1. Introduction

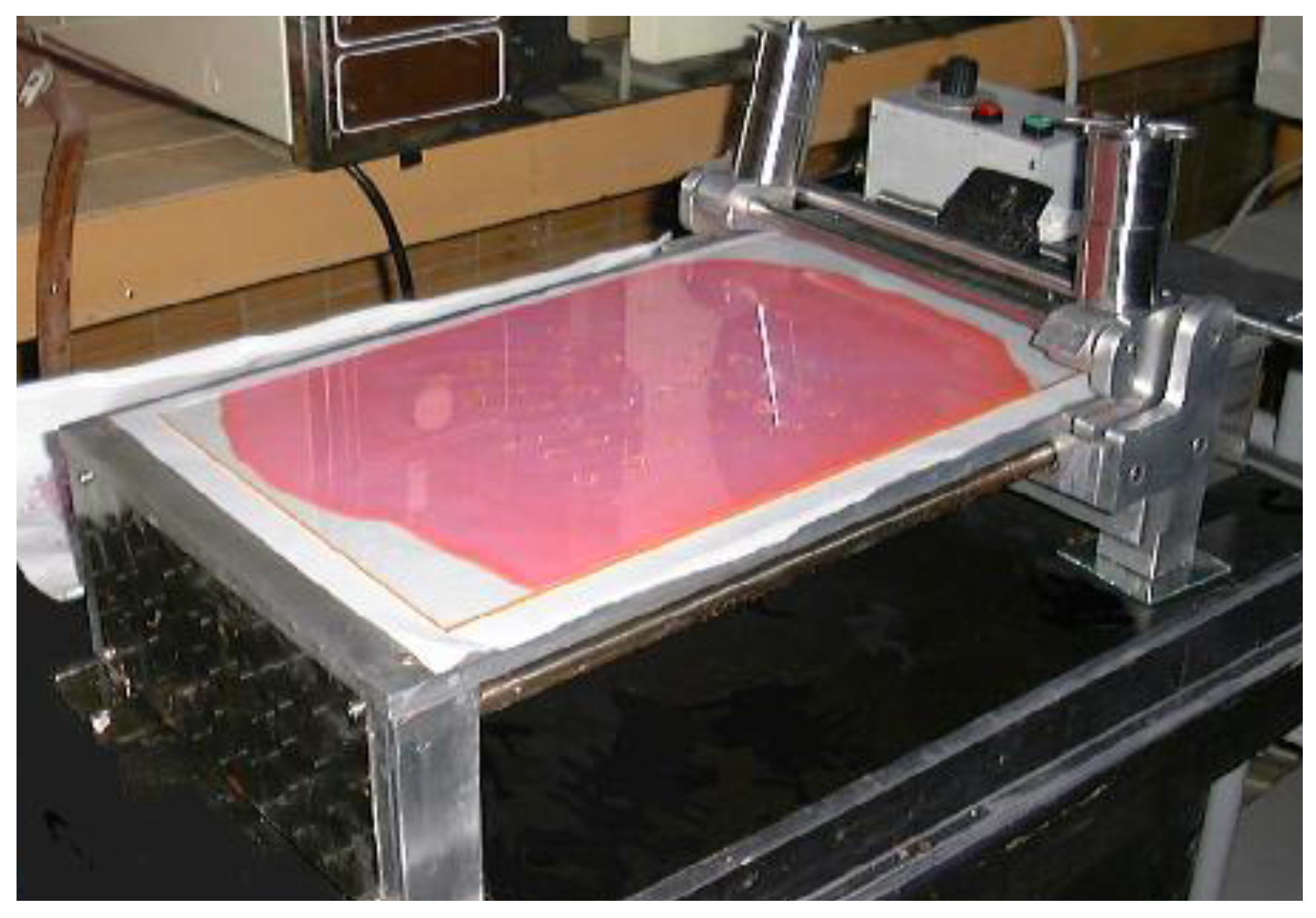

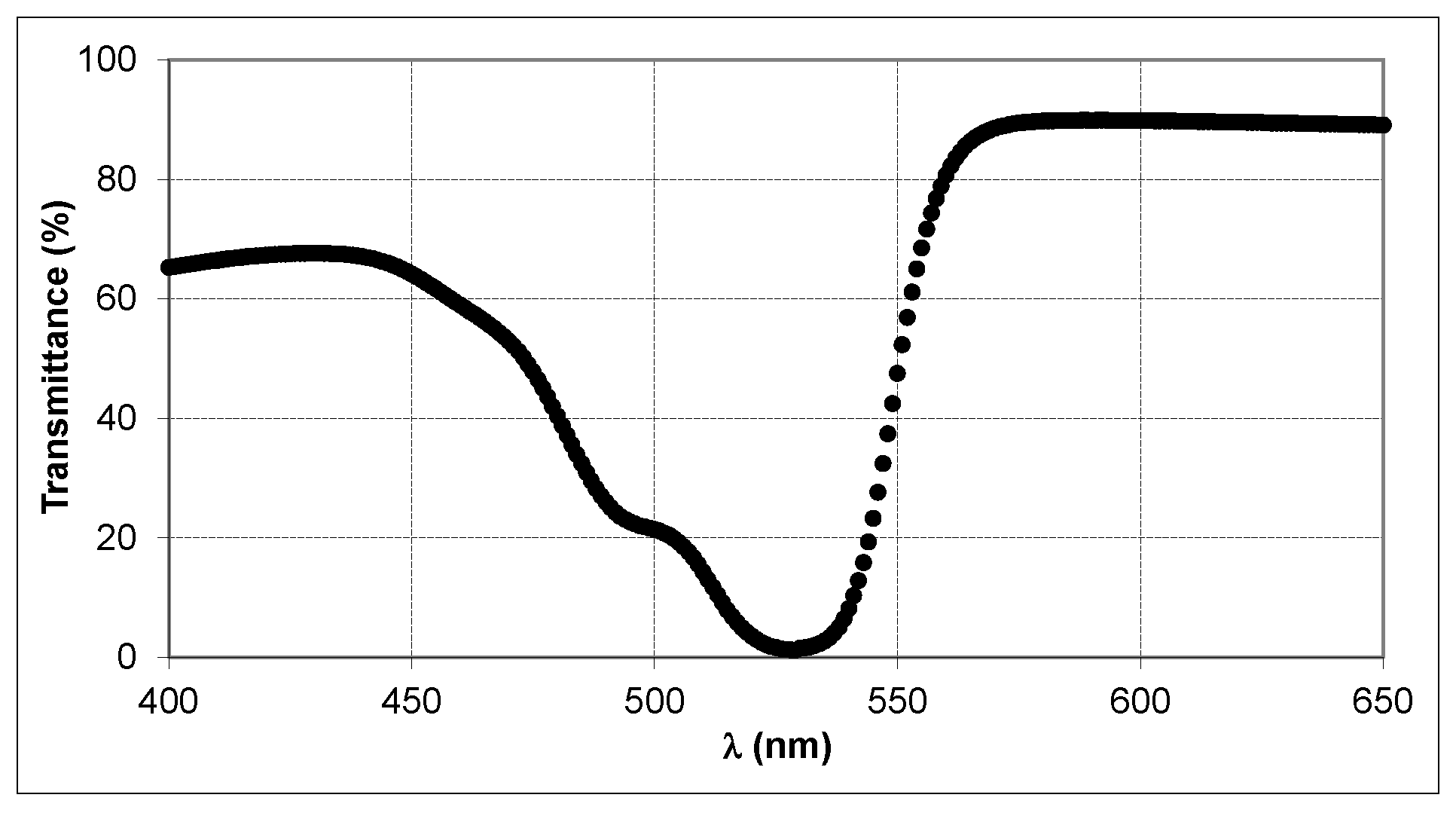

Photopolymers are materials whose main components are organic polymers, and they are mainly characterized for being sensitive to light with a particular wavelength. The basic formulation includes a sensitizing dye, an initiator which is a free radical generator, and one or more polymerizable monomers. These components are placed in a binder such as polyvinyl alcohol, polyacrylate, polyvinylchloride,

etc. These types of materials absorb light of a certain wavelength that excites the dye and activates the initiator. This substance generates free radicals, which react with the monomer to produce a polymerization reaction. The polymer chains generated in the photopolymerization reaction are responsible for the properties of these materials [

1].

These materials have many applications, such as the manufacture of photonic lattice structures [

2], photo-curable resins [

3] or polymer waveguides [

4] among others. This work will focus on their application as holographic recording materials.

Holography is an optical technique that allows the recording of an object wavefront (in amplitude and phase) in the material and its reconstruction. The recording is performed through the interference of the light beam coming from the object and a reference light beam. The interference of these two beams produces a pattern formed by “bright” and “dark” fringes, which modify the holographic recording material generating the hologram. Thus, the hologram is stored by means of the variation of certain material properties. When the hologram is illuminated with the reference beam, an identical wavefront to the object that was recorded is obtained.

Obtaining holograms of three-dimensional objects has sparked great worldwide interest. Among the different applications of holography, we can highlight holographic interferometry, which can be used to obtain information from some material properties [

5], the manufacture of lenses [

6,

7], holographic optical elements (HOEs) [

8,

9,

10] or data encryption [

11].

However, one of the fields of holography that has had more importance in recent years is the manufacturing of holographic memories [

12,

13,

14]. Our society has gotten used to generating a huge amount of information that must be processed and stored. One possibility to increase the storage density is to use not only the surface but also the entire material volume, which is directly achieved with holographic storage. If the stored objects are data pages, the holographic storage of all of them constitutes a holographic memory.

To increase the amount of holographically stored data, it is necessary that the object bits are as small as possible, so the material must be capable of resolving high spatial frequencies. However, the diffraction efficiency in photopolymers decreases as the spatial frequency increases, since they cannot resolve high spatial frequencies correctly [

15]. For this reason, in this work, a chain transfer agent named 4,4’-azobis (4-cyanopentanoic acid) (ACPA) is added to a polyvinyl alcohol (PVA)/acrylamide (AA) based photopolymer in order to increase the diffraction efficiency of the recorded gratings when high spatial frequencies are recorded in the material. In previous works, the proper functioning of materials containing ACPA in their composition has been demonstrated. Ortuño

et al. [

16] achieved a low noise level in 900 μm PVA/AA photopolymers, obtaining gratings with a maximum diffraction efficiency above 85% by using ACPA. This had a great significance considering that it was the first time that diffraction efficiencies as high as 80% had been obtained for 900 μm PVA/AA photopolymer layers. This result is due to the effect induced by ACPA thanks to the small size of the polymer chains. The photopolymer with ACPA has a high fraction of low molecular weight polymer chains, which allow a better definition of the three-dimensional sinusoidal contour of the fringes in the diffraction grating, thus leading to higher diffraction efficiencies. Moreover, the incorporation of ACPA has been used to improve the stability of high spatial frequency diffraction gratings [

15]. In this sense, the ACPA improved the fixation of the gratings, since the composition with ACPA experienced a smaller decrease of the diffraction efficiency after a curing process.

The standard photopolymer is composed by acrylamide (AA) as the polymerizable monomer, triethanolamine (TEA) as radical generator, polyvinyl alcohol (PVA) as binder and yellowish eosin (YE) as sensitizer. In addition, different concentrations of ACPA are incorporated into this composition to analyze the response of the material when gratings with high spatial frequencies (2658 lines/mm and 4553 lines/mm) are recorded in it. Once the diffraction efficiency is obtained, the experimental values are fitted using the Couple Wave Theory [

17] to obtain grating parameters such as the refractive index modulation and the optical thickness, which provide an indicator of the grating improvement with the incorporation of the ACPA into the photopolymer.

2. Chemical Process

The chemical processes that take place in the photopolymer materials are essentially initiation, propagation and termination.

During the initiation process, the photopolymer is illuminated by a wavelength at which the material is sensitive. Then, the initiator system formed by the dye and the radical generator absorbs photons and produces free radicals, which are combined with the monomers present in the photopolymer to generate chain initiators [

18]:

where

I is the initiator system,

hν indicates the energy absorption from the photons,

R• is the initiator of free radicals,

M is the monomer,

ki is the chain initiation kinetic constant and

M• is the chain initiator.

During the propagation process, the chain initiators are bound to other monomer molecules to form longer chains,

i.e., a chain initiator

M•1 is bound to a molecule

M to form another longer chain

M•2 and so on.

where

kp is the rate constant of propagation. Through the propagation process, a polymer chain is generated.

During the termination process, the macro-radical chains of polymer are combined together to finish the reaction according to the following equations:

where

ktc and

ktd are the rate constants of combination and disproportionation termination respectively.

Moreover, in this work an additional chemical process occurs as a result of the incorporation of a chain transfer agent (CTA) in the photopolymer composition: the chain transfer mechanism. The CTA produces a premature termination in the growth of macro-radicals in the propagation process (

M•n) and generates a new radical

A• that can start a new polymer chain by reacting with a monomer molecule. The chain transfer reactions can be written as:

where

XA is the CTA,

A• is the new radical produced in the reaction and

ktr, ka are the kinetic constants of the processes.

Due to premature termination of the reaction (as a result of the presence in the material of the CTA), the polymer chains stop growing and therefore chains become shorter. Moreover, thanks to the generation of new radicals, other chains can be formed and thus the polymerization rate does not decrease.

Therefore, the main effect to be achieved by introducing the CTA in the photopolymer composition is to reduce the length of the polymer chains in order to improve the material response when high spatial frequency gratings are recorded.

4. Results and Discussion

In this section, the results obtained from recording holographic transmission and reflection gratings are presented.

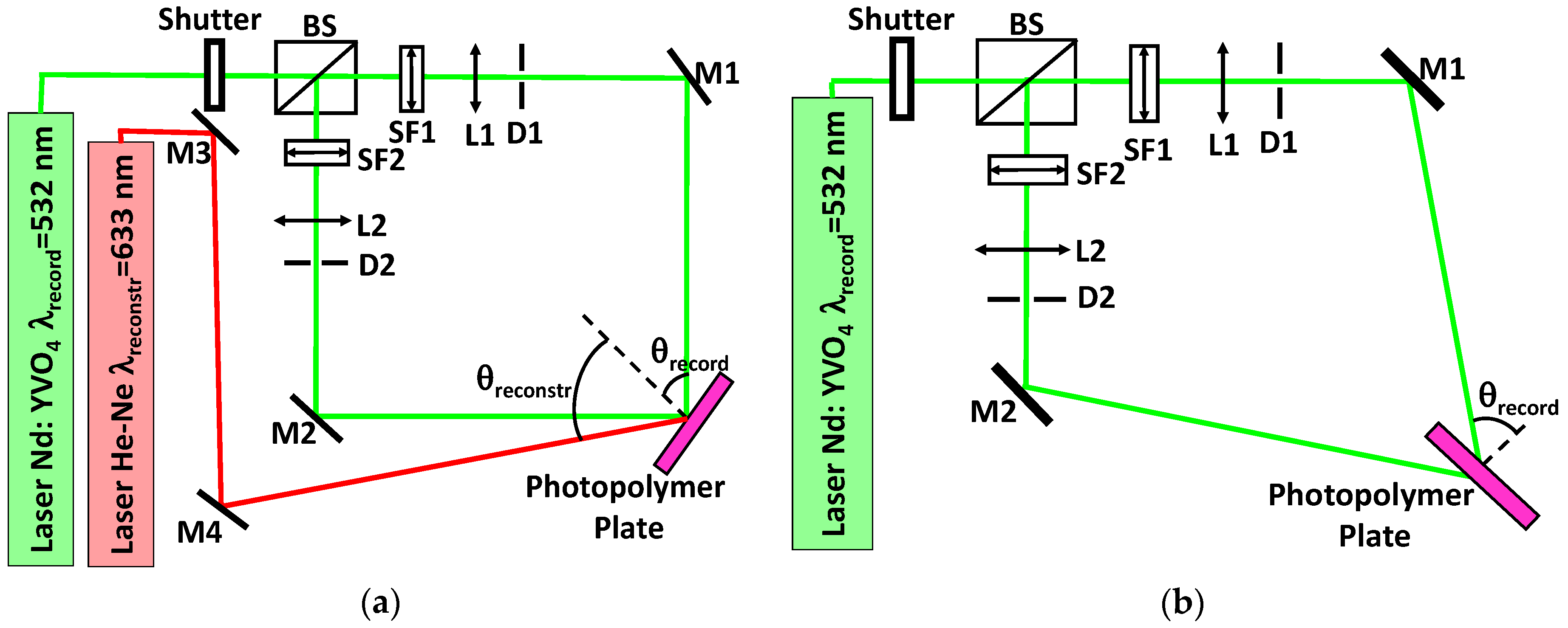

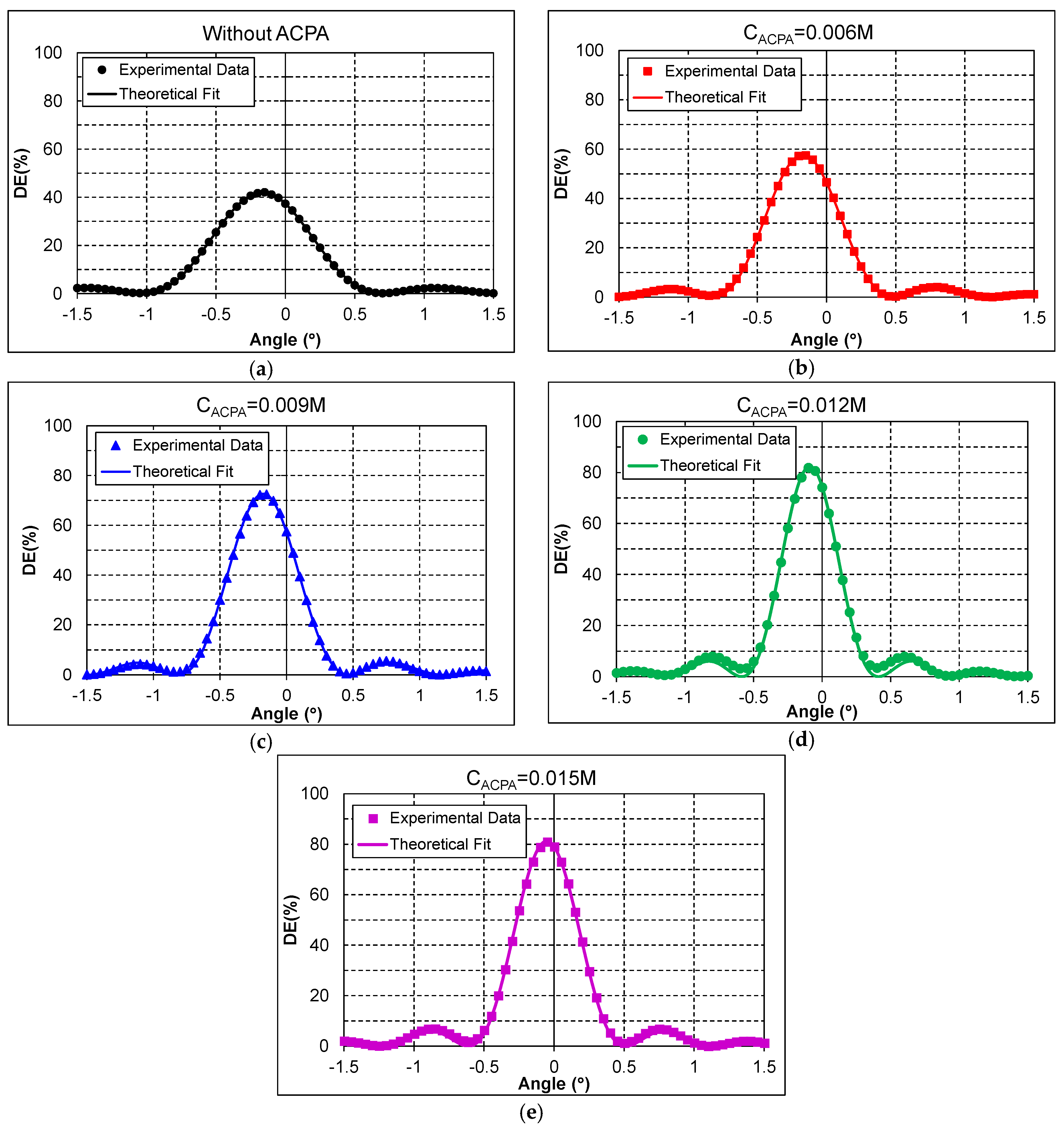

Firstly, transmission gratings with a spatial frequency of 2658 lines/mm were recorded in the photopolymers of

Table 1 using the holographic setup of

Figure 3a. The obtained results are presented in

Figure 4, in which each plot shows the experimental diffraction efficiency (DE) in percentage for the different ACPA concentrations. The reconstruction angle is represented in the horizontal axis, and the origin of the axes corresponds to the Bragg angle for the reconstruction wavelength, that is, an angle of 57.3° for a wavelength of 633 nm as was explained in

Section 3.2. Moreover, the theoretical fit of the experimental data with the Coupled Wave Theory [

17], explained in

Section 3.3., is represented with a solid line in each plot. The experimental spatial period,

Λexp, the refractive index modulation

Δn, and the grating thickness

d [

21] are the grating parameters which can be extracted from the fitting.

The DE obtained with composition 1 without ACPA is represented in

Figure 4a. The maximum diffraction efficiency (

DEMax) that was obtained is 42%. A

DEMax of 57% was obtained with composition 2 (ACPA concentration of 0.006 M), and it is represented in

Figure 4b. A

DEMax of 72% was obtained with composition 3 (ACPA concentration of 0.009 M), which is represented in

Figure 4c.

Figure 4d represents the

DE obtained with composition 4 (ACPA concentration of 0.012 M), for which a

DEMax of 82% was obtained. And finally,

Figure 4e depicts the DE obtained with composition 5 (ACPA concentration of 0.0015 M), for which a

DEMax of 81% was obtained. Higher concentrations of ACPA were tested, but the results were not included in this work since

DEMax was not improved.

For a better discussion and comparison of the obtained results, a summary of the main results of

Figure 4 is presented in

Table 2. One of the main results is that the

DEMax increases as the ACPA concentration in the photopolymer increases, obtaining a

DEMax of 82% with an ACPA concentration of 0.012 M. From this concentration,

DEMax remains constant with the increment of the ACPA concentration. In this sense, the presence of the ACPA in the photopolymer has produced a length reduction in the polymer chains, which has resulted in an increase of the

DEMax.

If our attention is now focused on the refractive index modulation

Δn and on the optical thickness

d obtained with the Coupled Wave Theory (Equation (11)), we can see that

Δn presents small variations between 0.00133 and 0.00154 for the different compositions. On the other hand, the optical thickness

d increases as the ACPA concentration does, and hence as

DEMax does. This result makes sense since the product

Δn ×

d is directly related to the diffraction efficiency of a grating [

22]. In fact, an increment of the

DEMax produces an increment in the product

Δn ×

d as can be seen in

Table 2. Therefore, if

Δn remains approximately constant, then

d must necessarily increase with the increment of the diffraction efficiency of the grating. The observed increment of the optical thickness

d can be qualitatively explained taking into account that, in the transmission geometry, both recording beams impinge symmetrically at the same sample face. Consequently, both recording beams undergo the same attenuation (due to the dye) at all the spatial positions of the sample where they interfere, and thus the beam ratio of the two beams is close to unity in all of the sample volumes. This fact allows for the ACPA to improve the grating formation in the entire sample volume, which, in turn, explains the increment of the optical thickness associated with the increment of ACPA concentration.

Moreover, the experimental spatial period

Λexp obtained from the fitting of experimental data of

Figure 4 (through Equation (11)) has been represented in

Table 2. With these values, the shrinkage can be calculated through Equation (14), taking into account that the theoretical spatial period for these gratings is

Λth = 0.3762 μm. For all the compositions in

Table 2, the values of the shrinkage are smaller than 0.2%, so it can be considered that these gratings are not shrinking.

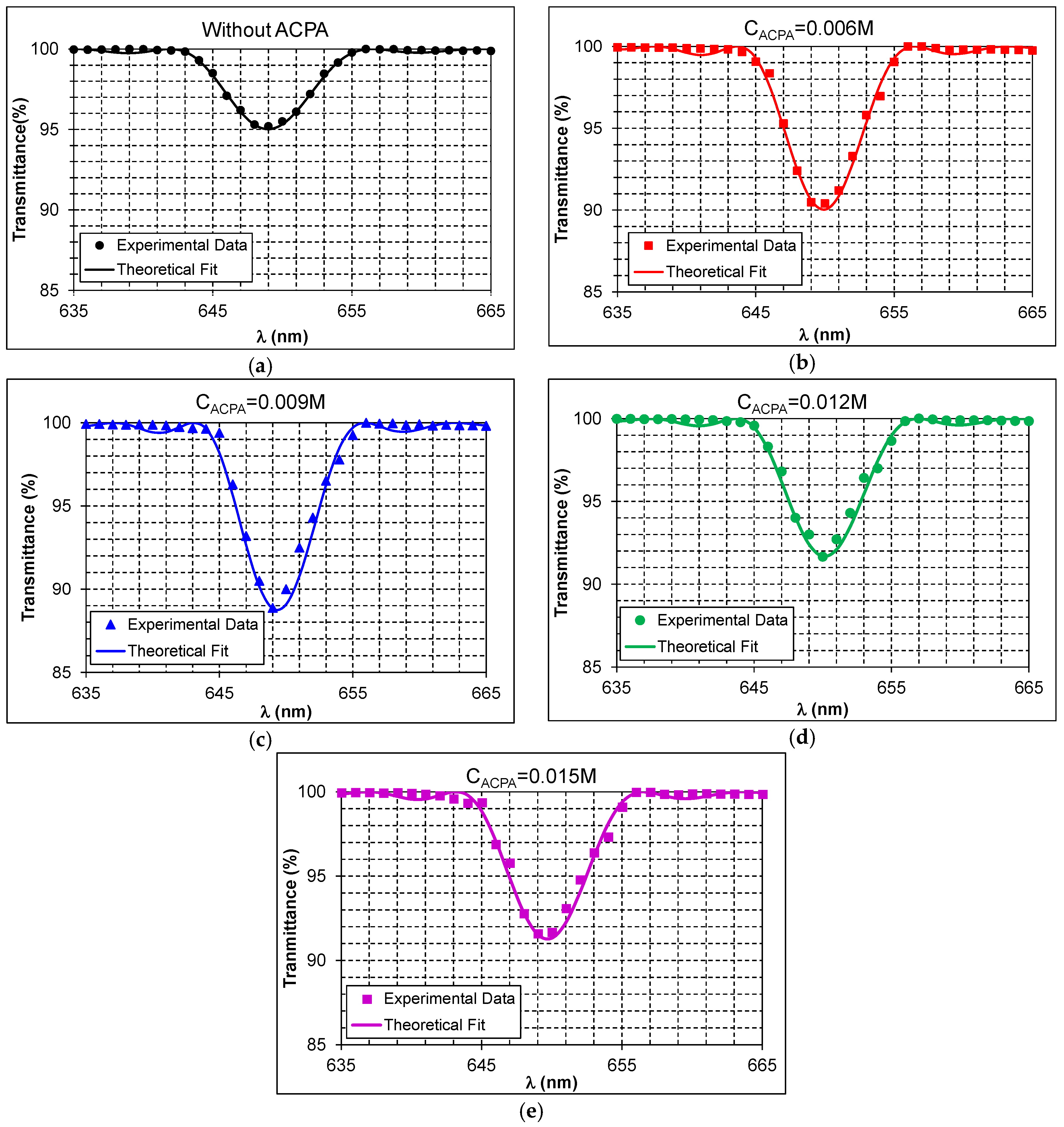

Secondly, reflection gratings with a spatial frequency of 4558 lines/mm were recorded in the photopolymers of

Table 1 with the setup of

Figure 3b, and the obtained results are presented in

Figure 5. In this case, each plot shows the experimental transmittance in percentage for a reflection grating with a different ACPA concentration.

As was explained in

Section 3.2, reflection gratings were reconstructed with a double beam spectrophotometer. The reconstruction angle was 0°, and the transmittances of the gratings were obtained as a function of the reconstruction wavelength. Like in

Figure 4, the theoretical fit of the experimental data with the Coupled Wave Theory [

17] is represented with a solid line in each plot, the spatial period

Λexp, the refractive index modulation

Δn as well as the grating thickness

d are also obtained. In this case, for each plot,

DEMax is calculated from the experimental data by means of Equation (8).

The

DEMax obtained for composition 1 without ACPA was 4.8% (

Figure 5a), whereas a

DEMax of 9.6% (

Figure 5b) was obtained for composition 2 (ACPA concentration of 0.006 M). On the other hand, a

DEMax of 11.1% (

Figure 5c) was obtained for composition 3 (ACPA concentration of 0.009 M), while a

DEMax of 8.3% (

Figure 5d) was obtained for composition 4 (ACPA concentration of 0.012 M). Finally, a

DEMax of 8.4% (

Figure 5e) was obtained for composition 5 (ACPA concentration of 0.0015 M).

A summary of the results of

Figure 5 is presented in

Table 3. In this case, the

DEMax increases with the ACPA concentration in the photopolymer until the highest diffraction efficiency (

DEMax of 11.1%) among all compositions of

Table 1 is reached for an ACPA concentration of 0.009M. With ACPA concentrations of 0.012 M and 0.015 M, the

DEMax slightly decreases (8.3% and 8.4%, respectively). Once again, the incorporation of the ACPA in the composition of the photopolymer, with the consequent reduction of the length in the polymer chains, produces an increment of the diffraction efficiency.

Regarding

Δn and d (obtained from the fitting of the experimental data of

Figure 5 through Equation (11)), we can see that the optical thickness for reflection gratings remains approximately constant in this case. Consequently, when

DEMax (and therefore the product

Δn ×

d) increases,

Δn also does, and when

DEMax and the product

Δn ×

d decrease,

Δn also decreases. The fact that the optical thickness remains approximately constant can be qualitatively explained taking into account that, in the reflection geometry, each recording beam impinges symmetrically at a different sample face. Thus, there will be a region inside the sample where both recordings beams undergo approximately the same attenuation and thus the beam ratio of the recording beams will be approximately equal to unity. This fact allows that the ACPA improves the grating formation in that region of the sample. However, outside such region, each of the recording beams will undergo a different attenuation, so the beam ratio will be different from unity, which avoids a suitable interference between the recording beams despite the presence of ACPA. Consequently, the ACPA concentration will only be able to improve the grating formation in a reduced region where the beam ratio is approximately equal to unity, which explains that

d does not significantly increase as the ACPA concentration does.

Moreover, the experimental spatial period

Λexp has been obtained from the experimental data of

Figure 5. The values calculated from the fitting through Equation (11) have been included in

Table 3. Like in the transmission geometry, the shrinkage has also been calculated through Equation (14) taking into account that the theoretical spatial period for these gratings is

Λth = 0.2194 μm. The values of shrinkage are included in

Table 3 (S%). As can be observed, the shrinkage value for the composition without ACPA (

S = 2.30%) is higher than the shrinkage values for the compositions with ACPA. However, all the shrinkage values range between 2.13% to 2.30%, so we can conclude that the ACPA has not a significant influence on shrinkage.

Finally, from the comparison of

Table 2 and

Table 3, it can be observed that the values of

Δn for the reflection gratings are greater than the ones obtained for transmission gratings. However, the

DE for reflection gratings is smaller than for transmission gratings, since the optical thickness (and thus the product

Δn ×

d) in the reflection gratings is much smaller than in the transmission ones. In fact, unlike in the transmission geometry, the recording beams in the reflection geometry do not necessarily undergo the same attenuation at the interference region inside the sample. Consequently, the spatial region where the beam ratio is close to unity is much smaller than in the case of transmission gratings. Furthermore, this fact implies that the grating improvement due to the ACPA will be restricted to a much smaller region (where the beam ratio is close to unity) than in the case of transmission gratings, which explains that the optical thickness does not significantly improve with the ACPA.

5. Conclusions

In this paper, holographic transmission gratings with a spatial frequency of 2658 lines/mm and holographic reflection gratings with a spatial frequency of 4558 lines/mm were recorded in a PVA/AA based photopolymer. A CTA, specifically ACPA, in this work is incorporated into this material to improve its response at high spatial frequencies. The ACPA concentrations have been modified to determine the optimal composition that allows for obtaining a maximum diffraction efficiency in each geometry.

For the transmission geometry, it has been obtained that the incorporation of the ACPA into the standard photopolymer produces two times the diffraction efficiency than in the photopolymer without ACPA. Although the presence of ACPA in the material has not significantly improved the refractive index modulation, it has improved the grating formation in the entire volume of the material, which causes an optical thickness increment and, in turn, a diffraction efficiency increment.

For the reflection geometry, the presence of ACPA has also produced twice the diffraction efficiency than in the photopolymer without ACPA. In this case, the optical thickness of the grating has only increased slightly due to the geometry of the recording system. However, the ACPA has improved refractive index modulation, thereby improving the diffraction efficiency of the grating.

Shrinkage has also been calculated for the transmission and reflection gratings. For transmission gratings, the shrinkage was below 0.2%, so it can be considered that such gratings do not have shrinkage. In the case of reflection gratings, the shrinkage was approximately constant, ranging between 2.1% and 2.3% for all the analyzed compositions, and thus the ACPA did not have an appreciable influence on the shrinkage.