Effects on the Physical and Mechanical Properties of Porous Concrete for Plant Growth of Blast Furnace Slag, Natural Jute Fiber, and Styrene Butadiene Latex Using a Dry Mixing Manufacturing Process

Abstract

:1. Introduction

2. Materials

2.1. Materials

| Fineness (cm2/g) | Specific Gravity | Stability (%) | Setting Time | Compressive Strength (MPa) | |||

|---|---|---|---|---|---|---|---|

| Initial (min) | Final (min) | 3 days | 7 days | 28 days | |||

| 3200 | 3.15 | 0.02 | 220 | 400 | 20 | 30 | 38 |

| Chemical Composition (%) | |||||||

|---|---|---|---|---|---|---|---|

| SiO2 | Al2O3 | Fe2O3 | CaO | MgO | MnO | TiO | S |

| 33.1 | 13.9 | 0.29 | 42.4 | 6.1 | 0.4 | 0.96 | 0.66 |

| Type of Aggregate | Maximum Size (mm) | Specific Gravity | Absorption (%) | Fineness Modulus |

|---|---|---|---|---|

| Natural aggregate | 25 | 2.65 | 0.35 | 6.92 |

| Blast furnace slag aggregate | 25 | 2.36 | 5.0 | 6.80 |

| Elastic Modulus (GPa) | Specific Gravity | Fiber Length (mm) | Fiber Diameter (mm) | Tensile Strength (MPa) | Surface |

|---|---|---|---|---|---|

| 61 | 1.26 | 3 | 0.015 | 510 | Hydrophilic |

| Solids Content (%) | Styrene Content (%) | Butadiene Content (%) | pH | Specific Gravity | Surface Tension (dyne/cm) | Particle Size (A) | Viscosity (cps) |

|---|---|---|---|---|---|---|---|

| 46.5 | 34 ± 1.5 | 66 ± 1.5 | 11.0 | 1.02 | 30.57 | 1700 | 42 |

2.2. Mix Proportions

| Type of Mix | Unit Weight (kg/m3) | ||||||

|---|---|---|---|---|---|---|---|

| Water | Cement | Blast Furnace Slag | Natural Coarse Aggregate | Blast Furnace Slag Aggregate | Natural Jute Fiber | SB Latex | |

| No. 1 | 84 | 128 | 192 | 1200 | - | - | - |

| No. 2 | 84 | 128 | 192 | 960 | 240 | 0 | - |

| No. 3 | 84 | 128 | 192 | 720 | 480 | 0 | - |

| No. 4 | 84 | 128 | 192 | 480 | 720 | 0 | - |

| No. 5 | 84 | 128 | 192 | 240 | 960 | 0 | - |

| No. 6 | 84 | 128 | 192 | - | 1200 | 0 | - |

| No. 7 | 84 | 128 | 192 | 1200 | - | 1.2 | - |

| No. 8 | 84 | 128 | 192 | 960 | 240 | 1.2 | - |

| No. 9 | 84 | 128 | 192 | 720 | 480 | 1.2 | - |

| No. 10 | 84 | 128 | 192 | 480 | 720 | 1.2 | - |

| No. 11 | 84 | 128 | 192 | 240 | 960 | 1.2 | - |

| No. 12 | 84 | 128 | 192 | - | 1200 | 1.2 | - |

| No. 13 | 72 | 128 | 192 | 1200 | - | - | 16 |

| No. 14 | 72 | 128 | 192 | 960 | 240 | - | 16 |

| No. 15 | 72 | 128 | 192 | 720 | 480 | - | 16 |

| No. 16 | 72 | 128 | 192 | 480 | 720 | - | 16 |

| No. 17 | 72 | 128 | 192 | 240 | 960 | - | 16 |

| No. 18 | 72 | 128 | 192 | - | 1200 | - | 16 |

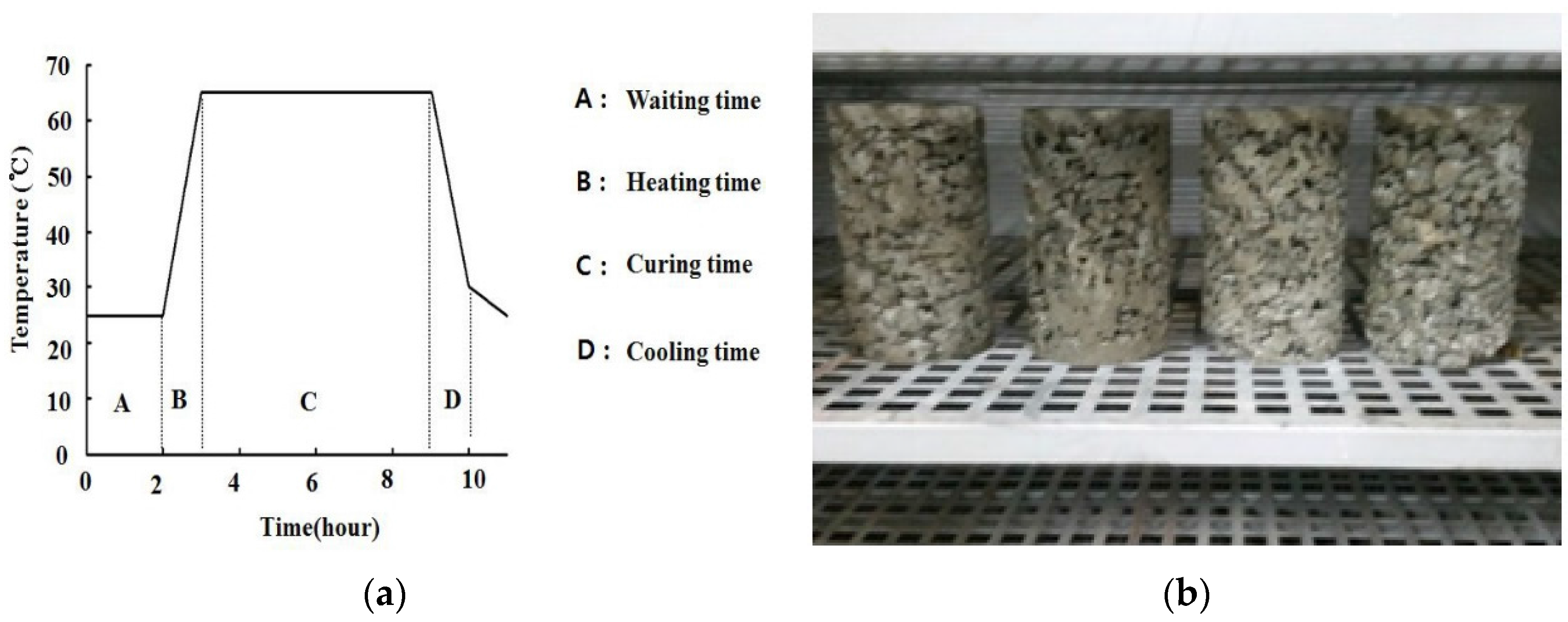

3. Test methods

3.1. Void Ratio

3.2. Compressive Strength

3.3. Repeated Freezing and Thawing Cycles Test

4. Results

4.1. Void Ratio

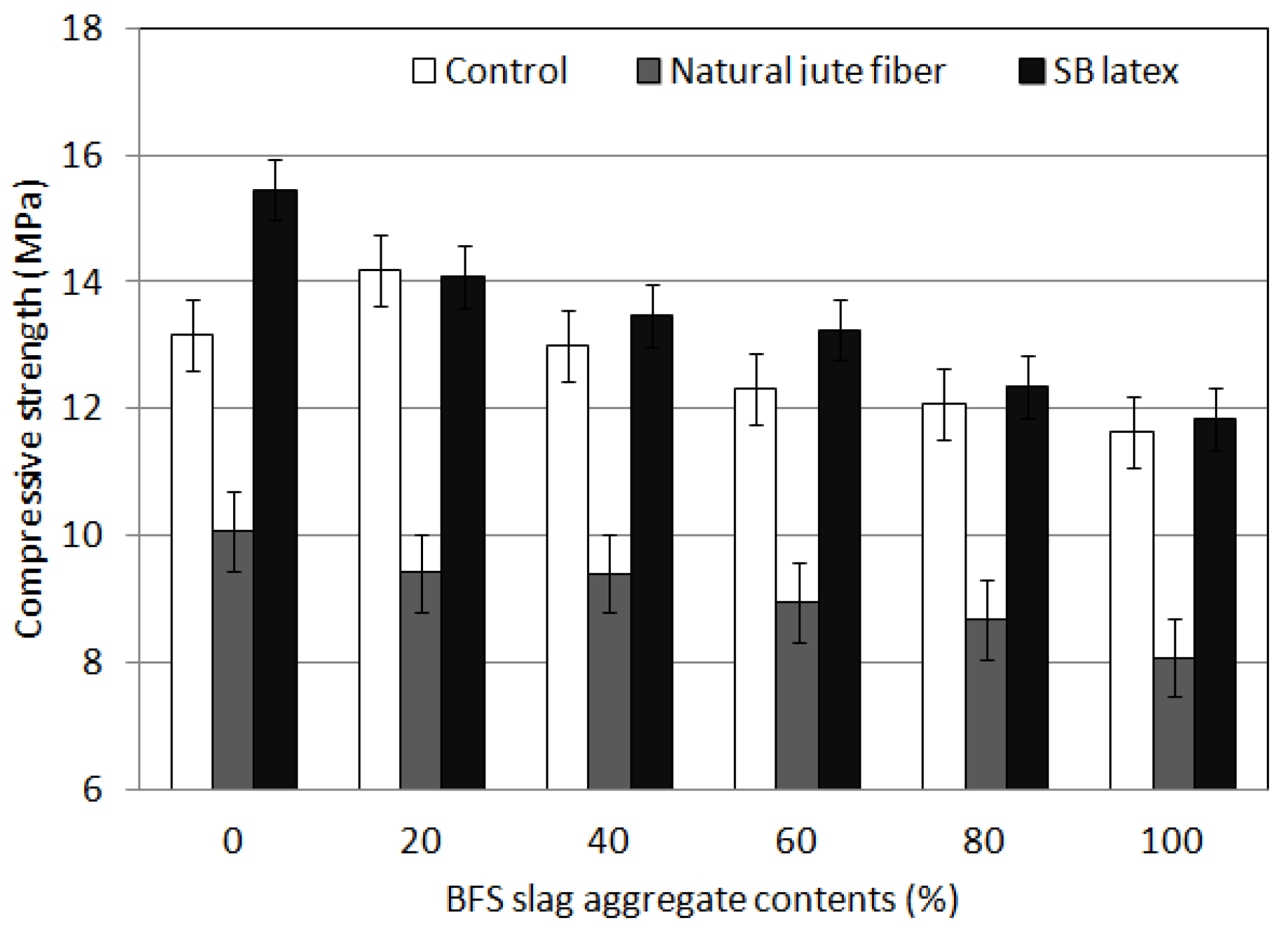

4.2. Compressive Strength

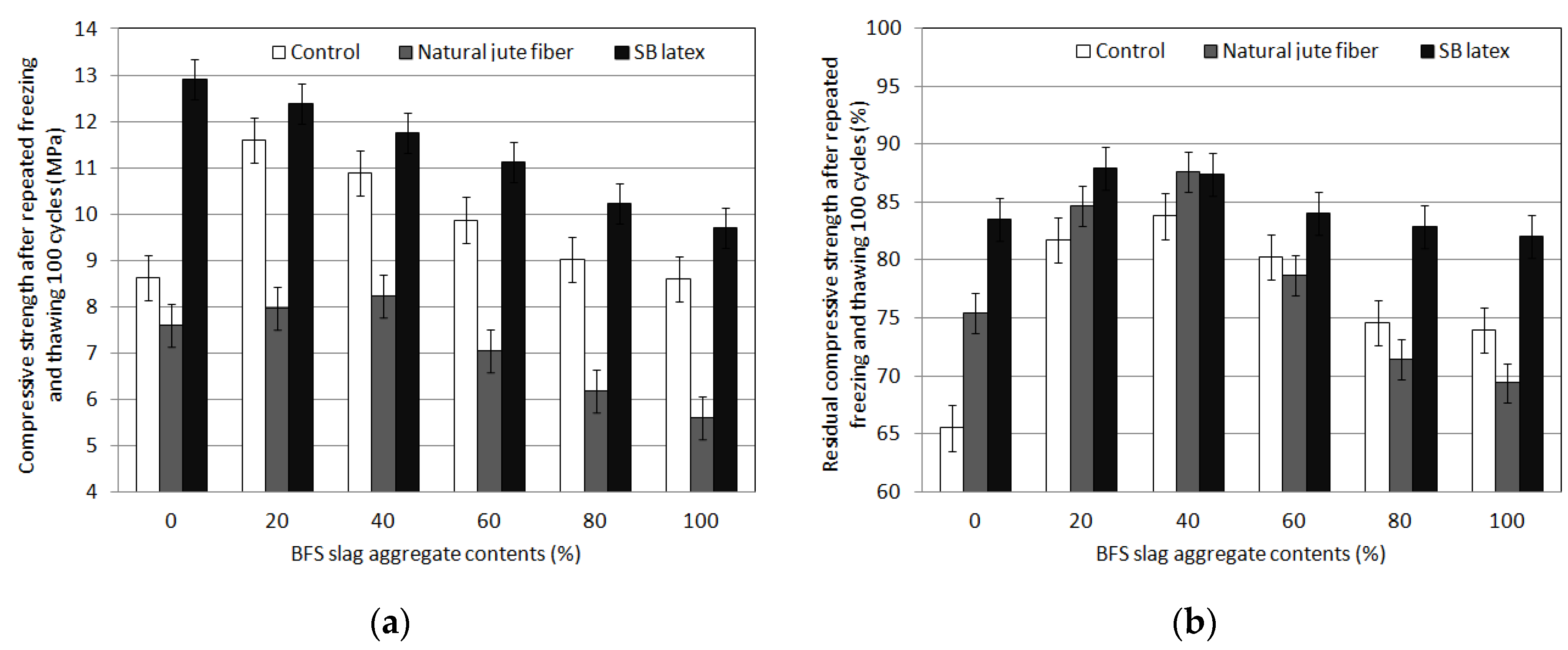

4.3. Repeated Freezing and Thawing Cycles

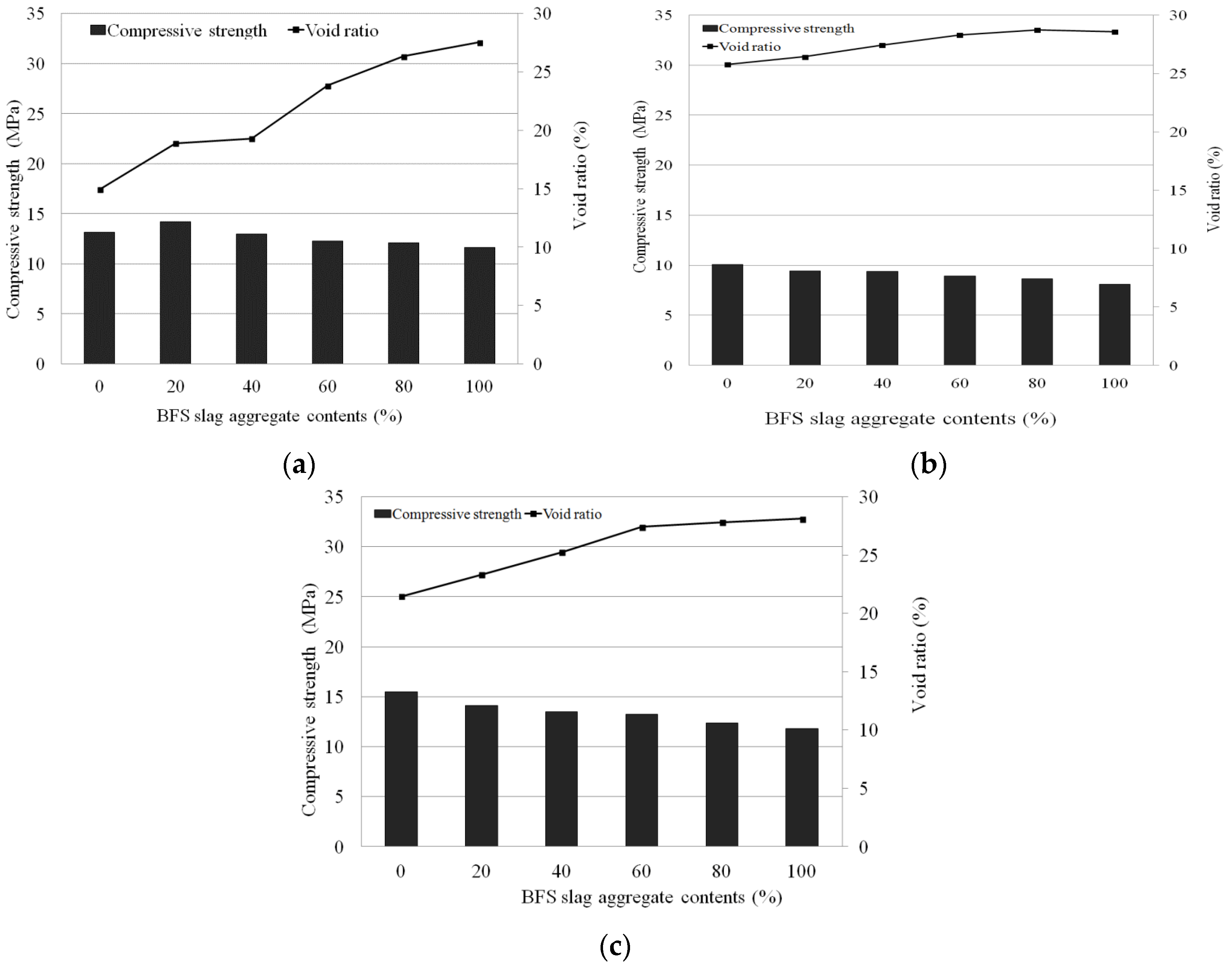

4.4. Relationship between Compressive Strength and Void Ratio

4.5. Relationship between Cyclic Freeze/Thaw Resistance and Void Ratio

5. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Sung, C.Y.; Kim, Y.I. Void Ratio and Strength of Porous Polymer Concrete and Initial Growth Properties within Planting Block with Binder Contents. J. KSAE 2010, 52, 101–110. [Google Scholar] [CrossRef]

- Kim, D.H.; Kim, C.S.; Park, C.G. Physical and Mechanical Properties of Non-Cement Porous Concrete with Alkali-Activator Contents. J. KSAE 2010, 55, 59–64. [Google Scholar] [CrossRef]

- Oh, R.O.; Kim, C.S.; Kim, H.H.; Jeon, J.H.; Kwon, W.S.; Par, C.G. Physical·Mechanical and Temperature Properties of Fiber Reinforced Porous Green Roof Hwang-toh Concrete. J. KSAE 2013, 55, 59–64. [Google Scholar] [CrossRef]

- Kim, H.H.; Kim, S.M.; Park, J.S.; Park, S.W.; Jeon, J.H.; Lee, J.H.; Chan, S.S.; Park, C.G. Effect of Blast Furnace Slag, Hwang-toh and Reinforcing Fibers on The Physical and Mechanical Properties of Porous Concrete Using Blast Furnace Slag Coarse Aggregate. J. KSAE 2010, 57, 9–17. [Google Scholar]

- Lee, J.H.; Park, J.S.; Park, C.G. Effect of Reinforcing Fiber on Mechanical Properties and Chemical Resistance of Porous Concrete with Hwang-toh. J. KSCE 2011, 31, 105–113. [Google Scholar]

- Sung, C.Y. Freezing and Thawing Properties of Polypropylene Fiber Reinforced Eco-concrete. J. KSAE 2006, 48, 59–66. [Google Scholar] [CrossRef]

- Han, S.H.; Yong, M.J. The Future of Concrete Admixture Industry for Low Carbon, Green Growth. Mag. Concr. Res. 2009, 21, 41–43. [Google Scholar]

- Yang, K.H.; Oh, S.J.; Song, J.K. Mechanical Properties of Alkali-Activated Slag-Based Concrete Using Lightweight Aggregates. J. KCI 2008, 20, 405–412. [Google Scholar]

- Mun, H.Y.; Jung, S.J.; Lim, N.K. Blast-Furnace Slag Aggregate. Mag. Concr. Res. 1997, 9, 18–22. [Google Scholar]

- Jeon, J.H.; Cha, S.S.; Park, C.G. Performance Evaluation of Porous Hwang-Toh Concrete Using Blast Furnace Slag Cement. J. KSAE 2010, 52, 9–17. [Google Scholar]

- Park, S.B.; Lee, B.C.; Kim, J.H.; Yun, D.Y. Planting-Ability Valuation of Porous Concrete Using Industrial By-Products. J. KCI 2002, 14, 623–629. [Google Scholar]

- Korea Ministry of Environment. Performance Standard for Environment Mark Certification (Permeableconcrete-EL245-2003/4/2012-36); Korea Ministry of Environment: Seoul, Korea, 2015.

- American Society for Testing and Materials. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM C39/C39M-15a; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- American Society for Testing and Materials. Standard Test Method for Resistance of Concrete to Rapid Freezing and Thawing; ASTM C666/C666M-15; ASTM International: West Conshohocken, PA, USA, 2015. [Google Scholar]

- Song, W.J.; Fu, H.Y.; Wang, G.Y. Cement paste characteristics and porous concrete properties. Constr. Build. Mater. 2008, 22, 894–901. [Google Scholar]

- Song, W.J.; Fu, H.Y.; Wang, G.Y. Study on a Kind of Eco-concrete Retaining Wall’s Block with Water Purification Function. Procedia Eng. 2012, 28, 182–189. [Google Scholar]

- Park, S.B.; Mang, T. An experimental study on the water-purification properties of porous concrete. Cem. Concr. Res. 2014, 34, 177–184. [Google Scholar] [CrossRef]

- Lian, C.; Zhuge, Y.; Beecham, S. The relationship between void ratio and strength for porous concrete. Constr. Build. Mater. 2011, 25, 4294–4298. [Google Scholar] [CrossRef]

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Kim, H.-H.; Kim, C.-S.; Jeon, J.-H.; Park, C.-G. Effects on the Physical and Mechanical Properties of Porous Concrete for Plant Growth of Blast Furnace Slag, Natural Jute Fiber, and Styrene Butadiene Latex Using a Dry Mixing Manufacturing Process. Materials 2016, 9, 84. https://doi.org/10.3390/ma9020084

Kim H-H, Kim C-S, Jeon J-H, Park C-G. Effects on the Physical and Mechanical Properties of Porous Concrete for Plant Growth of Blast Furnace Slag, Natural Jute Fiber, and Styrene Butadiene Latex Using a Dry Mixing Manufacturing Process. Materials. 2016; 9(2):84. https://doi.org/10.3390/ma9020084

Chicago/Turabian StyleKim, Hwang-Hee, Chun-Soo Kim, Ji-Hong Jeon, and Chan-Gi Park. 2016. "Effects on the Physical and Mechanical Properties of Porous Concrete for Plant Growth of Blast Furnace Slag, Natural Jute Fiber, and Styrene Butadiene Latex Using a Dry Mixing Manufacturing Process" Materials 9, no. 2: 84. https://doi.org/10.3390/ma9020084