Dielectric Spectroscopy in Biomaterials: Agrophysics

Abstract

:1. Introduction

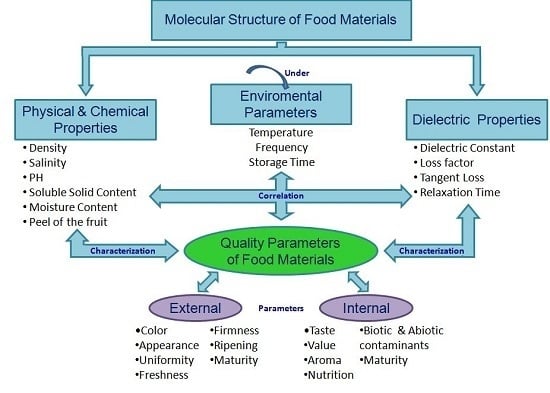

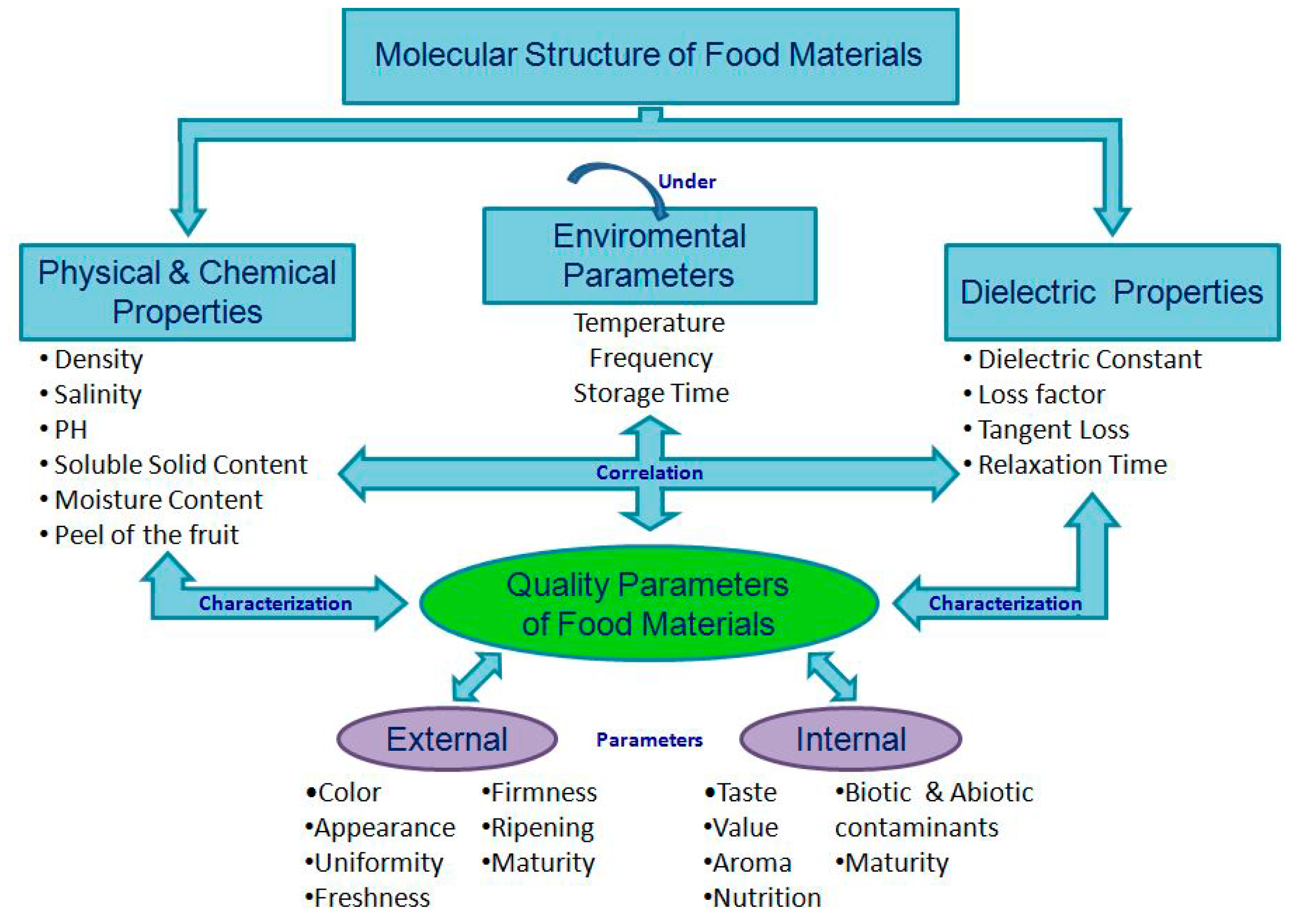

2. Dielectric Properties

2.1. Electrical Conductivity

2.2. Permittivity and Loss Factor

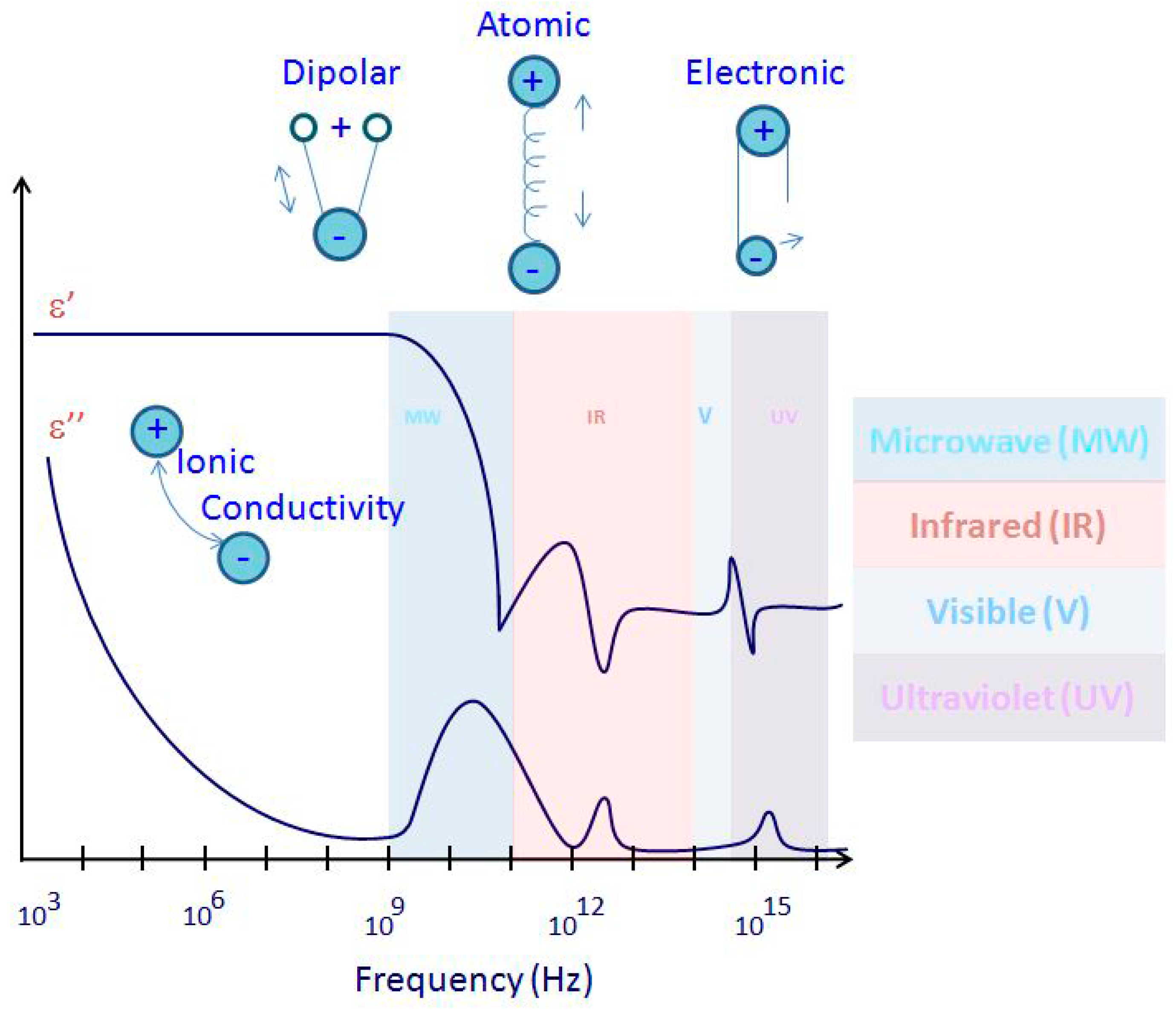

2.3. Polarization of Dielectrics

2.4. Power Density and Penetration Depth

2.5. A Sensing Technique

3. Factors, Sensors, and Equipment

3.1. Factors Affecting Dielectric Properties

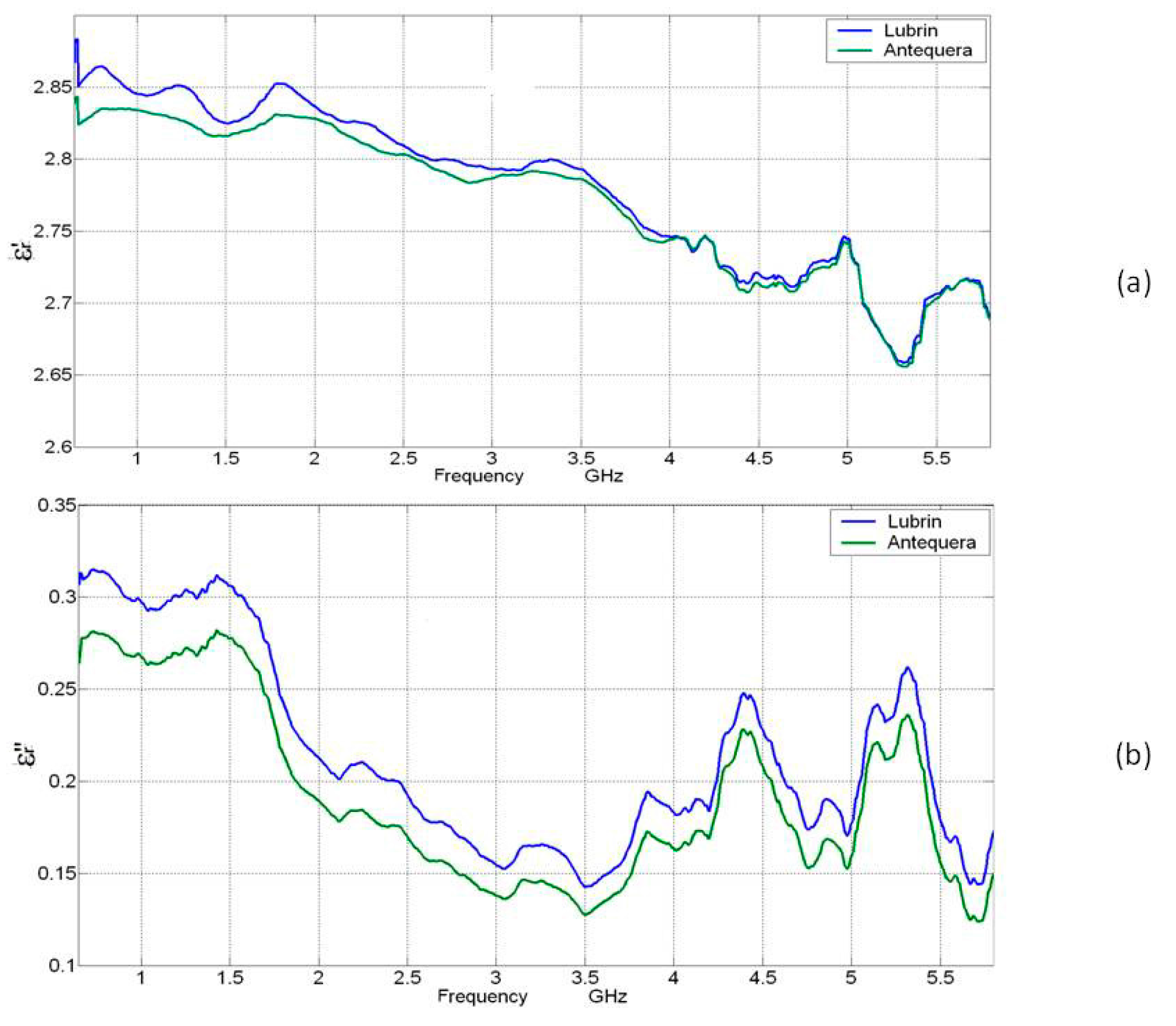

3.1.1. Frequency

3.1.2. Temperature

3.1.3. Molecular Structure

3.1.4. Water Content

3.1.5. Salinity, Fat, and Other Constituents

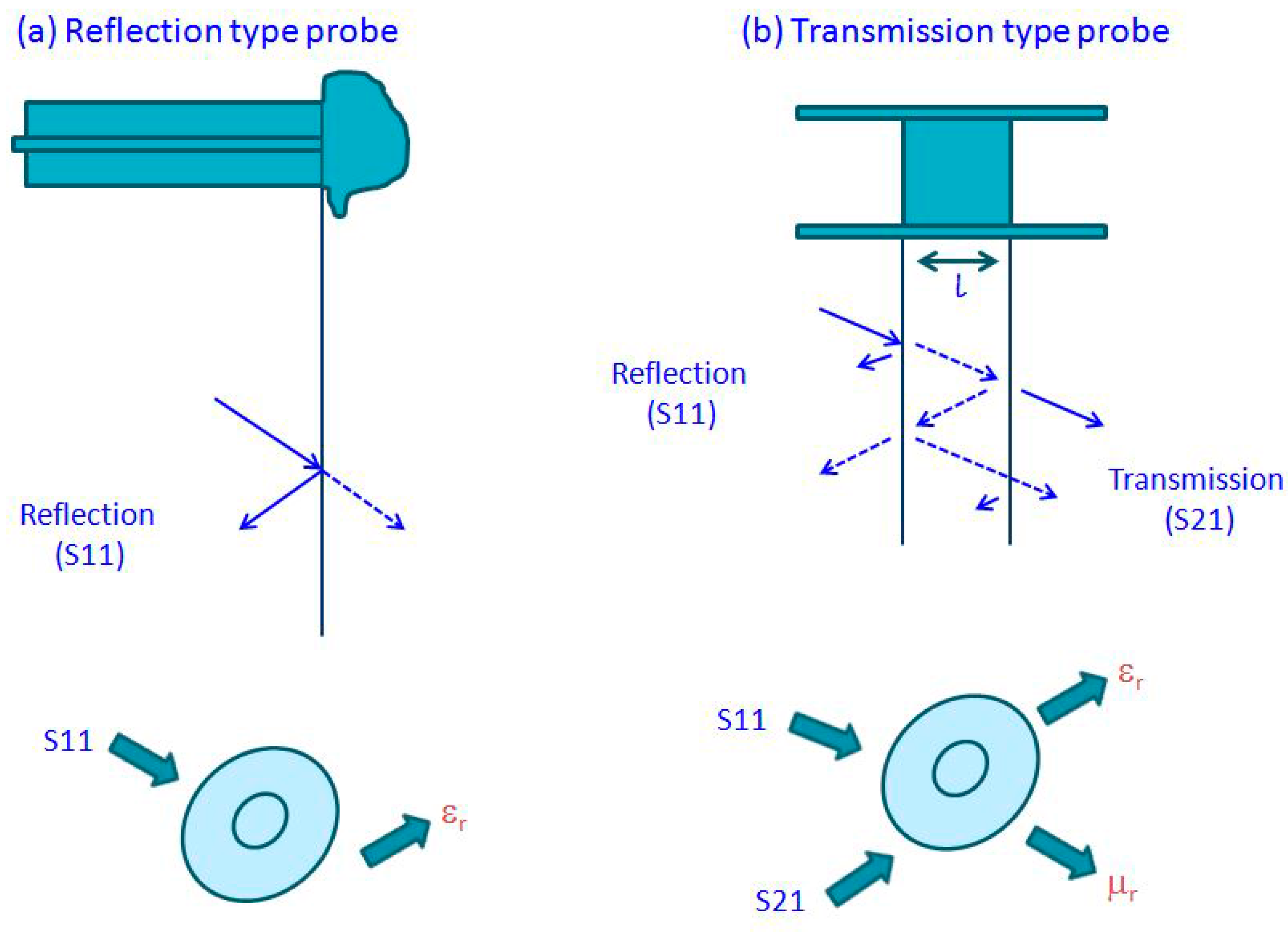

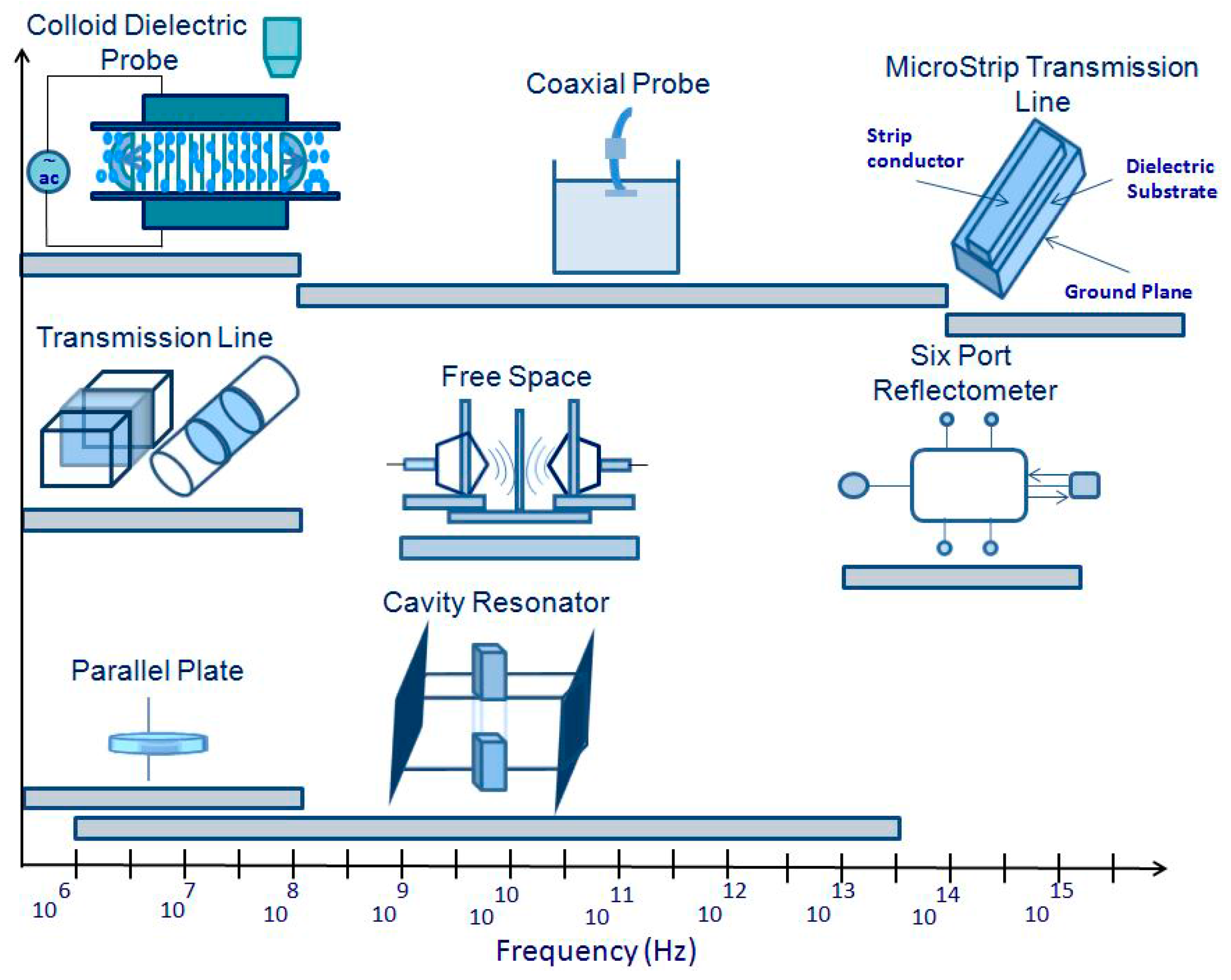

3.2. Dielectric Sensors

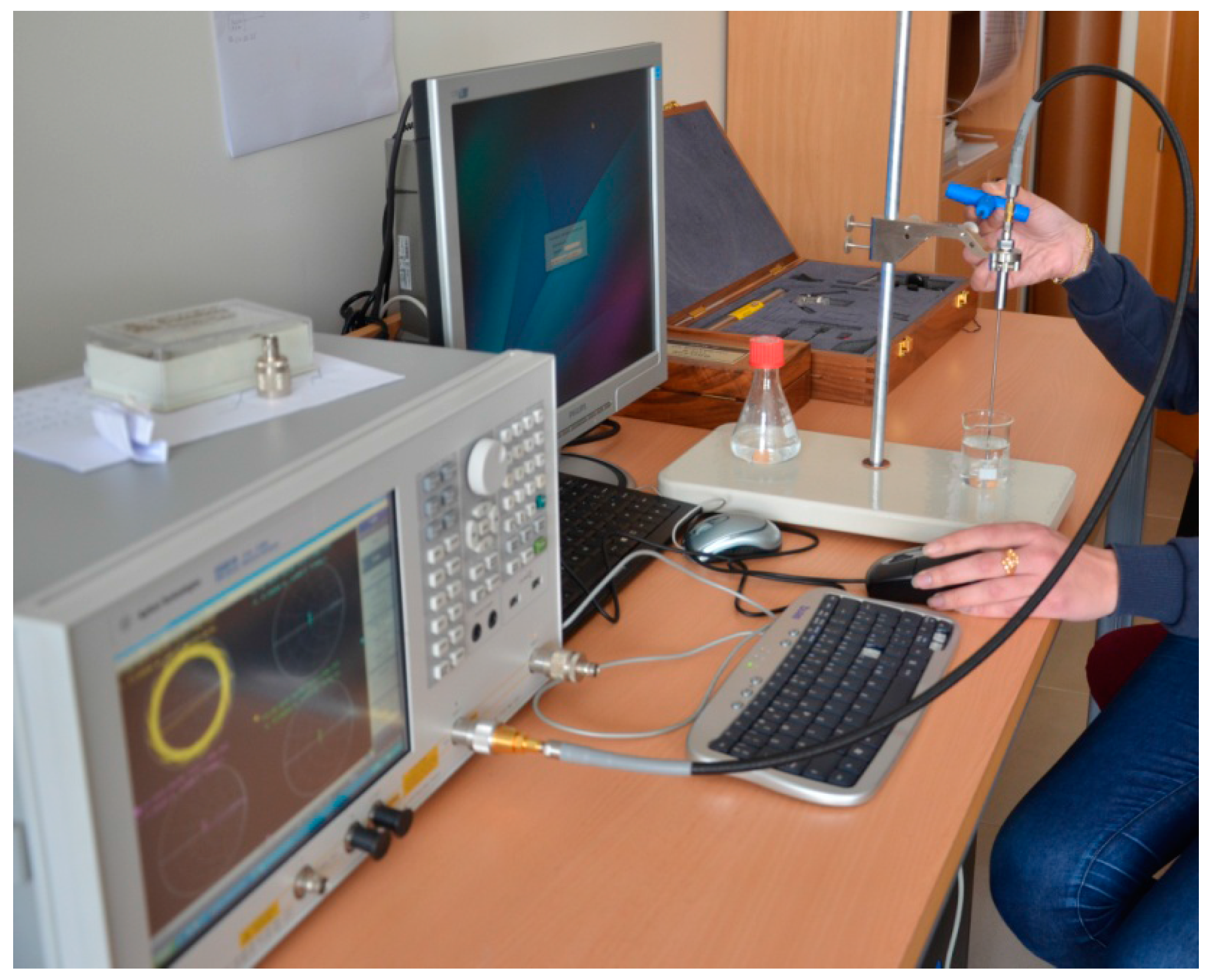

3.3. Measuring Equipments

3.4. Microwave Heating

3.5. Measuring Techniques

4. Applications

4.1. Fruit and Vegetables

4.2. Granular Materials of Agricultural Origin

4.3. Liquid Materials of Agricultural Origin

4.4. Dairy Products

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

Abbreviations

| σ | Electrical Conductivity |

| ε | Complex Dielectric Permittivity |

| δe | Dissipation Factor |

| A | Unit Cross Sectional Area |

| c | Speed of light |

| μ0 | Magnetic Constant |

| E | Electric field |

| |E| | Electric field strength inside the load |

| f | Frequency |

| FDR | Reflectometric Frequency Domain |

| L | Unit Length |

| MW | Microwave |

| P | Polarization |

| Pv | Energy developed per unit volume |

| R | Resistance |

| RF | Radio Frequency |

| SMA | Sub Miniature version A |

| SPR | Six-port reflectometer |

| tanσ | Loss Tangent |

| TDR | Time-Domain Reflectometry |

| TE | Transverse Electric |

| TM | Transverse Magnetic |

| tp | Travel time |

| VNA | Vector Network Analyzer |

| ε’ | Dielectric Constant |

| ε’’ | Loss Factor |

| ε0 | Relative permittivity of vacuum |

| εabs | Absolute Permittivity |

| Dielectric constant at high frequencies | |

| εσ´´ | Inertia of Ionic Conductivity |

| εD´´ | Inertia of Dipole molecules |

| εr | Relative Permittivity |

| εr* | Relative dielectric permittivity |

| Ω | Angular frequency |

| εs | Dielectric constant at low frequencies |

| τ | Relaxation Time |

References

- Khaled, D.E.; Novas, N.; Gazquez, J.A.; Garcia, R.M.; Manzano-Agugliaro, F. Fruit and vegetable quality assessment via dielectric sensing. Sensors 2015, 15, 15363–15397. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, H.M.; Windham, A.D.; Al-Ejji, M.M.; Al-Qahtani, N.H.; Hassan, M.K.; Mauritz, K.A.; Buchanan, J.P. Preparation and preliminary dielectric characterization of structured C60-Thiol-Ene polymer nanocomposites assembled using the Thiol-Ene click reaction. Materials 2015, 8, 7795–7804. [Google Scholar] [CrossRef]

- Du, C.J.; Sun, D.W. Learning techniques used in computer vision for food quality evaluation: A review. J. Food Eng. 2006, 72, 39–55. [Google Scholar] [CrossRef]

- Nelson, S. Dielectric Properties of Agricultural Materials and Their Applications; Academic Press: London, UK, 2015. [Google Scholar]

- Barbosa-Canovas, G.V.; Juliano, P.; Peleg, M. Engineering properties of foods, in food engineering. In Encyclopaedia of Life Support Systems (EOLSS); EOLSS: Oxford, UK, 2006. [Google Scholar]

- Trabelsi, S.; Paz, A.M.; Nelson, S.O. Microwave dielectric method for the rapid, non-destructive determination of bulk density and moisture content of peanut hull pellets. Biosyst. Eng. 2013, 115, 332–338. [Google Scholar] [CrossRef]

- Waser, R. Nanoelectronics and Information Technology, 3rd ed.; John Wiley & Sons: New York, NY, USA, 2012. [Google Scholar]

- Sosa-Moralesa, M.E.; Tiwari, G.; Wang, S.; Tang, J.; Garcia, H.S.; Lopez-Malo, A. Dielectric heating as a potential post-harvest treatment of disinfesting mangoes, Part I: Relation between dielectric properties and ripening. Biosyst. Eng. 2009, 103, 297–303. [Google Scholar] [CrossRef]

- Jha, S.N.; Narsaiah, K.; Basediya, A.L.; Sharma, R.; Jaiswal, P.; Kumar, R.; Bhardwaj, R. Measurement techniques and application of electrical properties for nondestructive quality evaluation of foods—A review. J Food Sci. Technol. 2011, 48, 387–411. [Google Scholar] [CrossRef] [PubMed]

- Maezawa, S.; Akimoto, K. Characteristics of electrical conductivity of low-temperature sensitive vegetables. Res. Bull Fac. Agric. Gifu Univ. 1996, 61, 81–86. [Google Scholar]

- Dejmek, P.; Miywaki, O. Relationship between the rheological properties of potato tuber tissue after various forms of processing. Biosci. Biotechnol. Biochem. 2002, 66, 1218–1223. [Google Scholar] [CrossRef] [PubMed]

- Ahmed, J.; Seyhun, N.; Ramaswamy, H.S.; Giorgio, L. Dielectric properties of potato puree in microwave frequency range as influenced by concentration and temperature. Int. J. Food. Prop. 2009, 12, 896–909. [Google Scholar] [CrossRef]

- Nyfors, E.; Vainikainen, P. Industrial Microwave Sensors, Microwave Symposium Digest; IEEE MTT-S International: Boston, MA, USA, 1991; Volume 3, pp. 1009–1012. [Google Scholar] [CrossRef]

- Talens, C.; Castro-Giraldez, M.; Fito, P.J. Study of the effect of microwave power coupled with hot air drying on orange peel by dielectric spectroscopy. LWT-Food Sci. Technol. 2016, 66, 622–628. [Google Scholar] [CrossRef]

- Kar, S.K. Structural and Electrical Studies of Ba (FeNb) 0.5O3 based High Dielectric Constant Materials Synthesized by Conventional and Microwave Processing Techniques. Ph.D. Thesis, National Institute of Technology, Rourkela, India, August 2014. [Google Scholar]

- Zhang, Y.; Wu, J.; Liang, L.; Zhou, G.; Jin, B.; Feng, Y. Effect of loss and coupling on the resonance of metamaterial: An equivalent circuit approach. Sci. China Inform. Sci. 2014, 57, 1–8. [Google Scholar] [CrossRef]

- Mudgett, R.E. Electrical Properties of Foods; Rao, M.A., Rizvi, S.S.H., Eds.; Marcel Dekker: New York, NY, USA, 1986; pp. 329–390. [Google Scholar]

- Ohlsson, T. Dielectric properties and microwave processing. In Food Properties and Computer-Aided Engineering of Food Processing Systems; Springer: Dordrecht, The Netherlands, 1989; pp. 73–92. [Google Scholar]

- Modest, M.F. Radiative Heat Transfer, 3rd ed.; Academic Press: Oxford, UK, 2013. [Google Scholar]

- Buffler, C.R. Viscosity and dielectric property measurements. J. Food Sci. 1993, 63, 983–986. [Google Scholar]

- Turner, M.M. Numerical effects on energy distribution functions in particle-in-cell simulations with Monte Carlo collisions: Choosing numerical parameters. Plasma Sources Sci. Technol. 2013, 22, 055001–055002. [Google Scholar] [CrossRef]

- Kildishev, A.V.; Boltasseva, A.; Shalaev, V.M. Planar photonics with metasurfaces. Science 2013, 339, 1232009. [Google Scholar] [CrossRef] [PubMed]

- Toyoda, K. The utilization of electric properties. In The Handbook of Non-Destructive Detection; Sumio, K., Ed.; Science Forum: Tokyo, Japan, 2003; pp. 108–126. [Google Scholar]

- El Khaled, D.; Castellano, N.N.; Gazquez, J.A.; Salvador, R.G.; Manzano-Agugliaro, F. Cleaner quality control system using bioimpedance methods: A review for fruits and vegetables. J. Clean. Prod. 2015. [Google Scholar] [CrossRef]

- Zoughi, R. Microwave Non-Destructive Testing and Evaluation Principles; Springer Science & Business Media: Dordrecht, The Netherlands, 2014. [Google Scholar]

- Zhang, M.; Soleimani, M. Simultaneous reconstruction of permittivity and conductivity using multi-frequency admittance measurement in electrical capacitance tomography. Meas. Sci. Technol. 2016, 27, 025405. [Google Scholar] [CrossRef]

- Venkatesh, M.S.; Raghavan, G.S.V. An overview of microwave processing and dielectric properties of agri-food materials. Biosys. Eng. 2004, 88, 1–18. [Google Scholar] [CrossRef]

- Sadahira, M.S.; Rodrigues, M.I.; Akhtar, M.; Murray, B.S.; Netto, F.M. Effect of egg white protein-pectin electrostatic interactions in a high sugar content system on foaming and foam rheological properties. Food Hydrocolloids 2016, 58, 1–10. [Google Scholar] [CrossRef]

- Park, S.H.; Nguyen, L.T.; Min, S.; Balasubramaniam, V.M.; Sastry, S.K. In Situ Thermal, Volumetric and Electrical Properties of Food Matrices Under Elevated Pressure and the Techniques Employed to Measure Them. In High Pressure Processing of Food; Part of the series Food Engineering Series; Springer: New York, NY, USA, 2016. [Google Scholar]

- Agranovich, D.; Renhart, I.; Ishai, P.B.; Katz, G.; Bezman, D.; Feldman, Y. A microwave sensor for the characterization of bovine milk. Food Control 2016, 63, 195–200. [Google Scholar] [CrossRef]

- Boreddy, S.R.; Subbiah, J. Temperature and moisture dependent dielectric properties of egg white powder. J. Food Eng. 2016, 168, 60–67. [Google Scholar] [CrossRef]

- Ozturk, S.; Kong, F.; Trabelsi, S.; Singh, R.K. Dielectric properties of dried vegetable powders and their temperature profile during radio frequency heating. J. Food Eng. 2016, 169, 91–100. [Google Scholar] [CrossRef]

- Xu, Y.; Xie, X.; Duan, Y.; Wang, L.; Cheng, Z.; Cheng, J. A review of impedance measurements of whole cells. Biosens. Bioelectron. 2016, 77, 824–836. [Google Scholar] [CrossRef] [PubMed]

- Tran, A.P.; Bogaert, P.; Wiaux, F.; Vanclooster, M.; Lambot, S. High-resolution space-time quantification of soil moisture along a hillslope using joint analysis of grood penetrating radar and frequency domain reflectometry data. J. Hydrol. 2015, 523, 252–261. [Google Scholar] [CrossRef]

- Chen, R.P.; Chen, Y.M.; Xu, W.; Yu, X. Measurement of electrical conductivity of pore water in saturated sandy soils using time domain reflectometry (TDR) measurements. Can. Geotech. J. 2010, 47, 197–206. [Google Scholar] [CrossRef]

- Kaatze, U. Non-conducting and conducting reference liquids for the calibration of dielectric measurement systems. In Proceedings of the 7th Conference ISEMA on Electromagnetic Wave Interaction with Water and Moist Substances, Hamamatsu, Japan, 15–18 April 2007.

- Matyushov, D.V.; Richert, R. Communication: Temperature derivative of the dielectric constant gives access to multipoint correlations in polar liquids. J. Chem. Phys. 2016, 144, 041102. [Google Scholar] [CrossRef] [PubMed]

- Stuchly, M.A.; Stuchly, S.S. Dielectric properties of biological substances—Tabulated. J. Microw. Power 1980, 15, 19–25. [Google Scholar]

- Hou, L.; Johnson, J.A.; Wang, S. Radio frequency heating for postharvest control of pests in agricultural products: A review. Postharvest Biol. Technol. 2016, 113, 106–118. [Google Scholar] [CrossRef]

- Stier, R.F. Tests to monitor quality of deep-frying fats and oils. Eur. J. Lipid Sci. Technol. 2004, 106, 766–771. [Google Scholar] [CrossRef]

- Beneroso, D.; Albero-Ortiz, A.; Monzó-Cabrera, J.; Díaz-Morcillo, A.; Arenillas, A.; Menéndez, J.A. Dielectric characterization of biodegradable wastes during pyrolysis. Fuel 2016, 172, 146–152. [Google Scholar] [CrossRef]

- Tulasidas, T.N.; Raghavan, G.S.V.; Mujumdar, A.S. Microwave drying of grapes in a single mode cavity at 2,450 MHz-II: Quality and energy aspects. Drying Technol. 1995, 13, 1973–1992. [Google Scholar] [CrossRef]

- Laybourn, A.; Katrib, J.; Palade, P.A.; Easun, T.L.; Champness, N.R.; Schröder, M.; Kingman, S.W. Understanding the electromagnetic interaction of metal organic framework reactants in aqueous solution at microwave frequencies. Phys. Chem. Chem. Phys. 2016, 18, 5419–5431. [Google Scholar] [CrossRef] [PubMed]

- Skierucha, W.; Wilczek, A.; Szypłowska, A. Dielectric spectroscopy in agrophysics. Int. Agrophys. 2012, 26, 187–197. [Google Scholar] [CrossRef]

- Kent, M.; Kress-Rogers, E. Microwave moisture and density measurements in particulate solids. Trans. Inst. Meas. Control 1986, 8, 167–168. [Google Scholar] [CrossRef]

- Nelson, S.O.; You, T.S. Microwave dielectric properties of corn and wheat kernels and soybeans. Trans. ASABE 1989, 32, 242–249. [Google Scholar] [CrossRef]

- Alange, R.C.; Khirade, P.P.; Birajdar, S.D.; Humbe, A.V.; Jadhav, K.M. Structural, magnetic and dielectrical properties of Al–Cr Co-substituted M-type barium hexaferrite nanoparticles. J. Mol. Struct. 2016, 1106, 460–467. [Google Scholar] [CrossRef]

- Trabelsi, S.; Nelson, S.O. Microwave sensing of quality attributes of agricultural and food products. IEEE Instrum. Meas. Mag. 2016, 19, 36–41. [Google Scholar] [CrossRef]

- Lewicki, P.P. Water as the determinant of food engineering properties. A review. J. Food Eng. 2004, 61, 483–495. [Google Scholar] [CrossRef]

- Zabaleta, L.; Albisu, M.; Ojeda, M.; Gil, P.F.; Etaio, I.; Perez-Elortondo, F.J.; Barron, L.J.R. Occurrence of sensory defects in semi-hard ewe’s raw milk cheeses. Dairy Sci. Technol. 2016, 96, 53–65. [Google Scholar] [CrossRef]

- Agilent. Basics of Measuring the Dielectric Properties of Materials; Application Note, 32; Keysight Technologies: Santa Clara, CA, USA, 2006. [Google Scholar]

- Kraszewski, A. Microwave aquametry: An effective tool for nondestructive moisture sensing. Subsurface Sens. Technol. Appl. 2001, 2, 347–362. [Google Scholar] [CrossRef]

- Ohlsson, T.; Bengtsson, N.E.; Risman, P.O. The frequency and temperature dependence of dielectric food data as determined by a cavity perturbation technique. J. Microw. Power 1974, 9, 129–145. [Google Scholar]

- Chelkowski, A. Physics of Dielectrics, 3rd ed.; Wydawnictwo Naukowe, P.W.N., Ed.; Warsaw, Poland, 1993. [Google Scholar]

- Rattanadecho, P.; Makul, N. Microwave-assisted drying: A review of the state-of-the-art. Drying Technol. 2016, 34, 1–38. [Google Scholar] [CrossRef]

- Ball, P.; Hallsworth, J.E. Water structure and chaotropicity: Their uses, abuses and biological implications. Phys. Chem. Chem. Phys. 2015, 17, 8297–8305. [Google Scholar] [CrossRef] [PubMed]

- Thomas, M.; Corry, B. A computational assessment of the permeability and salt rejection of carbon nanotube membranes and their application to water desalination. Phil. Trans. R. Soc. A 2016, 374, 20150020. [Google Scholar] [CrossRef] [PubMed]

- Chandrasekaran, S.; Ramanathan, S.; Basak, T. Microwave food processing—A review. Food Res. Int. 2013, 52, 243–261. [Google Scholar] [CrossRef]

- Wang, Y.; Zhang, L.; Gao, M.; Tang, J.; Wang, S. Temperature-and moisture-dependent dielectric properties of macadamia nut kernels. Food Bioprocess Tech. 2013, 6, 2165–2176. [Google Scholar] [CrossRef]

- Albert, A.; Salvador, A.; Fiszman, S.M. A film of alginate plus salt as an edible susceptor in microwaveable food. Food Hydrocolloids 2012, 27, 421–426. [Google Scholar] [CrossRef]

- Datta, A.K.; Nelson, S.O. Fundamental physical aspects of microwave absorption and heating in handbook of microwave technology for food applications. CHIPS 2000. [Google Scholar]

- Nakonieczna, A.; Paszkowski, B.; Wilczek, A.; Szypłowska, A.; Skierucha, W. Electrical impedance measurements for detecting artificial chemical additives in liquid food products. Food Control 2016, 66, 116–129. [Google Scholar] [CrossRef]

- Yu, D.U.; Shrestha, B.L.; Baik, O.D. Radio Frequency Dielectric Properties of Bulk Canola Seeds under Different Temperatures, Moisture Contents, and Frequencies for Feasibility of Radio Frequency Disinfestation. Int. J. Food Prop. 2015, 18, 2746–2763. [Google Scholar] [CrossRef]

- Venkatesh, M.S.; Raghavan, G.S.V. An overview of dielectric properties measuring technique. Can. Biosys. Eng. 2005, 47, 15–30. [Google Scholar]

- O’Driscoll, E.; O’Donnell, G.E. Industrial power and energy metering—A state-of-the-art review. J. Clean. Prod. 2013, 41, 53–64. [Google Scholar] [CrossRef]

- Agilent. Solutions for Measuring Permittivity and Permeability with LCR Meters and Impedance Analyzers; Application Note, 28; Keysight Technologies: Santa Clara, CA, USA, 2008. [Google Scholar]

- Rai, M. The investigation of MINIVNAPRO Vector Network Analyzer. Ph.D. Thesis, University of Applied Science, Helsinki, Finland, 2015. [Google Scholar]

- Agilent. Agilent 85070E Dielectric Probe Kit 200MHzto 50 GHz; Technical Overview, 12; Keysight Technologies: Santa Clara, CA, USA, 2008. [Google Scholar]

- Skierucha, W.; Walczak, R.T.; Wilczek, A. Comparison of open-ended coax and TDR sensors for the measurement of soil dielectric permittivity in microwave frequencies. Int. Agrophys. 2004, 18, 355–362. [Google Scholar]

- Singh, A.; Singh, S. Design and optimization of a modified Sierpinski fractal antenna for broadband applications. Appl. Soft Comput. 2016, 38, 843–850. [Google Scholar] [CrossRef]

- Shang, J.Q.; Rowe, R.K.; Umana, J.A.; Scholte, J.W. A complex permittivity measurement system for undisturbed/ compacted soils. Geotech. Test. J. 1999, 22, 165–174. [Google Scholar]

- Zhadobov, M.; Augustine, R.; Sauleau, R.; Alekseev, S.; Di Paola, A.; Le Quément, C.; Le Dréan, Y. Complex permittivity of representative biological solutions in the 2–67 GHz range. Bioelectromagnetics 2012, 33, 346–355. [Google Scholar] [CrossRef] [PubMed]

- Darne, C.; Xie, L.M.; Wosik, W.; Wosik, J. Complex Permittivity Measurements of Single-walled Carbon Nanotubes at Microwave Frequencies. Une 2016, 13, 15. [Google Scholar]

- Guo, W.; Zhu, X.; Yue, R.; Liu, H.; Liu, Y. Dielectric properties of Fuji apples from 10 to 4500 MHz during storage. J. Food Process. Preserv. 2011, 35, 884–890. [Google Scholar] [CrossRef]

- Skierucha, W.; Wilczek, A. A FDR sensor for measuring complex soil dielectric permittivity in the 10–500 MHz frequency range. Sensors 2010, 10, 3314–3329. [Google Scholar] [CrossRef] [PubMed]

- Wilczek, A.; Skierucha, W.; Szyplowska, A. Influence of moisture and salinity of soil on its dielectric permittivity. Acta Agrophys. 2011, 197, 5–87. [Google Scholar]

- Fleckenstein, M.; Fischer, S.; Bohlen, O.; Bäker, B. Thermal Impedance Spectroscopy-A method for the thermal characterization of high power battery cells. J. Power Sources 2013, 223, 259–267. [Google Scholar] [CrossRef]

- Bogena, H.; Huisman, J.A.; Oberdorster, C.; Vereecken, H. Evaluation of a low-cost soil water content sensor for wireless network applications. J. Hydrol. 2007, 344, 32–42. [Google Scholar] [CrossRef]

- Su, S.L.; Singh, D.N.; Baghini, M.S. A critical review of soil moisture measurement. Measurement 2014, 54, 92–105. [Google Scholar] [CrossRef]

- Kiviharju, K.; Salonen, K.; Moilanen, U.; Eerikäinen, T. Biomass measurement online: The performance of in situ measurements and software sensors. J. Ind. Microbiol. Biot. 2008, 35, 657–665. [Google Scholar] [CrossRef] [PubMed]

- Damez, J.L.; Clerjon, S. Quantifying and predicting meat and meat products quality attributes using electromagnetic waves: An overview. Meat Sci. 2013, 95, 879–896. [Google Scholar] [CrossRef] [PubMed]

- Kunle, O.F.; Egharevba, H.O.; Ahmadu, P.O. Standardization of herbal medicines—A review. Int. J. Biodivers. Conserv. 2012, 4, 101–112. [Google Scholar] [CrossRef]

- Skierucha, W.; Szypłowska, A.; Wilczek, A. Aquametry in agrophysics. In Advances in Agrophysical Research; InTech: Richardson, TX, USA, 2013. [Google Scholar]

- Malicki, M.A.; Walczak, R.T. Evaluating soil salinity status from bulk electrical conductivity and permittivity. Eur. J. Soil Sci. 1999, 50, 505–514. [Google Scholar] [CrossRef]

- Kupfer, K.; Trinks, E. Simulations and experiments for detection of moisture profiles with tdr in a saline environment. In Electromagnetic Aquametry; Kupfer, K., Ed.; Springer: New York, NY, USA, 2005. [Google Scholar]

- Subedi, S.; Kawamoto, K.; Karunarathna, A.K.; Moldrup, P.; Wollesen de Jonge, L.; Komatsu, T. Mini tensiometer-time domain reflectometry coil probe for measuring soil water retention properties. Soil Sci. Soc. Am. J. 2013, 77, 1517–1528. [Google Scholar] [CrossRef]

- Lin, C.P.; Tang, S.H.; Lin, C.H.; Chung, C.C. An improved modeling of TDR signal propagation for measuring complex dielectric permittivity. J. Earth Sci. 2015, 26, 827–834. [Google Scholar] [CrossRef]

- Janik, G. Spatial variability of soil moisture as information on variability of selected physical properties of soil. Int. Agrophys. 2008, 22, 35–43. [Google Scholar]

- Piuzzi, E.; Cataldo, A.; Catarinucci, L. Enhanced reflectometry measurements of permittivities and levels in layered petrochemical liquids using an ‘in-situ’ coaxial probe. Measurement 2009, 42, 685–696. [Google Scholar] [CrossRef]

- Durham, G.N. Using TDR Technology for Earthwork Compaction Quality Control; Presentation to the California Geotechnical Engineers Association: Sacramento, CA, USA, 2003. [Google Scholar]

- Skierucha, W. Temperature dependence of time domain reflectometry—Measured soil dielectric permittivity. J. Plant Nutr. Soil Sci. 2009, 172, 186–193. [Google Scholar] [CrossRef]

- Tseng, K.H.; Shiao, Y.F.; Chang, R.F.; Yeh, Y.T. Optimization of microwave-based heating of cellulosic biomass using Taguchi method. Materials 2013, 6, 3404–3419. [Google Scholar] [CrossRef]

- Guo, W.; Liu, Y.; Zhu, X.; Wang, S. Temperature dependent dielectric properties of honey associated with dielectric heating. J. Food Eng. 2011, 102, 209–216. [Google Scholar] [CrossRef]

- Wang, S.; Monzon, M.; Johnson, J.A.; Mitcham, E.J.; Tang, J. Industrial-scale radio frequency treatments for insect control in walnuts. Postharvest Biol. Technol. 2007, 45, 240–246. [Google Scholar] [CrossRef]

- Mishra, R.R.; Sharma, A.K. Microwave–material interaction phenomena: Heating mechanisms, challenges and opportunities in material processing. Compos. Part A Appl. Sci. Manuf. 2016, 81, 78–97. [Google Scholar] [CrossRef]

- Piyasena, P.; Dussault, C.; Koutchma, T.; Ramaswamy, H.; Awuah, G. Radio frequency heating of foods: Principles, applications and related properties—A review. Crit. Rev. Food Sci. Nutr. 2003, 43, 587–606. [Google Scholar] [CrossRef] [PubMed]

- Hlavacova, Z. Low frequency electric properties utilization in agriculture and food treatment. Res. Agric. Eng. 2003, 49, 125–136. [Google Scholar]

- Icier, F.; Baysal, T. Dielectric properties of food materials-2: Measurement techniques. Crit. Rev. Food Sci. Nutr. 2004, 44, 473–478. [Google Scholar] [CrossRef] [PubMed]

- Nelson, S.O.; Forbus, W.; Lawrence, K. Permittivities of fresh fruits and vegetables at 0.2 to 20 GHz. J. Microw. Power Electromagn. Energy 1994, 29, 81–93. [Google Scholar] [CrossRef] [PubMed]

- Herve, A.G.; Tang, J.; Luedecke, L.; Feng, H. Dielectric properties of cottage cheese and surface treatment using microwaves. J. Food Eng. 1998, 37, 389–410. [Google Scholar] [CrossRef]

- Nelson, S.O.; Bartley, P.G. Frequency and temperature dependence of the dielectric properties of food materials. Trans. ASAE 2002, 45, 1223–1227. [Google Scholar] [CrossRef]

- Nelson, S.O. Dielectric properties measurement techniques and applications. Trans. ASAE 1999, 42, 523–529. [Google Scholar] [CrossRef]

- Liao, X.; Raghavan, G.S.V.; Meda, V.; Yaylayan, V.A. Dielectric properties of supersaturated a- d-glucose aqueous solutions at 2450 MHz. J. Microw. Power Electromagn. Energy 2001, 36, 131–138. [Google Scholar] [PubMed]

- Kraszewski, A. Microwave aquametry—Electromagnetic interaction with water containing materials. Biosyst. Eng. 1996, 7, 1017–2394. [Google Scholar]

- González, A.M.; García, Á.; Benavente-Peces, C.; Pardo, L. Revisiting the characterization of the losses in piezoelectric materials from impedance spectroscopy at resonance. Materials 2016, 9, 72. [Google Scholar] [CrossRef]

- Puranik, S.; Kumbhakarne, A.K.; Mehrotra, S. Dielectric properties of honey-water mixture between 10 MHz and 10 GHz using time domain technique. J. Microw. Power Electromagn. Energy 1991, 24, 196–201. [Google Scholar]

- Kraszewski, A. Microwave aquametry. J. Microw. Power 1980, 15, 209–220. [Google Scholar]

- Keam, R.B.; Holmes, W.S. Uncertainty analysis of measurement of complex permittivity using micro strip transmission line. In Proceedings of the SBMO/IEEE MTT-S, Rio de Janeiro, Brazil, 24–27 July 1995.

- Hasted, J.B. Aqueous Dielectrics; Chapman and Hall: London, UK, 1973. [Google Scholar]

- Bientinesi, M.; Petarca, L.; Cerutti, A.; Bandinelli, M.; De Simoni, M.; Manotti, M.; Maddinelli, G. A radiofrequency/microwave heating method for thermal heavy oil recovery based on a novel tight-shell conceptual design. J. Petrol. Sci. Eng. 2013, 107, 18–30. [Google Scholar] [CrossRef]

- Lakerveld, R.; Sturm, G.S.; Stankiewicz, A.I.; Stefanidis, G.D. Integrated design of microwave and photocatalytic reactors. Where are we now? Curr. Opin. Chem. Eng. 2014, 5, 37–41. [Google Scholar] [CrossRef]

- Mudgett, R.E. Dielectric properties of food. In Microwaves in the Food Processing Industry; Decareau, R.V., Ed.; Academic: Orlando, FL, USA, 1985; pp. 15–37. [Google Scholar]

- Kato, K. Electrical density sorting and estimation of soluble solids content of watermelon. J. Agric. Eng. Res. 1997, 67, 161–170. [Google Scholar] [CrossRef]

- Garcia, A.; Torres, J.L.; De Blas, M. Dielectric properties of fruits. J. Food Eng. 2001, 48, 203–211. [Google Scholar]

- Bibi, F.; Guillaume, C.; Sorli, B.; Gontard, N. Plant polymer as sensing material: Exploring environmental sensitivity of dielectric properties using interdigital capacitors at ultra high frequency. Sens. Actuators B Chem. 2016. [Google Scholar] [CrossRef]

- Al Juhaimi, F.; Uslu, N.; Bozkurt, D.; Ghafoor, K.; Babiker, E.E.; Özcan, M.M. Effects of oven and microwave drying on phenolic contents and antioxidant activities in four apple cultivars. Qual. Assur. Saf. Crop. 2016, 8, 51–55. [Google Scholar] [CrossRef]

- Khan, M.S. Electrical and Optical Properties of Some Oil Seeds and Grains. Available online: http://shodhganga.inflibnet.ac.in/handle/10603/15081 (accessed on 15 January 2014).

- Jiao, Y.; Tang, J.; Wang, S.; Koral, T. Influence of dielectric properties on the heating rate in free-running oscillator radio frequency systems. J. Food Eng. 2014, 120, 197–203. [Google Scholar] [CrossRef]

- Moura, E.E.; Berbert, P.A.; Berbert-Molina, M.A.; Oliveira, M.T.R. Performance analysis of RF dielectric models for density-independent estimation of moisture content in sorghum. Powder Technol. 2013, 246, 369–378. [Google Scholar] [CrossRef]

- Shrestha, B.; Baik, O.D. Radio frequency selective heating of stored-grain insects at 27.12 MHz: A feasibility study. Biosyst. Eng. 2013, 114, 195–204. [Google Scholar] [CrossRef]

- Bansal, N.; Dhaliwal, A.S.; Mann, K.S. Dielectric properties of corn flour from 0.2 to 10 GHz. J. Food Eng. 2015, 166, 255–262. [Google Scholar] [CrossRef]

- Lizhi, H.; Toyoda, K.; Ihara, I. Dielectric properties of edible oils and fatty acids as a function of frequency, temperature, moisture and composition. J. Food Eng. 2008, 88, 151–158. [Google Scholar] [CrossRef]

- Shaw, T.M.; Galvin, J.A. High frequency heating characteristics of vegetable tissues determining from electrical conductivity measurements. In Proceedings of the Institution of Radio Engineering, CA, USA, 2006; Institute of Radio Engineering and Electronics Publication: Chaberska, Prague, 1949; Volume 37, pp. 83–86. [Google Scholar]

- Thompson, D.R.; Zachariah, G.L. Dielectric theory and bioelectrical measurements [Part II. Experimental (Apples)]. Trans. ASAE 1971, 14, 214–215. [Google Scholar]

- Guo, W.; Nelson, S.O.; Trabelsi, S.; Kays, S.J. Dielectric properties of honeydewmelons and correlation with quality. J. Microw. Power Electromagn. Energ. 2007, 41, 44–54. [Google Scholar]

- Ikediala, J.N.; Tang, J.; Drake, S.R.; Neven, L.G. Dielectric properties of apple cultivars and codling moth larvae. Trans. ASAE 2001, 43, 1175–1184. [Google Scholar] [CrossRef]

- Guo, W.; Nelson, S.O.; Trabelsi, S.; Kays, S.J. 10–1800 MHz dielectric properties of fresh apples during storage. J. Food Eng. 2007, 83, 562–569. [Google Scholar] [CrossRef]

- Castro-Giráldez, M.; Fito, P.J.; Chenoll, C.; Fito, P. Development of a dielectric spectroscopy technique for the determination of apple (Granny Smith) maturity. Innov. Food Sci. Emerg. Technol. 2010, 11, 749–754. [Google Scholar] [CrossRef]

- Guo, W.; Zhu, X.; Nelson, S.O.; Yue, R.; Liu, H.; Liu, Y. Maturity effects on dielectric properties of apples from 10 to 4500 MHz. LWT–Food Sci. Technol. 2011, 44, 224–230. [Google Scholar] [CrossRef]

- Bengtsson, N.E.; Risman, P.O. Dielectric properties of food at 3 GHz as determined by a cavity perturbation technique. II. Measurements on food materials. J. Microw. Power 1971, 6, 107–123. [Google Scholar]

- Jha, S.N.; Matsuoka, T.; Kawano, S. Changes in electrical resistance of eggplant with gloss, weight and storage period. Biosyst. Eng. 2004, 87, 119–123. [Google Scholar] [CrossRef]

- Nelson, S.O.; Trabelsi, S.; Kays, S.J. Dielectric spectroscopy of honeydew melons from 10 MHz to 1.8 GHz for quality sensing. Trans. ASABE 2006, 49, 1977–1982. [Google Scholar] [CrossRef]

- Kent, M. Electrical and Dielectric Properties of Food Materials. A Bibliography and Tabulated Data; Science and Technology: Hornchurch, UK, 1987. [Google Scholar]

- Pace, W.; Westphal, W.B.; Goldblith, S.A. Dielectric properties of commercial cooking oils. J. Food Sci. 1968, 33, 30–36. [Google Scholar] [CrossRef]

- Bohigas, X.; Tejada, J. Dielectric properties of acetic acid and vinegar in the microwave frequencies range 1–20 GHz. J. Food Eng. 2009, 94, 46–51. [Google Scholar] [CrossRef]

- Zhu, X.; Guo, W.; Wu, X. Frequency- and temperature dependent dielectric properties of fruit juices associated with pasteurization by dielectric heating. J. Food Eng. 2012, 109, 258–266. [Google Scholar] [CrossRef]

- Garcia, A.; Torres, J.L.; De Blas, M.; De Francisco, A.; Illanes, R. Dielectric characteristics of grape juice and wine. Biosyst. Eng. 2004, 88, 343–349. [Google Scholar] [CrossRef]

- Bohigas, X.; Amigó, R.; Tejada, J. Characterization of sugar content in yoghurt by means of microwave spectroscopy. Food Res. Int. J. 2008, 41, 104–109. [Google Scholar] [CrossRef]

- Nunes, A.C.; Bohigas, X.; Tejada, J. Dielectric study of milk for frequencies between 1 and 20 GHz. J. Food Eng. 2006, 76, 250–255. [Google Scholar] [CrossRef]

| Technique | Frequency Range (Hz) | Description | Material | Advantages | Disadvantages |

|---|---|---|---|---|---|

| Cavity Perturbation | 106 to 1014 | Based on:

|

|

|

|

| Open-Ended Coaxial Probe | 5 × 108 to 1011 |

|

|

|

|

| Transmission Line | <108 |

|

|

|

|

| Resonator | 5 × 107 < 1011 |

|

|

| – |

| Waveguide | 109 to 2 × 1010 |

|

| – | – |

| Time Domain Spectroscopy | 107 to 1010 |

|

|

|

|

| Free Space | 109 to 1011 | Sample placed between two antennas:

|

|

| – |

| Micro strip transmission line | 7 × 1010 to 1011 |

| – |

| – |

| Six-port reflectometer | 5 × 1010 to 7 × 1010 |

|

|

| – |

| Colloid dielectric probe | 75 × 103 to 3 × 107 |

|

|

|

|

| Concept | Product | Reference | Frequency (MHz) | Result |

|---|---|---|---|---|

| Fruit & Vegetables | Apple | [123] | 3–40 |

|

| [124] | 300–900 |

| ||

| [125] | – |

| ||

| [126] | – |

| ||

| [127,128] | 500 |

| ||

| Apple juice | [101] | 200 |

| |

| Apple peels | [129] | – |

| |

| Apple pulp | [74] | – |

| |

| Carrot | [123] | 2–40 |

| |

| Cooked peas | [130] | 2800 |

| |

| Eggplant | [131] | – |

| |

| Grape | [1] | – |

| |

| Guava | [1] | – |

| |

| Macadamia nut kernels | [59] | – |

| |

| Mango | [4] | – |

| |

| Mashed potatoes | [130] | 2800 |

| |

| Melons | [132] | – |

| |

| [113] | 10–1800 |

| ||

| Orange | [1] |

| ||

| Peach | [123] | 4–40 |

| |

| Potato | [123] | 1–40 |

| |

| Potato starch | [133] | 1200–18,000 | – | |

| Granular materials | Raw potatoes | [134] | – |

|

| chickpea, lentil, soybean, green pea | [9] | 10–1800 | – | |

| Grain | [4] | – |

| |

| Liquid materials | Acetic acid & vinegar | [135] | 0.1–1 |

|

| Fruit juice | [136] | – | – | |

| Wine & grape juice | [137] | 200–3000 | – | |

| Dairy products | Natural yoghurt | [138] | 1000–20,000 |

|

| UHT milk | [139] | 1000–20,000 |

|

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

El Khaled, D.; Castellano, N.N.; Gázquez, J.A.; Perea-Moreno, A.-J.; Manzano-Agugliaro, F. Dielectric Spectroscopy in Biomaterials: Agrophysics. Materials 2016, 9, 310. https://doi.org/10.3390/ma9050310

El Khaled D, Castellano NN, Gázquez JA, Perea-Moreno A-J, Manzano-Agugliaro F. Dielectric Spectroscopy in Biomaterials: Agrophysics. Materials. 2016; 9(5):310. https://doi.org/10.3390/ma9050310

Chicago/Turabian StyleEl Khaled, Dalia, Nuria N. Castellano, Jose A. Gázquez, Alberto-Jesus Perea-Moreno, and Francisco Manzano-Agugliaro. 2016. "Dielectric Spectroscopy in Biomaterials: Agrophysics" Materials 9, no. 5: 310. https://doi.org/10.3390/ma9050310