Nb5+-Doped SrCoO3−δ Perovskites as Potential Cathodes for Solid-Oxide Fuel Cells

Abstract

:1. Introduction

2. Experimental

3. Results and Discussion

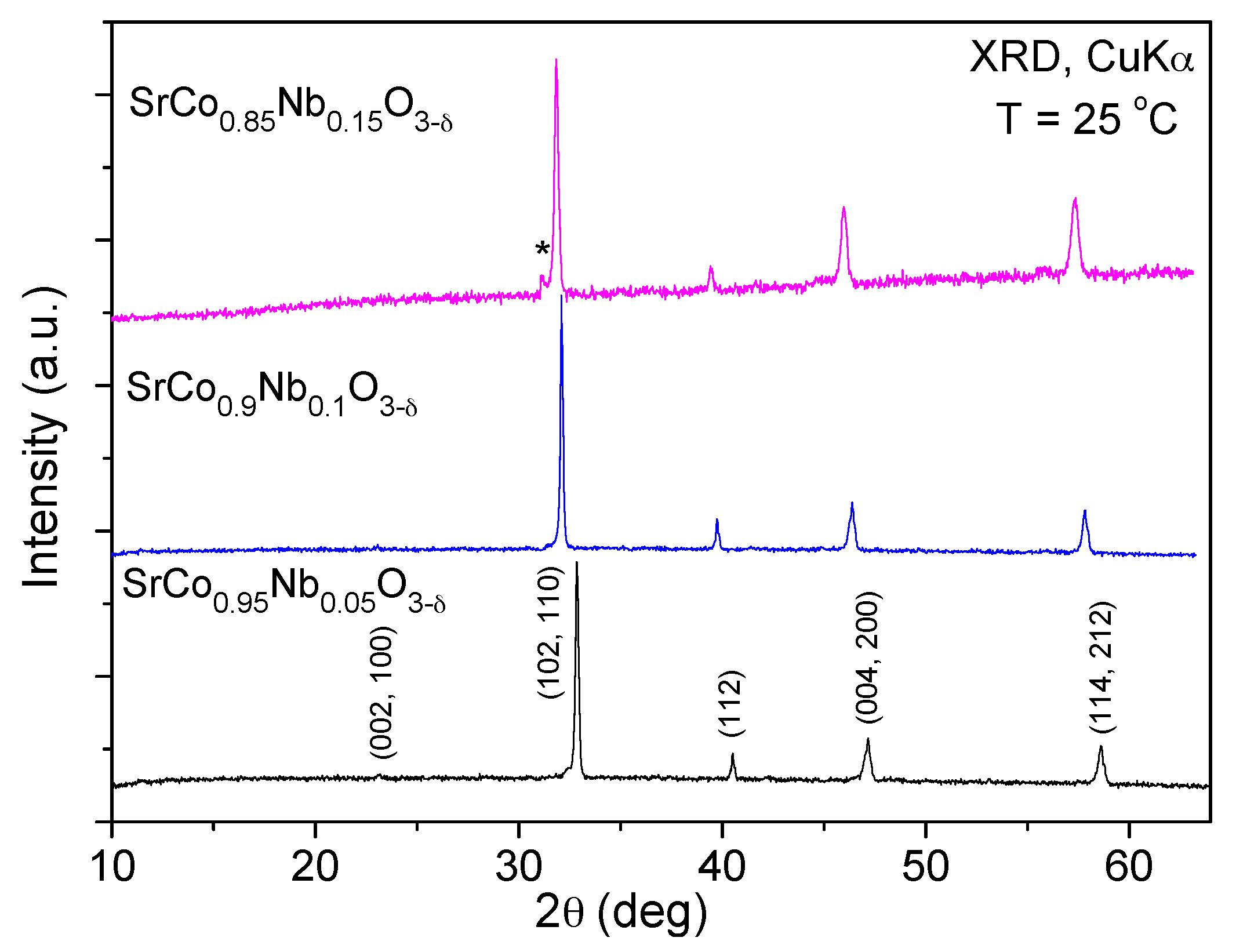

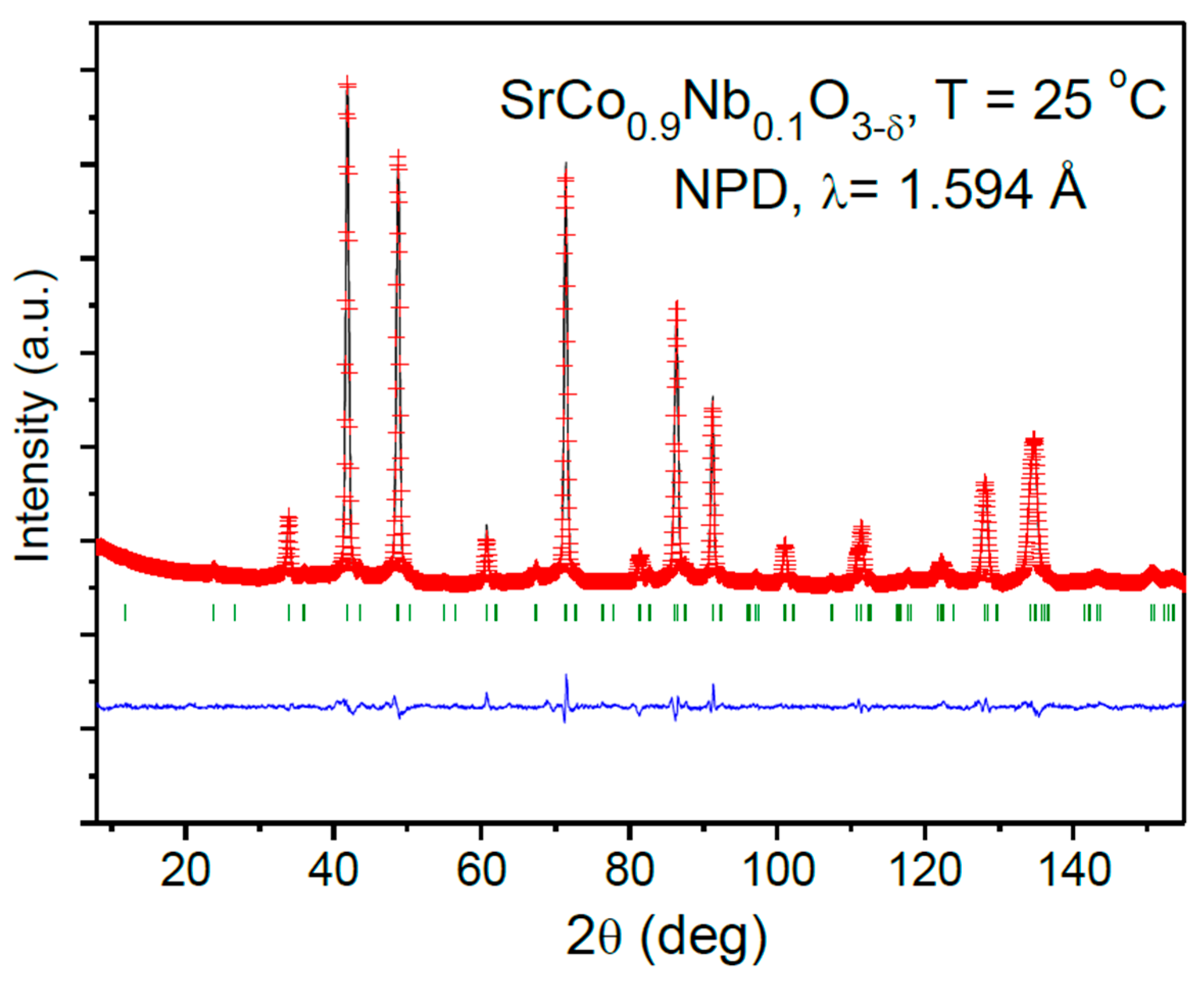

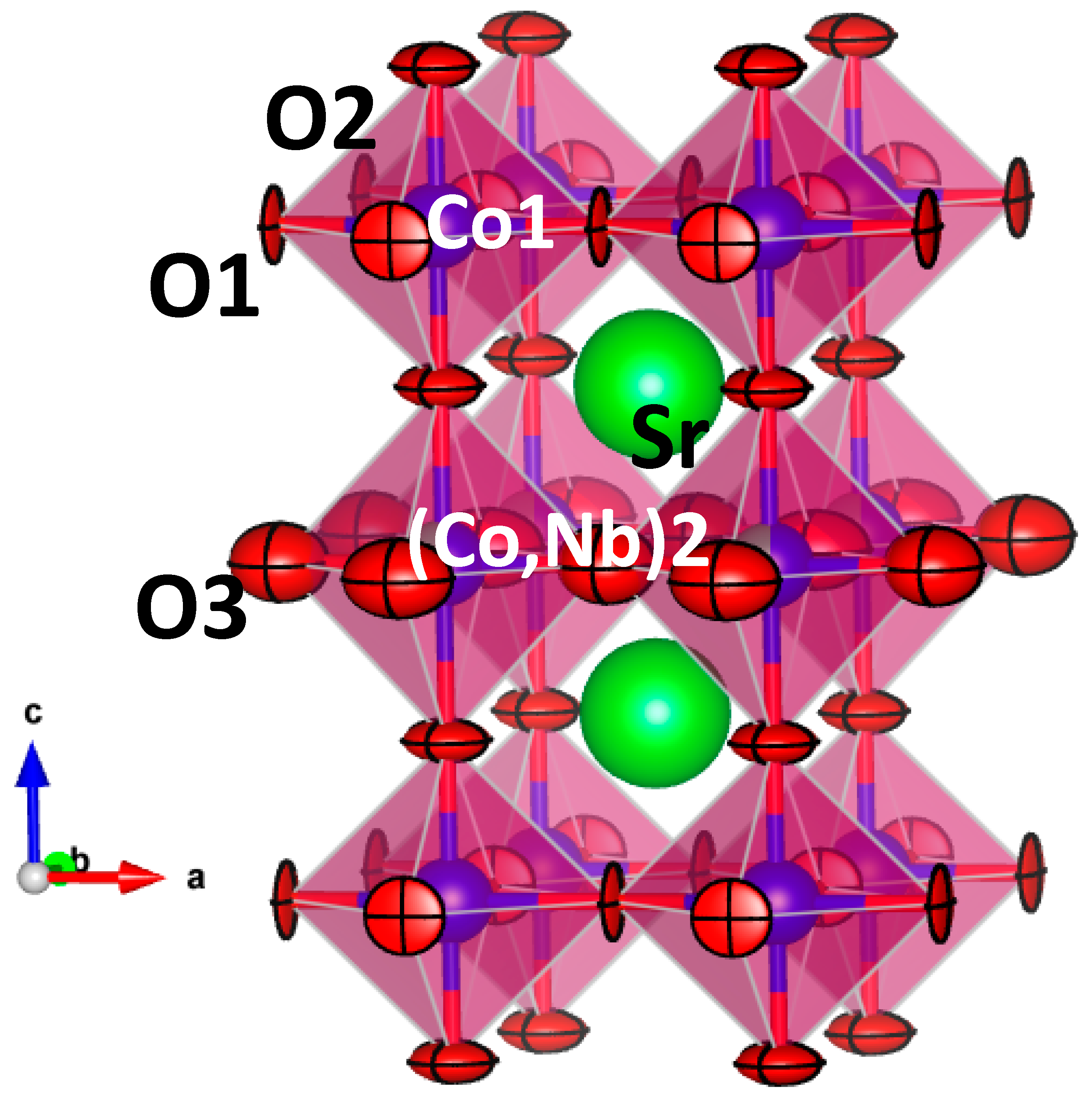

3.1. Crystallographic Characterization

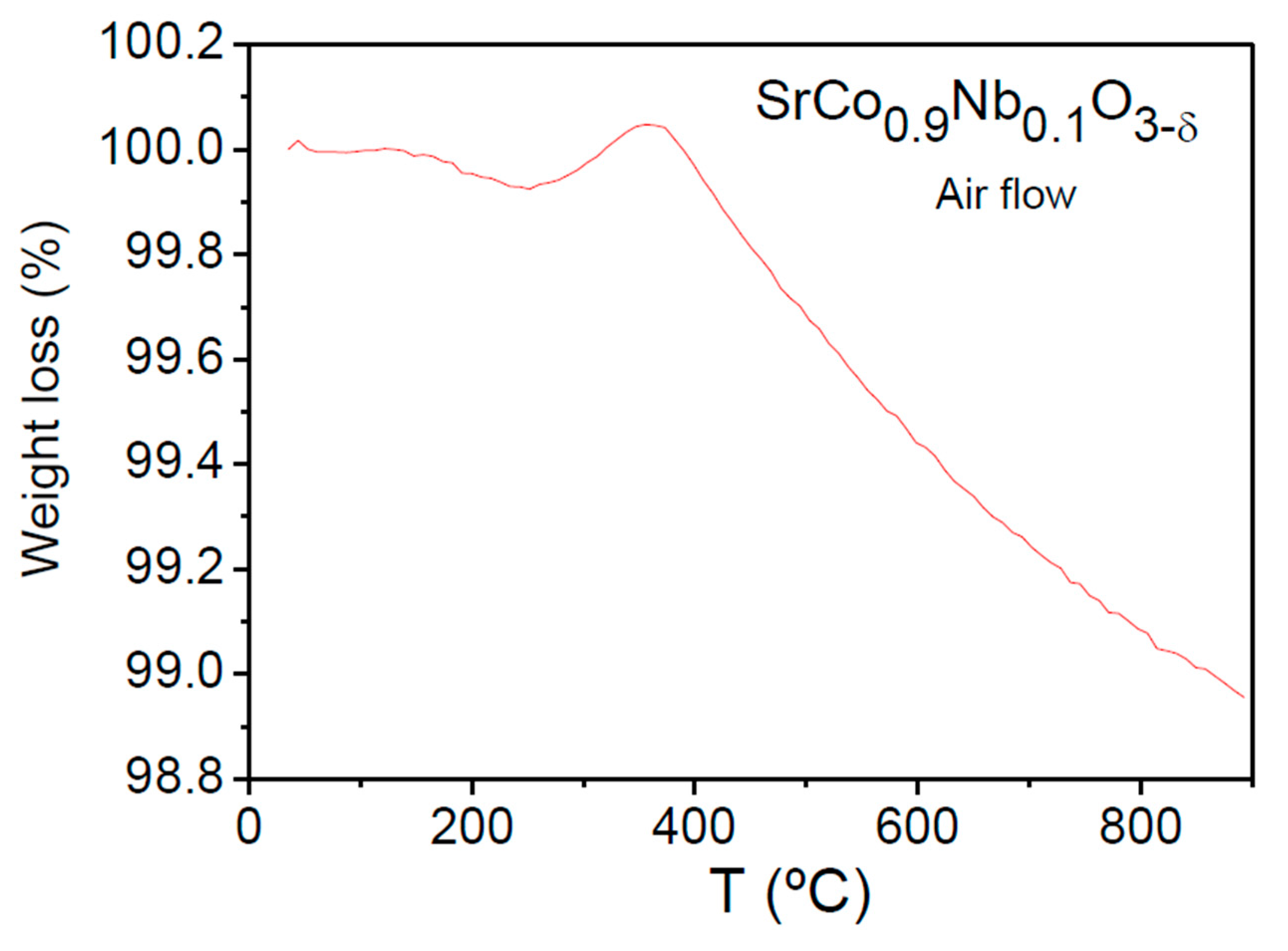

3.2. Thermal Analysis (TGA)

3.3. Thermal Expansion Measurements

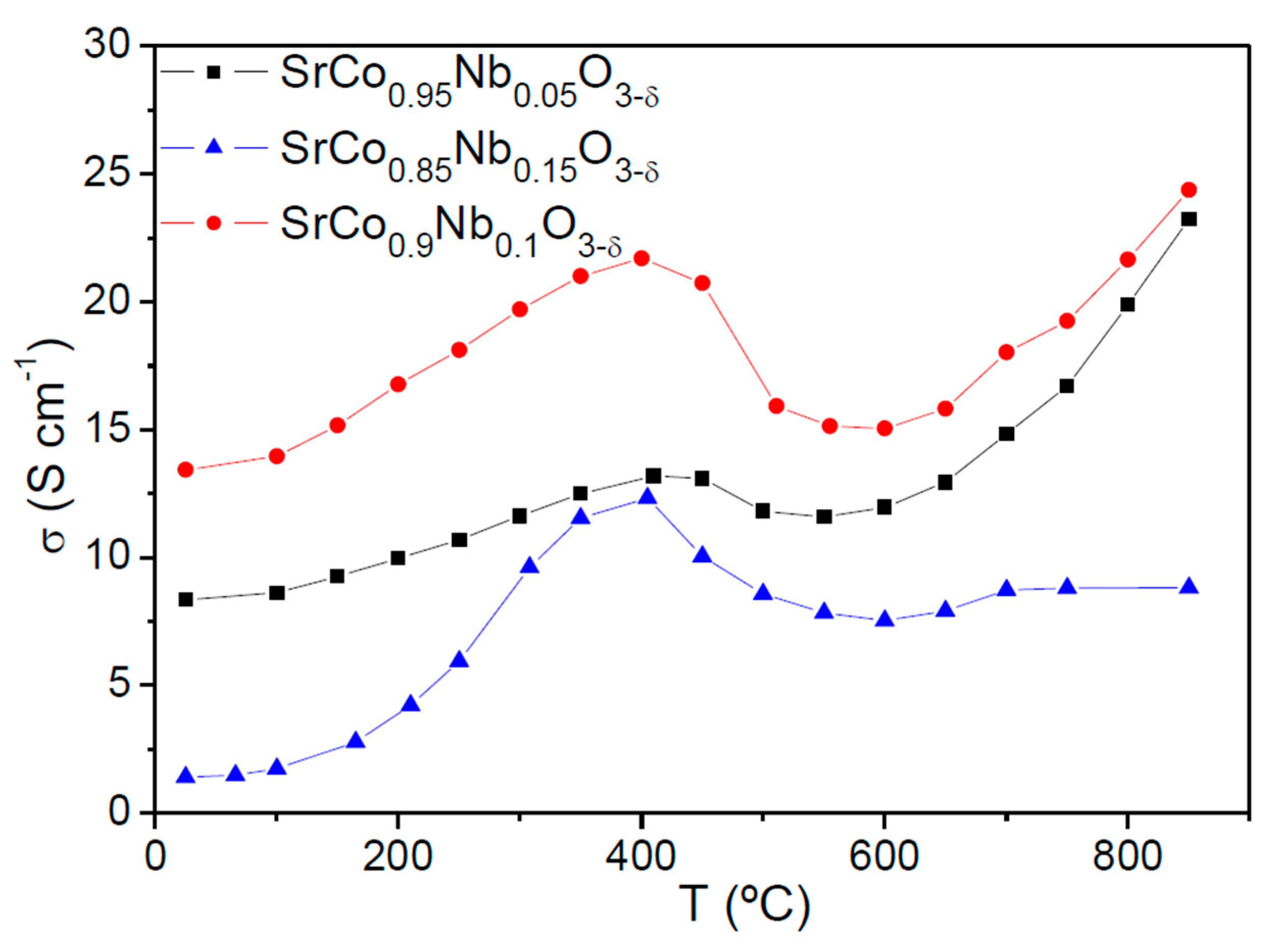

3.4. Electrical Conductivity Measurements

3.5. Chemical Compatibility

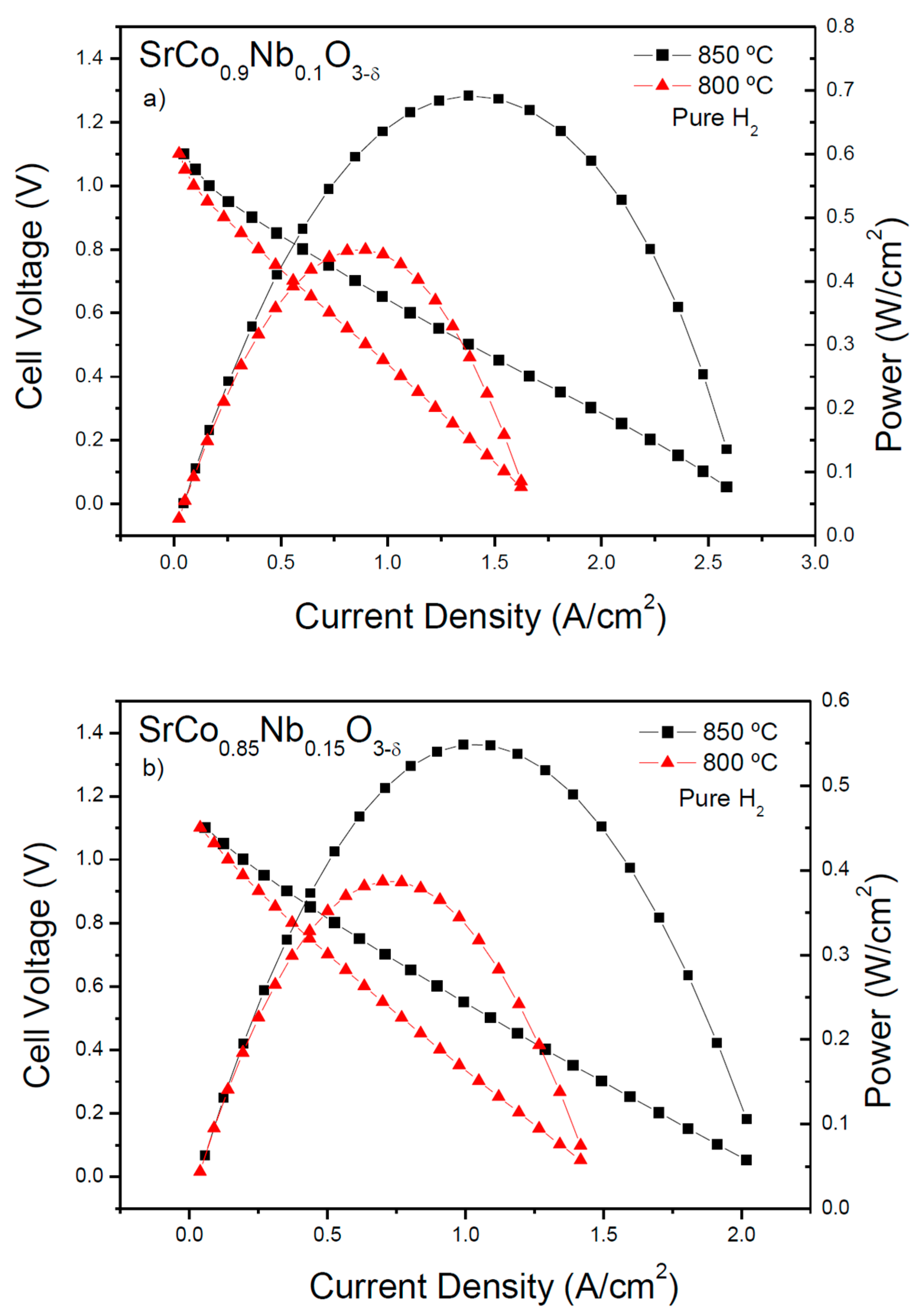

3.6. Fuel-Cell Tests

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Kendall, K. High—Temperature Solid Oxide Fuel Cells for the 21st Century, 2nd ed.; Academic Press: Cambridge, MA, USA, 2016; pp. 1–24. [Google Scholar]

- Nagai, T.; Ito, W.; Sakon, T.R. Relationship between Cation Substitution and Stability of Perovskite Structure in SrCoO3–δ-based Mixed Conductors. Solid State Ion. 2007, 177, 3433–3444. [Google Scholar] [CrossRef]

- Deng, Z.Q.; Liu, W.; Chen, C.S.; Lu, H.; Yang, W.S. Germanium and Iron Co-Substituted SrCoO2.5+δ as Oxygen Permeable Membrane. Solid State Ion. 2004, 170, 187–190. [Google Scholar] [CrossRef]

- Zeng, P.; Ran, R.; Chen, Z.; Zhou, W.; Gu, H.; Shao, Z.; Liu, S. Efficient Stabilization of Cubic Perovskite SrCoO3−δ by B-site Low Concentration Scandium Doping Combined with Sol–Gel Synthesis. J. Alloys Compd. 2008, 455, 465–470. [Google Scholar] [CrossRef]

- Shao, Z.P.; Haile, S.M. A High-Performance Cathode for the Next Generation of Solid-Oxide Fuel Cells. Nature 2004, 431, 170–173. [Google Scholar] [CrossRef] [PubMed]

- Zhou, W.; Ran, R.; Shao, Z. Progress in understanding and development of Ba0.5Sr0.5Co0.8Fe0.2O3−δ-based cathodes for intermediate-temperature solid-oxide fuel cells: A review. J. Power Sources 2009, 192, 231–246. [Google Scholar] [CrossRef]

- Tunney, J.J.; Post, M.L.; Du, X.; Yang, D. Temperature Dependence and Gas-Sensing Response of Conduction for Mixed Conducting SrFeyCozOx Thin Films. J. Electrochem. Soc. 2002, 149, 113–118. [Google Scholar] [CrossRef]

- Svarcova, S.; Wiik, K.; Tolchard, J.; Bouwmeester, H.J.M.; Grande, T. Structural Instability of Cubic Perovskite BaxSr1−xCo1−yFeyO3–δ. Solid State Ion. 2008, 178, 1787–1791. [Google Scholar] [CrossRef]

- Bucher, E.; Egger, A.; Caraman, G.B.; Sitte, W. Stability of the SOFC Cathode Material (Ba,Sr)(Co,Fe)O3−δ in CO2-Containing Atmospheres. J. Electrochem. Soc. 2008, 155, 1218–1224. [Google Scholar] [CrossRef]

- Deng, Z.Q.; Yang, W.S.; Liu, W.; Chen, C.S. Relationship between transport properties and phase transformations in mixed-conducting oxides. J. Solid State Chem. 2006, 179, 362–369. [Google Scholar] [CrossRef]

- Takeda, Y.; Kanno, R.; Takada, T.; Yamamoto, O.; Takano, M.; Bando, Y. Phase relation and oxygen-non-stoichiometry of Perovskite-like Compound SrCoOx (2.29 < x > 2.80). Z. Anorg. Allg. Chem. 1986, 540, 259–270. [Google Scholar]

- De la Calle, C.; Aguadero, A.; Alonso, J.A.; Fernández-Díaz, M.T. Correlation between reconstructive phase transitions and transport properties from SrCoO2.5 brownmillerite: A neutron diffraction study. Solid State Sci. 2008, 10, 1924–1935. [Google Scholar] [CrossRef]

- Li, Y.; Kim, Y.N.; Cheng, J.; Alonso, J.A.; Hu, Z.; Chin, Y.; Takami, T.; Fernández-Díaz, M.T.; Lin, H.J.; Chen, C.T.; et al. Oxygen-Deficient Perovskite Sr0.7Y0.3CoO2.65−δ as a Cathode for Intermediate-Temperature Solid Oxide Fuel Cells. Chem. Mater. 2011, 23, 5037–5044. [Google Scholar] [CrossRef]

- Liu, T.; Li, Y.; Goodenough, J.B. Sr0.7Ho0.3CoO3−δ as a Potential Cathode Material for Intermediate-Temperature Solid Oxide Fuel Cells. J. Power Sources 2012, 199, 161–164. [Google Scholar] [CrossRef]

- Aguadero, A.; Pérez-Coll, D.; Alonso, J.A.; Skinner, S.J.; Kilner, J. A new family of Mo-doped SrCoO3−δ perovskites for application in reversible solid state electrochemical cells. Chem. Mater. 2012, 24, 2655–2663. [Google Scholar] [CrossRef]

- Wang, S.F.; Hsu, Y.F.; Yeh, C.T.; Huang, C.C.; Lu, H.C. Characteristics of SrCo1−xSnxO3−δ cathode materials for use in solid oxide fuel cells. Solid State Ion. 2012, 227, 10–16. [Google Scholar] [CrossRef]

- Aguadero, A.; Alonso, J.A.; Perez-Coll, D.; de la Calle, C.; Fernández-Díaz, M.T.; Goodenough, J.B. SrCo0.95Sb0.05O3−δ as cathode material for high power density solid oxide fuel cells. Chem. Mater. 2010, 22, 789–798. [Google Scholar] [CrossRef]

- Cascos, V.; Martínez-Coronado, R.; Alonso, J.A. New Nb-doped SrCo1−xNbxO3−δ perovskites performing as cathodes in solid-oxide fuel cells. Int. J. Hydrog. Energy 2014, 39, 14349–14354. [Google Scholar] [CrossRef]

- Rietveld, H.M.A. Profile refinement method for nuclear and magnetic structures. J. Appl. Crystallogr. 1969, 2, 65–71. [Google Scholar] [CrossRef]

- Rodríguez-Carvajal, J. Recent advances in magnetic structure determination by neutron powder diffraction. Physica B 1993, 192, 55–69. [Google Scholar] [CrossRef]

- Martínez-Coronado, R.; Alonso, J.A.; Aguadero, A.; Fernández-Díaz, M.T. Optimized energy conversion efficiency in solid oxide fuel cells implementing SrMo1−xFexO3−δ perovskites as anodes. J. Power Sources 2012, 208, 153–158. [Google Scholar] [CrossRef]

- Shannon, R.D. Revised effective ionic radio and systematic studies of interatomic distances in halides and chalcogenides. Acta. Crystallogr. A 1976, 32, 751–767. [Google Scholar] [CrossRef]

- Cascos, V.; Troncoso, L.; Alonso, J.A. New families of Mn+-doped SrCo1−xMxO3−δ perovskites performing as cathodes in solid-oxide fuel cells. Int. J. Hydrog. Energy 2015, 40, 11333–11341. [Google Scholar] [CrossRef]

- Chen, Z.; Ran, R.; Zhou, W.; Shao, Z.; Liu, S. Assessment of Ba0.5Sr0.5Co1−yFeyO3−δ (y = 0.0–1.0) for prospective application as cathode for IT-SOFCs or oxygen permeating membrane. Electrochim. Acta 2007, 52, 7343–7351. [Google Scholar] [CrossRef]

| SrCo1−xNbxO3−δ | x = 0.05 | x = 0.1 | x = 0.15 |

| a (Å) | 3.8574(5) | 3.8621(4) | 3.8928(6) |

| c (Å) | 7.743(1) | 7.748(1) | 7.7807(2) |

| V (Å)3 | 115.22(3) | 115.56(2) | 118.30(4) |

| Reliability Factors | |||

| Rp | 2.74 | 2.81 | 4.55 |

| Rwp | 3.56 | 3.78 | 5.87 |

| Rexp | 2.76 | 2.71 | 4.57 |

| χ2 | 1.67 | 1.94 | 1.65 |

| RBragg (%) | 8.82 | 7.78 | 14.6 |

| SrCo1−xNbxO3−δ | x = 0.05 | x = 0.1 |

| a (Å) | 3.85477(4) | 3.85929(6) |

| c (Å) | 7.7420(1) | 7.7455(2) |

| V (Å)3 | 115.041(3) | 115.362(4) |

| Sr 2h (½, ½, z) | ||

| z | 0.2585(3) | 0.2564(4) |

| Biso (Å2) | 1.32(3) | 1.15(3) |

| focc | 1.00 | 1.00 |

| (Co,Nb)1 1a (0, 0, 0) | ||

| Biso (Å2) | 0.5(1) | 0.3(1) |

| focc (Co,Nb) | 0.982/0.018 | 1/0.00 |

| (Co,Nb)2 1b (0, 0, ½) | ||

| Biso (Å2) | 1.1(1) | 1.8(2) |

| focc (Co,Nb) | 0.918/0.082 | 0.911/0.089 |

| O1 2f (½, 0, 0) | ||

| Beq (Å2) | 0.94(5) | 1.37 |

| β11 * | - | 19(0) |

| β22 | - | 358(37) |

| β33 | - | 78(8) |

| focc | 0.96(1) | 0.999(1) |

| O2 2g (0, 0, z) | ||

| z | 0.7643(6) | 0.7624(5) |

| Beq (Å2) | 2.7(2) | 1.88 |

| β11 | - | 425(38) |

| β22 | - | 425(38) |

| β33 | - | 24(6) |

| focc | 0.991(3) | 1.00 |

| O3 2e (½, 0, ½) | ||

| Beq (Å2) | 3.2(1) | 3.07 |

| β11 | - | 544(39) |

| β22 | - | 672(63) |

| β33 | - | 82(12) |

| focc | 0.776(1) | 0.829(1) |

| Reliability factors | ||

| Rp | 4.26 | 2.22 |

| Rwp | 5.55 | 2.94 |

| Rexp | 3.5 | 1.85 |

| χ2 | 2.51 | 2.52 |

| RBragg (%) | 2.74 | 2.34 |

| Distances (Å) | ||

| Co1-O1 (×4) | 1.9274(2) | 1.92964(3) |

| Co1-O2 (×2) | 1.830(6) | 1.840(3) |

| (Co,Nb)2-O2 (×2) | 2.041(6) | 2.032(3) |

| (Co,Nb)2-O3 (×4) | 1.9274(2) | 1.92964(3) |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cascos, V.; Alonso, J.A.; Fernández-Díaz, M.T. Nb5+-Doped SrCoO3−δ Perovskites as Potential Cathodes for Solid-Oxide Fuel Cells. Materials 2016, 9, 579. https://doi.org/10.3390/ma9070579

Cascos V, Alonso JA, Fernández-Díaz MT. Nb5+-Doped SrCoO3−δ Perovskites as Potential Cathodes for Solid-Oxide Fuel Cells. Materials. 2016; 9(7):579. https://doi.org/10.3390/ma9070579

Chicago/Turabian StyleCascos, Vanessa, José Antonio Alonso, and María Teresa Fernández-Díaz. 2016. "Nb5+-Doped SrCoO3−δ Perovskites as Potential Cathodes for Solid-Oxide Fuel Cells" Materials 9, no. 7: 579. https://doi.org/10.3390/ma9070579