Micromechanical Modeling of Fiber-Reinforced Composites with Statistically Equivalent Random Fiber Distribution

Abstract

:1. Introduction

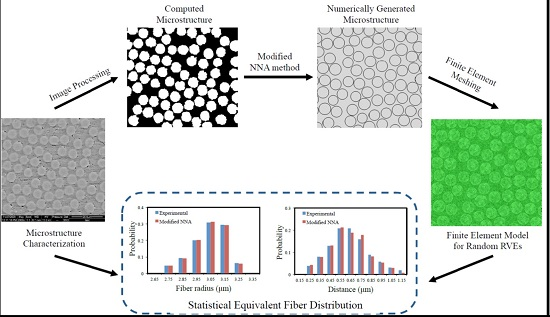

2. Algorithm Development

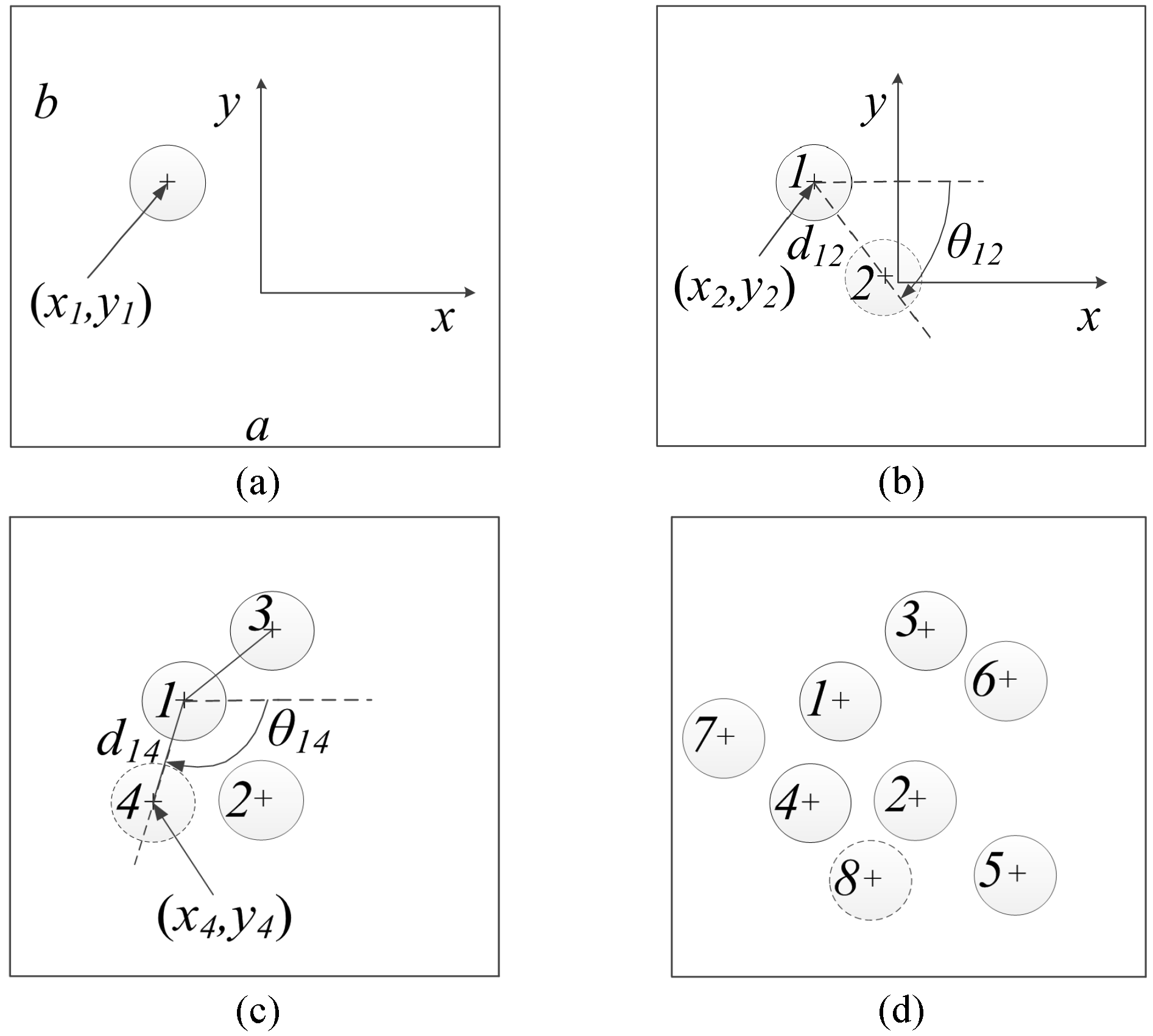

- Consider a rectangular objective window with length a and width b, a random fiber is first created in the central area of the window with the coordinates of the center (x1, y1), as shown in Figure 2a. The diameter of fibers can be identical or variable, and, in this study, the values are drawn from the experimentally measured diameter distribution. The RVE size must be large enough to be representative in predicting the mechanical properties of the composite material. As from the study of Trias et al. [12], a minimum length and width of 50 times of the fiber radius is recommended.

- Following the realistic nearest neighbor distribution, a nearest neighbor distance is assigned to the newly generated fiber (for example, fiber #1 for the first cycle).

- A new fiber (fiber #2) is then generated around the current reference fiber (fiber #1). The position of the new fiber is calculated based on the inter-fiber distance d12 and the orientation angle θ12 (see Figure 2b), which are determined based on the probability equation and the distribution of nearest fiber distance and orientation angle.

- In the original NNA method, the newly generated fiber (fiber #2) is checked and if the inter-fiber distance between it and the reference fiber is less than the nearest neighbor distance of the reference fiber, it will be regenerated. This rule could result in the increase of the inter-fiber distance and a relatively low frequency of small inter-fiber distance distribution. To overcome this issue, a random number P with the value between 0 and 1 is generated and is associated with a probability selection rule. If P is less than a predefined threshold value P0 (0 < P0 < 0.3), the newly generated fiber will be kept even though it does not satisfy the nearest neighbor distance. P0 is taken as 0.15 in this work.

- Steps 2–4 are repeated to generate more fibers around the current reference fiber, until the maximum iteration numbers (usually between 3 and 5) are reached. The inter-fiber distances between each newly generated fiber and all the existing fibers need to be examined separately. For example, in Figure 2c, the inter-fiber distance between fiber #1 and fiber #4 should be larger than the nearest neighbor distance of fiber #1. However, the probability selection rule of step 4 always applies.

- Followed by the generation of each new fiber, the frequency of the nearest neighbor distance of fibers needs to be updated. The equation is expressed aswhere Li is the updated frequency of nearest neighbor distance for the ith cycle (each cycle corresponds to a different fiber serving as the reference fiber), is the initial frequency of nearest neighbor distance for the ith cycle, N represents the estimated total number of fibers, and Ni represents the fibers already generated during the ith cycle.

- The current cycle ends when there is no more new fiber generation around the current reference fiber. The reference fiber is then switched to a different fiber based on the fiber number, e.g., fiber #2 will be the reference fiber of the second cycle.

- The above process is repeated until the requested fiber volume ratio or maximum number of cycles is reached.

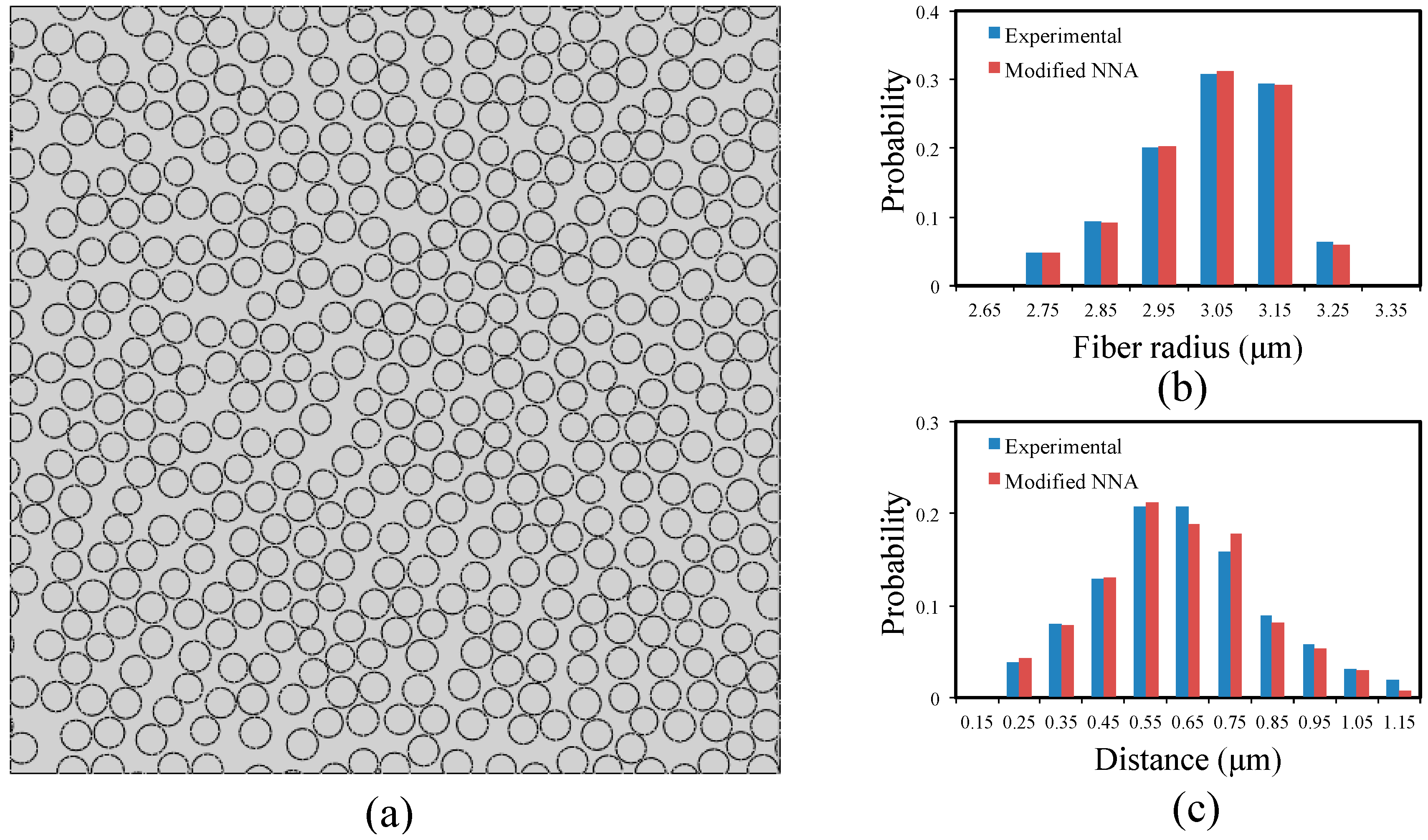

3. Statistical Characterization

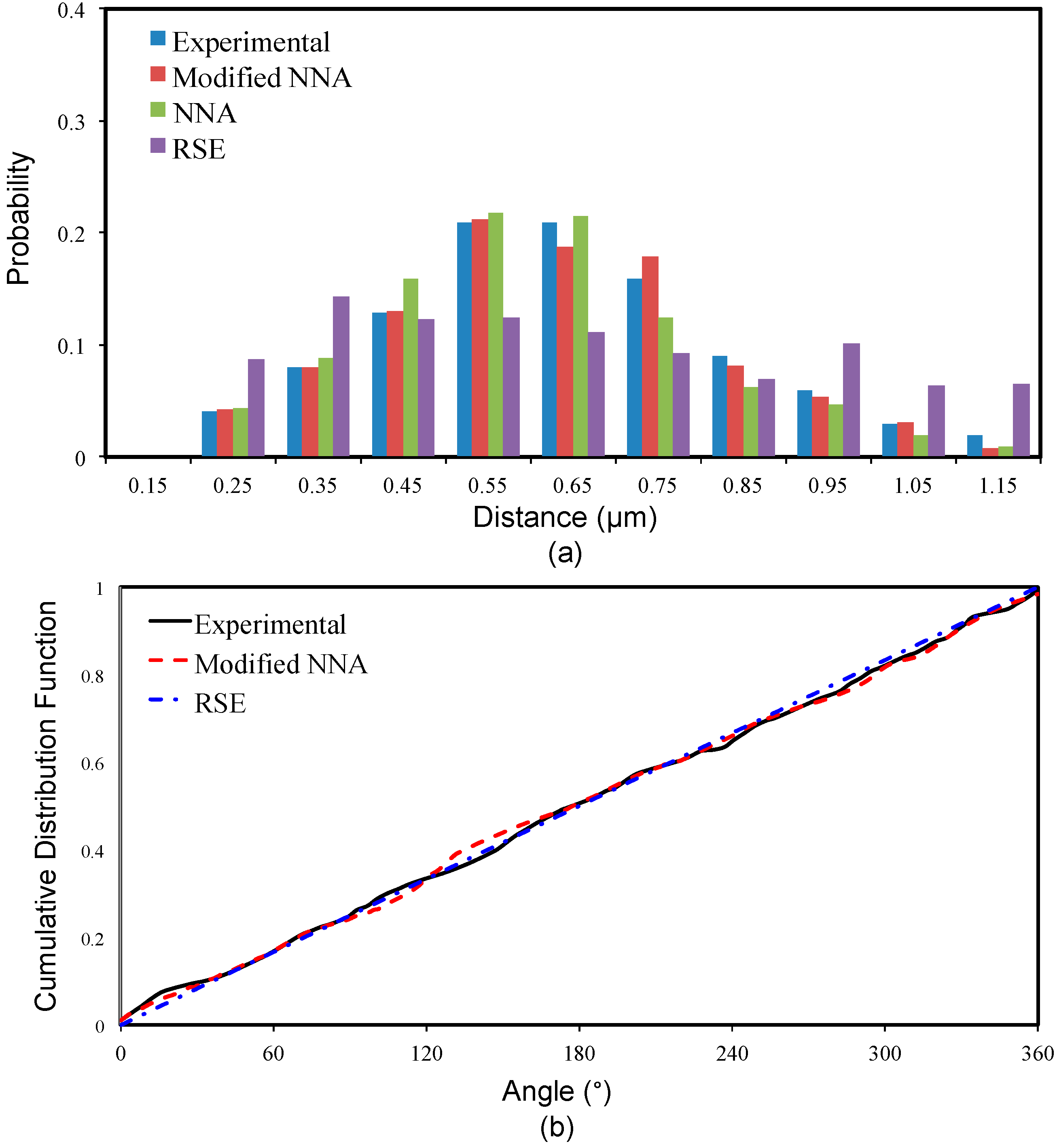

3.1. Nearest Neighbor Distance

3.2. Nearest Neighbor Orientation

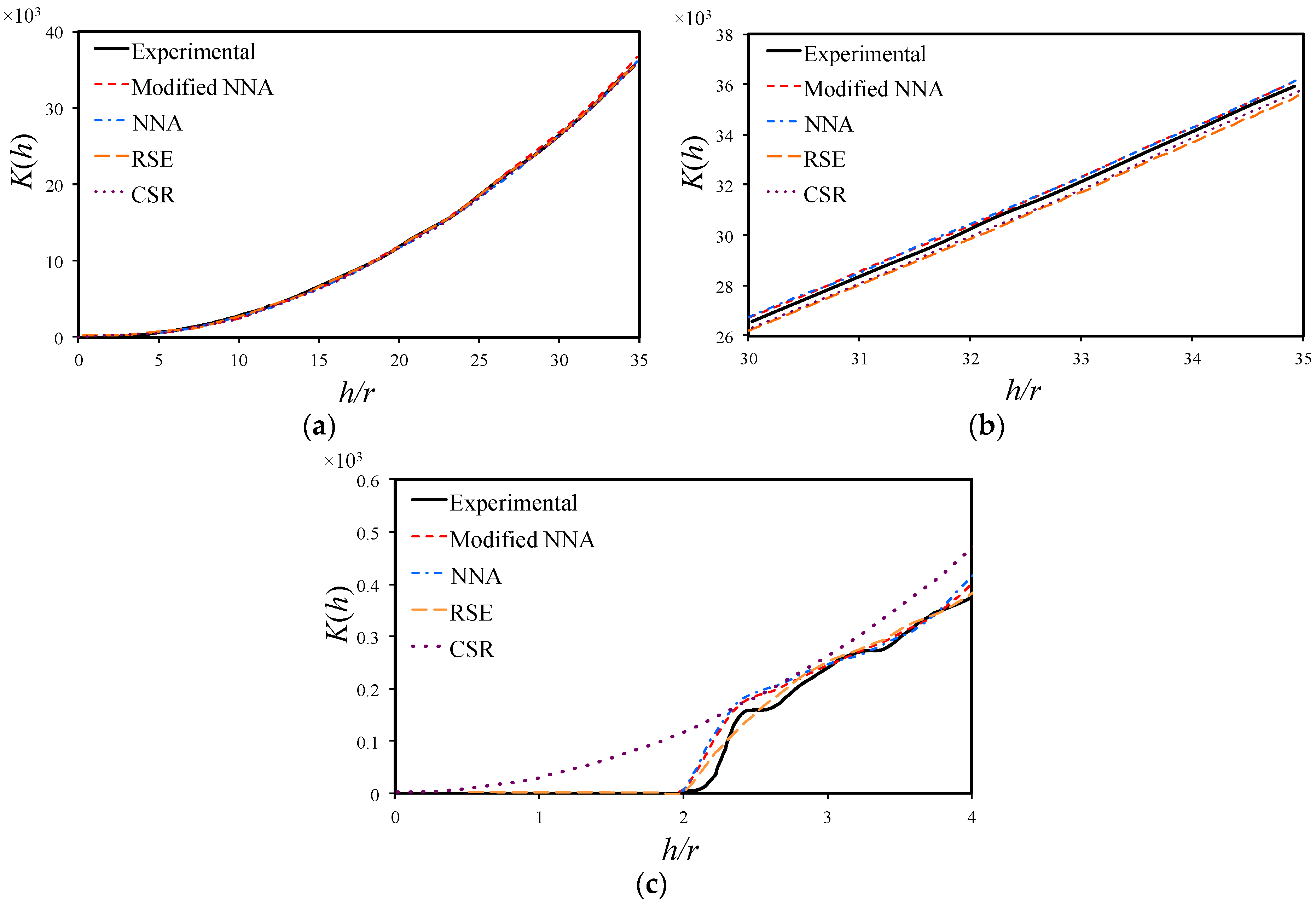

3.3. Ripley’s K Function

3.4. Radial Distribution Function

4. Prediction of Elastic Properties

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Chamis, C.C.; Murthy, P.L. ICAN: Integrated composites analyzer. J. Compos. Technol. Res. 1986, 8, 8–17. [Google Scholar]

- Aboudi, J. Micromechanical analysis of composites by the method of cells-update. Appl. Mech. Rev. 1996, 49, S83–S91. [Google Scholar] [CrossRef]

- Goldberg, R.K.; Roberts, G.D.; Gilat, A. Analytical studies of the high strain rate tensile response of a polymer matrix composite. J. Adv. Mater. 2004, 36, 14–24. [Google Scholar]

- Herakovich, C.T. Mechanics of Fibrous Composites; John Wiley & Sons, Inc.: New York, NY, USA, 1998. [Google Scholar]

- Sun, C.; Vaidya, R. Prediction of composite properties from a representative volume element. Compos. Sci. Technol. 1996, 56, 171–179. [Google Scholar] [CrossRef]

- Sonon, B.; Massart, T.J. A Level-Set Based Representative Volume Element Generator and XFEM Simulations for Textile and 3D-Reinforced Composites. Materials 2013, 6, 5568–5592. [Google Scholar] [CrossRef]

- Brockenbrough, J.; Suresh, S.; Wienecke, H. Deformation of metal-matrix composites with continuous fibers: Geometrical effects of fiber distribution and shape. Acta Metall. Mater. 1991, 39, 735–752. [Google Scholar] [CrossRef]

- Pyrz, R. Quantitative description of the microstructure of composites. Part I: Morphology of unidirectional composite systems. Compos. Sci. Technol. 1994, 50, 197–208. [Google Scholar] [CrossRef]

- Romanov, V.; Lomov, S.V.; Swolfs, Y.; Orlova, S.; Gorbatikh, L.; Verpoest, I. Statistical analysis of real and simulated fibre arrangements in unidirectional composites. Compos. Sci. Technol. 2013, 87, 126–134. [Google Scholar] [CrossRef]

- Gusev, A.A.; Hine, P.J.; Ward, I.M. Fiber packing and elastic properties of a transversely random unidirectional glass/epoxy composite. Compos. Sci. Technol. 2000, 60, 535–541. [Google Scholar] [CrossRef]

- Sun, C.; Saffari, P.; Ranade, R.; Sadeghipour, K.; Baran, G. Finite element analysis of elastic property bounds of a composite with randomly distributed particles. Compos. Part A Appl. Sci. Manuf. 2007, 38, 80–86. [Google Scholar] [CrossRef]

- Trias, D.; Costa, J.; Mayugo, J.; Hurtado, J. Random models versus periodic models for fibre reinforced composites. Comput. Mater. Sci. 2006, 38, 316–324. [Google Scholar] [CrossRef]

- Hojo, M.; Mizuno, M.; Hobbiebrunken, T.; Adachi, T.; Tanaka, M.; Ha, S.K. Effect of fiber array irregularities on microscopic interfacial normal stress states of transversely loaded UD-CFRP from viewpoint of failure initiation. Compos. Sci. Technol. 2009, 69, 1726–1734. [Google Scholar] [CrossRef] [Green Version]

- Zhang, T.; Yan, Y. A comparison between random model and periodic model for fiber-reinforced composites based on a new method for generating fiber distributions. Polym. Compos. 2015. [Google Scholar] [CrossRef]

- Yang, Z. Effect of Interphase on the Prediction of Mechanical Properties for Unidirectional Composites. Ph.D. Thesis, Harbin Institute of Technology, Harbin, China, 2010. [Google Scholar]

- Hinrichsen, E.L.; Feder, J.; Jøssang, T. Geometry of random sequential adsorption. J. Stat. Phys. 1986, 44, 793–827. [Google Scholar] [CrossRef]

- Feder, J. Random sequential adsorption. J. Theor. Biol. 1980, 87, 237–254. [Google Scholar] [CrossRef]

- Ramsden, J. Review of new experimental techniques for investigating random sequential adsorption. J. Stat. Phys. 1993, 73, 853–877. [Google Scholar] [CrossRef]

- Yang, S.; Tewari, A.; Gokhale, A.M. Modeling of non-uniform spatial arrangement of fibers in a ceramic matrix composite. Acta Mater. 1997, 45, 3059–3069. [Google Scholar] [CrossRef]

- Buryachenko, V.; Pagano, N.; Kim, R.; Spowart, J. Quantitative description and numerical simulation of random microstructures of composites and their effective elastic moduli. Int. J. Solids Struct. 2003, 40, 47–72. [Google Scholar] [CrossRef]

- Barker, G. Computer Simulations of Granular Materials. In Granular Matter; Springer New York: New York, NY, USA, 1994; pp. 35–83. [Google Scholar]

- Wongsto, A.; Li, S. Micromechanical FE analysis of UD fibre-reinforced composites with fibres distributed at random over the transverse cross-section. Compos. Part A Appl. Sci. Manuf. 2005, 36, 1246–1266. [Google Scholar] [CrossRef]

- Wang, Z.; Wang, X.; Zhang, J.; Liang, W.; Zhou, L. Automatic generation of random distribution of fibers in long-fiber-reinforced composites and mesomechanical simulation. Mater. Des. 2011, 32, 885–891. [Google Scholar] [CrossRef]

- Melro, A.; Camanho, P.; Pinho, S. Generation of random distribution of fibres in long-fibre reinforced composites. Compos. Sci. Technol. 2008, 68, 2092–2102. [Google Scholar] [CrossRef]

- Vaughan, T.; McCarthy, C. A combined experimental-numerical approach for generating statistically equivalent fibre distributions for high strength laminated composite materials. Compos. Sci. Technol. 2010, 70, 291–297. [Google Scholar] [CrossRef]

- Yang, L.; Yan, Y.; Ran, Z.; Liu, Y. A new method for generating random fibre distributions for fibre reinforced composites. Compos. Sci. Technol. 2013, 76, 14–20. [Google Scholar] [CrossRef]

- Liu, K.C.; Ghoshal, A. Validity of random microstructures simulation in fiber-reinforced composite materials. Compos. Part B Eng. 2014, 57, 56–70. [Google Scholar] [CrossRef]

- Ripley, B.D. Modelling spatial patterns. J. R. Stat. Soc. Ser. B (Methodol.) 1977, 39, 172–212. [Google Scholar]

- Matsuda, T.; Ohno, N.; Tanaka, H.; Shimizu, T. Effects of fiber distribution on elastic–viscoplastic behavior of long fiber-reinforced laminates. Int. J. Mech. Sci. 2003, 45, 1583–1598. [Google Scholar] [CrossRef]

- Abaqus 6.11 Analysis User’s Manual; Dassault Systemes Corp.: Providence, RI, USA; Available online: https://www.sharcnet.ca/Software/Abaqus/6.11.2/books/usb/default.htm (accessed on 25 July 2016).

- Soden, P.; Hinton, M.; Kaddour, A. Lamina properties, lay-up configurations and loading conditions for a range of fibre-reinforced composite laminates. Compos. Sci. Technol. 1998, 58, 1011–1022. [Google Scholar] [CrossRef]

- Vu-Bac, N.; Silani, M.; Lahmer, T.; Zhuang, X.; Rabczuk, T. A unified framework for stochastic prediction of mechanical properties of polymeric nanocomposites. Comput. Mater. Sci. 2015, 96, 520–535. [Google Scholar] [CrossRef]

- Trias, D. Analysis and Simulation of Transverse Random Fracture of Long Fiber Reinforced Composites. Ph.D. Thesis, University of Girona, Girona, Spain, 2005. [Google Scholar]

| Properties | Carbon Fiber T300 | Epoxy Resin 914C |

|---|---|---|

| Longitudinal Young’s Modulus E1 (GPa) | 230 | 4 |

| Transverse Young’s Modulus E2 (GPa) | 15 | 4 |

| Longitudinal Shear Modulus G12 (GPa) | 15 | 1.481 |

| Transverse Shear Modulus G23 (GPa) | 7 | 1.481 |

| Major Poisson’s Ratio ν12 | 0.2 | 0.35 |

| Transverse Poisson’s Ratio ν23 | 0.07 | 0.35 |

| Properties | E1 (GPa) | E2 (GPa) | G12 (GPa) | G23 (GPa) | ν12 | ν23 |

|---|---|---|---|---|---|---|

| Prediction 1 | 137.98 | 8.21 | 4.58 | 3.08 | 0.2758 | 0.3243 |

| Prediction 2 | 138.27 | 8.22 | 4.55 | 3.09 | 0.2747 | 0.3243 |

| Prediction 3 | 138.49 | 8.25 | 4.55 | 3.08 | 0.2747 | 0.3233 |

| Prediction 4 | 138.32 | 8.22 | 4.53 | 3.10 | 0.2737 | 0.3262 |

| Prediction 5 | 138.38 | 8.20 | 4.58 | 3.10 | 0.2747 | 0.3262 |

| Prediction 6 | 138.14 | 8.21 | 4.55 | 3.07 | 0.2758 | 0.3243 |

| Prediction 7 | 138.33 | 8.24 | 4.59 | 3.10 | 0.2747 | 0.3243 |

| Prediction 8 | 138.40 | 8.20 | 4.54 | 3.10 | 0.2737 | 0.3262 |

| Average | 138.29 | 8.22 | 4.56 | 3.09 | 0.2747 | 0.3249 |

| Standard Deviation | 0.152 | 0.016 | 0.019 | 0.011 | 0.00074 | 0.00107 |

| Experimental [31] | 138.00 | 11.00 | 5.50 | 3.93* | 0.2800 | 0.4000 |

| Error (%) | 0.20 | −25.28 | −17.13 | −21.391 | −1.88 | −18.78 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, W.; Dai, Y.; Zhang, C.; Gao, X.; Zhao, M. Micromechanical Modeling of Fiber-Reinforced Composites with Statistically Equivalent Random Fiber Distribution. Materials 2016, 9, 624. https://doi.org/10.3390/ma9080624

Wang W, Dai Y, Zhang C, Gao X, Zhao M. Micromechanical Modeling of Fiber-Reinforced Composites with Statistically Equivalent Random Fiber Distribution. Materials. 2016; 9(8):624. https://doi.org/10.3390/ma9080624

Chicago/Turabian StyleWang, Wenzhi, Yonghui Dai, Chao Zhang, Xiaosheng Gao, and Meiying Zhao. 2016. "Micromechanical Modeling of Fiber-Reinforced Composites with Statistically Equivalent Random Fiber Distribution" Materials 9, no. 8: 624. https://doi.org/10.3390/ma9080624