1. Introduction

Syntactic foams (SFs) are foams in which porosity is introduced via hollow particles dispersed within a matrix material. Polymer matrix SFs have found widespread application in the offshore and oil industry, where they serve as buoyancy devices that can withstand much higher hydrostatic loads than other types of foams [

1,

2]. Such superior mechanical performance is attributed to the considerable strength of hollow particles used not only as lightweight filler, but also in the strengthening phase. Prominent among these filler materials are hollow glass microspheres, fly ash cenospheres, and ceramic and in some cases even metallic hollow spheres [

3,

4]. Of these, the former two are available in size ranges below a few hundred micrometers, while the ceramic spheres typically come in sizes ranging from micrometers to millimeters.

Metal matrix SFs (MMSFs) also show great application potential, based both on performance and cost, but their adoption in industry has been slow [

5,

6,

7]. Processes for their production are typically either melt-based or powder metallurgical techniques. Melt infiltration of either geometrically confined loose hollow particles or of sintered or otherwise bonded preforms has been demonstrated for several matrix materials: aluminum matrix syntactic foams have, for example, been produced in combination with various fillers by Weise

et al. (glass microspheres, [

8]), Luong

et al. (cenospheres, [

9]) or Szlancsik

et al. (Fe hollow spheres, [

10]) while magnesium matrices have been scrutinized by Gupta

et al. [

11] and Luong

et al. [

12]. Zinc foams have also been synthesized using pressure assisted infiltration [

8]. Higher melting matrix materials are typically processed powder metallurgically: there are exceptions in the case of iron and steel matrices [

13,

14], but titanium, for example, is generally treated using powder metallurgy (PM) techniques due to its even higher melting point and reactivity [

15,

16].

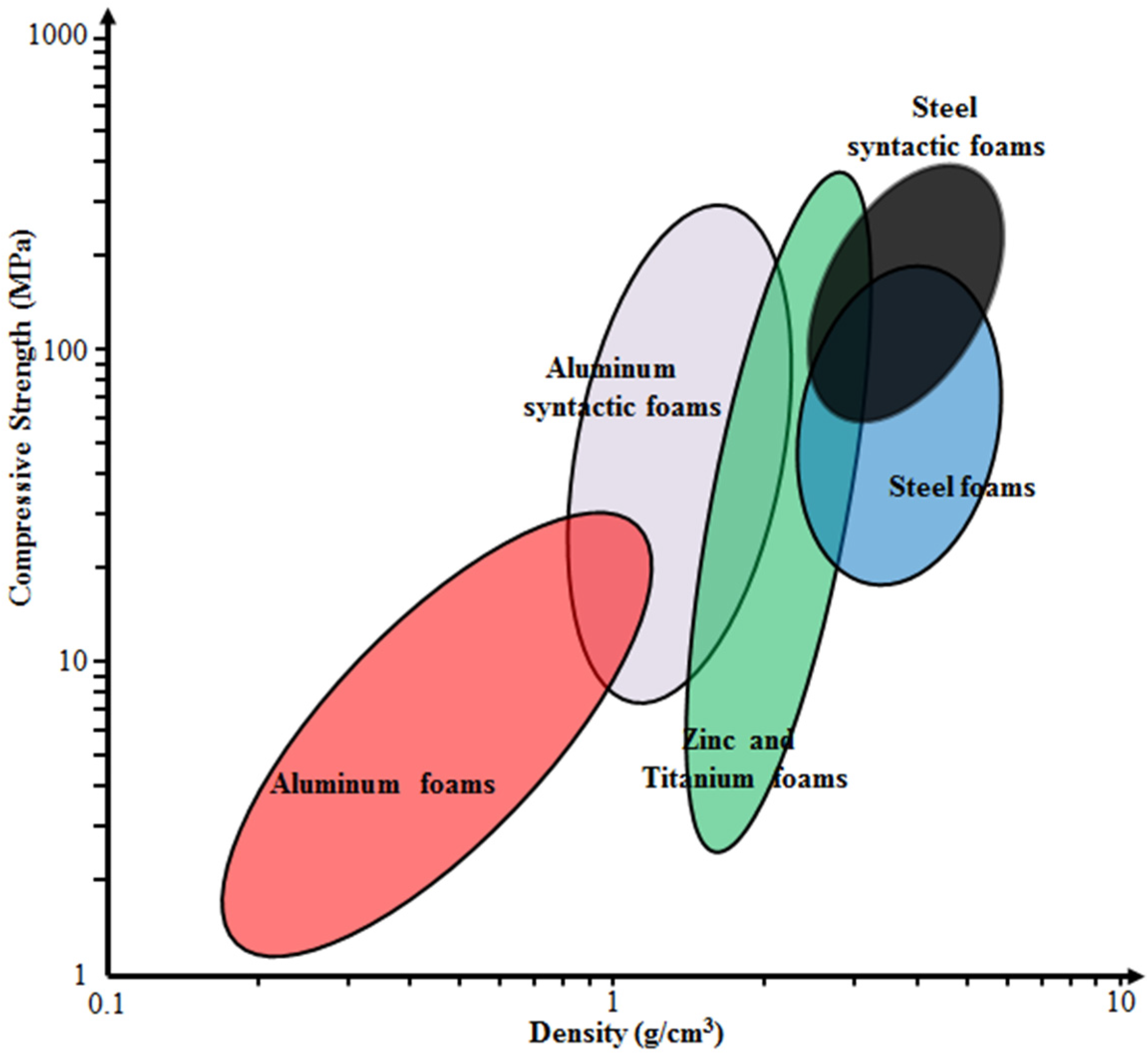

A qualitative comparison of mechanical properties of many of these materials with conventional types of metal foams is shown in

Figure 1, underlining that SFs typically outperform their non-syntactic counterparts in terms of both absolute and density-normalized compressive strength, whereas lowest absolute density is often achieved through other processes [

17]. Generally, in return for their high density, the steel matrix SFs have higher strength than MMSFs. In addition, they represent another option for replacing conventional steel foams, which show comparable density, but typically at lower strength.

In this work, two types of SFs filled with 5 and 10 wt.% Fillite alumino-silicate cenospheres, composed, according to supplier specifications, of approximately 55–65 wt.% SiO

2, 27–33 wt.% Al

2O

3 and a balance of Fe

2O

3, are studied [

18]. Choice of these materials is based on previous experience from studies dedicated to Invar (FeNi36) matrix SFs [

17,

19,

20,

21]. Originally, the metal powder injection molding (MIM) process for production of MMSFs had been successfully developed using Fe99.7 materials as matrix [

22,

23]. However, observation of the tensile behavior of these foams and notably their low ductility under these conditions has led to the assumption that residual stresses brought in during the cooling step following sintering might account for this behavior, and Invar might thus be a preferable matrix material based on its coefficient of thermal expansion, which is better matched to the glass microspheres used as filler in these studies. Investigation of this effect is still ongoing, without fully conclusive results yet, even though the Invar matrix foams did in fact show the expected higher ductility under tensile load [

19]. Despite this positive effect, a microstructural comparison of glass microsphere SFs with matrices of Fe99.7 (sintered at 900 °C), Invar (1000 °C) and 316L (1200 °C) revealed onset of disintegration of glass microspheres at sintering temperatures of 1000 °C, until the full loss of all spheres when sintering at 1200 °C.

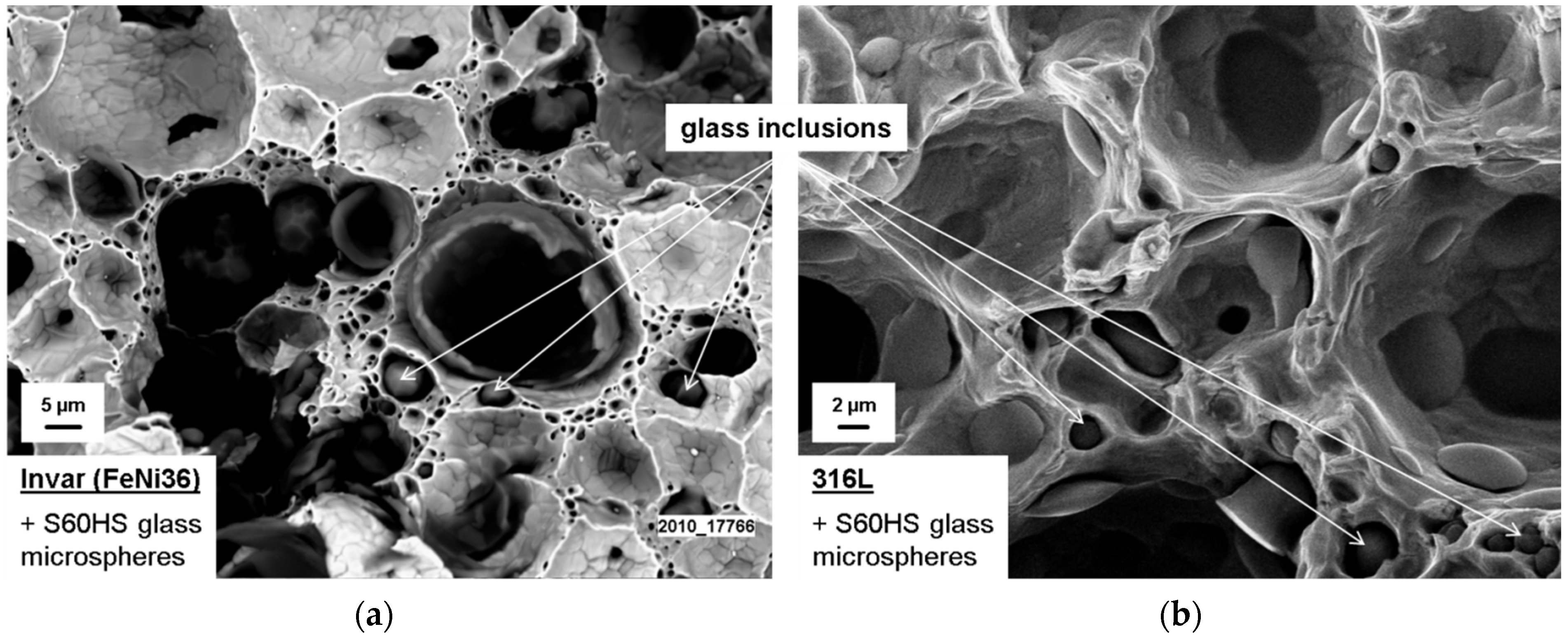

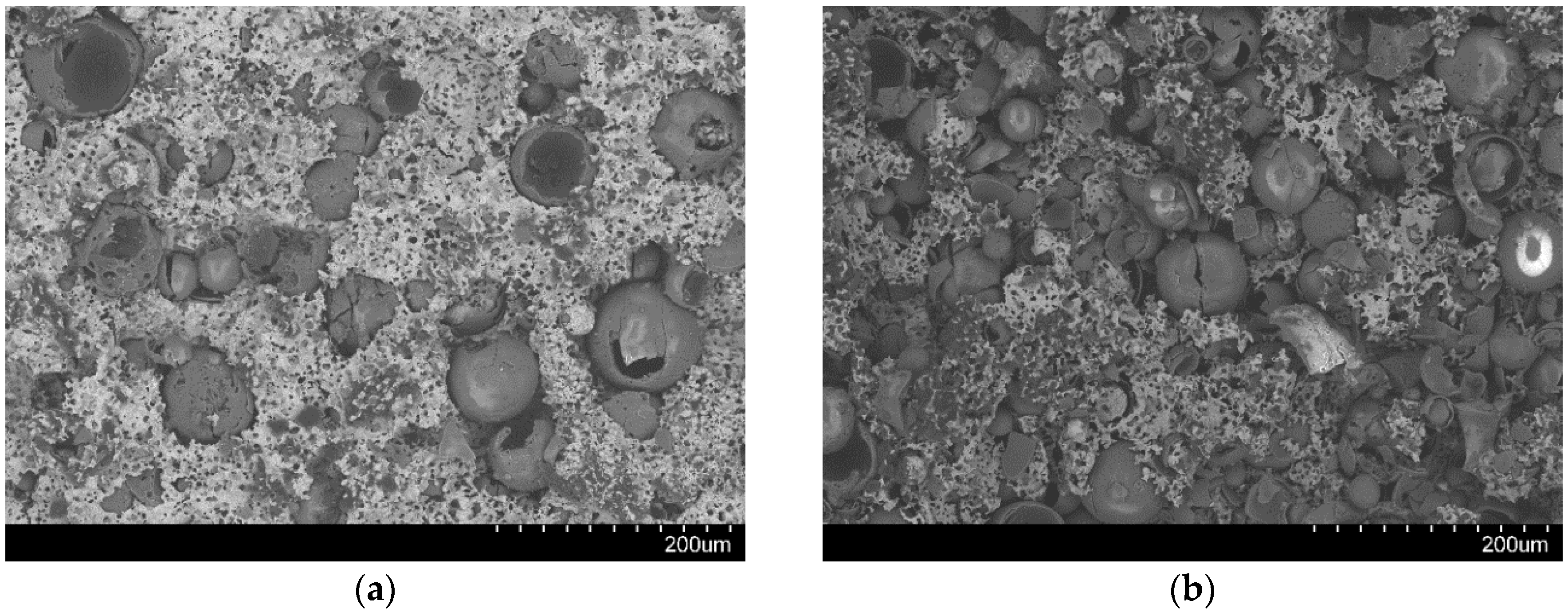

Figure 2 illustrates this effect on fracture surfaces of the respective materials: for Fe99.7, glass microspheres generally show spherical shape and smooth surfaces (not depicted here, see [

20,

23]). For Invar, the originally identical microspheres now seem less regular in shape, and satellite glass phases can be observed in between pores within the matrix (

Figure 2a) For 316L, the same satellite phases dominate the image, while the inner pore surfaces only occasionally show coverage by glass, which never extends over the entire pore surface area (

Figure 2b).

A similar effect is observed when comparing the experimentally measured to the theoretically expected densities (the latter based on rule of mixtures applied to matrix density, filler particle density and volume fraction of filler): the higher the sintering temperature, the greater the level to which the measured density exceeds the theoretical one. This phenomenon is usually understood as reflecting the microsphere’s lack of resistance against sinter shrinkage, which gets more pronounced the higher the sintering temperature is chosen [

21].

Both effects underline the need for filler of increased thermal stability, and cenospheres comprising higher quality ceramics such as Al

2O

3 and SiO

2 have potential to be useful in this regard [

18,

21]. Consequently, the present study scrutinizes the structural features of Invar matrix SFs filled with cenospheres rather than glass microspheres. In addition, a link to properties is established through an evaluation of compressive strength across a wide range of strain rates from quasi-static to highly dynamic.

3. Discussion

Figure 7 shows the engineering compressive stress-strain behavior of the Invar material and its SFs filled with different kinds of hollow particles at a strain rate of 10

−3·s

−1. Invar exhibits higher strength in comparison to its SFs at the same strain level. Additionally, the Invar SFs filled with cenospheres have lower strength than the Invar-GM SFs having comparable density [

20]. In view of the expected positive influence of the cenospheres on structural features of the foams, the actual realization of which is supported by the density measurements reported in

Table 1 as well as the optical micrographs depicted in

Figure 3, this may seem surprising. It must however be assumed that the said structural effect is counterbalanced by the generally lower strength of the cenospheres (see

Section 4,

Table 3, on filler particle characteristics according to supplier specification). This lower strength can be explained by defects in the shell resulting in a generally lower quality of cenospheres, which are an industrial waste product [

6]. In general, this observation is another indication of the fact that iron and steel matrix SFs would greatly benefit from higher strength and stiffness, but having at the same time thermally stable microspheres as advanced filler particles. Currently, such alternatives, for which ceramics like SiC or Al

2O

3 would be attractive candidates, are not available in the small size ranges matching the requirements of the MIM process,

i.e., at diameters roughly below 100 µm. From the available experimental data, the true potential of such optimized iron/steel matrix SFs is hard to estimate, since, in the present case, structural effects and filler particle characteristics are superimposed.

The yielding behavior of SFs is controlled by a complex concurrence of processes, including the matrix material plastic deformation and the hollow particles breakage. Other kinds of SFs such as the aluminum matrix variants reported by [

6,

26] show a peak stress between the elastic and plateau regions. The cracks that propagate to the matrix material from the broken cell wall of hollow particles were observed, while the stress had a significant drop [

26,

27]. The cracks lead to the structure collapsing under the compressive loading. The development of cracks in the matrix is due to two reasons: (1) a strong interfacial bonding between matrix and fillers [

26]; (2) the insufficient fracture toughness of matrix material to plastically prevent cracks [

14]. In contrast, the yielding transition between the elastic and plateau regions of Invar SFs is a smooth curve. It clearly shows that there is no significant collapse in structure of matrix material after the cenopheres fail. Due to the fact that yielding transition is a distinct segment, the yield strength specified by the offset strain of 0.2% should be used to define the end of the elastic region and the beginning of material yielding. The yield strength of Invar SFs from the present work is plotted over density in

Figure 8 and contrasted with corresponding values of other steel SFs collected from references [

13,

14,

17,

20,

21,

22,

28,

29,

30,

31]. Generally, the yield strength increases with density, thus showing the same trend as reported earlier for other variants of MMSFs in [

6,

20]. According to

Figure 8, Invar SFs filled with cenospheres provide lower yield strength than other steel SFs synthesized via the MIM route, but containing glass microballoons. As discussed above, this observation can be related to the lowered mechanical characteristics of cenospheres (1500–3000 psi or 10.3–20.7 MPa [

18], compared to 18,000 psi or 124.1 MPa for S60HS glass microballoons [

24]). However, these retain their relevance, as they can provide other options for structural applications requiring high strength over 100 MPa, which only few other MMSFs reach [

6].

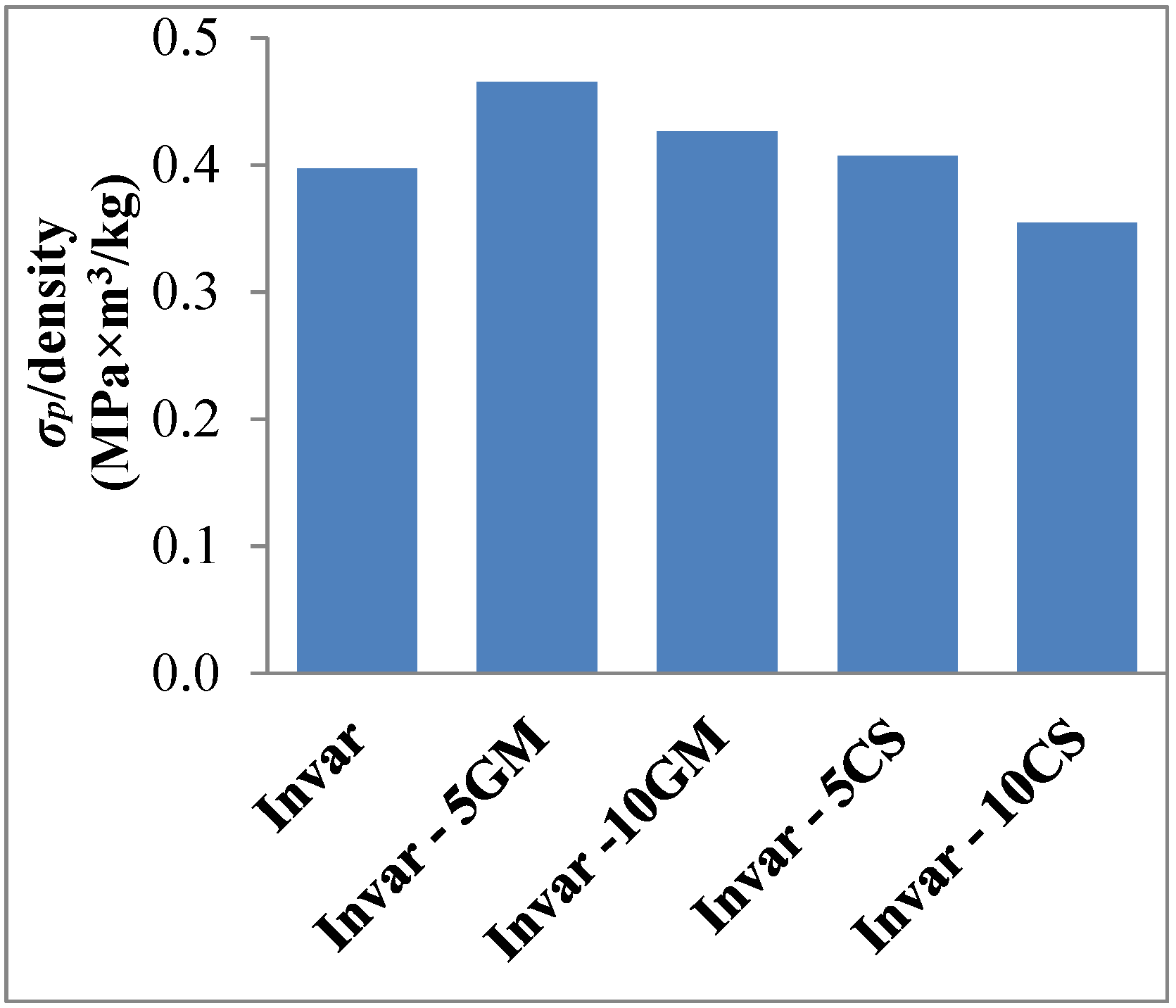

In order to evaluate the compressive mechanical performance with the contribution of cenosphere strength, the plateau onset strength, which is the stress at the intersection between tangent lines of the elastic and plateau regions, was specified [

32]. The plateau onset stress is considered as a point at which plastic deformation of matrix material and filler fracture happen at the same time. Its value for Invar-5CS and Invar-10CS is 207 and 143 MPa, respectively. In comparison to the yield strength (306 MPa) of the pure Invar matrix material [

20], Invar-5CS and Invar-10CS have a 32% and 53% lower strength. This is no surprise result because the Invar matrix material has a solid structure and thus higher density than its SF structure. This point has previously been stressed when contrasting Invar-5GM and Invar-10GM material variants with their cenosphere-based counterparts. The reduced strength of the latter, which at first sight seems to contradict the improvement in structural aspects, is likely the reflection of the lower strength of the filler particles. The plateau onset stress over density of Invar SFs and the matrix yield strength over density are plotted in

Figure 9. After eliminating the effect of density on the plateau onset stress value, the results obtained for Invar-5CS materials can be comparable to those associated with a pure Invar matrix.

Figure 9 illustrates this effect of the filler on SF strength.

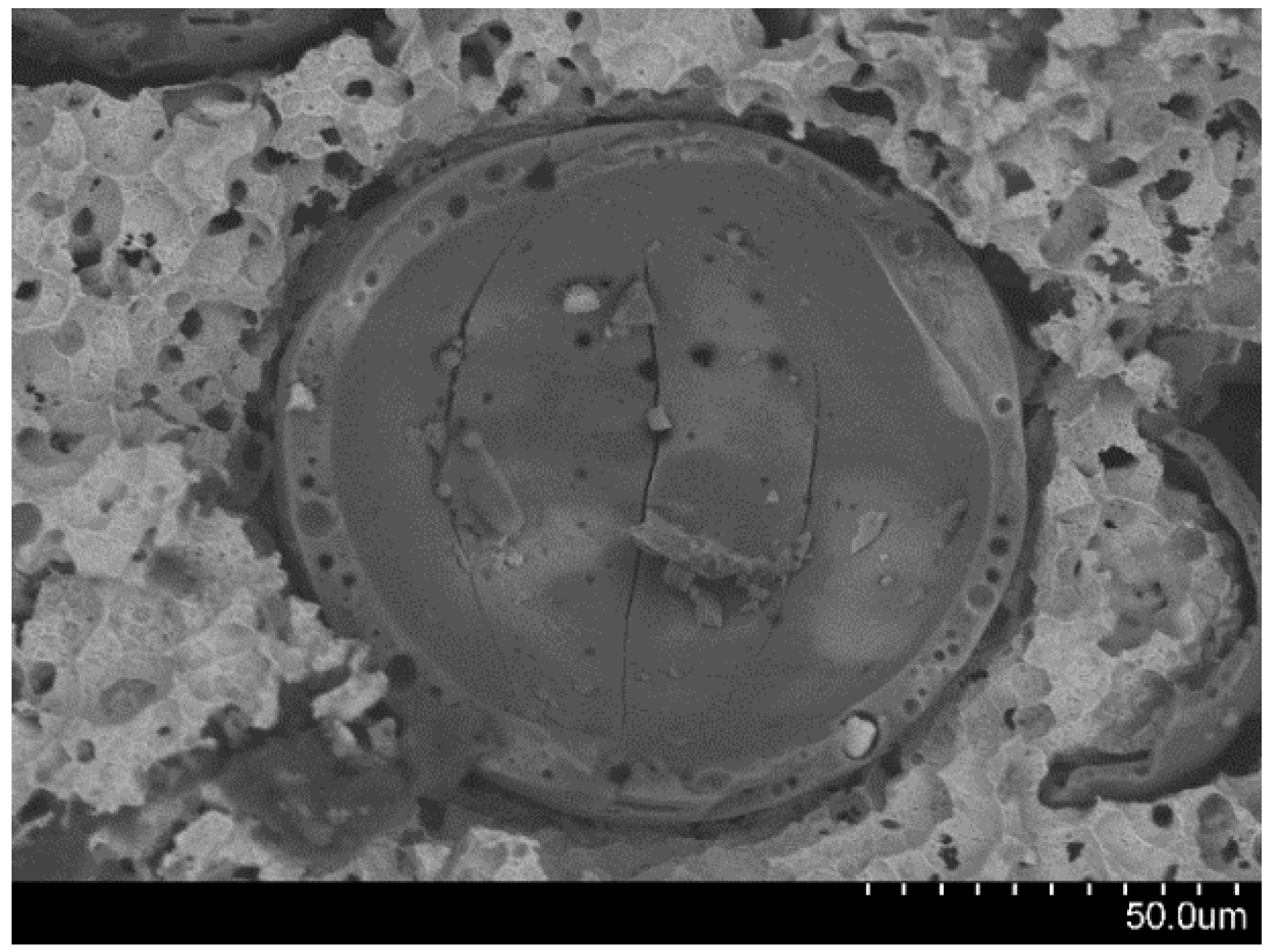

In the plateau region, stress levels show a gradual increase, impeding the distinction between the former and the densification region. To investigate the state of cenospheres in this region, the Invar-CS specimens were tested at a strain rate of 10

−3·s

−1, and deformation was stopped at an early stage within the plateau region (5% strain) and the samples subsequently etched in nitric acid of 1.0 vol.% to reveal the state of the cenospheres at this point. As shown in

Figure 10, most cenospheres had already failed at this early stage of the plateau region. The respective crack can be seen on the shell and has the same pattern, developing in the same direction of loading (

Figure 11). Possible explanations of this effect include progressive strain hardening as a consequence of density gradients and stress localization in the porous structure. In stochastic foams like those produced in the liquid state via blowing agents, such effects have been alternatively interpreted as consecutive compression of regions of increasing density stacked in the direction of compression [

33], as a result of dominating ductile failure of the matrix and ensuing strain hardening [

34], or as combinations of both effects [

34,

35]. In the present case, due to the greater homogeneity of SFs, strain hardening may be considered the dominant effect. It is worth noting in this respect that, contrary to many infiltration-based SFs [

8], in MIM-based materials, the filler particles do not form a continuous, brittle network within the matrix, but are dispersed, allowing transfer of part of the ductility of the matrix to the combination of filler and matrix. Alternatively, Peroni

et al. [

23] have suggested a mechanism for development of deformation bands in syntactic foams: the inhomgeneity of the stress distribution might lead to local initiation of failure at peak stress sites. Failure of microspheres at such sites would weaken the respective cross-section and lead to it becoming a preferred site of deformation. Similar effects have been observed computationally in polymer matrix syntactic foams, where fracture of weaker particles causes localized stress concentration, leading to other hollow particles in the vicinity breaking until the stress is sufficiently low [

36]. Strain hardening and local densification would lead to strengthening of this initial deformation band and initiation of plastic deformation, first through failure of microspheres in other, now weakest, cross sections [

22,

23].

Crushing of cenosphere fragments within the pores they originally lined may come in as an additional, secondary explanation.

Figure 12a shows the facture face near the border of Invar-10CS specimen after the densification point. The crushed cell walls of cenospheres are easily recognized as darker fragments, while the Invar matrix shows up in a brighter color. The cell walls were debonded from the matrix during the plateau region as shown in

Figure 12b. It can be explained by debonding development following the gap at the interface between the matrix and filler that is constituted during the cooling process from the sintering temperature by the difference of their thermal expansion coefficient [

28]. Since the SFs are porous structures, the energy absorption capacity of Invar SFs mainly related to the plateau region is of interest in order to judge the materials’ application potential.

Figure 13 plots the energy absorption capacity of the presently studied materials at a total strain of 50% in comparison to corresponding results obtained for other types of iron/steel SFs [

14,

20]. The diagram obtained shows that already, in combination with cenospheres, the material shows characteristics that compare favorably with the related materials considered here. In the lower density range around 4–4.5g/cm

3, the higher carbon content level carbon steel syntactic foams studied by Castro

et al. [

13,

14] reach similar energy absorption capacity levels, though at a significantly more brittle overall behavior. Transformation induced plasticity (TRIP) steels also studied by Castro

et al. [

14] promise more characteristics in this respect and almost exactly match MIM-based Invar-CS SFs in terms of energy absorption. In these studies, however, the steel matrices are combined with higher strength ceramic microspheres [

14]. As has been pointed out repeatedly above, availability of these materials as micro-scale fillers suitable for the MIM process would be expected to significantly raise the properties of our materials as well. Besides, in view of differences in part sizes (typically larger in the melt-based process suggested by Castro

et al. [

13,

14]) and geometrical complexity (typically higher in the powder metallurgical MIM process), these two material synthesis variants must be seen as docile complementary rather than competing technologies.

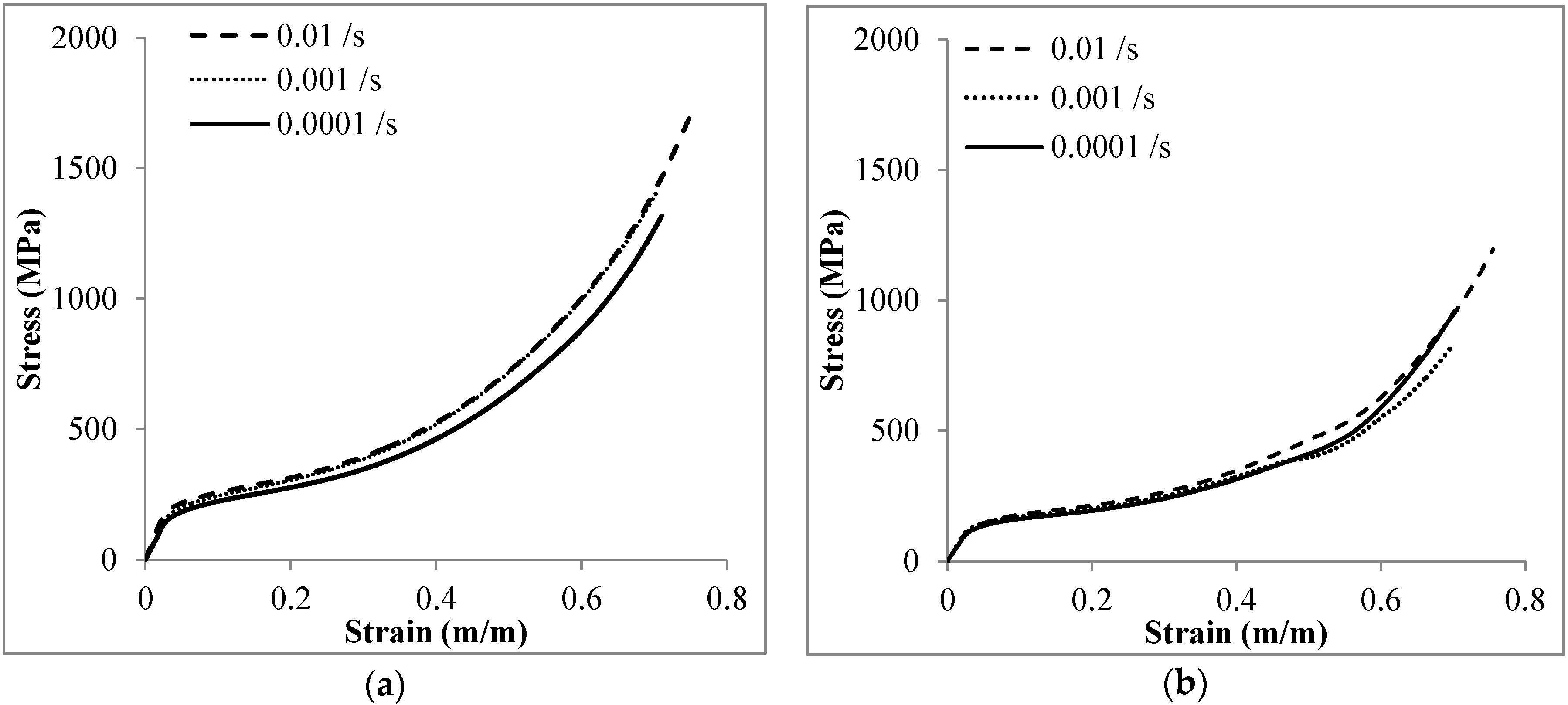

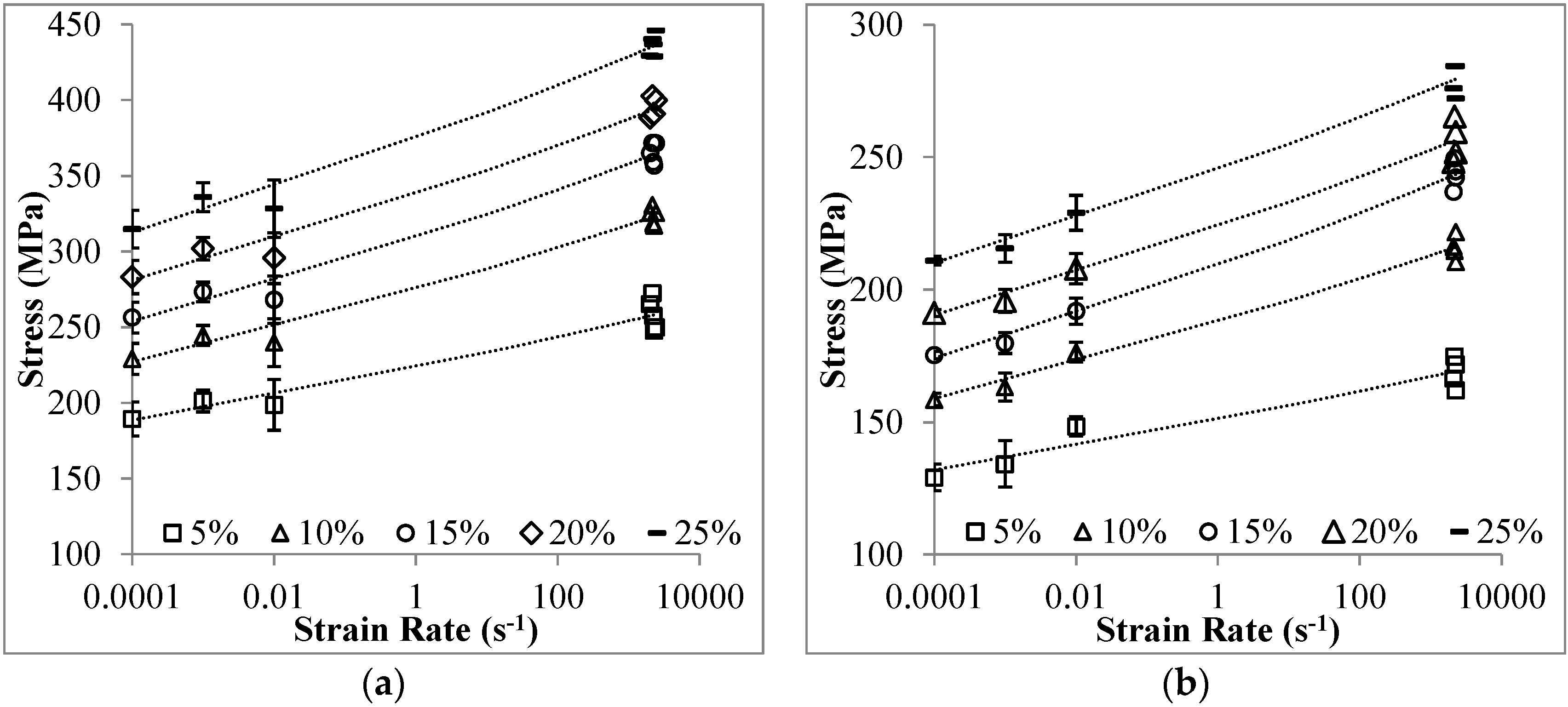

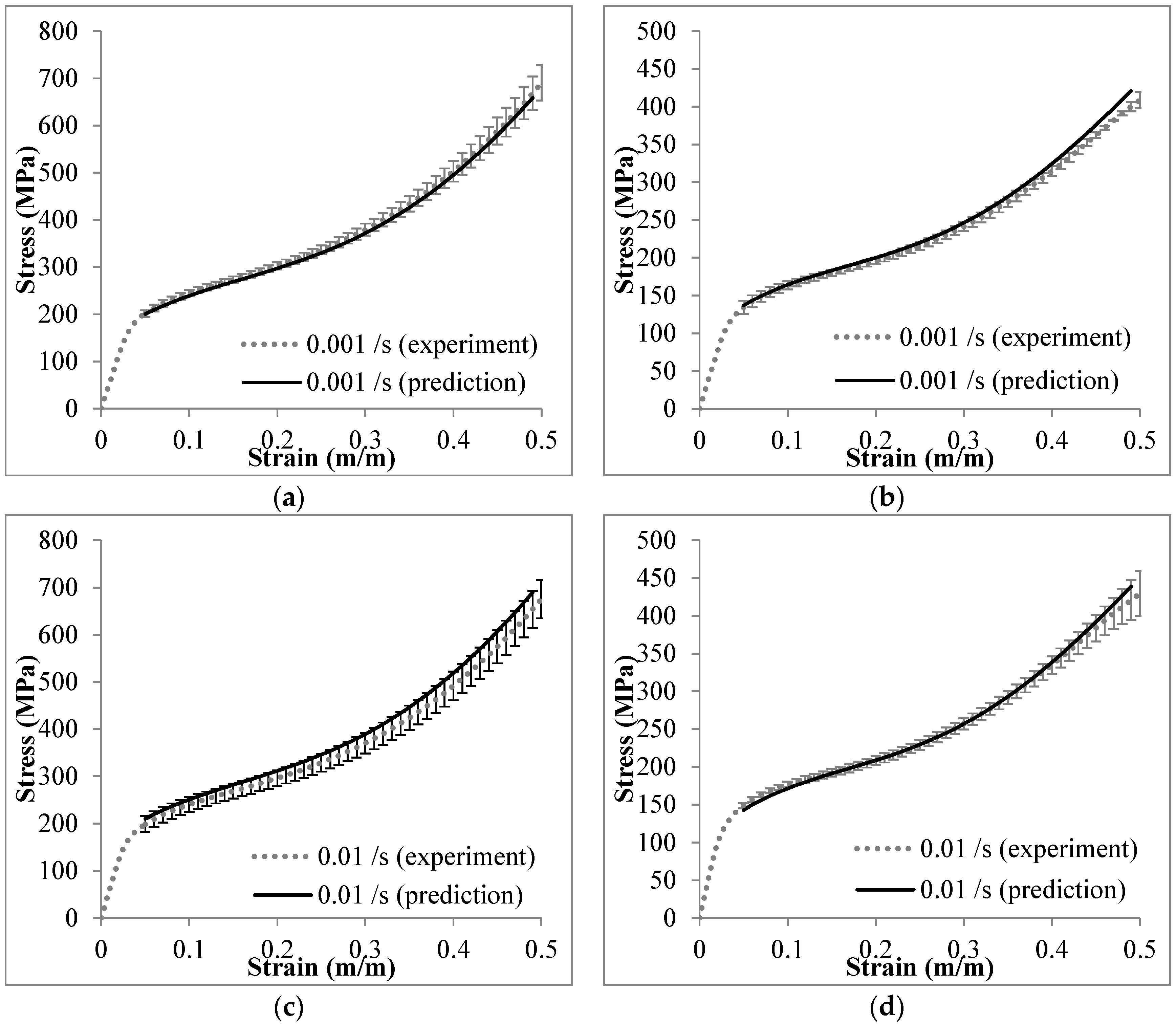

The strain rate sensitivity of a material at a certain strain level is expressed by [

37]:

where

σ1 and

σ2 are stresses at identical strain values corresponding to different strain rates of

and

, respectively; the exponent

m represents the strain rate sensitivity. The stresses at strain from 5% to 25% are plotted over the logarithmic scale of strain rate in

Figure 14. The power-law fitting curves are generated for these stresses over strain rate from 10

−4 to 2500 s

−1. The fitting curves are mostly inside the range of stress deviation. The strain rate sensitivity parameter

m is the slope of the dashed lines as plotted in

Figure 14. The parameter

m is specified as 0.020 and 0.018 for Invar-5CS and Invar-10CS, respectively. Based on this formulation, the stress at an arbitrary strain rate can be predicted if the stress value at certain strain rates and the strain rate relation (

m parameter) are known. The plateau stresses in the range of 5%–50% strain for Invar-CS SFs are constructed from the one at strain rate of 10

−4·s

−1, and the predictions for three individual, deviating strain rates, plotted in

Figure 15. The predicted result at each quasi-static strain rate is compared to the average stress-strain curve with the standard deviation (see

Figure 15a–d), and the one at high strain rate is directly compared to the experimental curve (see

Figure 15e,f). Predicted stresses receive higher error markings at the beginning and end stage of the plateau region, an observation which is associated with the fact that in yielding and densification transition zones, higher complexity of deformation processes makes these less predictable. However, the error between the experimental and prediction results is reported at less than 10%.

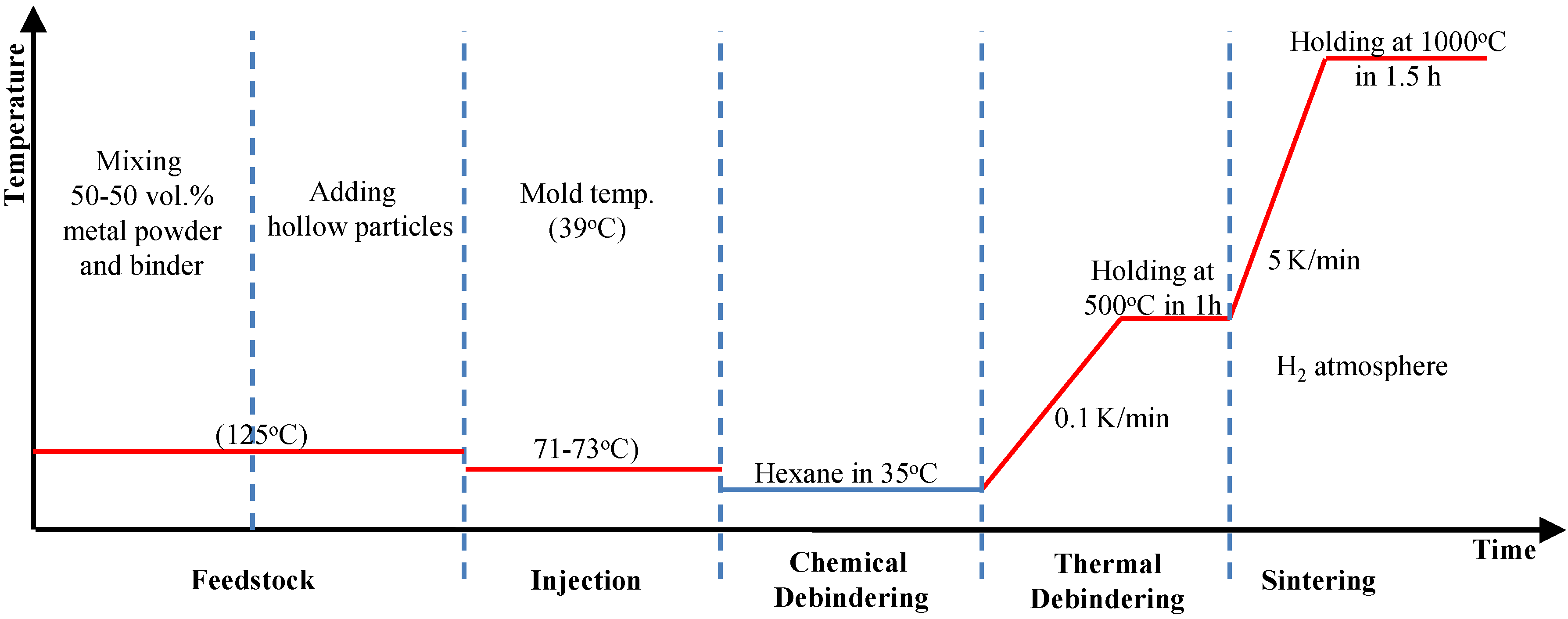

4. Materials and Methods

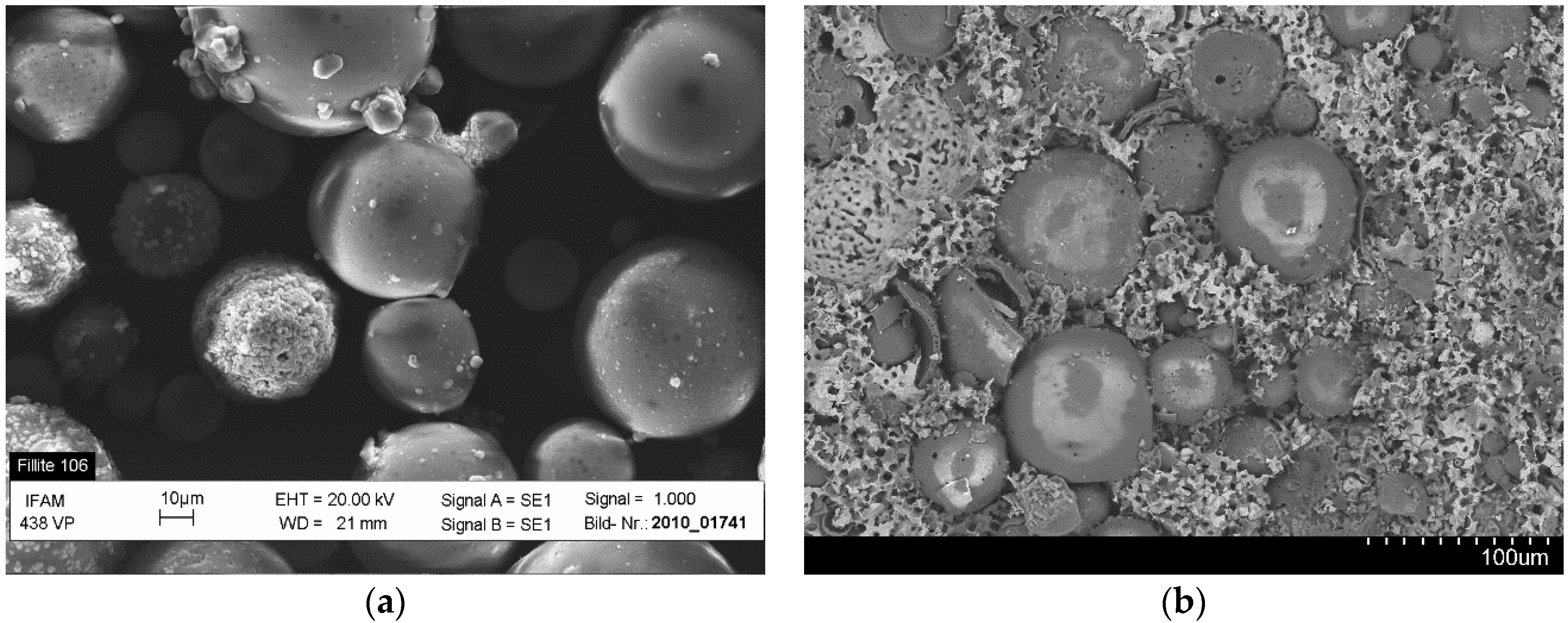

Two types of Invar SFs-filled 5 and 10 wt.% cenospheres were synthesized by the metal powder injection molding method (MIM), which has been described in detail in relation to MMSFs, e.g., by Peroni

et al. [

23] and by Weise

et al. [

19]. The Invar composition of 64 wt% Fe and 36 wt% Ni was achieved by mixing the respective elementary powders. The Omya Fillite

® FG (106) Alumino-silicate Cenospheres (Omya GmbH, D-50679 Köln, Germany)were used and salient properties obtained from the datasheet provided by the supplier are listed in

Table 3 [

18]. The MIM process is depicted in

Figure 16. In the first step, the metal powders were mixed with the binder material (polymer-wax blend, 50 vol.% related to the metal-binder mixture without hollow particles) followed by cenospheres to yield the homogeneous feedstock, which is injected into the mold at a pressure of 10 bar. The temperatures of mixing and injection steps are 125 °C and 71–73 °C (mold temperature 39 °C), respectively. The binder was removed from the green part by chemical (Hexane solvent, 24h at 35 °C) and thermal steps (heating up at 0.1 K/min to 500 °C and holding at this temperature for 1 h). Finally the sample was sintered at a temperature of 1000 °C, and this temperature was ramped up at 5 K/min, with a holding time of 1.5 h in a hydrogen atmosphere. Afterwards, sintered parts where slowly cooled to room temperature within the furnace. Previous studies on Invar and 316L matrices have indicated that neither the configuration of the initial powder mixture [

19] nor the duration of the final sintering step [

17] have a dominant influence on the mechanical properties.

In order to study the compressive properties of Invar SFs under the quasi-static and high strain rate loading, cylindrical specimens, with a ratio of length to diameter of 1:1, were machined. The average diameters of Invar-5CS and Invar 10-CS specimens were 4.4 and 4.6 mm, respectively. An Instron 4469 machine (Intron, Norwood, MA, USA) with 50 kN load cell was used to conduct the quasi-static compression tests on 3 specimens of each type with the initial nominal strain rates of 10−4, 10−3 and 10−2·s−1. A lubricant of Dow Corning-Molykote 111 (Ellsworth Adhesives, Germantown, WI, USA) was used to minimize the friction effect between the cylindrical specimens and compression platens.

The high strain rate compression tests were conducted by using a split-Hopkinson pressure bar (SHPB) setup. The Invar SF specimen was sandwiched between the incident and transmitter bars. The incident and transmitter bars used in these tests were made of Inconel steel. The stress (

); strain (

); and strain rate (

) were calculated by the following equations:

where

and

are the reflected and transmitted axial strain pulses, respectively, with respect to time; in addition,

A and

E are the cross-section area and Young’s modulus of the bar materials, respectively;

l0 and

A0 are the initial length and cross-section area of the specimen, respectively;

cb is the sound wave velocity in the bar; and

is a time variable used for integration. The representative strain rate for each stress-strain curve was calculated as the average value of the plateau region of the strain rate-strain graph. The details about the in-house developed SHPB configuration can be found in references [

9,

12,

20,

26,

38]. The microstructure of Invar SFs before and after the mechanical experiments was observed by using the Hitachi S-3400N scanning electron microscope (SEM, Hitachi, Tokyo, Japan) and a Nikon EPIPHOT 200 microscope fitted with a Nikon DS-Fi1 digital camera (Nikon, Shizuoka, Japan).