Microstructure and Antiwear Property of Laser Cladding Ni–Co Duplex Coating on Copper

Abstract

:1. Introduction

2. Materials and Methods

2.1. Materials

2.2. Methods

3. Results and Discussion

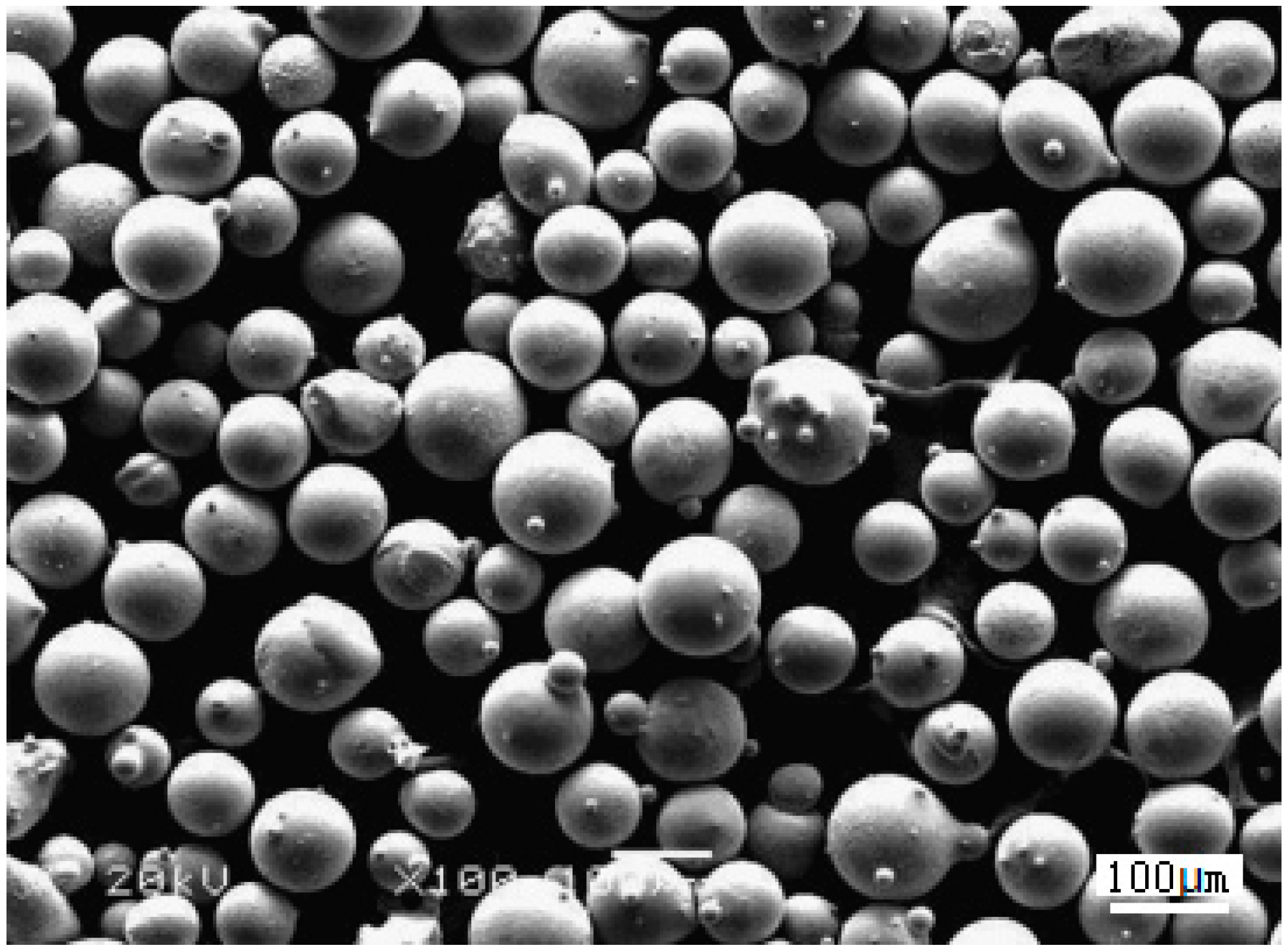

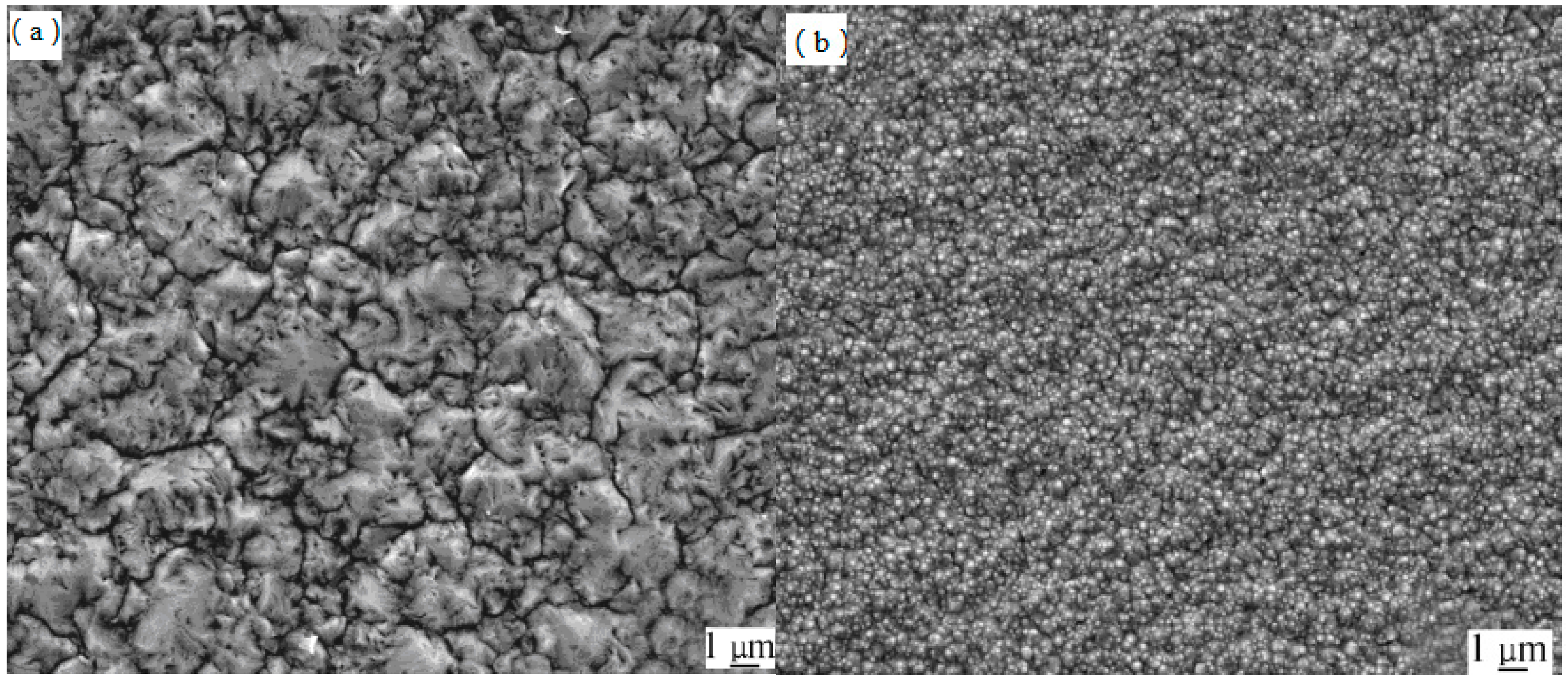

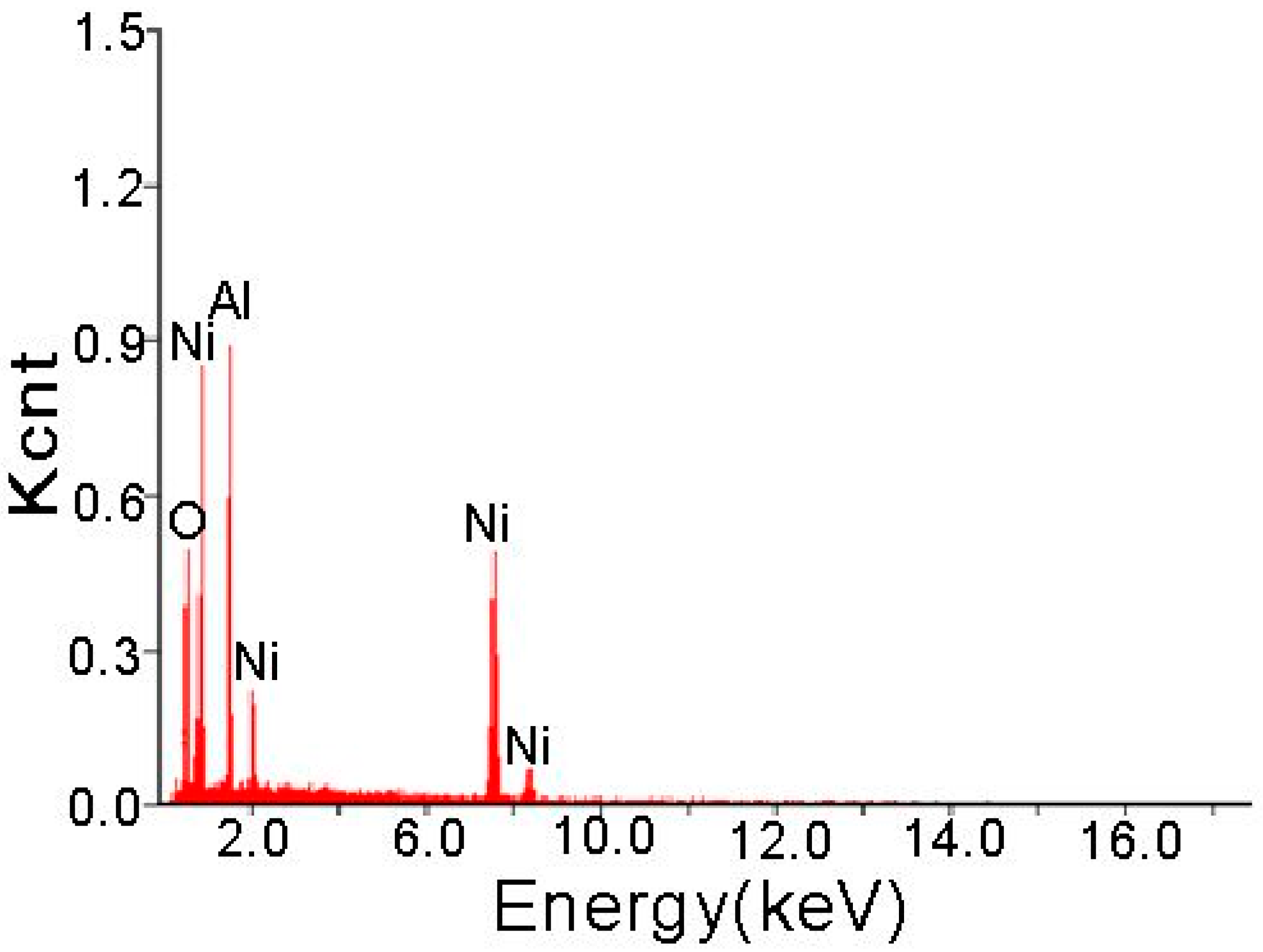

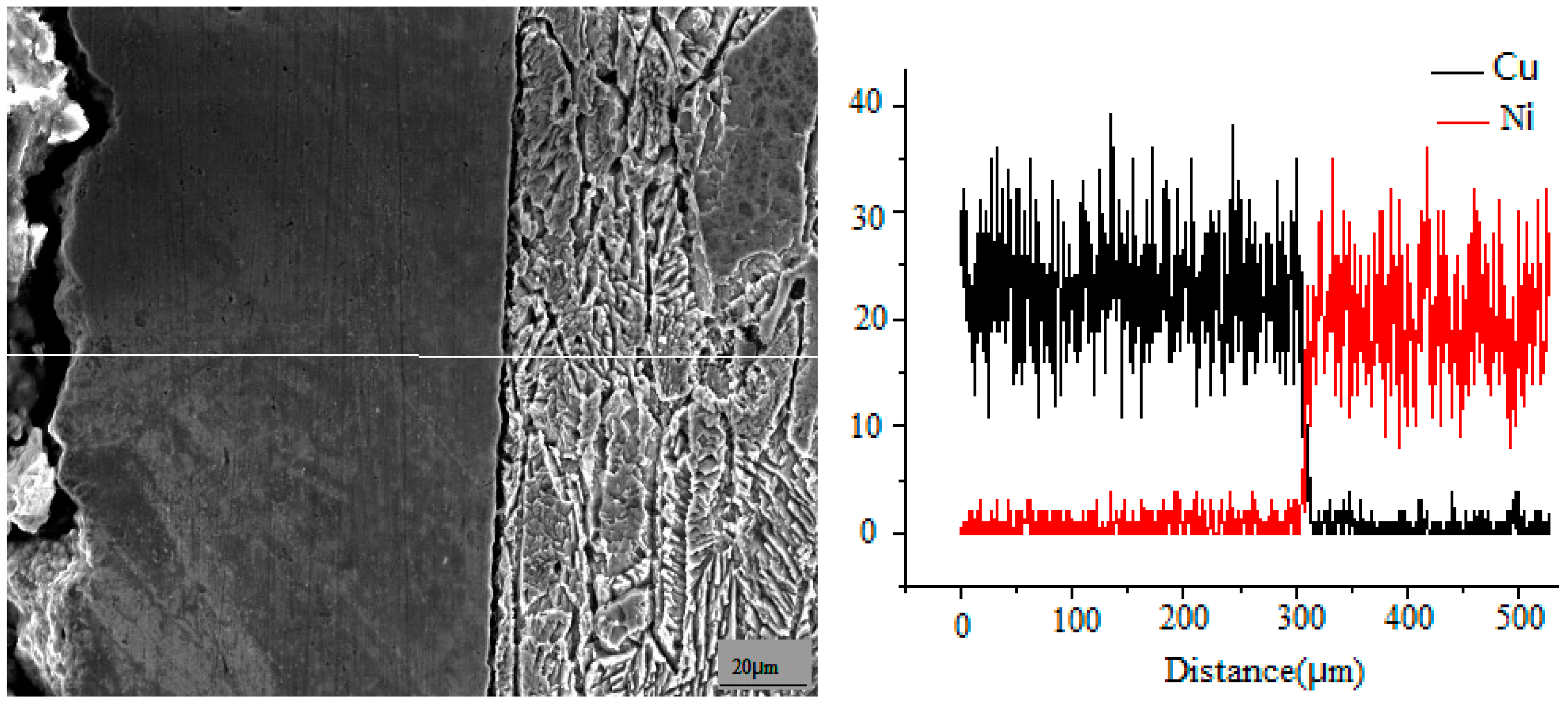

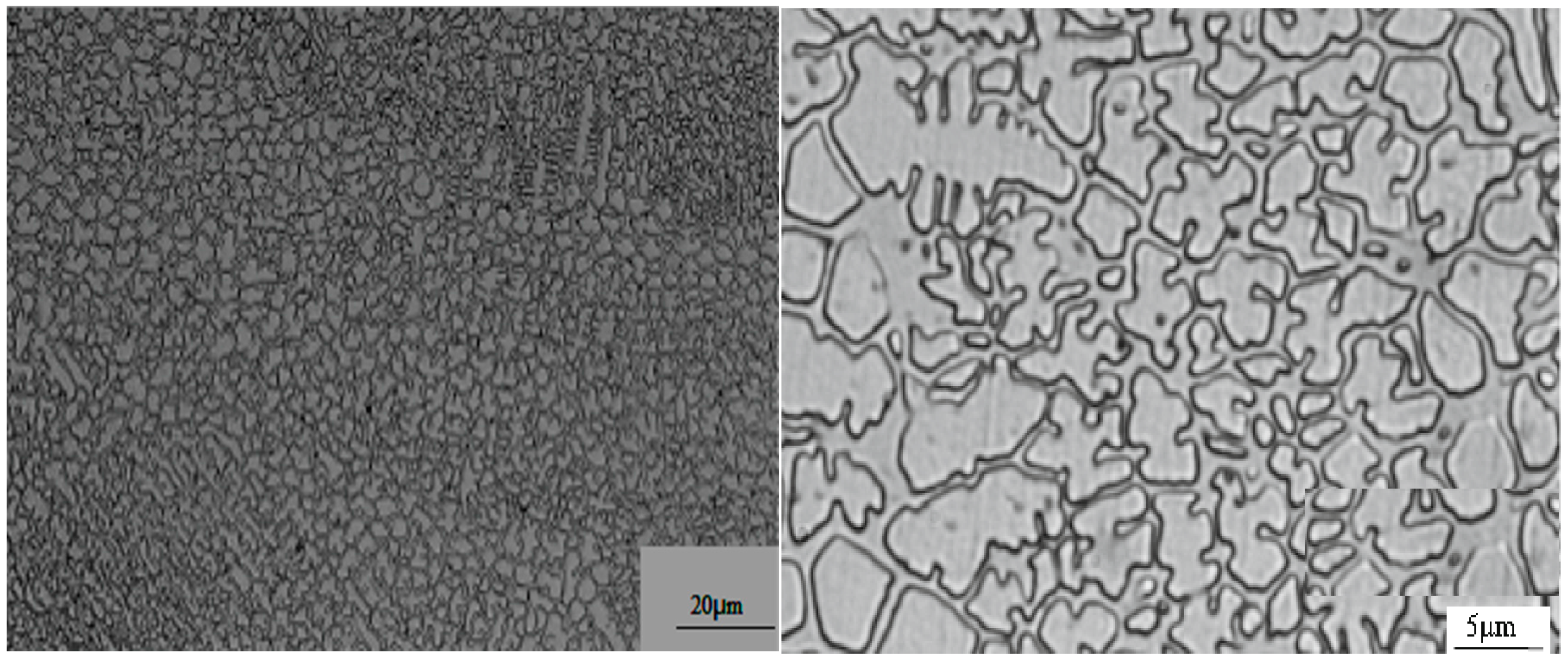

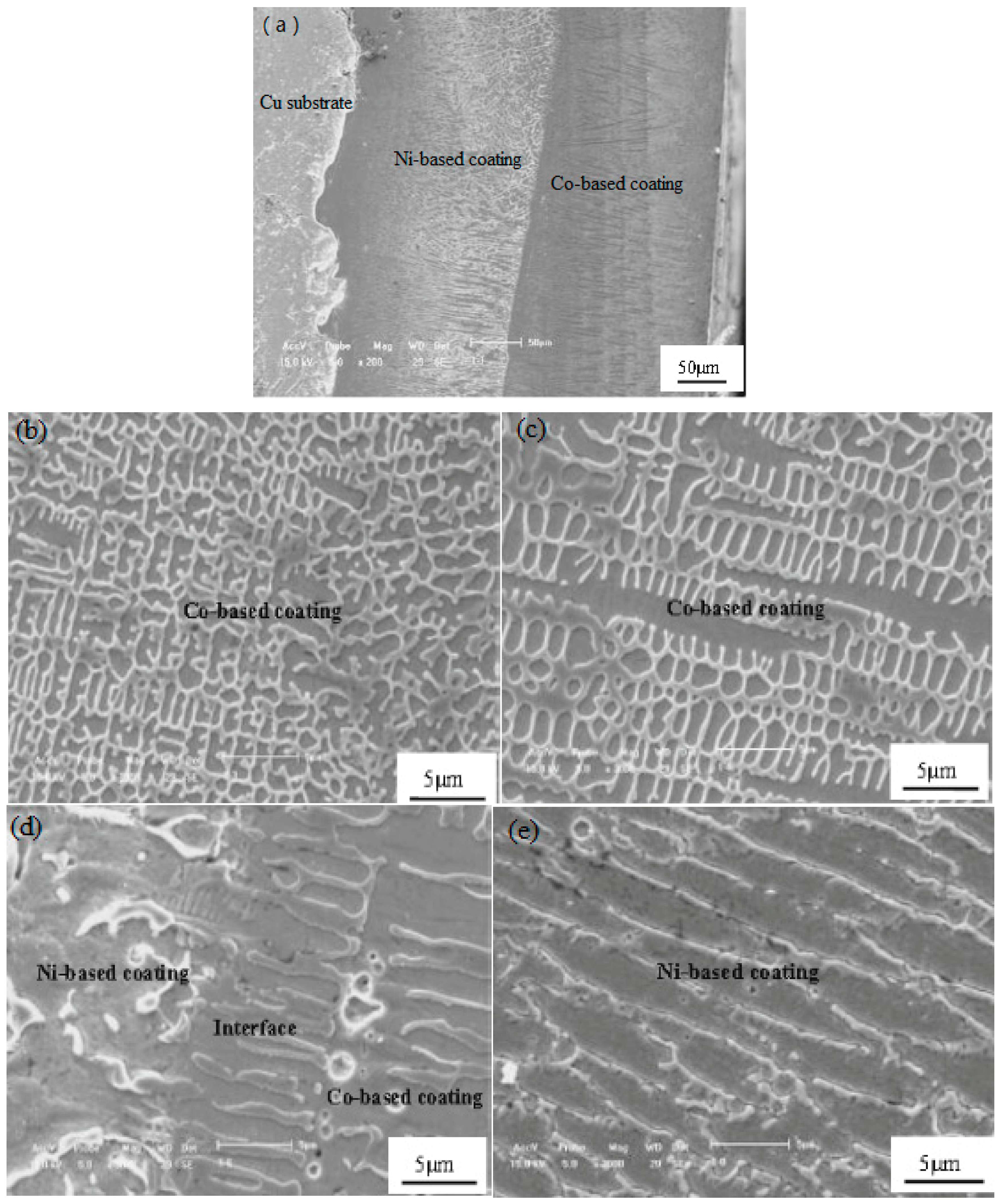

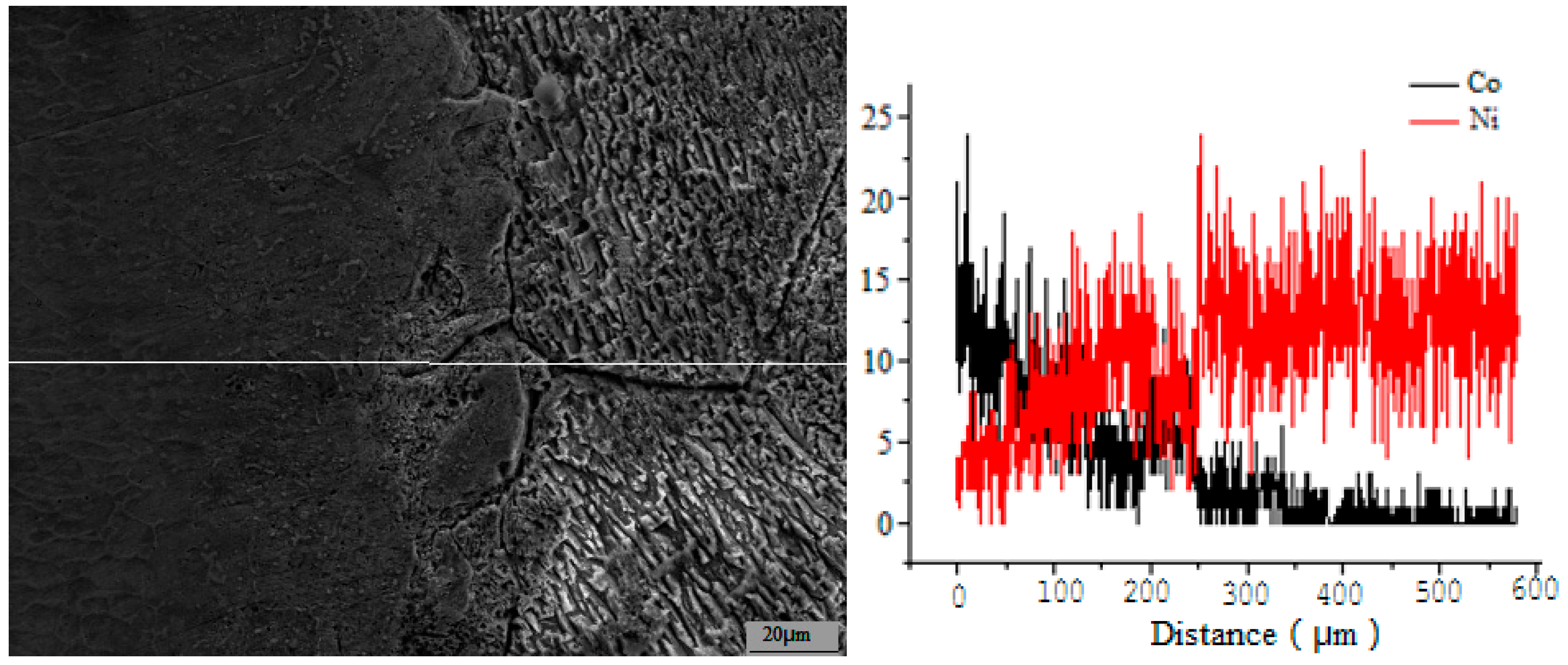

3.1. Morphology and Microsturcture of Coatings

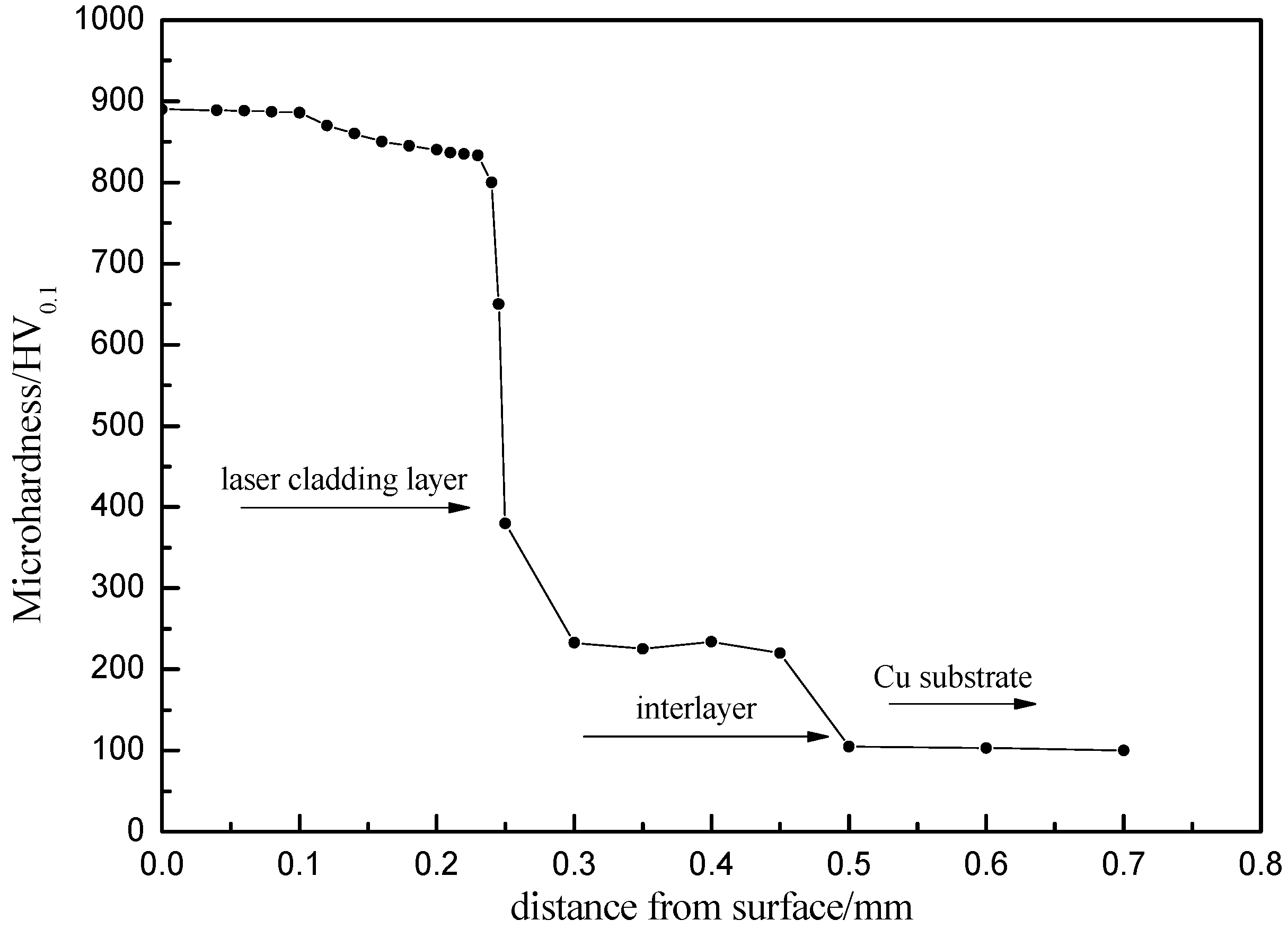

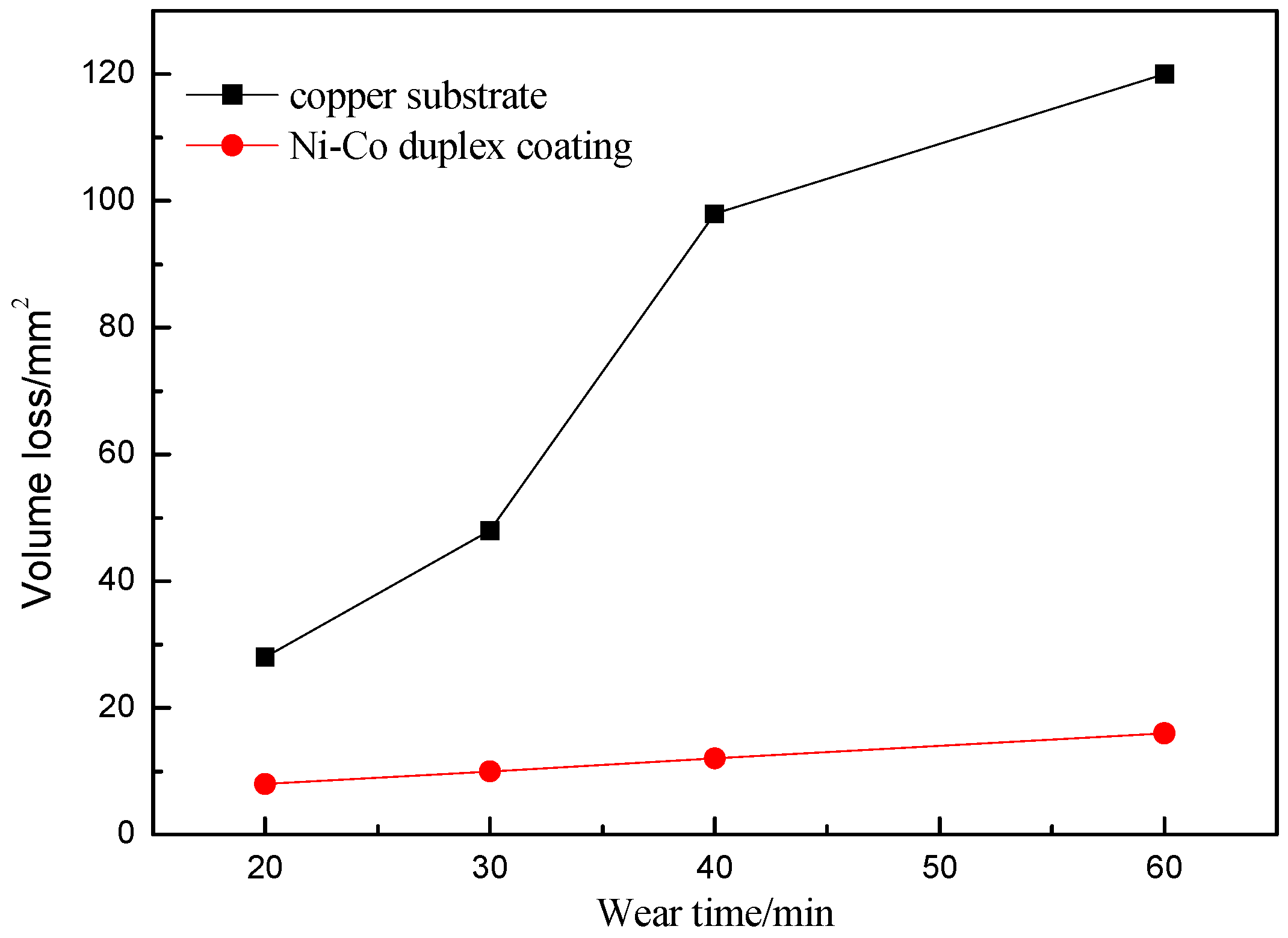

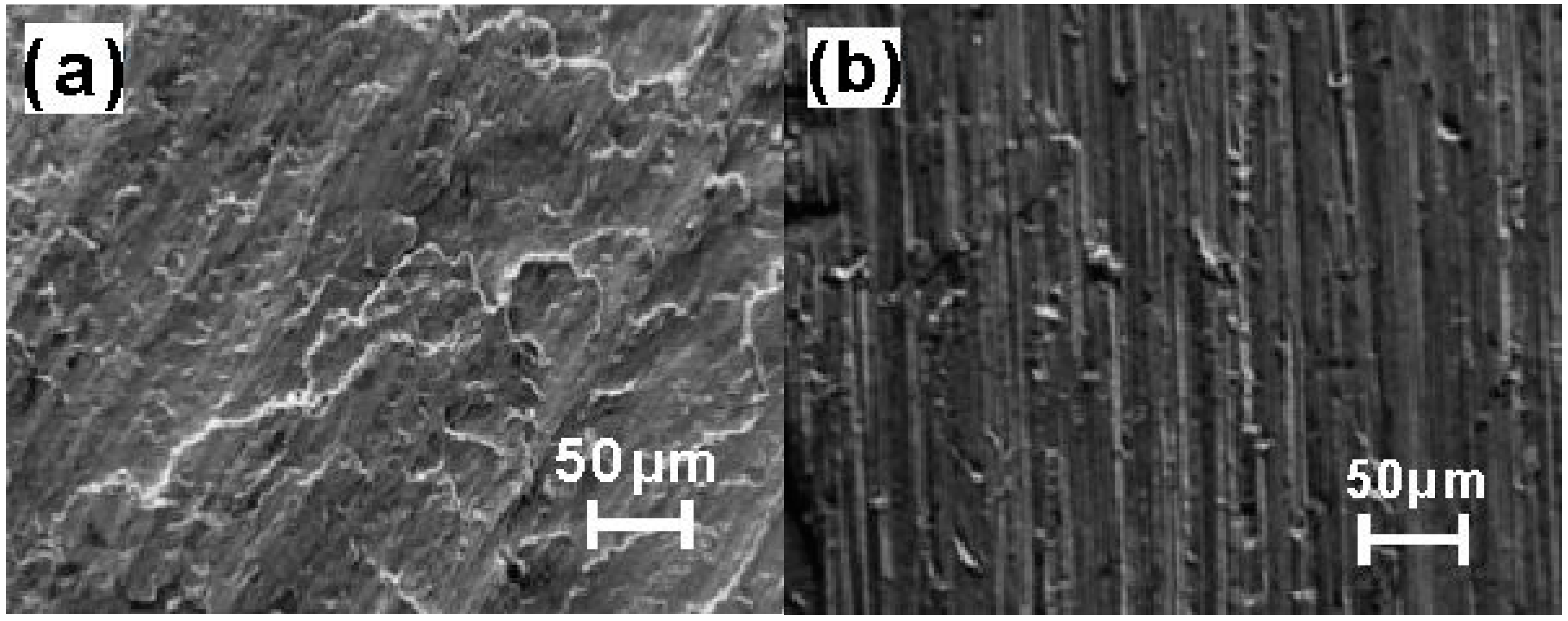

3.2. Microhardness and Wear Resistance of the Coatings

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Bateni, M.R.; Ashrafizadeh, F.; Szpunar, J.A.; Drew, R.A.L.; Kobryn, P.A.; Moore, E.H.; Semiatin, S.L. Effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti-6Al-4V. Scr. Mater. 2000, 43, 299–305. [Google Scholar]

- Farnia, A.; Ghaini, F.M.; Ocelik, V.; de Hosson, J.; Th, M. Microsructural characterization of Co-based coating deposited by low power pulse laser cladding. J. Mater. Sci. 2013, 48, 2714–2723. [Google Scholar] [CrossRef]

- Ahsana, M.N.; Pinkerton, A.J.; Moat, R.J.; Shackleton, J.A. comparative study of laser direct metal deposition characteristics using gas and plasma-atomized Ti-6Al-4V powders. Mater. Sci. Eng. A 2011, 528, 7648–7657. [Google Scholar] [CrossRef]

- He, L.; Tan, Y.F.; Wang, X.L.; Jing, Q.F.; Hong, X. Tribological properties of laser cladding TiB2 particles reinforced Ni-base alloy composite coatings on aluminum alloy. Rare Met. 2015, 34, 789–796. [Google Scholar] [CrossRef]

- Yao, B.; Ma, X.L.; Lin, F.; Ge, W.J. Microstructure and mechanical properties of Ti-6Al-4V components fabricated by laser micro cladding deposition. Rare Met. 2015, 34, 445–451. [Google Scholar] [CrossRef]

- Li, X.Z.; Liu, Z.D.; Wang, Y.T. Microstructure and corrosion properties of laser cladding MoNi based alloy coatings. Sci. China 2014, 57, 980–989. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.; Tao, X.; Chen, S. Laser cladding of Ni-based alloy on copper substrate. J. Univ. Sci. Technol. Beijing 2006, 13, 329–332. [Google Scholar] [CrossRef]

- Zhang, Y.Z.; Tu, Y.; Xi, M.Z.; Shi, L.K. Characterization on laser clad nickel based alloy coating on pure copper. Surf. Coat. Technol. 2008, 202, 5924–5928. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.L.; Yu, Z.S.; Lu, Q.H.; Yang, S.L.; Li, C.G. Microstructure and tribological properties of laser-clad Ni-Cr/TiB2 composite coatings on copper with the addition of CaF2. Surf. Coat. Technol. 2012, 206, 4046–4053. [Google Scholar] [CrossRef]

- Dehm, G.; Bamberger, M. Laser cladding of Co-based hardfacing on Cu substrate. J. Mater. Sci. 2002, 37, 5345–5353. [Google Scholar] [CrossRef]

- Adak, B.; Nash, P.; Chen, D.J.; Swiglo, A. Microstructural characterization of laser cladding of Cu-30Ni. J. Mater. Sci. 2005, 40, 2051–2054. [Google Scholar] [CrossRef]

- He, B.L.; Liu, J.; Wang, B. Study on the methods of the surface self-nanocrystalline technology and its effect on the materials properties. Appl. Mech. Mater. 2011, 80, 673–677. [Google Scholar] [CrossRef]

- Lu, K.; Lu, J. Nanostructured surface layer on metallic materials induced by surface mechanical attrition treatment. Mater. Sci. Eng. A 2004, 375–377, 38–45. [Google Scholar] [CrossRef]

- Wang, Y.S.; Liu, N.W.; Zhu, F.D. Microstructure and wear resistance of laser cladding of Ni-based alloy on copper substrate. Mater. Sci. Forum 2011, 663–665, 1061–1064. [Google Scholar] [CrossRef]

- Liu, F.; Liu, C.S.; Chen, S.Y.; Tao, X.Q.; Zhang, Y. Laser cladding Ni-Co duplex coating on copper substrate. Opt. Laser Eng. 2012, 48, 792–799. [Google Scholar] [CrossRef]

- Yan, H.; Zhang, P.L.; Yu, Z.S.; Li, C.G.; Li, R.D. Development and characterization of laser surface cladding (Ti, W) C reinforced Ni30Cu alloy composite coating on copper. Opt. Laser Technol. 2012, 44, 1351–1358. [Google Scholar] [CrossRef]

- Chen, S.Y.; Liang, J.; Liu, C.S.; Sun, K.; Mazumeder, J. Preparation of a novel Ni/Co-based alloy gradient coating on surface of the crystallizer copper alloy by laser. Appl. Surf. Sci. 2011, 258, 1443–1450. [Google Scholar] [CrossRef]

| Component | NiSO4·6H2O | Al2O3 | NiCl2·6H2O | CH3(CH2)11SO3Na | H2BO3 |

|---|---|---|---|---|---|

| g/L | 280 | 30 | 45 | 0.1 | 40 |

| Element | Co | Ni | Cr | Si | W | Fe | C |

|---|---|---|---|---|---|---|---|

| Wt % | 50 | 12 | 25 | 3 | 8 | 2 | 0.75 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Liang, Z.; Zhang, J.; Ning, Z.; Jin, H. Microstructure and Antiwear Property of Laser Cladding Ni–Co Duplex Coating on Copper. Materials 2016, 9, 634. https://doi.org/10.3390/ma9080634

Wang Y, Liang Z, Zhang J, Ning Z, Jin H. Microstructure and Antiwear Property of Laser Cladding Ni–Co Duplex Coating on Copper. Materials. 2016; 9(8):634. https://doi.org/10.3390/ma9080634

Chicago/Turabian StyleWang, Yiyong, Zhipeng Liang, Junwei Zhang, Zhe Ning, and Hui Jin. 2016. "Microstructure and Antiwear Property of Laser Cladding Ni–Co Duplex Coating on Copper" Materials 9, no. 8: 634. https://doi.org/10.3390/ma9080634