Fatigue Life Prediction of Fiber-Reinforced Ceramic-Matrix Composites with Different Fiber Preforms at Room and Elevated Temperatures

Abstract

:1. Introduction

2. Materials and Experimental Procedures

2.1. Unidirectional and Cross-Ply C/SiC Composite

2.2. 2D C/SiC Composite

2.3. 2.5D C/SiC Composite

2.4. 3D C/SiC Composite

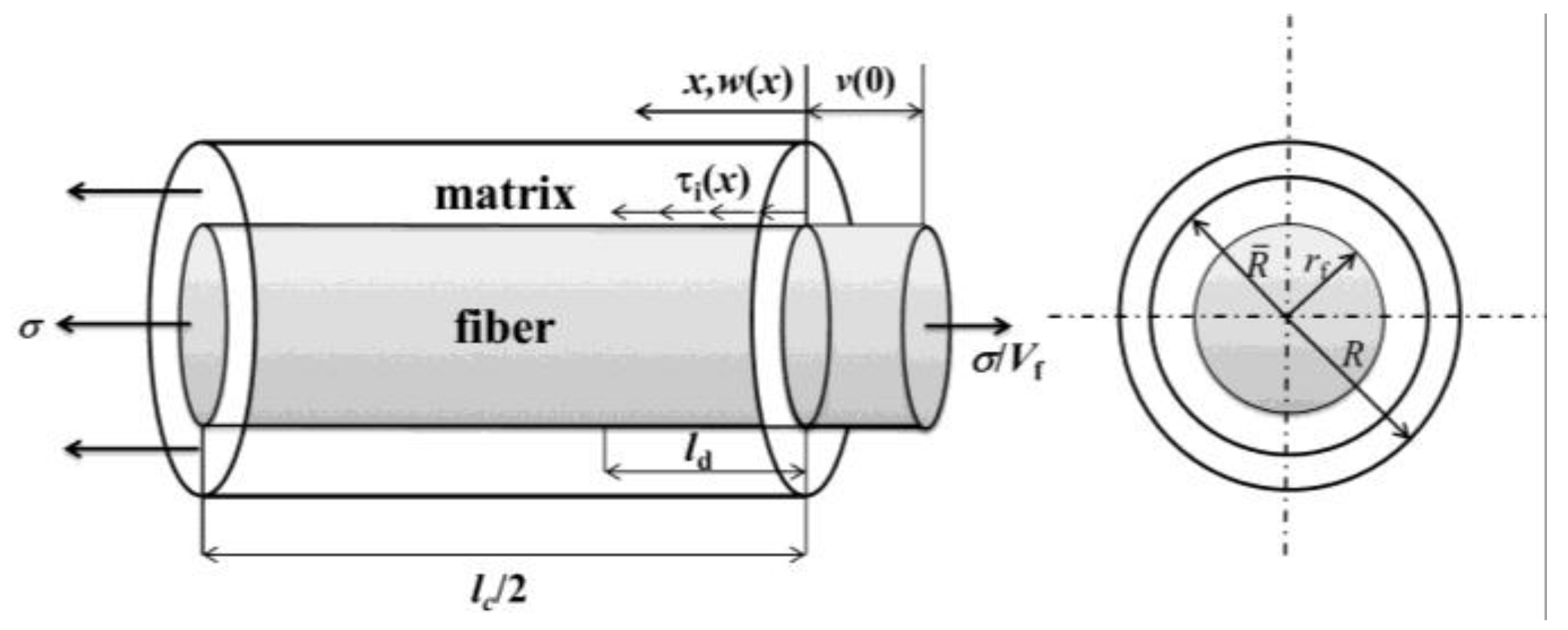

3. Stress Analysis

4. Damage Models

4.1. Matrix Multicracking

4.2. Interface Debonding

4.3. Interface Wear

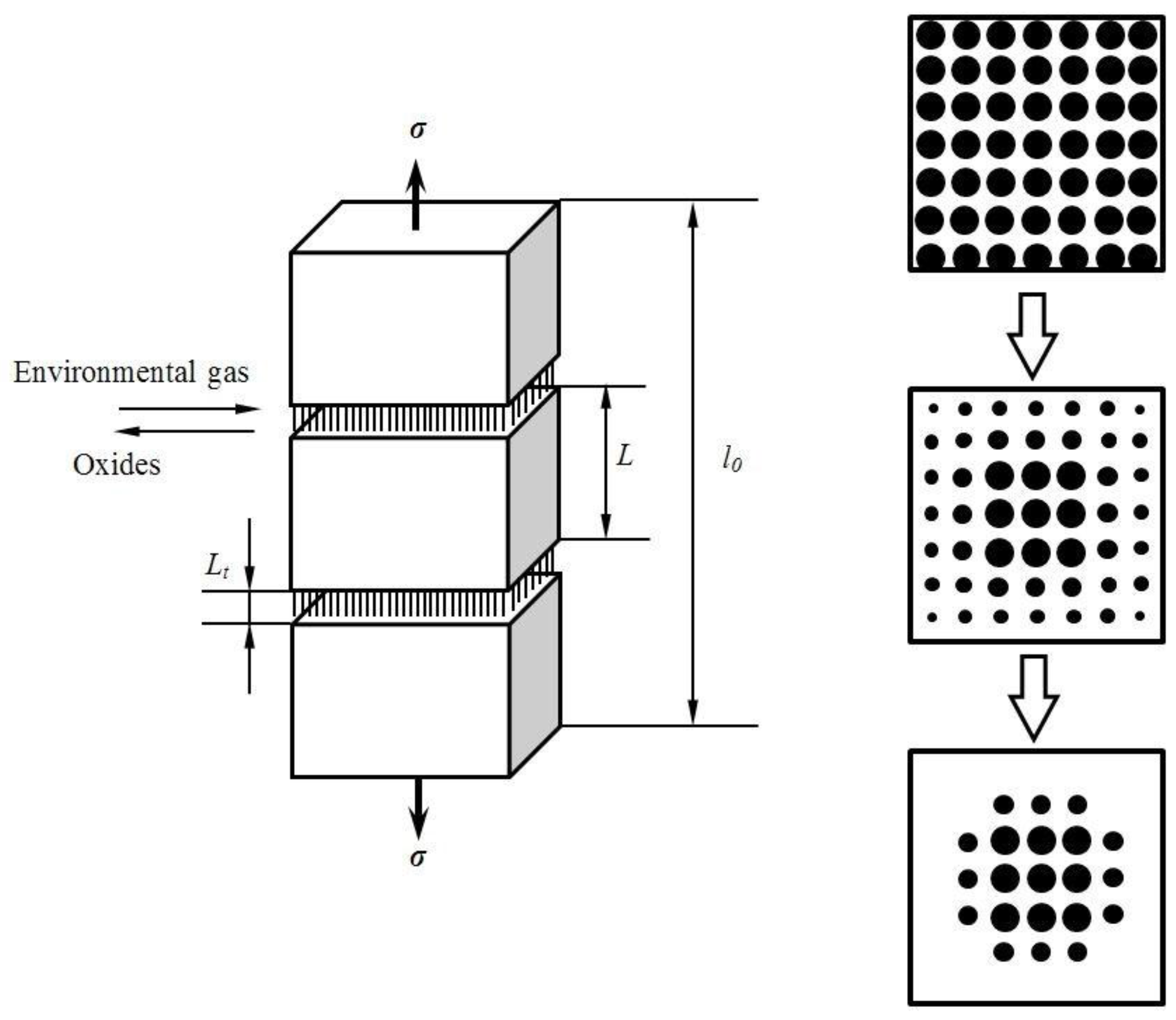

4.4. Interface and Fibers Oxidation

5. Fatigue Life Prediction Model

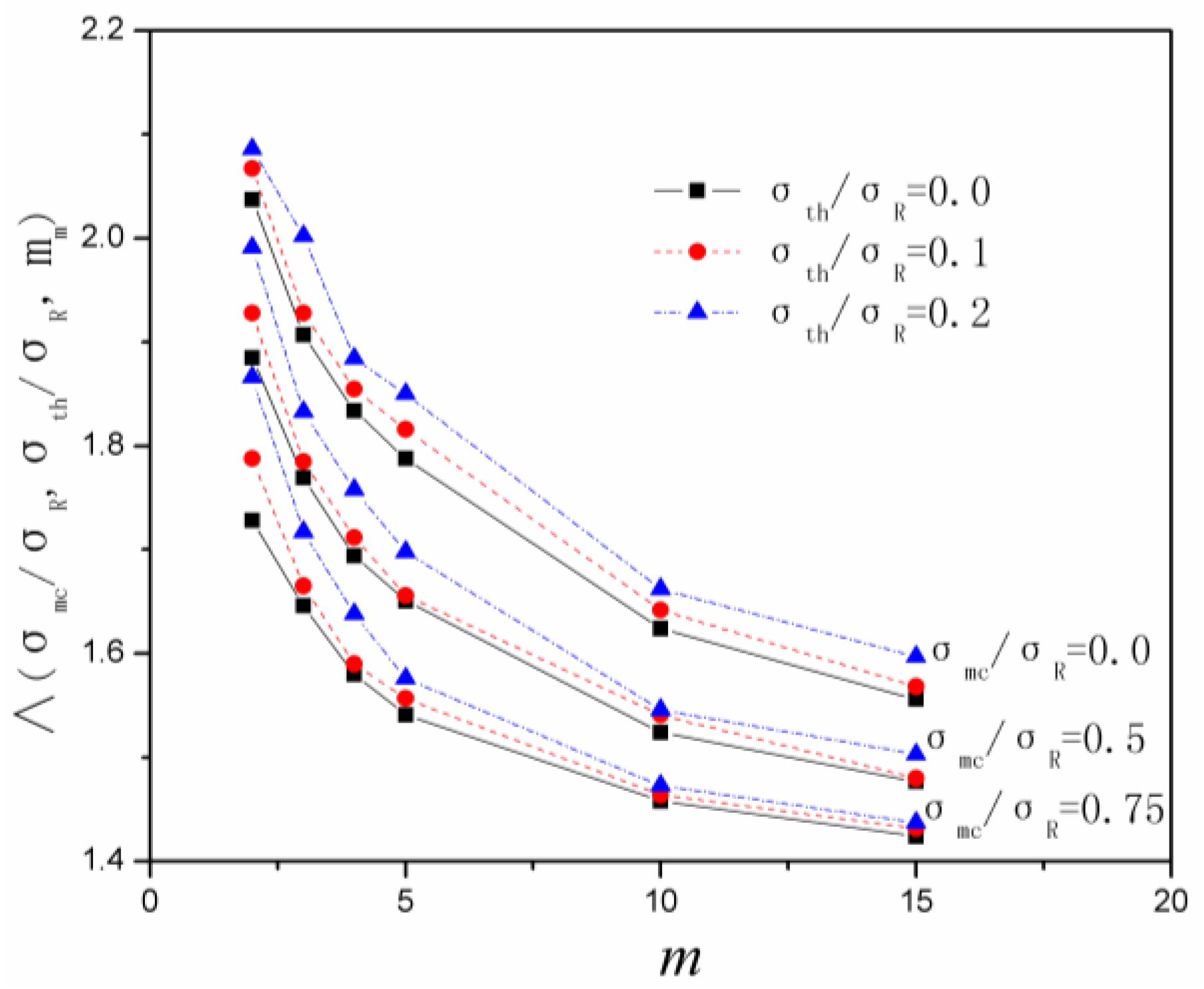

5.1. Life Prediction Model at Room Temperature

5.2. Life Prediction at Elevated Temperatures in the Oxidative Environment

6. Experimental Comparisons

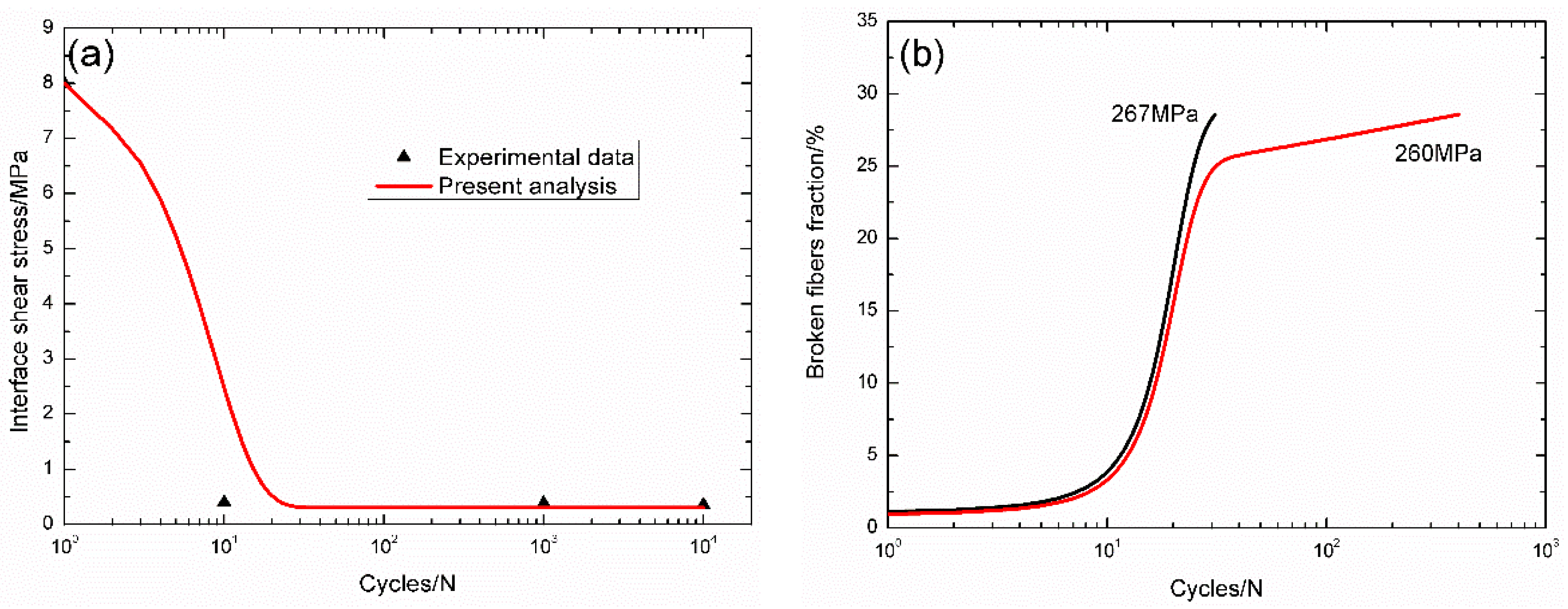

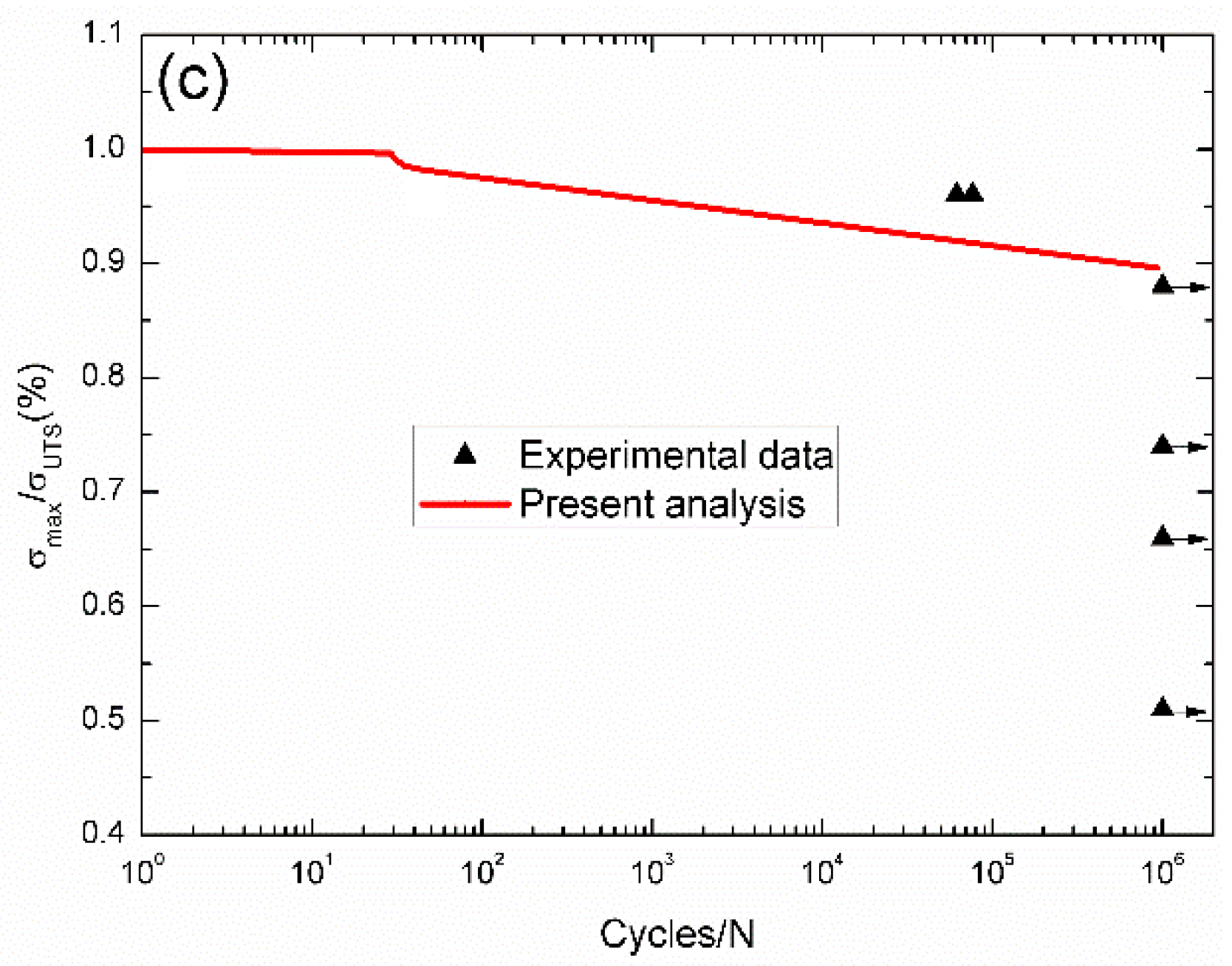

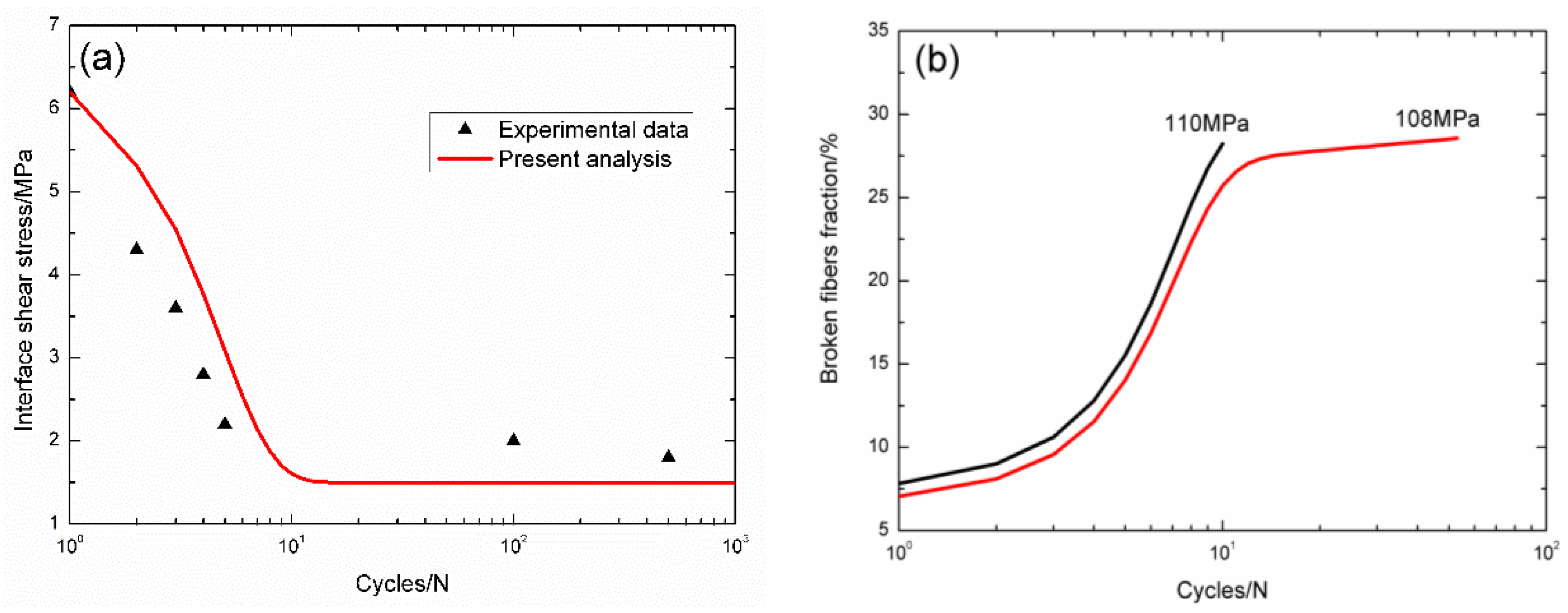

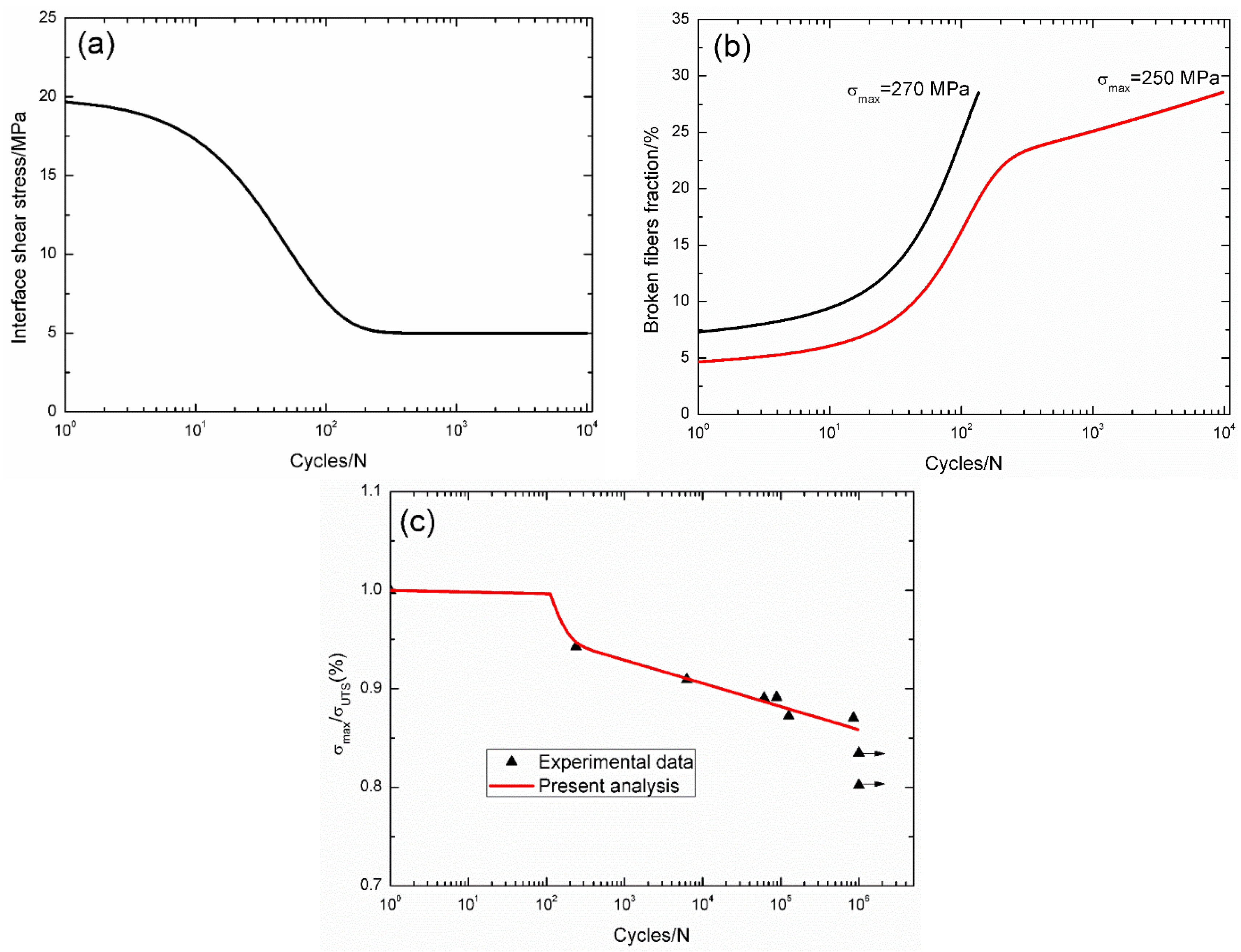

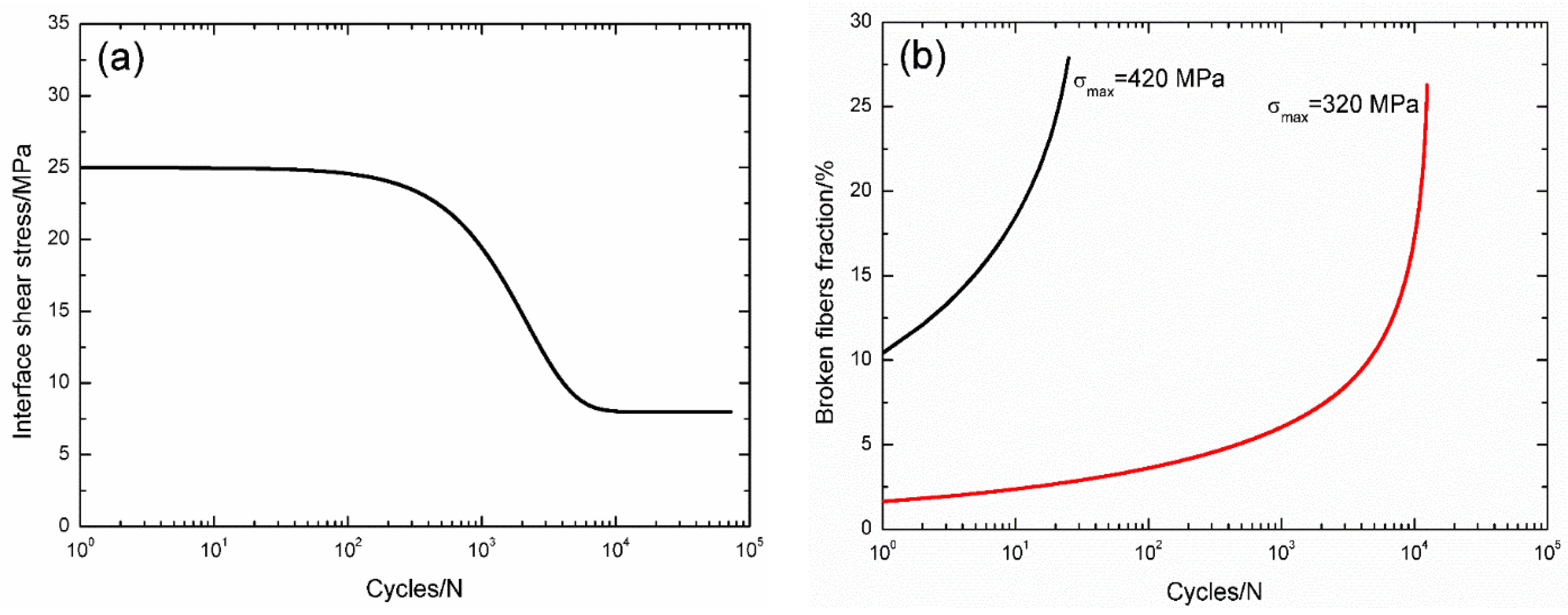

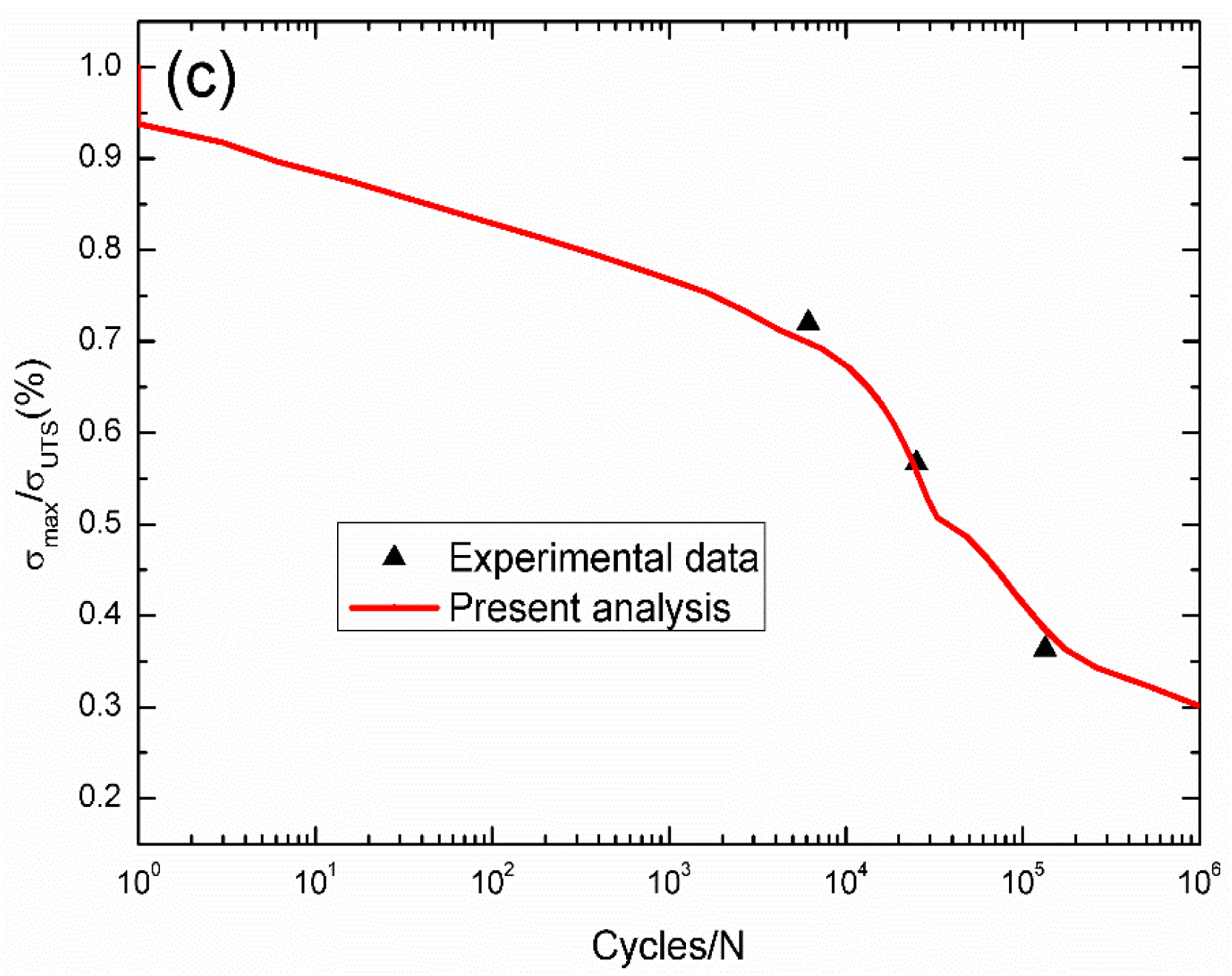

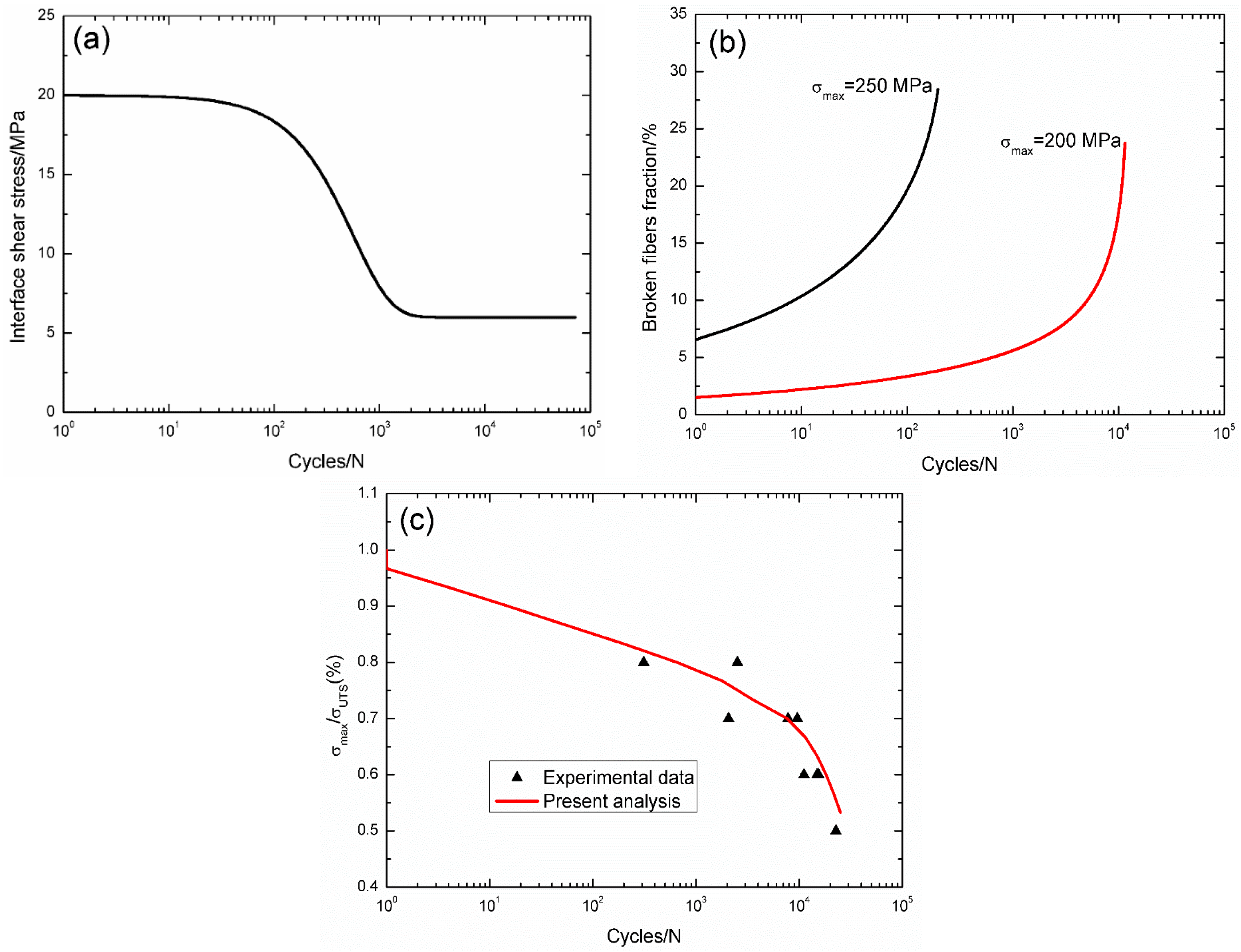

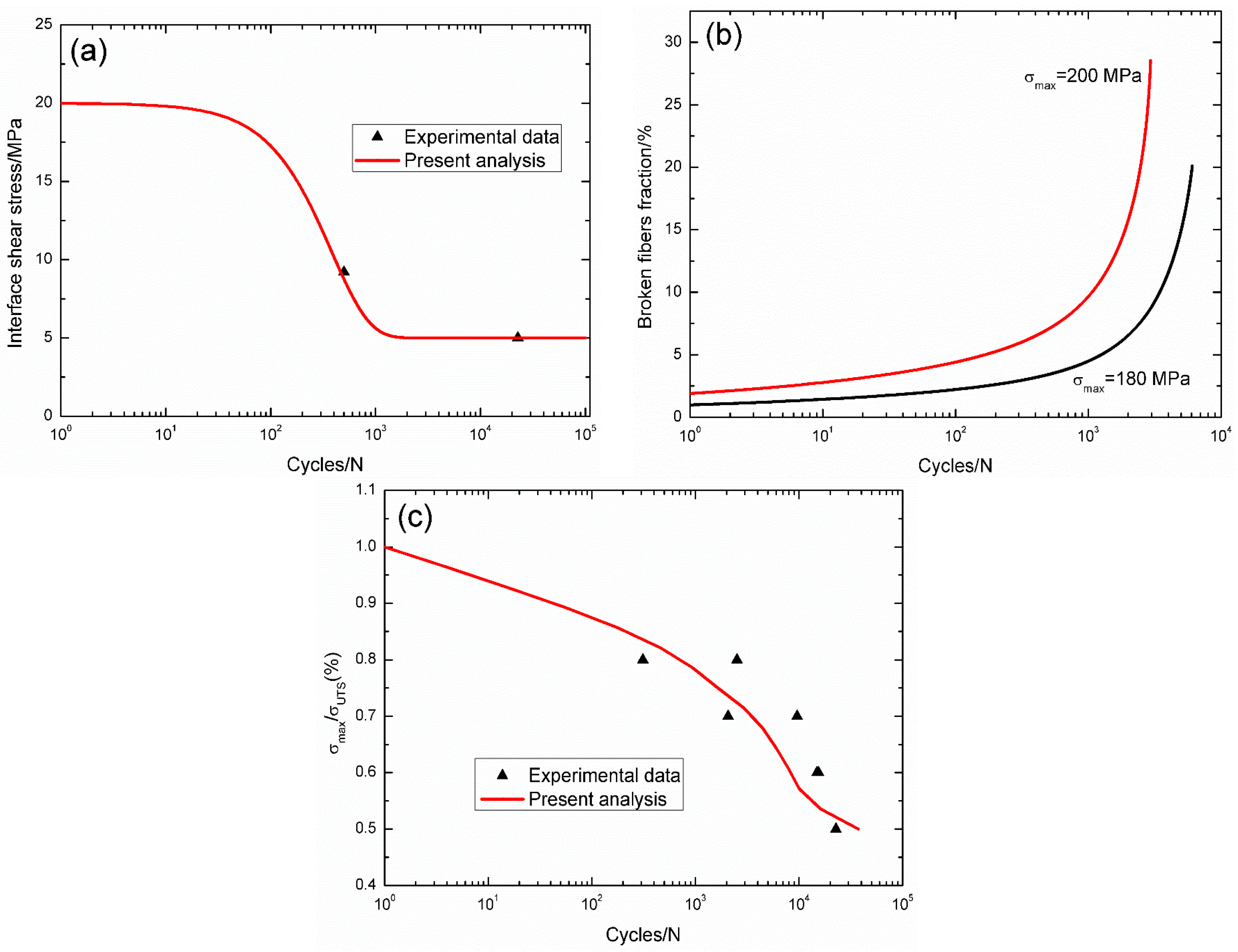

6.1. Life Prediction at Room Temperature

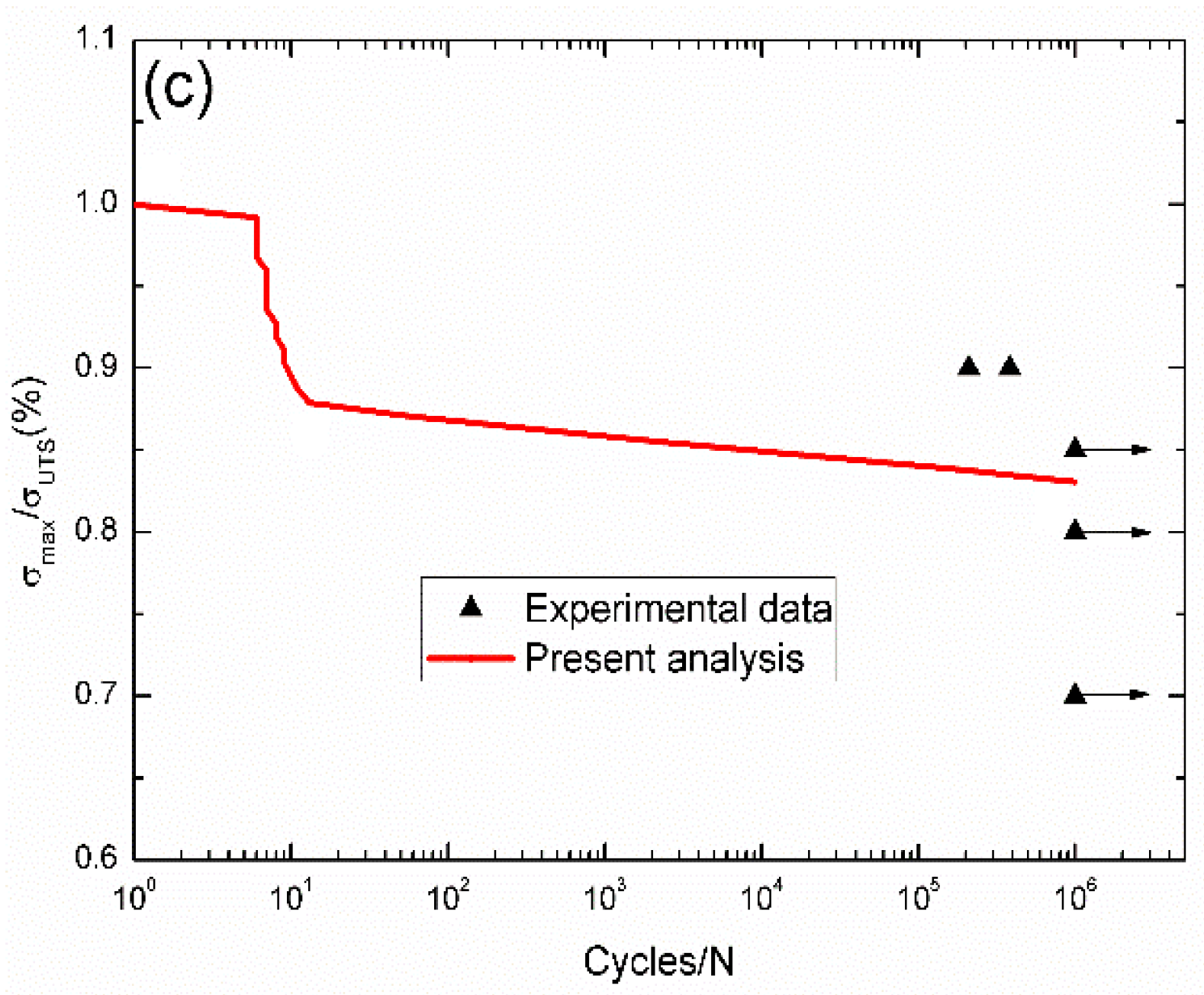

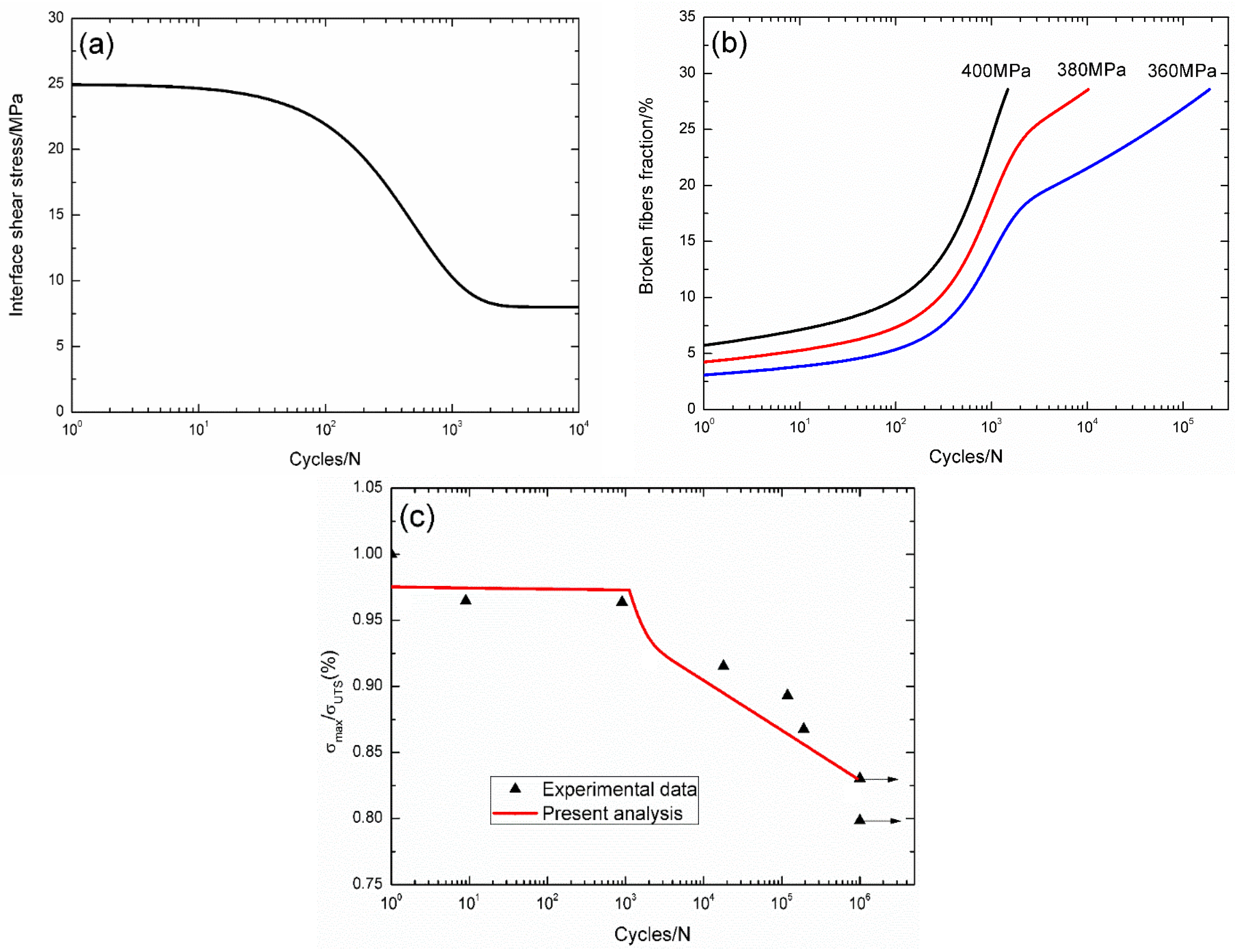

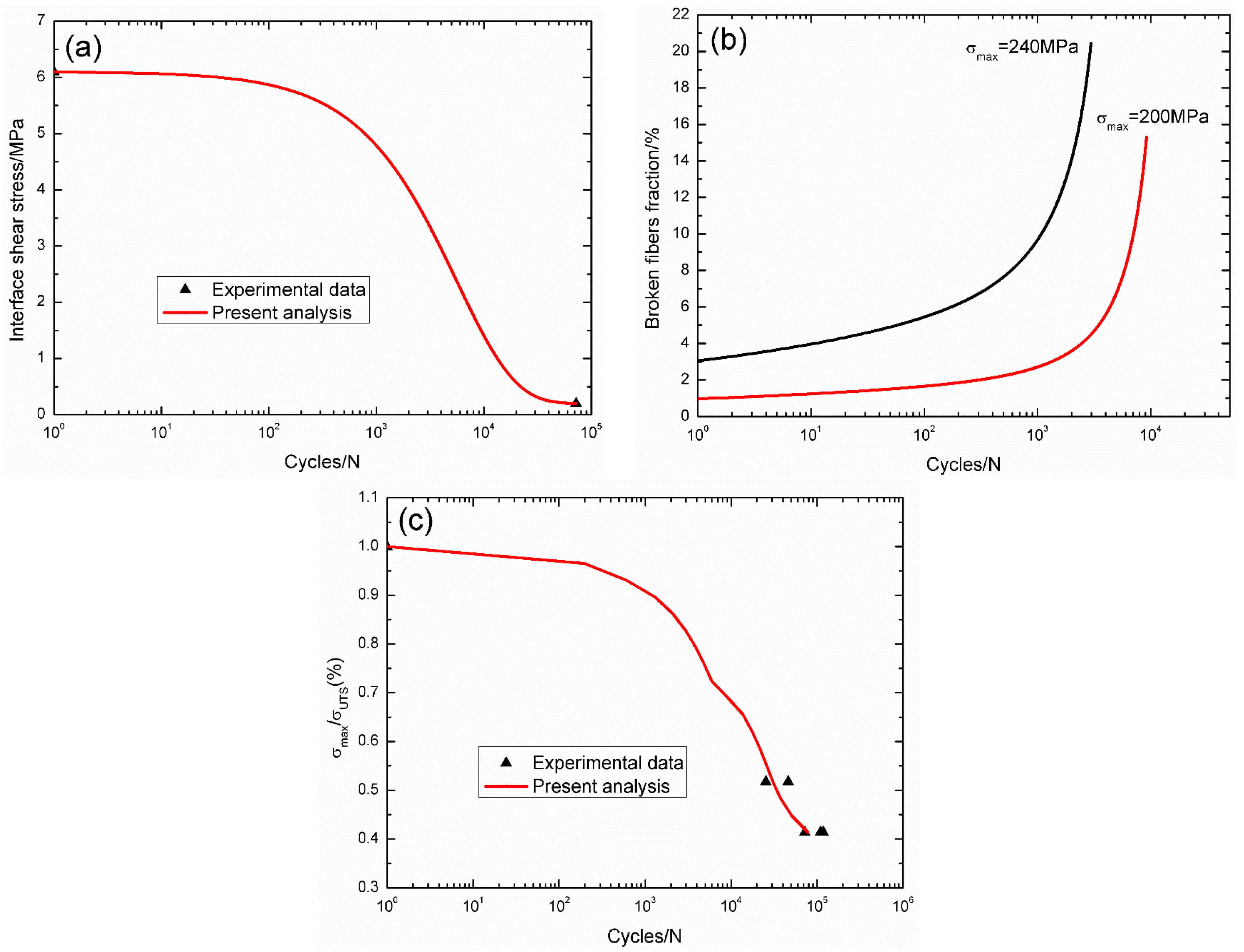

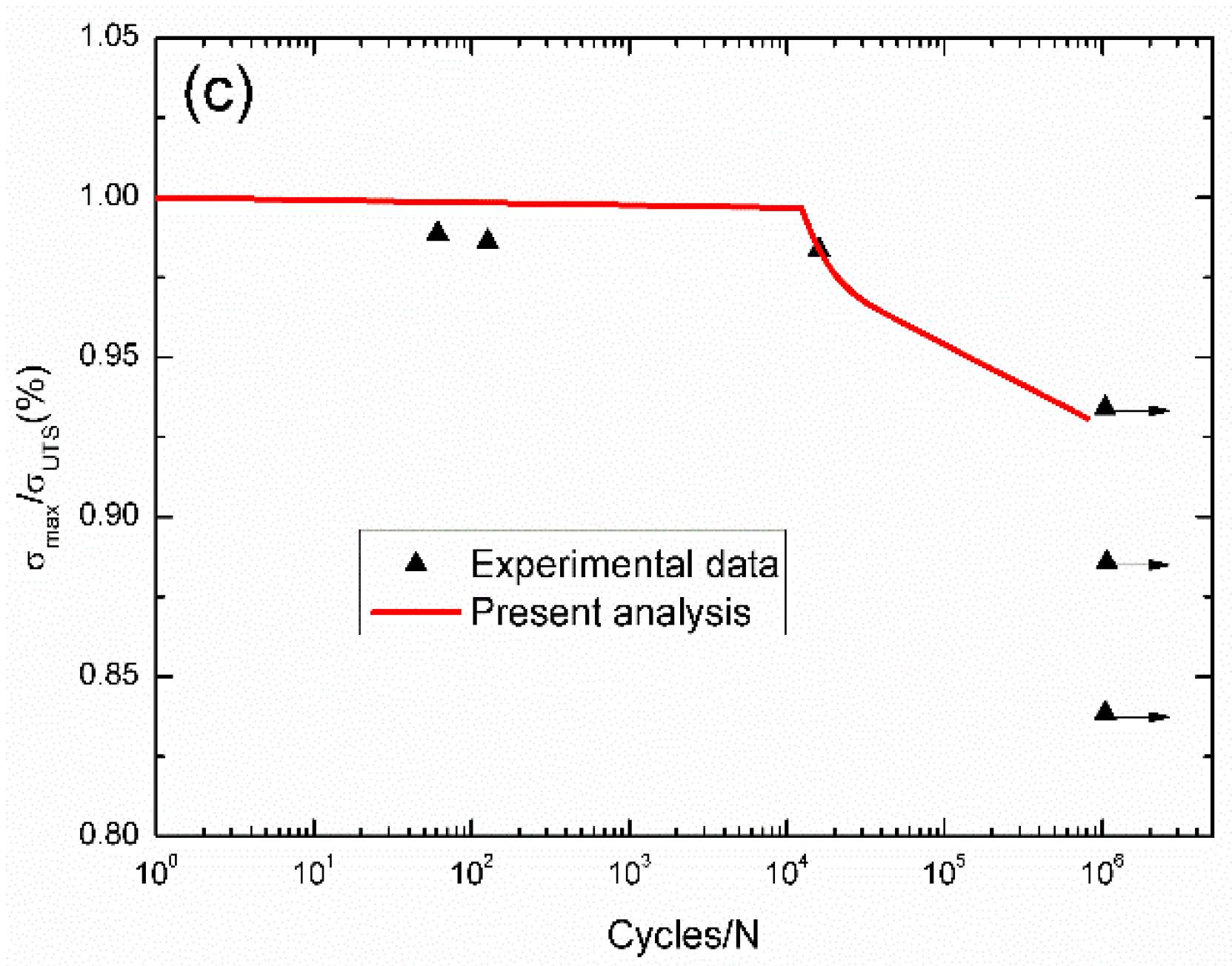

6.2. Life Prediction at Elevated Temperatures

7. Conclusions

- The broken fiber fraction versus applied cycles curve can be divided into two regions, i.e., at the initial loading cycles, the broken fiber fraction increases rapidly due to the degradation of interface shear stress and fiber strength; and when interface shear stress approaches the steady-state value, fibers’ failure is mainly controlled by fiber strength degradation, which makes the broken fiber fraction increase slowly.

- The predicted fatigue life S–N curves can also be divided into two regions, i.e., the region I is controlled by the degradation of interface shear stress and fiber strength; and the region II is only controlled by the degradation of fiber strength.

- The fatigue life of unidirectional, cross-ply, 2D and 2.5D C/SiC composites at elevated temperatures in air or oxidative environments is greatly reduced compared with that at room temperature, mainly attributed to oxidation of PyC interphase and carbon fibers; however, at 1300 °C in vacuum, the fatigue life and fatigue limit increase compared with that at room temperature.

Acknowledgments

Conflicts of Interest

References

- Naslain, R. Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: An overview. Compos. Sci. Technol. 2004, 64, 155–170. [Google Scholar] [CrossRef]

- Bednarcyk, B.A.; Mital, S.K.; Pineda, E.J.; Arnold, S.M. Multiscale modeling of ceramic matrix composites. In Proceedings of the 56th AIAA/ASCE/AHS/ASC Structures, Structural Dynamics, and Materials Conference, Kissimmee, FL, USA, 5–9 January 2015.

- Li, L.B. Fatigue hysteresis of carbon fiber-reinforced ceramic-matrix composites at room and elevated temperatures. Appl. Compos. Mater. 2016, 23, 1–27. [Google Scholar] [CrossRef]

- Li, L.B. Modeling fatigue hysteresis behavior of unidirectional C/SiC ceramic-matrix composite. Compos. Part B 2014, 66, 466–474. [Google Scholar] [CrossRef]

- Gowayed, Y.; Ojard, G.; Santhosh, U.; Jefferso, G. Modeling of crack density in ceramic matrix composites. J. Compos. Mater. 2015, 49, 2285–2294. [Google Scholar] [CrossRef]

- Evans, A.G.; Zok, F.W.; McMeeking, R.M. Fatigue of ceramic matrix composites. Acta Metall. Mater. 1995, 43, 859–875. [Google Scholar] [CrossRef]

- Pailler, F.; Lamon, J. Micromechanics based model of fatigue/oxidation for ceramic matrix composites. Compos. Sci. Technol. 2005, 65, 369–374. [Google Scholar] [CrossRef]

- Reynaud, P. Cyclic fatigue of ceramic-matrix composites at ambient and elevated temperatures. Compos. Sci. Technol. 1996, 56, 809–814. [Google Scholar] [CrossRef]

- Li, L.B. Fatigue damage models and life prediction of long-fiber-reinforced ceramic matrix composites. Ph.D. Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2010. [Google Scholar]

- American Society for Testing Materials. Standard Practice for Constant-Amplitude, Axial, Tension-Tension Cyclic Fatigue of Continuous Fiber-Reinforced Advanced Ceramics at Ambient Temperatures; ASTM C 1360-10; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Shuler, S.F.; Holmes, J.W.; Wu, X. Influence of loading frequency on the room-temperature fatigue of a carbon-fiber/SiC-matrix composite. J. Am. Ceram. Soc. 1993, 76, 2327–2336. [Google Scholar] [CrossRef]

- Mall, S.; Engesser, J.M. Effects of frequency on fatigue behavior of CVI C/SiC at elevated temperature. Compos. Sci. Technol. 2006, 66, 863–874. [Google Scholar] [CrossRef]

- Cheng, Q.Y.; Tong, X.Y.; Zheng, X.; Zhou, J.; Yao, L.J.; Li, B. Experimental investigation on the fatigue characteristics about high temperature of plain-woven C/SiC composite. J. Mech. Strength 2010, 32, 819–825. [Google Scholar]

- Yang, F.S. Research on Fatigue Behavior of 2.5D Woven Ceramic Matrix Composites. Master’s Thesis, Nanjing University of Aeronautics and Astronautics, Nanjing, China, 2011. [Google Scholar]

- Zhang, C.Y.; Wang, X.W.; Liu, Y.S.; Wang, B.; Han, D.; Qiao, S.; Guo, Y. Tensile fatigue of a 2.5D-C/SiC composite at room temperature and 900 °C. Mater. Des. 2013, 49, 814–819. [Google Scholar] [CrossRef]

- Du, S.M.; Qiao, S.R.; Ji, G.C.; Han, D. Tension-tension fatigue behavior of 3D-C/SiC composite at room temperature and 1300 °C. Mater. Eng. 2002, 9, 22–25. [Google Scholar]

- Budiansky, B.; Hutchinson, J.W.; Evans, A.G. Matrix fracture in fiber-reinforced ceramics. J. Mech. Phys. Solids 1986, 34, 167–189. [Google Scholar] [CrossRef]

- Daniel, I.M.; Lee, J.W. The behavior of ceramic matrix fiber composites under longitudinal loading. Compos. Sci. Technol. 1993, 46, 105–113. [Google Scholar] [CrossRef]

- Aveston, J.; Cooper, G.A.; Kelly, A. Single and multiple fracture. In The Properties of Fiber Composites; National Physical Laboratory, IPC: London, UK, 1971; pp. 15–26. [Google Scholar]

- Zok, F.W.; Spearing, S.M. Matrix crack spacing in brittle matrix composites. Acta Metall. Mater. 1992, 40, 2033–2043. [Google Scholar] [CrossRef]

- Zhu, H.; Weitsman, Y. The progression of failure mechanisms in unidirectional reinforced ceramic composites. J. Mech. Phys. Solids 1994, 42, 1601–1632. [Google Scholar] [CrossRef]

- Solti, J.P.; Mall, S.; Robertson, D.D. Modeling damage in unidirectional ceramic-matrix composites. Compos. Sci. Technol. 1995, 54, 55–66. [Google Scholar] [CrossRef]

- Curtin, W.A. Multiple matrix cracking in brittle matrix composites. Acta Metall. Mater. 1993, 41, 1369–1377. [Google Scholar] [CrossRef]

- Hsueh, C.H. Crack-wake interface debonding criterion for fiber-reinforced ceramic composites. Acta Mater. 1996, 44, 2211–2216. [Google Scholar] [CrossRef]

- Gao, Y.; Mai, Y.; Cotterell, B. Fracture of fiber-reinforced materials. J. Appl. Math. Phys. 1988, 39, 550–572. [Google Scholar] [CrossRef]

- Sun, Y.J.; Singh, R.N. The generation of multiple matrix cracking and fiber-matrix interfacial debonding in a glass composite. Acta Mater. 1998, 46, 1657–1667. [Google Scholar] [CrossRef]

- Rouby, D.; Louet, N. The frictional interface: A tribological approach of thermal misfit, surface roughness and sliding velocity effects. Compos. Part A 2002, 33, 1453–1459. [Google Scholar] [CrossRef]

- Holmes, J.W.; Cho, C.D. Experimental observation of frictional heating in fiber-reinforced ceramics. J. Am. Ceram. Soc. 1992, 75, 929–938. [Google Scholar] [CrossRef]

- Staehler, J.M.; Mall, S.; Zawada, L.P. Frequency dependence of high-cycle fatigue behavior of CVI C/SiC at room temperature. Compos. Sci. Technol. 2003, 63, 2121–2131. [Google Scholar] [CrossRef]

- Lee, S.S.; Stinchcomb, W.W. Damage mechanisms of cross-ply Nicalon/CAS-II laminate under cyclic tension. Ceram. Eng. Sci. Proc. 1994, 15, 40–48. [Google Scholar]

- Lamouroux, F.; Camus, G.; Thebault, J. Kinetics and mechanisms of oxidation of 2D woven C/SiC composites: I, experimental approach. J. Am. Ceram. Soc. 1994, 77, 2049–2057. [Google Scholar] [CrossRef]

- Halbig, M.C.; McGuffin-Cawley, J.D.; Eckel, A.J.; Brewer, D.N. Oxidation kinetics and stress effects for the oxidation of continuous carbon fibers within a microcracked C/SiC ceramic matrix composite. J. Am. Ceram. Soc. 2008, 91, 519–526. [Google Scholar] [CrossRef]

- Filipuzzi, L.; Naslain, R. Oxidation mechanisms and kinetics of 1D-SiC/C/SiC composite materials: II, Modelling. J. Am. Ceram. Soc. 1994, 77, 467–480. [Google Scholar] [CrossRef]

- Naslain, R.; Guette, A.; Rebillat, F.; Gallet, S.; Lamouroux, F.; Filipuzzi, L.; Louchet, C. Oxidation mechanisms and kinetics of SiC-matrix composites and their constituents. J. Mater. Sci. 2004, 39, 7303–7316. [Google Scholar] [CrossRef]

- Lara-Curzio, E. Analysis of oxidation-assisted stress-rupture of continuous fiber-reinforced ceramic matrix composites at intermediate temperatures. Compos. Part A 1999, 30, 549–554. [Google Scholar] [CrossRef]

- Casas, L.; Martinez-Esnaola, J.M. Modelling the effect of oxidation on the creep behavior of fiber-reinforced ceramic matrix composites. Acta Mater. 2003, 51, 3745–3757. [Google Scholar] [CrossRef]

- Curtin, W.A. Stress-strain behavior of brittle matrix composites. Comprehensive Composite Materials; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2000; Volume 4, pp. 47–76. [Google Scholar]

- Xia, Z.H.; Curtin, W.A. Toughness-to-brittle transitions in ceramic-matrix composites with increasing interfacial shear stress. Acta Mater. 2000, 48, 4879–4892. [Google Scholar] [CrossRef]

- Curtin, W.A.; Ahn, B.K.; Takeda, N. Modeling brittle and tough stress-strain behavior in unidirectional ceramic matrix composites. Acta Mater. 1998, 46, 3409–3420. [Google Scholar] [CrossRef]

| Items | UD [9] | CP [9] | 2D [11] | 2.5D [14] | 3D [16] |

|---|---|---|---|---|---|

| Vf/(%) | 40 | 40 | 45 | 45 | 45 |

| ψ | 1.0 | 0.5 | 0.5 | 0.75 | 0.93 |

| rf/(μm) | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| mf | 5 | 5 | 5 | 5 | 5 |

| τio/(MPa) | 8 | 6.2 | 25 | 20 | 20 |

| τimin/(MPa) | 0.3 | 1.5 | 8 | 8 | 5 |

| ω | 0.04 | 0.06 | 0.002 | 0.001 | 0.02 |

| λ | 1.5 | 1.8 | 1.0 | 1.0 | 1.0 |

| p1 | 0.02 | 0.01 | 0.018 | 0.02 | 0.012 |

| p2 | 1.0 | 0.8 | 1.0 | 1.2 | 1.0 |

| Items | UD [9] | CP [9] | 2D [12] | 2D [13] | 2.5D [14] | 2.5D [15] | 3D [16] |

|---|---|---|---|---|---|---|---|

| Vf/(%) | 40 | 40 | 45 | 40 | 45 | 40 | 45 |

| ψ | 1.0 | 0.5 | 0.5 | 0.5 | 0.75 | 0.75 | 0.93 |

| rf/(μm) | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 | 3.5 |

| mf | 5 | 5 | 5 | 5 | 5 | 5 | 5 |

| τio/(MPa) | 6.1 | 5.5 | 25 | 20 | 20 | 25 | 20 |

| τimin/(MPa) | 0.2 | 0.4 | 8 | 6 | 5 | 5 | 8 |

| ω | 0.001 | 0.001 | 0.0001 | 0.0005 | 0.008 | 0.003 | 0.002 |

| λ | 0.8 | 1.0 | 1.2 | 1.2 | 1.2 | 1.2 | 1.0 |

| p1 | 0.02 | 0.02 | 0.02 | 0.02 | 0.03 | 0.03 | 0.018 |

| p2 | 1.0 | 1.0 | 1.0 | 1.0 | 1.2 | 1.2 | 1.0 |

© 2016 by the author; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Li, L. Fatigue Life Prediction of Fiber-Reinforced Ceramic-Matrix Composites with Different Fiber Preforms at Room and Elevated Temperatures. Materials 2016, 9, 207. https://doi.org/10.3390/ma9030207

Li L. Fatigue Life Prediction of Fiber-Reinforced Ceramic-Matrix Composites with Different Fiber Preforms at Room and Elevated Temperatures. Materials. 2016; 9(3):207. https://doi.org/10.3390/ma9030207

Chicago/Turabian StyleLi, Longbiao. 2016. "Fatigue Life Prediction of Fiber-Reinforced Ceramic-Matrix Composites with Different Fiber Preforms at Room and Elevated Temperatures" Materials 9, no. 3: 207. https://doi.org/10.3390/ma9030207