Preparation of a Carbon Doped Tissue-Mimicking Material with High Dielectric Properties for Microwave Imaging Application

Abstract

:1. Introduction

2. Methodology

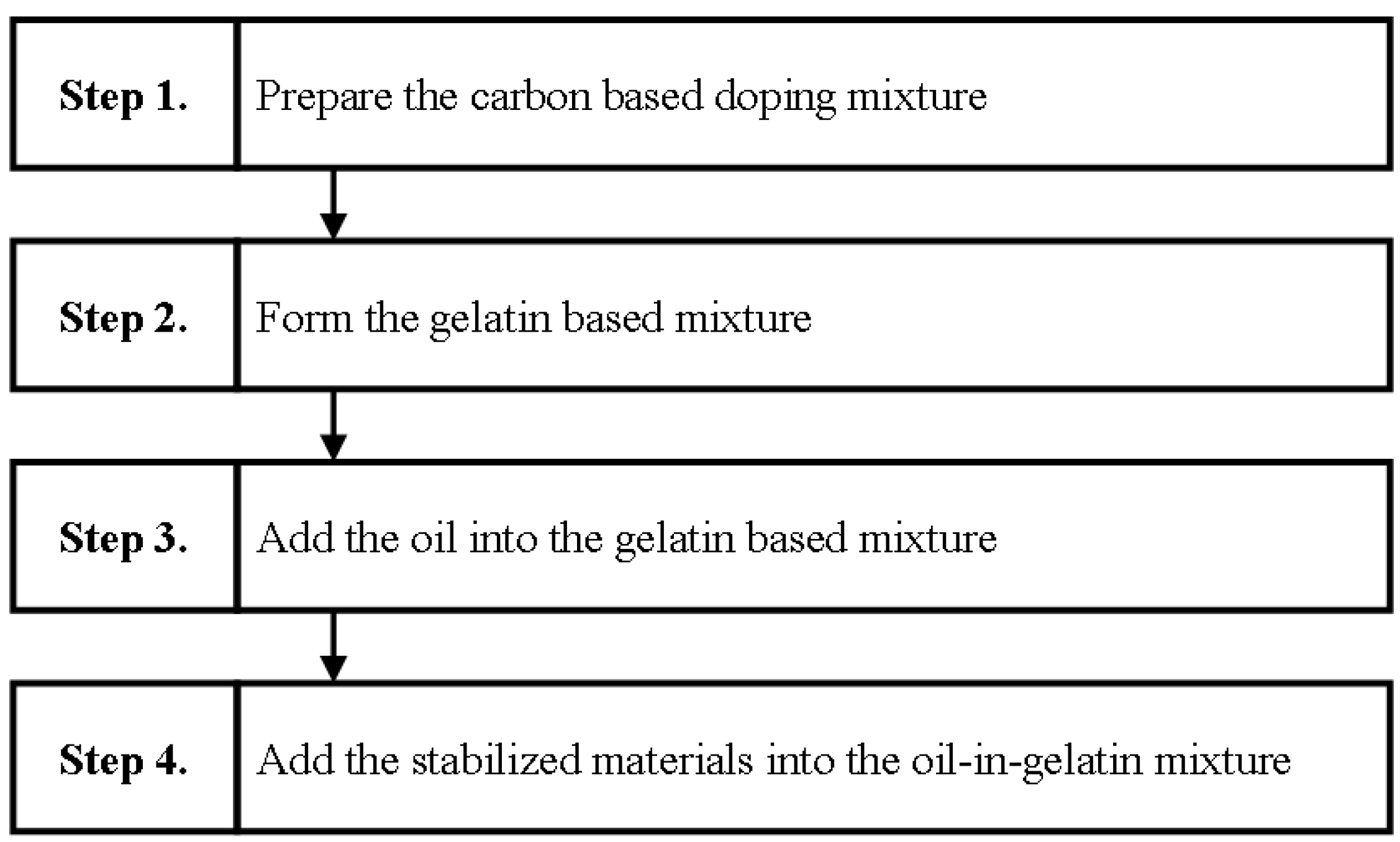

2.1. Preparation of the Tissue-Mimicking Materials

- During step 1:

- During step 2:

- During step 3:

- During the step 4:

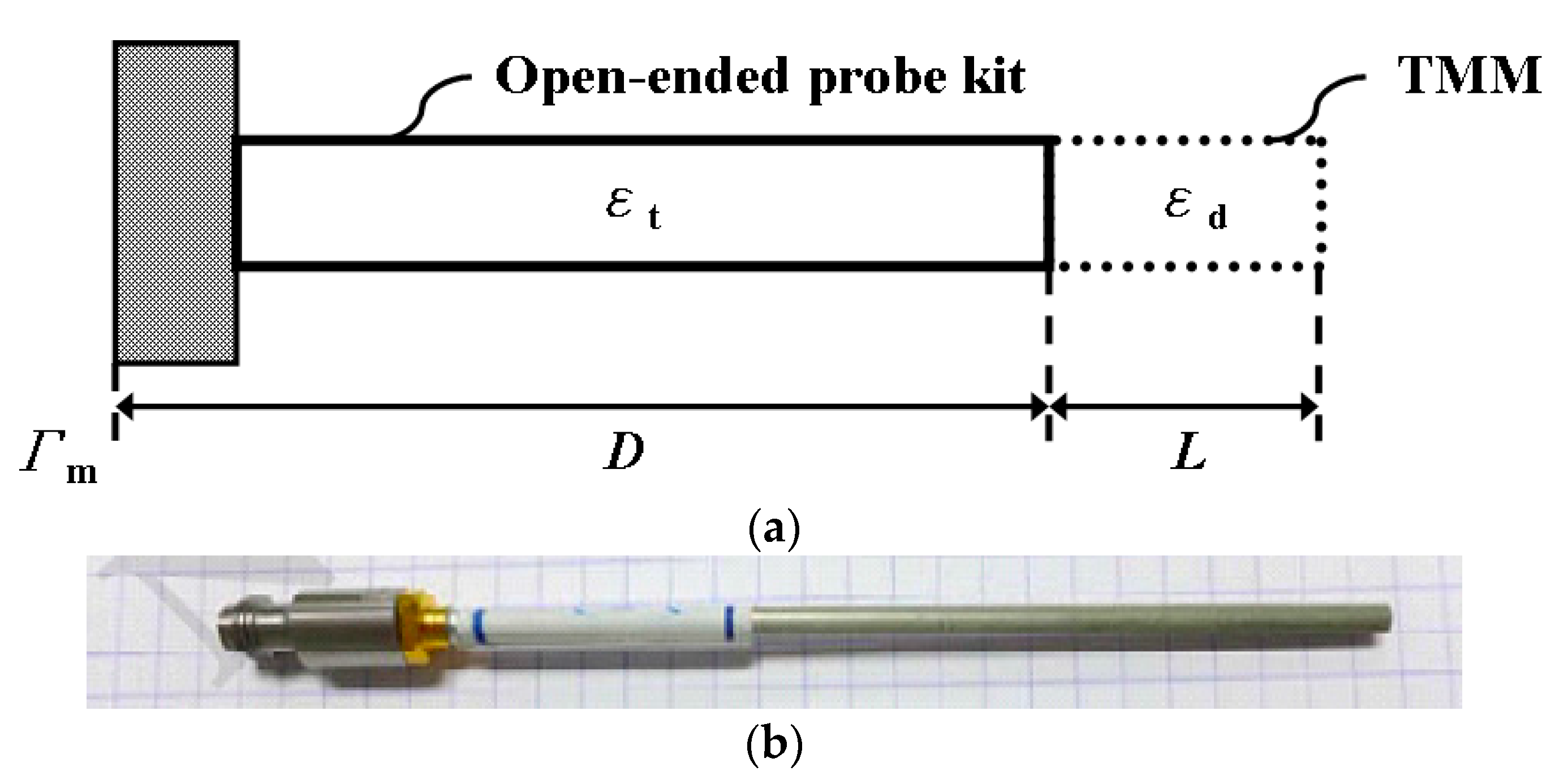

2.2. Measurement of the Tissue-Mimicking Material

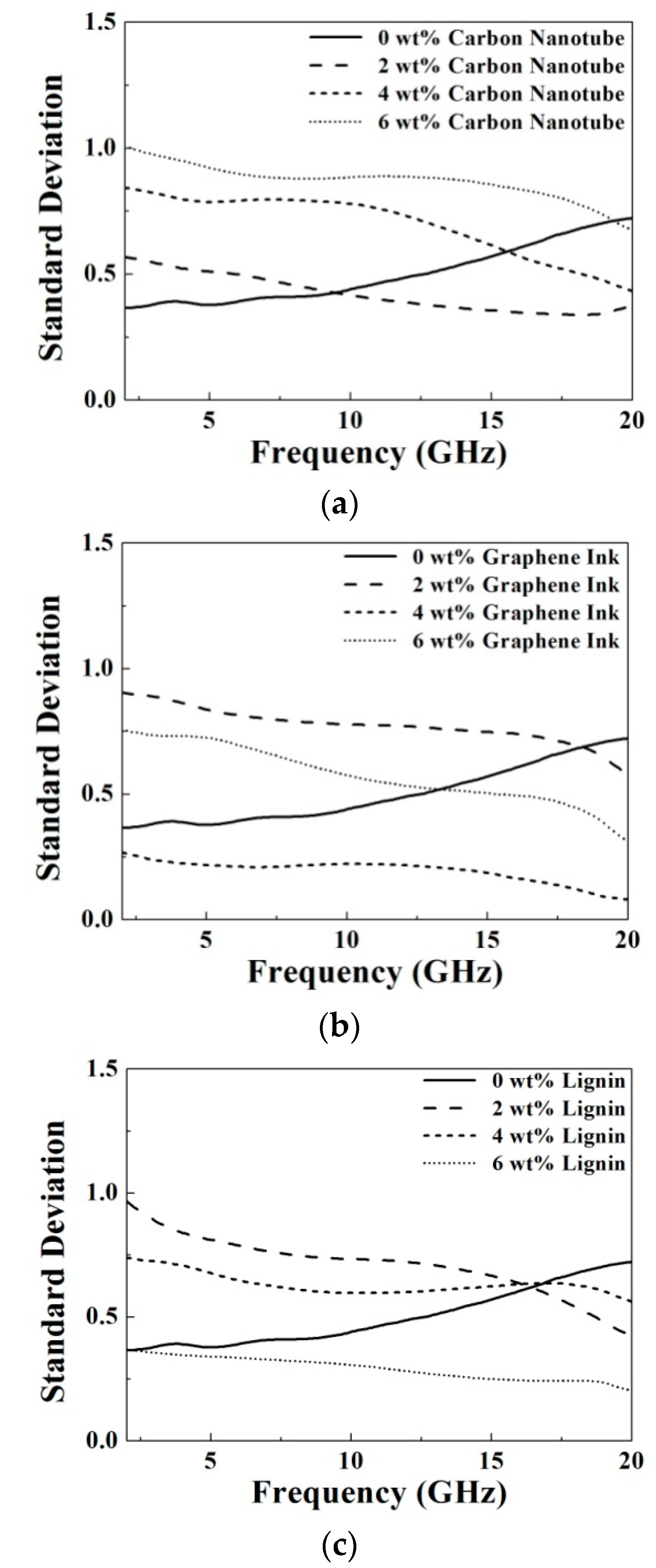

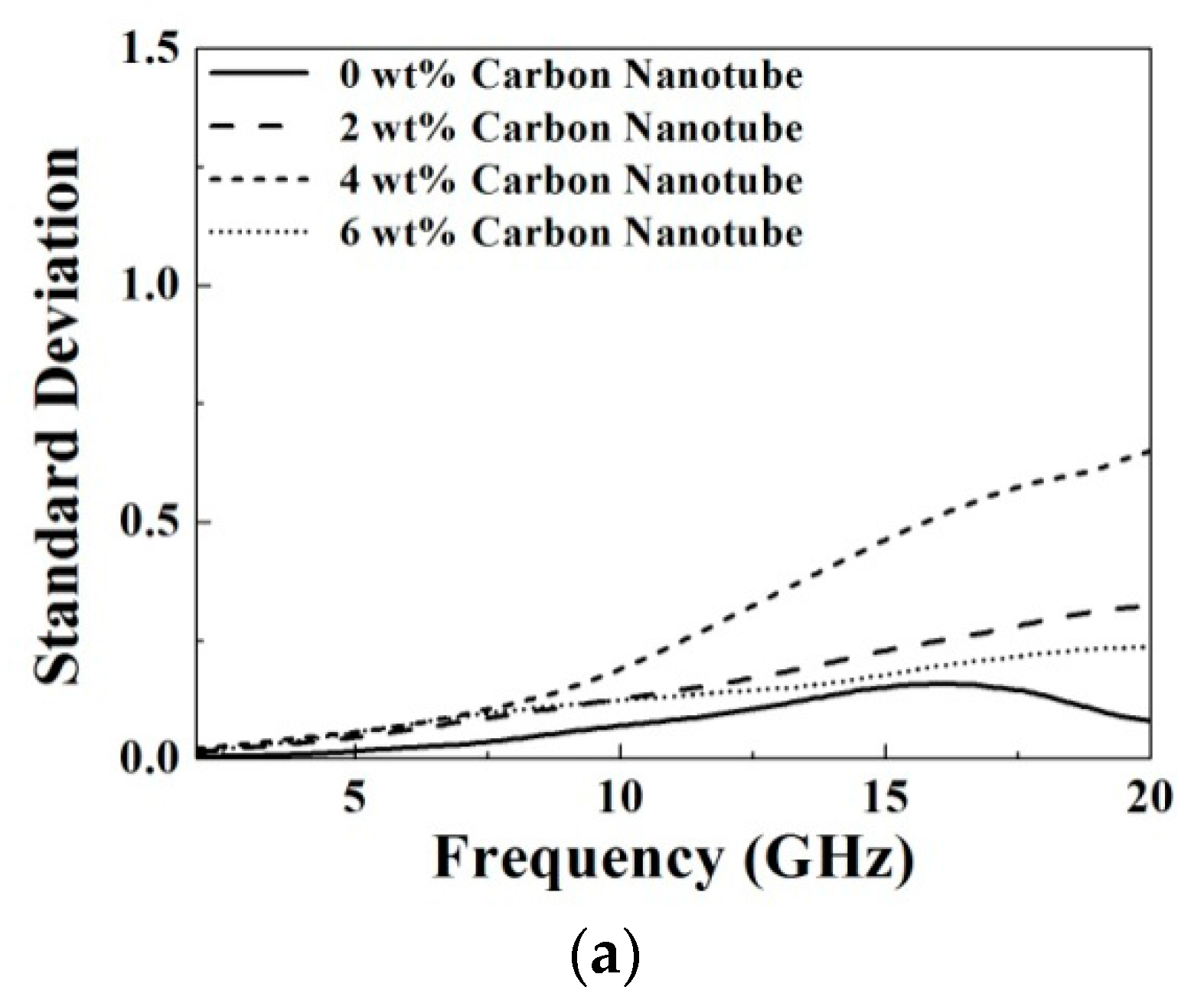

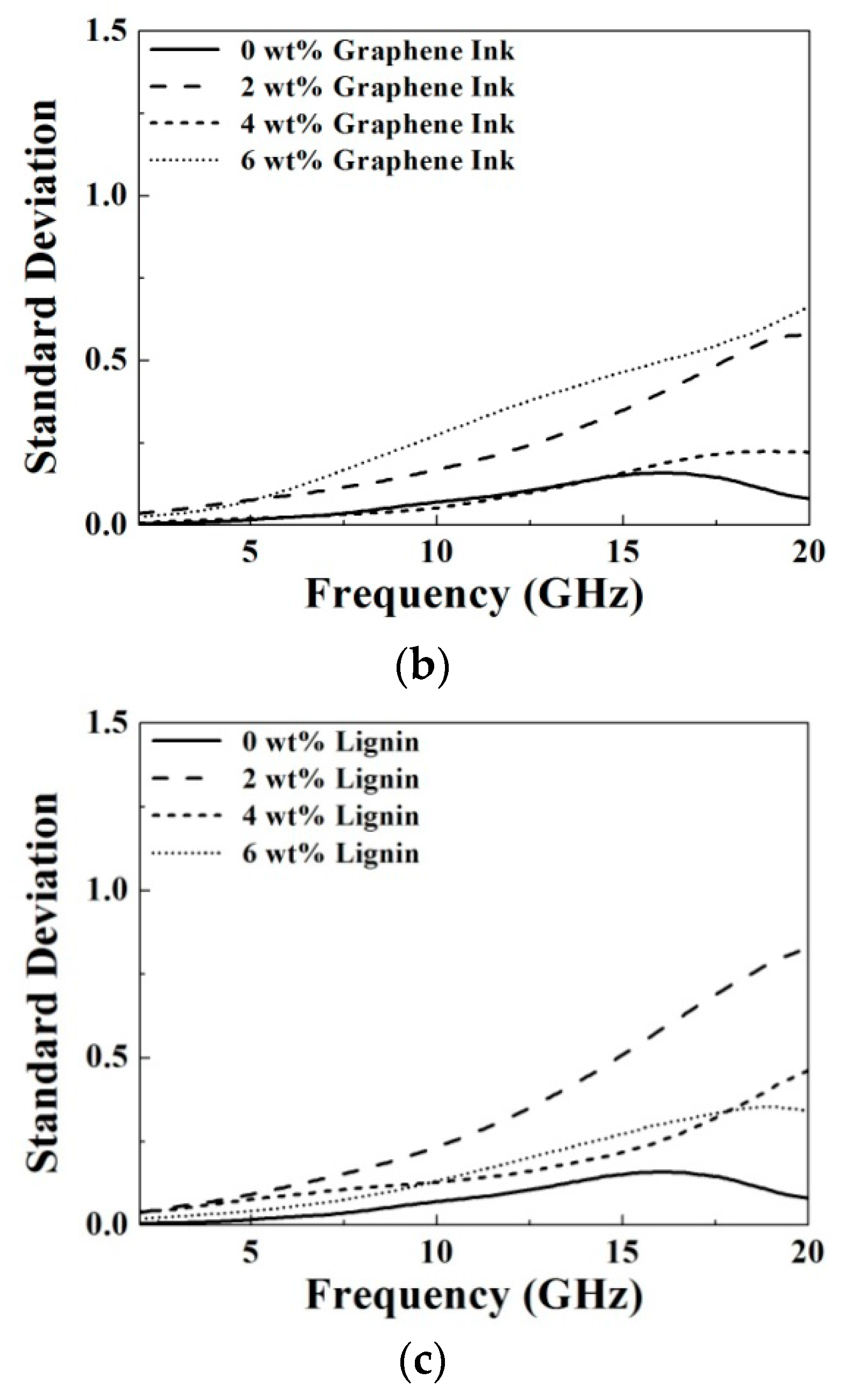

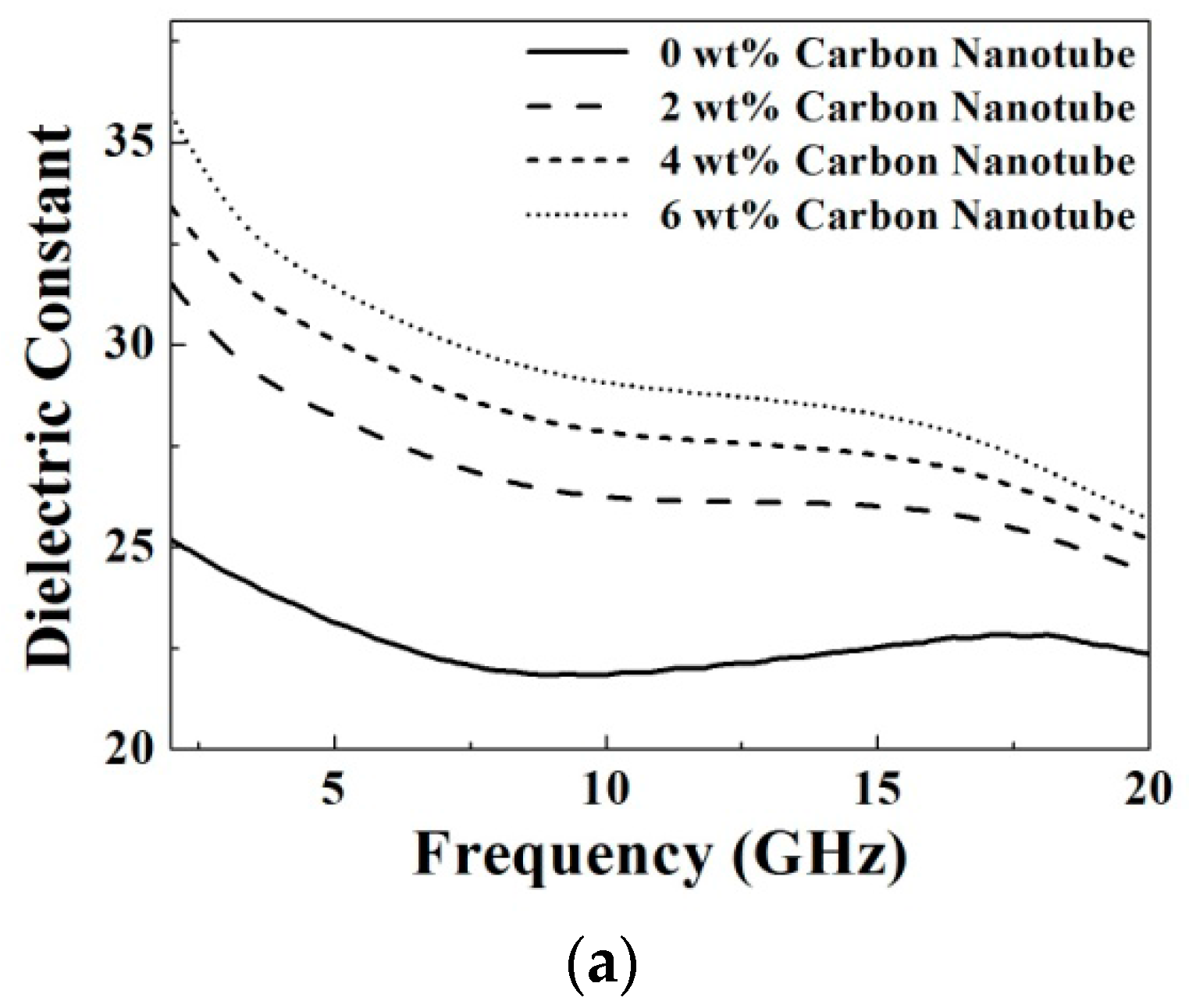

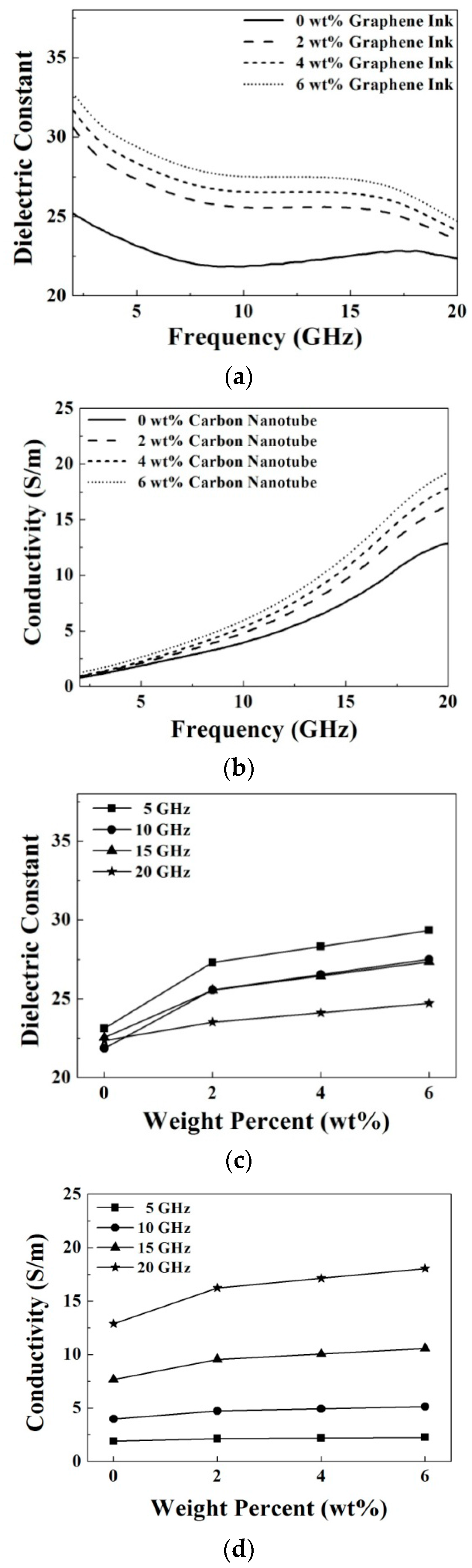

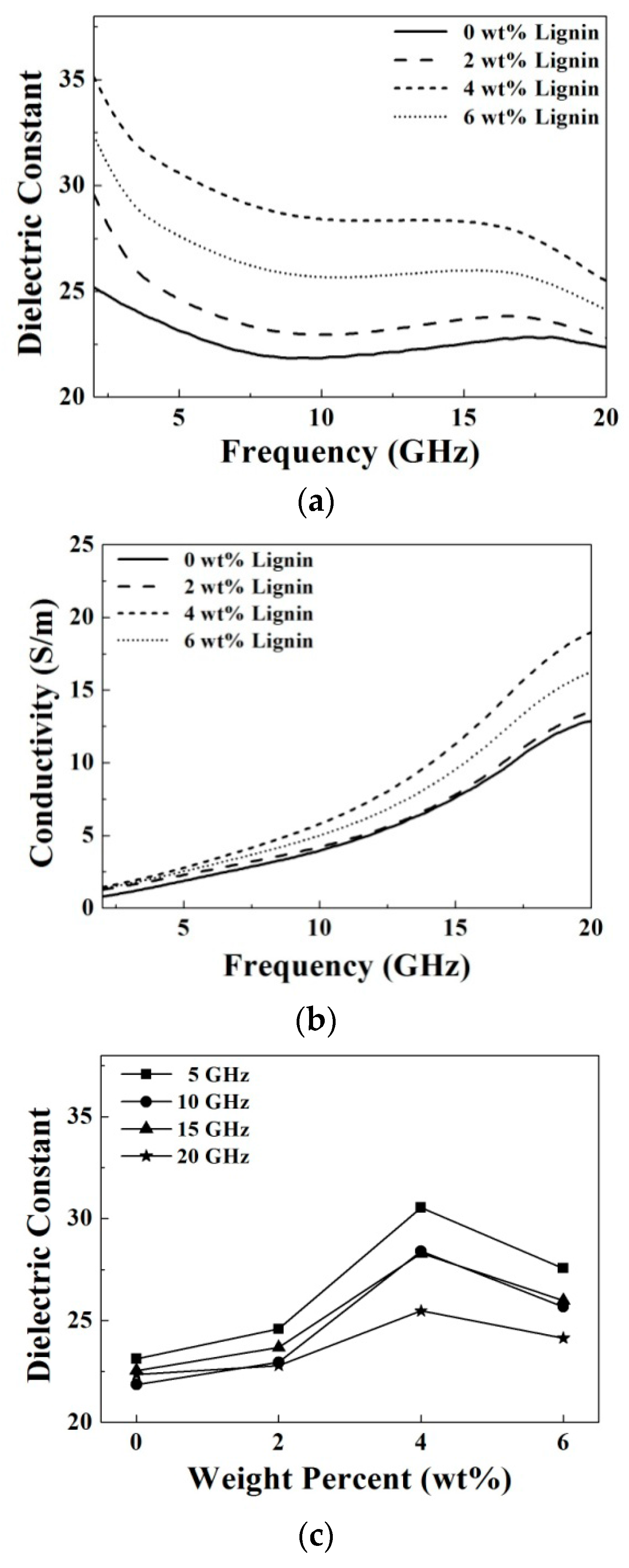

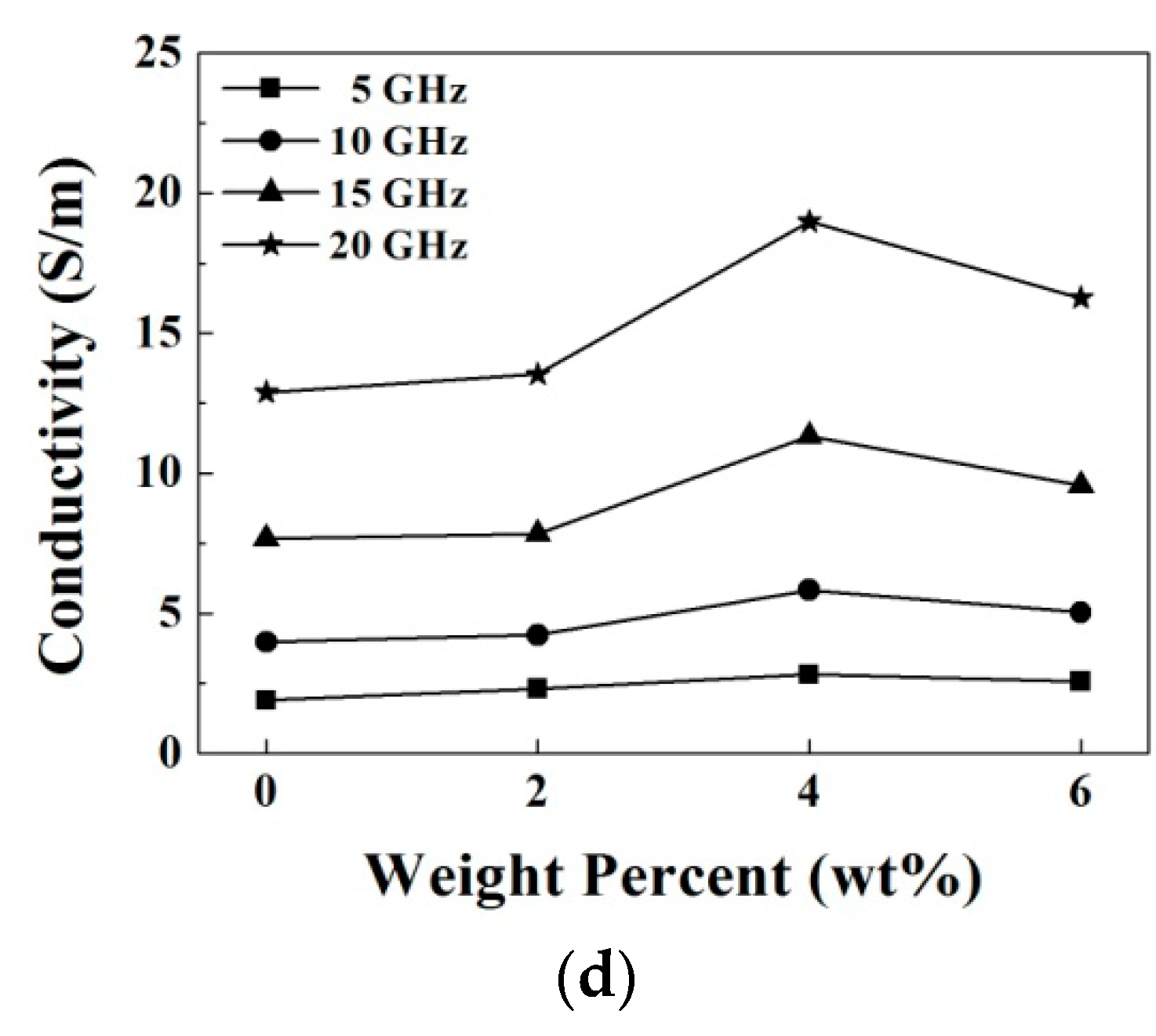

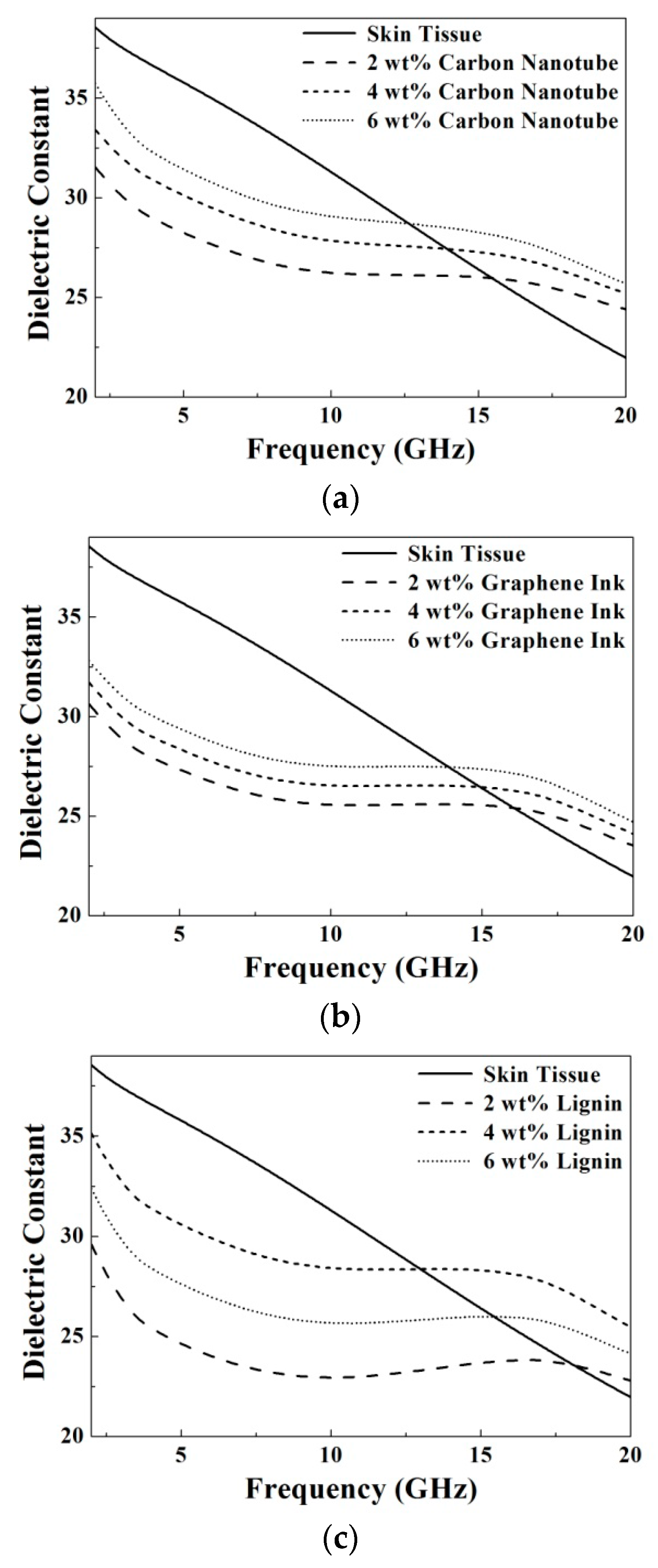

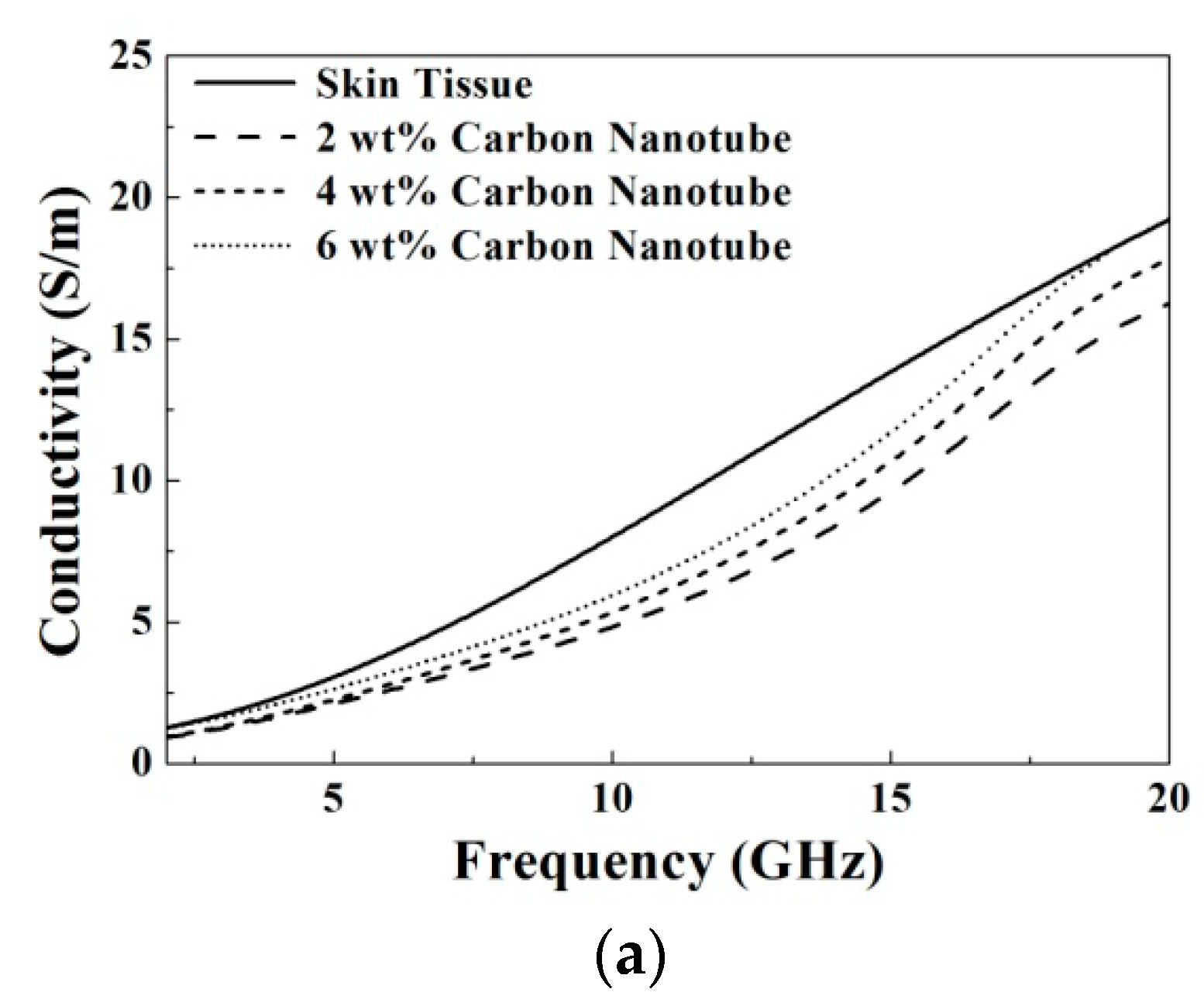

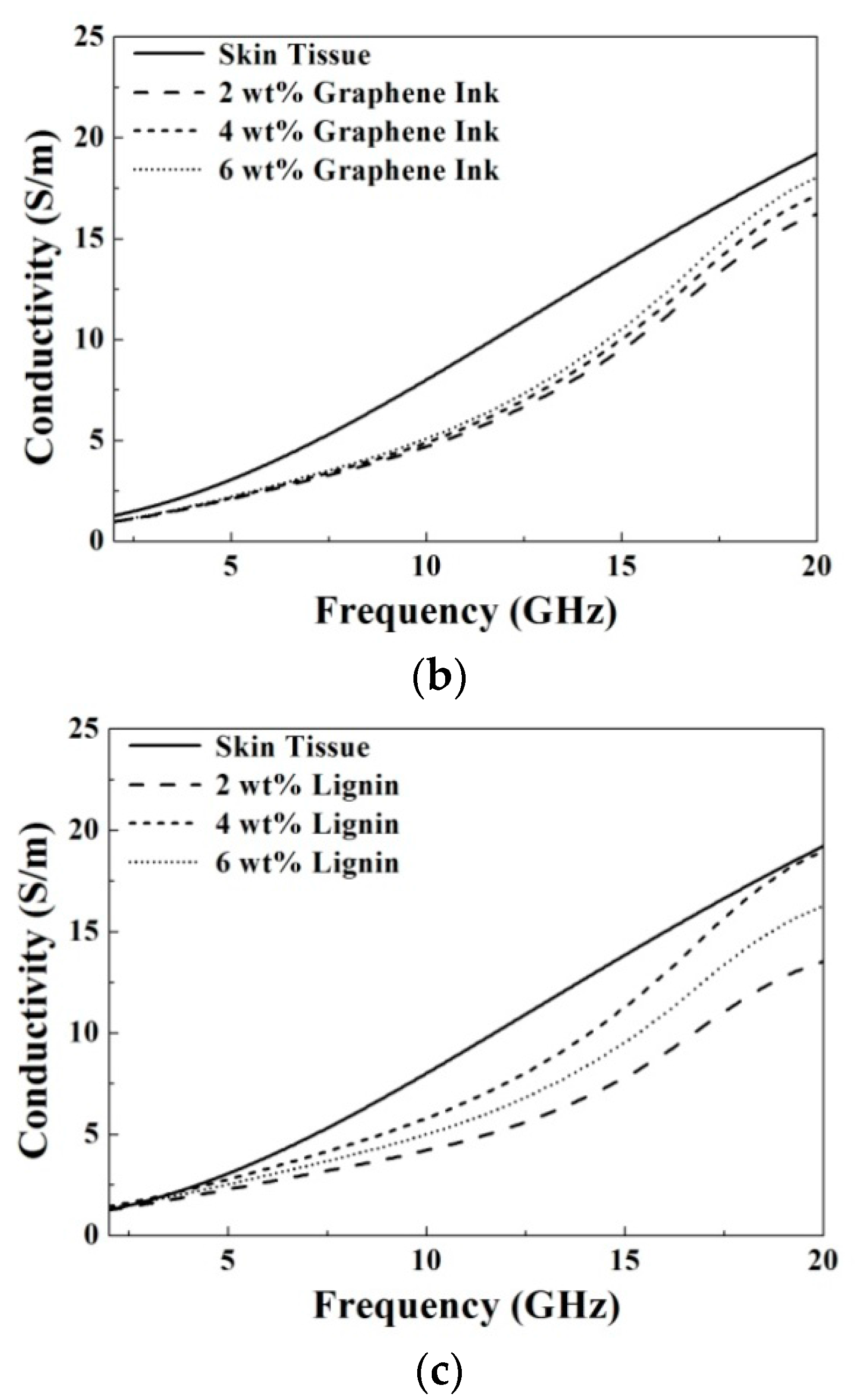

3. Results and Discussion

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Li, X.; Bond, E.J.; Veen, B.D.V.; Hagness, S.C. An overview of ultra-wideband microwave imaging via space-time beamforming for early-stage breast-cancer detection. IEEE Antennas Propag. Mag. 2005, 47, 19–34. [Google Scholar]

- Lai, J.C.Y.; Soh, C.B.; Gunawan, E.; Low, K.S. Homogeneous and heterogeneous breast phantoms for ultra-wideband microwave imaging applications. Prog. Electromagn. Res. 2010, 100, 397–415. [Google Scholar] [CrossRef]

- Hahn, C.; Noghanian, S. Heterogeneous breast phantom development for microwave imaging using regression models. Int. J. Biomed. Imag. 2012, 6, 1–12. [Google Scholar] [CrossRef] [PubMed]

- Moll, J.; Kelly, T.N.; Byrne, D.; Sarafianou, M.; Krozer, V.; Craddock, I.J. Microwave radar imaging of heterogeneous breast tissue integrating a priori information. Int. J. Biomed. Imaging 2014, 17, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Said, M.S.M.; Seman, N.; Jaafar, H. Characterization of human head phantom based on its dielectric properties for wideband microwave imaging application. J. Teknol. 2015, 73, 43–49. [Google Scholar] [CrossRef]

- Bini, M.G.; Ignesti, A.; Millanta, L.; Olmi, R.; Rubino, N.; Vanni, R. The polyacrylamide as a phantom material for electromagnetic hyperthermia studies. IEEE Trans. Biomed. Eng. 1984, 31, 317–322. [Google Scholar] [CrossRef] [PubMed]

- Andreuccetti, D.; Bini, M.; Ignesti, A.; Olmi, R.; Rubino, N.; Vanni, R. Use of polyacrylamide as a tissue-equivalent material in the microwave range. IEEE Trans. Biomed. Eng. 1988, 35, 275–277. [Google Scholar] [CrossRef] [PubMed]

- Youngs, I.J.; Treen, A.S.; Fixter, G.; Holden, S. Design of solid broadband human tissue simulant materials. IEE Proc. Sci. Meas. Technol. 2002, 149, 232–238. [Google Scholar] [CrossRef]

- Lazebnik, M.; Madsen, E.L.; Frank, G.R.; Hagness, S.C. Tissue-mimicking phantom materials for narrowband and ultrawideband microwave applications. Phys. Med. Boil. 2005, 50, 4245–4258. [Google Scholar] [CrossRef] [PubMed]

- Solanki, L.S.; Singh, S.; Singh, D. Development and modeling of the dielectric properties of tissue-mimicking phantom materials for ultra-wideband microwave breast cancer detection. Optik Inter. J. Light Electr. Opt. 2016, 127, 2217–2225. [Google Scholar] [CrossRef]

- Gabriel, C. Tissue equivalent material for hand phantoms. Phys. Med. Boil. 2007, 52, 4205–4210. [Google Scholar] [CrossRef] [PubMed]

- Garrett, J.; Fear, E. Stable and flexible materials to mimic the dielectric properties of human soft tissues. IEEE Antennas Wirel. Propag. Lett. 2014, 13, 599–602. [Google Scholar] [CrossRef]

- Liu, L.; Kong, L.B.; Matitsine, S. Tunable effective permittivity of nanotube composites. Appl. Phys. Lett. 2008, 93, 113–106. [Google Scholar] [CrossRef]

- Sarkanen, K.V.; Ludwig, C.H. Lignins: Occurrence, Formation, Structure, and Reactions; Wiley Intersci: New York, NY, USA, 1971. [Google Scholar]

- Marinho, B.; Ghislandi, M.; Tkalya, E.; Koning, C.E.; de With, G. Electrical conductivity of compacts of graphene, multi-wall carbon nanotubes, carbon black and graphite powder. Powder Tech. 2012, 221, 351–358. [Google Scholar] [CrossRef]

- Kharade, A.Y.; Kale, D.D. Lignin-filled polyolefins. J. Appl. Polym. Sci. 1999, 72, 1321–1326. [Google Scholar] [CrossRef]

- Berube, D.; Ghannouchi, F.; Savard, P. A comparative study of four open-ended coaxial probe models for permittivity measurements of lossy dielectric/biological materials at microwave frequencies. IEEE Trans. Microw. Theory Tech. 1996, 44, 1928–1934. [Google Scholar] [CrossRef]

- Popovic, D.; McCartney, L.; Beasley, C.; Lazebnik, M.; Okoniewski, M.; Hagness, S.C.; Booske, J.H. Precision open-ended coaxial probes for in vivo and ex vivo dielectric spectroscopy of biological tissues at microwave frequencies. IEEE Trans. Microw. Theory Tech. 2005, 53, 1713–1722. [Google Scholar] [CrossRef]

- Shi, S.L.; Zhang, L.Z.; Li, J.S. Electric and dielectric properties of multiwall carbon nanotube/polyaniline composites. J. Polym. Res. 2009, 16, 395–399. [Google Scholar] [CrossRef]

- Gabriel, S.; Lau, R.W.; Gabriel, C. The dielectric properties of biological tissues: II. Measurements in the frequency range 10 Hz to 20 GHz. Phys. Med. Biol. 1996, 41, 2251–2269. [Google Scholar] [CrossRef] [PubMed]

| Doping Materials | N-Propanol | P-Toluic Acid | Di Water | Gelatin | Mixed Oil | Surfactant | Formaldehyde |

|---|---|---|---|---|---|---|---|

| 2 | 1.651 | 0.041 | 39.2 | 7.221 | 31.979 | 17.743 | 0.165 |

| 4 | 1.617 | 0.04 | 38.4 | 7.074 | 31.326 | 17.381 | 0.162 |

| 6 | 1.583 | 0.04 | 37.6 | 6.926 | 30.674 | 17.019 | 0.158 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lan, S.-W.; Weng, M.-H.; Yang, R.-Y.; Chang, S.-J.; Chung, Y.-S.; Yu, T.-C.; Wu, C.-S. Preparation of a Carbon Doped Tissue-Mimicking Material with High Dielectric Properties for Microwave Imaging Application. Materials 2016, 9, 559. https://doi.org/10.3390/ma9070559

Lan S-W, Weng M-H, Yang R-Y, Chang S-J, Chung Y-S, Yu T-C, Wu C-S. Preparation of a Carbon Doped Tissue-Mimicking Material with High Dielectric Properties for Microwave Imaging Application. Materials. 2016; 9(7):559. https://doi.org/10.3390/ma9070559

Chicago/Turabian StyleLan, Siang-Wen, Min-Hang Weng, Ru-Yuan Yang, Shoou-Jinn Chang, Yaoh-Sien Chung, Tsung-Chih Yu, and Chun-Sen Wu. 2016. "Preparation of a Carbon Doped Tissue-Mimicking Material with High Dielectric Properties for Microwave Imaging Application" Materials 9, no. 7: 559. https://doi.org/10.3390/ma9070559