Thermal Mechanical Processing Effects on Microstructure Evolution and Mechanical Properties of the Sintered Ti-22Al-25Nb Alloy

Abstract

:1. Introduction

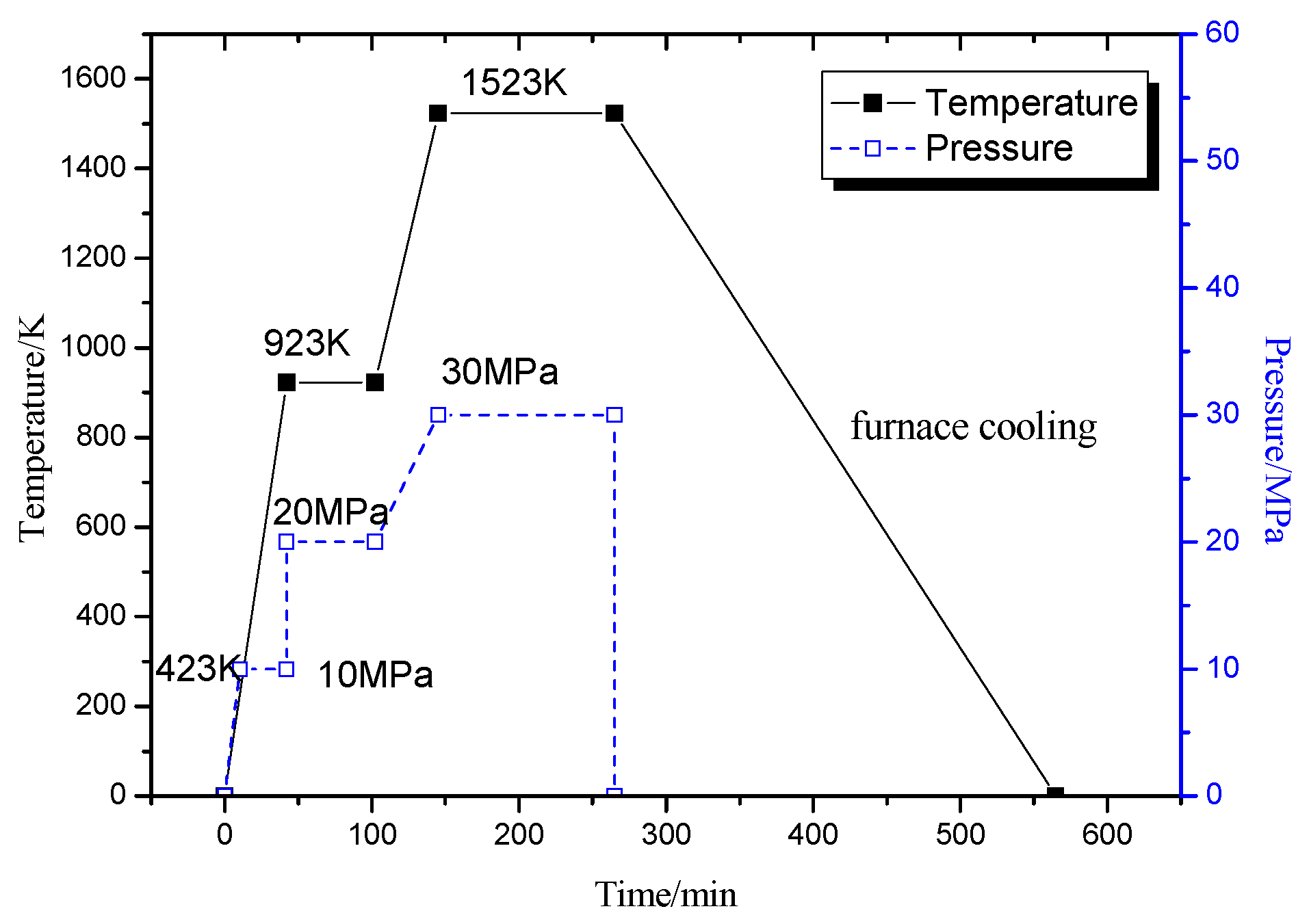

2. Materials and Methods

3. Results and Discussion

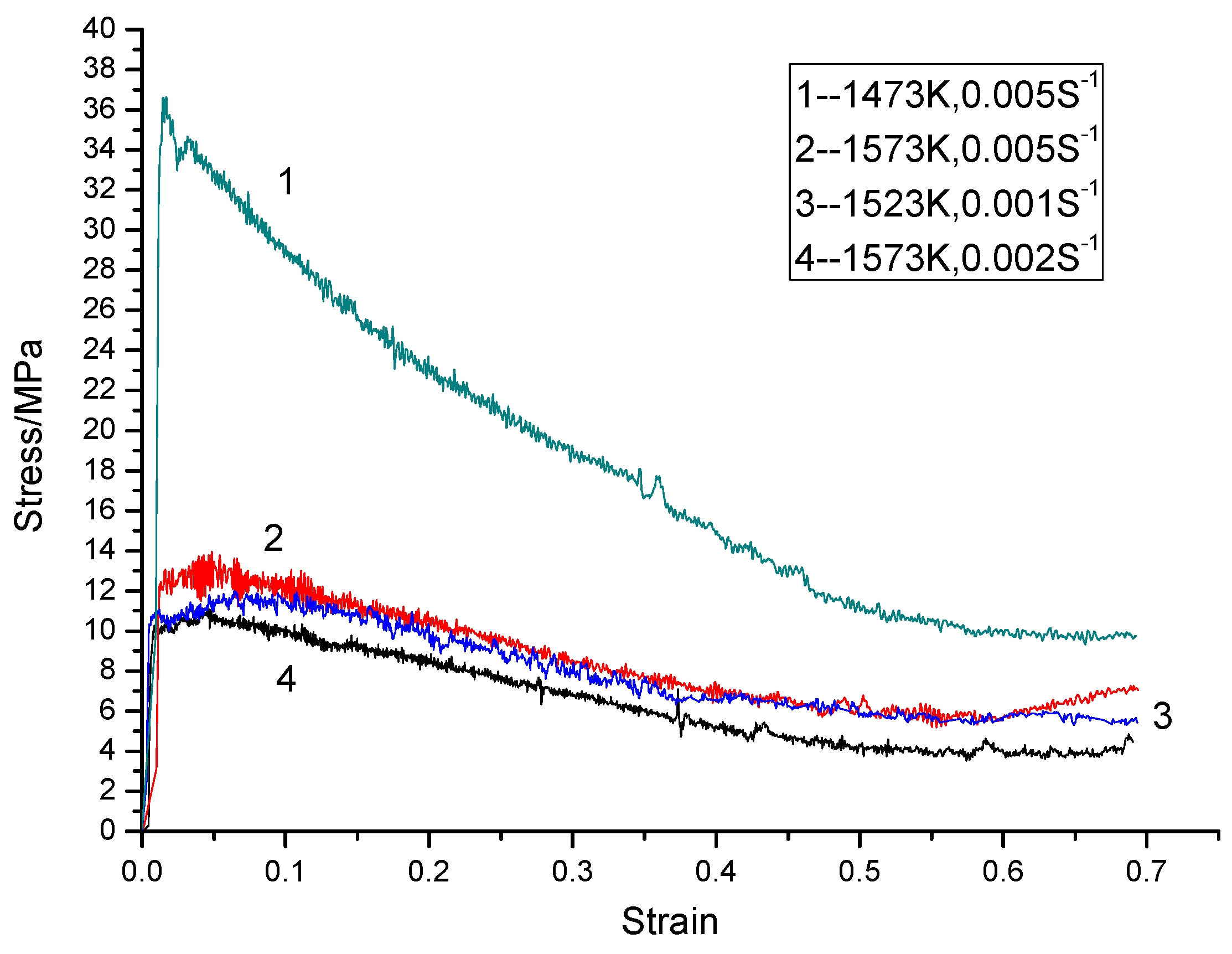

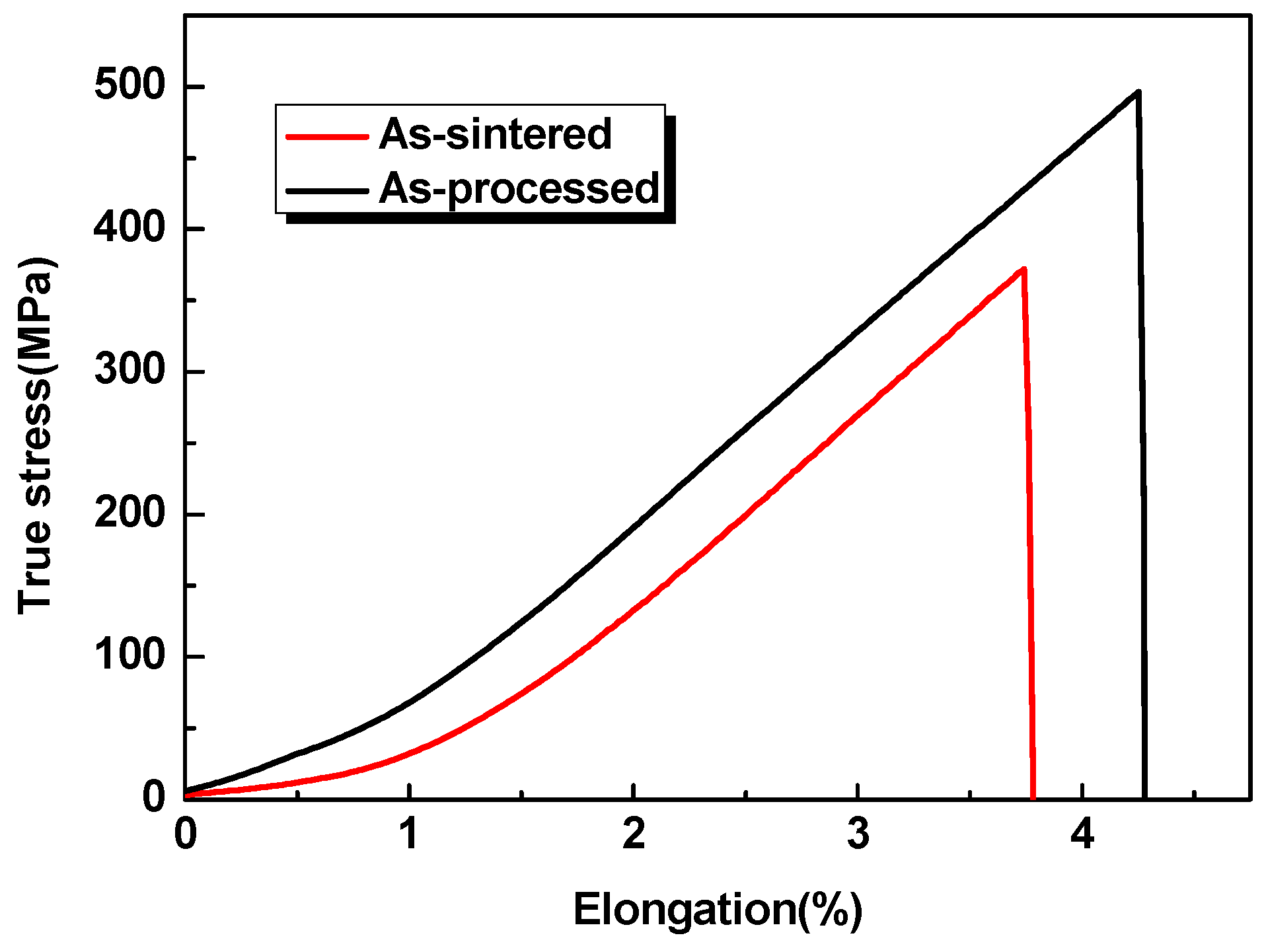

3.1. Tensile Behaviors

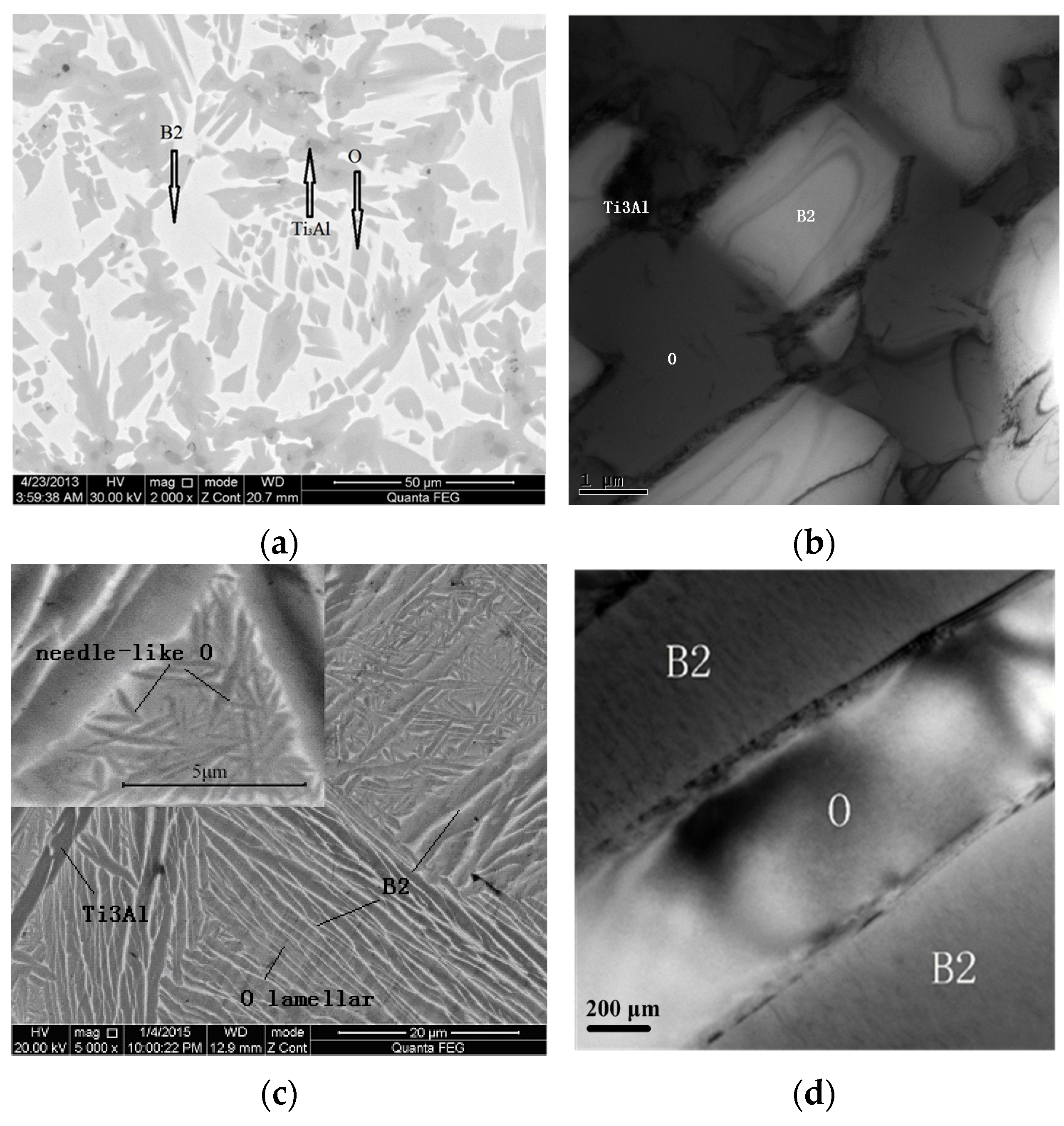

3.2. Microstructure Characterization

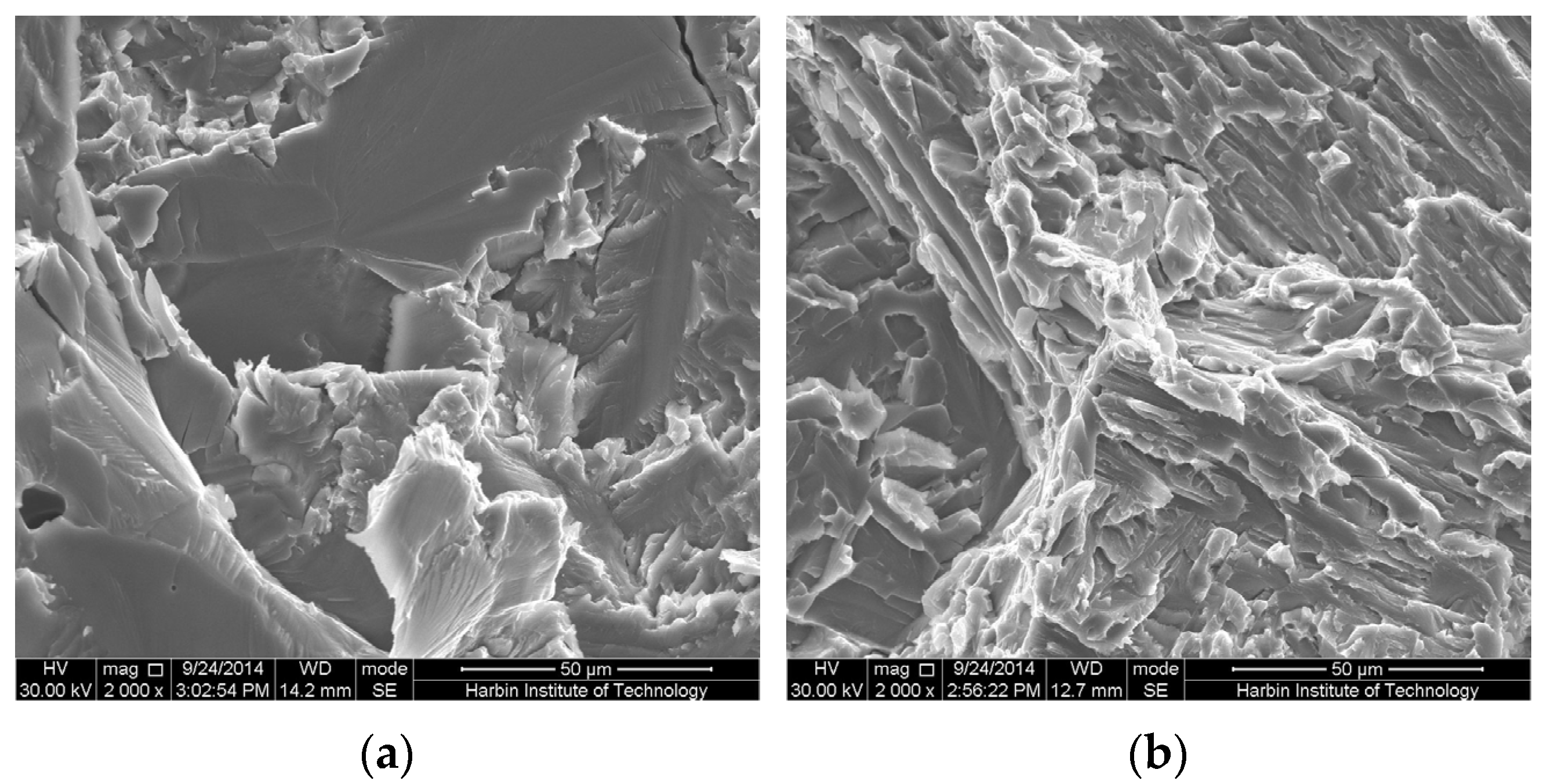

3.3. Fracture Toughness and Fracture Mechanism Analyses

4. Conclusions

- The sintered Ti-22Al-25Nb alloy was processed by isothermal forging. The microstructure was homogenous compared to the as-sintered alloy. The morphology of O phase changed from the coarse lath O to the lamellar O and acicular O. The distribution of O phase was relatively homogeneous.

- While the sintered alloy was processed by isothermal forging, the tensile strength and elongation increased from 340 MPa, 3.6% to 500 MPa, 4.2%, respectively. In addition, the fracture toughness (KIC) was enhanced from 7 to 15 MPa·m−1/2.

- Judging by the fractography observations, a typical embrittlement fracture consisting of cleavage and quasi-cleavage fracture was developed. The morphologies of O phase within B2 phase had a key effect on improving strength and ductile. The fracture mechanism changing from cleavage fracture to quasi-cleavage fracture mainly resulted from morphologies and the distribution of O phase. Meanwhile, the interfaces in the transformed O/B2 colony, not the grain size, predominantly controlled fracture toughness in the Ti-22Al-25Nb alloy.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Banerjee, D.; Gogia, A.K.; Nandy, T.K. A new ordered orthorhombic phase in a Ti3Al-Nb alloy. Acta Metall. 1988, 36, 135–158. [Google Scholar] [CrossRef]

- Gogia, A.K.; Nandy, T.K.; Banerjee, D.; Carisey, T.; Strudel, J.L.; Franchet, J.M. Microstructure and mechanical properties of orthorhombic alloys in the Ti-Al-Nb system. Intermetallics 1998, 6, 741–748. [Google Scholar] [CrossRef]

- Nandy, T.K.; Banerjee, D. Creep of the orthorhombic phase based on the intermetallic Ti2AlNb. Intermetallics 2000, 8, 915–928. [Google Scholar] [CrossRef]

- Wang, W.; Zeng, W.; Xue, C.; Liang, X.; Zhang, J. Microstructural evolution, creep, and tensile behavior of a Ti-22Al-25Nb orthorhombic alloy. Mater. Sci. Eng. A 2014, 603, 176–184. [Google Scholar] [CrossRef]

- Xue, C.; Zeng, W.; Wang, W.; Liang, X.; Zhang, J. The enhanced tensile property by introducing bimodal size distribution of lamellar O for O+B2 Ti2AlNb based alloy. Mater. Sci. Eng. A 2013, 587, 54–60. [Google Scholar]

- Xue, C.; Zeng, W.; Xu, B.; Liang, X.; Zhang, J.; Li, S. B2 grain growth and particle pinning effect of Ti-22Al-25Nb orthorhombic intermetallic alloy during heating process. Intermetallics 2012, 29, 41–47. [Google Scholar] [CrossRef]

- Boehlert, C.J. Microstructure, creep, and tensile behavior of a Ti-12Al-38Nb (at.%) beta+orthorhombic alloy. Mater. Sci. Eng. A 1999, 267, 82–98. [Google Scholar] [CrossRef]

- Boehlert, C.J. The effects of forging and rolling on microstructure in O+BCC Ti-Al-Nb alloys. Mater. Sci. Eng. A 2000, 279, 118–129. [Google Scholar] [CrossRef]

- Kamat, S.V.; Gogia, A.K.; Banerjee, D. Effect of alloying elements and heat treatment on the fracture toughness of Ti-Al-Nb alloys. Actamaterialia 1998, 46, 239–251. [Google Scholar]

- Germann, L.; Banerjee, D.; Guédou, J.Y.; Strudel, J.-L. Effect of composition on the mechanical properties of newly developed Ti2AlNb-based titanium aluminide. Intermetallics 2005, 13, 920–924. [Google Scholar] [CrossRef]

- Xue, C.; Zeng, W.; Wang, W.; Liang, X.; Zhang, J. Coarsening behavior of lamellar orthorhombic phase and its effect on tensile properties for the Ti–22Al–25Nb alloy. Mater. Sci. Eng. A 2014, 31, 320–325. [Google Scholar]

- Wang, W.; Zeng, W.; Gang, Y.; Li, D.; Zheng, Y.; Liang, X. Effect of heat treatment on microstructure and mechanical properties of Ti2AlNb alloy. Titanium Ind. Progress 2015, 32, 16–19. [Google Scholar]

- Jia, J.; Zhang, K.; Lu, Z. Dynamic recrystallization kinetics of a powder metallurgy Ti-22Al-25Nb alloy during hot compression. Mater. Sci. Eng. A 2014, 607, 630639. [Google Scholar] [CrossRef]

- Wang, W.; Zeng, W.; Xue, C.; Liang, X.; Zhang, J. Microstructure control and mechanical properties from isothermal forging and heat treatment of Ti–22Al–25Nb (at.%) orthorhombic alloy. Intermetallics 2015, 56, 79–86. [Google Scholar] [CrossRef]

- Boehlert, C.J.; Majumdar, B.S.; Seetharaman, V.; Miracle, D.B. Part I. The microstructural evolution in Ti-Al-Nb O+Bcc orthorhombic alloys. Metall. Mater. Trans. A 1999, 30, 2305–2323. [Google Scholar] [CrossRef]

- Sadi, F.A.; Servant, C. On the B2→O phase transformation in Ti-Al-Nb alloys. Mater. Sci. Eng. A 2003, 346, 19–28. [Google Scholar] [CrossRef]

- Zhang, K.; Liu, M.; Lei, Z.; Chen, Y. Microstructure Evolution and Tensile Properties of Laser-TIG Hybrid Welds of Ti2AlNb-Based Titanium Aluminide. J. Mater. Eng. Perform. 2014, 23, 3778–3785. [Google Scholar] [CrossRef]

- Boehlert, C.J. Part III. The tensile behavior of Ti-Al-NbO+Bcc orthorhombic alloys. Metall. Mater. Trans. A 2001, 32, 1977–1988. [Google Scholar] [CrossRef]

- Peng, J.H.; Mao, Y. Tensile properties and fracture behavior of Ti2AlNb based alloys at room temperature. Trans. Nonferrous Met. Soc. China 2000, 3, 378–381. [Google Scholar]

- Emura, S.; Araoka, A.; Hagiwara, M. B2 grain size refinement and its effect on room temperature tensile properties of a Ti–22Al–27Nb orthorhombic intermetallic alloy. Scr. Mater. 2003, 5, 629–634. [Google Scholar] [CrossRef]

- Kumpfert, J. Intermetallic alloys based on orthorhombic titanium aluminide. Adv. Eng. Mater. 2001, 13, 851–864. [Google Scholar] [CrossRef]

- Zhong, Q.; Zhao, Z.; Zhang, Z. Development of fractography and research of fracture micromechanism. J. Mech. Strength 2005, 27, 358–370. [Google Scholar]

- Nandy, T.K.; Banerjee, D. Deformation mechanisms in the O phase. Intermetallics 2000, 9–11, 1269–1282. [Google Scholar] [CrossRef]

- Yakovenkova, L.I.; Karkina, L.E.; Elkina, O.A. Experimental and theoretical investigation of the dislocation mechanisms of microcrack nucleation in Ti3Al. Russ. Metall. 2010, 4, 285–291. [Google Scholar] [CrossRef]

- Popille, F.; Douin, J. The dislocation microstructure in orthorhombic O Ti2AlNb deformed between room temperature and 800 °C. Philos. Mag. A 1996, 5, 1401–1418. [Google Scholar] [CrossRef]

- Banerjee, D. Deformation of the O and α 2 phases in the Ti-Al-Nb system. Philos. Mag. A 1995, 72, 1559–1587. [Google Scholar] [CrossRef]

- Cao, R.; Lin, Y.; Chen, J.; Hu, D. Fracture process and Mechanism in fully lamellar TiAl alloys with tensile tests. Chin. J. Mech. Eng. 2008, 44, 40–45. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wang, Y.; Lu, Z.; Zhang, K.; Zhang, D. Thermal Mechanical Processing Effects on Microstructure Evolution and Mechanical Properties of the Sintered Ti-22Al-25Nb Alloy. Materials 2016, 9, 189. https://doi.org/10.3390/ma9030189

Wang Y, Lu Z, Zhang K, Zhang D. Thermal Mechanical Processing Effects on Microstructure Evolution and Mechanical Properties of the Sintered Ti-22Al-25Nb Alloy. Materials. 2016; 9(3):189. https://doi.org/10.3390/ma9030189

Chicago/Turabian StyleWang, Yuanxin, Zhen Lu, Kaifeng Zhang, and Dalin Zhang. 2016. "Thermal Mechanical Processing Effects on Microstructure Evolution and Mechanical Properties of the Sintered Ti-22Al-25Nb Alloy" Materials 9, no. 3: 189. https://doi.org/10.3390/ma9030189