3.1. Optimal Conditions

The performance of the photo-Fenton system depends on different variables such as pH, initial iron concentration and hydrogen peroxide dosage [

22]. Obviously, defining the optimal levels of all three variables would require a large number of experiments. To simplify the experimental analysis, we should understand the roles of these variables.

First, it is well known that the Fenton reaction depends strongly on the ferrous ion concentration. Some studies have reported that an increase in the concentration of Fe(III) ions increases the rate of degradation continuously and there is no optimum value [

23]. However, this has not been confirmed by other studies yet [

24]. There is a possible existence of a limiting catalytic concentration of Fe

2+ above which the rate of the reaction does not increase, or it becomes lower. However, the hypothesis of application of an optimized amount of metal is very important since one of the main disadvantages associated with the homogeneous photo-Fenton reaction is the formation of large amounts of metal containing sludge at the end of the process. Such sludge does not only deliver a high environmental impact, implying additional associated costs, but these also represent the loss of significant quantities of catalytic metals [

25].

Operating pH is one of the crucial factors affecting the rates of degradation, and for the photo-Fenton oxidations strongly acidic conditions are favored. A maximum catalytic activity was observed around PH = 2.8 [

26,

27]. This activity diminishes drastically with an increase or decrease of pH. For higher pH values, low activity is detected because of the decrease of free iron species due to ferric oxyhydroxide precipitation, formation of different complex species and breakdown of H

2O

2 to O

2 and H

2O [

28,

29]. Low activity at pH values, more acidic than the optimal level, results from Fe(III) forming different complex species in solution [

30].

The amount of hydrogen peroxide is another parameter that influences the photo-Fenton process. It has been shown that increasing the concentration of H

2O

2 at optimum pH increases the rate of degradation continuously. However, there have been no reports where an optimum has been observed with respect to the hydrogen peroxide concentration beyond which the rate of degradation significantly drops [

26].

3.2. RSM Model Development

In this study, the effect of three factors on the photo-Fenton process including hydrogen peroxide, pH and ferrous ion concentration were selected as factors in the Central Composite Design. As a response, the Total Organic Carbon (TOC) removal rate was chosen, a total number of 20 experiments were employed for the response surface modeling (

Table 2), and the order of experiments was arranged randomly. The observed and predicted results for the percent TOC removal are also depicted in

Table 2.

The MODDE software was used to calculate the coefficients of the second-order fitting equation and the model suitability was tested using the ANOVA test. Therefore, the second-order polynomial equation should be expressed by Equation (11) (conf. Equation (9)):

According to the monomial coefficient value of regression model Equation (11), X1 = −2.2 (H2O2), X2 = −11.9 (pH) and X3 = 10.2 (ferrous ion concentration), and the order of priority among the main effect of impact factors is pH value (X2) > ferrous ion concentration (X3) > H2O2 concentration (X1).

3.3. Statistical Analysis

In

Table 3, the results of the analysis of variance (ANOVA) are summarized to test the soundness of the model. Analysis of variance (ANOVA) is a statistical technique that subdivides the total variation in a set of data into component parts associated with specific sources of variation for the purpose of testing hypotheses on the parameters of the model [

28,

31]. The mean squares values were calculated by dividing the sum of the squares of each variation source by their degrees of freedom, and a 95% confidence level (α = 0.05) was used to determine the statistical significance in all analyses.

Results were assessed with various descriptive statistics such as the

p-value,

F-value, and the degree of freedom (df); the determination coefficient (

R2) of each coefficient in Equation (10) was determined by Fisher’s

F-test and values of probability >

F. As shown in

Table 3, a small probability value (

p < 0.001) indicates that the model was highly significant and could be used to predict the response function accurately. Goodness-of-fit for the model was also evaluated by coefficients of determination

R2 (correlation coefficient) and adjusted coefficients of determination

R2adj. The large value of the correlation coefficient

R2 = 0.986 indicated a high reliability of the model in predicting of TOC removal percentages, by which 98.6% of the response variability can be explained by the model.

3.4. Effects of Model Parameters and Their Interactions

The significance of each model parameter was determined by means of Fischer’s

F-value and

p-value. The

F-value is the test for comparing the curvature variance with residual variance and probability >

F (

p-value) is the probability of seeing the observed

F-value if the null hypothesis is true. Small probability values call for rejection of the null hypothesis and the curvature is not significant. Therefore, the larger the value of

F and the smaller the value of

p, the more significant the corresponding coefficient is [

32]. As shown in

Table 3, we concluded that the independent variables of the quadratic model, including the pH value (

X2), the ferrous ion concentration (

X3) and the second-order effect of the pH value (X

22), are highly significant parameters because

p < 0.001. Moreover, the H

2O

2 value (

X1), the interactions between the H

2O

2 concentration (

X1) and pH value (

X2), the interactions between the H

2O

2 concentration (

X1) and ferrous ion concentration (

X3) and the second-order effect of the ferrous ion value (

X32) are significant because

p < 0.05. The

p value >0.05 means that the model terms are insignificant. We can see from

Table 3 that interactions between the pH (

X2) and ferrous ion concentration (

X3), and the second-order H

2O

2 value (

X12) are insignificant.

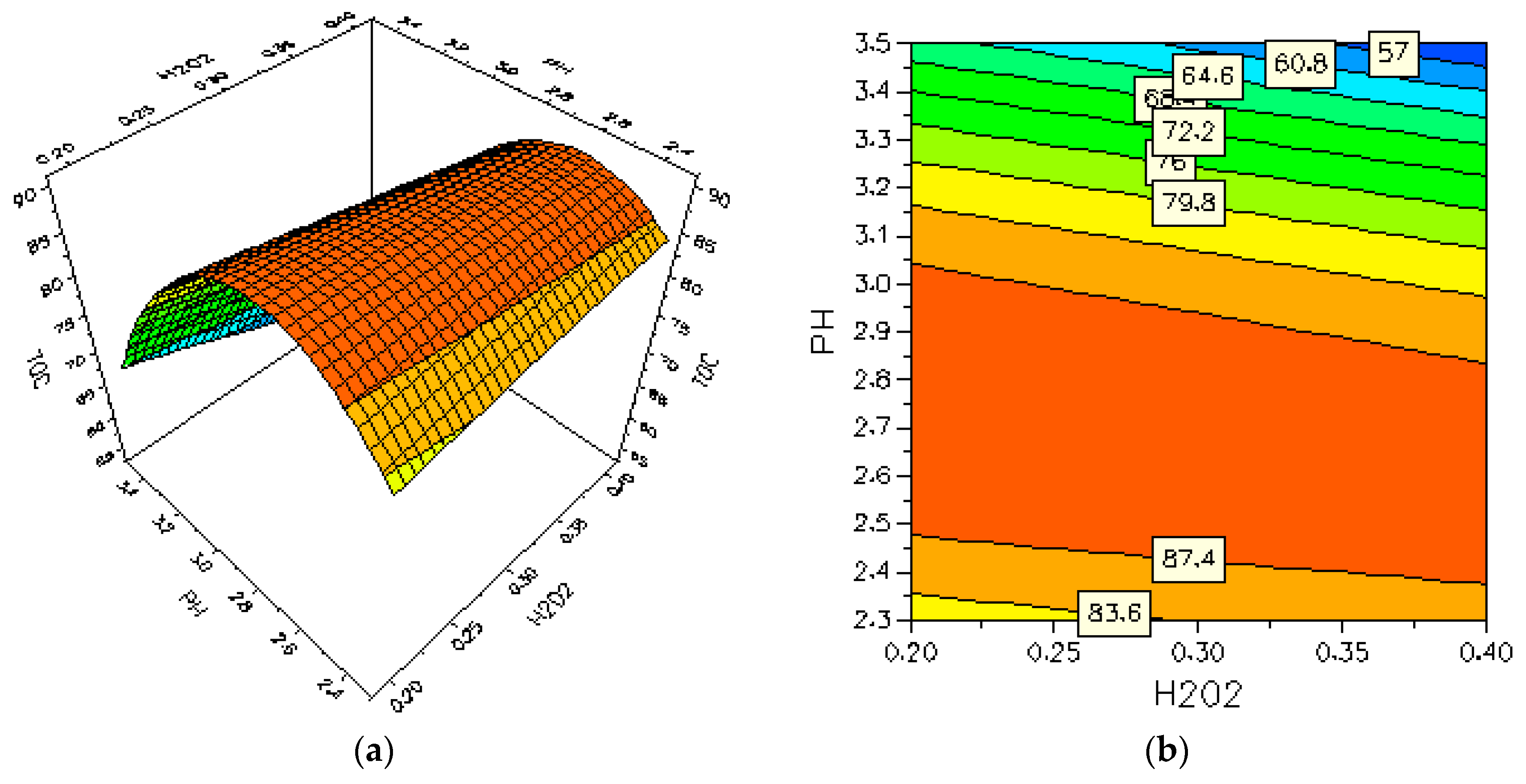

The MODDE software was used to produce three-dimensional (3D) response surfaces and two-dimensional (2D) contour plots. The 3D surfaces and 2D contour plots are graphical representations of the regression equation for the optimization of reaction conditions and are the most useful approach in revealing the conditions of the reaction system. In such plots, the response functions of two factors are presented while all other factors are at the fixed levels. The results of the interactions between three independent variables and the dependent variable are shown in

Figure 3.

As it can be seen in

Figure 3, depending on the reaction, the H

2O

2 concentration, pH and Fe(II) concentration may have a positive or negative effect on the TOC removal.

Figure 3a,b shows the interaction effect of pH and H

2O

2 concentration on the TOC removal rate. As it can be seen in the plots, there is an increase in the TOC removal rate with an increase of pH, with the maximum TOC removal rate in the pH range of 2.48 to 3.05. Beyond this value range, the TOC removal starts to decrease with the increase of the pH. Previous studies have also reported a maximum catalytic activity around the pH range of 2.8 [

28,

31]. On the other hand, the effect of H

2O

2 concentration on the TOC removal rate has similar trends, regardless of the pH value. The TOC removal rate decreased slightly with the increase of H

2O

2. It can be concluded from the contour plots that the optimum region of the TOC removal rate is in the pH range of 2.48 to 3.05.

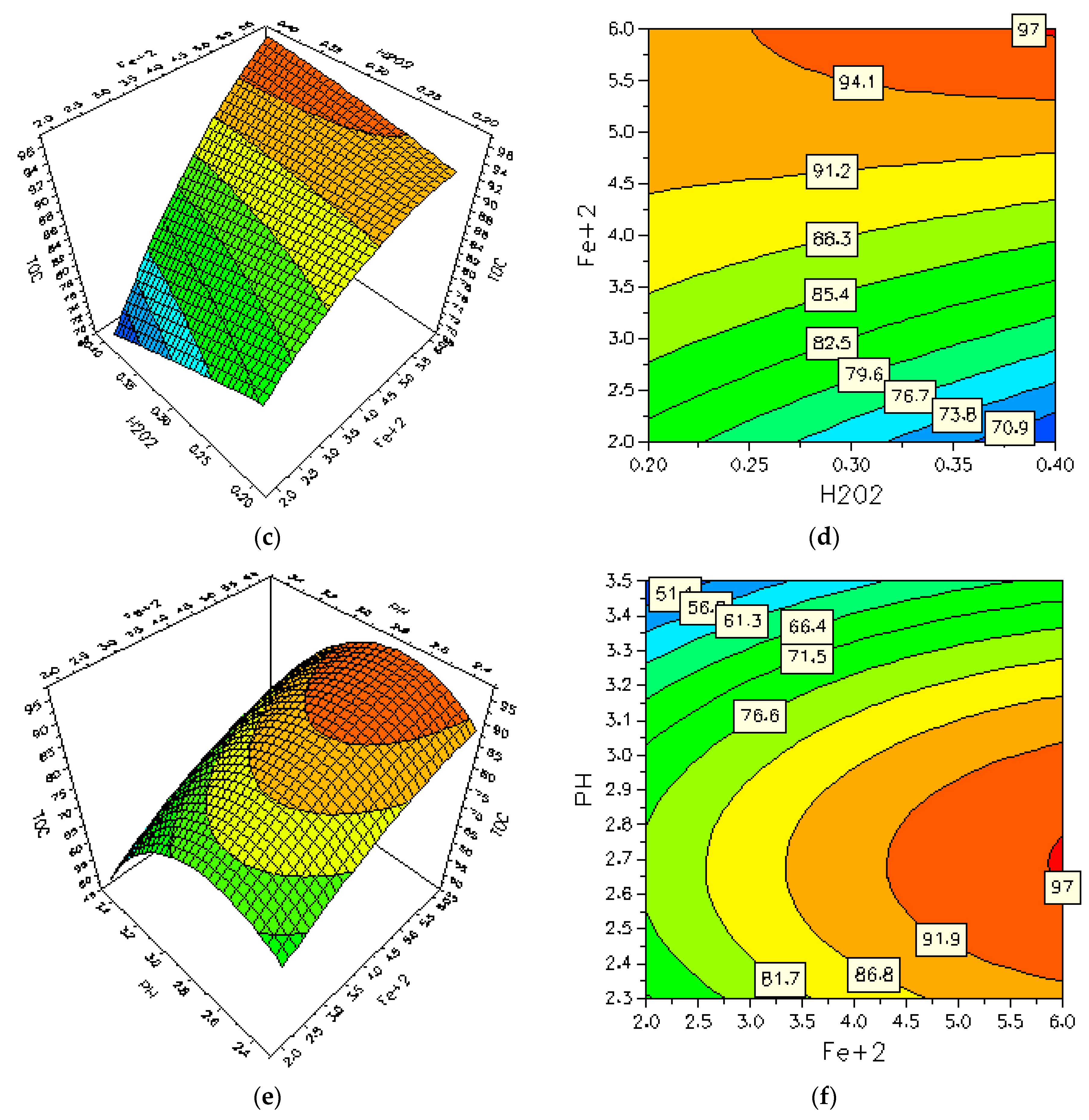

Figure 3c,d show the interaction effect of the Fe

2+ and H

2O

2 concentration on the TOC removal rate. As can be seen in the plots, the increase of the Fe

2+ concentration leads to an increase in the TOC removal rate. The ferrous ion acts as a catalytic agent in the decomposition of hydrogen peroxide. The increase in the initial concentration of the ferrous ion leads to more decomposition of the hydrogen peroxide and an increase in the degradation rate. We can see from the contour plots (

Figure 3d) that the TOC removal rate is larger than 91.5% in the Fe

2+ concentration range of 4.4–6.0 g∙L

−1 either at a low or high level of H

2O

2 dosage. Therefore, it can be concluded that the increasing H

2O

2 concentration gradually decreases the TOC removal rate. Increasing the H

2O

2 concentration may promote an inhibitory effect by the hydroxyl radicals scavenging (Equation (4)) and the formation of another radical (HO

2), which has an oxidation potential considerably smaller than HO

. [

21].

Figure 3e,f show the interaction effect of the pH and Fe

2+ concentration on the TOC removal rate. For a pH value below 2.4, the amount of soluble iron Fe

3+ decreases, inhibiting the radical OH formation [

33]. pH values above 3.0 lead to the precipitation of iron hydroxides, inhibiting both the regeneration of the active species of Fe

2+ and the formation of hydroxyl radicals. The contour plots show that the optimum region for the TOC removal rate is in the pH range of 2.6–2.7 and the Fe

2+ concentration is in the range of 5.8–6.0 mg∙L

−1, respectively.