Energy Storage Characteristics of BiFeO3/BaTiO3 Bi-Layers Integrated on Si

Abstract

:1. Introduction

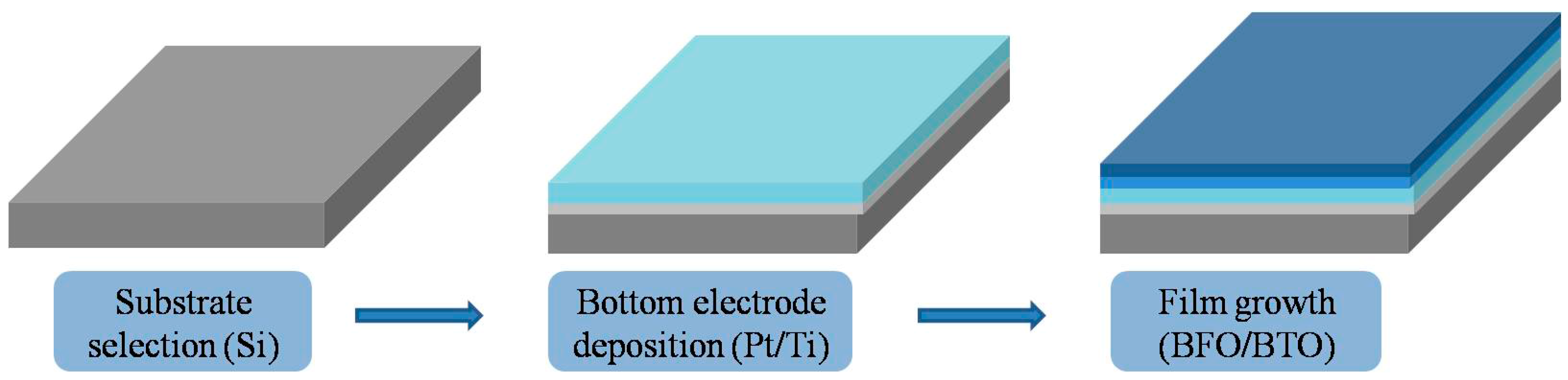

2. Experimental Section

3. Results

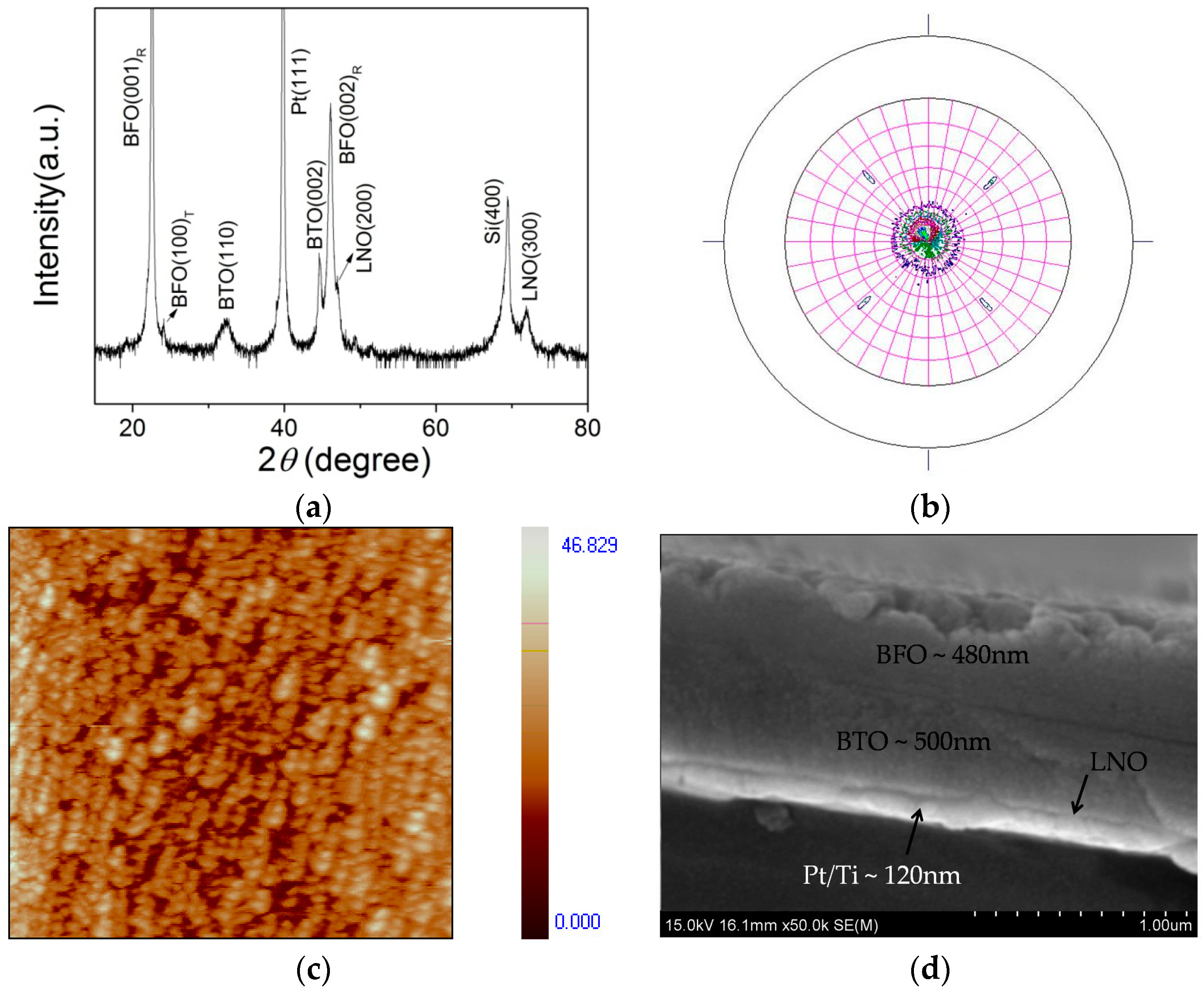

3.1. Microstructures and Crystallographic Orientations

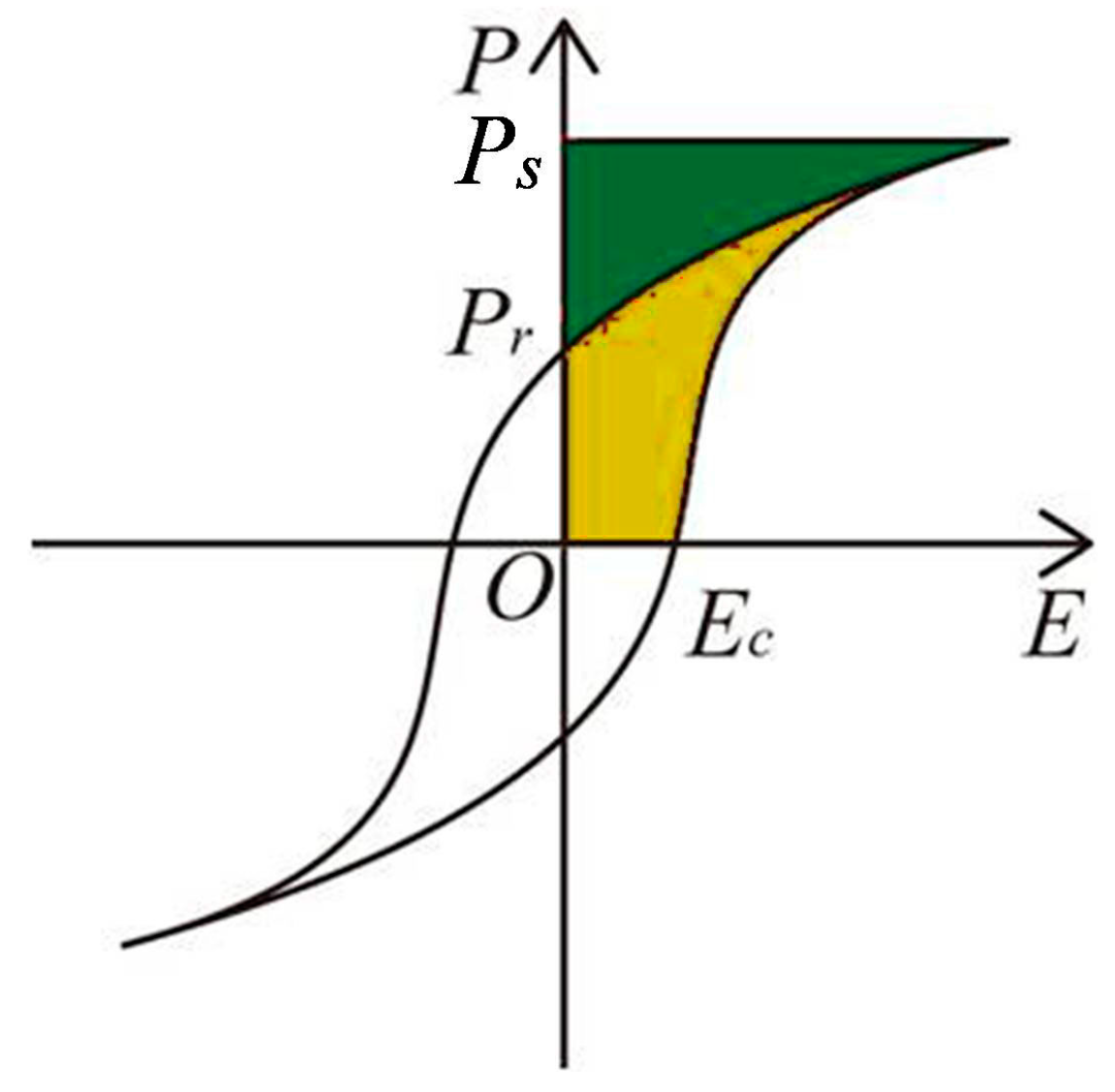

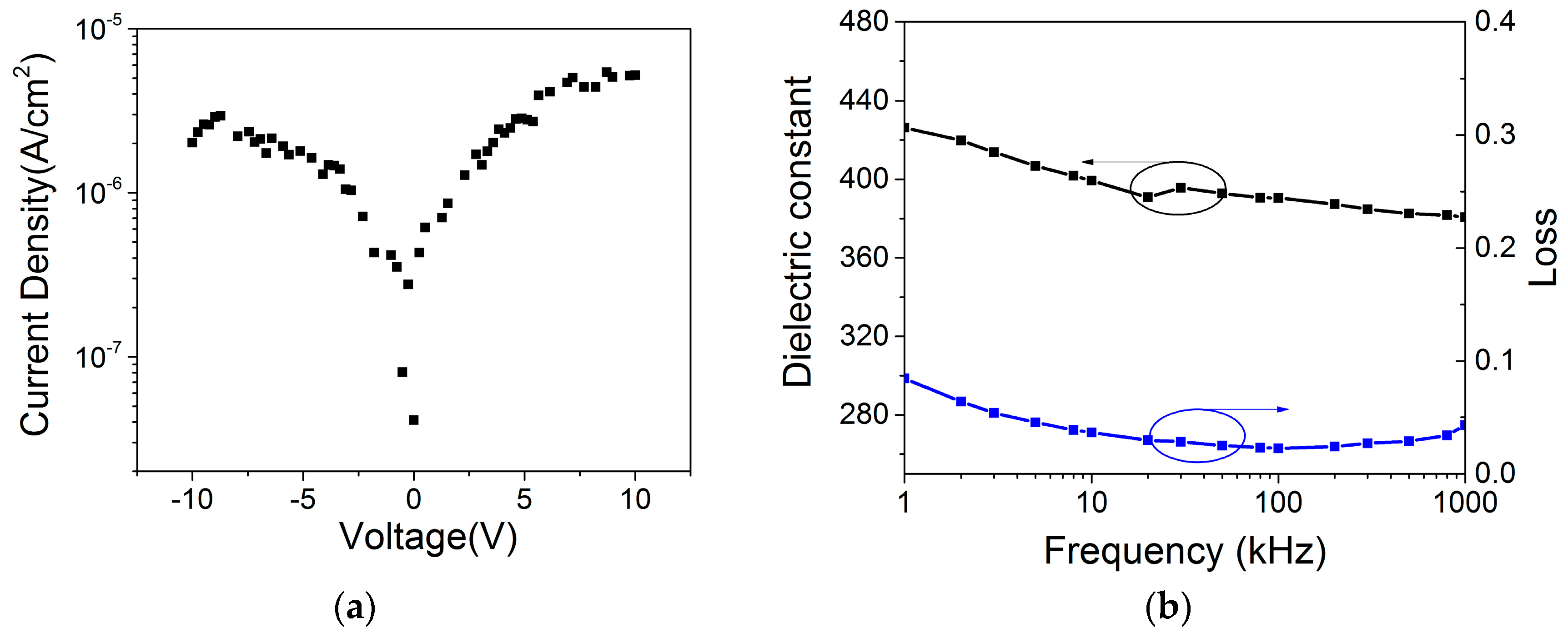

3.2. Energy Storage Characteristics from the P-E Hysteresis Loop

4. Conclusions

Acknowledgments

Conflicts of Interest

Notes

References

- Wang, Y.; Zhou, X.; Chen, Q.; Chu, B.; Zhang, Q. Recent development of high energy density polymers for dielectric capacitors. IEEE Trans. Dielectr. Electr. Insul. 2010, 17, 1036–1042. [Google Scholar] [CrossRef]

- Hao, X.; Wang, Y.; Yang, J.; An, S.; Xu, J. High energy-storage performance in Pb0.91La0.09(Ti0.65Zr0.35) O3 relaxor ferroelectric thin films. J. Appl. Phys. 2012, 112, 114111. [Google Scholar] [CrossRef]

- Hao, X.; Wang, Y.; Zhang, L.; Zhang, L.; An, S. Composition-dependent dielectric and energy-storage properties of (Pb,La)(Zr,Sn,Ti) O3 antiferroelectric thick films. Appl. Phys. Lett. 2013, 102, 163903. [Google Scholar] [CrossRef]

- Zhang, L.; Hao, X.; Zhang, L. Enhanced energy-storage performances of Bi2O3–Li2O added (1 − x)(Na0.5Bi0.5) TiO3–xBaTiO3 thick films. Ceram. Int. 2014, 40, 8847–8851. [Google Scholar] [CrossRef]

- Xie, Z.; Yue, Z.; Ruehl, G.; Peng, B.; Zhang, J.; Yu, Q.; Zhang, X.; Li, L. Bi(Ni1/2Zr1/2)O3-PbTiO3 relaxor-ferroelectric films for piezoelectric energy harvesting and electrostatic storage. Appl. Phys. Lett. 2014, 104, 243902. [Google Scholar] [CrossRef]

- Xie, Z.; Peng, B.; Meng, S.; Zhou, Y.; Yue, Z. High–Energy-Storage Density Capacitors of Bi (Ni1/2Ti1/2) O3–PbTiO3 Thin Films with Good Temperature Stability. J. Am. Ceram. Soc. 2013, 96, 2061–2064. [Google Scholar] [CrossRef]

- Xie, Z.; Peng, B.; Zhang, J.; Zhang, X.; Yue, Z.; Li, L.; Trolier-McKinstry, S.E. Highly (100)-Oriented Bi(Ni1/2Hf1/2)O3-PbTiO3Relaxor-Ferroelectric Films for Integrated Piezoelectric Energy Harvesting and Storage System. J. Am. Ceram. Soc. 2015, 98, 2968–2971. [Google Scholar] [CrossRef]

- Xie, Z.; Yue, Z.; Peng, B.; Zhang, J.; Zhao, C.; Zhang, X.; Ruehl, G.; Li, L. Large enhancement of the recoverable energy storage density and piezoelectric response in relaxor-ferroelectric capacitors by utilizing the seeding layers engineering. Appl. Phys. Lett. 2015, 106, 202901. [Google Scholar] [CrossRef]

- Xie, Z.; Peng, B.; Zhang, J.; Zhang, X.; Yue, Z.; Li, L. Effects of thermal anneal temperature on electrical properties and energy-storage density of Bi(Ni1/2Ti1/2)O3–PbTiO3 thin films. Ceram. Int. 2015, 41, 206–212. [Google Scholar] [CrossRef]

- Lee, B.D.; Lee, H.R.; Yoon, K.H.; Cho, Y.S. Microwave dielectric properties of magnesium calcium titanate thin films. Ceram. Int. 2005, 31, 143–146. [Google Scholar] [CrossRef]

- Huang, C.L.; Chen, Y.B. Structure and electrical characteristics of RF magnetron sputtered MgTiO3. Surf. Coat. Technol. 2006, 200, 3319–3325. [Google Scholar] [CrossRef]

- Tkach, A.; Almeida, A.; Moreira, J.A.; Perez de la Cruz, J.; Romaguera-Barcelay, Y.; Vilarinho, P.M. Low-temperature dielectric response of NaTaO3 ceramics and films. Appl. Phys. Lett. 2012, 100, 192909. [Google Scholar] [CrossRef]

- Liu, G.Z.; Wang, C.; Wang, C.C.; Qiu, J.; He, M.; Xing, J.; Jin, K.J.; Lu, H.B.; Yang, G.Z. Effects of interfacial polarization on the dielectric properties of BiFeO3 thin film capacitors. Appl. Phys. Lett. 2008, 92, 122903. [Google Scholar] [CrossRef]

- Lee, S.J.; Kang, K.Y.; Kim, J.W.; Han, S.K.; Jeong, S.D. Low-Frequency Dielectric Properties of Sol-Gel Derived BaTiO3 Thin Films. In Proceedings of the Materials Research Society, Nashville, TN, USA, 28 September–1 October 2011.

- Yuan, M.; Zhang, W.; Wang, X.; Pan, W.; Wang, L.; Ouyang, J. In situ preparation of high dielectric constant, low-loss ferroelectric BaTiO3 films on Si at 500 °C. Appl. Surf. Sci. 2013, 270, 319–323. [Google Scholar] [CrossRef]

- Zhu, H.; Sun, X.; Kang, L.; Zhang, Y.; Yu, Z.; Ouyang, J.; Pan, W. Microstructural and electrical characteristics of epitaxial BiFeO3 thick films sputtered at different Ar/O2 flow ratios. CrystEngComm 2016, 18, 4604–4612. [Google Scholar] [CrossRef]

- Gao, Y.; Yuan, M.; Sun, X.; Ouyang, J. In situ preparation of high quality BaTiO3 dielectric films on Si at 350–500 °C. J. Mater. Sci. Mater. Electron. 2016. [Google Scholar] [CrossRef]

- Lee, C.C.; Wu, J.M. Effect of film thickness on interface and electric properties of BiFeO3 thin films. Appl. Surf. Sci. 2007, 253, 7069–7073. [Google Scholar] [CrossRef]

- Yan, F.; Zhu, T.J.; Lai, M.O.; Lu, L. Influence of oxygen pressure on the ferroelectric properties of BiFeO3 thin films on LaNiO3/Si substrates via laser ablation. Appl. Phys. A 2010, 101, 651–654. [Google Scholar] [CrossRef]

- Dho, J.; Qi, X.; Kim, H.; MacManus-Driscoll, J.L.; Blamire, M.G. Large Electric Polarization and Exchange Bias in Multiferroic BiFeO3. Adv. Mater. 2006, 18, 1445–1448. [Google Scholar] [CrossRef]

- Zhu, H.; Liu, M.; Zhang, Y.; Yu, Z.; Ouyang, J.; Pan, W. Increasing energy storage capabilities of space-charge dominated ferroelectric thin films using interlayer coupling. Acta Mater. 2016, 122, 252–258. [Google Scholar] [CrossRef]

- Hussain, S.; Hasanain, S.K.; Hassnain Jaffari, G.; Ismat Shah, S. Thickness dependent magnetic and ferroelectric properties of LaNiO3 buffered BiFeO3 thin films. Curr. Appl. Phys. 2015, 15, 194–200. [Google Scholar] [CrossRef]

- Yuan, M.L. Medium Temperature Preparation of BaTiO3 Thin Film Capacitors with High Breakdown Voltages and Large Electric Energy Densities. Master’s Thesis, Shandong University, Jinan, China, 2014. [Google Scholar]

- Zhang, W.; Gao, Y.; Kang, L.; Yuan, M.; Yang, Q.; Cheng, H.; Pan, W.; Ouyang, J. Space-charge dominated epitaxial BaTiO3 heterostructures. Acta Mater. 2015, 85, 207–215. [Google Scholar] [CrossRef]

- Tagantsev, A.K.; Landivar, M.; Colla, E.; Setter, N. Identification of passive layer in ferroelectric thin films from their switching parameters. J. Appl. Phys. 1995, 78, 2623. [Google Scholar] [CrossRef]

- Roytburd, A.L.; Zhong, S.; Alpay, S.P. Dielectric anomaly due to electrostatic coupling in ferroelectric-paraelectric bilayers and multilayers. Appl. Phys. Lett. 2005, 87, 092902. [Google Scholar] [CrossRef]

- Liu, Y.T.; Ku, C.S.; Chiu, S.J.; Lee, H.Y.; Chen, S.Y. Ultrathin oriented BiFeO3 films from deposition of atomic layers with greatly improved leakage and ferroelectric properties. ACS Appl. Mater. Interfaces 2014, 6, 443–449. [Google Scholar] [CrossRef] [PubMed]

- Simões, A.Z.; Riccardi, C.S.; Dos Santos, M.L.; Garcia, F.G.; Longo, E.; Varela, J.A. Effect of annealing atmosphere on phase formation and electrical characteristics of bismuth ferrite thin films. Mater. Res. Bull. 2009, 44, 1747–1752. [Google Scholar] [CrossRef]

- Kawae, T.; Terauchi, Y.; Tsuda, H.; Kumeda, M.; Morimoto, A. Improved leakage and ferroelectric properties of Mn and Ti codoped BiFeO3 thin films. Appl. Phys. Lett. 2009, 94, 112904. [Google Scholar] [CrossRef]

- Wang, C.; Jin, K.J.; Xu, Z.T.; Wang, L.; Ge, C.; Lu, H.B.; Guo, H.Z.; He, M.; Yang, G.Z. Switchable diode effect and ferroelectric resistive switching in epitaxial BiFeO3 thin films. Appl. Phys. Lett. 2011, 98, 192901. [Google Scholar] [CrossRef]

- Sun, S.; Wang, Y.; Fuierer, P.A.; Tuttle, B.A. Annealing effects on the internal bias field in ferroelectric PZT thin films with self-polarization. Integr. Ferroelectr. 1999, 23, 25–43. [Google Scholar] [CrossRef]

- Yan, F.; Zhu, T.J.; Lai, M.O.; Lu, L. Effect of bottom electrodes on nanoscale switching characteristics and piezoelectric response in polycrystalline BiFeO3 thin films. J. Appl. Phys. 2011, 110, 084102. [Google Scholar] [CrossRef]

| Sputtering Parameters | BFO | BTO | LNO |

|---|---|---|---|

| Sputtering power (W) | 100 | ||

| Substrate temperature (°C) | 500 | ||

| Sputtering pressure (Pa) | 1.2 | 0.3 | |

| Sputtering atmosphere | Ar + O2 (4:1 flow ratio) | ||

| Cooling atmosphere and pressure | Pure oxygen, 2.5 Pa | ||

| Pt/Ti sputtering parameters | 300 °C, 0.3 Pa, 55 W, pure Ar | ||

© 2016 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Liu, M.; Zhu, H.; Zhang, Y.; Xue, C.; Ouyang, J. Energy Storage Characteristics of BiFeO3/BaTiO3 Bi-Layers Integrated on Si. Materials 2016, 9, 935. https://doi.org/10.3390/ma9110935

Liu M, Zhu H, Zhang Y, Xue C, Ouyang J. Energy Storage Characteristics of BiFeO3/BaTiO3 Bi-Layers Integrated on Si. Materials. 2016; 9(11):935. https://doi.org/10.3390/ma9110935

Chicago/Turabian StyleLiu, Menglin, Hanfei Zhu, Yunxiang Zhang, Caihong Xue, and Jun Ouyang. 2016. "Energy Storage Characteristics of BiFeO3/BaTiO3 Bi-Layers Integrated on Si" Materials 9, no. 11: 935. https://doi.org/10.3390/ma9110935