Thermal Stability and Magnetic Properties of Polyvinylidene Fluoride/Magnetite Nanocomposites

Abstract

:1. Introduction

2. Experimental

2.1. Materials

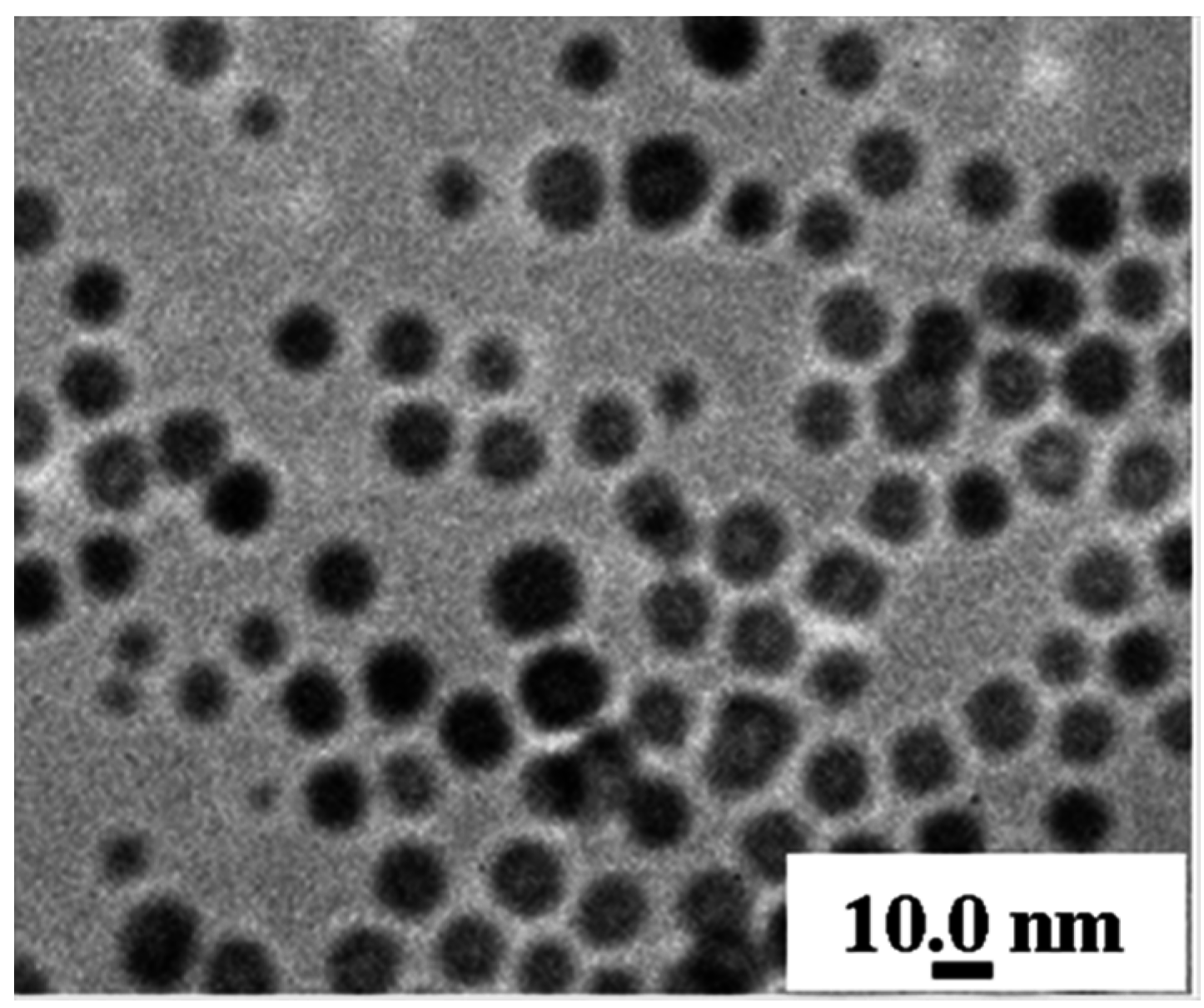

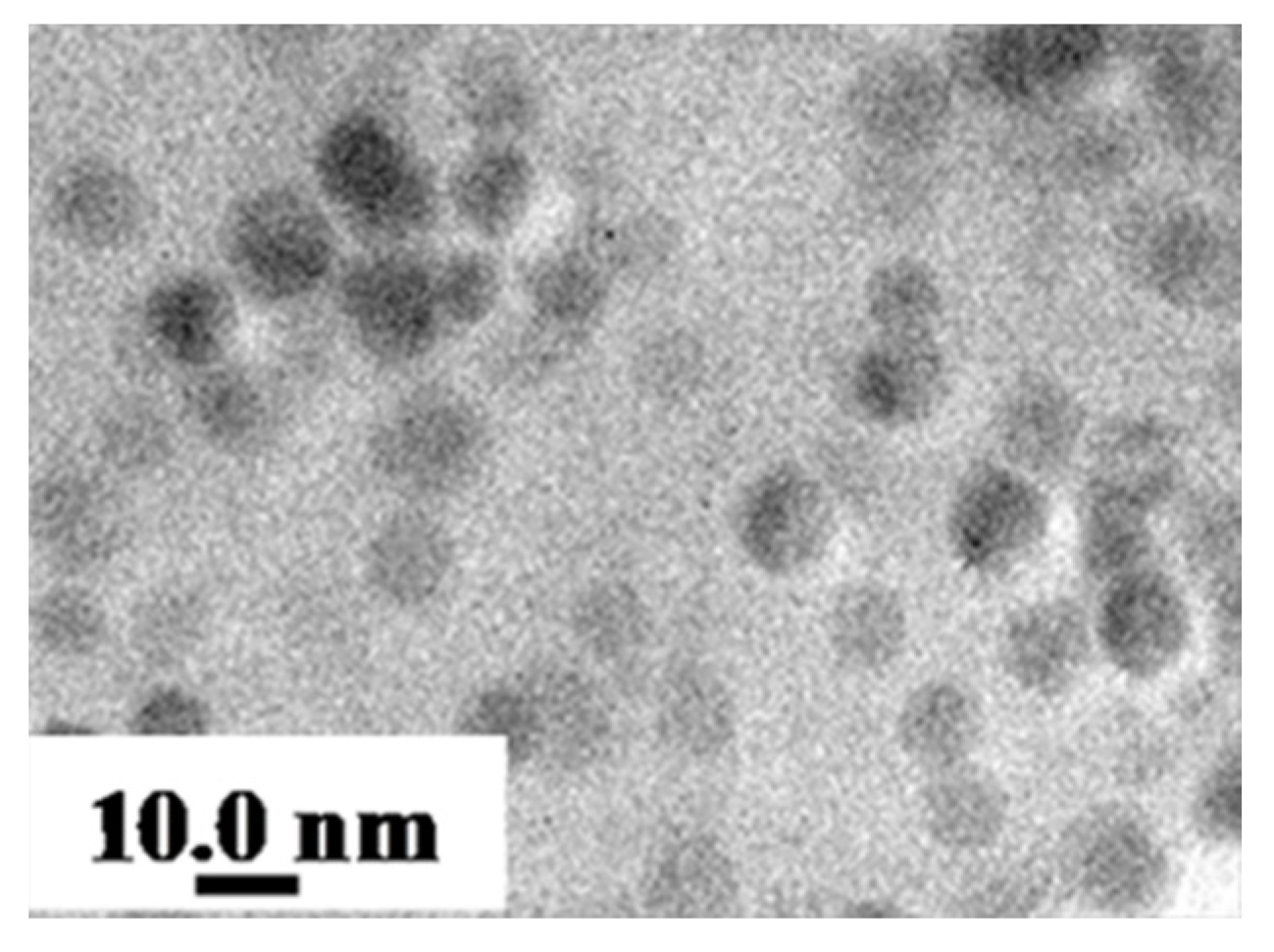

2.2. Synthesis of Monodispersed Magnetite Nanoparticles

2.3. Fabrication of PVDF/Magnetite Composites

2.4. Characterization of PVDF/Magnetite Composites

3. Results and Discussion

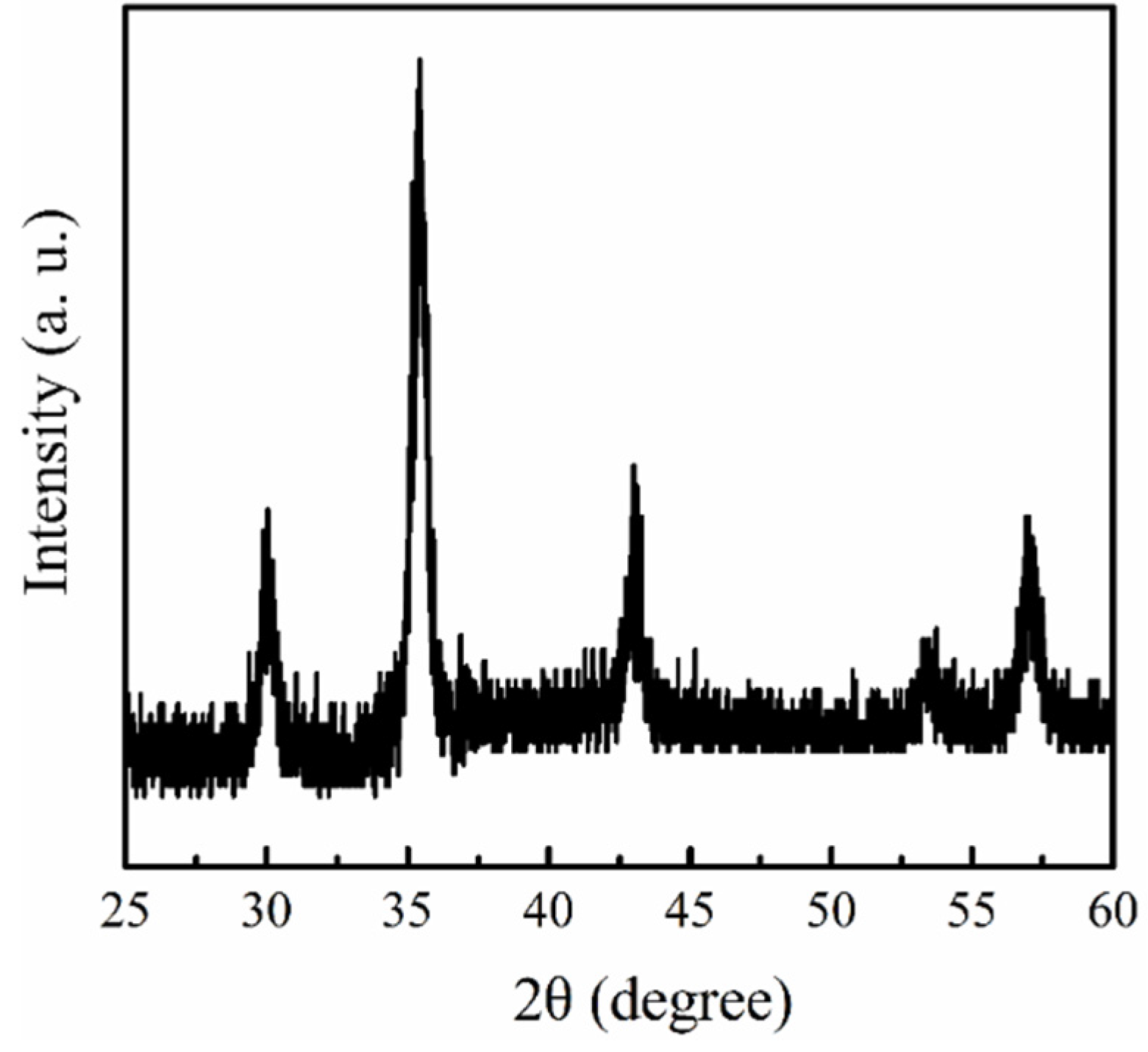

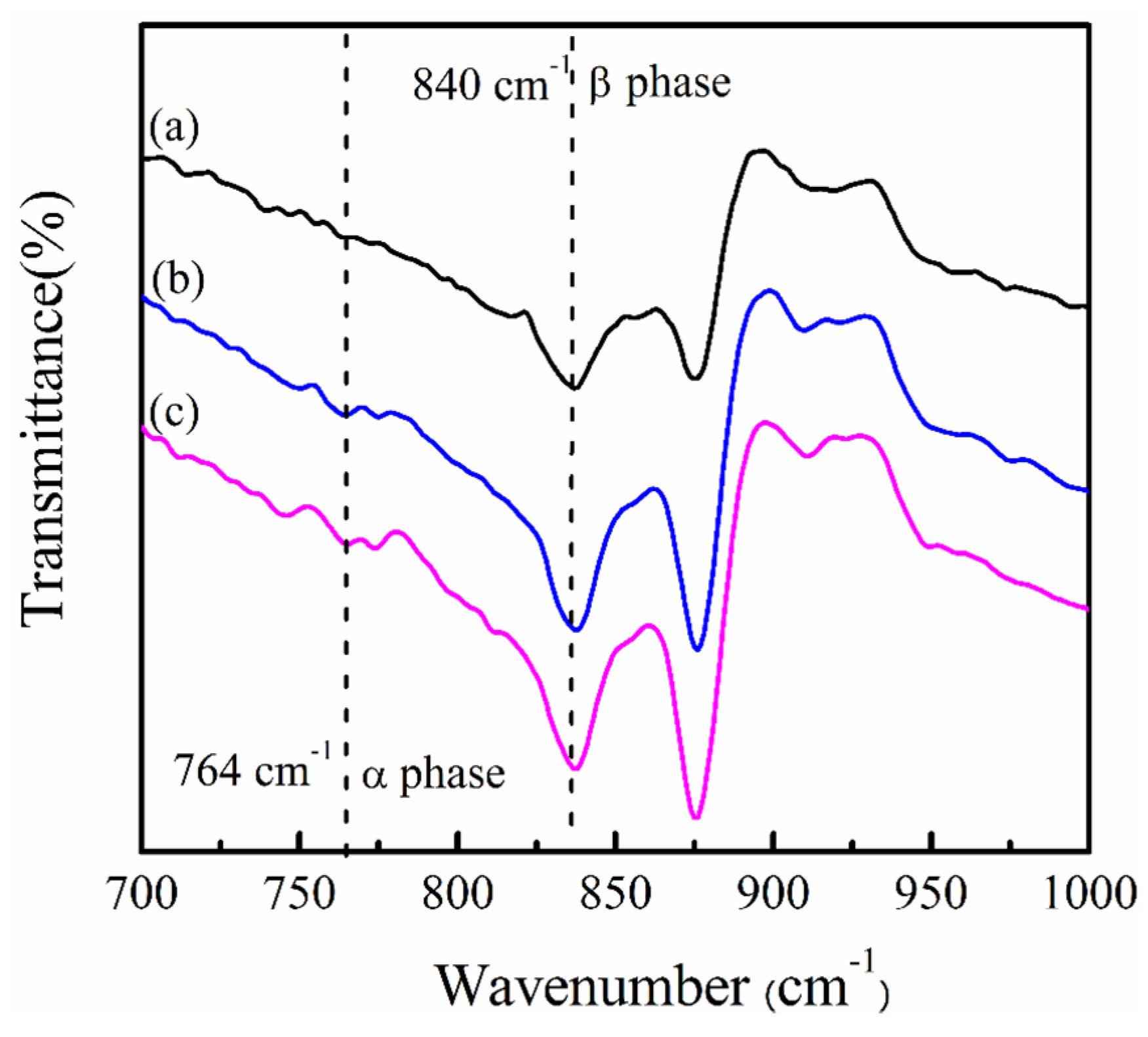

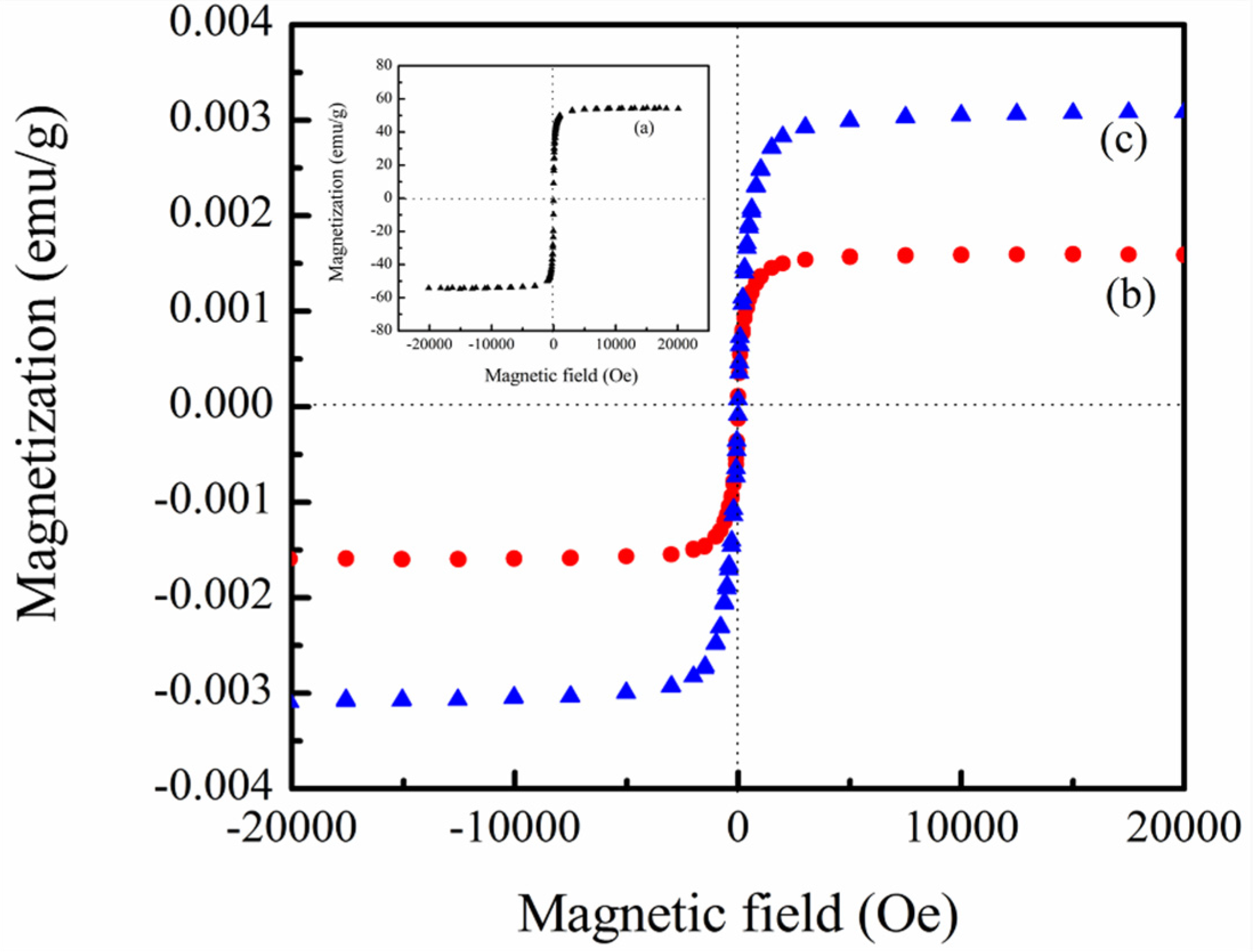

3.1. Characterization and Physical Properties of PVDF/Magnetite Composites

| d33 (pC/N) | |||||

|---|---|---|---|---|---|

| Electrical Field Poling | 0 MV/m | 14 MV/m | 21 MV/m | 28 MV/m | 35 MV/m |

| PVDF | 7.3 ± 0.1 | 14.6 ± 0.2 | 19.2 ± 0.2 | 31.4 ± 0.4 | 33.4 ± 0.4 |

| 1 wt % PVDF/magnetite | 7.6 ± 0.1 | 22.4 ± 0.2 | 24.5 ± 0.3 | 36.7 ± 0.4 | 37.6 ± 0.4 |

| 2 wt % PVDF/magnetite | 7.8 ± 0.1 | 26.4 ± 0.2 | 28.2 ± 0.3 | 39.8 ± 0.5 | 40.6 ± 0.5 |

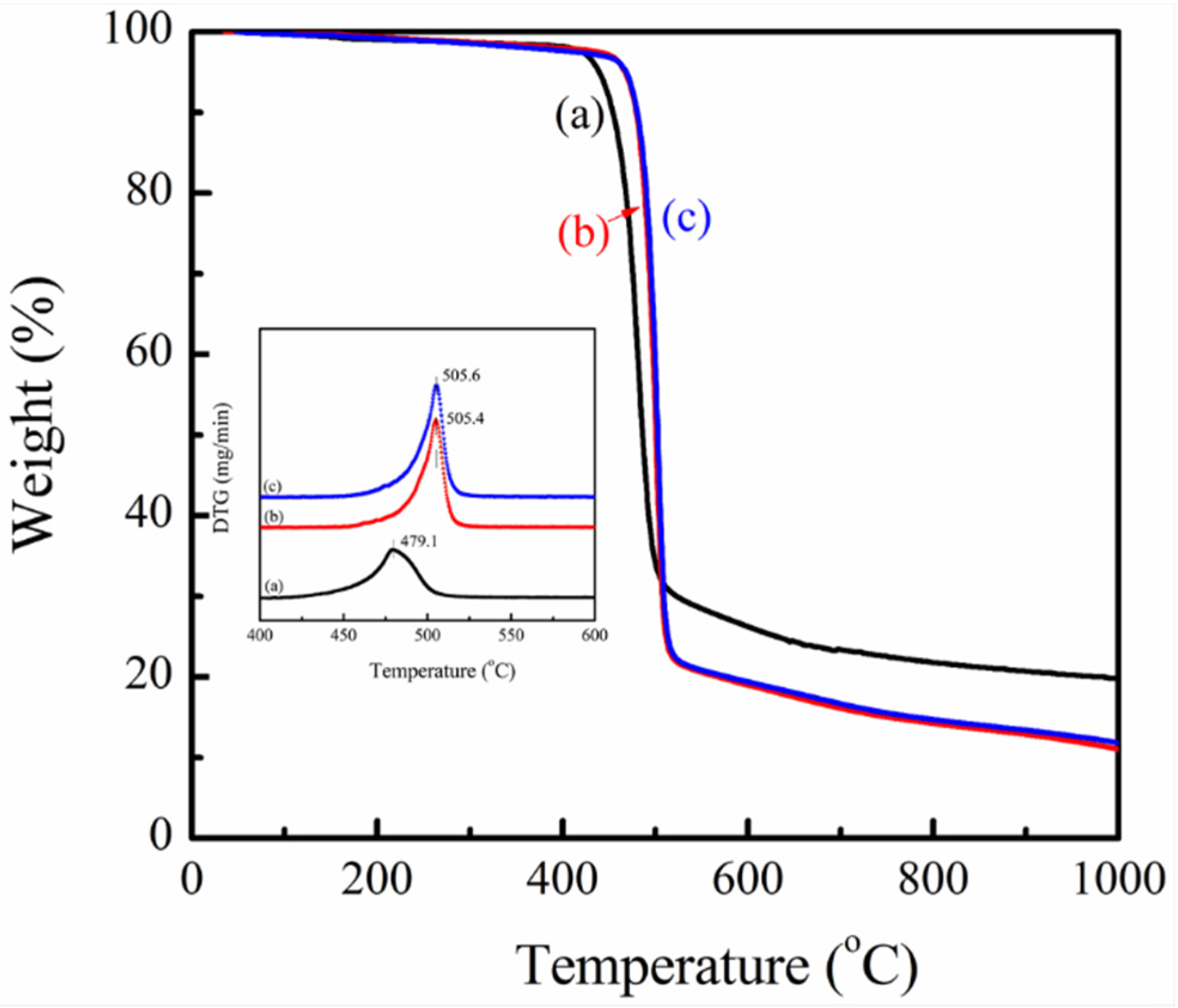

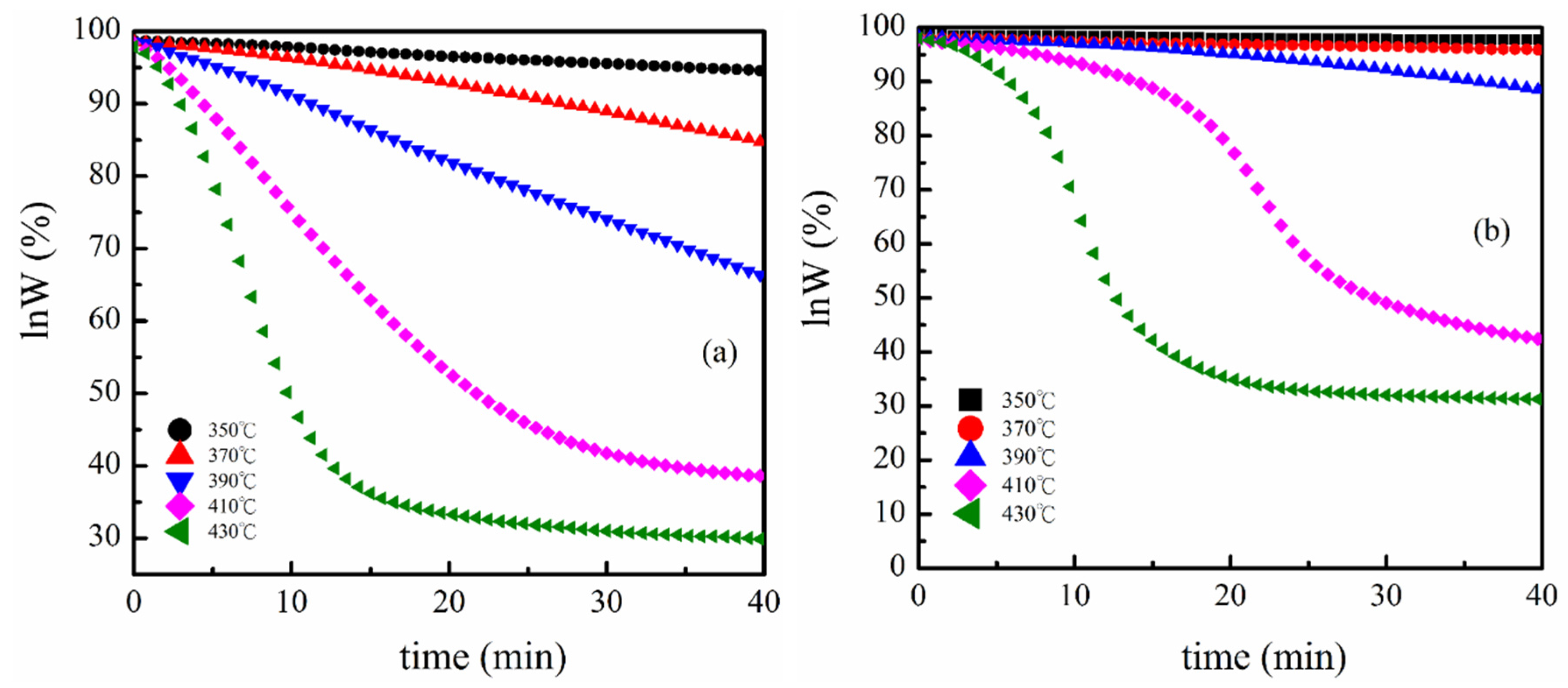

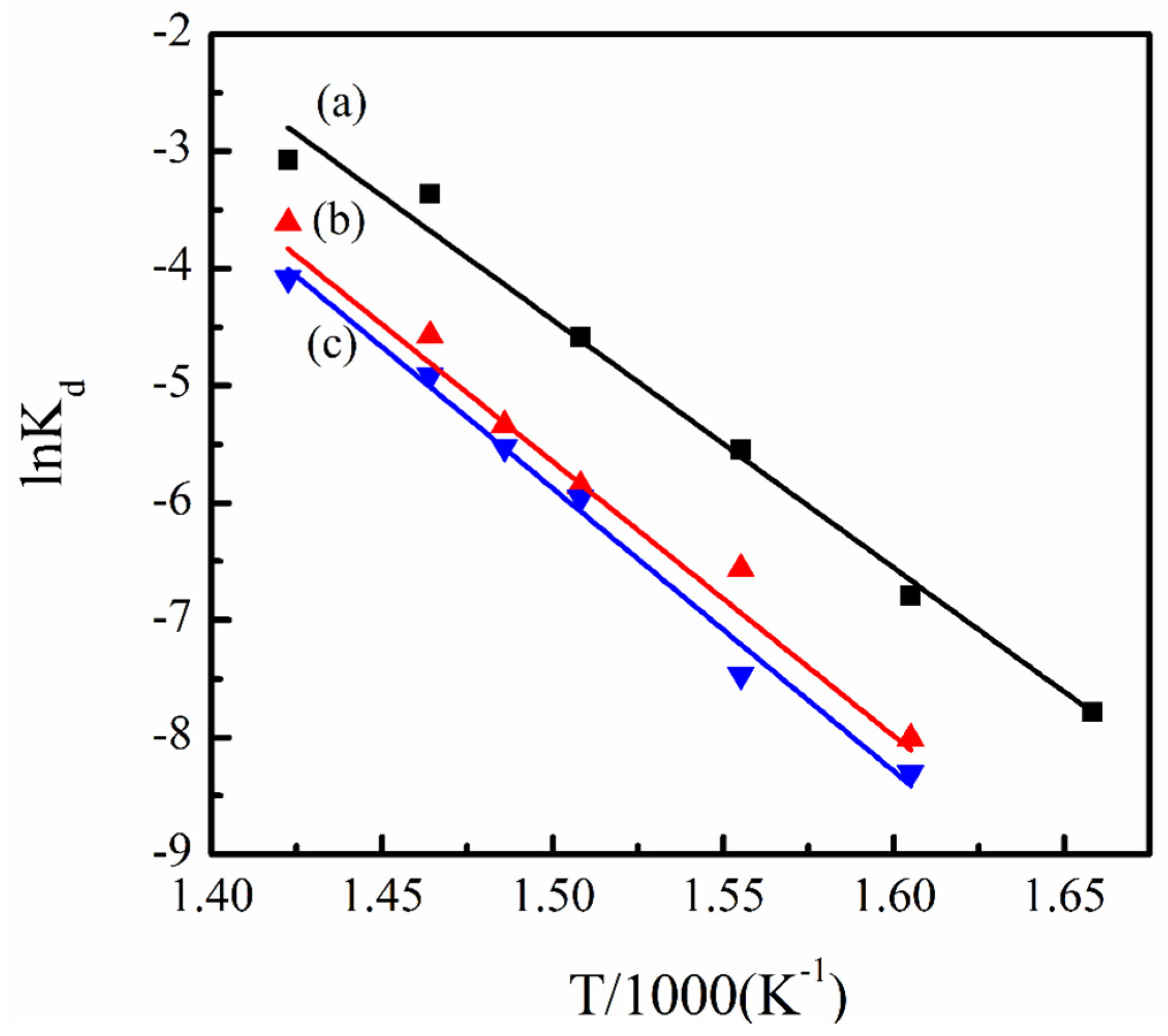

3.2. Thermal Stability of PVDF/Magnetite Composites

4. Conclusions

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Yee, W.A.; Kotaki, M.; Liu, Y.; Lu, X.H. Morphology, polymorphism behavior and molecular orientation of electrospun poly(vinylidene fluoride) fibers. Polymer 2007, 48, 512–521. [Google Scholar] [CrossRef]

- Wang, M.; Shi, J.H.; Pramoda, K.P.; Goh, S.H. Microstructure, crystallization and dynamic mechanical properties of poly(vinylidene fluoride) composites containing poly(methyl methacrylate)-grafted multiwalled carbon nanotubes. Nanotechnology 2007, 18. [Google Scholar] [CrossRef]

- Salimi, A.; Yousefi, A.A. Conformational changes and phase transformation mechanisms in PVDF solution-cast films. J. Polym. Sci. Polym. Phys. 2004, 42, 3487–3495. [Google Scholar] [CrossRef]

- Lovinger, A.J. Ferroelectric polymers. Science 1983, 220, 1115–1121. [Google Scholar] [CrossRef] [PubMed]

- Sencadas, V.; Gregorio Filho, R.; Lanceros-Mendez, S. Processing and characterization of a novel nonporous poly(vinilidene fluoride) films in the β phase. J. Non-Cryst. Solid 2006, 352, 2226–2229. [Google Scholar] [CrossRef] [Green Version]

- Botelho, G.; Lanceros-Mendez, S.; Goncalves, A.M.; Sencadas, V.; Rocha, J.G. Relationship between processing conditions, defects and thermal degradation of poly(vinylidene fluoride) in the β-phase. J. Non-Cryst. Solid 2008, 354, 72–78. [Google Scholar] [CrossRef]

- Nalwa, H.S. Ferroelectric Polymers: Chemistry, Physics and Applications; Marcel Dekker Inc.: New York, NY, USA, 1995. [Google Scholar]

- Tashiro, K.; Takano, K.; Kobayashi, M.; Chatani, Y.; Tadokoro, H. Phase transition at a temperature immediately below the melting point of poly(vinylidene fluoride) form I: A proposition for the ferroelectric Curie point. Polymer 1983, 24, 199–204. [Google Scholar] [CrossRef]

- Darestani, M.T.; Coster, H.G.L.; Chilcott, T.C.; Fleming, S.; Nagarajan, V.; An, H. Piezoelectric membranes for separation process: Fabrication and piezoelectric properties. J. Membr. Sci. 2013, 434, 184–192. [Google Scholar] [CrossRef]

- Coster, H.G.L.; Darestani, M.T.; Chilcott, T.C. Production and characterization of piezo-electric membranes. Desalination 2011, 283, 52–57. [Google Scholar] [CrossRef]

- Mendes, S.; Costa, C.; Caparros, C.; Sencadas, V.; Lanceros-Méndez, S. Effect of filler size and concentration on the structure and properties of poly(vinylidene fluoride)/BaTiO3 nanocomposites. J. Mater. Sci. 2012, 47, 1378–1388. [Google Scholar] [CrossRef]

- Patro, T.U.; Mhalgi, M.V.; Khakhar, D.V.; Misra, A. Studies on poly(vinylidene fluoride)-clay nanocomposites: Effect of different clay modifiers. Polymer 2008, 49, 3486–3499. [Google Scholar] [CrossRef]

- Lund, A.; Gustafsson, C.; Bertilsson, H.; Rychwalski, R.W. Enhancement of β phase crystals formation with the use of nanofillers in PVDF films and fibres. Compos. Sci. Technol. 2011, 71, 222–229. [Google Scholar] [CrossRef]

- An, N.L.; Liu, H.Z.; Ding, Y.C.; Zhang, M.; Tang, Y.P. Preparation and electroactive properties of a PVDF/nano-TiO2 composite film. Appl. Surf. Sci. 2011, 257, 3831–3835. [Google Scholar] [CrossRef]

- Martins, P.; Costa, C.M.; Lanceros-Mendez, S. Nucleation of electroactive β-phase poly(vinilidene fluoride) with CoFe2O4 and NiFe2O4 nanofillers: a new method for the preparation of multiferroic nanocomposites. Appl. Phys. A Mater. Sci. Process. 2011, 103, 233–237. [Google Scholar] [CrossRef]

- Prabhakaran, T.; Hemalatha, J. Ferroelectric and magnetic studies on unpoled poly(vinylidine fluoride)/Fe3O4 magnetoelectric nanocomposite structures. Mater. Chem. Phys. 2013, 137, 781–787. [Google Scholar] [CrossRef]

- Bhatt, A.S.; Bhat, D.K.; Santosh, M.S. Crystallinity, conductivity and magnetic properties of PVDF-Fe3O4 composite films. J. Appl. Polym. Sci. 2011, 119, 968–972. [Google Scholar] [CrossRef]

- Martins, P.; Costa, C.M.; Benelmekki, M.; Botelhob, G.; Lanceros-Mendez, S. On the origin of the electroactive poly(vinylidene fluoride) β-phase nucleation by ferrite nanoparticles via surface electrostatic interactions. Cryst. Eng. Comm. 2012, 14, 2807–2811. [Google Scholar] [CrossRef]

- Martins, P.; Lopes, A.C.; Lanceros-Méndez, S. Electroactive phases of poly(vinylidene fluoride): Determination, processing and applications. Prog. Polym. Sci. 2014, 39, 683–706. [Google Scholar] [CrossRef]

- Martins, P.; Lanceros-Méndez, S. Polymer-based magnetoelectric materials. Adv. Funct. Mater. 2013, 23, 3371–3385. [Google Scholar] [CrossRef]

- Goncalves, R.; Martins, P.M.; Caparros, C.; Martins, P.; Benelmekki, M.; Botelho, G.; Lanceros-Mendez, S.; Lasheras, A.; Gutierrez, J.; Barandiaran, J.M. Nucleation of the electroactive β-phase, dielectric and magnetic response of poly(vinylidene fluoride) composites with Fe2O3 nanoparticles. J. Non-Cryst. Solid 2013, 361, 93–99. [Google Scholar] [CrossRef]

- Pavlidou, S.; Papaspyrides, C.D. A review on polymer-layered silicate nanocomposites. Prog. Polym. Sci. 2008, 33, 1119–1198. [Google Scholar] [CrossRef]

- Ouyang, Z.W.; Chen, E.C.; Wu, T.M. Enhanced piezoelectric and mechanical properties of electroactive polyvinylidene fluoride/iron oxide composites. Mater. Chem. Phys. 2015, 149–150, 172–178. [Google Scholar] [CrossRef]

- Wu, T.M.; Yen, S.J.; Chen, E.C.; Sung, T.W.; Chiang, R.K. Conducting and magnetic behaviors of monodispersed iron oxide/polypyrrole nanoomposites synthesized by in situ chemical oxidative polymerization. J. Polym. Sci. A Polym. Chem. 2007, 45, 4647–4655. [Google Scholar] [CrossRef]

- Lidmila, E.J.B. What is really measured on a d33-meter? J. Eur. Ceram. Soc. 2001, 21, 1413–1415. [Google Scholar]

- Izyumskaya, N.; Alivov, Y.I.; Cho, S.J.; Morkoccedil, H.; Lee, H.; Kang, Y.S. Processing, structure, properties, and applications of PZT thin films. Crit. Rev. Solid State Mater. Sci. 2007, 32, 111–202. [Google Scholar] [CrossRef]

- JCPDS Card 03-065-3107. International Centre for Diffraction Data: Newtown Square, PA, USA.

- Sencadas, V.; Gregorio, R.; Lanceros-Mendez, S. α to β phase transformation and microstructural changes of PVDF films induced by uniaxial stretch. J. Macromol. Sci. B Phys. 2009, 48, 514–525. [Google Scholar] [CrossRef]

- Inoue, M.; Tada, Y.; Suganuma, K.; Ishiguro, H. Thermal stability of poly(vinylidene fluoride) films pre-annealed at various temperatures. Polym. Degrad. Stab. 2007, 92, 1833–1840. [Google Scholar] [CrossRef]

- Zhang, Y.; Jiang, S.; Fan, M.; Zeng, Y.; Yu, Y.; He, J. Piezoelectric formation mechanisms and phase transformation of poly(vinylidene fluoride)/graphite nanosheets nanocomposites. J. Mater. Sci. Mater. Electron. 2013, 24, 927–932. [Google Scholar] [CrossRef]

- Ye, Y.; Jiang, Y.; Wu, Z.; Zeng, H. Phase transition of poly(vinylidene fluoride) under electric fields. Integr. Ferroelectr. 2006, 80, 245–251. [Google Scholar] [CrossRef]

- Huan, Y.; Liu, Y.; Yang, Y.; Wu, Y. Influence of extrusion, stretching and poling on the structural and piezoelectric properties of poly (vinylidene fluoride-hexafluoropropylene)c opolymer films. J. Appl. Polym. Sci. 2007, 104, 858–862. [Google Scholar] [CrossRef]

- Freeman, E.S.; Carroll, B. The application of thermoanalytical techniques to reaction kinetics. J. Phys. Chem. 1958, 62, 394–397. [Google Scholar] [CrossRef]

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ouyang, Z.-W.; Chen, E.-C.; Wu, T.-M. Thermal Stability and Magnetic Properties of Polyvinylidene Fluoride/Magnetite Nanocomposites. Materials 2015, 8, 4553-4564. https://doi.org/10.3390/ma8074553

Ouyang Z-W, Chen E-C, Wu T-M. Thermal Stability and Magnetic Properties of Polyvinylidene Fluoride/Magnetite Nanocomposites. Materials. 2015; 8(7):4553-4564. https://doi.org/10.3390/ma8074553

Chicago/Turabian StyleOuyang, Zen-Wei, Erh-Chiang Chen, and Tzong-Ming Wu. 2015. "Thermal Stability and Magnetic Properties of Polyvinylidene Fluoride/Magnetite Nanocomposites" Materials 8, no. 7: 4553-4564. https://doi.org/10.3390/ma8074553