Recent Health and Safety Incident Trends Related to the Storage of Woody Biomass: A Need for Improved Monitoring Strategies

Abstract

:1. Introduction

2. Materials and Methods

2.1. Biomass Storage Incident Analysis

2.2. Real-Time Pile Monitoring

3. Results

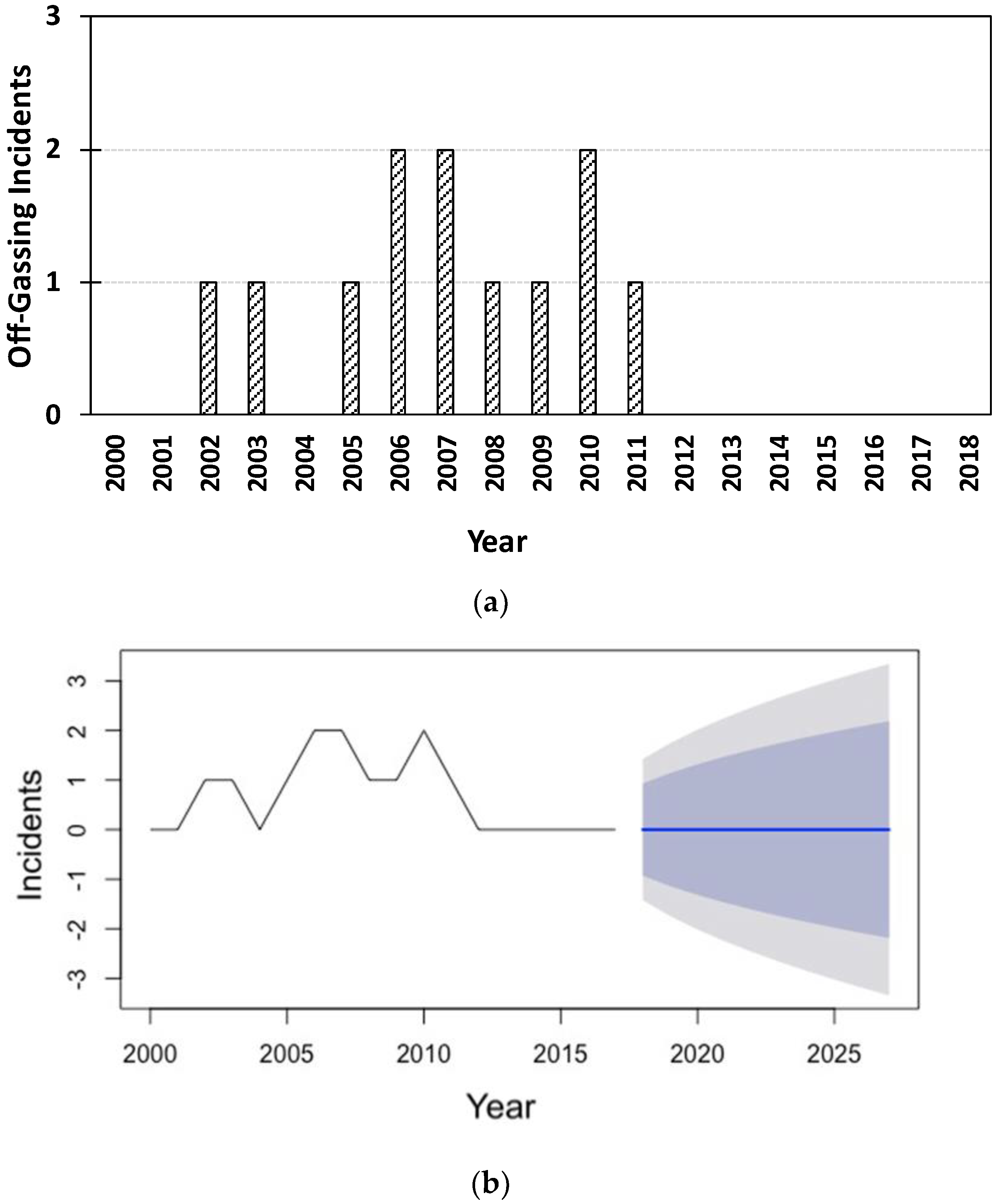

3.1. Biomass Storage Incident Analysis

3.2. Real-Time Pile Temperature Monitoring

4. Discussion

4.1. Biomass Storage Incident Analysis

4.2. Real-Time Pile Monitoring

5. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

| Reference & Incident Date | Category | Location | Description and Damages |

|---|---|---|---|

| [39] Incident: 26 May 2001. | Dust explosion | Gaylord, (USA) | (26 May 2001) Following an explosion and fire at a press board manufacturing plant the day before, firemen opened a silo to extinguish burning wood chips. When firefighters opened the silo to pour water on the flames, the sudden infusion of oxygen caused the second blast. One firefighter was seriously burned and 5 were treated for smoke inhalation. |

| [40] Incident: 2002. | Uncertain cause (fire) | Athens, Maine (USA) | In 2002, a fire started in a smoldering fuel pile at the Boralex construction and demolition debris incinerator. Several people were reportedly taken to the hospital for smoke inhalation. |

| [30] Incident: May 2002. | Off-gassing (suffocation) | Port of Rotterdam, Netherlands | In May 2002, one worker died and several others were injured onboard a ship from British Columbia (MV Weaver Arrow) due to the gas discharge of pellets being stored in transport. |

| [41] Incident: 28 March 2003. | Dust explosion | Bar Sur Aube, France | In a furniture factory, an explosion occurred inside a silo of wood chips feeding the boiler. Minor damages with no reported injuries. |

| [42] Incident: 7 May 2003. | Dust explosion | Gaillon, France | A deflagration occurred on a cyclone filter inside a sawmill/wood shop. The fire engulfed 500 m2 of a production building roof and 300 m2 of roof on a maintenance building. One person sustained skin burns on the shoulders. |

| [43] Incident: 6 October 2003. | Self-heating | Rambervillers, France | In a wood panel manufacturing plant, a fire broke out on a stock of 1200 tons of chips. The accident was caused by the self-ignition of chips. No reported injuries. |

| [32] Incident: 2003. | Off-gassing | USA | One death occurred in a cargo hold carrying timber due to off-gassing. No further information available. |

| [44] Incident: 15 April 2004. | Uncertain cause (fire) | Saint-Florentin, France | A fire broke out on a 150 m3 outdoor pile of untreated waste wood from a planing workshop (when loading chippings into a semi-trailer). A firefighter received minor burns to one hand during the intervention. |

| [6] Incident: 2005. | Off-gassing (suffocation) | Gruvon, Sweden | A seaman suffocated on the wood freighter “Eken” when he went down the stairs to the cargo room which was filled with pulpwood. |

| [45] Incident: 25 January 2005. | Dust explosion | Corbenay, France | A wood dust explosion occurred in a manufacturing plant in a 360 m3 silo containing 30 m3 of dry chips. The accident occurred while the reservoir was being emptied (just 5 days after an earlier fire at the site). No reported injuries. |

| [46] Incident: December 2005. | Self-heating | Southwestern Ontario | A large wood chip pile (400’ × 75’ × 30’) being stored for a greenhouse operation caught on fire (self-ignited). Two months later, another section of the pile self-ignited. |

| [40] Incident: October 2006. | Uncertain cause (fire) | Livermore Falls, Maine (USA) | In October 2006, a fuel pile caught fire at Beaver Wood Energy’s biomass power facility in Livermore Falls, Maine (and burned for over a month). |

| [30] Incident: November 2006. | Off-gassing (suffocation) | Port of Helsingborg, Sweden | In November 2006, one worker was killed, one seriously injured, and several rescue workers were injured due to off gassing from biomass storage in transport aboard the MS Saga Spray (from British Columbia). |

| [6] Incident: 2006. | Off-gassing (suffocation) | Skelleftehamn, Sweden | A seaman onboard the “Noren” died when he entered a storage compartment filled with woodchips. |

| [40] Incident: May 2007. | Uncertain cause (fire) | Sittard, Netherlands | An explosion occurred at a biomass energy facility in Sittard, Netherlands on 10 May 2007. |

| [6] Incident: 2007. | Off-gassing (suffocation) | Timra, Sweden | The captain and one seaman onboard the “Fembria” (wood-freighter) died when they walked into a storage compartment filled with timber wood. |

| [6] Incident: 2007. | Off-gassing (suffocation) | Finland | A person died when walking into a 10 tonne wood pellet silo. |

| [6] Incident: 2008. | Off-gassing (suffocation) | Finland | Another person died when walking into a 10 tonne wood pellet silo. |

| [40] Incident: 4 July 2009. | Self-heating (suspected) | White City, Oregon (USA) | An 80-foot-high biomass (woodchip) pile caught on fire at the Biomass One power plant in White City, Oregon on 4 July 2009. No reported injuries. |

| [6] Incident: 2009. | Off-gassing (suffocation) | Bornholm, Denmark | Two seamen died onboard the “Amirante” when they entered a cargo room filled with wood pellets (pellets were loaded one day prior to the incident). |

| [47] Incident: August 2010. | Dust explosion | Marion, USA | A fire blazed through AJ Stove & Pellet plant 2 August 2010. The fire started in the plant’s storage hopper by the back of the building. The spark of the fire was a dust explosion. The business was shut down while the owners made improvements. No injuries. |

| [6,30] Incident: January 2010. | Off-gassing (suffocation) | Germany | A 43-year-old engineer died in a small town in Germany after he opened a pellet bunker door (storage room contained 155 tons of pellets). A second worker who was standing right behind him was also affected but still able to call the emergency services. |

| [6,30] Incident: November 2010. | Off-gassing (suffocation) | Ireland | A 38-year-old man in Ireland died after entering the 7-tonne wood pellet storage room. His wife and another man were treated in hospital after trying to pull him to safety. |

| [48] Incident: 21 June 2011. | Dust explosion (suspected) | Waycross, Georgia (USA) | An explosion occurred in a biomass wood pellet processing plant near Waycross on 21 June 2011, causing extensive damage to the processing facility. No reported injuries. |

| [49] Incident: October 2011. | Self-heating | South Shields, UK | A 200-tonne stockpile of biomass pellets is understood to have spontaneously combusted within a concrete storage unit (30 October 2011). Around 25 tonnes of wood had been burned in the fire, with firefighters spending more than 12 hours battling the fire. No injuries. |

| [50] Incident: 23 November 2011 | Uncertain cause (fire) | Nanton, Alberta (Canada) | A large wood chip pile caught fire at Chinook Feeders (Nanton, Alberta) during a very high wind period (which fed the flames and spread the fire in the surrounding area). No reported injuries. |

| [6,30] Incident: February 2011. | Off-gassing (suffocation) | Switzerland | A 28-year-old woman who was four months pregnant was found dead from suffocation in an 82-m3 pellet storeroom. |

| [28] Incident: January 2012. | Dust explosion | Burns Lake, British Columbia | Excessive wood dust led to an explosion which destroyed the Babine Forest Products sawmill in Burns Lake, British Columbia on 20 January 2012. Two workers were killed, and 19 others were injured. |

| [51] Incident: 27 February 2012. | Self-heating (suspected) | Essex, UK | A very large fire burned inside the wood pellet silos of RWE’s Tilbury Power Station in Essex, UK on 27 February 2012. (Fire began in a wood hopper; smoldering wood pellets were suspected of triggering the dust fire). |

| [52] Incident: 11 May 2012. | Dust explosion | Copenhagen, Denmark | A wood dust explosion occurred in a wood pellet silo at the Amager Power Station in Copenhagen, Denmark on 11 May 2012. (Occurred during “bang and clean” cleaning method). Three people were injured, one with severe burns. |

| [53] Incident: 17 December 2012. | Self-heating (suspected) | Copenhagen, Denmark | A fire started in a wood silo containing wood pellets at the Amager Power station in Copenhagen on 17 December 2012. No reported injuries. |

| [27] Incident: 24 April 2012. | Dust explosion | Prince George, British Columbia | A huge explosion and fire occurred at Lakeland Mills sawmill in Prince George, BC on 24 April 2012. Two workers died, 24 were injured. |

| [54] Incident: 2012. | Uncertain cause (fire) | Upper Leacock Township, (USA) | A fire broke out in storage silos at the Ironstone Mills plant. The fire began when two feet of sawdust left at the bottom of the silo had started to smoulder. The loss in sawdust material was estimated to be worth about $500. No injuries. |

| [55] Incident: 2013. | Dust explosion | East Providence, (USA) | A dust explosion and fire occurred at the Inferno Wood Pellets Company facility. Notably, the owners had invested capital to bring the building up to code and even received a license to operate the facility. One worker was injured. |

| [56] Incident: 2013. | Dust explosion | Kimball Place, (USA) | The explosion and fire broke out at the Creative Biomass plant. The fire activated the sprinkler systems in the single storey part of the old grain mill, and another fire broke out at another six-storey part of the building. Initial investigations believe that the dust collection system malfunctioned. No injuries. |

| [57] Incident: 2013. | Dust explosion | Woodville, USA | A dust explosion took place at a German Pellet plant in 2013. The explosion occurred in one of the silos which subsequently caused a fire to break out into another silo. The plant production capacity was listed as 578,000 metric tons of pellets per year. No injuries. |

| [58] Incident: 2013. | Dust explosion | Taupo, New Zealand | A dust explosion (sawdust) occurred at a Rotokawa wood pellet plant. The explosion started in the silo and ducting of the facility. The result of the fire did not cause any physical damage to the building itself, though it had to be put out of commission for several days. No injuries. |

| [59] Incident: 2013. | Self-heating (suspected) | Shakopee, USA | A fire broke out in two of the fuel storage silos at the Koda combined-heat-and-power biomass facility (2013). The 23.4 MW facility burns wood chips, oat hulls and other organic materials to generate electricity for Xcel Energy Inc. The fire burned for over a week and damaged a conveyor belt and a truck unloading facility. No injuries. |

| [60] Incident: 2014. | Self-heating | Ilkeston, England | A fire broke out at the Arcwood Recycling facility in a pile of 8000 tonnes of stored wood. Investigations determined that the wood was stored too close to a gas supply, suggesting non-compliance with regulations. As a result, the owner of the facility pleaded guilty to safety failures. No injuries. |

| [61] Incident: 29 April 2014. | Dust explosion | Moray, Scotland | Seven people (including firefighters) were injured in a fire and explosion at an industrial estate in Moray, Scotland. The incident involved a wood dust silo bin, in which the company burned excess sawdust. |

| [62] Incident: 2 June 2014. | Uncertain cause (fire) | South Yorkshire, England | A large wood chip pile fire took place at R. Plevin & Sons wood recycling plant in Crow Edge (Yorkshire) on 2 June 2014. |

| [63] Incident: 2014. | Self-heating | Teeside, UK | A series of fires occurred at a Teeside wood recycling company from December 2013 until April 2014. The company was fined as a result for an environmental offence. The UK Wood Recycling (UKWR) plant was ordered to pay £71,335 and a victim surcharge of £120 at a Teesside Crown Court. No injuries. |

| [64] Incident: March 2014. | Dust explosion | St. Augustine, Florida (USA) | Indianhead Biomass Services plant: An explosion occurred in March 2014, injuring two workers. |

| [64] Incident: July 2014. | Dust explosion | St. Augustine, Florida (USA) | Indianhead Biomass Services plant: Another explosion occurred in July 2014, injuring two workers. |

| [65] Incident: 2014. | Uncertain cause (fire) | Aurangabad, India | A pile of bagasse and biomass waste stored at the Shendra Green Energy biomass power facility caught fire. No injuries. |

| [66] Incident: 2015. | Self-heating | Montril, Spain | A major fire broke out in a pile of biomass chips at the Las Azucenas dock in Montril. No injuries. |

| [67] Incident: 2015. | Self-heating | Tracy, USA | A Tracy Storage Facility owned by Agra Marketing Group caught fire after not following biomass pile size regulations. The facility is a 40-acre “storage and solar drying facility” for agricultural by-products. The fire required 500,000 to 1 million gallons of water to extinguish the fire. No reported injuries. |

| [66] Incident: January 2015. | Self-heating | Fort St. John, British Columbia | A “hog pile” of leftover tree bark was believed to have spontaneously combusted at a wood processing mill near Fort St. John, British Columbia. It took eight hours to contain the fire. |

| [68] Incident: 15 January 2015. | Uncertain cause (fire) | Port of Southampton, England | Large biomass pile (owned by Eco Sustainable Solutions Limited) caught on fire at King George Graving Dock on 13 January 2015. |

| [40] Incident: 30 January 2015. | Uncertain cause (fire) | Motril, Spain | A major fire broke out in a pile of biomass chips on 30 January 2015. |

| [69] Incident: 23 September 2015. | Dust explosion (suspected) | Borssele, Zeeland (Netherlands) | Two explosions occurred in a biomass powerplant on 23 September 2015, were thought to be started by dust igniting in the biomass storage facility which was being dismantled. Four people were hospitalized, two of which were seriously injured. |

| [70] Incident: 5 November 2015. | Self heating | Port of Tyne, UK | Wood pellets began to smolder in a cargo hold of a ship carrying 11,000 tonnes of wood pellets (November 2015). 100 tonnes of smoldering pellets were unloaded and left to cool on the dock side. |

| [71] Incident: 15 December 2015. | Uncertain cause (fire) | Alexandra Docks, (Newport) Wales, UK | ~20,000 tons of woodchips caught fire on 5 December 2015 at the Newport Docks. Several attempts were needed to put out the blaze. |

| [72] Incident: 27 August 2016. | Uncertain cause (fire) | Ballachulish Bridge, UK | A building full of wood chips caught on fire near Ballachulish Bridge on 27 August 2016. No reported injuries. |

| [73] Incident: 11 September 2016. | Uncertain cause (fire) | White City, Oregon (USA) | 2 sawdust fires were reported from Biomass One on 11 September 2016 (flames over 25 feet high). Fire origin was unclear. No reported injuries. |

| [74] Incident: 12 March 2017. | Self heating | Chokchai district, Thailand | 500 tonne biomass pile caught on fire at the Advanced Agro-Power Plant in Tambon, Chokchai (Thailand) on 12 March 2017 due to accumulated heat. |

| [75] Incident: 12 April 2017. | Uncertain cause (fire) | Springfield, Massachusetts (USA) | A wood chip silo fire at Springfield Power (owned by Korea East West Power Company) took place on 12 April 2017. No serious injuries. |

| [76] Incident: 15 April 2017. | Self heating (suspected) | Port Arthur, Texas (USA) | A persistent smoldering fire started in a wood pellets silo (German Pellets) on Sat, 15 April 2017. It took ~2 weeks to completely extinguish the fire. No injuries. |

| [77] Incident: 11 June 2017. | Uncertain cause (fire) | West Sussex, England | A fire occurred in a 500 tonne pile of wood chippings within a 3000 m2 warehouse at Rabbit Waste Management (stored for incineration). No reported injuries. |

| [78] Incident: 10 June 2017. | Uncertain cause (fire) | Cottondale, Florida (USA) | Enviva’s wood pellet mill caught fire on 10 June 2017. Two workers were treated for smoke inhalation. |

| [79] Incident: 15 July 2017. | Self-heating (suspected) | Lumby, British Columbia | A wood chip pile (reserve pile for Tolka Industries) caught on fire in the middle of Lundy, BC. The fire chief deemed the cause as being spontaneous combustion. No reported injuries. |

| [80] Incident: 24 August 2017. | Self Heating (suspected) | Prince George, British Columbia | 24 August 2017: Finished pellets began smoldering in a silo at Pacific Bioenergy Plant. No injuries. |

| [81] Incident: 2 November 2017. | Uncertain cause (fire) | Williams Lake, British Columbia | A large fire occurred at Tolko’s Lakeview sawmill in Williams Lake BC. Several flare-ups took place afterwards. Significant damages were incurred but no injuries were reported. |

| [82] Incident: 29 December 2017. | Uncertain cause (fire) | Kenora, Ontario | A fire took place on 29 December 2017 at Kenora Forest Products sawmill. Two kilns were destroyed (damages estimated at $850,000). No reported injuries. |

| [83] Incident: 6 February 2018. | Self heating (suspected) | Port Alberni, British Columbia | A fire took place at Western Forest Products’ Alberni pacific Division Mill (Port Alberni, BC) on 6 February. The fire was thought to have started in a hog pile which was smoldering before fire crews arrived. |

Appendix B

Appendix C

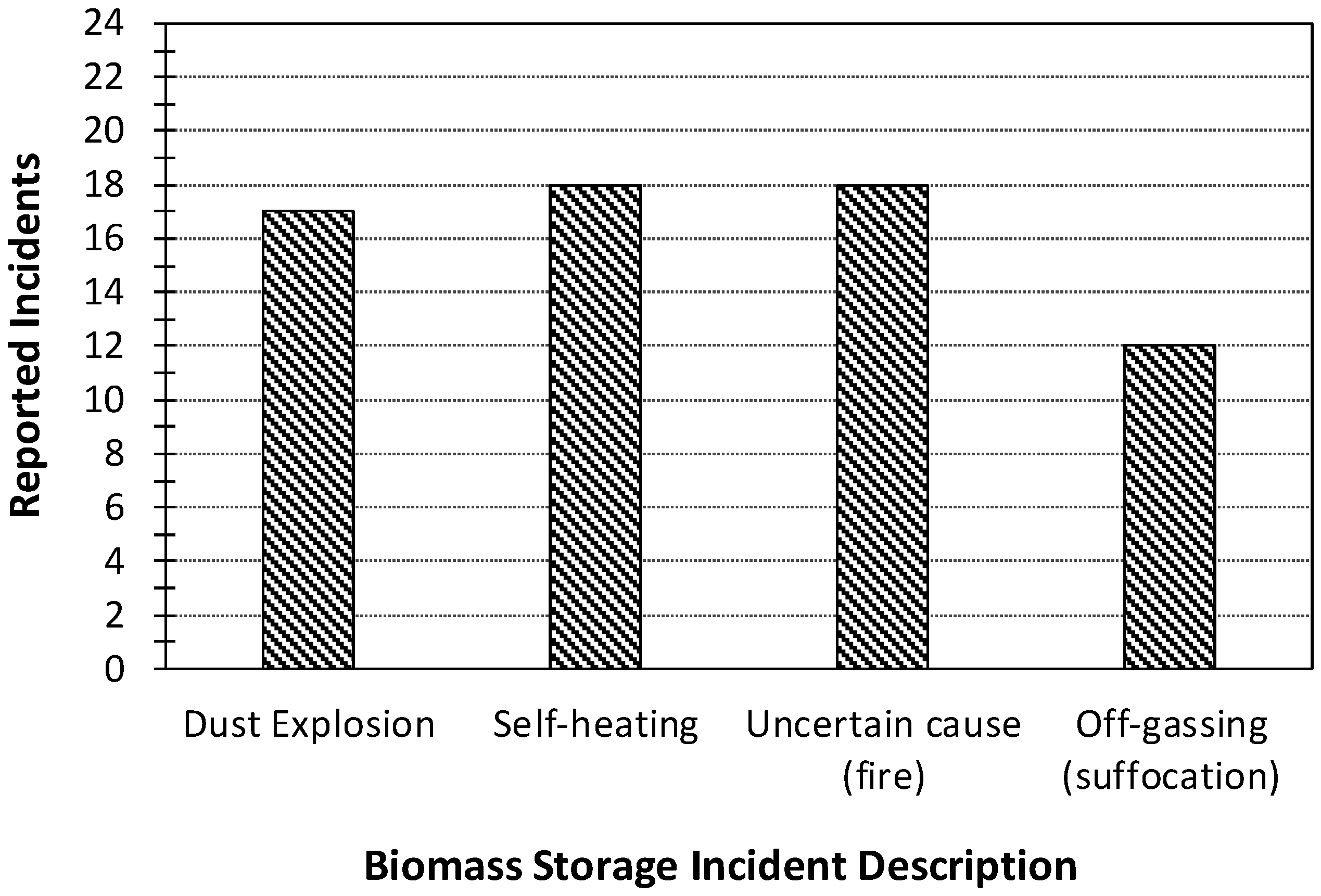

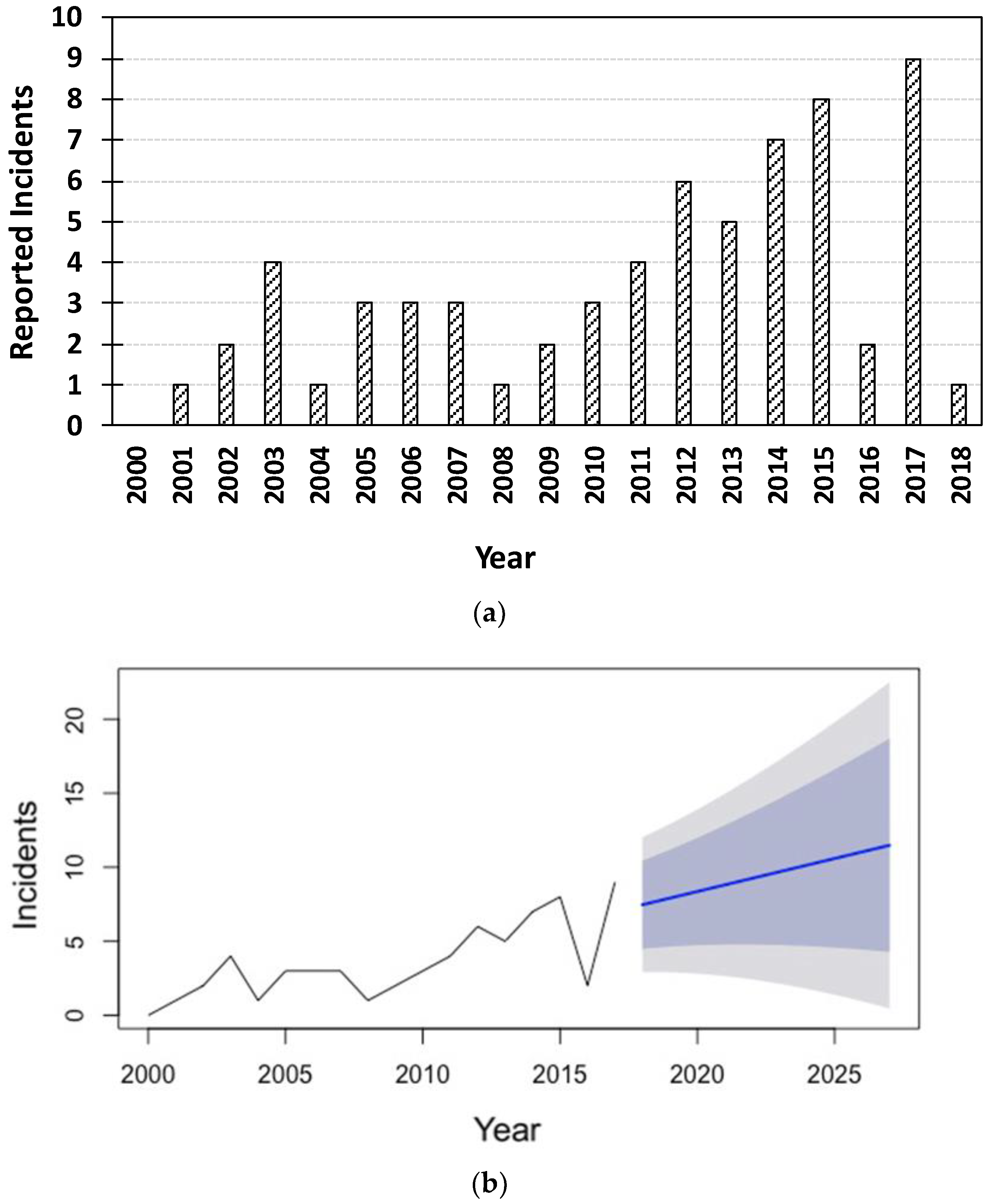

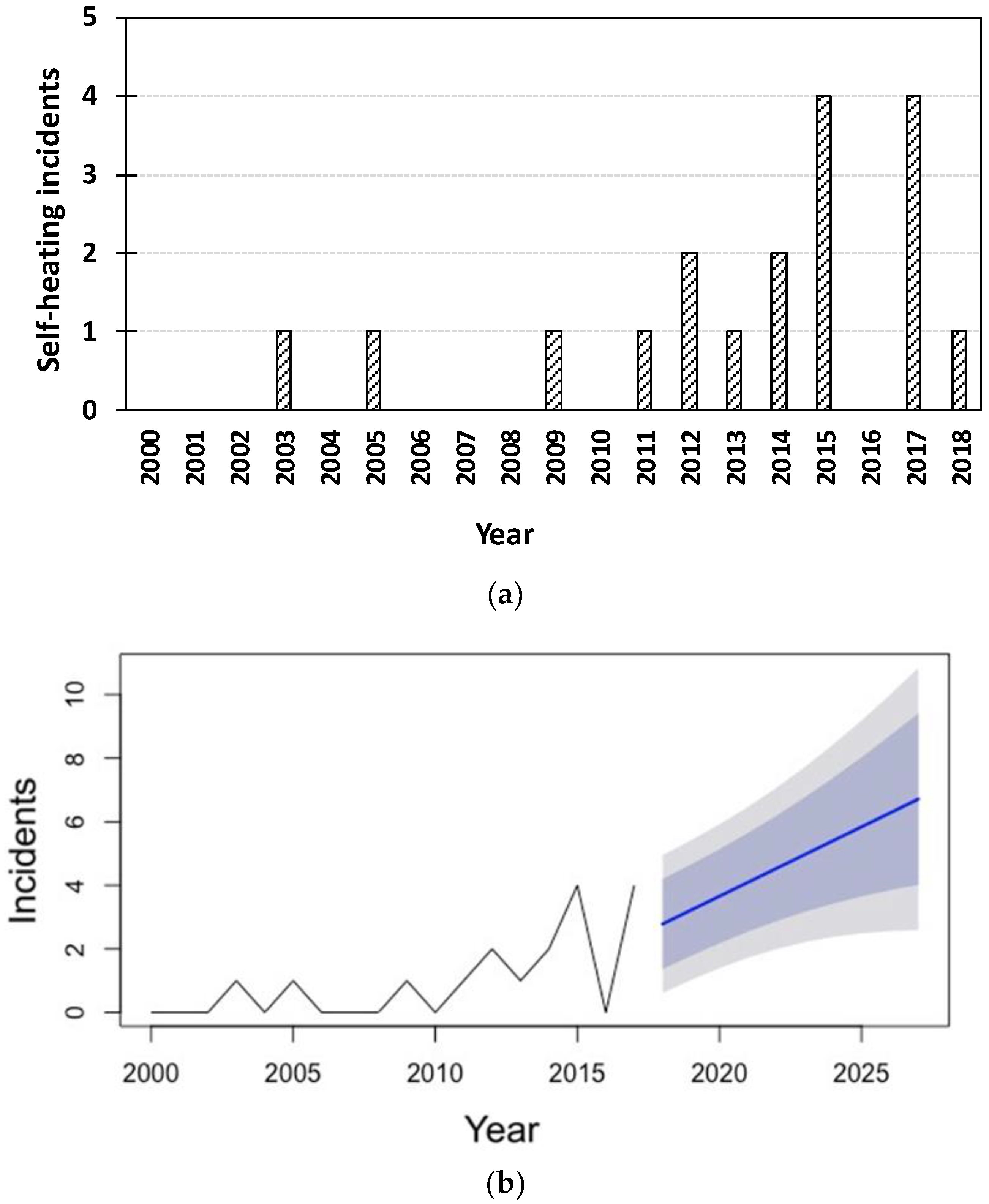

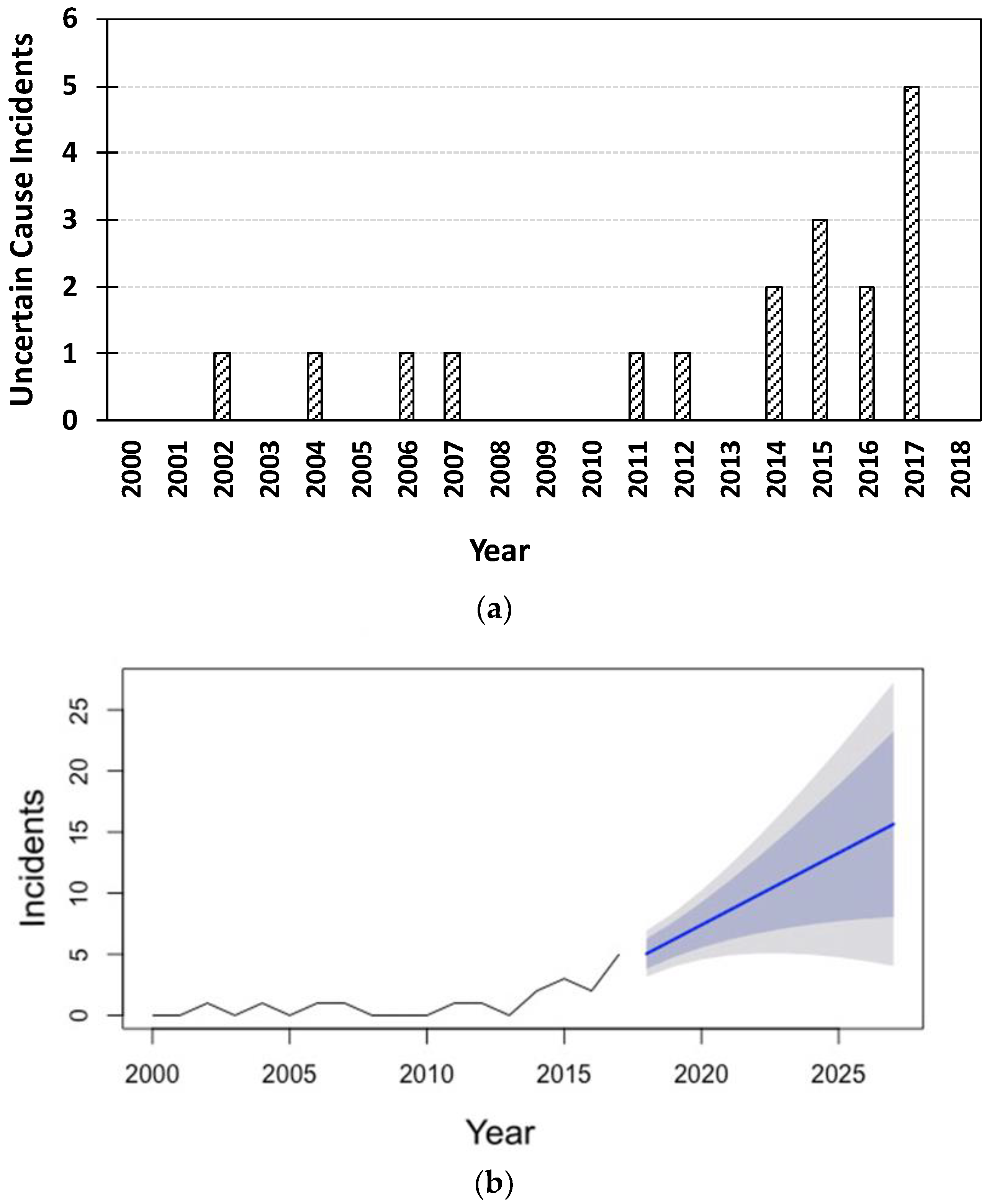

| Year | Dust Explosion | Self-Heating | Uncertain Cause (Fire) | Off-Gassing (Suffocation) | Reported Incident Total |

|---|---|---|---|---|---|

| 2000 | |||||

| 2001 | 1 | 1 | |||

| 2002 | 1 | 1 | 2 | ||

| 2003 | 2 | 1 | 1 | 4 | |

| 2004 | 1 | 1 | |||

| 2005 | 1 | 1 | 1 | 3 | |

| 2006 | 1 | 2 | 3 | ||

| 2007 | 1 | 2 | 3 | ||

| 2008 | 1 | 1 | |||

| 2009 | 1 | 1 | 2 | ||

| 2010 | 1 | 2 | 3 | ||

| 2011 | 1 | 1 | 1 | 1 | 4 |

| 2012 | 3 | 2 | 1 | 6 | |

| 2013 | 4 | 1 | 5 | ||

| 2014 | 3 | 2 | 2 | 7 | |

| 2015 | 1 | 4 | 3 | 8 | |

| 2016 | 2 | 2 | |||

| 2017 | 4 | 5 | 9 | ||

| 2018 | 1 | 1 | |||

| Total: | 17 | 18 | 18 | 12 | 65 |

| Incident Type | North America | Europe | Scandinavia (Denmark, Norway, Sweden) | Oceania (New Zealand) | Asia |

|---|---|---|---|---|---|

| Dust Explosion | 10 | 5 | 1 | 1 | |

| Self-heating | 9 | 7 | 1 | 1 | |

| Uncertain Cause (Fire) | 9 | 8 | 1 | ||

| Off-Gassing | 1 | 6 | 5 | ||

| Total: | 29 | 26 | 7 | 1 | 2 |

References

- Janze, P. Biomass Storage Pile Basics. 2011. Available online: http://www.advancedbiomass.com/2011/11/biomass-storage-pile-basics/ (accessed on 29 January 2018).

- Sovacool, B.K.; Andersen, R.; Sorensen, S.; Sorensen, K.; Tienda, V.; Vainorius, A.; Schirach, O.A.; Bjørn-Thygesen, F. Balancing safety with sustainability: assessing the risk of accidents for modern low-carbon energy systems. J. Clean. Prod. 2016, 112, 3952–3965. [Google Scholar] [CrossRef]

- Moreno, V.C.; Cozzani, V. Major accident hazard in bioenergy production. J. Loss Prev. Process Ind. 2015, 35, 135–144. [Google Scholar] [CrossRef]

- Back, E.L. Auto-ignition in hygroscopic, organic materials-especially forest products-as initiated by moisture absorption from the ambient atmosphere. Fire Saf. J. 1981, 4, 185–196. [Google Scholar] [CrossRef]

- Krigstin, S.; Wetzel, S. A Review of Mechanisms Responsible for Changes to Stored Woody Biomass Fuels. Fuel 2016, 175, 75–86. [Google Scholar] [CrossRef]

- Stelte, W. Guideline: Storage and Handling of Wood Pellets. Available online: https://www.teknologisk.dk/_/media/52682_RK%20report%20storage%20and%20handling%20of%20pellets.pdf (accessed on 28 March 2017).

- Ferrero, F.; Lohrer, C.; Schmidt, B.; Noll, M.; Malow, M. A mathematical model to predict the heating-up of large-scale wood piles. J. Loss Prev. Process Ind. 2009, 22, 439–448. [Google Scholar] [CrossRef]

- Hellenbrand, K.E.; Reade, A.E. Microorganisms associated with fuel wood chips and their impact on indoor air quality: A review. Int. Biodeterior. Biodegrad. 1992, 29, 19–43. [Google Scholar] [CrossRef]

- Ernstson, M.L.; Rasmuson, A. Mathematical modeling of transport processes and degradation reactions in piles of forest fuel material. Fuel 1993, 72, 1515–1524. [Google Scholar] [CrossRef]

- Ashman, J.M.; Jones, J.M.; Williams, A. Some characteristics of the self-heating of the large scale storage of biomass. Fuel Process. Technol. 2018, 174, 1–8. [Google Scholar] [CrossRef]

- HSE. Safe Handling of Combustible Dusts: Precautions Against Explosions. Health and Safety Executive Books. Available online: http://www.hse.gov.uk/pUbns/priced/hsg103.pdf (accessed on 10 January 2018).

- Wilen, C.; Rautalin, A. Handling and feeding of biomass to pressurized reactors: safety engineering. Bioresour. Technol. 1993, 46, 77–85. [Google Scholar] [CrossRef]

- Koppejan, J.; Lönnermark, A.; Persson, H.; Larsson, I.; Blomqvist, P.; Arshadi, M.; Valencia-Reyes, E.; Melin, S.; Howes, P.; Wheeler, P.; et al. Health and Safety Aspects of Solid Biomass Storage, Transportation and Feeding. Available online: www.ieabioenergy.com/wp-content/uploads/2013/10/Health-and-Safety-Aspects-of-Solid-Biomass-Storage-Transportation-and-Feeding.pdf (accessed on 28 March 2017).

- Abbasi, T.; Abbasi, S.A. Dust explosions–Cases, causes, consequences, and control. J. Hazard. Mater. 2007, 140, 7–44. [Google Scholar] [CrossRef] [PubMed]

- Simpson, A.; Sandys, V.; Stagg, S.; Pocock, D.; Hemingway, M. Safe Storage of Wood Pellets and Wood Chip Fuel (RR1077 Research Report). Health and Safety Executive Books. Available online: http://www.hse.gov.uk/research/rrpdf/rr1077.pdf (accessed on 8 March 2018).

- Svedberg, U.; Högberg, H.-E.; Högberg, J.; Galle, B. Emission of Hexanal and Carbon Monoxide from Storage of Wood Pellets, a Potential Occupational and Domestic Health Hazard. Ann. Occup. Hyg. 2004, 48, 339–349. [Google Scholar] [CrossRef]

- NRC. Acute Exposure Guideline Levels for Selected Airborne Chemicals; The National Academies Press: Washington, DC, USA, 2010. [Google Scholar]

- OSHA. Confined or Enclosed Spaces and Other Dangerous Atmospheres. United States Department of Labor. Available online: https://www.osha.gov/SLTC/etools/shipyard/shiprepair/confinedspace/oxygendeficient.html (accessed on 8 March 2018).

- HSE. Safe Work in Confined Spaces. Health and Safety Executive. Available online: www.hse.gov.uk/pUbns/priced/l101.pdf (accessed on 2 February 2018).

- NIOSH. Immediate Dangers to Life or Health (IDLH) Values. The National Institute for Occupational Safety and Health (NIOSH). Available online: https://www.cdc.gov/niosh/idlh/intridl4.html (accessed on 29 February 2018).

- OSHA. Health Hazards: Wood Dust. United States Department of Labor. Available online: https://www.osha.gov/SLTC/etools/sawmills/dust.html (accessed on 8 March 2018).

- Crook, B.; Botheroyd, E.M.; Travers Glass, S.A.; Gould, J.R.M. The Exposure of Scottish Wood Bark Chip Handlers to Microbially Contaminated Airborne Dust. Ann. Occup. Hyg. 1994, 38, 903–906. [Google Scholar] [CrossRef]

- Makridakis, S.S.C. Wheel Wright. In Forecasting: Methods and Applications, 3rd ed.; John Wiley and Sons: New York, NY, USA, 1988. [Google Scholar]

- Maia, A.; de Carvalho, F. Holt’s exponential smoothing and neural network models for forecasting interval-valued time series. Int. J. Forecast. 2011, 27, 740–759. [Google Scholar] [CrossRef]

- Hanke, J.E.; Wichern, D.W. Business Forecasting, 8th ed.; Pearson Education International: Harlow, UK, 2008. [Google Scholar]

- Johnson, D. Investigating Claims Involving Spontaneous Combustion (May 21). Available online: http://www.claimsjournal.com/news/national/2013/05/21/229361.htm (accessed on 28 March 2017).

- Hoekstra, G. WorkSafeBC Pinpoints Wood-Dust Concerns at Pellet Plants (January 5). Available online: http://www.vancouversun.com/WorkSafeBC+pinpoints+wood+dust+concerns+pellet+plants/10089375/story.html (accessed on 1 February 2018).

- CBC News. Babine Forest Products fined $1M for Burns Lake Sawmill Explosion (April 3). Available online: www.cbc.ca/news/canada/british-columbia/babine-forest-products-fined-1m-for-burns-lake-sawmill-explosion-1.2597280 (accessed on 7 February 2018).

- Chisholm, J. Deadly BC Wood Dust Explosions Place Emphasis on Precautions. Available online: https://www.mcscs.jus.gov.on.ca/english/FireMarshal/FireServiceResources/messenger/OFM_Mr_2014-01_A5.html (accessed on 9 March 2018).

- Murray, G. WPAC-Proper Handling of Wood Pellets. Available online: https://www.canadianbiomassmagazine.ca/pellets/wpac-–-proper-handling-5899 (accessed on 2 February 2018).

- WPAC. Material Safety Data Sheet for Wood Pellets in Bulk. Available online: https://www.pellet.org/images/2009-05-05_MSDS_Bulk_Pellets.pdf (accessed on 1 March 2018).

- Gauthier, S.; Grass, H.; Lory, M.; Kramer, T.; Thali, M.; Bartsch, C. Lethal Carbon Monoxide Poisoning in Wood Pellet Storerooms—Two Cases and a Review of the Literature. Ann. Occup. Hyg. 2012, 56, 755–763. [Google Scholar] [CrossRef] [Green Version]

- Simpson, A.; Hemingway, A.; Seymour, C. Dangerous (toxic) atmospheres in UK wood pellet and wood chip fuel storage. J. Occup. Environ. Hyg. 2016, 13, 699–707. [Google Scholar] [CrossRef] [PubMed]

- Tremier, A.; de Guardia, A.; Massiani, C.; Paul, E.; Martel, J.L. A respirometric method for characterising the organic composition and biodegradation kinetics and the temperature influence on the biodegradation kinetics, for a mixture of sludge and bulking agent to be co-composted. Bioresour. Technol. 2005, 96, 169–180. [Google Scholar] [CrossRef] [PubMed]

- Torrent, J.G.; Anez, N.F.; Pejic, L.M.; Mateos, L.M. Assessment of self-ignition risks of solid biofuels by thermal analysis. Fuel 2015, 143, 484–491. [Google Scholar] [CrossRef]

- Blijderveen, M.; Gucho, E.M.; Bramer, E.A.; Brem, G. Spontaneous ignition of wood, char and RDF in a lab scale packed bed. Fuel 2010, 89, 2393–2404. [Google Scholar] [CrossRef]

- Taraba, B.; Podstawka, T.; Mucha, M. Towards indication gases of spontaneous heating of biomass. Fuel 2018, 222, 610–616. [Google Scholar] [CrossRef]

- Rentizelas, A.A.; Tolis, A.J.; Tatsiopoulos, I.P. Logistics issues of biomass: the storage problem and the multi-biomass supply chain. Renew. Sustain. Energy Rev. 2009, 13, 887–894. [Google Scholar] [CrossRef] [Green Version]

- ARIA. 20579. Republique Francais. Available online: https://www.aria.developpement-durable.gouv.fr/accident/20579_en/?lang=en (accessed on 9 March 2018).

- The Biomass Monitor. [Exclusive] Bioenergy Industry Fires and Explosions. Available online: https://thebiomassmonitor.org/2015/01/10/biomass-industry-plays-with-fire-gets-burned-2/ (accessed on 20 January 2018).

- ARIA. Fire and Explosion in Sawdust Silo. Available online: https://www.aria.developpement-durable.gouv.fr/accident/24332_en/?lang=en (accessed on 9 March 2018).

- ARIA. Silo Explosion Followed by Fire. Available online: https://www.aria.developpement-durable.gouv.fr/accident/24555_en/?lang=en (accessed on 9 March 2018).

- ARIA. 25978. Republique Francais. Available online: https://www.aria.developpement-durable.gouv.fr/accident/25978_en/?lang=en (accessed on 9 March 2018).

- ARIA. Softwood Chips Fire. Available online: https://www.aria.developpement-durable.gouv.fr/accident/26931_en/?lang=en (accessed on 9 March 2018).

- ARIA. Explosion of A Woodchip Refiner and Fire. Available online: https://www.aria.developpement-durable.gouv.fr/fiche_detaillee/29011_en/?lang=en (accessed on 9 March 2018).

- Kooren, R. Demystifying the Source of Mysterious Fires. Available online: www.origin-and-cause.com/resources/blog/the-subtle-signature-of-spontaneous-combustion (accessed on 1 February 2018).

- Fitch, J. Firefighters Respond to Blaze at AJ Stove & Pellet (August 2). Available online: http://articles.herald-mail.com/2010-08-02/news/25197644_1_fire-marshal-franklin-county-air-unit-firefighters (accessed on 7 February 2018).

- Stepzinski, T. Explosion Damages Waycross Plant; No Injuries Reported (June 21). Available online: http://jacksonville.com/news/crime/2011-06-21/story/explosion-damages-waycross-plant-no-injuries-reported# (accessed on 29 January 2018).

- Butcher, J. Firefighters Battle Huge Biomass Fire at Port of Tyne (June 25). Available online: http://www.thejournal.co.uk/news/north-east-news/firefighters-battle-huge-biomass-fire-4422494 (accessed on 7 February 2018).

- Read, S. Winds Fan Feedlot Fire (November 23). Available online: www.nantonnews.com/2011/11/23/winds-fan-feedlot-fire (accessed on 10 January 2018).

- Jones, S. Firefighters Battle Essex Power Station Blaze (February 27). Available online: https://www.theguardian.com/uk/2012/feb/27/firefighters-essex-power-station-blaze (accessed on 7 February 2018).

- CPH Post. Amager Explosion Injures Three (May 11). Available online: http://cphpost.dk/news/local-news/amager-explosion-injures-three.html (accessed on 7 February 2018).

- CPH Post. Fire at City Power Plant Expected to Burn for Days (December 17). Available online: http://cphpost.dk/news/local-news/fire-at-city-power-plant-expected-to-burn-for-days.html (accessed on 7 February 2018).

- Robinson, R. Silo Fire Hits Upper Leacock Business (March 5). Available online: http://lancasteronline.com/news/silo-fire-hits-upper-leacock-business/article_bc401650-241e-5aa2-8ee5-3c1200e3b763.html (accessed on 7 February 2018).

- NBC 10 News. Fire Chief: Dust Caused Pellet Company Explosion (August 20). Available online: http://turnto10.com/archive/fire-reported-at-east-providence-wood-pellet-company (accessed on 5 February 2018).

- Bock, L. Fire Badly Damages Fitchburg Mill (November 13). Available online: http://www.telegram.com/article/20131113/news/131119976 (accessed on 18 January 2018).

- Beaumont Enterprise. German Pellet Plant in Woodville Has Fire in Silo (April 30). Available online: http://www.beaumontenterprise.com/jasper/news/article/German-pellet-Plant-in-Woodville-has-fire-in-Silo-5442052.php (accessed on 19 January 2018).

- Waikato Times. Fire after Sawdust Explosion (September 3). Available online: http://www.stuff.co.nz/waikato-times/news/9122122/Fire-after-sawdust-explosion (accessed on 29 January 2018).

- Shaffer, D. Restart of Koda Energy Power Plant Uncertain (May 3). Available online: http://www.startribune.com/restart-of-koda-energy-power-plant-uncertain/206053941/?refer=y (accessed on 11 January 2018).

- Telegraph Derby. Arcwood Recycling Boss Admits Putting Life at Risk after Fire Burned in Stanton-by-Dale for Two Months (February 24). Available online: http://www.derbytelegraph.co.uk/month-blaze-arcwood-recycling-boss-admits-putting/story-20686427-detail/story.html#VCBe9mvXXTTgpgz8.99 (accessed on 29 January 2018).

- ICHEME. Firefighters among Seven Hurt in Forres Silo Explosion (29 April 2014). Loss Prevention Bulletin. Available online: http://www.icheme.org/lpb/news/2014/140429-firefighters-among-seven-hurt-in-forres-silo-explosion (accessed on 28 March 2018).

- The Star News. Firefighters Remain at Biomass Depot in South Yorkshire (June 3). Available online: http://www.thestar.co.uk/news/firefighters-remain-at-biomass-depot-in-south-yorkshire-1-6652028 (accessed on 29 January 2018).

- Preston, R. Teesside Wood Recycler Fined after Blaze (November 25, 2014). Available online: https://www.mrw.co.uk/latest/teesside-wood-recycler-fined-after-blaze/10015194.article (accessed on 10 January 2018).

- OSHA. Indianhead Biomass Services Explosion Severely Injures 2 Workers 2nd Explosion in 4 Months Results in more OSHA Citations. Available online: https://www.osha.gov/news/newsreleases/region6/01292015 (accessed on 7 February 2018).

- The Times of India. Major Fire Breaks out at Biomass Waste Power Plant (June 23). Available online: http://timesofindia.indiatimes.com/city/aurangabad/Major-fire-breaks-out-at-biomass-waste-power-plant/articleshow/37067482.cms (accessed on 20 January 2018).

- Euroweekly News. Firefighters Tackle Biomass Blaze at Motril Harbour (February 2). Available online: https://www.euroweeklynews.com/3.0.15/index.php/news/on-euro-weekly-news/axarquia-costa-tropical/item/125588-firefighters-tackle-biomass-blaze-at-motril-harbour (accessed on 1 February 2018).

- Moore, G. Improper Practices Fueled Fire (May 21). Available online: http://www.goldenstatenewspapers.com/tracy_press/news/improper-practices-fueled-fire/article_9388f1ba-000f-11e5-b7d2-2b5656d08c03.html (accessed on 19 January 2018).

- Southern Daily Echo. Fears Raised over Impact of Controversial Biomass Plant after Woodchip Blaze at Southampton Docks (January 15). Available online: http://www.dailyecho.co.uk/news/11724303.DOCKS_FIRE__Fears_over_biomass_plant_reignited_after_woodchip_blaze/ (accessed on 7 February 2018).

- Walsh, L. Four Injured after Explosions at Part Biomass-Fired Plant (September 23). Available online: http://www.endswasteandbioenergy.com/article/1365364/four-injured-explosions-part-biomass-fired-plant (accessed on 7 February 2018).

- Silfverskoild, P. Massive Emergency Response to Fire Alert on Ship Carrying 11,000 Tonnes of Wood Pellets in Port of Tyne (November 5). Available online: http://www.shieldsgazette.com/news/massive-emergency-response-to-fire-alert-on-ship-carrying-11-000-tonnes-of-wood-pellets-in-port-of-tyne-1-7554167 (accessed on 7 February 2018).

- BBC News. Wood Recycling Firm Fined 20,000 for Newport Docks Fire (November 10). Available online: www.bbc.com/news/uk-wales-south-east-wales-37935807 (accessed on 18 January 2018).

- Campbell, R. Fire Crews Tackle Burning Woodchip Building (August 27). Available online: https://www.pressandjournal.co.uk/fp/news/highlands/1009447/fire-crews-tackle-burning-woodchip-building/ (accessed on 18 January 2018).

- Stiles, G. Firefighters Battle Fire at Biomass One. Mail Tribune (September 11). Available online: www.mailtribune.com/news/20160911/ (accessed on 30 January 2018).

- The Nation. Sunday’s Fire at Power Plant’s Biomass Fuels Pile Put out Monday (March 13). Available online: http://www.nationmultimedia.com/detail/breakingnews/30308923 (accessed on 29 January 2018).

- Wolfe, R. Big Response to Fire in Woodchip Silo at Springfield Power (April 12). Available online: www.vnews.com/Fire-in-Springfield-9234812 (accessed on 8 February 2018).

- Kotrba, R. Mitigating Pellet Silo Fires (July 26). Available online: http://biomassmagazine.com/articles/14548/mitigating-pellet-silo-fires (accessed on 7 February 2018).

- Perchard, E. Firefighters Containing Large Wood Chip Fire at EFW Site. Available online: https://resource.co/article/firefighters-containing-large-wood-chip-fire-efw-site-11918 (accessed on 29 February 2018).

- Voegele, E. Enviva’s Cottondale Plant Idle Less than 1 Day Following Fire (June 12). Available online: http://biomassmagazine.com/articles/14445/envivaundefineds-cottondale-plant-idle-less-than-1-day-following-fire (accessed on 20 January 2018).

- Bouey, K. Wood Chip Pile Fire Doused (July 16). Available online: https://www.castanet.net/news/Vernon/201931/Wood-chip-pile-fire-doused (accessed on 7 February 2018).

- Nielsen, M. Workers Removing Smouldering Pellets from Silo at Pacific Bioenergy (August 25). Available online: www.princegeorgecitizen.com/news/local-news/workers-removing-smouldering-pellets-from-silo-at-pacific-bioenergy-1.22177481 (accessed on 8 February 2018).

- CBC News. Fire Continues to Flare up at Williams Lake, B.C. Sawmill. Available online: www.cbc.ca/news/canada/british-columbia/fire-tolko-williams-lake-1.4389411 (accessed on 7 February 2018).

- Atik, T. Extensive Fire at Kenora Sawmill Destroys Two Kilns (January 2). Available online: https://www.woodbusiness.ca/sawmilling/health-safety/sawmill-fire-in-kenora-destroys-two-kilns-4681 (accessed on 10 January 2018).

- Atik, T. Hog Pile Fire at Western Forest Products Mill in Port Alberni, BC (February 13). Available online: https://www.woodbusiness.ca/industry-news/news/hog-pile-fire-at-western-forest-products-mill-in-port-alberni-bc-4743 (accessed on 29 February 2018).

© 2018 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Krigstin, S.; Wetzel, S.; Jayabala, N.; Helmeste, C.; Madrali, S.; Agnew, J.; Volpe, S. Recent Health and Safety Incident Trends Related to the Storage of Woody Biomass: A Need for Improved Monitoring Strategies. Forests 2018, 9, 538. https://doi.org/10.3390/f9090538

Krigstin S, Wetzel S, Jayabala N, Helmeste C, Madrali S, Agnew J, Volpe S. Recent Health and Safety Incident Trends Related to the Storage of Woody Biomass: A Need for Improved Monitoring Strategies. Forests. 2018; 9(9):538. https://doi.org/10.3390/f9090538

Chicago/Turabian StyleKrigstin, Sally, Suzanne Wetzel, Nivatha Jayabala, Christopher Helmeste, Sebnem Madrali, Joy Agnew, and Sylvain Volpe. 2018. "Recent Health and Safety Incident Trends Related to the Storage of Woody Biomass: A Need for Improved Monitoring Strategies" Forests 9, no. 9: 538. https://doi.org/10.3390/f9090538