Joining Technologies for Automotive Battery Systems Manufacturing

Abstract

:1. Introduction

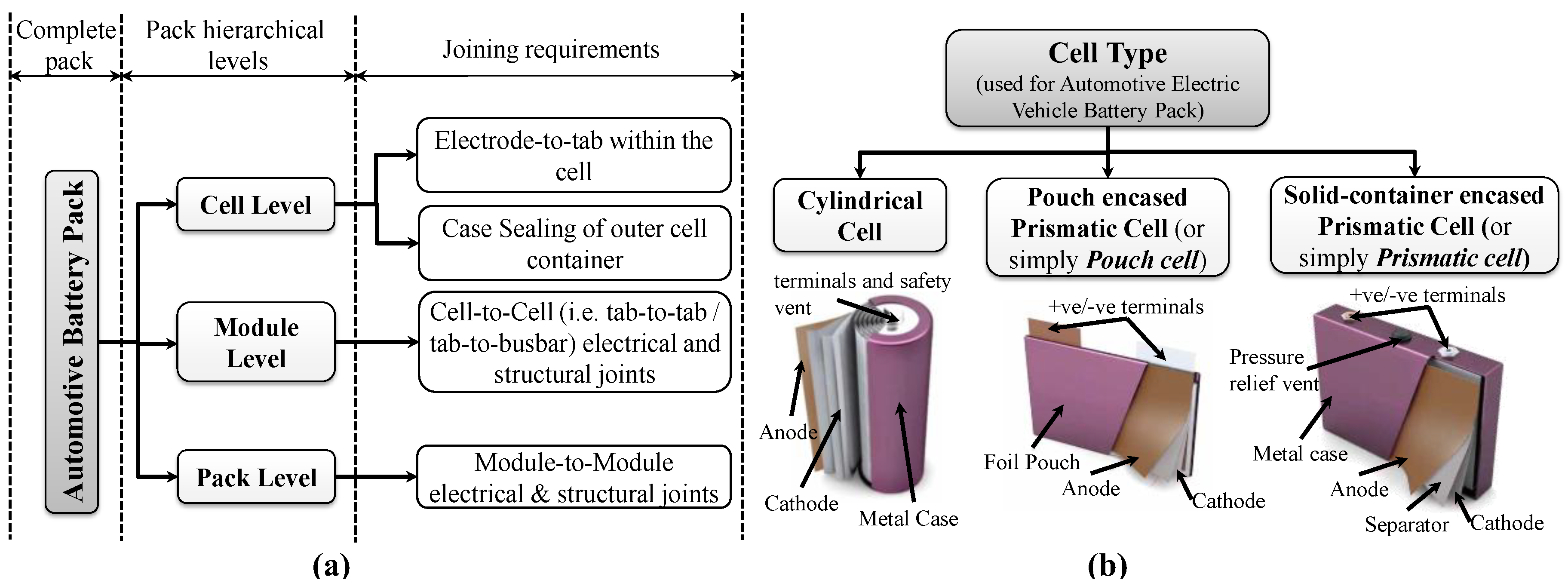

Overview of Key Joining Challenges

- Electrical and thermal challenges: (i) Producing joints with low electrical resistance—lower electrical resistance at the joint results in low energy loss, low heat generation, and subsequently, lower joint temperature increase during charging and discharging. (ii) Producing joints with low thermal input—low thermal input is preferable, especially when joining with fusion type welding processes, as exposing the cell to high heat may melt or disturb the safety vent, compromise seals, or cause internal shorting. (iii) High thermal fatigue resistance—thermal fatigue resistance of battery interconnects is an important criterion for long-term durability and reliability performance.

- Material and metallurgical challenges: (i) Compatibility for dissimilar materials joining—dissimilar materials may create intermetallic layers, which are not preferred because of their higher electrical resistance and brittle nature compared with parent materials. Therefore, joints with low intermetallic is preferable. (ii) Variability of materials and surfaces—highly conductive and reflective materials, any surface coatings or oxide layers, joint stack-ups (especially varying thicknesses and/or multiple sheets) also need to be overcome for satisfactory joints.

- Mechanical challenges: (i) Durable joint strength—the joint area/nugget size that can be achieved by the joining methods should have satisfactory joint strength with low strength variability. (ii) Avoid mechanical and vibrational damage when joining—excessive deformation of, or transmission of vibration into, the cell may damage internal connection. Precautions must be taken to avoid these as induced residual stress or vibrational energy may be released and cause joint failure.

2. Major and Emerging Joining Technologies—A Comprehensive Review

2.1. Ultrasonic Welding or Ultrasonic Metal Welding (UMW)

2.2. Resistance Spot/Projection Welding

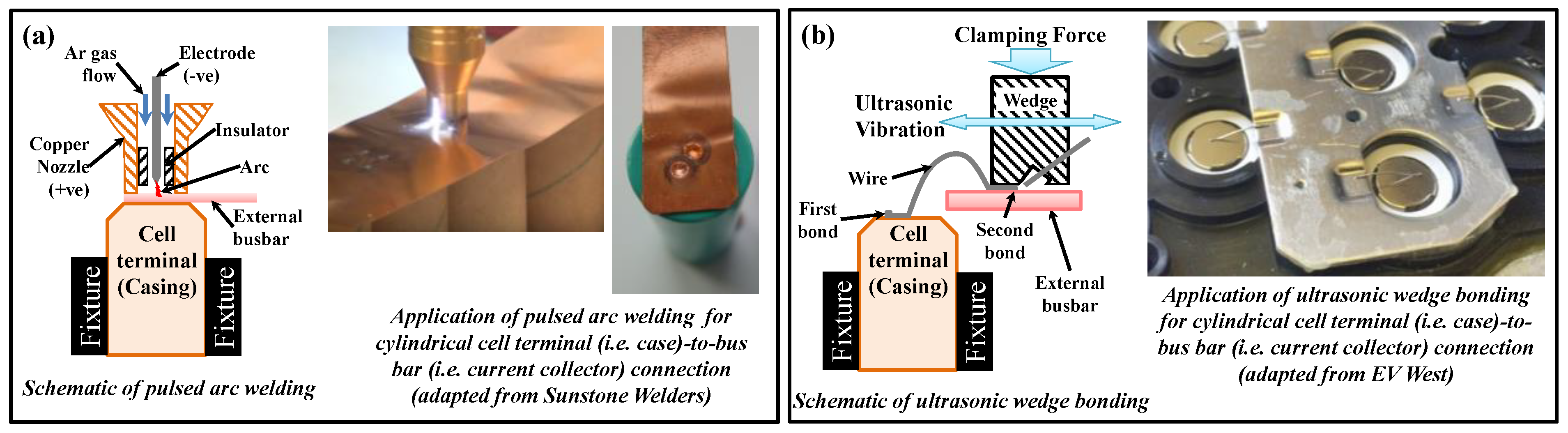

2.3. Micro-TIG or Pulsed Arc Welding (PAW)

2.4. Ultrasonic Wedge Bonding

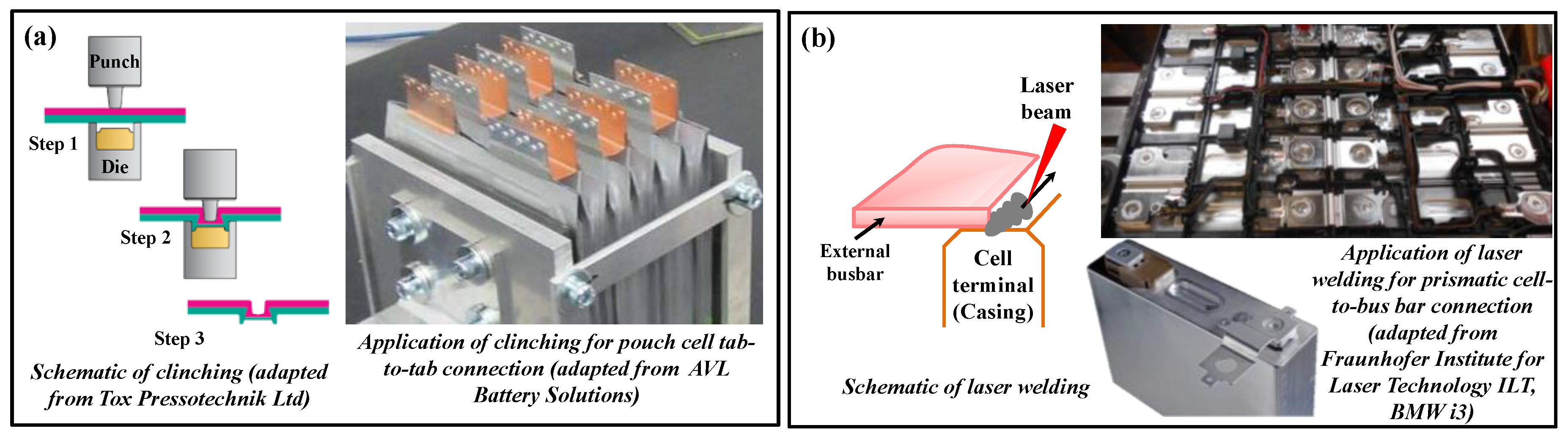

2.5. Micro-Clinching

2.6. Soldering

2.7. Laser Welding

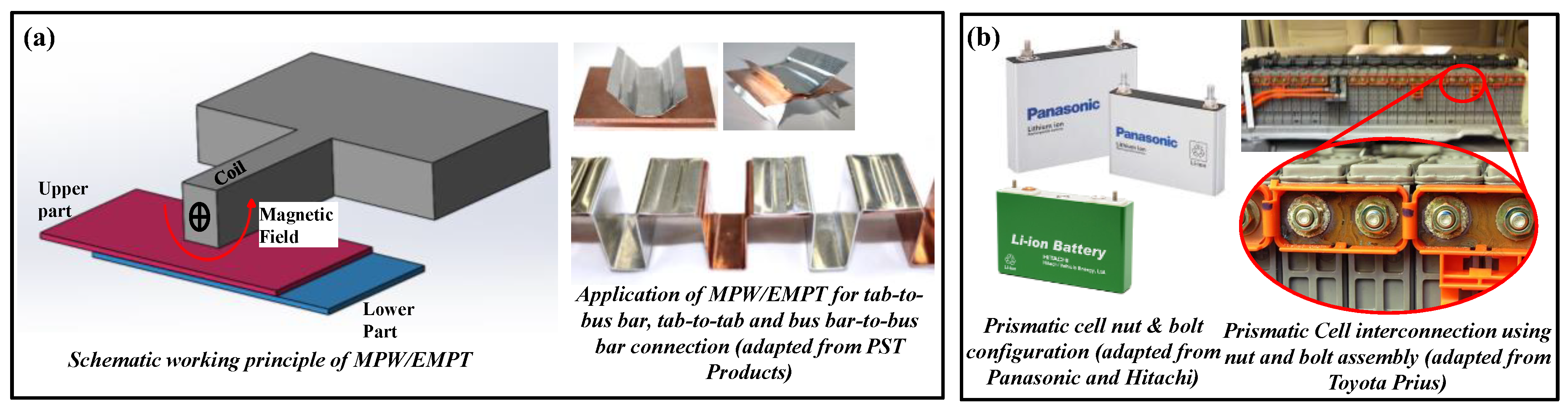

2.8. Magnetic Pulse Welding (MPW)/Electromagnetic Pulse Technology (EMPT)

2.9. Mechanical Assembly

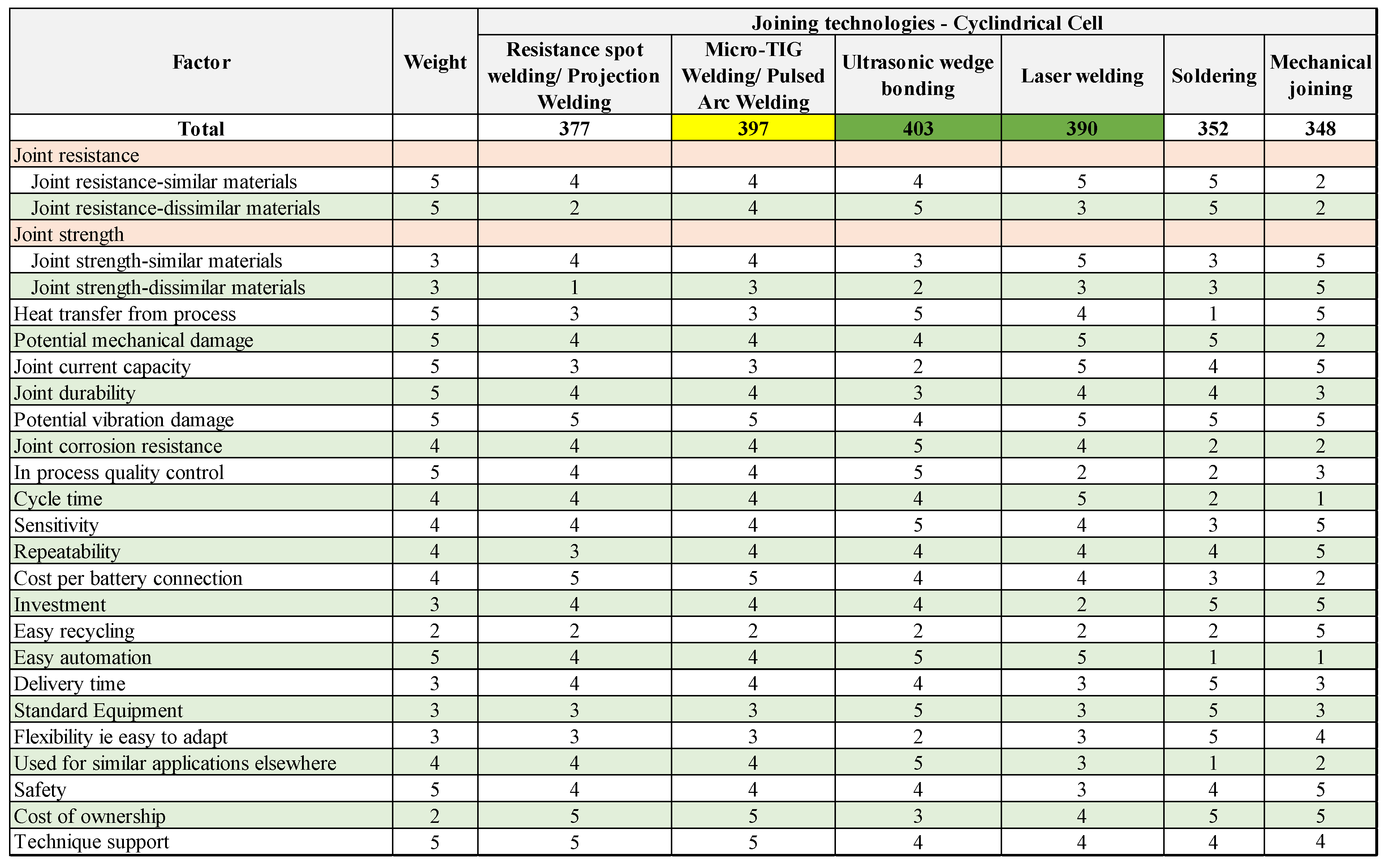

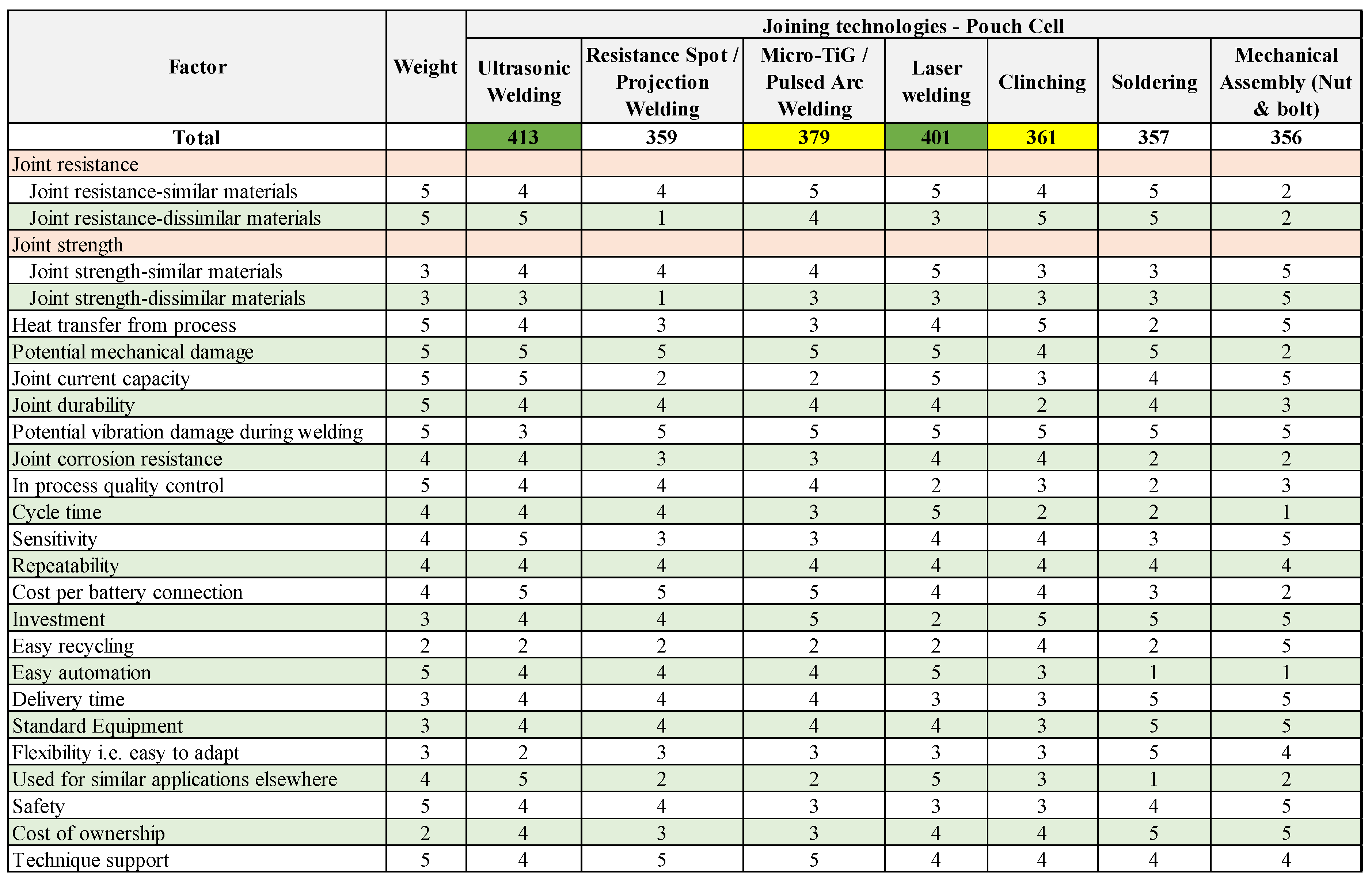

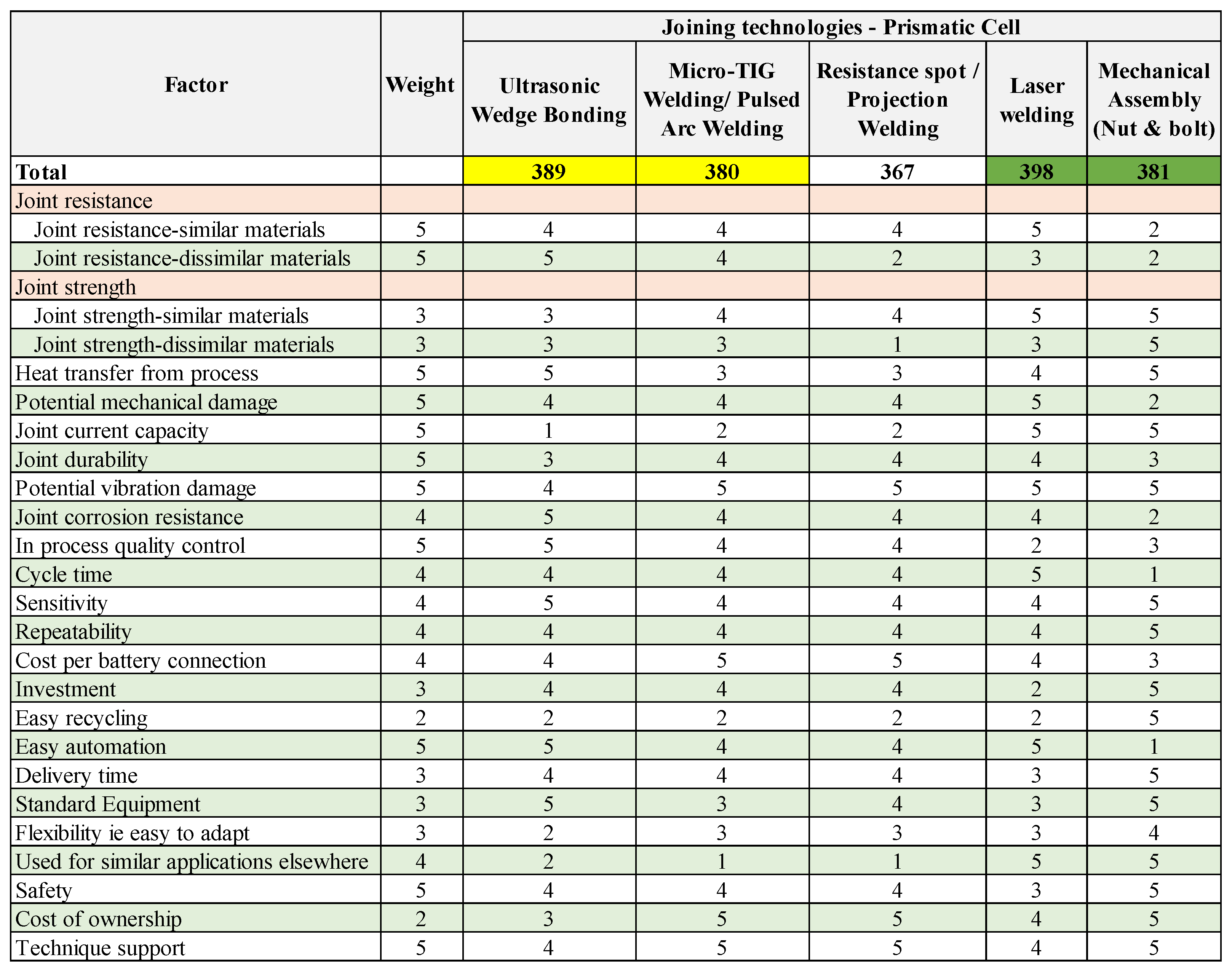

3. Evaluation, Applicability and Feasibility of Joining Technologies

3.1. Battery Pack Hierarchical Joining

3.1.1. Joining of Cylindrical Cell Based Battery Pack

- Cell level joining: The assembly process for cylindrical cells requires joining methods at two levels, which are (i) electrode foil-to-tab joining and (ii) terminal welding (i.e., tab-to-case/can). Ultrasonic and resistance spot welding are the most commonly used joining methods for electrode foil-to-tab and terminal welding, respectively [27]. Laser welding is also feasible for electrode foil-to-tab joining, however, tight part-to-part tolerance has to be maintained for satisfactory joints. Terminal welding is not be feasible by laser welding if line of sight is obscured.

- Module and pack level joining: Because of the physical size and form of a cylindrical cell, external current collectors are added to connect cells. Physical projections reduce the contact area in projection welding, allowing concentrated heat generation at the point of contact, and formation of the weld nugget faster and at a lower current level compared with conventional spot welding [28], reducing potential damage to the RSW-electrode. Similar to resistance welding, advances in high-frequency power supplies, increased low-current control, and arc stability, have enabled much finer TIG welding, such as pulsed arc welding. Pulsed arc welding offers excellent copper to copper joining with a fairly relaxed process window with respect to part fit-up and positioning tolerances of the electrode to the parts [29]. As ultrasonic welding exerts high frequency vibration under locally applied force, there is a risk that a cell may suffer internal damage to the electrode. Therefore, ultrasonic welding of cylindrical cells at module level may not be appropriate without steps to mitigate the possibility of damage. However, ultrasonic wedge bonding has been used for cell-to-cell connections. In the Tesla battery pack [30], each of the cells has two wires that act as fuses (one each for the anode and cathode) and are connected using ultrasonic wedge bonding. Laser welding is emerging as an efficient alternative for forming joints between cylindrical cell terminals and external current collectors, that is, bus bars. However, part-to-part fit-up needs to be carefully controlled to achieve satisfactory joints using laser welding. By designing proper jigs and fixtures, a large number of cylindrical cells can be connected to produce a battery module. Permanent joining, such as welding, may not be suitable for large pack level joining because of battery maintenance and service requirements [13]. As a consequence, mechanical nut and bolt assembly has been widely adopted at the pack level.

3.1.2. Joining of Pouch Cell Based Battery Pack

- Cell level joining: During fabrication of pouch cells, the joining operations are (i) electrode current collectors to positive and negative terminal tabs, and (ii) case sealing of pouch cell—an automated and standard process under vacuum [31]. Electrode-to-tab welds are conventionally made using ultrasonic technology because of the need to create a joint through a stack of foils. RSW is not appropriate as RSW-electrodes are prone to picking-up highly conductive cell terminal/electrode and tab materials [32]. However, fibre laser welding technology may be used for increased weld quality and strength [33]. The key to successful application of laser welding is to ensure that (a) the foils are in close contact, and (b) a pulsed laser is used to avoid overheating. In the case of pouch cell case sealing, typically, a compact heat sealer is used to seal aluminium–polymer laminate films.

- Module and pack level joining: Module designs typically position positive and negative terminal tabs either at opposite ends or the same end of the cell based on series or parallel connection requirements. Therefore, the cells are joined either by tab-to-tab or tab-to-bus bar connections. Ultrasonic welding has received significant attention for module level joining as a result of its ability to produce good welds for dissimilar materials and multiple thin layers. RSW or projection welding, pulsed arc welding, and clinching of tab-to-tab or tab-to-bus bar joints are feasible. However, process stability, joint characteristics, thermal input, and process control require further investigation. However, feasible soldering of pouch cell interconnects is not recommended as it raises concerns of joint strength under vibration, neutralisation of fluxes, risk of localised heat damage, and creation of debris in the joint area. As an alternative, MPW/EMPT has the potential for joining pouch cell tab-to-tab or tab-to-bus bar [25]. However, detailed investigation is required for MPW/EMPT application, as induced eddy currents may affect the physical parts/electrochemistry (e.g., potential cracks or internal joining between current collectors that leads to battery internal short-circuit) of the pouch cell. To mitigate the risk of damaging the pouch cell, or module sensors, a specially designed weld head and shielding plate may be required during EMPT welding. Laser welding is another alternative solution for pouch cell tab-to-tab or tab-to-bus bar joining. Fibre lasers are able to weld many material combinations including aluminium to aluminium, aluminium to steel, copper to steel, and copper to aluminium. Further investigations are required for fixture design, process parameter optimisation and process control. Generally, pack level (i.e., module-to-module) connections are made with mechanical fasteners.

3.1.3. Joining of Prismatic Cell Based Battery Pack

- Cell level joining: The fabrication of prismatic cells involves similar joining operations to cylindrical and pouch cells (i) between current collector tabs and electrode foil(s), (ii) between collector tab and battery terminal, and (iii) case sealing. Ultrasonic welding is most commonly used for joining current collector tabs with electrode foil(s) [31]. Resistance spot welding is used to connect current collector tabs with the case or with the top cap of the case [27]. Typically, prismatic cell positive and negative terminals are based on mechanical nut and bolt assembly. Laser welding is also used for cell level joining and traditionally case sealing. As reported by Shannon [12], laser welding has potential for a number of manufacturing applications, such as case sealing [34] and terminal welding.

- Module and pack level joining: As a result of the stackable form of prismatic cells, battery pack modularity and various design configurations for parallel or series connections are readily achievable. Module and pack level joining is mainly performed with mechanical nut and bolt fasteners or clip fitting. Mechanical nut and bolt assembly has the advantage of easy disassembly and higher joint strength compared with other reported joining techniques. However, there are issues with high contact resistance and maximum torque (to avoid internal damage) that can be sustained by the cell stud. In some cases, laser welding has also been used for connecting cell terminal with bus bar [35]. Ultrasonic wedge bonding and micro-TIG between terminal and bus bar may be feasible for prismatic cells. However, design changes may be required for UWB since cell terminals are not directly connected with bus bars. Application of these methods requires investigation of wire thickness, heat input, current carrying capacity, and so on.

3.2. Joining Technology Recommendation for Battery Manufacturing

4. Conclusions

- Cylindrical, pouch, and prismatic cells based battery pack construction are discussed in detail, with limitations of the specific technologies identified where their use is infeasible. Further, applicability of joining methods is discussed with hierarchical levels of battery manufacturing.

- Key joining challenges are identified for battery systems manufacture, including electrical, thermal, material, metallurgical, and mechanical challenges.

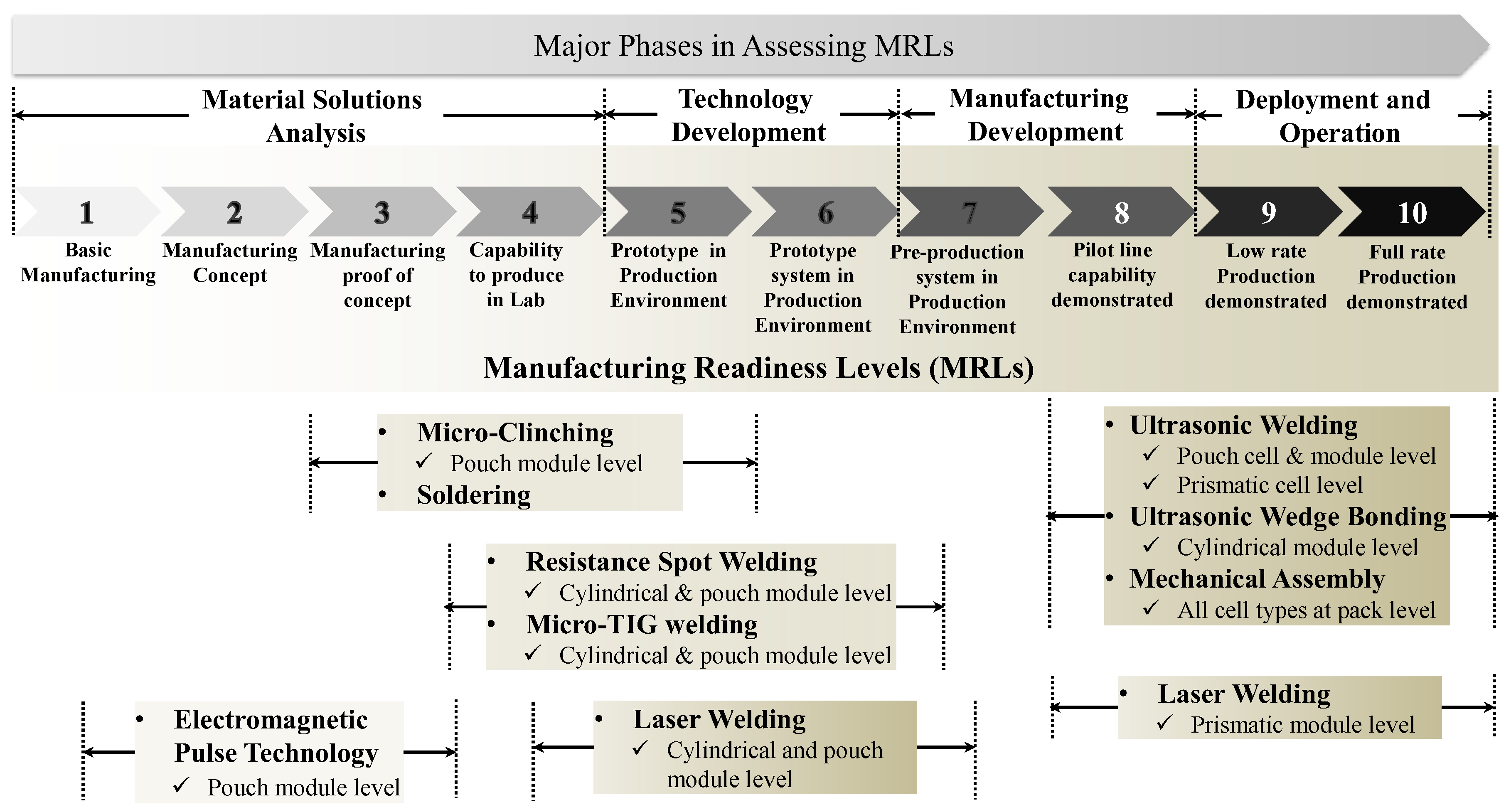

- Joining techniques are described with respect to MRLs and suitability of the identified joining technologies is quantified. Recommendations for further investigation of joining technologies are made based on Pugh matrix scores, MRLs, and application potential.

Author Contributions

Funding

Conflicts of Interest

References

- Faria, R.; Moura, P.; Delgado, J.; de Almeida, A.T. A Sustainability Assessment of Electric Vehicles as a Personal Mobility System. Energy Convers. Manag. 2012, 61, 19–30. [Google Scholar] [CrossRef]

- Whittingham, M.S. History, Evolution, and Future Status of Energy Storage. Proc. IEEE 2012, 100, 1518–1534. [Google Scholar] [CrossRef]

- Becker, J.; Nemeth, T.; Wegmann, R.; Sauer, D. Dimensioning and Optimization of Hybrid Li-Ion Battery Systems for EVs. World Electr. Veh. J. 2018, 9, 19. [Google Scholar] [CrossRef]

- Pfriem, M.; Gauterin, F. Development of Real-World Driving Cycles for Battery Electric Vehicles. World Electr. Veh. J. 2016, 8, 14–24. [Google Scholar] [CrossRef]

- JMBS. Our Guide to Batteries; Johnson Matthey Battery Systems: Milton Keynes, UK, 2015. [Google Scholar]

- Zhang, C.; Li, L. A Coupled Thermal-Mechanical Analysis of Ultrasonic Bonding Mechanism. Metall. Mater. Trans. B 2009, 40, 196–207. [Google Scholar] [CrossRef]

- De Vries, E. Mechanics and Mechanisms of Ultrasonic Metal Welding; The Ohio State University: Columbus, OH, USA, 2004. [Google Scholar]

- Siddiq, A.; Ghassemieh, E. Thermomechanical Analyses of Ultrasonic Welding Process Using Thermal and Acoustic Softening Effects. Mech. Mater. 2008, 40, 982–1000. [Google Scholar] [CrossRef]

- Kim, T.H.; Yum, J.; Hu, S.J.; Spicer, J.P.; Abell, J.A. Process Robustness of Single Lap Ultrasonic Welding of Thin, Dissimilar Materials. CIRP Ann.-Manuf. Technol. 2011, 60, 17–20. [Google Scholar] [CrossRef]

- Shawn Lee, S.; Hyung Kim, T.; Jack Hu, S.; Cai, W.W.; Abell, J.A.; Li, J. Characterization of Joint Quality in Ultrasonic Welding of Battery Tabs. J. Manuf. Sci. Eng. 2013, 135, 021004. [Google Scholar] [CrossRef]

- Brand, M.J.; Schmidt, P.A.; Zaeh, M.F.; Jossen, A. Welding Techniques for Battery Cells and Resulting Electrical Contact Resistances. J. Energy Storage 2015, 1, 7–14. [Google Scholar] [CrossRef]

- Shannon, G. Improve Tab to Terminal Connections in Battery Pack Manufacturing; Amada Miyachi America Inc.: Monrovia, CA, USA, 2016. [Google Scholar]

- Lee, S.S.; Kim, T.H.; Hu, S.J.; Cai, W.W.; Abell, J.A. (Eds.) Joining Technologies for Automotive Lithium-Ion Battery Manufacturing: A Review. In Proceedings of the ASME 2010 International Manufacturing Science and Engineering Conference, Erie, PA, USA, 12–15 October 2010. [Google Scholar]

- Zhou, Y.; Gorman, P.; Tan, W.; Ely, K.J. Weldability of Thin Sheet Metals During Small-Scale Resistance Spot Welding Using an Alternating-Current Power Supply. J. Electr. Mater. 2000, 29, 1090–1099. [Google Scholar] [CrossRef]

- Park, M.; Hirata, Y. Research on Generation of Micro-Plasma Arc and Its Power Intensity. Weld. Int. 2017, 31, 284–290. [Google Scholar] [CrossRef]

- Hirata, Y. Pulsed Arc Welding. Weld. Int. 2003, 17, 98–115. [Google Scholar] [CrossRef]

- Ji, H.; Li, M.; Wang, C.; Guan, J.; Bang, H.S. Evolution of the Bond Interface During Ultrasonic Al–Si Wire Wedge Bonding Process. J. Mater. Process. Technol. 2007, 182, 202–206. [Google Scholar] [CrossRef]

- Lum, I.; Mayer, M.; Zhou, Y. Footprint Study of Ultrasonic Wedge-Bonding with Aluminum Wire on Copper Substrate. J. Electron. Mater. 2006, 35, 433–442. [Google Scholar] [CrossRef]

- Balawender, T.; Sadowski, T.; Kneć, M. Technological Problems and Experimental Investigation of Hybrid: Clinched—Adhesively Bonded Joint. Arch. Metall. Mater. 2011, 56, 438–446. [Google Scholar] [CrossRef]

- Varis, J. Ensuring the Integrity in Clinching Process. J. Mater. Process. Technol. 2006, 174, 277–285. [Google Scholar] [CrossRef]

- Walsh, C. Laser Welding—Literature Review; University of Cambridge: Cambridge, UK, 2002. [Google Scholar]

- Steen, W.M.; Mazumder, J. Laser Welding. In Laser Material Processing; Steen, W.M., Mazumder, J., Eds.; Springer: London, UK, 2010; pp. 199–249. [Google Scholar]

- Schmalen, P.; Plapper, P.; Cai, W. Process Robustness of Laser Braze-Welded Al/Cu Connectors. SAE Int. J. Altern. Power 2016, 5, 195–204. [Google Scholar] [CrossRef]

- Schäfer, R.; Pasquale, P.; Elsen, A. (Eds.) Material Hybrid Joining of Sheet Metals by Electromagnetic Pulse Technology. In Key Engineering Materials; Trans Tech Publications: Zürich, Switzerland, 2011. [Google Scholar]

- Kashani, M. Application of Magnetic Pulse Welding in Lithium-Ion Batteries Production; Tokyo Metropolitan College of Technology: Tokyo, Japan, 2014. [Google Scholar]

- Bonenberger, P.R. The First Snap-Fit Handbook, 3rd ed.; Hanser: Munich, Germany, 2016; pp. I–XXII. [Google Scholar]

- Tagawa, K.; Brodd, R.J. Production Processes for Fabrication of Lithium-Ion Batteries. In Lithium-Ion Batteries: Science and Technologies; Yoshio, M., Brodd, R.J., Kozawa, A., Eds.; Springer: New York, NY, USA, 2009; pp. 181–194. [Google Scholar]

- Sun, X. Effect of Projection Height on Projection Collapse and Nugget Formation—A Finite Element Study. Weld. J. 2001, 80, 211s–216s. [Google Scholar]

- Shannon, G. Selecting, Applying the Right Technology for Welding Batteries. 2014. Available online: http://weldingdesign.com/operations/selecting-applying-right-technology-welding-batteries?page=3 (accessed on 13 December 2016).

- Berdichevsky, G.; Kelty, K.; Straubel, J.; Toomre, E. The Tesla Roadster Battery System; Tesla Motors: Palo Alto, CA, USA, 2006. [Google Scholar]

- Reinhart, G.; Zeilinger, T.; Kurfer, J.; Westermeier, M.; Thiemann, C.; Glonegger, M.; Wunderer, M.; Tammer, C.; Schweier, M.; Heinz, M. Research and Demonstration Center for the Production of Large-Area Lithium-Ion Cells; Springer: Berlin/Heidelberg, Germany, 2013; pp. 3–12. [Google Scholar]

- Dong, S.; Kelkar, G.; Zhou, Y. Electrode Sticking During Micro-Resistance Welding of Thin Metal Sheets. IEEE Trans. Electron. Packag. Manuf. 2002, 25, 355–361. [Google Scholar] [CrossRef]

- Shannon, G. Battery Welding: Using Lasers for Tab Welding Applications. Amada Miyachi Blog, 2015. Available online: http://info.amadamiyachi.com/blog/laser-welding-tabs-for-battery-pack-manufacture (accessed on 13 December 2016).

- Mikolajczak, C.; Kahn, M.; White, K.; Long, R.T. Lithium-Ion. Batteries Hazard and Use Assessment; Springer Science & Business Media: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- Automotive Battery—Battery Module | Samsung Sdi. Available online: http://www.samsungsdi.com/automotive-battery/products/battery-module.html (accessed on 22 December 2016).

| Id | Joining Technology | Advantages | Disadvantages | Issues and Concerns |

|---|---|---|---|---|

| 1 | Ultrasonic welding | Fast process, high strength and low resistance, able to join dissimilar materials, low energy consumption | Only suitable for pouch cells, two sided access, slow joining | Access of anvil and sonotrode needs to be well designed |

| 2 | Resistance spot/projection welding | Fast process, low cost, good quality control, easy automation | Difficult for highly conductive and dissimilar materials | Difficulty to produce large joints, joining of more than two layers |

| 3 | Micro-TIG/pulsed arc welding | Low cost, high joint strength and low resistance, able to join dissimilar materials, easy automation | High thermal input and heat affected zone, porosity | Difficult to join Al to steel |

| 4 | Ultrasonic wedge bonding | Fast process, acting as fuses, able to join dissimilar materials, low energy consumption and easy automation | Only suitable for small wires, low wire and joint strength | Clamping of the batteries is critical |

| 5 | Micro-Clinching | Cold process, no additional part, clean process, able to join dissimilar materials | Only suitable for pouch cells, two side access, slow joining | Loosening under vibration, moisture ingress |

| 6 | Soldering | Joining dissimilar materials, wide spread in electronics industry | High heat, fluxes required | Joint strength, debris, neutralisation of fluxes |

| 7 | Laser welding | High speed, less thermal input, non-contact process, easy Automation | High initial cost, additional shielding system may required | Need good joint fit-up (intimate contact), high reflective materials |

| 8 | Magnetic pulse welding | Solid state process, able to join dissimilar materials, high joint strength, dissimilar materials | Potential large distortion, rigid support required | Possibility of eddy current passing through the cells |

| 9 | Mechanical assembly | Easy dismounting and recycling, easy repair, cold process | Additional weight, high resistance, expensive | Potential mechanical damage and go loose |

| Module Level Joining | MRL | ||

|---|---|---|---|

| Low (1–3) | Medium (4–6) | High (7–10) | |

| Investigate pouch module level joining | MPW/EMPT | ||

| Cylindrical and pouch module level, further extend to prismatic module level | Laser Welding, Micro-TIG, RSW | ||

| Cylindrical module level, further extend to prismatic module level | Ultrasonic Wedge Bonding | ||

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Das, A.; Li, D.; Williams, D.; Greenwood, D. Joining Technologies for Automotive Battery Systems Manufacturing. World Electr. Veh. J. 2018, 9, 22. https://doi.org/10.3390/wevj9020022

Das A, Li D, Williams D, Greenwood D. Joining Technologies for Automotive Battery Systems Manufacturing. World Electric Vehicle Journal. 2018; 9(2):22. https://doi.org/10.3390/wevj9020022

Chicago/Turabian StyleDas, Abhishek, Dezhi Li, David Williams, and David Greenwood. 2018. "Joining Technologies for Automotive Battery Systems Manufacturing" World Electric Vehicle Journal 9, no. 2: 22. https://doi.org/10.3390/wevj9020022