An Investigation into the Use of Manufactured Sand as a 100% Replacement for Fine Aggregate in Concrete

Abstract

:1. Introduction

- Section 2 provides experimental details related to the use of a range of manufactured sands of varying fines content as a complete replacement for natural sand in concrete. It also presents the selection and justification of the fine aggregate characterisation tests used in this study.

- Section 3 presents the fresh and hardened concrete test results in combination with the fine aggregate characterization results and uses these to evaluate the properties that make manufactured sand suitable for concrete applications.

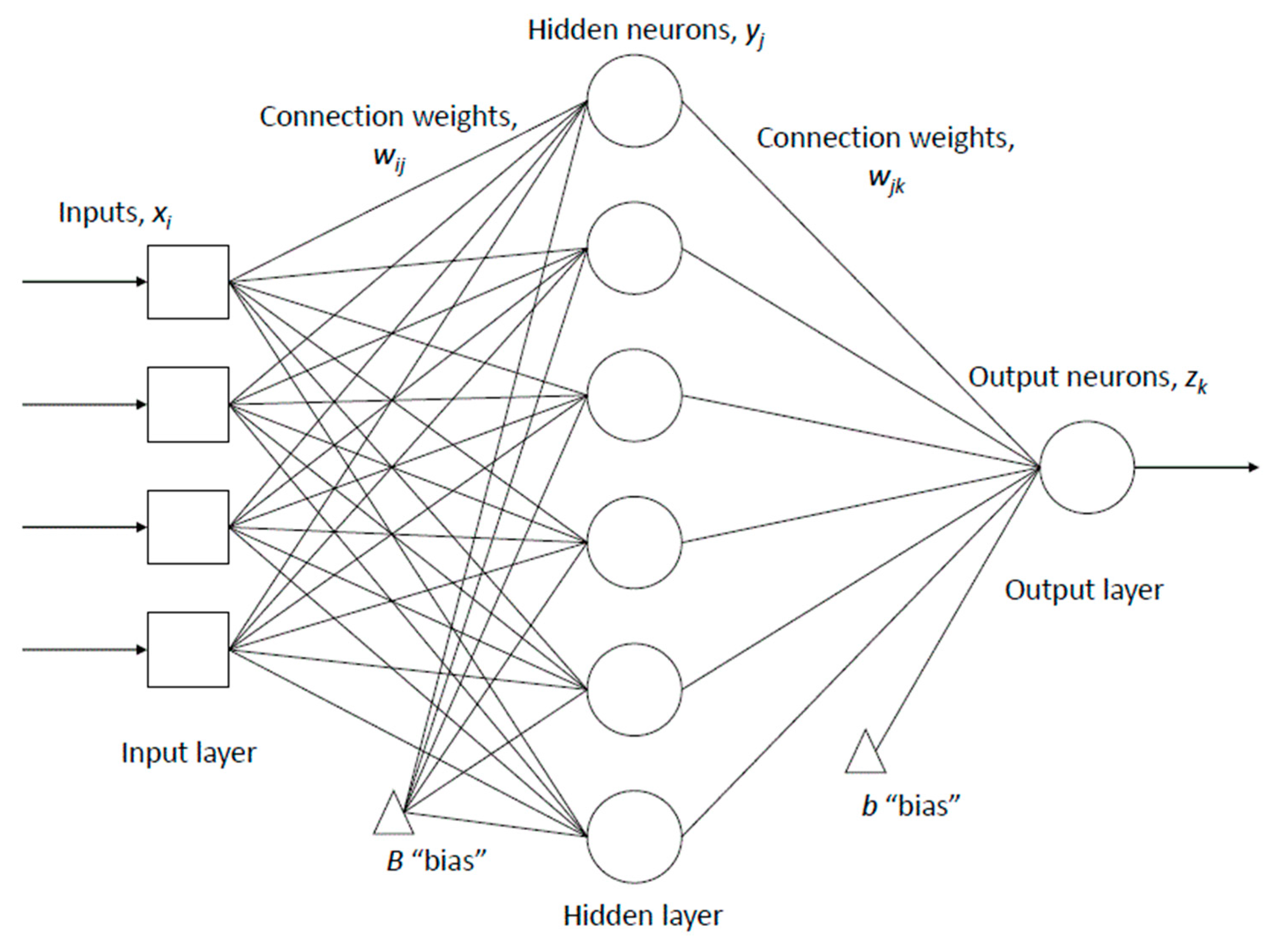

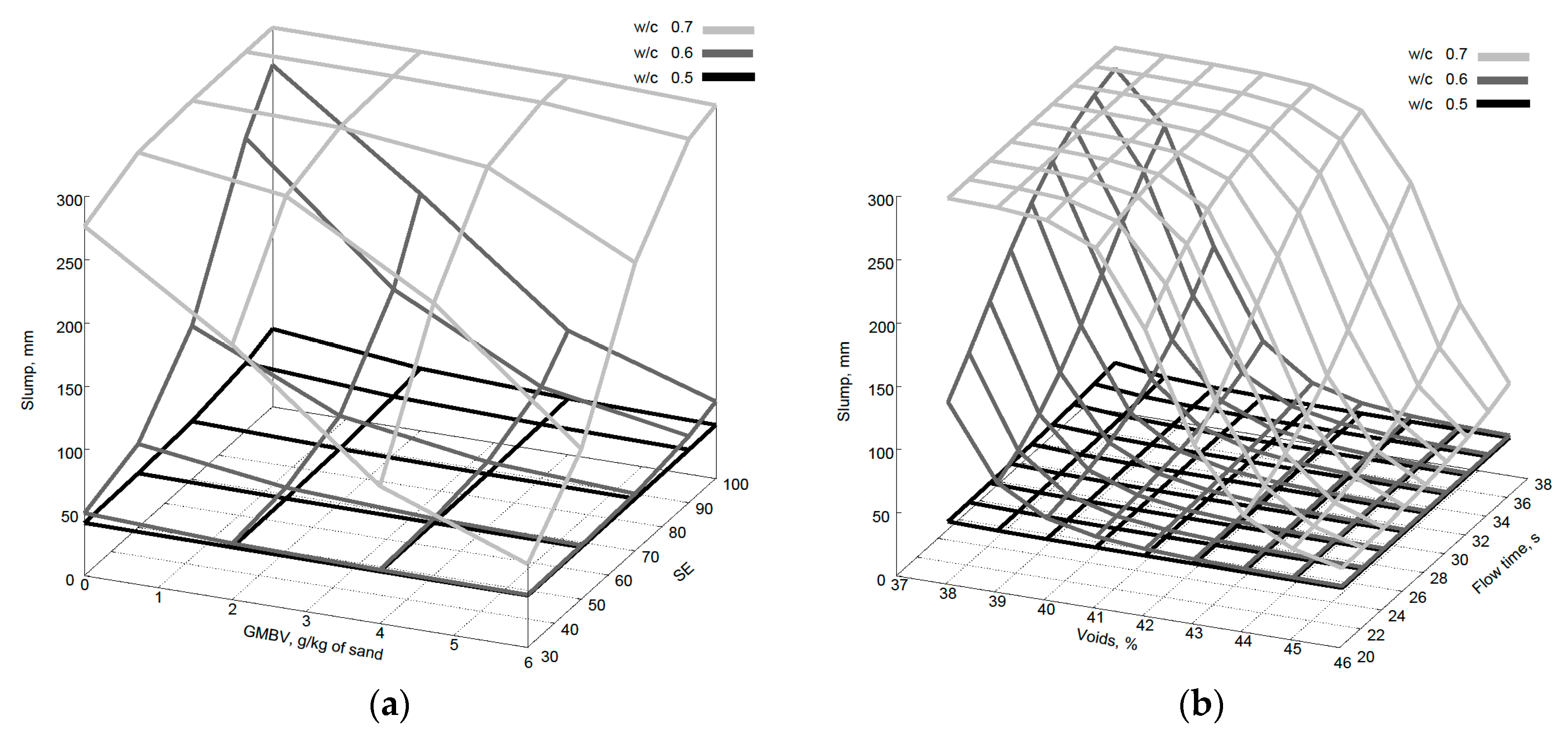

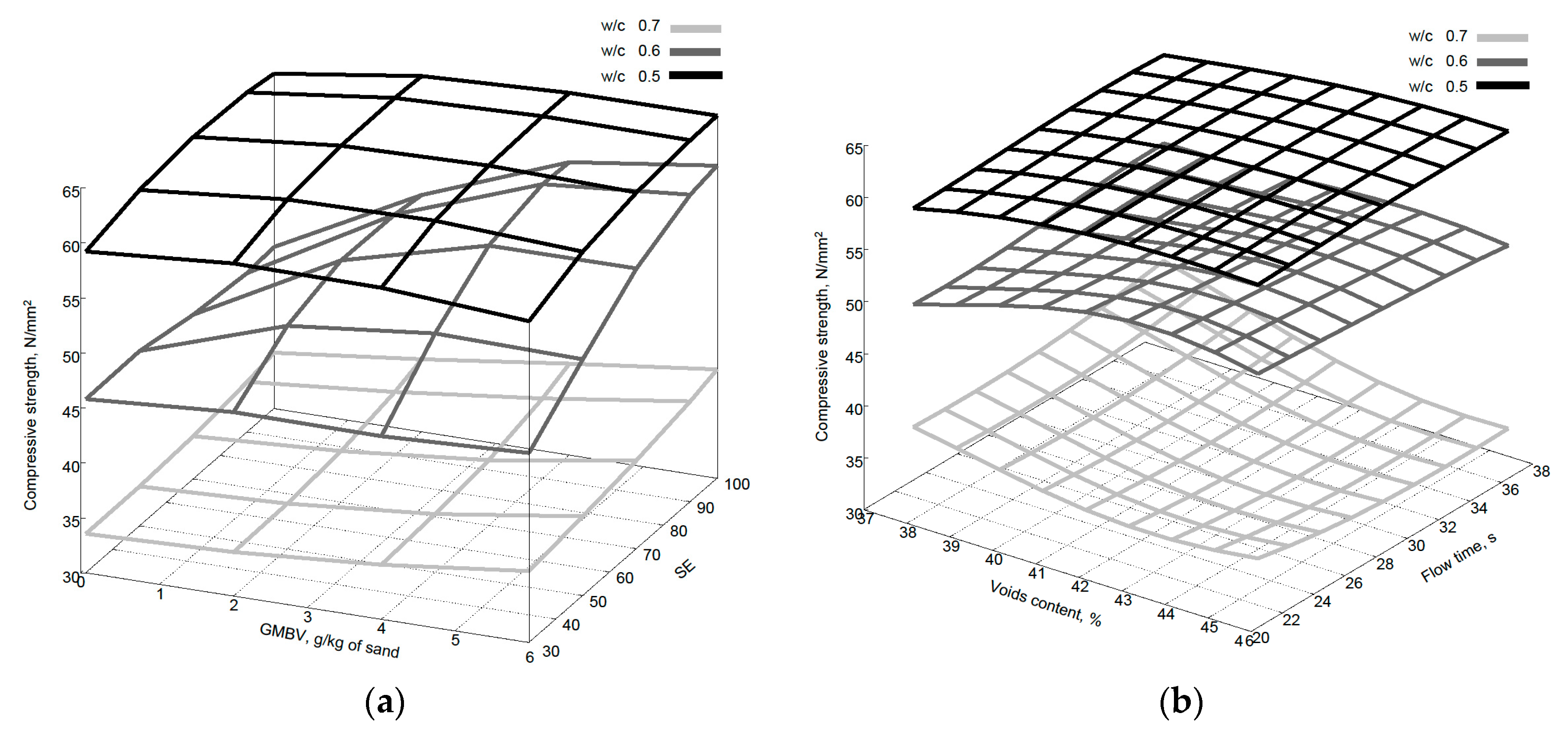

- Section 4 describes the development, training and evaluation of an ANN model using the data presented in Section 3 and a further series of validation concrete mixes. The ANN model is used to predict the compressive strength and workability of concrete using the properties of the fine aggregate as one of the main model input variables.

2. Materials and Methods

2.1. Materials

2.2. Fine Aggregate Tests

2.3. Concrete Tests, Curing and Specimen Details

2.4. Concrete Mix Composition

3. Results and Discussion

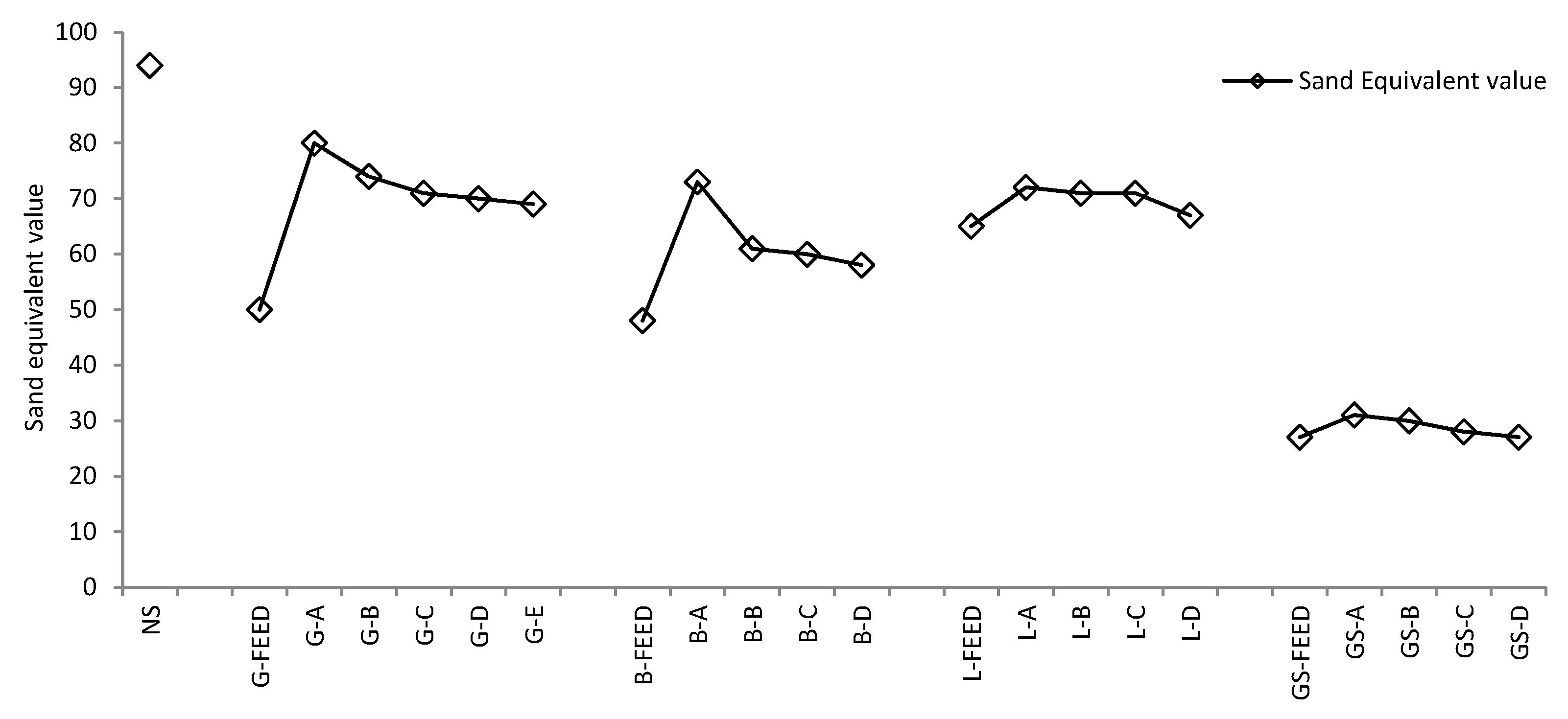

3.1. Fine Aggregate Characterisation Results

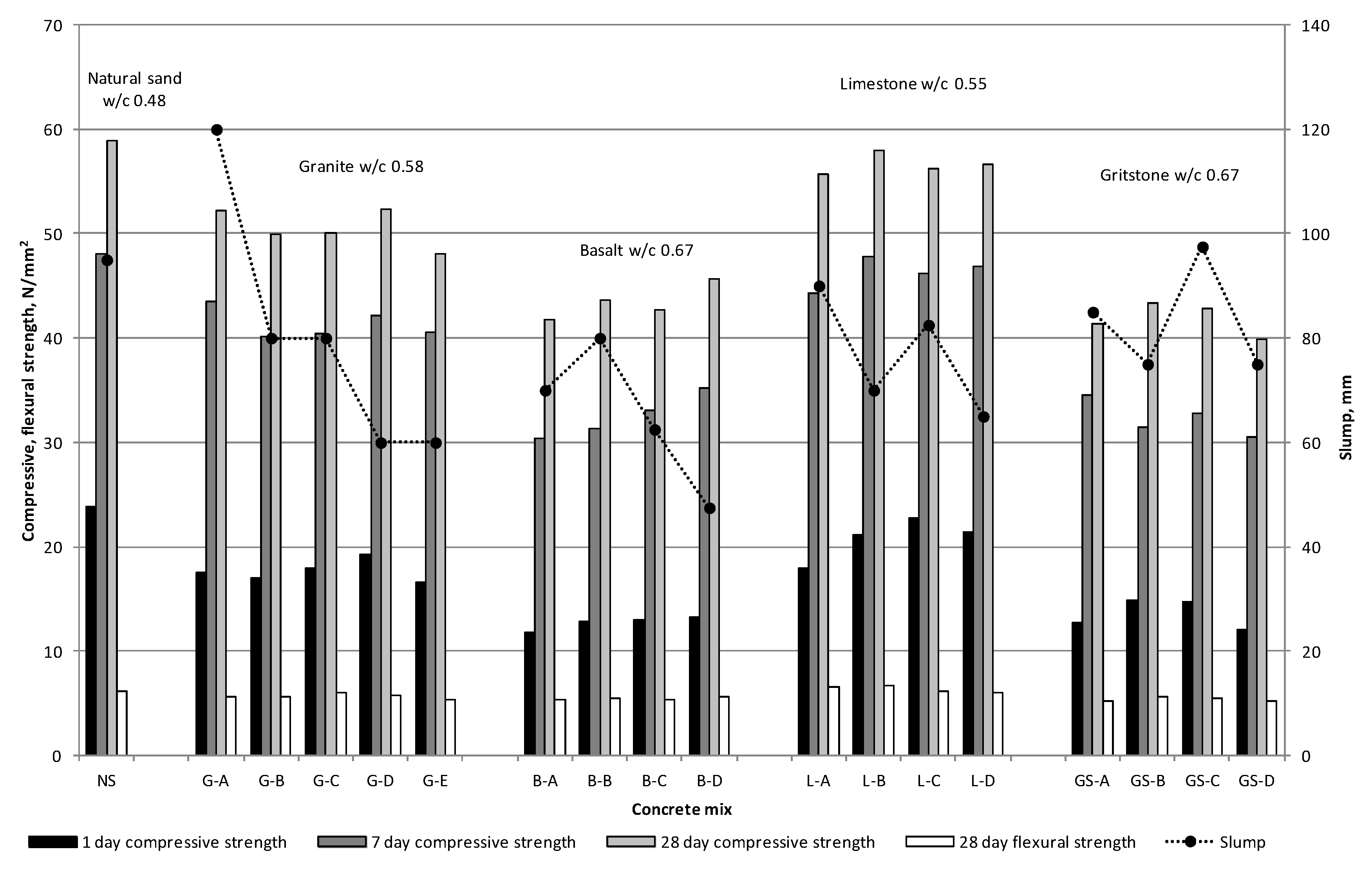

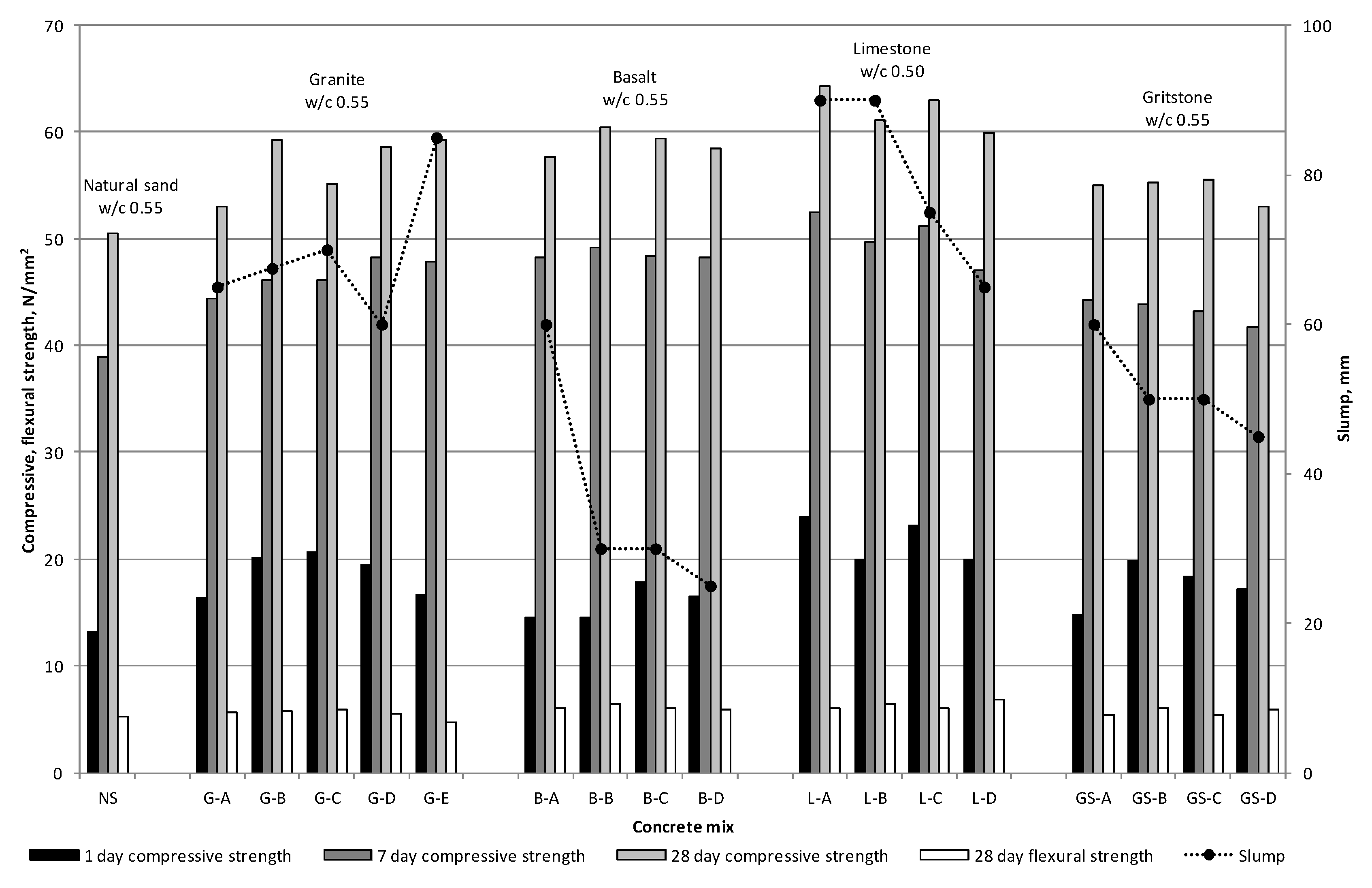

3.2. Concrete Results

4. Artificial Neural Network Modelling

4.1. Choice of Input Parameters

4.2. Dataset

4.3. Model Setup

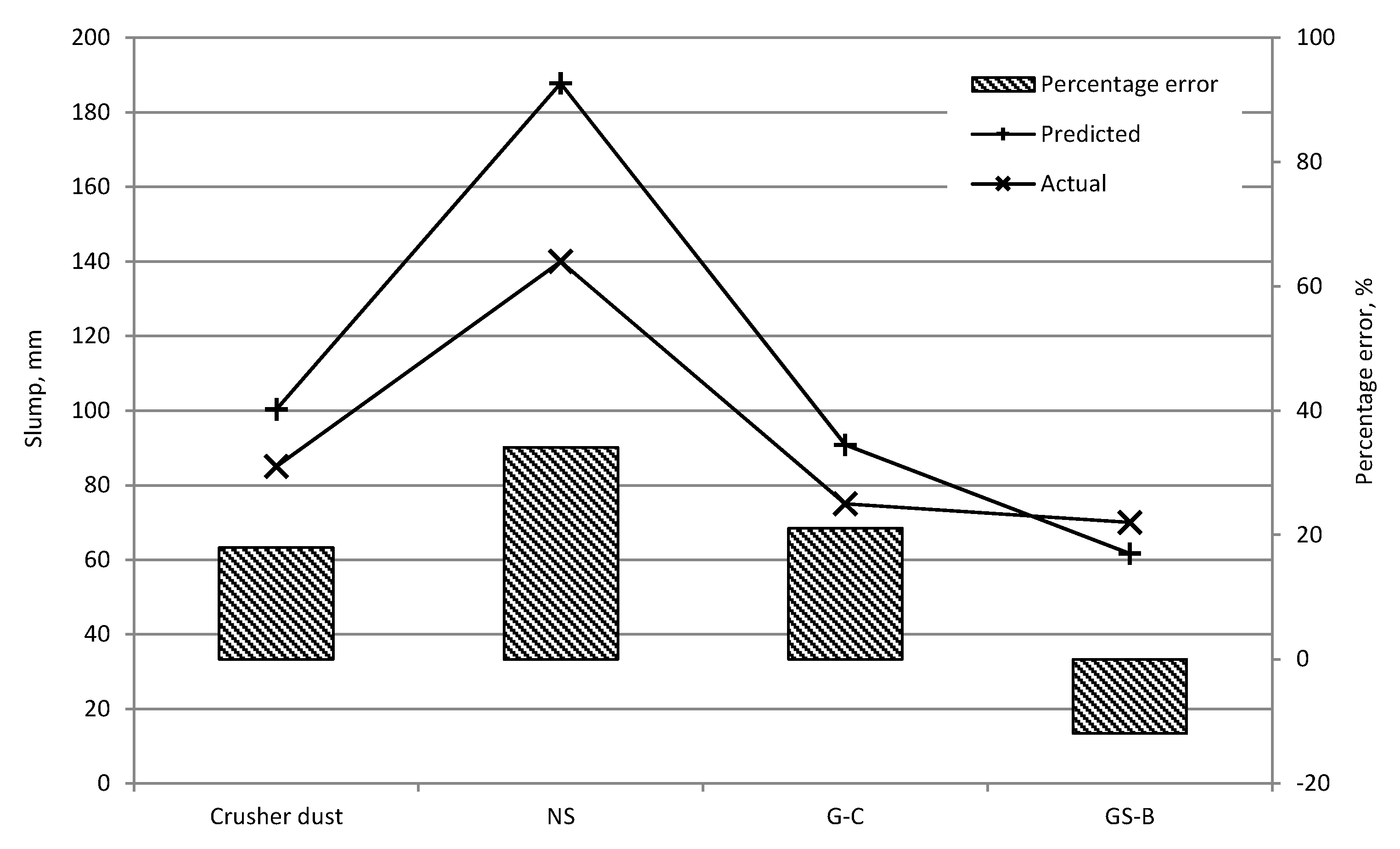

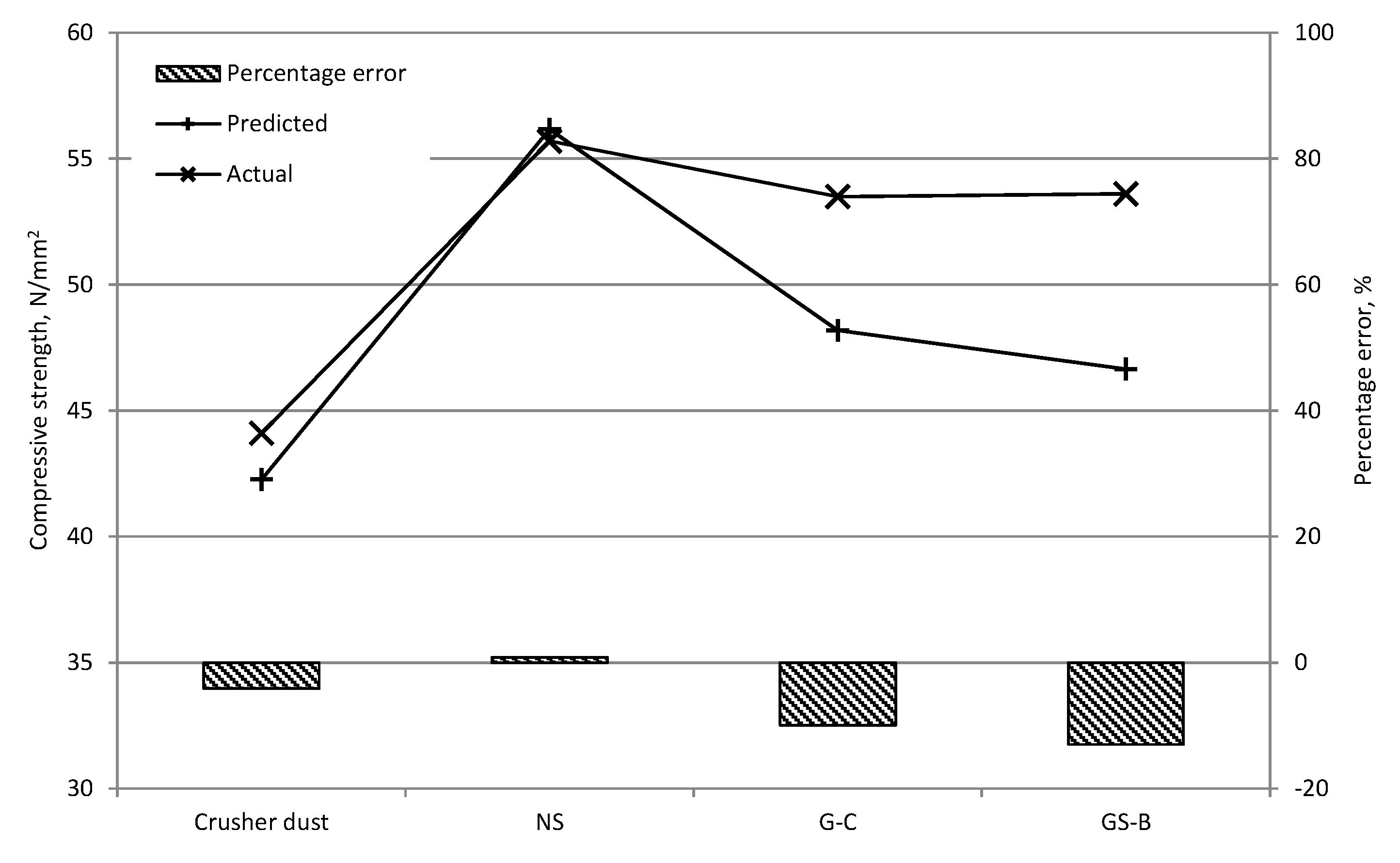

4.4. Model Evaluation

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Thomas, T.; Dumitru, I.; van Koeverden, M.; West, G.; Basford, G.; Lucas, G.; James, W.; Kovacs, T.; Clarke, P.; Guirguis, S. Manufactured Sand. National Test Methods and Specification Values. Available online: http://www.ccaa.com.au/imis_prod/documents/Library%20Documents/CCAA%20Reports/ManSand.pdf (accessed on 7 April 2016).

- Kaya, T.; Hashimoto, M.; Pettingell, H. The development of sand manufacture from crushed rock in Japan, using advanced VSI technology. In Proceedings of the International Center for Aggregates Research Symposium, Austin, TX, USA, 4–5 May 2009.

- Manning, D. Exploitation and Use of Quarry Fines; Report No: 087/MIST2/DACM/01; Mineral Solutions Limited: Manchester, UK, March 2004; pp. 1–60. Available online: http://www.sustainableaggregates.com/library/docs/mist/l0066_ma_2_4_003.pdf (accessed on 5 August 2015).

- Ahn, N.; Phelan, T.; Fowler, D.W.; Hudson, B. The Effects of High Fines on the Properties of Cement Mortar and Concrete. In Proceedings of the International Center for Aggregates Research 9th Annual Symposium, Austin, TX, USA, 22–25 April 2001.

- Marek, C.R. Importance of fine aggregate shape and grading on properties of concrete. In Proceedings of the International Center for Aggregates Research 3rd Annual Symposium, Austin, TX, USA, 1–4 March 1995.

- Gonçalves, J.P.; Tavares, L.M.; Toledo, F.R.D.; Fairbairn, E.M.R.; Cunha, E.R. Comparison of natural and manufactured fine aggregates in cement mortars. Cem. Concr. Res. 2007, 37, 924–932. [Google Scholar] [CrossRef]

- Li, B.; Ke, G.; Zhou, M. Influence of manufactured sand characteristics on strength and abrasion resistance of pavement cement concrete. Constr. Build. Mater. 2011, 25, 3849–3853. [Google Scholar] [CrossRef]

- Harrison, D.J.; Wilson, D.; Henney, P.J.; Hudson, J.M. Crushed Rock Sand in South Wales: A Reconnaissance Survey; Technical Report Report No: WF/00/003; British Geological Survey: Nottingham, UK, 2000; pp. 1–28. [Google Scholar]

- Quiroga, P.N.; Namshik, A.; David, W.F. Concrete mixtures with high microfines. ACI Mate J. 2006, 103, 258–264. [Google Scholar]

- Norvell, J.; Stewart, J.; Juenger, M.; Fowler, D. Influence of clays and clay-sized particles on concrete performance. J. Mater. Civ. Eng. 2007, 19, 1053–1059. [Google Scholar] [CrossRef]

- Li, B.; Zhou, M.; Wang, J. Effect of the methylene blue value of manufactured sand on performances of concrete. J. Adv. Concr. Technol. 2011, 9, 127–132. [Google Scholar]

- Celik, T.; Marar, K. Effects of crushed stone dust on some properties of concrete. Cem. Concr. Res. 1996, 26, 1121–1130. [Google Scholar] [CrossRef]

- Lohani, T.K.; Padhi, M.; Dash, K.P.; Jena, S. Optimum utilization of Quarry dust as partial replacement of sand in concrete. Int. J. Appl. Sci. Eng. Res. 2012, 1, 391–404. [Google Scholar]

- Pilegis, M.; Gardner, D.R.; Lark, B. Manufactured sand for a low carbon era. In Proceedings of the 8th International Conference: Concrete in the Low Carbon Era, Dundee, UK, 9–11 July 2012.

- Teychenne, D.C.; Franklin, R.E.; Erntroy, H.C. Design of Normal Concrete Mixes, 2nd ed.; Construction Research Communications Ltd.: Watford, UK, 1997; Available online: http://www.icie.ir/files/filebox/design%20of%20normal%20concrete%20mixes%20BRE.pdf (accessed on 2 March 2014).

- American Concrete Institute and Committee 211. Standard Practice for Selecting Proportions for Normal, Heavyweight, and Mass Concrete; American Concrete Institute: Detroit, MI, USA, 1997. [Google Scholar]

- Jones, M.R.; Zheng, L.; Newlands, M.D. Estimation of the filler content required to minimise voids ratio in concrete. Mag. Concr. Res. 2003, 55, 193–202. [Google Scholar] [CrossRef]

- Mohammed, M.H.; Emborg, M.; Pusch, R.; Knutsson, S. Packing Theory for Natural and Crushed Aggregate to Obtain the Best Mix of Aggregate: Research and Development. In Proceedings of the International Conference on Civil and Construction Engineering, Stockholm, Sweden, 11–12 July 2012.

- Al-Ansari, N.A.; Mohammed, M.H.; Pusch, R.; Knutsson, S. 2012 Optimization of Concrete by Minimizing Void Volume in Aggregate Mixture System. J. Adv. Sci. Eng. Res. 2012, 2, 208–222. [Google Scholar]

- Mangulkar, M.N.; Jamkar, S.S. Review of Particle Packing Theories Used For Concrete Mix Proportioning. Int. J. Sci. Eng. Res. 2013, 4, 143–148. [Google Scholar]

- De Larrard, F.; Sedran, T. Mixture-proportioning of high-performance concrete. Cem. Concr. Res. 2002, 32, 1699–1704. [Google Scholar] [CrossRef]

- Joudi-Bahri, I.; Lecomte, A.; Ouezdou, M.B.; Achour, T. Use of limestone sands and fillers in concrete without superplasticiser. Cem. Concr. Compos. 2012, 34, 771–780. [Google Scholar] [CrossRef]

- Alshihri, M.M.; Azmy, A.M.; El-Bisy, M.S. Neural networks for predicting compressive strength of structural light weight concrete. Constr. Build. Mater. 2009, 23, 2214–2219. [Google Scholar] [CrossRef]

- Duan, Z.H.; Kou, S.C.; Poon, C.S. Prediction of compressive strength of recycled aggregate concrete using artificial neural networks. Constr. Build. Mater. 2013, 40, 1200–1206. [Google Scholar] [CrossRef]

- Parichatprecha, R.; Nimityongskul, P. Analysis of durability of high performance concrete using artificial neural networks. Constr. Build. Mater. 2009, 23, 910–917. [Google Scholar] [CrossRef]

- Duan, Z.H.; Kou, S.C.; Poon, C.S. Using artificial neural networks for predicting the elastic modulus of recycled aggregate concrete. Constr. Build. Mater. 2013, 44, 524–532. [Google Scholar] [CrossRef]

- Tokyay, M.; Özdemir, M. Specimen Shape and Size Effect on the Compressive Strength of Higher Strength Concrete. Cem. Concr. Res. 1997, 27, 1281–1289. [Google Scholar] [CrossRef]

- Nikolaides, A.; Manthos, E.; Sarafidou, M. Sand equivalent and methylene blue value of aggregates for highway engineering. Found. Civ. Environ. Eng. 2007, 10, 111–121. [Google Scholar]

- Neville, A. Properties of Concrete, 4th ed.; Longman Group UK Limited: Harlow, UK, 1995; pp. 128–134. [Google Scholar]

- Li, B.; Wang, J.; Zhou, M. Effect of limestone fines content in manufactured sand on durability of low- and high-strength concretes. Constr. Build. Mater. 2011, 23, 2846–2850. [Google Scholar] [CrossRef]

- Menadi, B.; Kenai, S.; Khatib, J.; Aït-Mokhtar, A. Strength and durability of concrete incorporating crushed limestone sand. Constr. Build. Mater. 2009, 23, 625–633. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modelling slump flow of concrete using second-order regressions and artificial neural networks. Cem. Concr. Compos. 2007, 29, 474–480. [Google Scholar] [CrossRef]

- Multiple Back-Propagation. Available online: http://mbp.sourceforge.net/ (accessed on 10 April 2016).

- Fausett, L.V. Fundamentals of Neural Networks: Architectures, Algorithms, and Applications; Prentice-Hall: Englewood Cliffs, NJ, USA, 1994. [Google Scholar]

- Topçu, İ.B.; Sarıdemir, M. Prediction of compressive strength of concrete containing fly ash using artificial neural networks and fuzzy logic. Compos. Mater. Sci. 2008, 41, 305–311. [Google Scholar] [CrossRef]

- Yeh, I.-C. Modelling of strength of high-performance concrete using artificial neural networks. Cem. Concr. Res. 1998, 28, 1797–1808. [Google Scholar] [CrossRef]

- Donza, H.; Cabrera, O.; Irassar, E.F. High-strength concrete with different fine aggregate. Cem. Concr. Res. 2002, 32, 1755–1761. [Google Scholar] [CrossRef]

| Oxide | Oxide Composition (wt %) |

|---|---|

| SiO2 | 19.7 |

| Al2O3 | 4.8 |

| Fe2O3 | 3.1 |

| CaO | 63.6 |

| MgO | 1.2 |

| SO3 | 3.6 |

| Cl− | 0.1 |

| Free CaO | 2.3 |

| Na2Oeq 1 | 0.7 |

| LOI 2 | 2.7 |

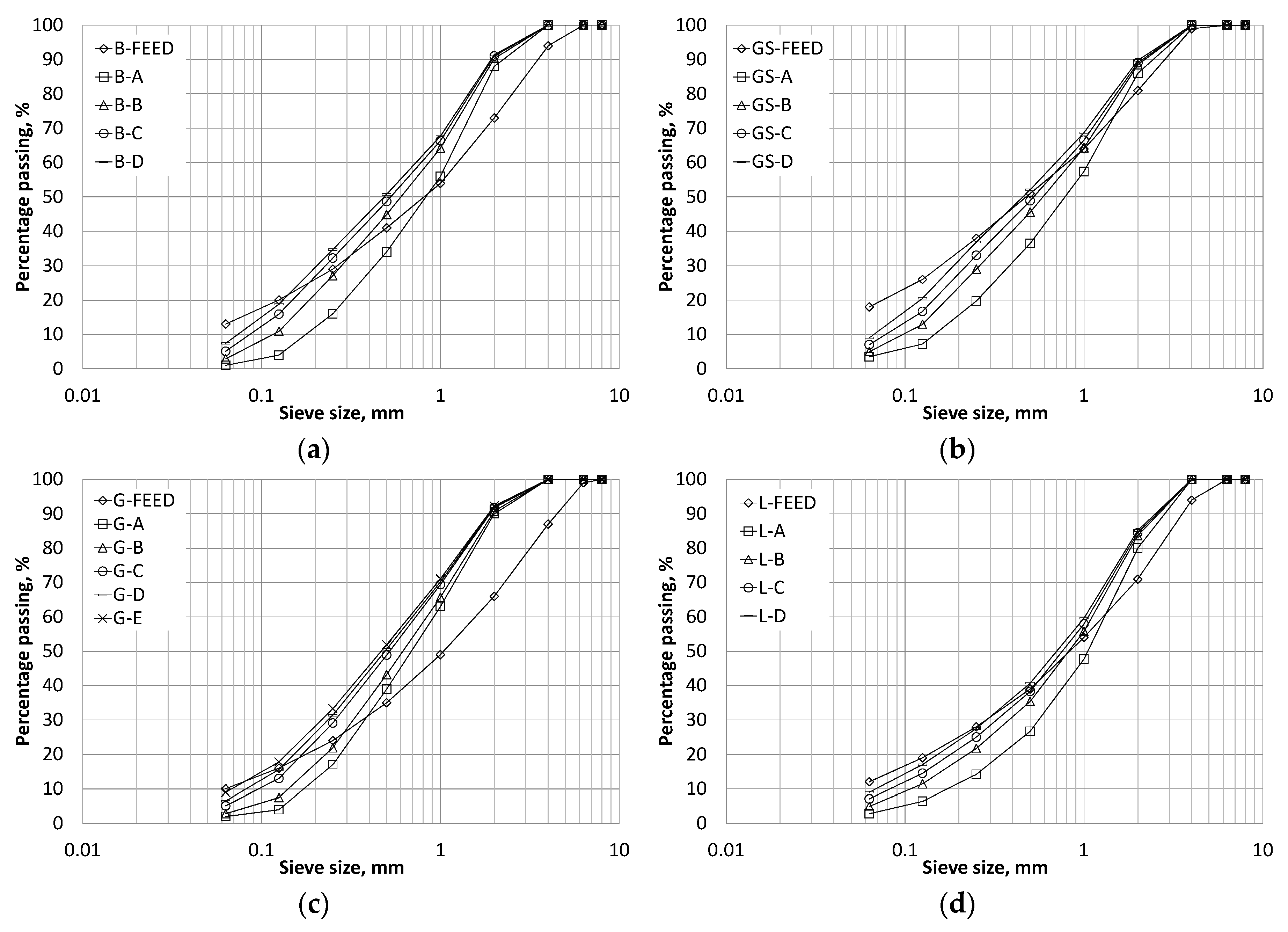

| Description | Fines Content 1 | Type | Notation |

|---|---|---|---|

| Sea dredged natural sand | 1.0 | Natural | NS |

| Basalt crusher dust | 10.0 | Crushed | B-FEED |

| Basalt sand | 1.0 | Manufactured | B-A |

| Basalt sand | 2.9 | Manufactured | B-B |

| Basalt sand | 5.1 | Manufactured | B-C |

| Basalt sand | 7.4 | Manufactured | B-D |

| Granite crusher dust | 13.0 | Crushed | G-FEED |

| Granite sand | 2.0 | Manufactured | G-A |

| Granite sand | 2.9 | Manufactured | G-B |

| Granite sand | 5.1 | Manufactured | G-C |

| Granite sand | 6.5 | Manufactured | G-D |

| Granite sand | 9.0 | Manufactured | G-E |

| Limestone crusher dust | 12.0 | Crushed | L-FEED |

| Limestone sand | 2.8 | Manufactured | L-A |

| Limestone sand | 4.9 | Manufactured | L-B |

| Limestone sand | 7.1 | Manufactured | L-C |

| Limestone sand | 9.0 | Manufactured | L-D |

| Gritstone crusher dust | 18.0 | Crushed | GS-FEED |

| Gritstone sand | 3.5 | Manufactured | GS-A |

| Gritstone sand | 5.0 | Manufactured | GS-B |

| Gritstone sand | 7.0 | Manufactured | GS-C |

| Gritstone sand | 9.0 | Manufactured | GS-D |

| Cement (kg/m3) | FA (kg/m3) | CA (kg/m3) | w/c Ratio | Admixture (L/m3) |

|---|---|---|---|---|

| 350 | 753 | 1040 | Varies 1 0.55 2 | 0 1 Varies 3 (refer to Section 3.2) |

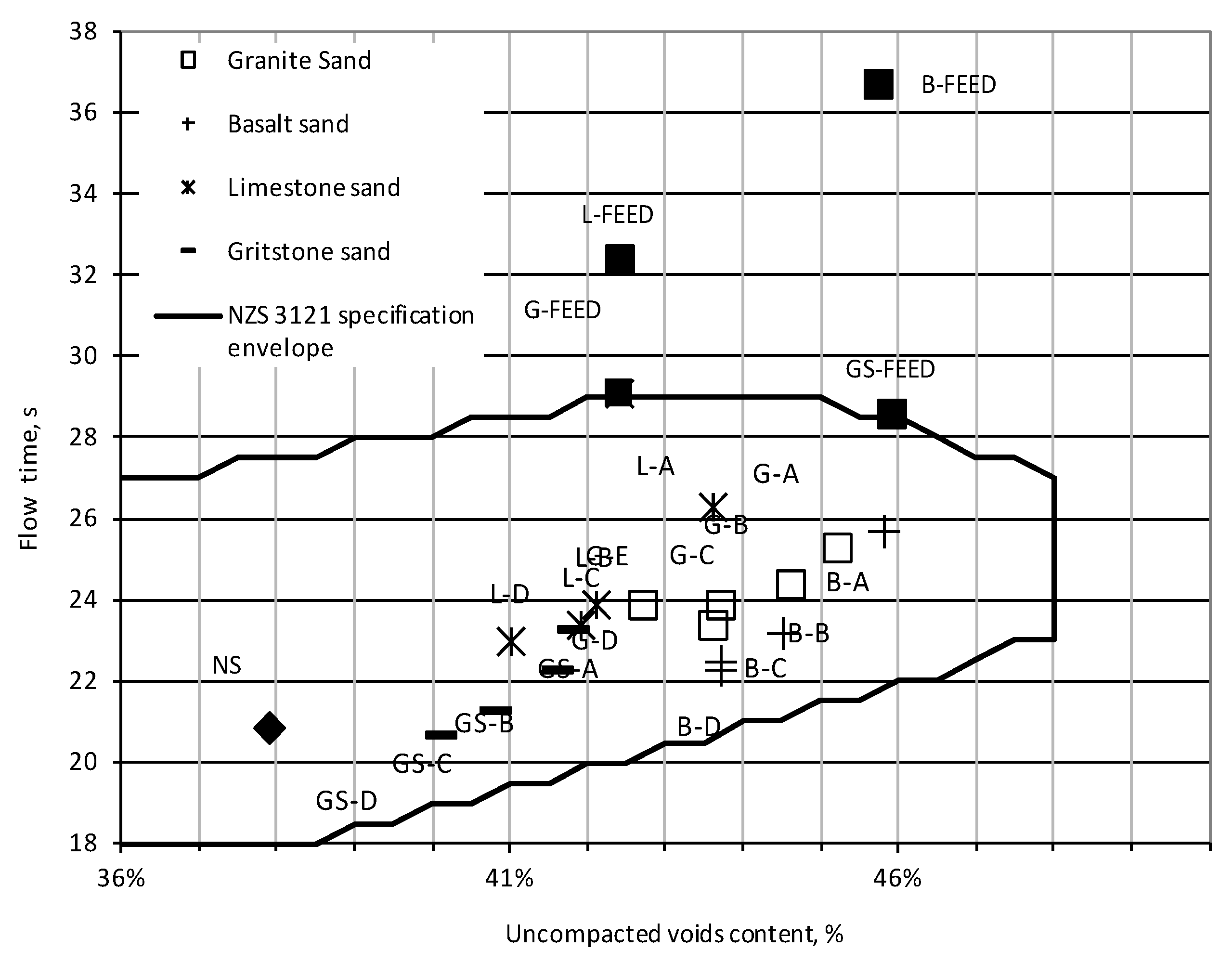

| Aggregate Property | NS | G-FEED | G-A G-B G-C G-D | B-FEED | B-A B-B B-C B-D | L-FEED | L-A L-B L-C L-D | GS-FEED | GS-A GS-B GS-C GS-D |

|---|---|---|---|---|---|---|---|---|---|

| WA24, % | 1.04 | 0.58 | 0.58 | 1.92 | 1.67 | 0.62 | 0.45 | 1.53 | 0.98 |

| ρrd, Mg/m3 | 2.63 | 2.62 | 2.61 | 2.83 | 2.87 | 2.85 | 2.85 | 2.64 | 2.57 |

| Mix Notation | Phase 1 | Phase 2 | |

|---|---|---|---|

| Entrapped Air (%) | Entrapped Air (%) | Admixture Dosage (L/m3) | |

| NS | 0.50 | 0.90 | 0.00 |

| G-A | 0.45 | 1.50 | 0.00 |

| G-B | 1.60 | 1.40 | 0.00 |

| G-C | 0.90 | 1.30 | 1.25 |

| G-D | 0.65 | 1.40 | 0.62 |

| G-E | 0.78 | 1.40 | 1.00 |

| B-A | 0.50 | 1.41 | 2.75 |

| B-B | 0.50 | 1.60 | 2.75 |

| B-C | 0.45 | 1.30 | 3.30 |

| B-D | 0.65 | 1.80 | 3.30 |

| L-A | 1.40 | 1.30 | 1.63 |

| L-B | 1.50 | 1.30 | 1.10 |

| L-C | 1.48 | 1.10 | 1.35 |

| L-D | 1.38 | 0.80 | 1.10 |

| GS-A | 1.40 | 1.28 | 2.45 |

| GS-B | 0.78 | 1.30 | 2.75 |

| GS-C | 1.00 | 1.35 | 2.75 |

| GS-D | 1.20 | 1.56 | 2.75 |

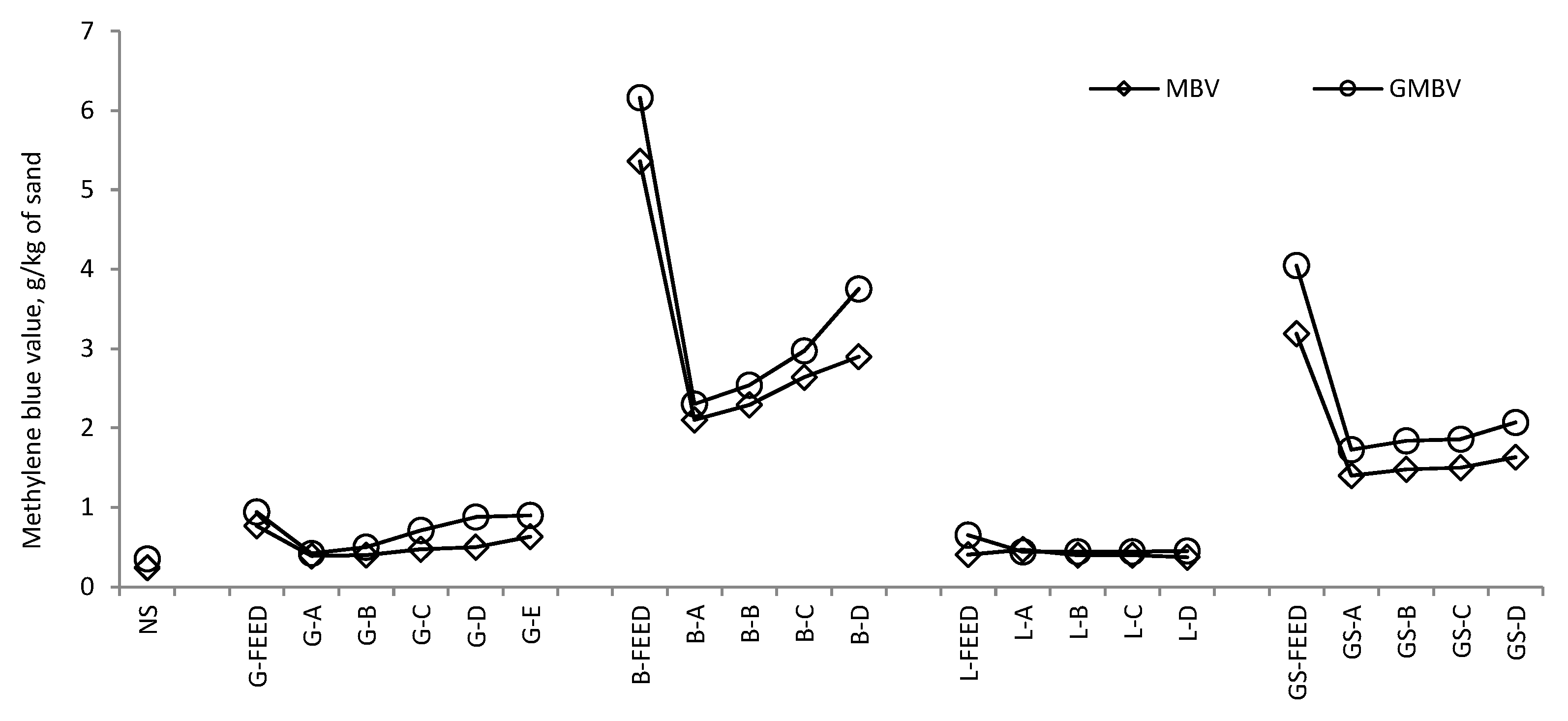

| Variable | Minimum | Maximum | Average | Influence |

|---|---|---|---|---|

| w/c ratio | 0.48 | 0.75 | 0.62 | Mix composition |

| Admixture (L/m3) | 0 | 3.3 | 1.65 | Mix composition |

| GMBV (g/kg of sand) | 0.35 | 6.16 | 3.26 | Quality of fines |

| SE | 27 | 94 | 60.5 | Quality of fines |

| Water absorption (%) | 0.45 | 1.92 | 1.19 | Quality of fines |

| Voids (%) | 37.9 | 45.9 | 41.9 | Grading, shape & texture |

| Flow time (s) | 20.7 | 36.7 | 28.7 | Grading, shape & texture |

| Fines (% of FA) | 1 | 18 | 9.5 | Grading |

| 28 days f’c (N/mm2) | 31.3 | 64.3 | – | Result |

| Slump (mm) | 25 | 300 1 | – | Result |

| Model | RMS (mm) | Model | RMS (N/mm2) |

|---|---|---|---|

| 8-8-1 slump | 13.36 | 8-8-1 strength | 2.70 |

| 8-6-1 slump | 13.58 | 8-6-1 strength | 2.61 |

| 8-4-1 slump | 11.50 | 8-4-1 strength | 2.87 |

| 8-2-1 slump | 7.97 | 8-2-1 strength | 4.09 |

| Validation Mix | w/c Ratio | Admixture (L/m3) | GMBV (g/Kg of Sand) | SE | Voids (%) | Flow Time (s) | Water Absorption (%) | Fines Content (%) |

|---|---|---|---|---|---|---|---|---|

| Crusher dust | 0.65 | 0 | 1.55 | 44 | 42.2 | 36.6 | 0.77 | 9.3 |

| NS | 0.51 | 0 | 0.35 | 94 | 37.9 | 20.9 | 1.04 | 1.0 |

| G-C | 0.60 | 0 | 0.71 | 71 | 43.7 | 23.9 | 0.58 | 5.1 |

| GS-B | 0.60 | 3 | 1.84 | 30 | 41.6 | 22.3 | 0.98 | 5.0 |

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pilegis, M.; Gardner, D.; Lark, R. An Investigation into the Use of Manufactured Sand as a 100% Replacement for Fine Aggregate in Concrete. Materials 2016, 9, 440. https://doi.org/10.3390/ma9060440

Pilegis M, Gardner D, Lark R. An Investigation into the Use of Manufactured Sand as a 100% Replacement for Fine Aggregate in Concrete. Materials. 2016; 9(6):440. https://doi.org/10.3390/ma9060440

Chicago/Turabian StylePilegis, Martins, Diane Gardner, and Robert Lark. 2016. "An Investigation into the Use of Manufactured Sand as a 100% Replacement for Fine Aggregate in Concrete" Materials 9, no. 6: 440. https://doi.org/10.3390/ma9060440