Production costs (thousand yen/ha) 2,3 | |||||||||

| Fossil fuels | 31.8 | 30.7 | 29.9 | 28.7 | 28.5 | 27.9 | 29.6 | 31.7 | 27.9 |

| (3.4) | (2.6) | (2.5) | (2.8) | (3.5) | (2.6) | (3.4) | (3.6) | (3.5) | |

| Electricity | 4.4 | 5.5 | 7.3 | 7.2 | 6.5 | 7.3 | 6.5 | 7.3 | 5.4 |

| (0.7) | (0.8) | (0.4) | (0.7) | (0.4) | (0.6) | (0.5) | (1.1) | (0.7) | |

| Seeds and seedlings | 66.8 | 46.3 | 32.8 | 23.9 | 23.4 | 20.5 | 18.1 | 16.6 | 16.1 |

| (5.3) | (5.4) | (3.3) | (0.9) | (2.6) | (1.4) | (1.9) | (1.1) | (0.5) | |

| Chemical fertilizers | 88.3 | 81.8 | 75.5 | 75.8 | 71.5 | 76.6 | 69.7 | 63.0 | 64.3 |

| (8.8) | (7.7) | (5.4) | (7.7) | (6.5) | (5.4) | (9.3) | (5.5) | (3.8) | |

| Purchased manure | 4.1 | 4.1 | 4.6 | 2.4 | 1.9 | 3.4 | 1.3 | 2.4 | 3.3 |

| (1.0) | (1.0) | (0.4) | (1.1) | (1.0) | (0.8) | (1.4) | (0.8) | (1.9) | |

| Pesticides | 72.5 | 68.6 | 66.5 | 64.3 | 62.4 | 66.4 | 61.7 | 55.2 | 49.5 |

| (3.8) | (2.8) | (3.6) | (3.3) | (3.1) | (5.4) | (4.5) | (4.2) | (3.4) | |

| Land improvement and irrigation | 42.5 | 43.6 | 47.3 | 49.0 | 52.7 | 55.8 | 51.7 | 55.7 | 49.0 |

| (7.0) | (10.1) | (5.5) | (6.2) | (13.1) | (5.5) | (7.5) | (3.9) | (5.3) | |

| Agricultural services | 232.4 | 180.8 | 112.1 | 81.5 | 67.6 | 55.9 | 58.9 | 57.0 | 51.6 |

| (19.7) | (14.9) | (15.1) | (8.4) | (11.7) | (9.8) | (9.7) | (8.8) | (4.8) | |

| Buildings | 107.4 | 82.9 | 56.0 | 37.7 | 30.5 | 25.7 | 33.8 | 38.2 | 33.4 |

| (35.0) | (23.8) | (10.8) | (6.3) | (4.5) | (5.5) | (4.4) | (5.1) | (4.0) | |

| Motor vehicles | 66.2 | 50.5 | 32.8 | 26.1 | 21.0 | 16.8 | 15.9 | 16.3 | 13.2 |

| (14.5) | (5.5) | (3.6) | (5.5) | (1.0) | (2.5) | (2.7) | (3.5) | (1.9) | |

| Agricultural machinery | 309.5 | 303.1 | 246.4 | 197.1 | 194.1 | 159.3 | 158.0 | 147.9 | 151.4 |

| (61.6) | (37.9) | (12.7) | (13.8) | (13.9) | (14.3) | (25.6) | (11.9) | (7.2) | |

| Rice yield (kg/ha) | 5084 | 5040 | 5113 | 5231 | 5277 | 5346 | 5419 | 5380 | 5207 |

| (131) | (80) | (72) | (128) | (93) | (139) | (189) | (194) | (131) | |

| Allocation ratio 4 | 0.978 | 0.977 | 0.978 | 0.978 | 0.977 | 0.978 | 0.979 | 0.974 | 0.976 |

| (0.002) | (0.003) | (0.004) | (0.002) | (0.003) | (0.004) | (0.005) | (0.003) | (0.006) | |

| Rice Farming Scale (ha Per Farm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| <0.5 | 0.5 to <1 | 1 to <2 | 2 to <3 | 3 to <5 | 5 to <7 | 7 to <10 | 10 to <15 | ≥15 | |

| Fossil fuels | 11.7 | 11.7 | 12.1 | 12.1 | 12.2 | 12.2 | 13.3 | 14.3 | 12.9 |

| (1.0) | (0.6) | (0.4) | (0.8) | (0.8) | (0.4) | (0.4) | (1.0) | (1.0) | |

| Electricity | 2.1 | 2.6 | 3.4 | 3.4 | 3.1 | 3.5 | 3.1 | 3.5 | 2.6 |

| (0.3) | (0.4) | (0.2) | (0.3) | (0.2) | (0.3) | (0.2) | (0.5) | (0.3) | |

| Seeds and seedlings | 2.0 | 1.4 | 1.0 | 0.7 | 0.7 | 0.6 | 0.5 | 0.5 | 0.5 |

| (0.15) | (0.16) | (0.10) | (0.03) | (0.08) | (0.04) | (0.06) | (0.03) | (0.01) | |

| Chemical fertilizers | 7.0 | 6.5 | 6.0 | 6.0 | 5.6 | 6.1 | 5.5 | 5.0 | 5.1 |

| (0.7) | (0.6) | (0.4) | (0.6) | (0.5) | (0.4) | (0.7) | (0.4) | (0.3) | |

| Purchased manure | 0.15 | 0.14 | 0.16 | 0.09 | 0.07 | 0.12 | 0.05 | 0.08 | 0.12 |

| (0.04) | (0.04) | (0.01) | (0.04) | (0.03) | (0.03) | (0.05) | (0.03) | (0.07) | |

| Pesticides | 4.7 | 4.5 | 4.3 | 4.2 | 4.1 | 4.3 | 4.0 | 3.6 | 3.2 |

| (0.2) | (0.2) | (0.2) | (0.2) | (0.2) | (0.4) | (0.3) | (0.3) | (0.2) | |

| Land improvement and irrigation | 2.0 | 2.1 | 2.2 | 2.3 | 2.5 | 2.6 | 2.4 | 2.6 | 2.3 |

| (0.3) | (0.5) | (0.3) | (0.3) | (0.6) | (0.3) | (0.4) | (0.2) | (0.3) | |

| Agricultural services | 11.0 | 8.6 | 5.3 | 3.9 | 3.2 | 2.6 | 2.8 | 2.7 | 2.4 |

| (0.9) | (0.7) | (0.7) | (0.4) | (0.6) | (0.5) | (0.5) | (0.4) | (0.2) | |

| Buildings | 5.0 | 3.8 | 2.6 | 1.7 | 1.4 | 1.2 | 1.6 | 1.8 | 1.5 |

| (1.6) | (1.1) | (0.5) | (0.3) | (0.2) | (0.3) | (0.2) | (0.2) | (0.2) | |

| Motor vehicles | 2.8 | 2.1 | 1.4 | 1.1 | 0.9 | 0.7 | 0.7 | 0.7 | 0.6 |

| (0.61) | (0.23) | (0.15) | (0.23) | (0.04) | (0.11) | (0.11) | (0.15) | (0.08) | |

| Agricultural machinery | 15.9 | 15.5 | 12.6 | 10.1 | 9.9 | 8.2 | 8.1 | 7.6 | 7.8 |

| (3.2) | (1.9) | (0.6) | (0.7) | (0.7) | (0.7) | (1.3) | (0.6) | (0.4) | |

| Total | 64.2 | 58.9 | 51.1 | 45.5 | 43.6 | 42.1 | 42.0 | 42.3 | 39.0 |

| (5.8) | (3.4) | (1.2) | (2.0) | (1.2) | (1.5) | (1.9) | (1.5) | (1.8) | |

| Rice Farming Scale (ha Per Farm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| <0.5 | 0.5 to <1 | 1 to <2 | 2 to <3 | 3 to <5 | 5 to <7 | 7 to <10 | 10 to <15 | ≥15 | |

| Average for each window | |||||||||

| 2005–2008 | 0.99998 | 0.866 | 0.782 | 0.929 | 0.931 | 1 | 1 | 0.99998 | 0.970 |

| 2006–2009 | 1 | 0.769 | 0.717 | 0.801 | 0.922 | 0.955 | 0.965 | 0.969 | 0.985 |

| 2007–2010 | 0.903 | 0.677 | 0.717 | 0.794 | 0.891 | 0.907 | 0.929 | 0.940 | 1 |

| 2008–2011 | 0.818 | 0.657 | 0.714 | 0.789 | 0.882 | 0.871 | 0.891 | 0.926 | 0.996 |

| Cumulative average | 0.930 | 0.742 | 0.732 | 0.828 | 0.907 | 0.933 | 0.946 | 0.959 | 0.988 |

| Rice Farming Scale (ha Per Farm) | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| <0.5 | 0.5 to <1 | 1 to <2 | 2 to <3 | 3 to <5 | 5 to <7 | 7 to <10 | 10 to <15 | ≥15 | |

| Fossil fuels | |||||||||

| Potential reduction (GJ/ha) | 0.153 | 0.267 | 0.329 | 0.109 | 0.024 | 0.059 | 0.161 | 0.387 | 0.060 |

| Potential reduction rate (%) | 1.3 | 2.3 | 2.7 | 0.9 | 0.2 | 0.5 | 1.2 | 2.7 | 0.5 |

| Electricity | |||||||||

| Potential reduction (GJ/ha) | 0.045 | 0.349 | 1.014 | 0.746 | 0.350 | 0.421 | 0.214 | 0.228 | 0.032 |

| Potential reduction rate (%) | 2.2 | 13.1 | 29.2 | 22.1 | 11.3 | 12.5 | 7.1 | 6.7 | 1.3 |

| Chemical fertilizers | |||||||||

| Potential reduction (GJ/ha) | 0.419 | 1.091 | 0.868 | 0.778 | 0.583 | 0.527 | 0.563 | 0.186 | 0.073 |

| Potential reduction rate (%) | 6.0 | 16.9 | 14.5 | 13.0 | 10.3 | 8.6 | 10.2 | 3.7 | 1.4 |

| Pesticides | |||||||||

| Potential reduction (GJ/ha) | 0.369 | 1.133 | 1.180 | 0.844 | 0.523 | 0.399 | 0.351 | 0.245 | 0.048 |

| Potential reduction rate (%) | 7.9 | 25.6 | 27.6 | 20.4 | 13.0 | 9.4 | 9.0 | 7.0 | 1.5 |

| Agricultural services | |||||||||

| Potential reduction (GJ/ha) | 1.525 | 4.603 | 2.662 | 1.249 | 0.283 | 0.206 | 0.073 | 0.114 | 0.080 |

| Potential reduction rate (%) | 14.2 | 54.5 | 51.7 | 31.9 | 9.1 | 7.5 | 2.7 | 4.4 | 3.4 |

| Agricultural machinery | |||||||||

| Potential reduction (GJ/ha) | 2.259 | 7.032 | 4.582 | 1.702 | 1.361 | 0.296 | 0.379 | 0.052 | 0.005 |

| Potential reduction rate (%) | 14.1 | 44.6 | 36.2 | 17.0 | 13.6 | 3.6 | 4.7 | 0.7 | 0.1 |

| Rice yield | |||||||||

| Potential increase (kg/ha) | 0.02 | 26.1 | 36.2 | 22.3 | 0 | 0 | 3.6 | 10.1 | 10.8 |

| Potential increase rate (%) | 0.0004 | 0.5 | 0.7 | 0.4 | 0 | 0 | 0.1 | 0.2 | 0.2 |

© 2018 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Masuda, K. Energy Efficiency of Intensive Rice Production in Japan: An Application of Data Envelopment Analysis. Sustainability 2018, 10, 120. https://doi.org/10.3390/su10010120

Masuda K. Energy Efficiency of Intensive Rice Production in Japan: An Application of Data Envelopment Analysis. Sustainability. 2018; 10(1):120. https://doi.org/10.3390/su10010120

Chicago/Turabian StyleMasuda, Kiyotaka. 2018. "Energy Efficiency of Intensive Rice Production in Japan: An Application of Data Envelopment Analysis" Sustainability 10, no. 1: 120. https://doi.org/10.3390/su10010120