Evaluation of Workpiece Temperature during Drilling of GLARE Fiber Metal Laminates Using Infrared Techniques: Effect of Cutting Parameters, Fiber Orientation and Spray Mist Application

Abstract

:1. Introduction

2. Materials and Methods

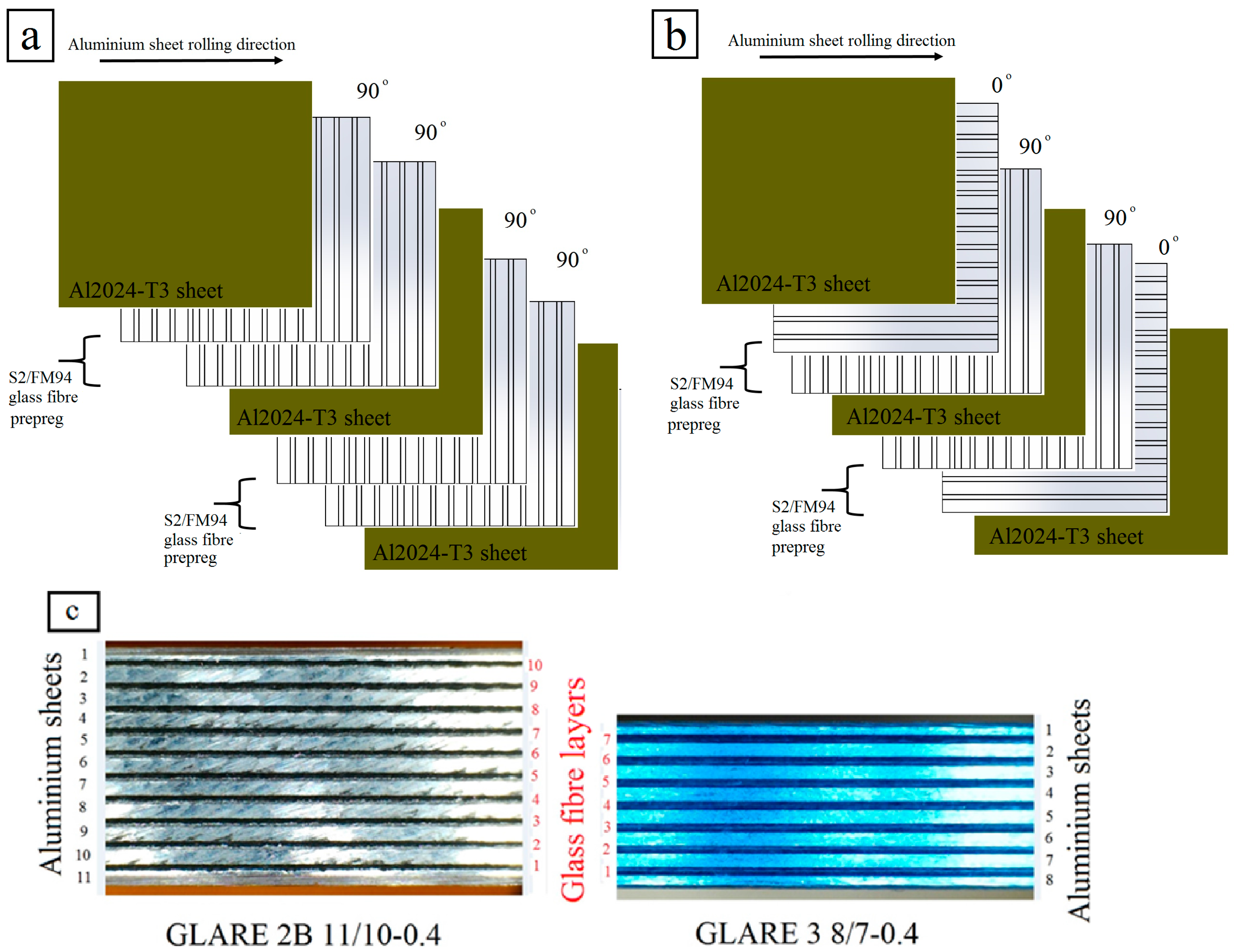

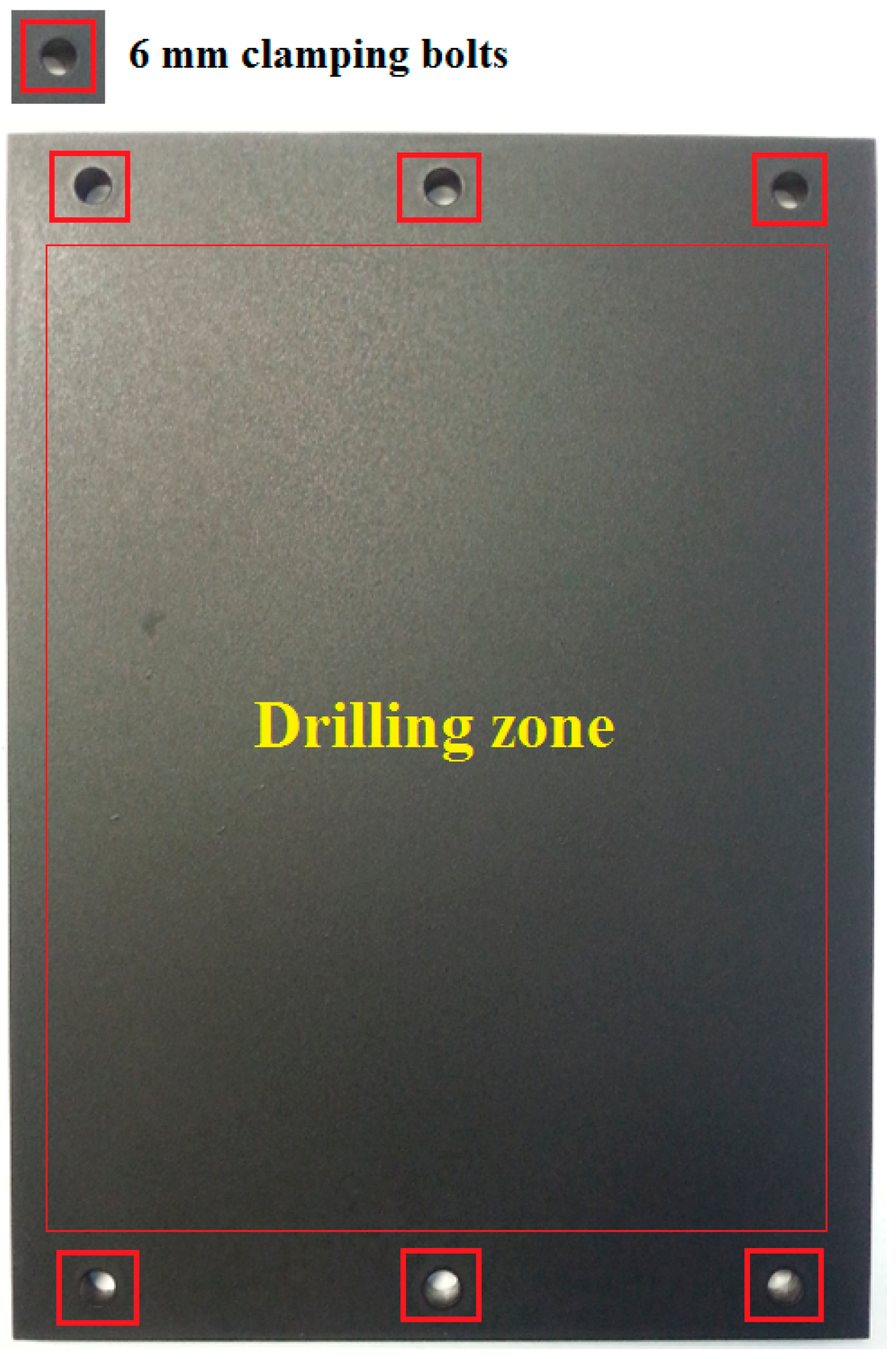

2.1. Workpiece and Cutting Tool

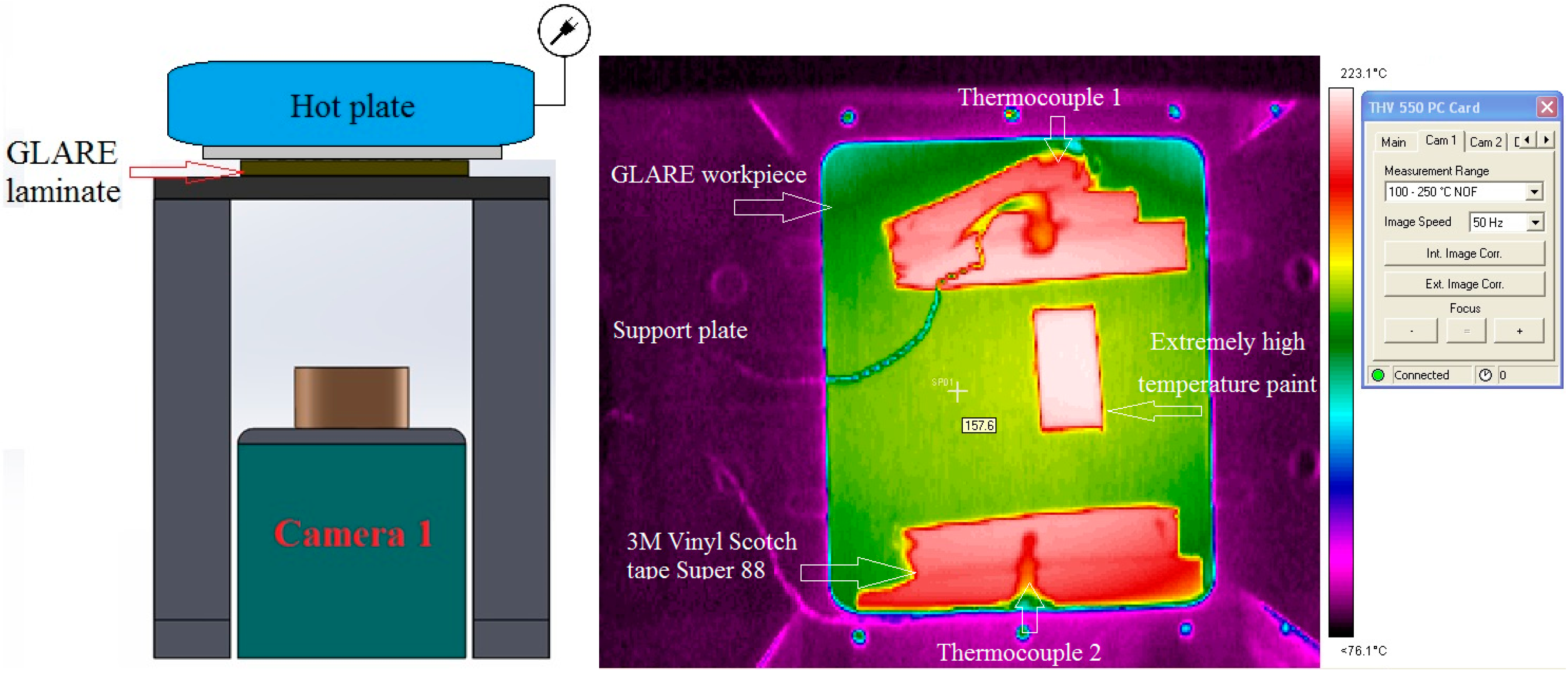

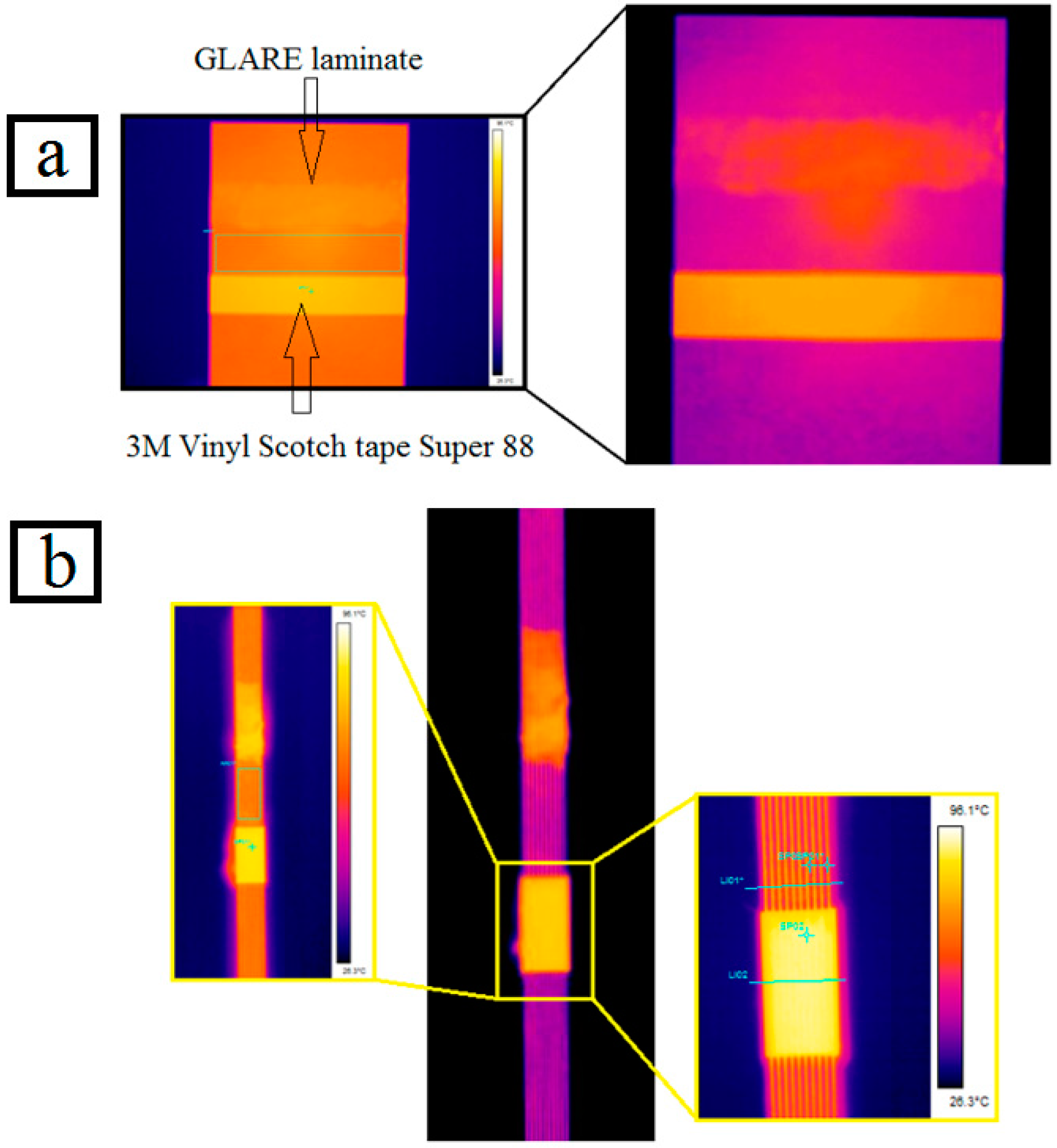

2.2. Determining the Emissivity of the Surfaces GLARE Fiber Metal Laminate

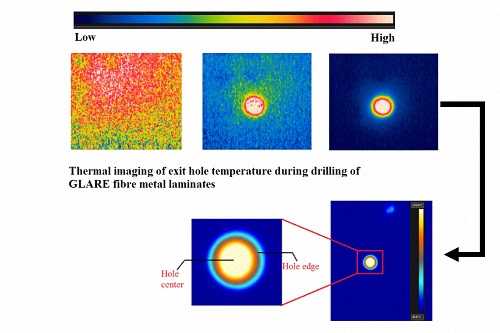

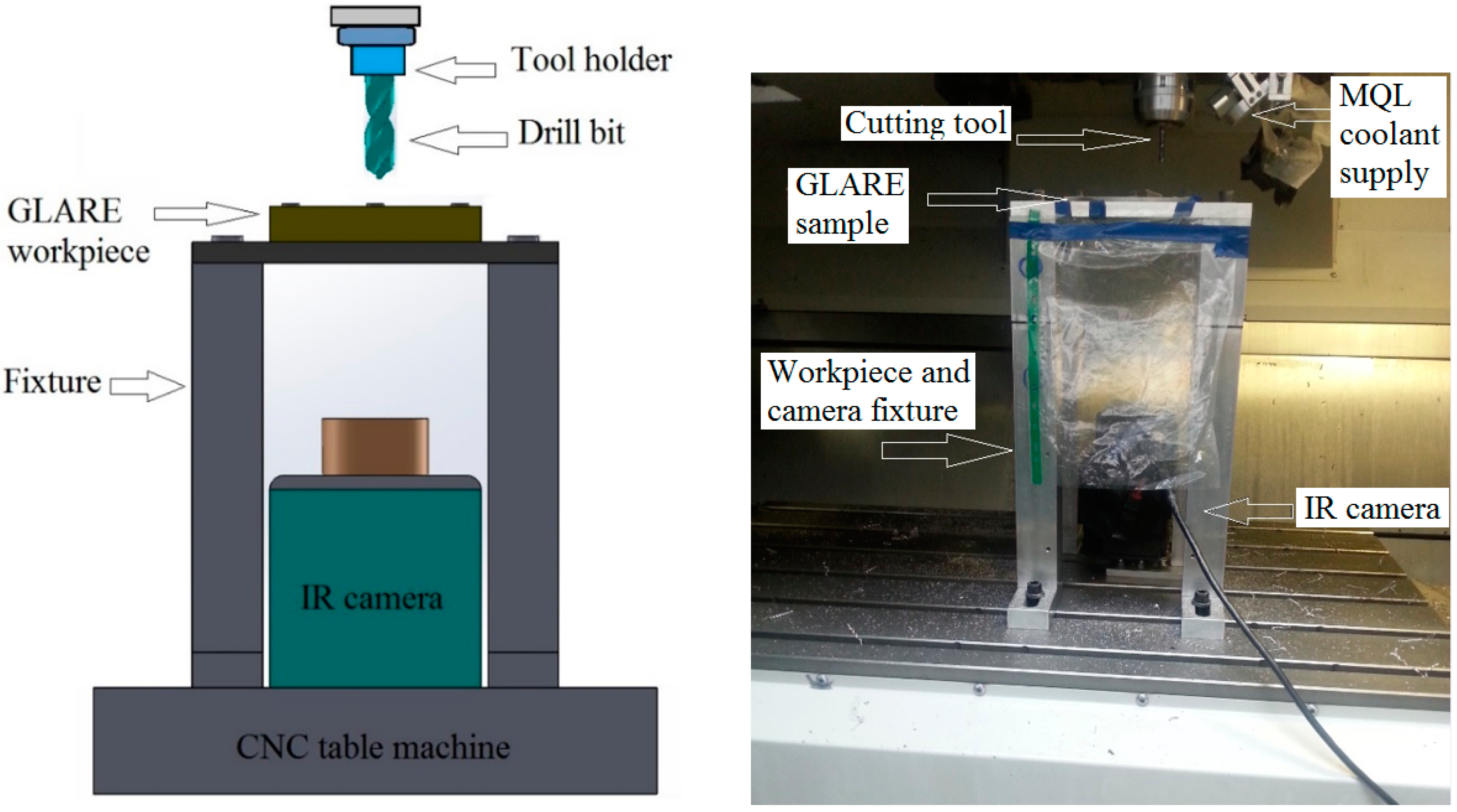

2.3. Measuring the Temperature at the Exit Side of Drilled Holes

3. Results and Discussion

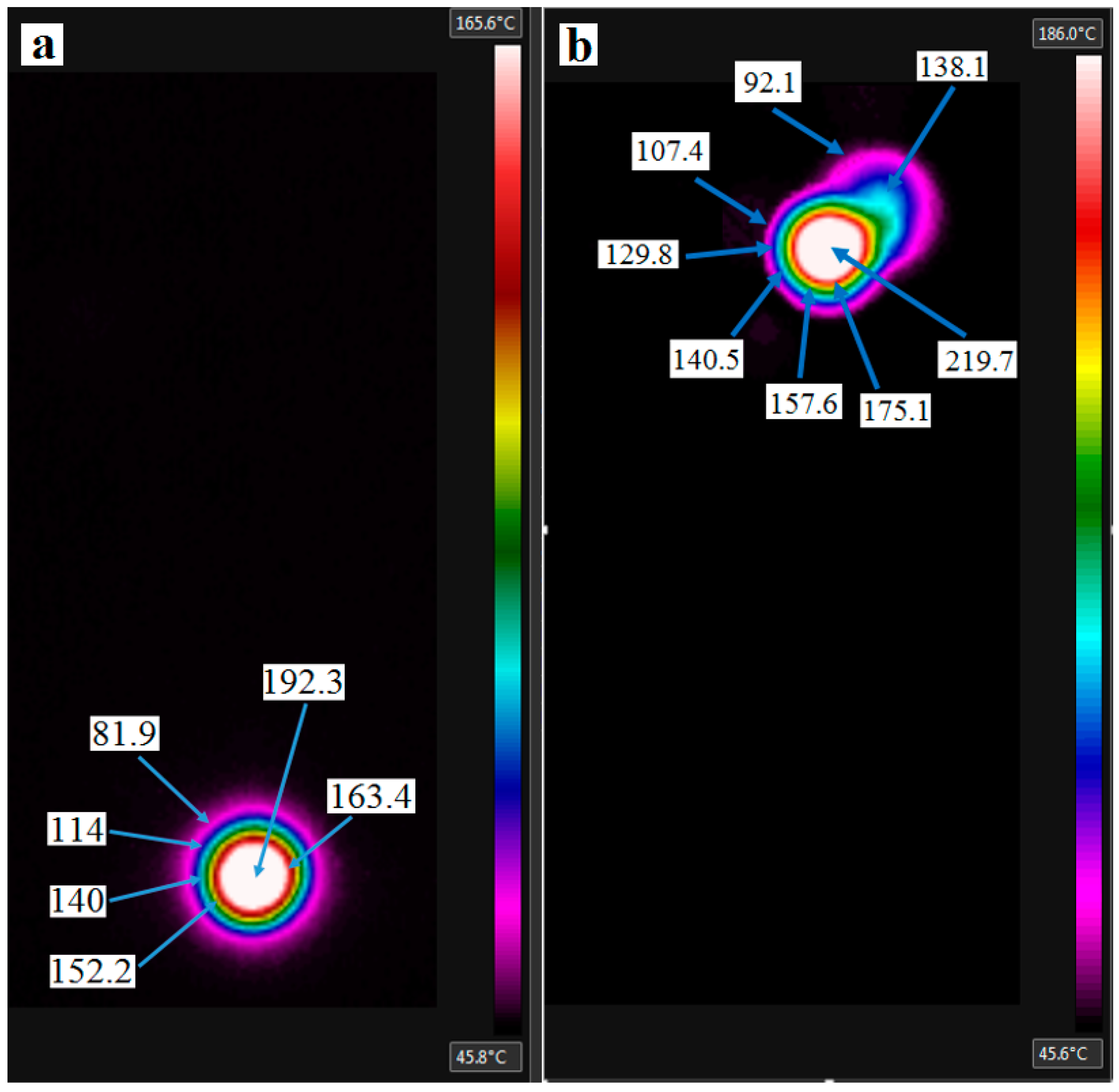

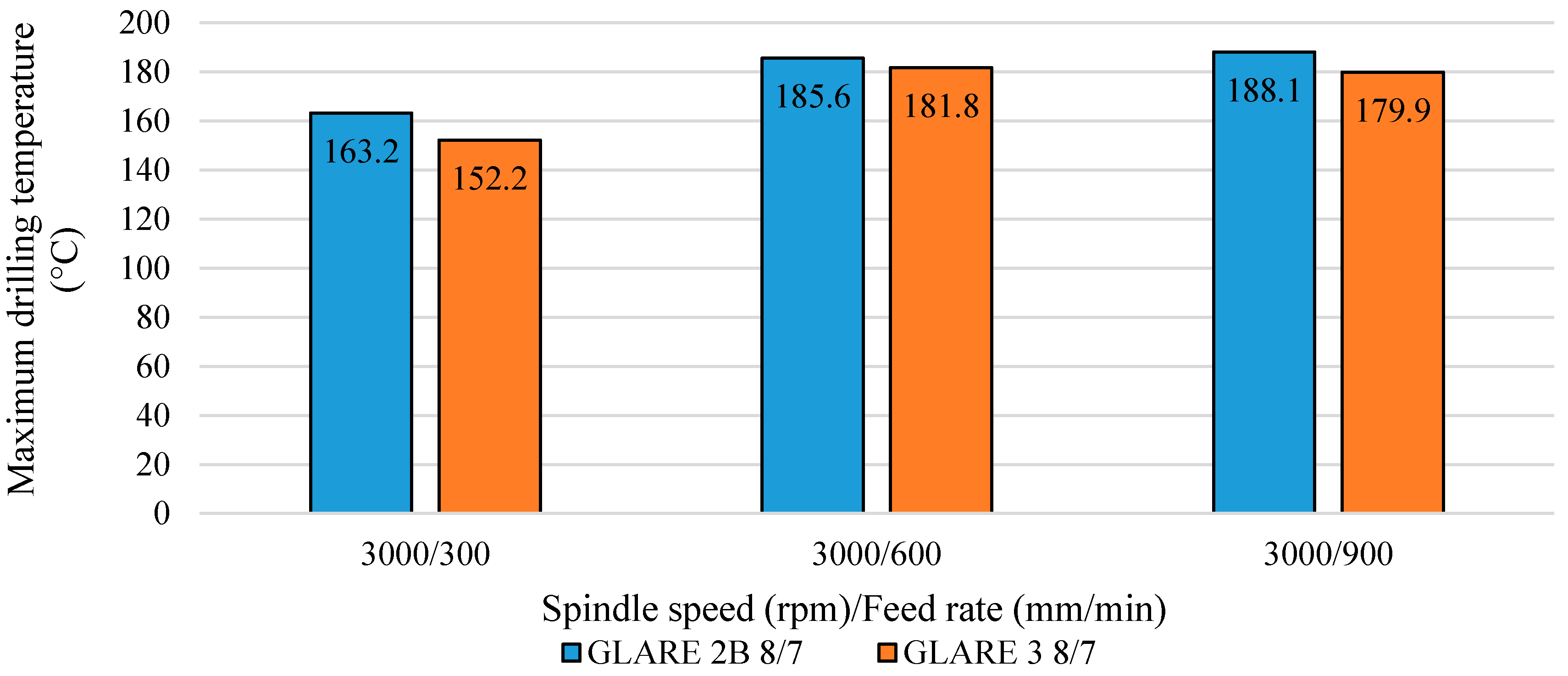

3.1. The Effect of Fiber Orientation on Drilling Workpiece Temperature

3.2. The Effect of MQL Coolant on Workpiece Temperature

4. Conclusions

- The temperature of the bottom surface of the workpiece increased as drilling progress. The investigation indicated that both drilling parameters, i.e., spindle speed and feed rate, influence the cutting temperature during machining.

- The maximum temperature at the bottom surface when drilling GLARE fiber metal laminates was measured by employing infrared temperature techniques. The measured temperature reached up to 245.1 °C at a spindle speed of 9000 rpm and a feed rate of 300 mm/min when drilling at room temperature and up to 192.3 °C when drilling under minimum quantity lubrication cooling.

- In GLARE 2B 8/7 and GLARE 3 8/7, the maximum temperature was found to increase with the increase of the feed rate when drilling at spindle speed 3000 rpm under dry conditions (room temperature). Increasing the feed rate from 300 mm/min to 900 mm/min increased the temperature by 15.2% in GLARE 2B 8/7 and by 18.2% in GLARE 3 8/7.

- The difference in maximum drilling temperature between GLARE 2B and GLARE 3 ranged from 4 to 10 °C under the tested cutting parameters.

- The fiber orientation in GLARE laminates influences the maximum drilling temperature, such that GLARE laminates with same fiber orientation as GLARE 2B (90°/90°) will be susceptible to higher drilling temperatures than laminates with different fiber orientation, such as GLARE 3 (0°/90°).

- In GLARE 2B 11/10, the maximum temperature was found to depend on the level of the feed rate when drilling at spindle speed 6000 and 9000 rpm under dry (room temperature) and MQL conditions, increasing the feed rate from 300 mm/min to 600 mm/min increased the temperature by 17.2% under dry and decreased it by 14.5% using MQL.

- The application of MQL cooling can considerably reduce the machining temperatures in GLARE, the efficiency of MQL increase with the increase of the feed rate due to improved lubrication and reduced drilling time.

- The largest reduction in workpiece temperature when using MQL compared to dry drilling was achieved when drilling at spindle speed 6000 and 9000 rpm and feed rates of 900 mm/min. The reduction in maximum drilling temperature reached 75%.

- The infrared thermos vision techniques used in the current study suggests the possibility of using those methods to measure the temperatures fields in the machining processes, which can be also used as an effective tool for temperature monitoring. The emissivity of GLARE found in the current study can be used as an input for future studies for the purpose of monitoring the machining temperature of GLARE laminates.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Vlot, A.; Gunnink, J.W. Fibre Metal Laminates: An Introduction; Springer: Berlin/Heidelberg, Germany, 2001. [Google Scholar]

- Sinke, J. Manufacturing of glare parts and structures. Appl. Compos. Mater. 2003, 10, 293–305. [Google Scholar] [CrossRef]

- Brinksmeier, E. Machinability of carbon-fiber-reinforced and glare materials. CIRP Encycl. Prod. Eng. 2014. [Google Scholar] [CrossRef]

- Paul, S.; Hoogstrate, A.; Van Praag, R. Abrasive water jet machining of glass fibre metal laminates. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 1459–1469. [Google Scholar] [CrossRef]

- Ramulu, M.; Pahuja, R.; Hashish, M.; Isvilonanda, V. Abrasive waterjet machining effects on kerf quality in thin fiber metal laminate. In 2015 WJTA-IMCA Conference and Expo; WJTA®-IMCA®: New Orleans, LA, USA, 2015. [Google Scholar]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. The effects of minimum quantity lubrication and cryogenic liquid nitrogen cooling on drilled hole quality in glare fibre metal laminates. Mater. Des. 2016, 89, 996–1006. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. An experimental study on drilling of unidirectional glare fibre metal laminates. Compos. Struct. 2015, 133, 794–808. [Google Scholar] [CrossRef]

- Tyczynski, P.; Lemanczyk, J.; Ostrowski, R. Drilling of CFRP, GFRP, glare type composites. Aircr. Eng. Aerosp. Technol. 2014, 86, 312–322. [Google Scholar]

- Coesel, J.F.W. Drilling of Fibre-Metal Laminates. Master Thesis, Delft University of Technology, Delft, The Netherlands, 1994. [Google Scholar]

- Pawar, O.A.; Gaikhe, Y.S.; Tewari, A.; Sundaram, R.; Joshi, S.S. Analysis of hole quality in drilling glare fiber metal laminates. Compos. Struct. 2015, 123, 350–365. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; Hodzic, A. Evaluation of cryogenic cooling and minimum quantity lubrication effects on machining glare laminates using design of experiments. J. Clean. Prod. 2016, 135, 533–548. [Google Scholar] [CrossRef]

- Giasin, K.; Ayvar-Soberanis, S.; French, T.; Phadnis, V. 3d finite element modelling of cutting forces in drilling fibre metal laminates and experimental hole quality analysis. Appl. Compos. Mater. 2016. [Google Scholar] [CrossRef]

- Groover, M.P. Fundamentals of Modern Manufacturing: Materials Processes, and Systems; Wiley: Weinheim, Germany, 2007. [Google Scholar]

- Parashar, B.N.; Mittal, R. Elements of Manufacturing Processes; PHI Learning Pvt. Ltd.: Delhi, India, 2002. [Google Scholar]

- Rawat, S.; Attia, H. Wear mechanisms and tool life management of WC–CO drills during dry high speed drilling of woven carbon fibre composites. Wear 2009, 267, 1022–1030. [Google Scholar] [CrossRef]

- El-Hofy, H.A.-G. Fundamentals of Machining Processes: Conventional and Nonconventional Processes; CRC Press: Boca Raton, FL, USA, 2013. [Google Scholar]

- Ozek, C.; Demir, Z. Investigate the friction drilling of aluminium alloys according to the thermal conductivity. Tem J. Technol. Educ. Manag. Inf. 2013, 2, 93–101. [Google Scholar]

- Sheikh-Ahmad, J.Y. Machining of Polymer Composites; Springer: Berlin, Germany, 2009. [Google Scholar]

- Davim, J.P. Tribology in Manufacturing Technology; Springer: Berlin/Heidelberg, Germany, 2012. [Google Scholar]

- DeGarmo, E.P.; Black, J.T.; Kohser, R.A. Materials and Processes in Manufacturing; Wiley: Weinheim, Germany, 2003. [Google Scholar]

- Khan, Z.M. A Study of the Drilling of Advanced Carbon Fibre Composites. Ph.D. Thesis, University of Salford, Salford, UK, 1991. [Google Scholar]

- Fleischer, J.; Pabst, R.; Kelemen, S. Heat flow simulation for dry machining of power train castings. CIRP Ann. - Manuf. Technol. 2007, 56, 117–122. [Google Scholar] [CrossRef]

- Wang, C.-Y.; Chen, Y.-H.; An, Q.-L.; Cai, X.-J.; Ming, W.-W.; Chen, M. Drilling temperature and hole quality in drilling of CFRP/aluminum stacks using diamond coated drill. Int. J. Precis. Eng. Manuf. 2015, 16, 1689–1697. [Google Scholar] [CrossRef]

- Taskesen, A.; Kutukde, K. Non-contact measurement and multi-objective analysis of drilling temperature when drilling B4C reinforced aluminum composites. Trans. Nonferrous Metals Soc. China 2015, 25, 271–283. [Google Scholar] [CrossRef]

- Shetty, R.; Pai, R.; Kamath, V.; Rao, S.S. Steam as coolant and lubricant in turning of metal matrix composites. J. Zhejiang Univ. Sci. A 2008, 9, 1245–1250. [Google Scholar] [CrossRef]

- Kolesnyk, V.; Zajac, J.; Radchenko, S.; Adamian, M. The effect of cutting temperature on hole quality when drilling CFRP/metal stack. Вісник НТУ 2015, 4, 138–141. [Google Scholar]

- Kaynak, Y. Evaluation of machining performance in cryogenic machining of inconel 718 and comparison with dry and mql machining. Int. J. Adv. Manuf. Technol. 2014, 72, 919–933. [Google Scholar] [CrossRef]

- Manimaran, G.; Venkatasamy, R. Influence of cryogenic cooling on surface grinding of stainless steel 316. Cryogenics 2014, 59, 76–83. [Google Scholar] [CrossRef]

- Dhar, N.R.; Ahmed, M.T.; Islam, S. An experimental investigation on effect of minimum quantity lubrication in machining AISI 1040 steel. Int. J. Mach. Tools Manuf. 2007, 47, 748–753. [Google Scholar] [CrossRef]

- Abhang, L.; Hameedullah, M. Chip-tool interface temperature prediction model for turning process. Int. J. Eng. Sci. Technol. 2010, 2, 382–393. [Google Scholar]

- Kitagawa, T.; Kubo, A.; Maekawa, K. Temperature and wear of cutting tools in high-speed machining of inconel 718 and Ti-6Al-6V-2Sn. Wear 1997, 202, 142–148. [Google Scholar] [CrossRef]

- Nedić, B.P.; Erić, M.D. Cutting temperature measurement and material machinability. Therm. Sci. 2014, 18, 259–268. [Google Scholar]

- Bono, M.; Ni, J. A method for measuring the temperature distribution along the cutting edges of a drill. J. Manuf. Sci. Eng. 2002, 124, 921–923. [Google Scholar] [CrossRef]

- Bağci, E.; Ozcelik, B. Investigation of the effect of drilling conditions on the twist drill temperature during step-by-step and continuous dry drilling. Mater. Des. 2006, 27, 446–454. [Google Scholar]

- El-Wardany, T.I.; Mohammed, E.; Elbestawi, M.A. Cutting temperature of ceramic tools in high speed machining of difficult-to-cut materials. Int. J. Mach. Tools Manuf. 1996, 36, 611–634. [Google Scholar] [CrossRef]

- Ueda, T.; Sato, M.; Hosokawa, A.; Ozawa, M. Development of infrared radiation pyrometer with optical fibers—two-color pyrometer with non-contact fiber coupler. CIRP Ann.-Manuf. Technol. 2008, 57, 69–72. [Google Scholar] [CrossRef]

- Sato, M.; Aoki, T.; Tanaka, H.; Takeda, S. Variation of temperature at the bottom surface of a hole during drilling and its effect on tool wear. Int. J. Mach. Tools Manuf. 2013, 68, 40–47. [Google Scholar] [CrossRef]

- Ueda, T.; Nozaki, R.; Hosokawa, A. Temperature measurement of cutting edge in drilling -effect of oil mist. CIRP Ann. - Manuf. Technol. 2007, 56, 93–96. [Google Scholar] [CrossRef]

- Aramcharoen, A.; Chuan, S.K. An experimental investigation on cryogenic milling of inconel 718 and its sustainability assessment. Procedia CIRP 2014, 14, 529–534. [Google Scholar] [CrossRef]

- Rivero, A.; Aramendi, G.; Herranz, S.; de Lacalle, L.L. An experimental investigation of the effect of coatings and cutting parameters on the dry drilling performance of aluminium alloys. Int. J. Adv. Manuf. Technol. 2006, 28, 1–11. [Google Scholar] [CrossRef]

- Dandekar, C.; Orady, E.; Mallick, P. Drilling characteristics of an e-glass fabric-reinforced polypropylene composite and an aluminum alloy: A comparative study. J. Manuf. Sci. Eng. 2007, 129, 1080–1087. [Google Scholar] [CrossRef]

- Kalidas, S.; DeVor, R.E.; Kapoor, S.G. Experimental investigation of the effect of drill coatings on hole quality under dry and wet drilling conditions. Surf. Coat. Technol. 2001, 148, 117–128. [Google Scholar] [CrossRef]

- Le Coz, G.; Marinescu, M.; Devillez, A.; Dudzinski, D.; Velnom, L. Measuring temperature of rotating cutting tools: Application to MQL drilling and dry milling of aerospace alloys. Appl. Thermal Eng. 2012, 36, 434–441. [Google Scholar] [CrossRef]

- Vernaza-Pena, K.; Mason, J.; Li, M. Experimental study of the temperature field generated during orthogonal machining of an aluminum alloy. Exp. Mech. 2002, 42, 221–229. [Google Scholar] [CrossRef]

- Li, R.; Shih, A.J. Tool temperature in titanium drilling. Ann. Arbor 2007, 1001, 48109–42125. [Google Scholar] [CrossRef]

- Li, R.; Shih, A.J. Spiral point drill temperature and stress in high-throughput drilling of titanium. Int. J. Mach. Tools Manuf. 2007, 47, 2005–2017. [Google Scholar] [CrossRef]

- Fang, F.; Lee, L.; Liu, X. Mean flank temperature measurement in high speed dry cutting of magnesium alloy. J. Mater. Process. Technol. 2005, 167, 119–123. [Google Scholar] [CrossRef]

- Weinert, K.; Kempmann, C. Cutting temperatures and their effects on the machining behaviour in drilling reinforced plastic composites. Adv. Eng. Mater. 2004, 6, 684–689. [Google Scholar] [CrossRef]

- Krishna, A.S.R.; Reddy, P.R. Temperature prediction in orthogonal machining of A1/SICP composites. Int. J. Emerg. Technol. Adv. Eng. 2012, 2, 223–229. [Google Scholar]

- Brinksmeier, E.; Fangmann, S.; Rentsch, R. Drilling of composites and resulting surface integrity. CIRP Ann. - Manuf. Technol. 2011, 60, 57–60. [Google Scholar] [CrossRef]

- Ghafarizadeh, S.; Lebrun, G.; Chatelain, J.-F. Experimental investigation of the cutting temperature and surface quality during milling of unidirectional carbon fiber reinforced plastic. J. Compos. Mater. 2015. [Google Scholar] [CrossRef]

- Merino-Pérez, J.; Royer, R.; Ayvar-Soberanis, S.; Merson, E.; Hodzic, A. On the temperatures developed in CFRP drilling using uncoated WC-CO tools part I: Workpiece constituents, cutting speed and heat dissipation. Compos. Struct. 2015, 123, 161–168. [Google Scholar]

- Takeyama, H.; Iijima, N. Machinability of glassfiber reinforced plastics and application of ultrasonic machining. CIRP Ann. - Manuf. Technol. 1988, 37, 93–96. [Google Scholar] [CrossRef]

- Sreejith, P.; Krishnamurthy, R.; Malhotra, S.; Narayanasamy, K. Evaluation of pcd tool performance during machining of carbon/phenolic ablative composites. J. Mater. Process. Technol. 2000, 104, 53–58. [Google Scholar] [CrossRef]

- Zitoune, R.; Collombet, F.; Lachaud, F.; Piquet, R.; Pasquet, P. Experiment–calculation comparison of the cutting conditions representative of the long fiber composite drilling phase. Compos. Sci. Technol. 2005, 65, 455–466. [Google Scholar] [CrossRef]

- Abhishek, K.; Datta, S.; Mahapatra, S.S. Response surface modeling on machining of CFRP composites: Effect of process variables on surface roughness, MRR and tool-tip temperature. Int. J. Mechan. Eng. Res. 2013, 3, 407–414. [Google Scholar]

- Haddad, M.; Zitoune, R.; Bougherara, H.; Eyma, F.; Castanié, B. Study of trimming damages of CFRP structures in function of the machining processes and their impact on the mechanical behavior. Compos. Part B Eng. 2014, 57, 136–143. [Google Scholar] [CrossRef]

- Saleem, M.; Toubal, L.; Zitoune, R.; Bougherara, H. Investigating the effect of machining processes on the mechanical behavior of composite plates with circular holes. Compos. Part A Appl. Sci. Manuf. 2013, 55, 169–177. [Google Scholar] [CrossRef]

- Haddad, M.; Zitoune, R.; Eyma, F.; Castanie, B. Study of the surface defects and dust generated during trimming of CFRP: Influence of tool geometry, machining parameters and cutting speed range. Compos. Part A Appl. Sci. Manuf. 2014, 66, 142–154. [Google Scholar] [CrossRef]

- Wang, B.; Gao, H.; Cao, B.; Zhuang, Y.; Zhao, Z. Mechanism of damage generation during drilling of carbon/epoxy composites and titanium alloy stacks. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2014, 228, 698–706. [Google Scholar] [CrossRef]

- Alderliesten, R.C. Fatigue Crack Propagation and Delamination Growth in Glare; DUP Science: Lyngby, Danmark, 2005. [Google Scholar]

- De Vries, T.J. Blunt and Sharp Notch Behaviour of Glare Laminates; TU Delft, Delft University of Technology: Delft, The Netherlands, 2001. [Google Scholar]

- Mohit, G.; Frank, A.; Michael, F.; Galib, A. Predicting bearing strength of fiber metal laminates via progressive failure analysis. In 52nd aiaa/asme/asce/ahs/asc Structures, Structural Dynamics and Materials Conference; American Institute of Aeronautics and Astronautics: Reston, VA, USA, 2011. [Google Scholar]

- Yaghoubi, A.S.; Liaw, B. Damage assessments of ballistic impact behaviors of glare 5 (3/2) beams with various stacking sequences. In Dynamic Behavior of Materials; Springer: Berlin/Heidelberg, Germany, 2013; Volume 1, pp. 503–512. [Google Scholar]

- Hagenbeek, M. Characterisation of Fibre Metal Laminates under Thermomechanical Loadings; TU Delft, Delft University of Technology: Delft, The Netherlands, 2005. [Google Scholar]

- Giasin, K.; Hodzic, A.; Phadnis, V.; Ayvar-Soberanis, S. Assessment of cutting forces and hole quality in drilling Al2024 aluminium alloy: Experimental and finite element study. Int. J. Adv. Manuf. Technol. 2016, 1–21. [Google Scholar] [CrossRef]

- De Vries, T.J. Blunt and Sharp Notch Behaviour of Glare Laminates; Delft University Press: Delft, The Netherlands, 2001. [Google Scholar]

- Seo, H. Damage Tolerance and Durability of Glare Laminates; ProQuest: Ann Arbor, MI, USA, 2008. [Google Scholar]

- O’Sullivan, D.; Cotterell, M. Workpiece temperature measurement in machining. Proc. Inst. Mech. Eng. Part B J. Eng. Manuf. 2002, 216, 135–139. [Google Scholar] [CrossRef]

| Machining process | Cutting Tools Used | Workpiece Description | Objectives | Ref |

|---|---|---|---|---|

| AWJM | Orifice: Sapphire, diameter 0.381 mm Nozzle Length 76.2 mm, diameter 1.016 mm, Grit type Garnet, Mesh 80 Impact angle 90° | Titanium/Graphite (Ti/Gr) | Mrr K | [5] |

| Diamond orifice, diameter of 0.3 mm Insert diameter of 1.1 mm, length 51 mm and 90° impact angle, Garnet: olivine abrasive, Mesh 60 | GLARE 2–3/2–0.2 GLARE 2–3/2–0.3 GLARE 4–5/4–0.3 | B D Ke | [4] | |

| Milling | Not reported | GLARE | D F M | [3] |

| Drilling | 5 mm HSS TiN coated drill, HSS with 8% Co drill, carbide tipped HSS drill 5 and 5.5 mm solid carbide drill 4.8 mm diamond tipped HSS drill | GLARE 3–3/2–0.3 GLARE 3–2/1–0.3 GLARE3–4/3–0.3 | B C Z | [9] |

| 6 mm uncoated carbide drill | GLARE-like made of Al2024 sheets and fiberglass type R | C Z | [8] | |

| 6.35 solid carbide drills | GLARE 5 3/2–0.3 GLARE 6 3/2–0.3 | C Z F D B Ae | [10] | |

| 6 mm TiAlN coated carbide drill | GLARE 2B 11/10–0.4 GLARE 2B 8/7–0.4 GLARE 3 8/7–0.4 | C R Q B Z Y O | [6,7,11,12] |

| Material | Glare 3 8/7-0.4 | Glare 2B 8/7-0.4 | Glare 2B 11/10-0.4 |

|---|---|---|---|

| Thickness of Aluminum layer (mm) | 0.4064 | 0.4064 | 0.4064 |

| Thickness of S2 glass fiber layer (mm) | 0.266 | 0.266 | 0.266 |

| Total thickness (mm) | 5.113 | 5.113 | 7.130 |

| Metal Volume Fraction % (M.V.F.) | 63.58% | 63.58% | 62.69% |

| Workpiece dimensions (mm) | 200 × 150 | 200 × 150 | 200 × 150 |

| Mechanical Property | UD S2 Glass/FM 94 Epoxy Prepreg | Al2024-T3 | Units | |

|---|---|---|---|---|

| Young Modulus (E) | L | 54–55 | 72.2 | GPa |

| T | 9.4–9.5 | - | ||

| Ultimate tensile strength (σ) | L | 2640 | 455 | MPa |

| T | 57 | 448 | ||

| Ultimate strain % (ε) | L | 3.5–4.7 | 19 | - |

| T | 0.6 | - | ||

| Shear Modulus (G) | L | 5.55 | 27.6 | GPa |

| T | 3 | - | ||

| Poisson’s ratio (ν) | L | 0.33 | 0.33 | - |

| T | 0.0575 | - | ||

| Density (ρ) | - | 1980 | 2770 | kg/m3 |

| Thermal expansion coefficient (α) | L | 3.9–6.1 | 23.4 | (1/°C) 10−6 |

| T | 26.2–55.2 | 23.4 | ||

| Thermal conductivity (K) | L | 1.1–1.4 | 121 | W/m-K |

| T | 0.43–0.53 | - |

| Description | Test 1 | Test 2 | Test 3 |

|---|---|---|---|

| Camera type | Electrophysic PV320 20° lens | AGEMA 550 20° lens | FLIR SC640: 0.4 m away, 24° lens FLIR B400: 0.1 m away, 45° lens |

| No. of cameras used | 1 | 2 | 2 |

| Type of coating/tape applied | Black spray paint | Extremely high-temperature paint & 3M Vinyl Scotch tape Super 88 | 3M Vinyl Scotch tape Super 88 |

| Emissivity of coating used | 0.94 | 0.94 & 0.95 | 0.95 |

| Heat source used | Hotplate | Hotplate | Oven |

| Temperature level used | 60–70 °C | 60–90 °C | 90°C |

| T ambient | 24 °C | 24 °C | 24 °C |

| T reflect | - | 21 °C | 21 °C |

| Thermocouples used | Yes | Yes | No |

| E1 (Top and Bottom) | 0.8 | 0.82 | 0.832–0.843 |

| E2 (S2-FM94 plies) | 0.6 | 0.6 | 0.594–0.683 |

| E3 (Al2024 sheets) | 0.4 | - | 0.276–0.395 |

| Distance between camera and target surface | 0.5 m | 0.45 m | 0.4 m and 0.1 m |

| Spindle Speed (rpm) | |||

|---|---|---|---|

| Feed rate (mm/min) | 3000 | 6000 | 9000 |

| 300 | A,B | C,D | C,D |

| 600 | A,B | C,D | C,D |

| 900 | A,B | C,D | C,D |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Giasin, K.; Ayvar-Soberanis, S. Evaluation of Workpiece Temperature during Drilling of GLARE Fiber Metal Laminates Using Infrared Techniques: Effect of Cutting Parameters, Fiber Orientation and Spray Mist Application. Materials 2016, 9, 622. https://doi.org/10.3390/ma9080622

Giasin K, Ayvar-Soberanis S. Evaluation of Workpiece Temperature during Drilling of GLARE Fiber Metal Laminates Using Infrared Techniques: Effect of Cutting Parameters, Fiber Orientation and Spray Mist Application. Materials. 2016; 9(8):622. https://doi.org/10.3390/ma9080622

Chicago/Turabian StyleGiasin, Khaled, and Sabino Ayvar-Soberanis. 2016. "Evaluation of Workpiece Temperature during Drilling of GLARE Fiber Metal Laminates Using Infrared Techniques: Effect of Cutting Parameters, Fiber Orientation and Spray Mist Application" Materials 9, no. 8: 622. https://doi.org/10.3390/ma9080622