Influence of the Conditioning Method for Pre-Sintered Zirconia on the Shear Bond Strength of Bilayered Porcelain/Zirconia

Abstract

:1. Introduction

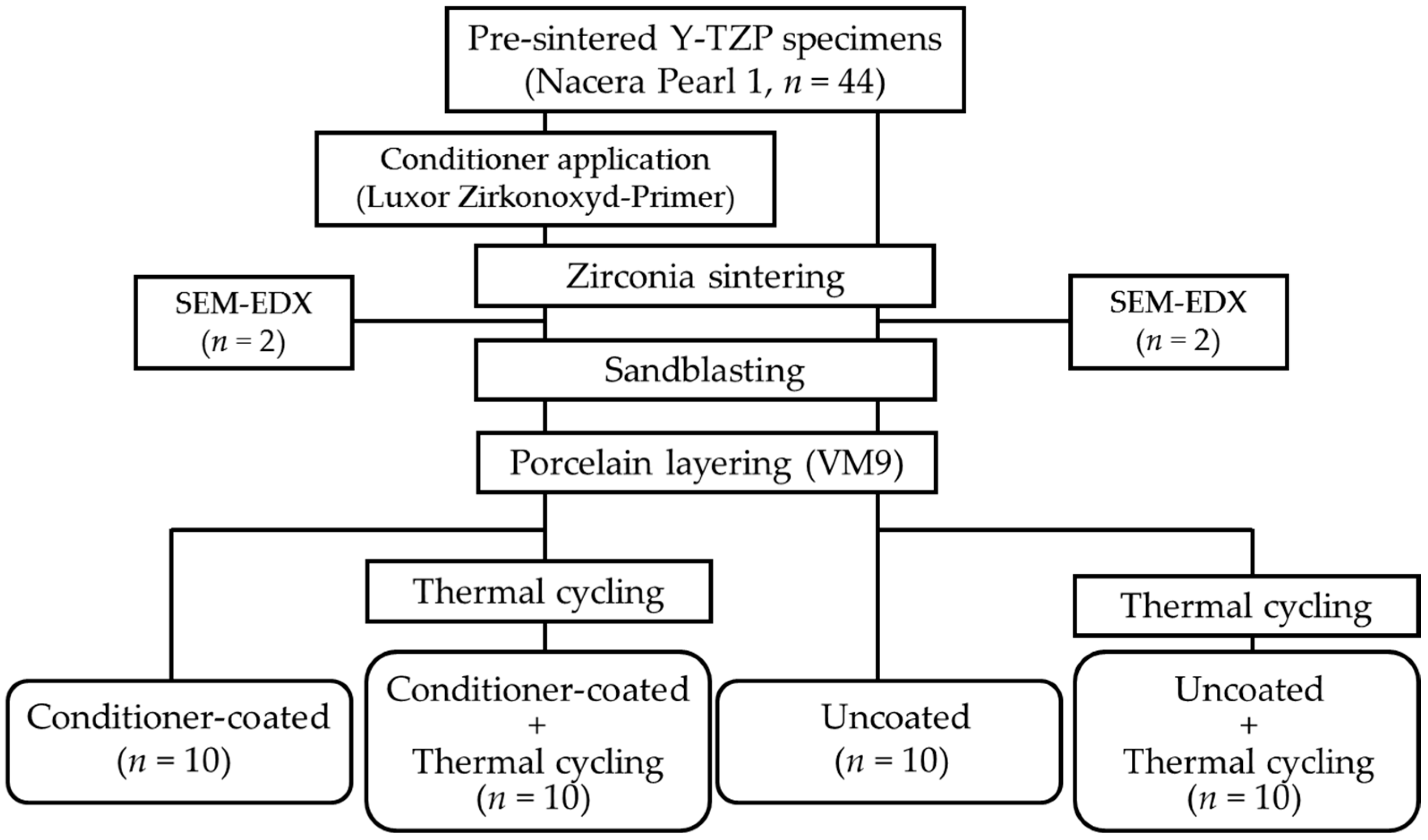

2. Materials and Methods

2.1. Materials

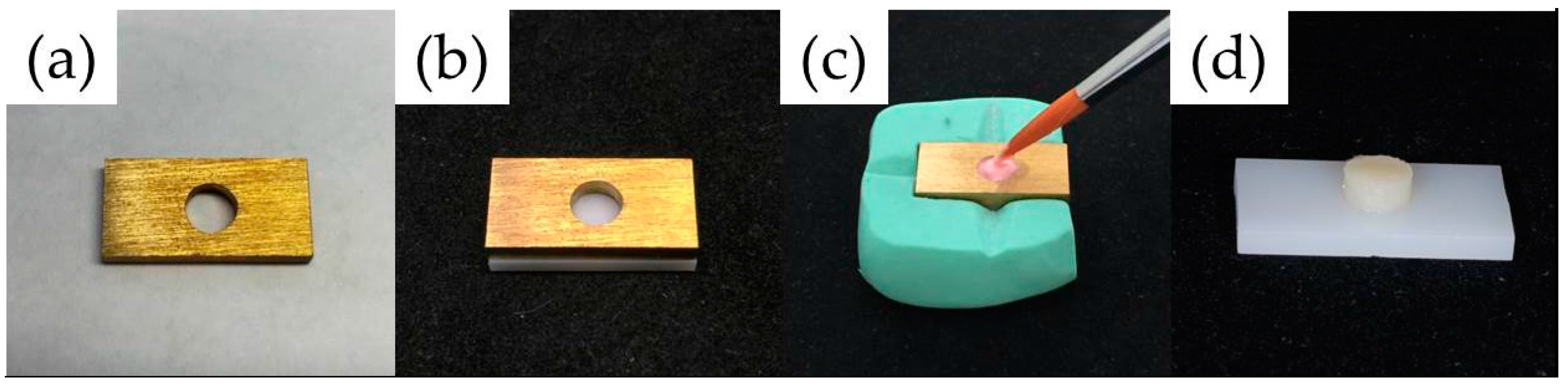

2.2. Preparation of Zirconia Substrates

2.3. Porcelain Layering

2.4. Shear Bond Strength Testing

2.5. Data Analysis

3. Results

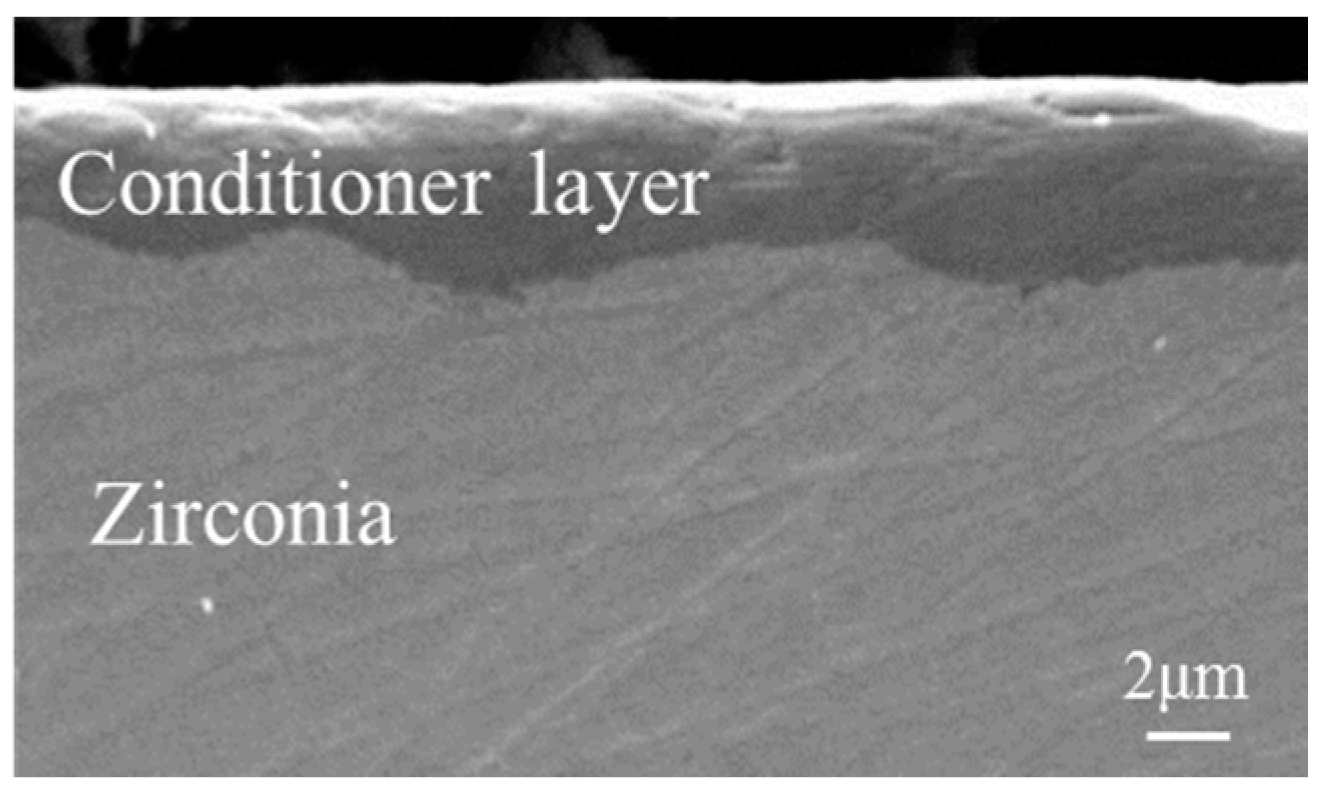

3.1. Surface Analysis

3.2. Shear Bond Strength

3.3. Analysis of Failure Modes

4. Discussion

5. Conclusions

- Conditioner-coated zirconia specimens did not show decreased shear bond strength compared with uncoated zirconia specimens, irrespective of thermal cycling;

- In the analysis of fractured specimen surfaces, adhesive fractures were dominantly observed in both conditioner-coated and uncoated zirconia specimens without thermal cycling; and

- In contrast, after thermal cycling the conditioner-coated zirconia specimens predominantly showed cohesive and mixed fractures (p = 0.0021), whereas uncoated zirconia specimens showed higher numbers of adhesive fractures (p = 0.0021).

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sailer, I.; Makarov, N.A.; Thoma, D.S.; Zwahlen, M.; Pjetursson, B.E. All-ceramic or metal-ceramic tooth-supported fixed dental prostheses (FDPs)? A systematic review of the survival and complication rates. Part I, Single crowns (SCs). Dent. Mater. 2015, 31, 603–623. [Google Scholar] [CrossRef] [PubMed]

- Stober, T.; Bermejo, J.L.; Schwindling, F.S.; Schmitter, M. Clinical assessment of enamel wear caused by monolithic zirconia crowns. J. Oral. Rehabil. 2016, 43, 621–629. [Google Scholar] [CrossRef] [PubMed]

- Kern, M. Bonding to oxide ceramics—Laboratory testing versus clinical outcome. Dent. Mater. 2015, 31, 8–14. [Google Scholar] [CrossRef] [PubMed]

- Koenig, V.; Vanheusden, A.J.; Le Goff, S.O.; Mainjot, A.K. Clinical risk factors related to failures with zirconia-based restorations, an up to 9-year retrospective study. J. Dent. 2013, 41, 1164–1174. [Google Scholar] [CrossRef] [PubMed]

- Fischer, J.; Grohmann, P.; Stawarczyk, B. Effect of zirconia surface treatments on the shear strength of zirconia/veneering ceramic composites. Dent. Mater. J. 2008, 27, 448–454. [Google Scholar] [CrossRef] [PubMed]

- Miyazaki, T.; Nakamura, T.; Matsumura, H.; Ban, S.; Kobayashi, T. Current status of zirconia restoration. J. Prosthodont. Res. 2013, 57, 236–261. [Google Scholar] [CrossRef] [PubMed]

- Komine, F.; Strub, J.; Matsumura, H. Bonding between layering materials and zirconia frameworks. Jpn. Dent. Sci. Rev. 2012, 48, 153–161. [Google Scholar] [CrossRef]

- Yoon, H.I.; Yeo, I.S.; Yi, Y.J.; Kim, S.H.; Lee, J.B.; Han, J.S. Effect of surface treatment and liner material on the adhesion between veneering ceramic and zirconia. J. Mech. Behav. Biomed. Mater. 2014, 40, 369–374. [Google Scholar] [CrossRef] [PubMed]

- Kim, H.J.; Lim, H.P.; Park, Y.J.; Vang, M.S. Effect of zirconia surface treatments on the shear bond strength of veneering ceramic. J. Prosthet. Dent. 2011, 105, 315–322. [Google Scholar] [CrossRef]

- Nishigori, A.; Yoshida, T.; Bottino, M.C.; Platt, J.A. Influence of zirconia surface treatment on veneering porcelain shear bond strength after cyclic loading. J. Prosthet. Dent. 2014, 112, 1392–1398. [Google Scholar] [CrossRef] [PubMed]

- Matani, J.D.; Kheur, M.; Jambhekar, S.S.; Bhargava, P.; Londhe, A. Evaluation of experimental coating to improve the zirconia-veneering ceramic bond strength. J. Prosthodont. 2014, 23, 626–633. [Google Scholar] [CrossRef] [PubMed]

- Canullo, L.; Micarelli, C.; Bettazzoni, L.; Magnelli, A.; Baldissara, P. Shear bond strength of veneering porcelain to zirconia after argon plasma treatment. Int. J. Prosthodont. 2014, 27, 137–139. [Google Scholar] [CrossRef] [PubMed]

- Ferrari, M.; Giovannetti, A.; Carrabba, M.; Bonadeo, G.; Rengo, C.; Monticelli, F.; Vichi, A. Fracture resistance of three porcelain-layered CAD/CAM zirconia frame designs. Dent. Mater. 2014, 30, 163–168. [Google Scholar] [CrossRef] [PubMed]

- Adhesion Promoter for Promoting Adhesion between Oxide Ceramic and a Veneer Material, in Particular FOR Dental Purposes, Method for the Use Thereof and Kit for the Production and Application Thereof. Available online: https://www.google.com/patents/WO2011050786A3?cl=en&dq=Olaf+gluck&hl=ja&sa=X&ved=0CB0Q6AEwAGoVChMIir-y4cy_yAIVCzsUCh3_swW4, 2012 (accessed on 28 July 2016).

- Sawada, T.; Spintzyk, S.; Schille, C.; Zöldföldi, J.; Paterakis, A.; Schweizer, E.; Stephan, I.; Rupp, F.; Geis-Gerstorfer, J. Influence of pre-sintered zirconia surface conditioning on shear bond strength to resin cement. Materials 2016, 9, 518. [Google Scholar] [CrossRef]

- International Organization for Standardization. Dentistry-Polymer-Based Crown and Bridge Materials; ISO 10477:2004; International Organization for Standardization: Geneva, Switzerland, 2004. [Google Scholar]

- Guess, P.C.; Kulis, A.; Witkowski, S.; Wolkewitz, M.; Zhang, Y.; Strub, J.R. Shear bond strengths between different zirconia cores and veneering ceramics and their susceptibility to thermocycling. Dent. Mater. 2008, 24, 1556–1567. [Google Scholar] [CrossRef] [PubMed]

- Wong, J.D.; Kei Lung, C.Y.; Tsoi, J.K.; Matininna, J.P. Effects of a zirconate coupling agent incorporated into an experimental resin composite on its compressive strength and bonding to zirconia. J. Mech. Behav. Biomed. Mater. 2014, 29, 171–176. [Google Scholar] [CrossRef] [PubMed]

- Benjamini, Y.; Hochberg, Y. Controlling the false discovery rate, a practical and powerful approach to multiple testing. J. R. Stat. Soc. Ser. B 1995, 57, 289–300. [Google Scholar]

- Choi, J.E.; Waddell, J.N.; Torr, B.; Swain, M.V. Pressed ceramics onto zirconia. Part 1, Comparison of crystalline phases present, adhesion to a zirconia system and flexural strength. Dent. Mater. 2011, 27, 1204–1212. [Google Scholar] [CrossRef] [PubMed]

- Qian, H.; Cui, C.; Su, T.; Zhang, F.; Sun, J. Exploring the optimal pre-sintering temperature on compressive strength and anti-fatigue property of graded zirconia-based glass/zirconia structure. Dent. Mater. J. 2016, 35, 341–344. [Google Scholar] [CrossRef] [PubMed]

- Zhang, Y.; Kim, J.W. Graded structures for damage resistant and aesthetic all-ceramic restorations. Dent. Mater. 2009, 25, 781–790. [Google Scholar] [CrossRef] [PubMed]

- Li, K.C.; Waddell, J.N.; Prior, D.J.; Ting, S.; Girvan, L.; van Vuuren, L.J.; Swain, M.V. Effect of autoclave induced low-temperature degradation on the adhesion energy between yttria-stabilized zirconia veneered with porcelain. Dent. Mater. 2013, 29, e263–e270. [Google Scholar] [CrossRef] [PubMed]

- Agustín-Panadero, R.; Román-Rodríguez, J.L.; Ferreiroa, A.; Solá-Ruíz, M.F.; Fons-Font, A. Zirconia in fixed prosthesis. A literature review. J. Clin. Exp. Dent. 2014, 6, 66–73. [Google Scholar] [CrossRef] [PubMed]

- Özkurt, Z.; Kazazoglu, E.; Unal, A. In vitro evaluation of shear bond strength of veneering ceramics to zirconia. Dent. Mater. J. 2010, 29, 138–146. [Google Scholar] [CrossRef] [PubMed]

- Su, N.; Yue, L.; Liao, Y.; Liu, W.; Zhang, H.; Li, X.; Wang, H.; Shen, J. The effect of various sandblasting conditions on surface changes of dental zirconia and shear bond strength between zirconia core and indirect composite resin. J. Adv. Prosthodont. 2015, 7, 214–223. [Google Scholar] [CrossRef] [PubMed]

- He, M.; Zhang, Z.; Zheng, D.; Ding, N.; Liu, Y. Effect of sandblasting on surface roughness of zirconia-based ceramics and shear bond strength of veneering porcelain. Dent. Mater. J. 2014, 33, 778–785. [Google Scholar] [CrossRef] [PubMed]

- Aboushelib, M.N.; de Jager, N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Dent. Mater. 2005, 21, 984–991. [Google Scholar] [CrossRef] [PubMed]

- Chintapalli, R.K.; Mestra Rodriguez, A.; Garcia Marro, F.; Anglada, M. Effect of sandblasting and residual stress on strength of zirconia for restorative dentistry applications. J. Mech. Behav. Biomed. Mater. 2014, 29, 126–137. [Google Scholar] [CrossRef] [PubMed]

- Ramos, C.M.; Cesar, P.F.; Mondelli, R.F.L.; Tabata, A.S.; de Souza Santos, J.; Borges, A.F.S. Bond strength and raman analysis of the zirconia-feldspathic porcelain interface. J. Prosthet. Dent. 2014, 112, 886–894. [Google Scholar] [CrossRef] [PubMed]

- Aboushelib, M.N.; Kleverlaan, C.J.; Feilzer, A.J. Microtensile bond strength of different components of core veneered all-ceramic restorations. Part II: Zirconia veneering ceramics. Dent. Mater. 2006, 22, 857–863. [Google Scholar] [CrossRef] [PubMed]

- Vidotti, H.A.; Pereira, J.R.; Insaurralde, E.; de Almeida, A.L.; do Valle, A.L. Thermo and mechanical cycling and veneering method do not influence Y-TZP core/veneer interface bond strength. Dent. Mater. 2013, 41, 307–312. [Google Scholar] [CrossRef] [PubMed]

- Blatz, M.B.; Bergler, M.; Ozer, F.; Holst, S.; Phark, J.H.; Chiche, G.J. Bond strength of different veneering ceramics to zirconia and their susceptibility to thermocycling. Am. J. Dent. 2010, 23, 213–216. [Google Scholar] [PubMed]

- Chevalier, J. What future for zirconia as a biomaterial? Biomaterials 2006, 27, 535–543. [Google Scholar] [CrossRef] [PubMed]

- Koenig, V.; Wulfman, C.P.; Derbanne, M.A.; Dupont, N.M.; Le Goff, S.O.; Tang, M.-L.; Seidel, L.; Dewael, T.Y.; Vanheusden, A.J.; Mainjota, A.K. Aging of monolithic zirconia dental prostheses: Protocol for a 5-year prospective clinical study using ex vivo analyses. Contemp. Clin. Trials Commun. 2016, 4, 25–32. [Google Scholar] [CrossRef]

- Oh, G.J.; Yun, K.D.; Lee, K.M.; Lim, H.P.; Park, S.W. Sintering behavior and mechanical properties of zirconia compacts fabricated by uniaxial press forming. J. Adv. Prosthodont. 2010, 2, 81–87. [Google Scholar] [CrossRef] [PubMed]

- Niu, X.; Rahbar, N.; Farias, S.; Soboyejo, W. Bio-inspired design of dental multilayers, experiments and model. J. Mech. Behav. Biomed. Mater. 2009, 2, 596–602. [Google Scholar] [CrossRef] [PubMed]

- Kim, J.W.; Liu, L.; Zhang, Y. Improving the resistance to sliding contact damage of zirconia using elastic gradients. J. Biomed. Mater. Res. B Appl. Biomater. 2010, 94, 347–352. [Google Scholar] [CrossRef] [PubMed]

- Al-Dohan, H.M.; Yaman, P.; Dennison, J.B.; Razzoog, M.E.; Lang, B.R. Shear strength of core-veneer interface in bi-layered ceramics. J. Prosthet. Dent. 2004, 91, 349–355. [Google Scholar] [CrossRef] [PubMed]

- Nakamura, T.; Sugano, T.; Usami, H.; Wakabayashi, K.; Ohnishi, H.; Sekino, T.; Yatani, H. Shear bond strength of veneering porcelain to porous zirconia. Dent. Mater. J. 2014, 33, 220–225. [Google Scholar] [CrossRef] [PubMed]

- Gain, A.K.; Song, H.Y.; Lee, B.T. Microstructure and mechanical properties of porous yttria stabilized zirconia ceramic using poly methyl methacrylate powder. Scr. Mater. 2006, 54, 2081–2085. [Google Scholar] [CrossRef]

| Procedure | Basic Temperature (°C) | Dry Time (min) | Temperature Increase (°C/min) | High Temperature (°C) | Hold Time (min) |

|---|---|---|---|---|---|

| Y-TZP sintering | 20 | - | 8 | 1380 | 120 |

| Porcelain firing | |||||

| 1st/2nd wash-bake | 500 | 6 | 55 | 930 | 1 |

| 1st dentin | 500 | 6 | 55 | 910 | 1 |

| 2nd dentin | 500 | 6 | 55 | 900 | 1 |

| Glaze | 500 | 4 | 80 | 900 | 1 |

| Source | DF | Sum of Squares | Mean Square | F | p |

|---|---|---|---|---|---|

| Conditioner application (A) | 1 | 0.0363 | 0.0363 | 0.0013 | 0.9714 |

| Thermal cycling (B) | 1 | 64.8929 | 64.8929 | 2.3259 | 0.1360 |

| (A) × (B) | 1 | 1.7189 | 1.7189 | 0.0616 | 0.8054 |

| Error | 36 | 1004.4042 | 27.9001 | ||

| Total | 39 | 1071.0523 |

| Group | Shear Bond Strength |

|---|---|

| Uncoated | 23.7 (4.1) A |

| Conditioner-coated | 24.2 (5.2) A |

| Uncoated + Thermal cycling | 21.6 (5.9) A |

| Conditioner-coated + Thermal cycling | 21.2 (5.8) A |

| Group | Cohesive | Mixed | Adhesive | p |

|---|---|---|---|---|

| Uncoated | 3 | 1 | 6 | A,B |

| Conditioner-coated | 1 | 1 | 8 | A |

| Uncoated + Thermal cycling | 1 | 1 | 8 | A |

| Conditioner-coated + Thermal cycling | 4 | 6 | 0 | B |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Spintzyk, S.; Yamaguchi, K.; Sawada, T.; Schille, C.; Schweizer, E.; Ozeki, M.; Geis-Gerstorfer, J. Influence of the Conditioning Method for Pre-Sintered Zirconia on the Shear Bond Strength of Bilayered Porcelain/Zirconia. Materials 2016, 9, 765. https://doi.org/10.3390/ma9090765

Spintzyk S, Yamaguchi K, Sawada T, Schille C, Schweizer E, Ozeki M, Geis-Gerstorfer J. Influence of the Conditioning Method for Pre-Sintered Zirconia on the Shear Bond Strength of Bilayered Porcelain/Zirconia. Materials. 2016; 9(9):765. https://doi.org/10.3390/ma9090765

Chicago/Turabian StyleSpintzyk, Sebastian, Kikue Yamaguchi, Tomofumi Sawada, Christine Schille, Ernst Schweizer, Masahiko Ozeki, and Jürgen Geis-Gerstorfer. 2016. "Influence of the Conditioning Method for Pre-Sintered Zirconia on the Shear Bond Strength of Bilayered Porcelain/Zirconia" Materials 9, no. 9: 765. https://doi.org/10.3390/ma9090765