A Modelling Study for Predicting Life of Downhole Tubes Considering Service Environmental Parameters and Stress

Abstract

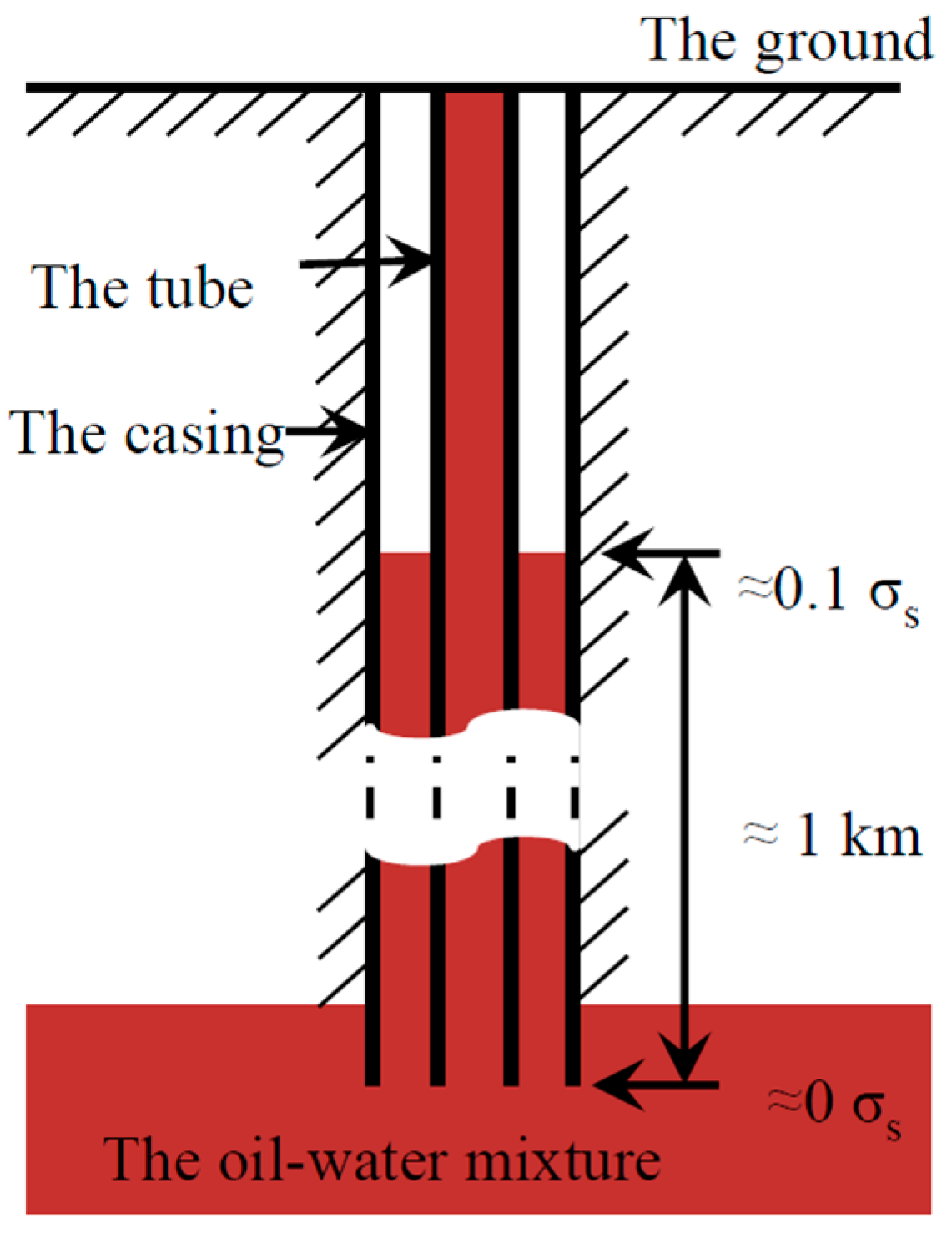

:1. Introduction

2. Criteria for Failure Judgment

3. Expression of Life Prediction Model

4. Experimental

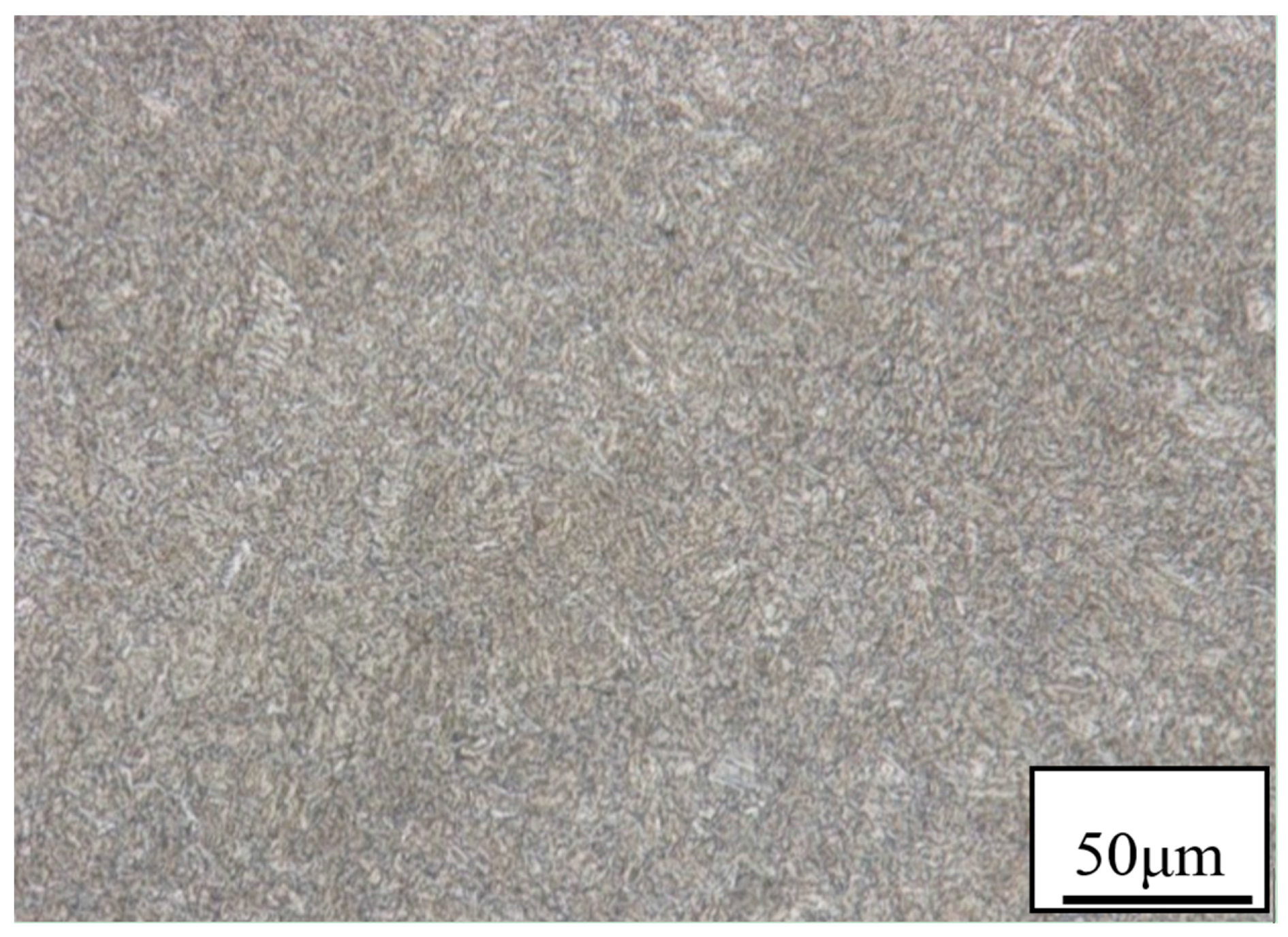

4.1. Material and Medium

4.2. Potentiodynamic Polarization Measurement

4.3. Immersion Test

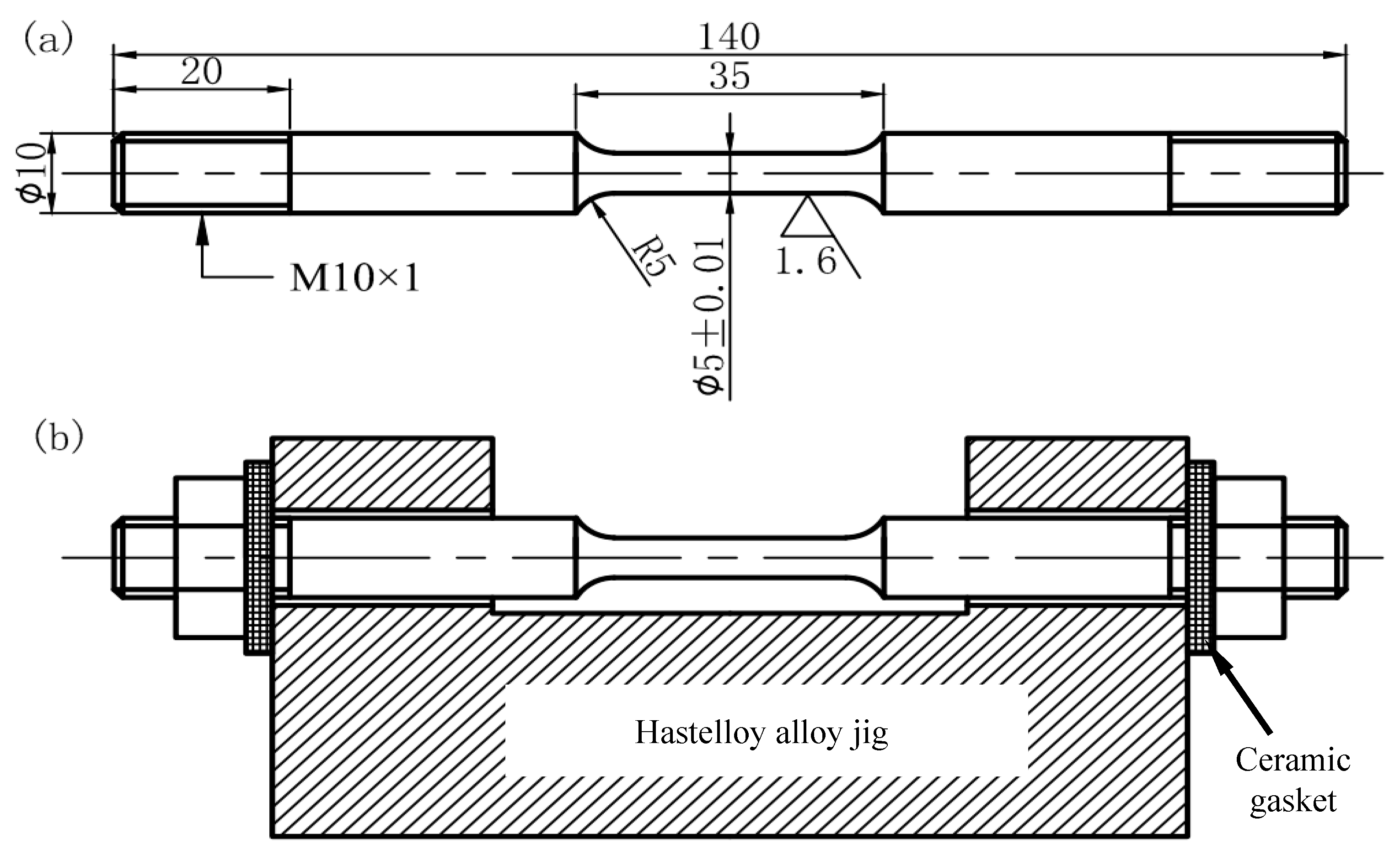

4.4. Tensile Tests after Immersion

5. Results

5.1. Potentiodynamic Polarization Curves

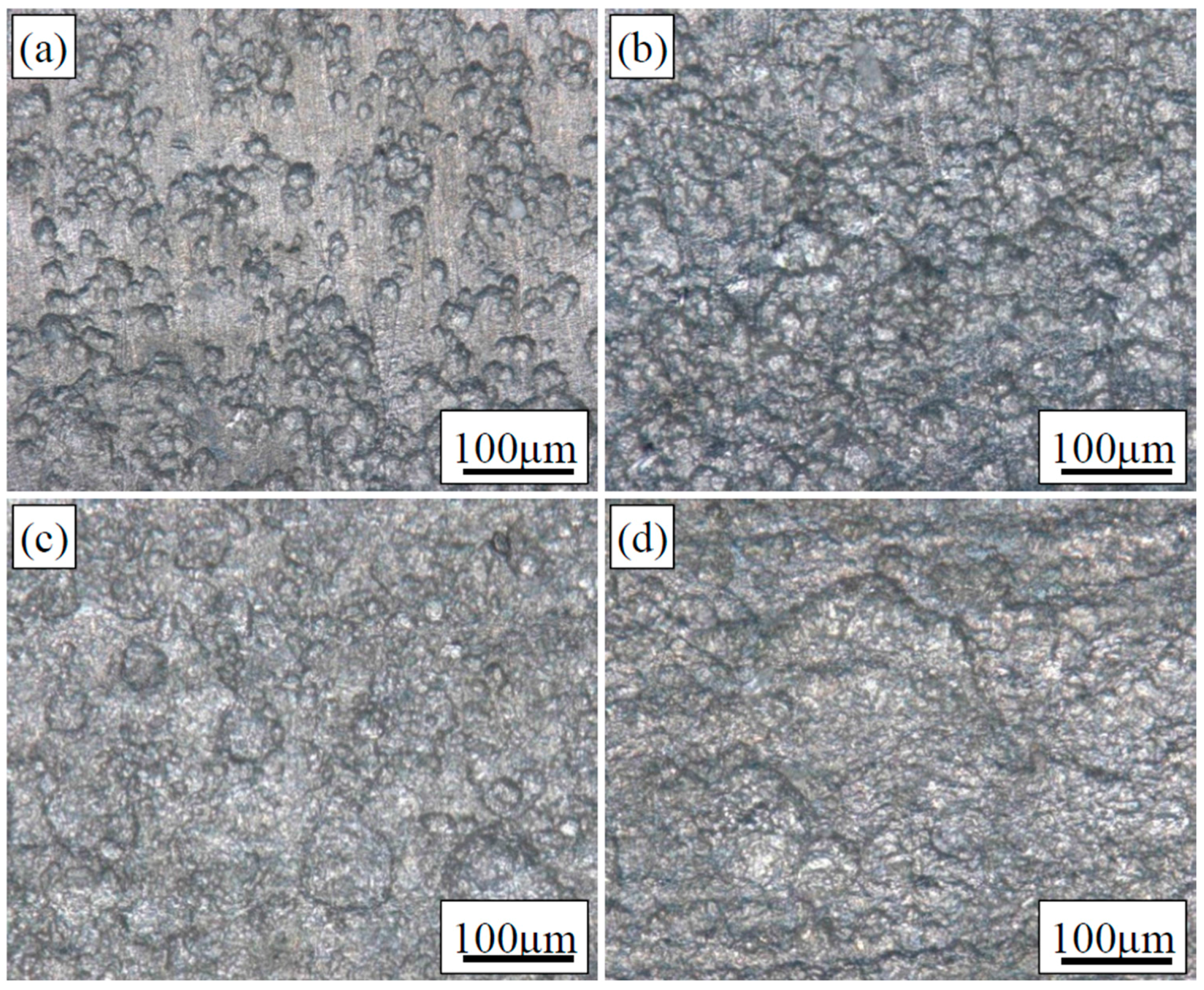

5.2. Corrosion Morphology

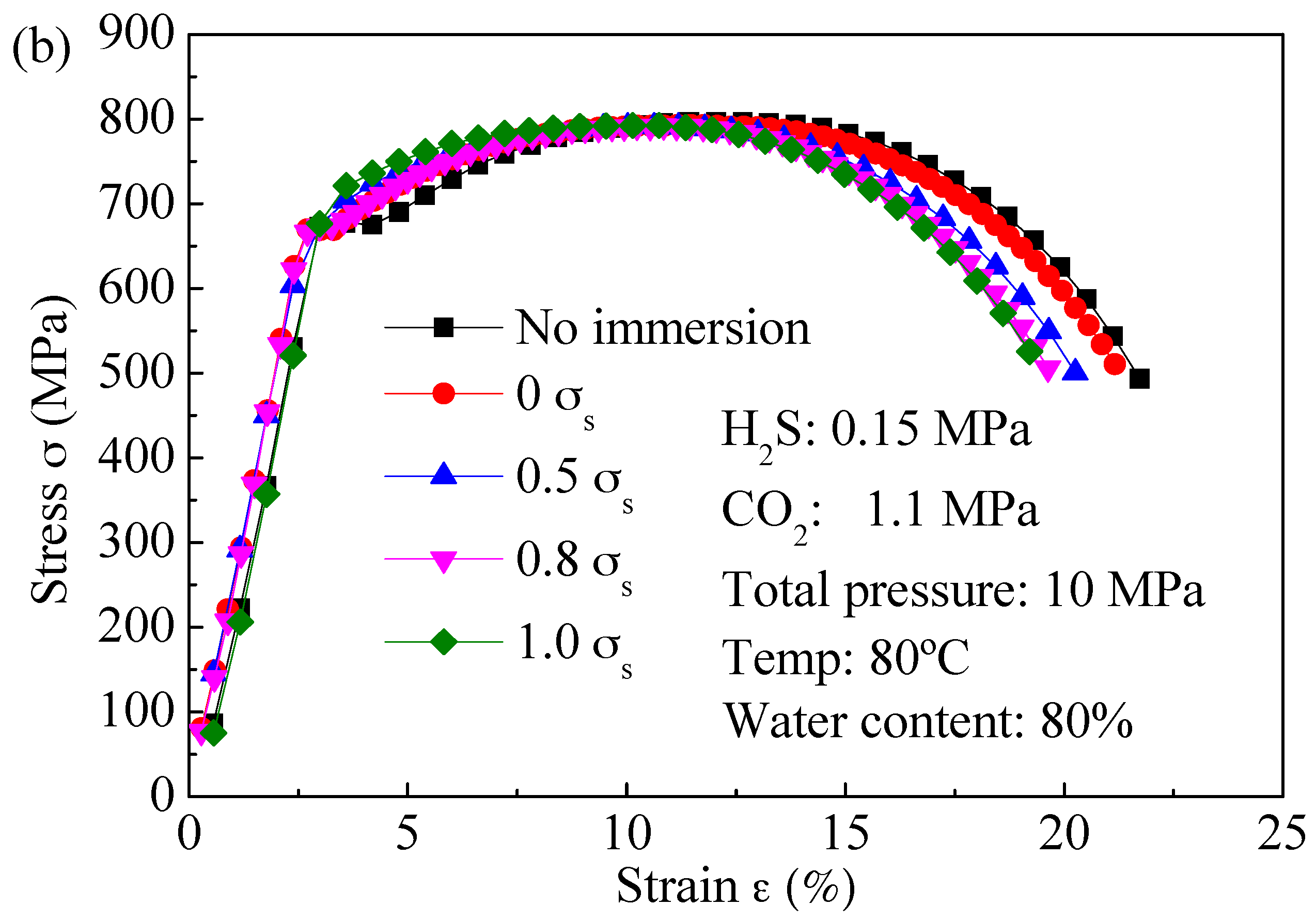

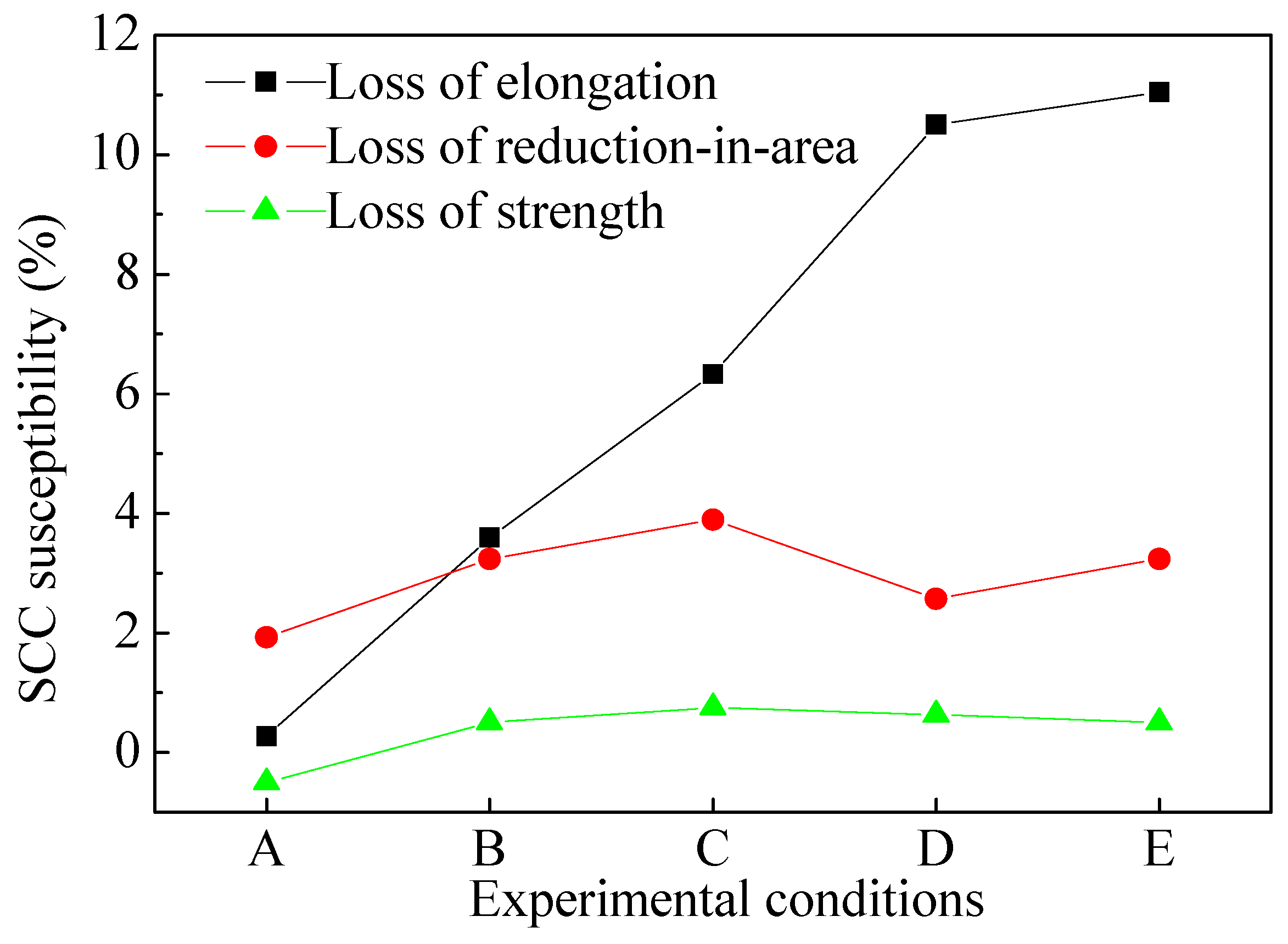

5.3. Tensile Properties after Immersion

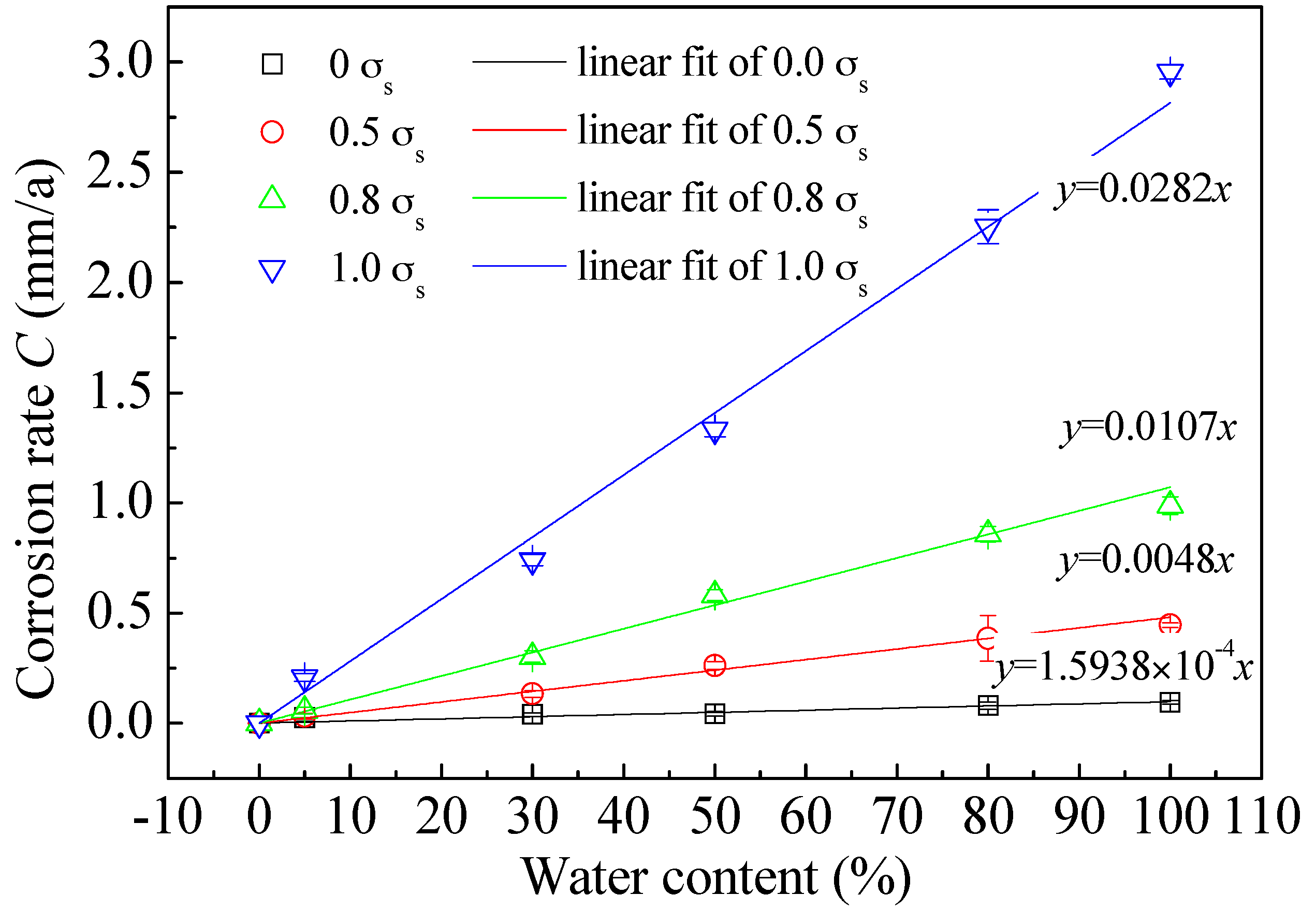

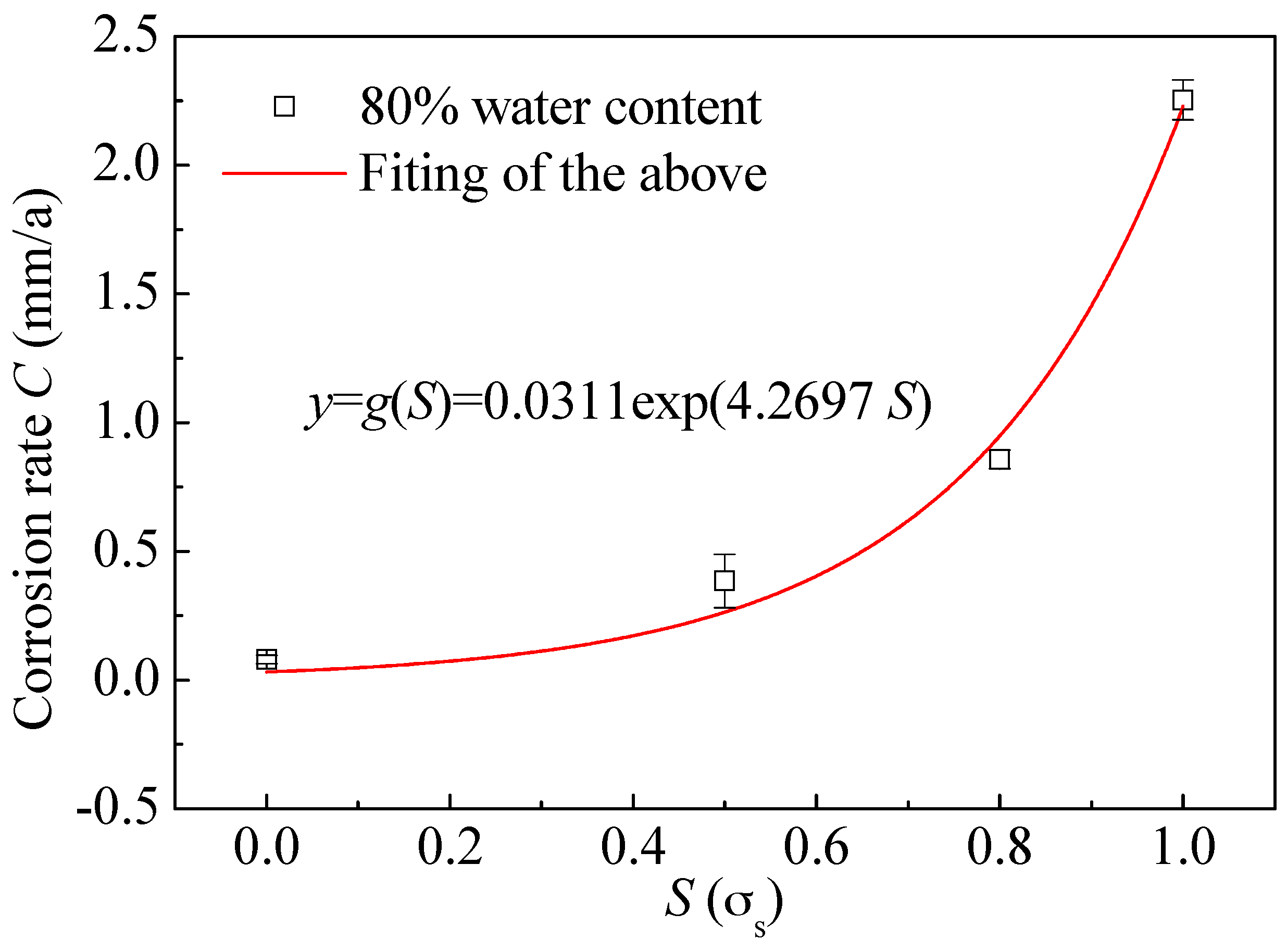

5.4. Corrosion Rates

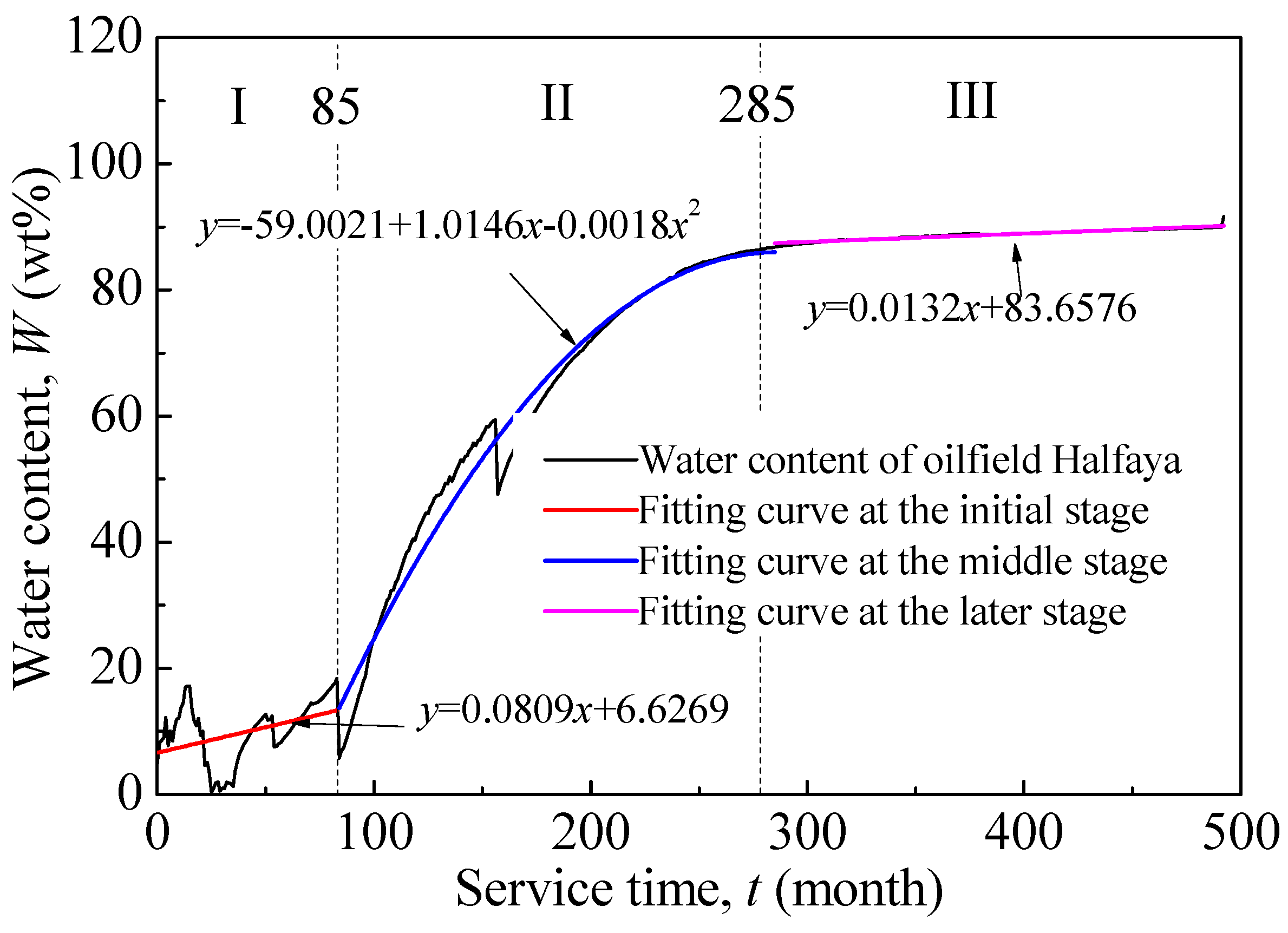

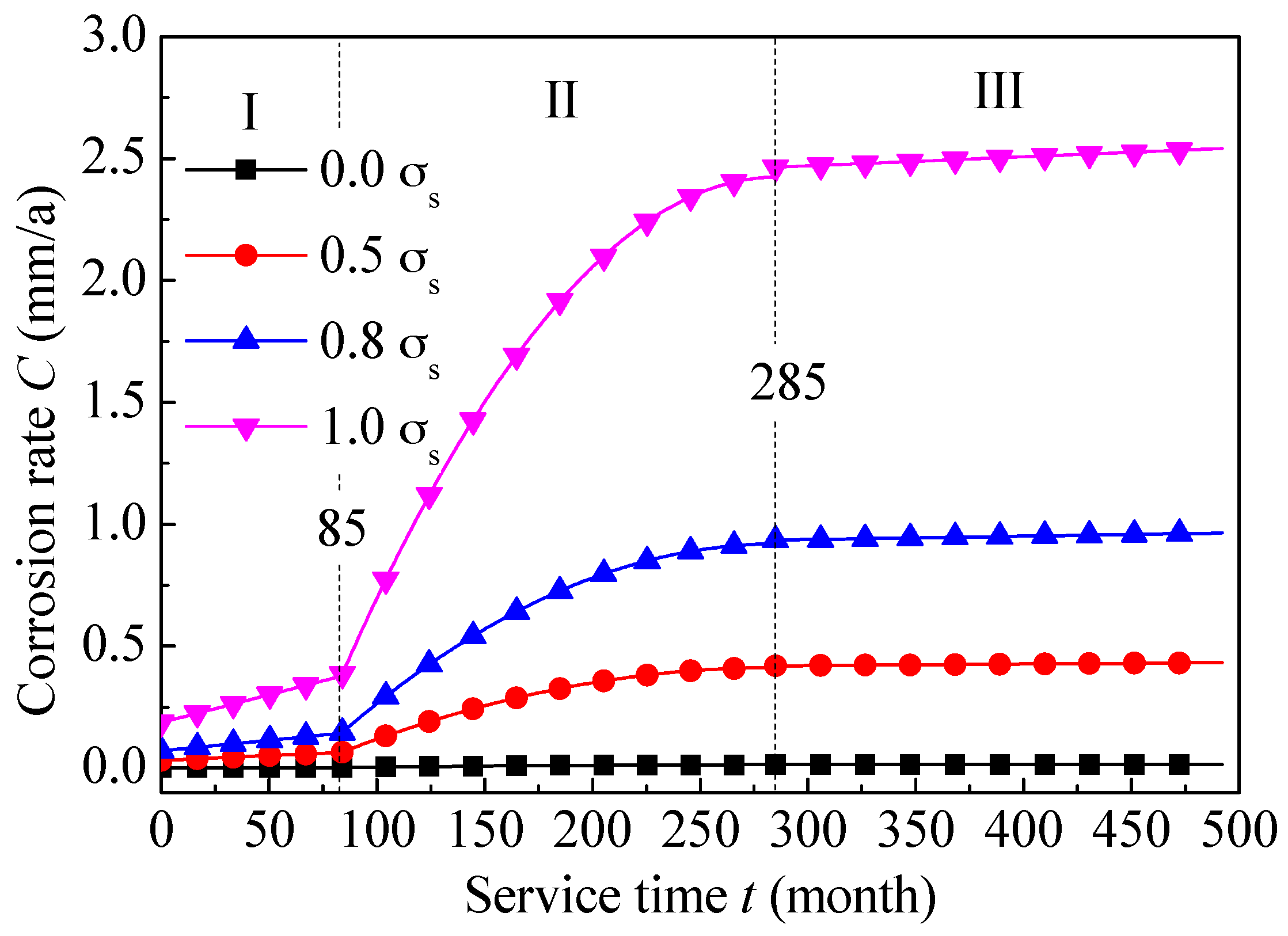

6. Life Prediction of L80 Oil Tube in Halfaya

6.1. Suitability of the Model

6.2. Mathematical Process

6.2.1. When the Initial Stress is Zero

6.2.2. When the Initial Stress is 0.1 σs

The Initial Stage (0–85th Months)

The Middle Stage (85th–285th Months)

6.2.3. The Last Stage (285th Month Onward)

6.3. Results of Life Prediction

7. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Xu, L.Y.; Cheng, Y.F. Development of a finite element model for simulation and prediction of mechanoelectrochemical effect of pipeline corrosion. Corros. Sci. 2013, 73, 150–160. [Google Scholar] [CrossRef]

- Zheng, M.; Luo, J.H.; Zhao, X.W.; Bai, Z.Q.; Wang, R. Effect of pre-deformation on the fatigue crack initiation life of X60 pipeline steel. Int. J. Press. Vessels Pip. 2005, 82, 546–552. [Google Scholar] [CrossRef]

- Song, F.M. Predicting the mechanisms and crack growth rates of pipelines undergoing stress corrosion cracking at high pH. Corros. Sci. 2009, 51, 2657–2674. [Google Scholar] [CrossRef]

- Hu, J.; Tian, Y.; Teng, H.; Yu, L.; Zheng, M. The probabilistic life time prediction model of oil pipeline due to local corrosion crack. Theor. Appl. Fract. Mech. 2014, 70, 10–18. [Google Scholar] [CrossRef]

- Caleyo, F.; Velázquez, J.C.; Valor, A.; Hallen, J.M. Markov chain modelling of pitting corrosion in underground pipelines. Corros. Sci. 2009, 51, 2197–2207. [Google Scholar] [CrossRef]

- Yang, L.; Wang, H. Residual life prediction to submarine pipeline corrosion based on the gray system theory model. Weld. Pip. Tube 2013, 36, 21–24. [Google Scholar]

- Zhang, D.S. Residual strength calculation & residual life prediction of general corrosion pipeline. Procedia Eng. 2014, 94, 52–57. [Google Scholar]

- Parkins, R.N. The application of stress corrosion crack growth kinetics to predicting lifetimes of structures. Corros. Sci. 1989, 29, 1019–1038. [Google Scholar] [CrossRef]

- Soltis, J.; Laycock, N.; Cook, A.; Krouse, D.; White, S.; Soltis, J.; Laycock, N.; Cook, A.; Krouse, D.; White, S. Artificial pit studies of anodic dissolution kinetics in localised corrosion of aluminium. ECS Trans. 2008, 11, 75–87. [Google Scholar]

- Ghahari, M.; Krouse, D.; Laycock, N.; Rayment, T.; Padovani, C.; Stampanoni, M.; Marone, F.; Mokso, R.; Davenport, A.J. Synchrotron X-ray radiography studies of pitting corrosion of stainless steel: Extraction of pit propagation parameters. Corros. Sci. 2015, 100, 23–35. [Google Scholar] [CrossRef]

- Laycock, P.J.; Cottis, R.A.; Scarf, P.A. Extrapolation of extreme pit depths in space and time. J. Electrochem. Soc. 1988, 137, 64–69. [Google Scholar] [CrossRef]

- Valor, A.; Caleyo, F.; Hallen, J.M.; Velázquez, J.C. Reliability assessment of buried pipelines based on different corrosion rate models. Corros. Sci. 2013, 66, 78–87. [Google Scholar] [CrossRef]

- Melchers, R.E. The effect of corrosion on the structural reliability of steel offshore structures. Corros. Sci. 2005, 47, 2391–2410. [Google Scholar] [CrossRef]

- Li, S.X.; Yu, S.R.; Zeng, H.L.; Li, J.H.; Liang, R. Predicting corrosion remaining life of underground pipelines with a mechanically-based probabilistic model. J. Pet. Sci. Eng. 2009, 65, 162–166. [Google Scholar] [CrossRef]

- Melchers, R.E. Long-term corrosion of cast irons and steel in marine and atmospheric environments. Corros. Sci. 2013, 68, 281–292. [Google Scholar] [CrossRef]

- Zhou, C.; Chen, X.; Wang, Z.; Zheng, S.; Li, X.; Zhang, L. Effects of environmental conditions on hydrogen permeation of X52 pipeline steel exposed to high H2S-containing solutions. Corros. Sci. 2014, 89, 30–37. [Google Scholar] [CrossRef]

- Timashev, S.A.; Bushinskaya, A.V. Markov approach to early diagnostics, reliability assessment, residual life and optimal maintenance of pipeline systems. Struct. Saf. 2015, 56, 68–79. [Google Scholar] [CrossRef]

- American Society of Mechanical Engineers. Manual for Determining the Reamaining Strength of Corroded Pipelines; ASME: New York, NY, USA, 2012. [Google Scholar]

- Anderson, T.L.; Osage, D.A. API 579: A comprehensive fitness-for-service guide. Int. J. Press. Vessels Pip. 2000, 77, 953–963. [Google Scholar] [CrossRef]

- Gordon, W.J. Blending-function methods of bivariate and multivariate interpolation and approximation. J. Numer. Anal. 1971, 8, 158–177. [Google Scholar] [CrossRef]

- American Society for Testing and Materials. Standard test method for tension testing of metallic materials. In Annual Book of ASTM Standards; ASTM International: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Zhao, W.; Zou, Y.; Matsuda, K.; Zou, Z. Characterization of the effect of hydrogen sulfide on the corrosion of X80 pipeline steel in saline solution. Corros. Sci. 2016, 102, 455–468. [Google Scholar] [CrossRef]

- Zhang, G.A.; Zeng, Y.; Guo, X.P.; Jiang, F.; Shi, D.Y.; Chen, Z.Y. Electrochemical corrosion behavior of carbon steel under dynamic high pressure H2S/CO2 environment. Corros. Sci. 2012, 65, 37–47. [Google Scholar] [CrossRef]

- Genchev, G.; Cox, K.; Tran, T.H.; Sarfraz, A.; Bosch, C.; Spiegel, M.; Erbe, A. Metallic oxygen-containing reaction products after polarisation of iron in H2S saturated saline solutions. Corros. Sci. 2015, 98, 725–736. [Google Scholar] [CrossRef]

- Liu, Z.Y.; Li, X.G.; Du, C.W.; Cheng, Y.F. Local additional potential model for effect of strain rate on SCC of pipeline steel in an acidic soil solution. Corros. Sci. 2009, 51, 2863–2871. [Google Scholar] [CrossRef]

| NaCl | NaHCO3 | Na2SO4 | CaCl2 | MgCl2·6H2O | pH |

|---|---|---|---|---|---|

| 236.5 | 1.01 | 0.64 | 26.64 | 12.68 | 6 |

| Water Content (wt %) | Preloading Stress (σs) | No. | Corrosion Rate (mm/a) | Average Corrosion Rate (mm/a) |

|---|---|---|---|---|

| 5 | 0 | 1 | 0.0132 | 0.0243 |

| 2 | 0.0354 | |||

| 0.5 | 1 | 0.0403 | 0.0311 | |

| 2 | 0.0219 | |||

| 0.8 | 1 | 0.0663 | 0.0562 | |

| 2 | 0.0461 | |||

| 1.0 | 1 | 0.1941 | 0.2069 | |

| 2 | 0.2197 | |||

| 30 | 0 | 1 | 0.0329 | 0.0384 |

| 2 | 0.0439 | |||

| 0.5 | 1 | 0.1219 | 0.1331 | |

| 2 | 0.1443 | |||

| 0.8 | 1 | 0.3201 | 0.3015 | |

| 2 | 0.2829 | |||

| 1.0 | 1 | 0.7584 | 0.7405 | |

| 2 | 0.7226 | |||

| 50 | 0 | 1 | 0.0507 | 0.0431 |

| 2 | 0.0355 | |||

| 0.5 | 1 | 0.2484 | 0.2608 | |

| 2 | 0.2932 | |||

| 0.8 | 1 | 0.5986 | 0.5813 | |

| 2 | 0.5640 | |||

| 1.0 | 1 | 1.3550 | 1.3322 | |

| 2 | 1.3094 | |||

| 80 | 0 | 1 | 0.0920 | 0.0797 |

| 2 | 0.0674 | |||

| 0.5 | 1 | 0.3111 | 0.3845 | |

| 2 | 0.4580 | |||

| 0.8 | 1 | 0.8316 | 0.8569 | |

| 2 | 0.8822 | |||

| 1.0 | 1 | 2.1980 | 2.2529 | |

| 2 | 2.3078 | |||

| 100 | 0 | 1 | 0.1002 | 0.0951 |

| 2 | 0.0900 | |||

| 0.5 | 1 | 0.4526 | 0.4455 | |

| 2 | 0.4384 | |||

| 0.8 | 1 | 1.0161 | 0.9870 | |

| 2 | 0.9579 | |||

| 1.0 | 1 | 2.9331 | 2.9558 | |

| 2 | 2.9785 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, T.; Liu, Z.; Du, C.; Hu, J.; Li, X. A Modelling Study for Predicting Life of Downhole Tubes Considering Service Environmental Parameters and Stress. Materials 2016, 9, 741. https://doi.org/10.3390/ma9090741

Zhao T, Liu Z, Du C, Hu J, Li X. A Modelling Study for Predicting Life of Downhole Tubes Considering Service Environmental Parameters and Stress. Materials. 2016; 9(9):741. https://doi.org/10.3390/ma9090741

Chicago/Turabian StyleZhao, Tianliang, Zhiyong Liu, Cuiwei Du, Jianpeng Hu, and Xiaogang Li. 2016. "A Modelling Study for Predicting Life of Downhole Tubes Considering Service Environmental Parameters and Stress" Materials 9, no. 9: 741. https://doi.org/10.3390/ma9090741