Effect of Moisture Exchange on Interface Formation in the Repair System Studied by X-ray Absorption

Abstract

:1. Introduction

2. Materials and Methods

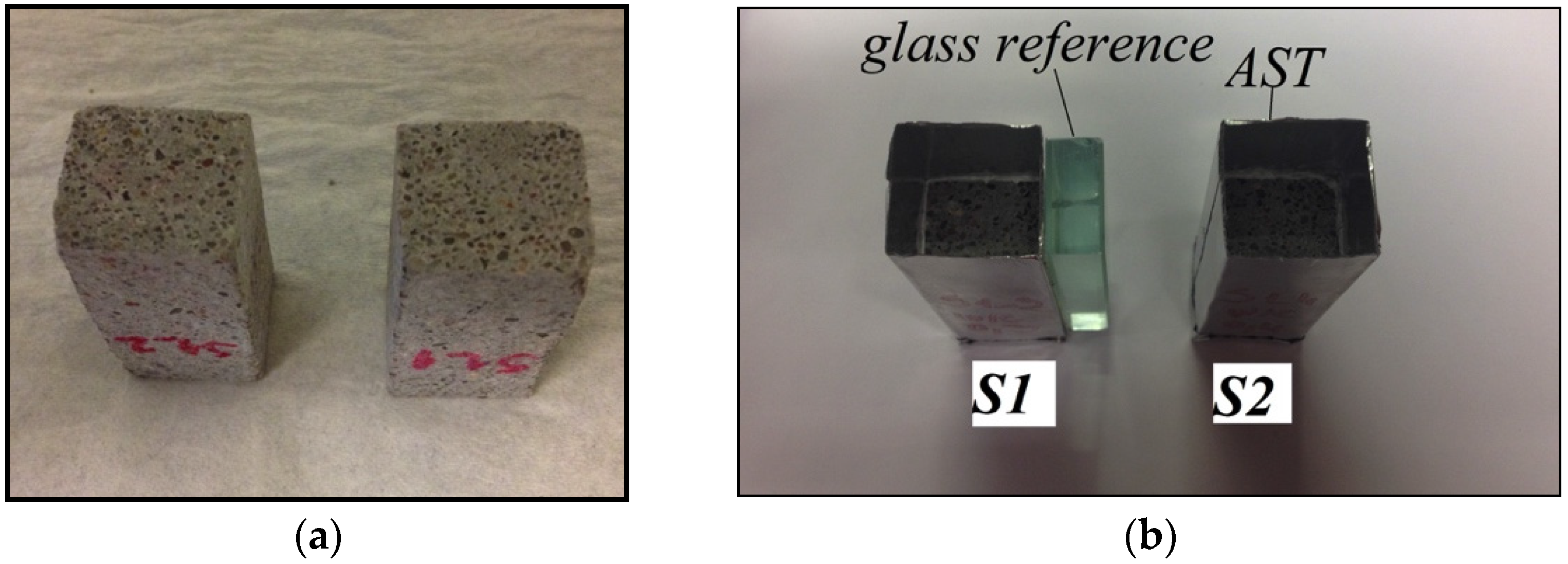

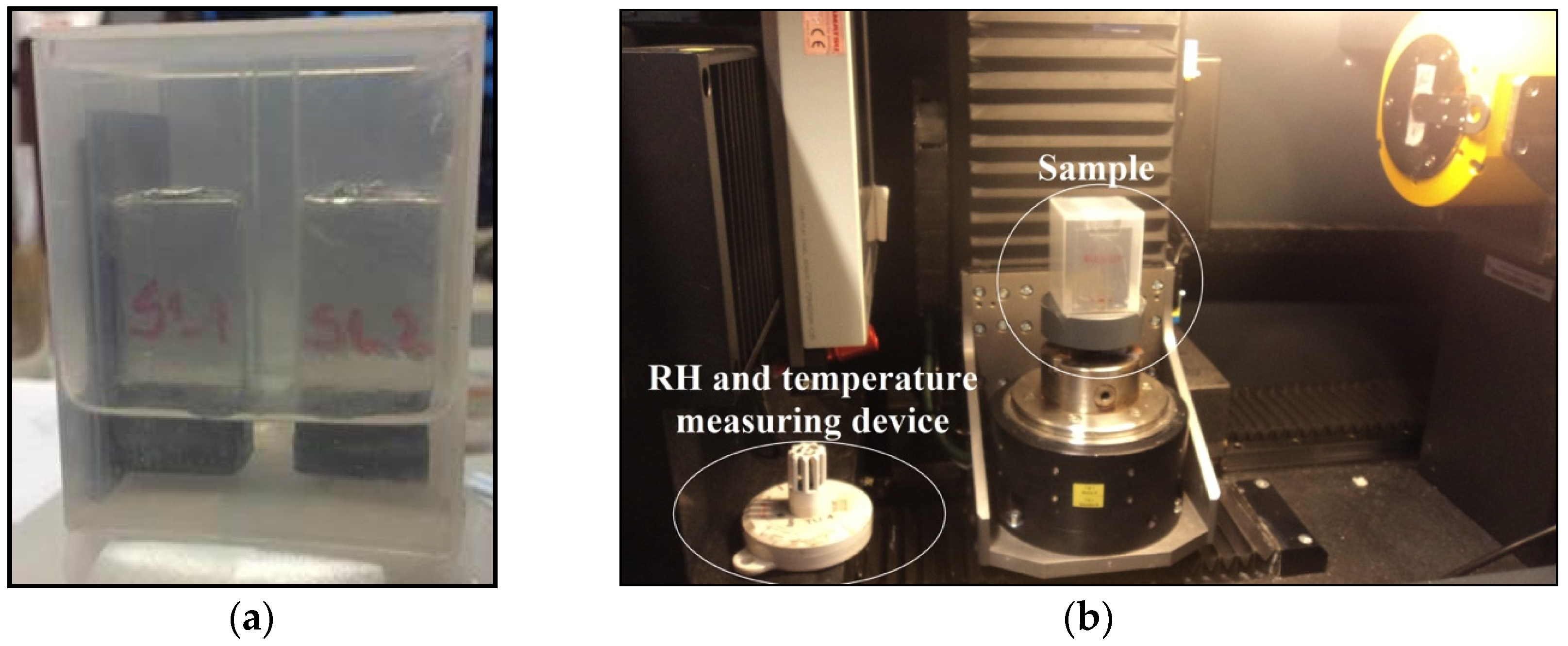

2.1. Materials and Sample Prepartion

2.2. X-ray Absorption for Moisture Content Measurements

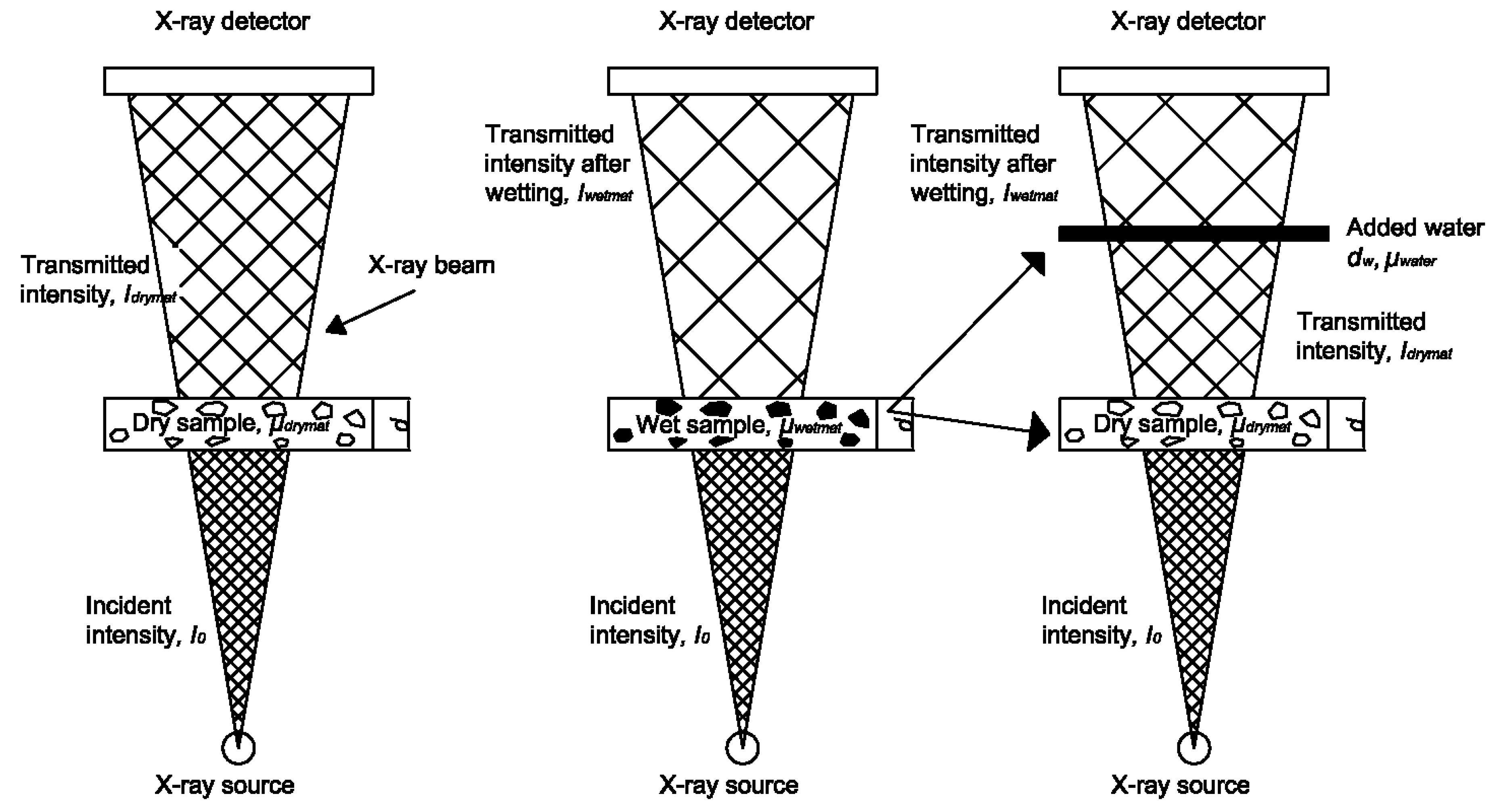

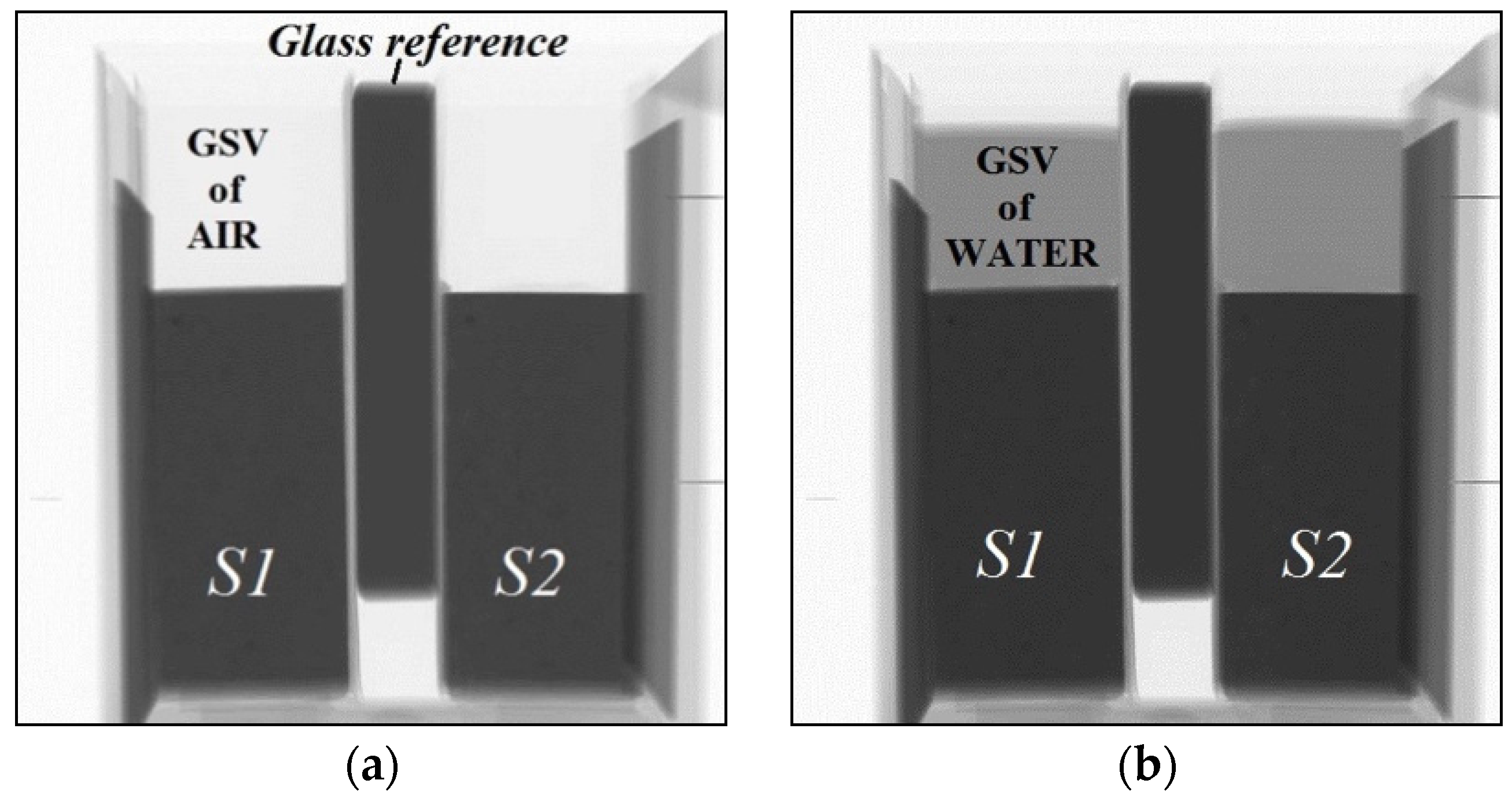

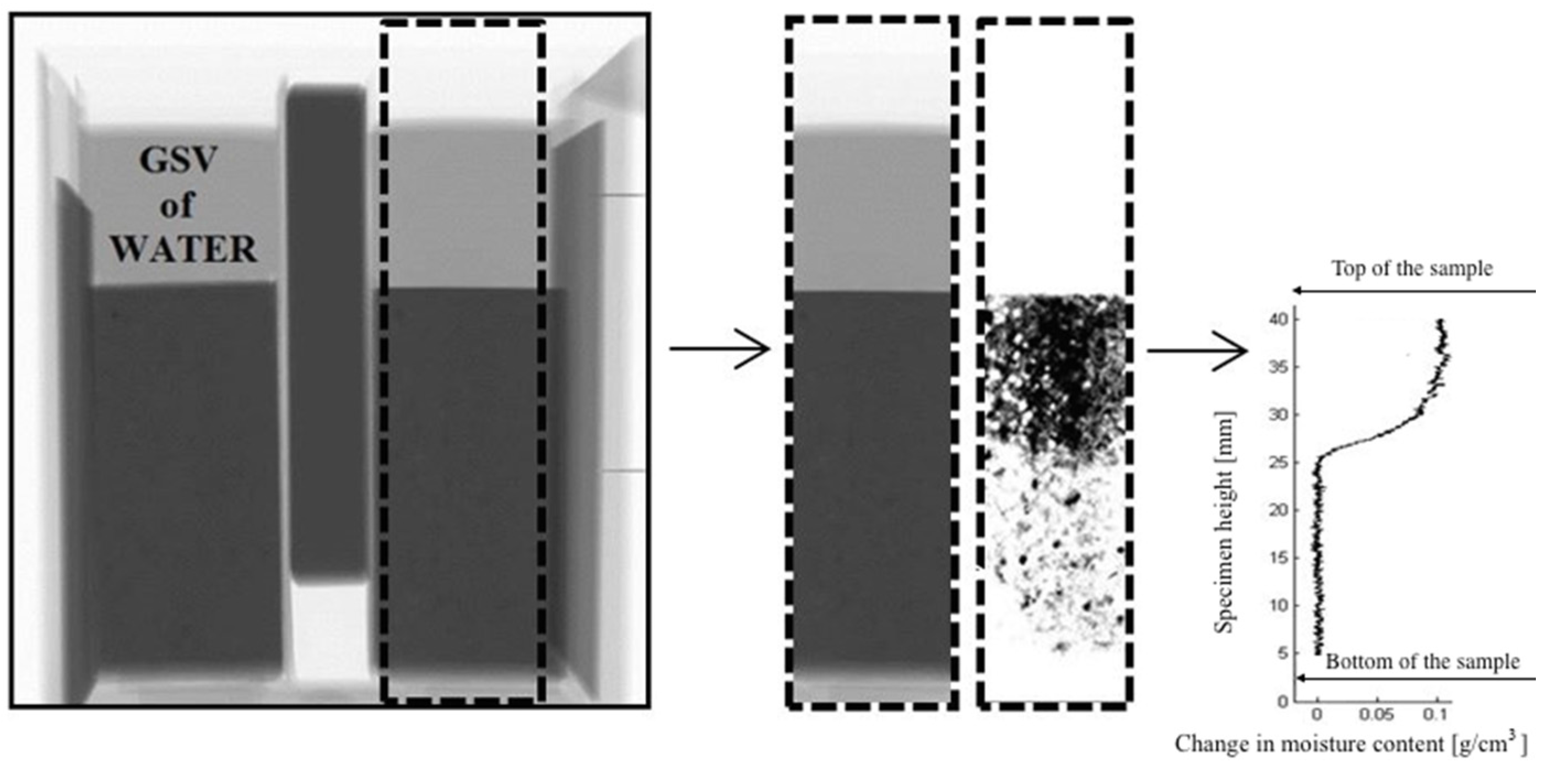

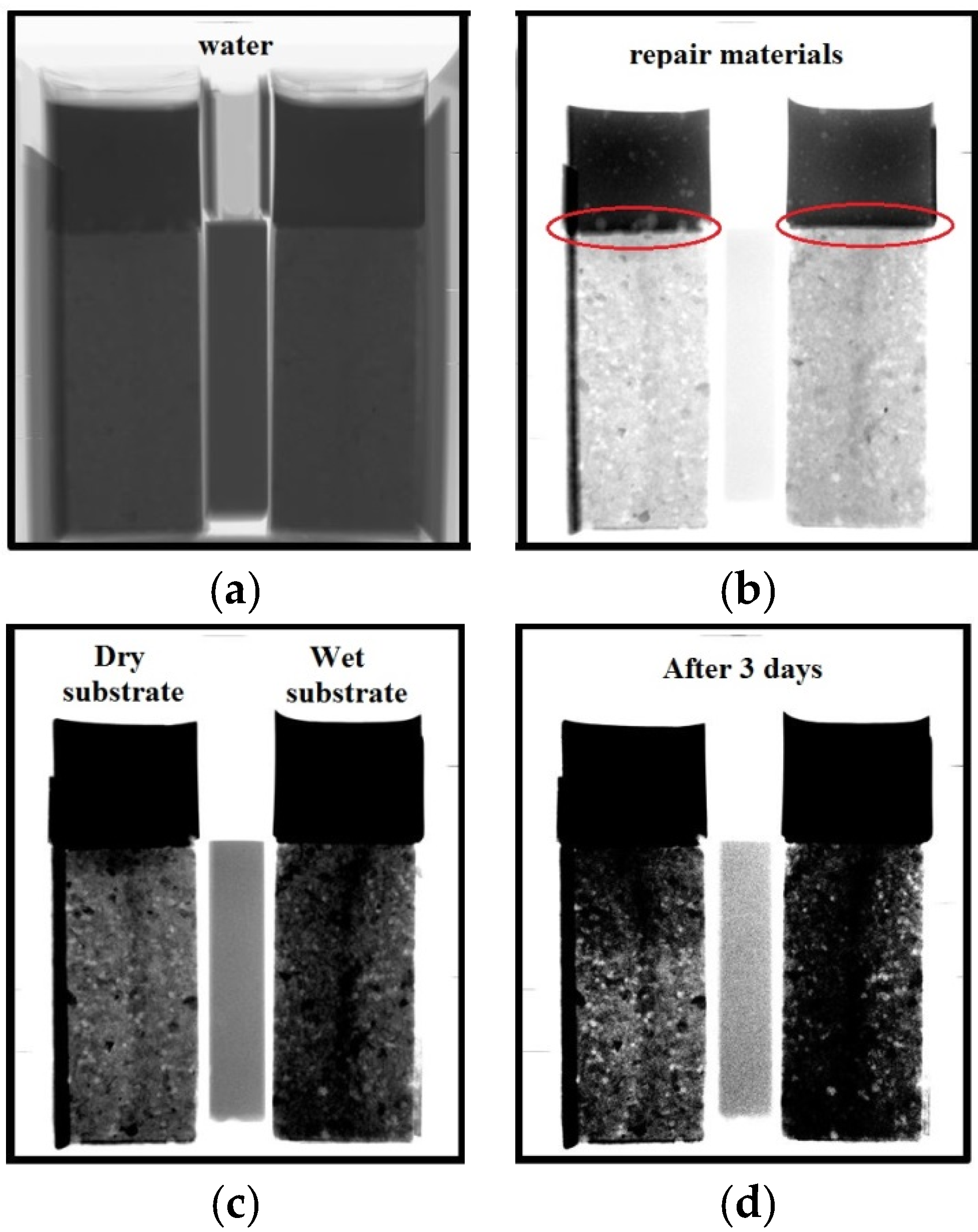

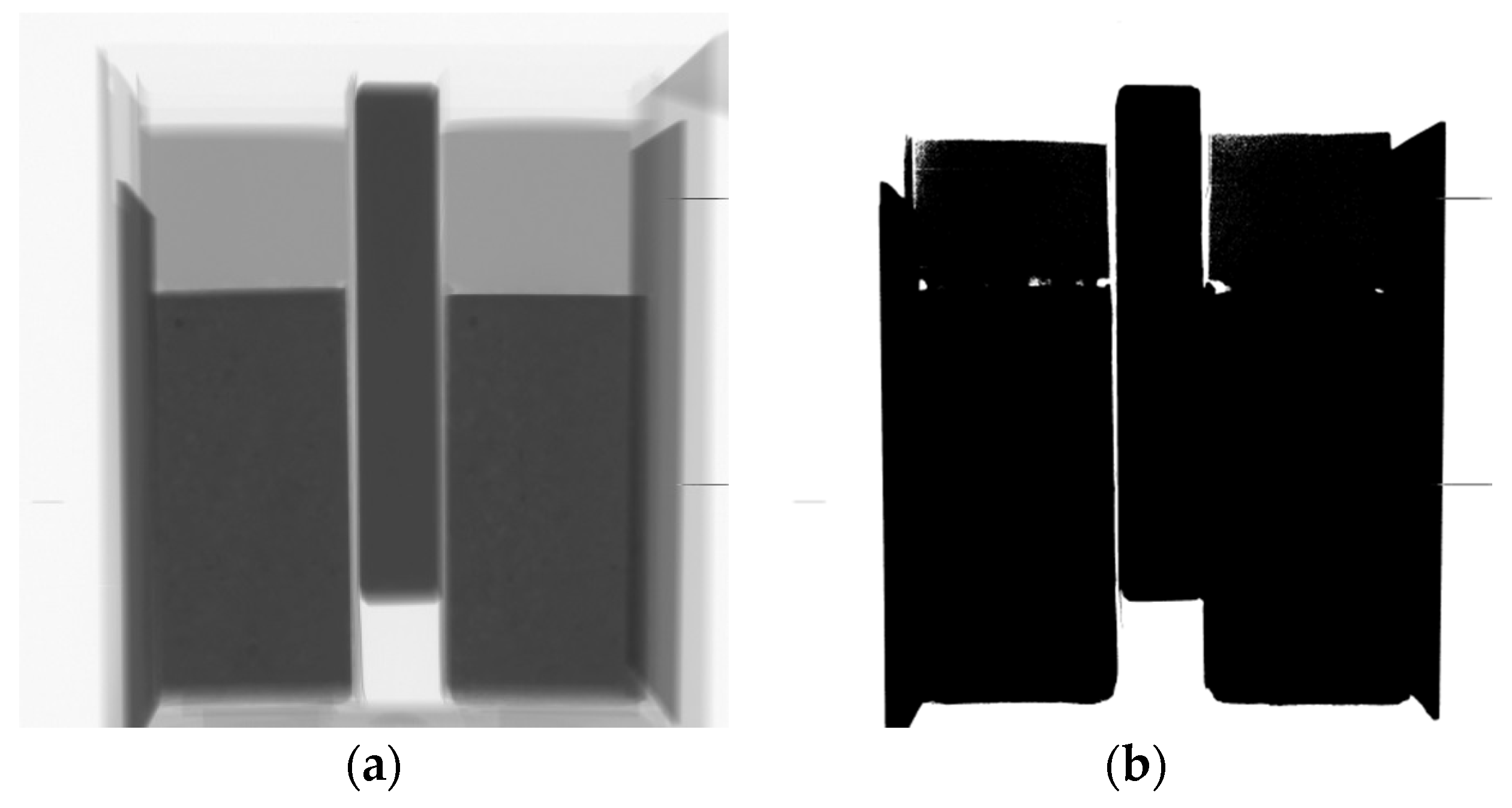

- The attenuation coefficient of water can be determined based on the GSV change of empty and water filled container with a known thickness (see Figure 4). The following formula can be used:where GSVwater is the greyscale value of water; GSVair the grey scale value of air; dwater is the thickness of water (which is equal to the thickness of the container); and µwater is the attenuation coefficient of water. The first image is made with a beam passing through an empty container and GSVair (corresponds to I0) is obtained (Figure 4a). The second image is made with a container filled with water and GSVwater (corresponds to I) is obtained (Figure 4b). Thus, the unknown µwater can be calculated based on Equation (2). Note that this equation is equivalent to Equation (1). Further discussion about the attenuation coefficient of water when polychromatic X-ray is used, is given in the following subsection.Figure 3. The moisture distribution is obtained by logarithmically subtracting an image of the dry sample Idry from the image of the wet sample Iwet, adopted from Reference [10].Figure 3. The moisture distribution is obtained by logarithmically subtracting an image of the dry sample Idry from the image of the wet sample Iwet, adopted from Reference [10].

- Once the attenuation coefficient of water is determined, GSV of the wet porous material can be correlated to GSV of the dry porous material according to the following equation (also derived from Equation (1)):where dw is the thickness of fictitious water layer equivalent to the additional moisture content in sample (see Figure 3) and can be expressed as:Here, Δcwater is the change of water content (g/cm3); d is the thickness of the sample; and ρw is the density of water. From these equations, Δcwater can be determined as:

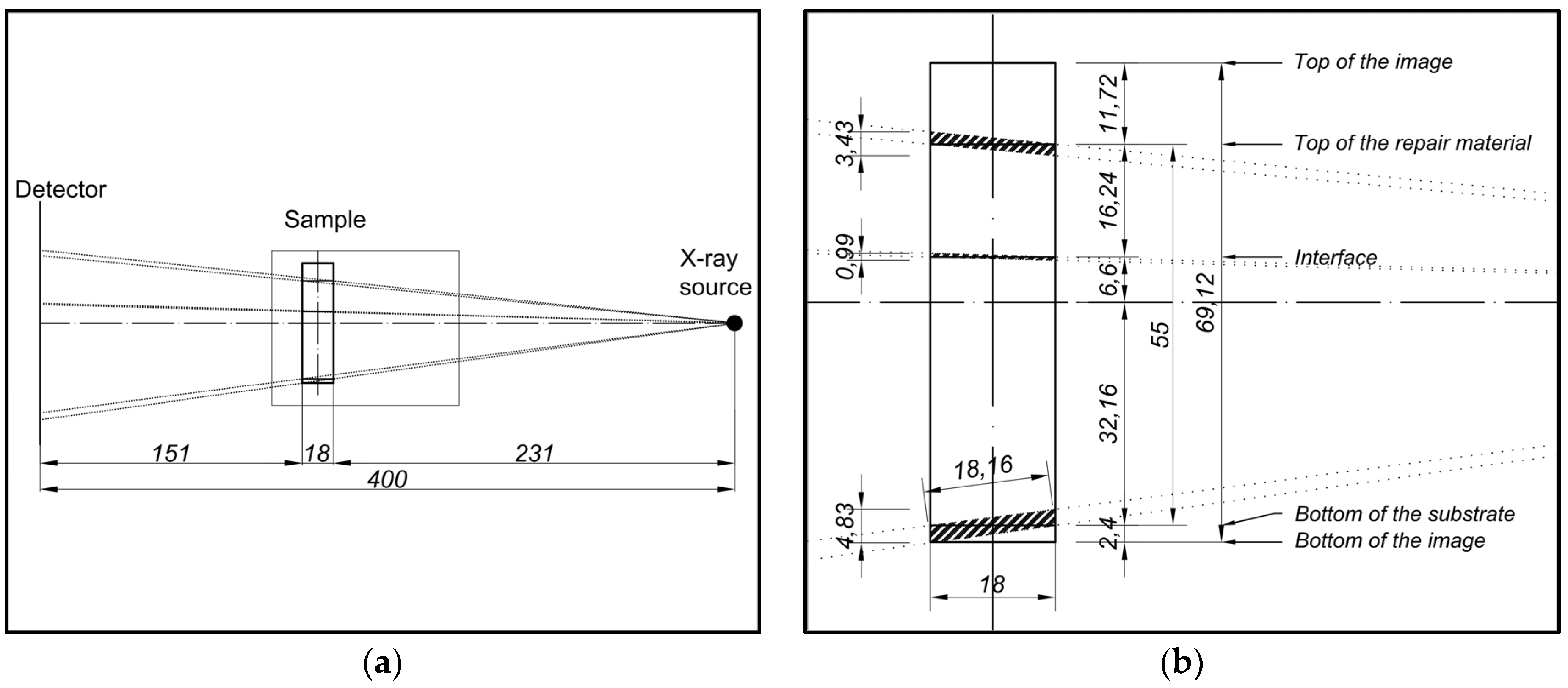

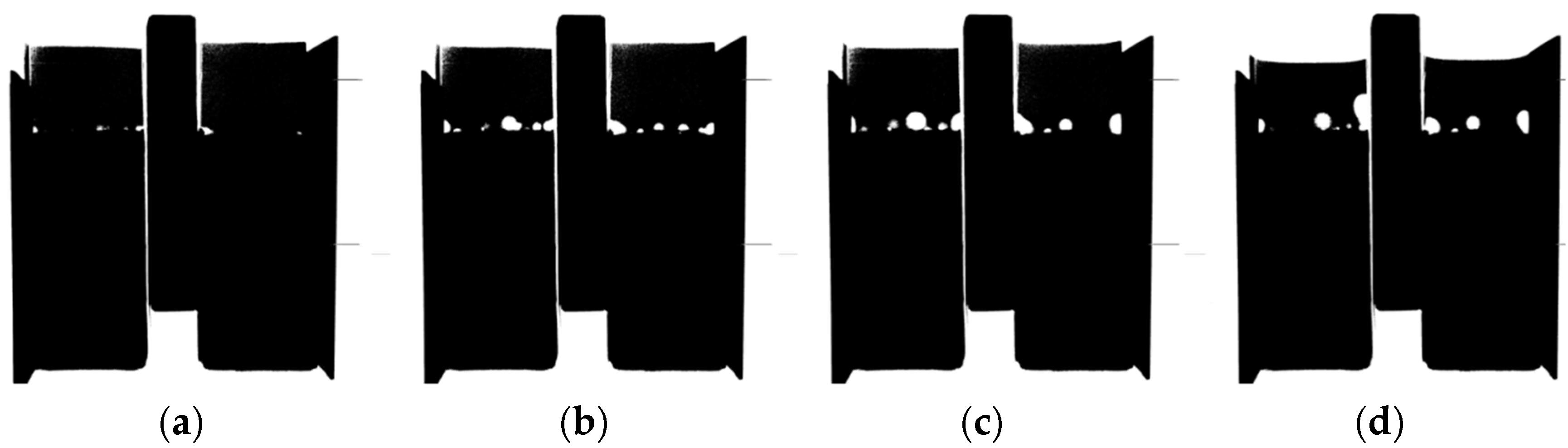

- In this study, only the middle part of the specimen (around 16 mm) is analyzed in order to exclude the influence of edges (see Figure 5). Obtained moisture profiles are then averaged over the specimen’s width. As a result, the change in moisture content is obtained as function of specimen height.

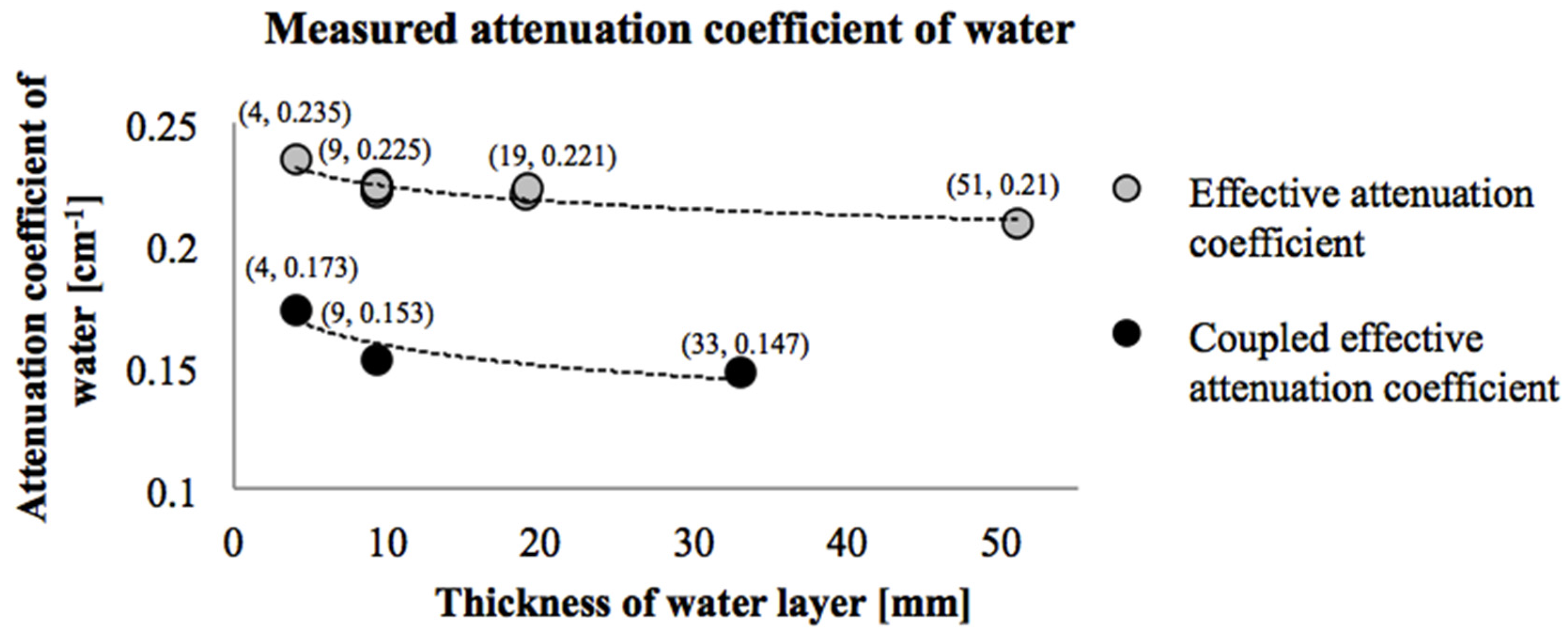

2.2.1. Determination of the Attenuation Coefficient

2.2.2. Limitations of the Experiment

2.3. Degree of Hydration Measurements

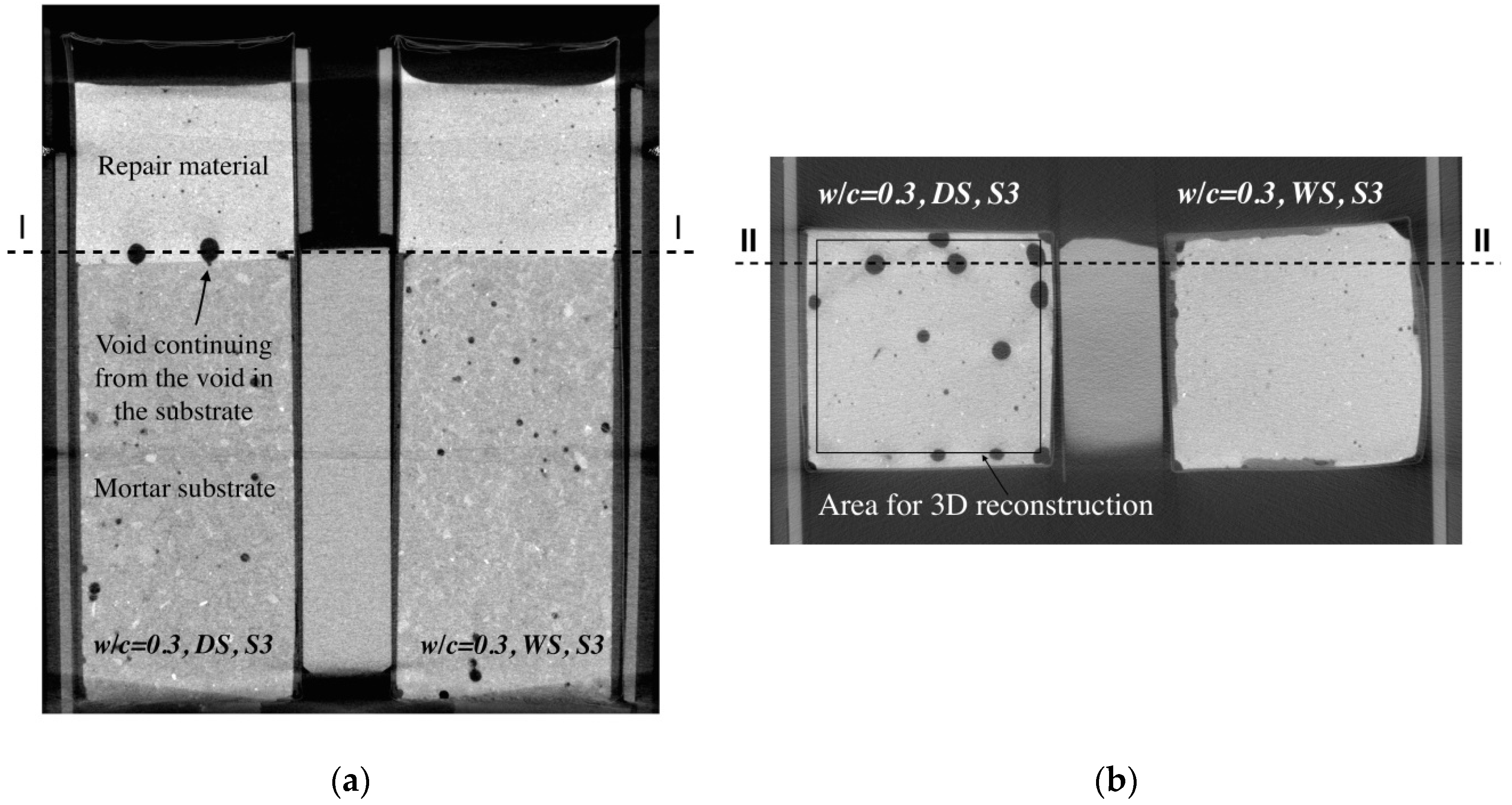

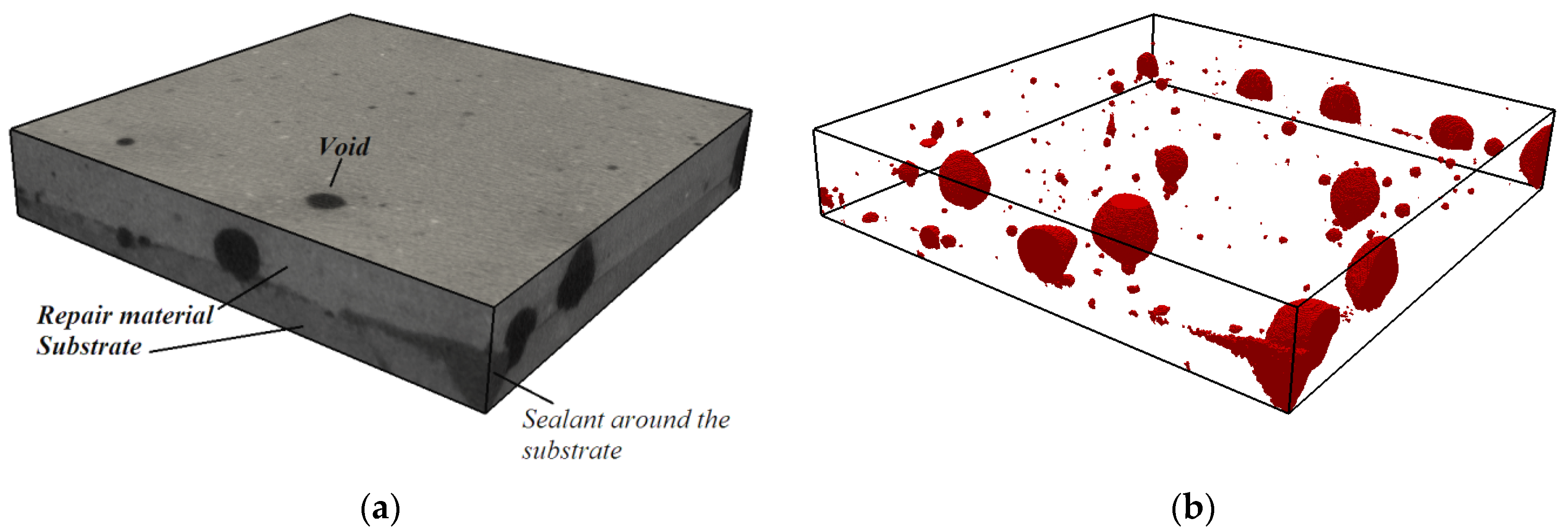

2.4. CT Scanning for the Mesostructure Characterization

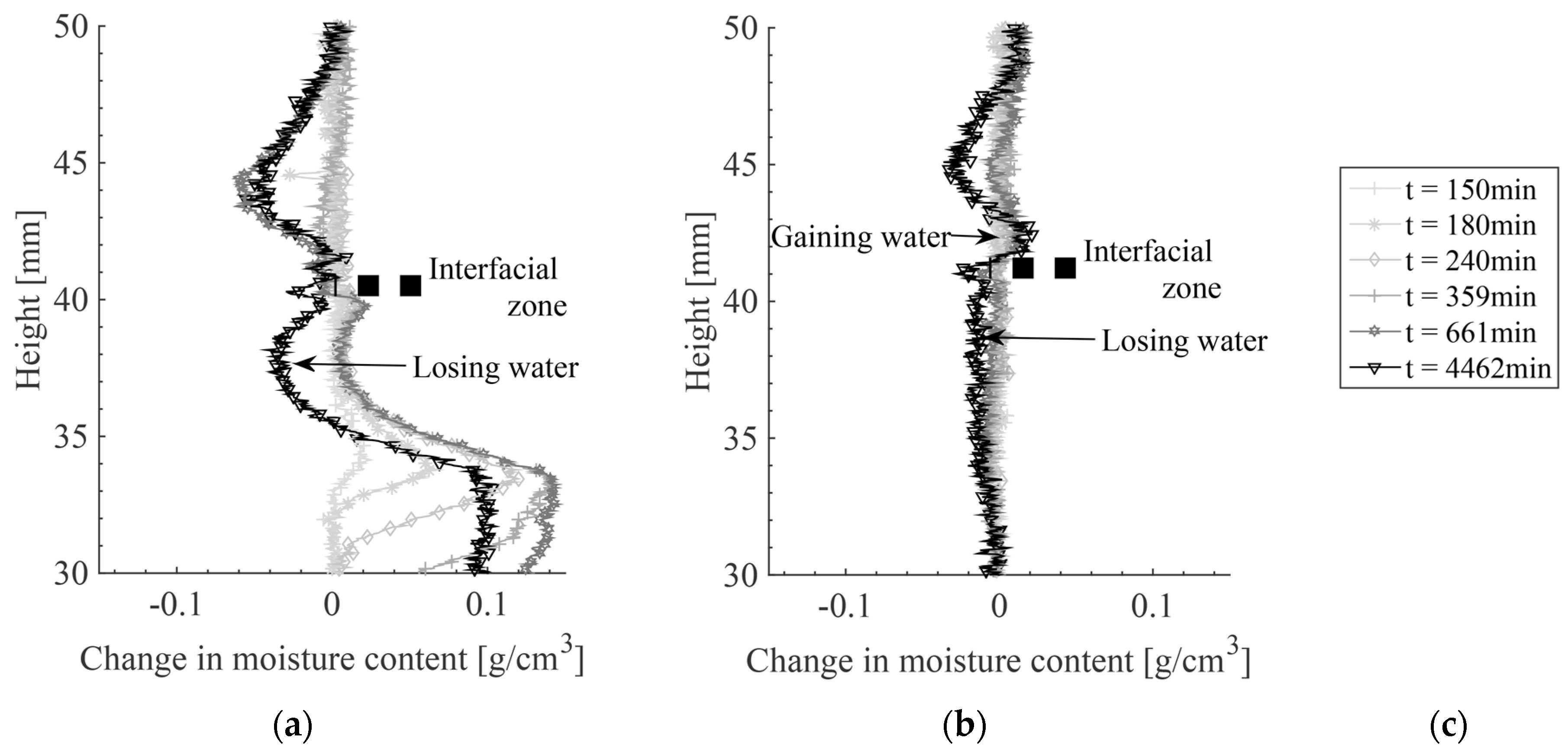

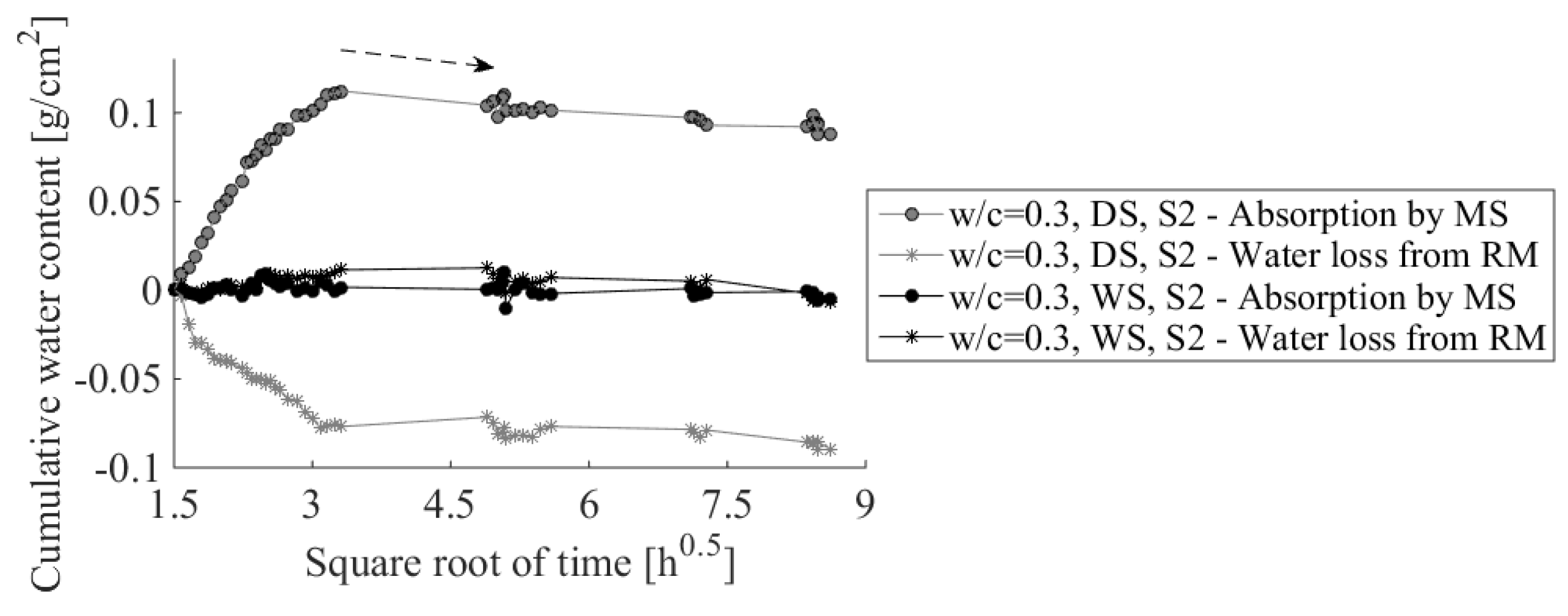

3. Moisture Movement in the Repair System and Discussion

4. Effects of Moisture Movement in the Repair System and Discussion

4.1. Effect of Moisture Movement on the Degree of Hydration of the Repair Material

4.2. Effect of Moisture Movement on Microstructure of the Repair Material and Interface

5. Conclusions

- Water exchange in a repair system has a critical influence on the microstructure formation of the bulk repair material and the interface. Water loss of the repair material by the substrate absorption reduces the effective w/c and degree of hydration of the repair material.

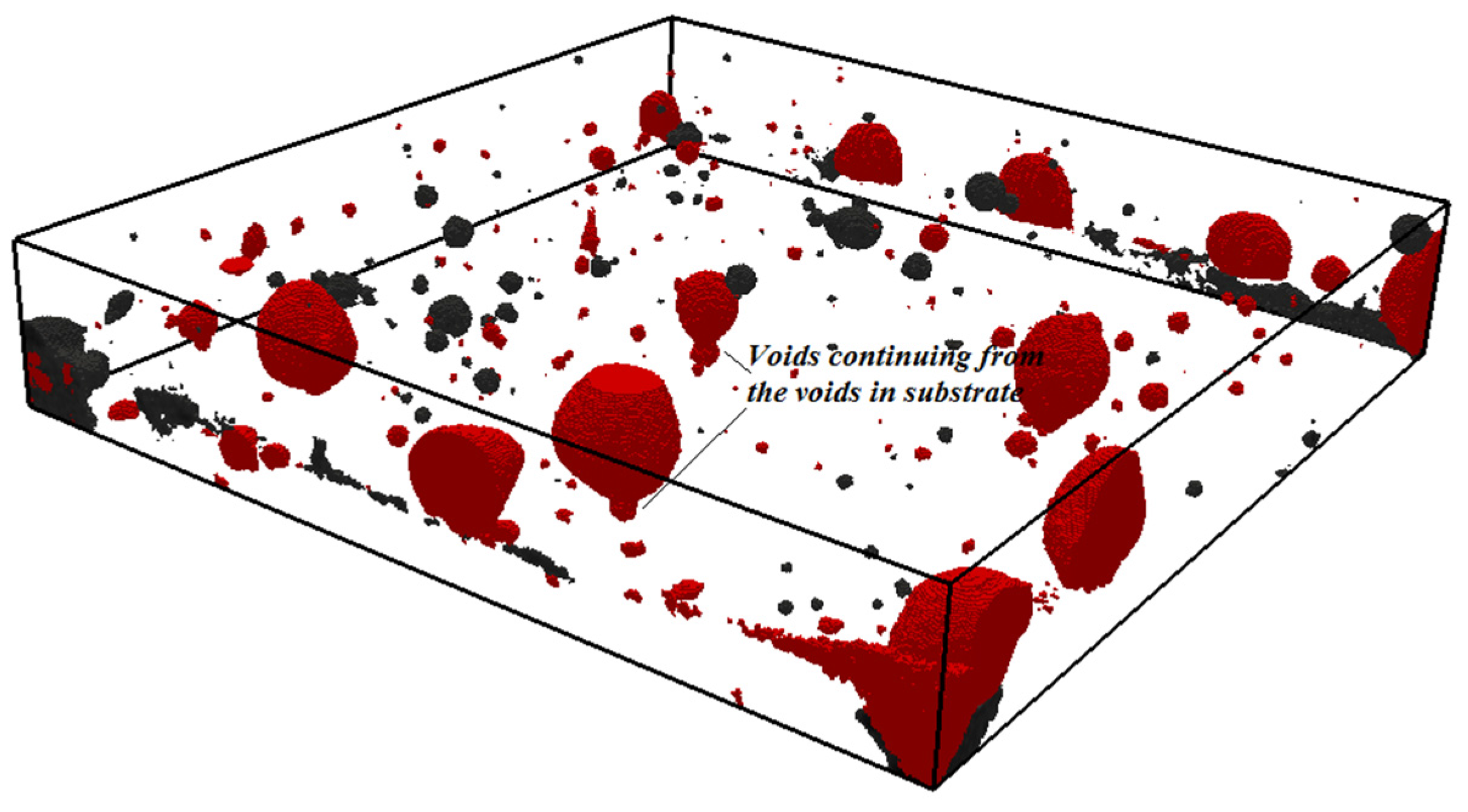

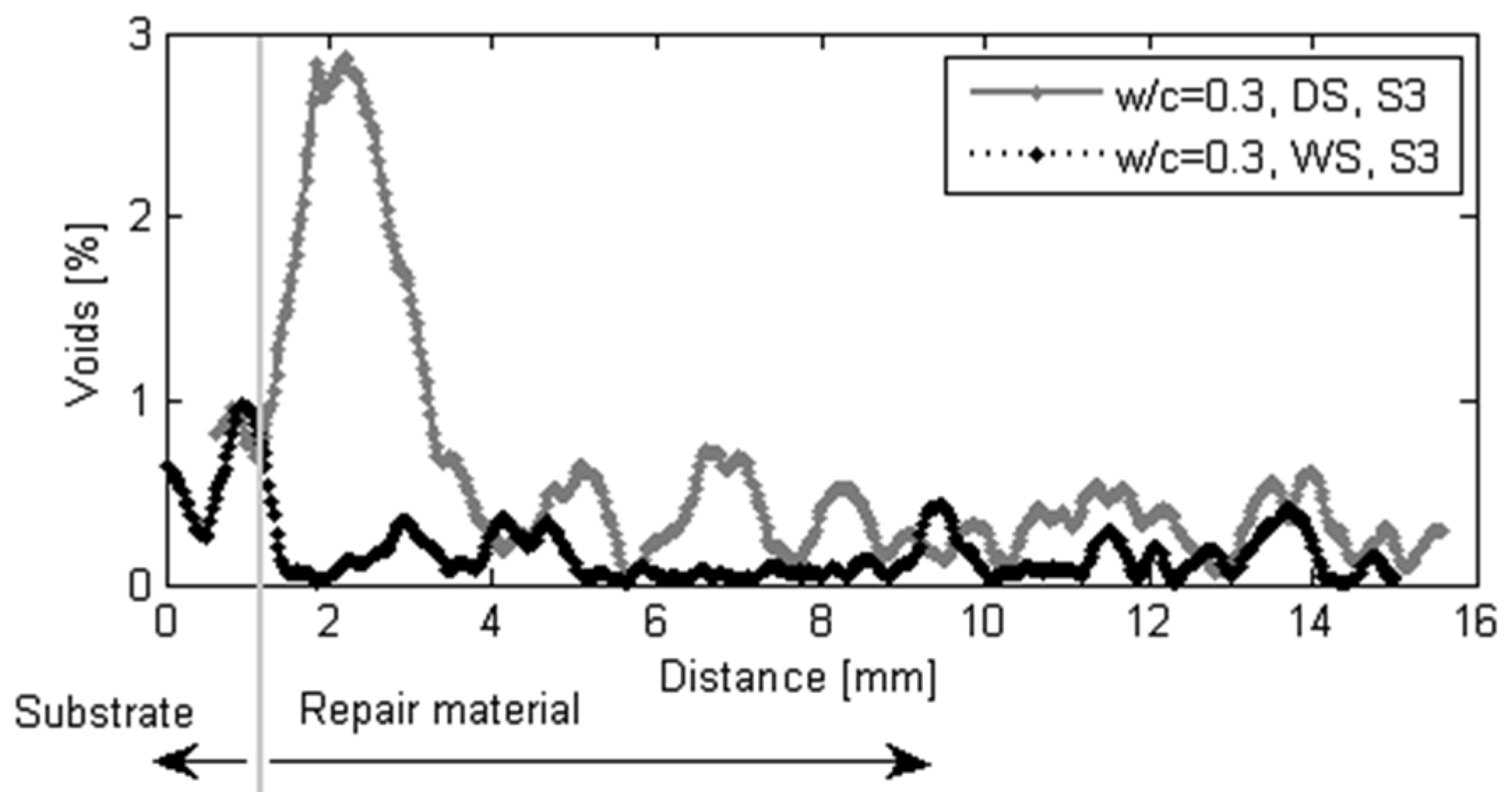

- The microstructure of the interface is significantly affected by the moisture exchange. Higher absorption of the substrate results in a more porous interface and bulk repair material. Pores and voids in the substrate, which are initially air-filled, are releasing this air to get water. Due to the high viscosity of the repair material and difficulties in compacting, this air remains entrapped at the interface.

- In the repair practice, the substrate should always be pre-saturated with the dry surface. Care should be taken that there is no water layer trapped at the surface of the substrate prior to the application of the material. This will provide a more uniform microstructure development in the repair material and a denser interface. Otherwise, properties of the repair material and the interface will be strongly influenced by the porosity, microcracks, moisture content, and absorption rate of the substrate. This is something that is difficult to control while designing repair systems.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Zhou, J. Performance of Engineered Cementitious Composites for Concrete Repairs. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 11 January 2011. [Google Scholar]

- Courard, L.; Lenaers, J.F.; Garbacz, A. Saturation level of the superficial zone of concrete and adhesion of repair systems. Constr. Build. Mater. 2011, 25, 2488–2494. [Google Scholar] [CrossRef]

- Brocken, H.; Spiekman, M.; Pel, L.; Kopinga, K.; Larbi, J. Water extraction out of mortar during brick laying: A NMR study. Mater. Struct. 1998, 31, 49–57. [Google Scholar] [CrossRef]

- Faure, P.; Caré, S.; Po, C.; Rodts, S. An MRI-SPI and NMR relaxation study of drying–hydration coupling effect on microstructure of cement-based materials at early age. J. Magn. Reson. Imaging. 2005, 23, 311–314. [Google Scholar] [CrossRef] [PubMed]

- Kazemi-Kamyab, H.; Denarie, E.; Bruhwiler, E.; Wang, B.; Thiery, M.; Faure, P.F.; Baroghel-Bouny, V. Characterization of Moisture Transfer in UHPFRC-Concrete Composite Systems at Early Age. In Proceedings of the 2nd International Conference on Microstructural-Related durability of Cementations Composites, Amsterdam, The Netherlands, 11–13 April 2012; Sun, W., Breugel, K.V., Miao, C., Ye, G., Chen, H., Eds.;

- Bentz, D.; Hansen, K. Preliminary observations of water movement in cement pastes during curing using X-ray absorption. Cem. Concr. Res. 2000, 30, 1157–1168. [Google Scholar] [CrossRef]

- Hall, C. Water sorptivity of mortars and concretes: A review. Mag. Concr. Res. 1989, 41, 51–61. [Google Scholar] [CrossRef]

- Ye, G. Experimental Study and Numerical Simulation of the Development of the Microstructure and Permeability of Cementitious Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 18 December 2003. [Google Scholar]

- Michel, A.; Pease, B.J.; Geiker, M.R.; Stang, H.; Olesen, J.F. Monitoring reinforcement corrosion and corrosion-induced cracking using non-destructive x-ray attenuation measurements. Cem. Concr. Res. 2011, 41, 1085–1094. [Google Scholar] [CrossRef]

- Roels, S.; Carmeliet, J. Analysis of moisture flow in porous materials using microfocus X-ray radiography. Int. J. Heat. Mass. Tran. 2006, 49, 4762–4772. [Google Scholar] [CrossRef]

- Pease, B.J.; Scheffler, G.A.; Janssen, H. Monitoring moisture movements in building materials using X-ray attenuation: Influence of beam-hardening of polychromatic X-ray photon beams. Constr. Build. Mater. 2012, 36, 419–429. [Google Scholar] [CrossRef]

- Juenger, M.C.G.; Jennings, H.M. Examining the relationship between the microstructure of calcium silicate hydrate and drying shrinkage of cement pastes. Cem. Concr. Res. 2002, 32, 289–296. [Google Scholar] [CrossRef]

- Neville, A.M. Properties of Concrete, 4th ed.; Pearson: Harlow, UK, 1997; pp. 35–37. [Google Scholar]

- Lam, L.; Wong, Y.; Poon, C. Degree of hydration and gel/space ratio of high-volume fly ash/cement systems. Cem. Concr. Res. 2000, 30, 747–756. [Google Scholar] [CrossRef]

- Lukovic, M.; Schlangen, E.; Ye, G.; Breugel, K.V. Moisture Exchange in Concrete Repair System Captured by X-ray Absorption. In Proceedings of the 4th International Conference on Concrete Repair, Leipzig, Germany, 5–7 October 2015.

- Koenders, E.A.B. Simulation of Volume Changes in Hardening Cement-Based Materials. Ph.D. Thesis, Delft University of Technology, Delft, The Netherlands, 23 September 1997. [Google Scholar]

- LWAC Material Properties State-of the-Art; Technical Report for European Union–Brite EuRamIII; European Union: Brussels, Belgium, 1998; pp. 32–34.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons by Attribution (CC-BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lukovic, M.; Ye, G. Effect of Moisture Exchange on Interface Formation in the Repair System Studied by X-ray Absorption. Materials 2016, 9, 2. https://doi.org/10.3390/ma9010002

Lukovic M, Ye G. Effect of Moisture Exchange on Interface Formation in the Repair System Studied by X-ray Absorption. Materials. 2016; 9(1):2. https://doi.org/10.3390/ma9010002

Chicago/Turabian StyleLukovic, Mladena, and Guang Ye. 2016. "Effect of Moisture Exchange on Interface Formation in the Repair System Studied by X-ray Absorption" Materials 9, no. 1: 2. https://doi.org/10.3390/ma9010002