Experimental and Numerical Study on the Strength of Aluminum Extrusion Welding

Abstract

:1. Introduction

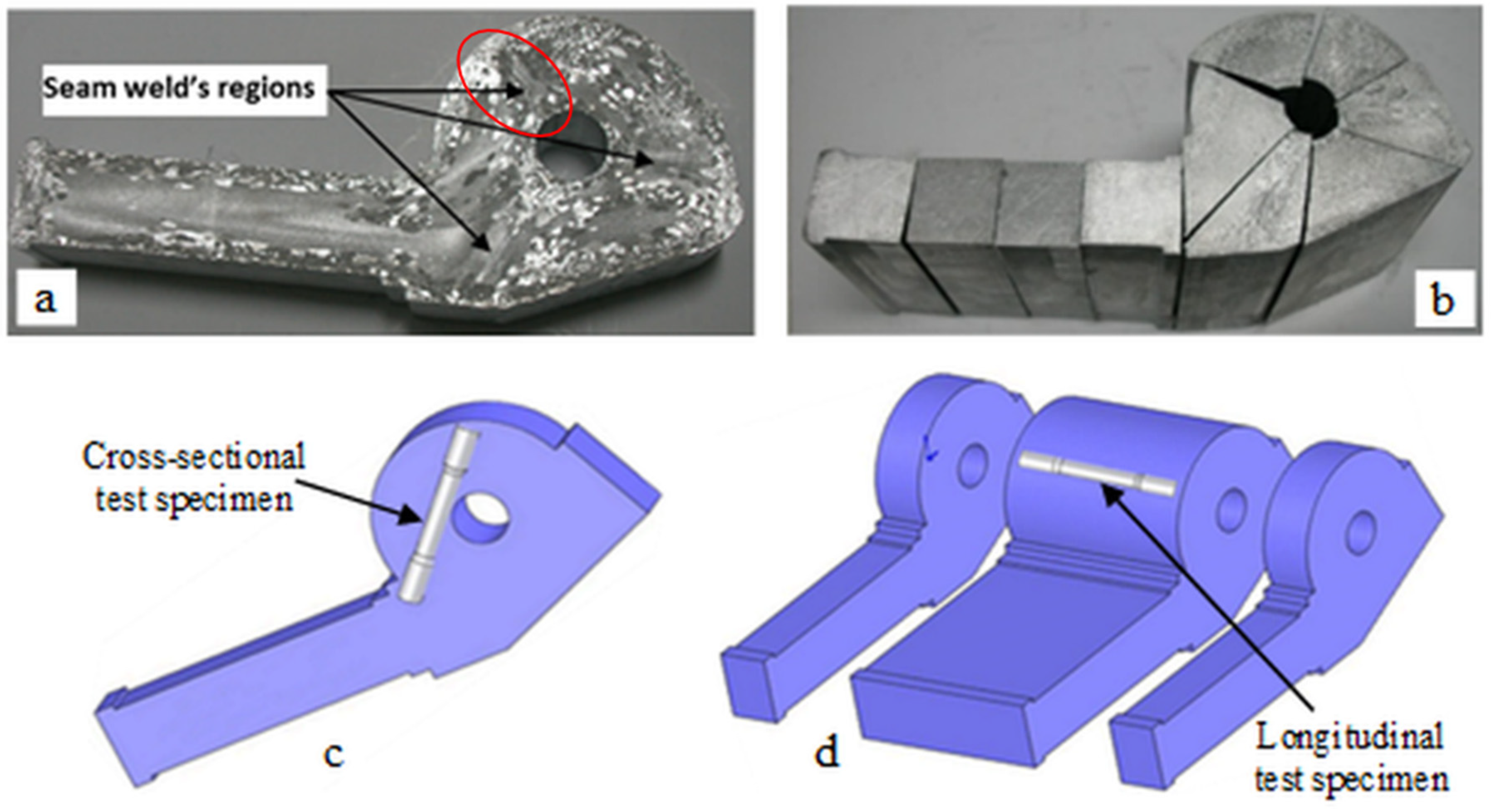

2. Materials and Method

2.1. Experimental Study

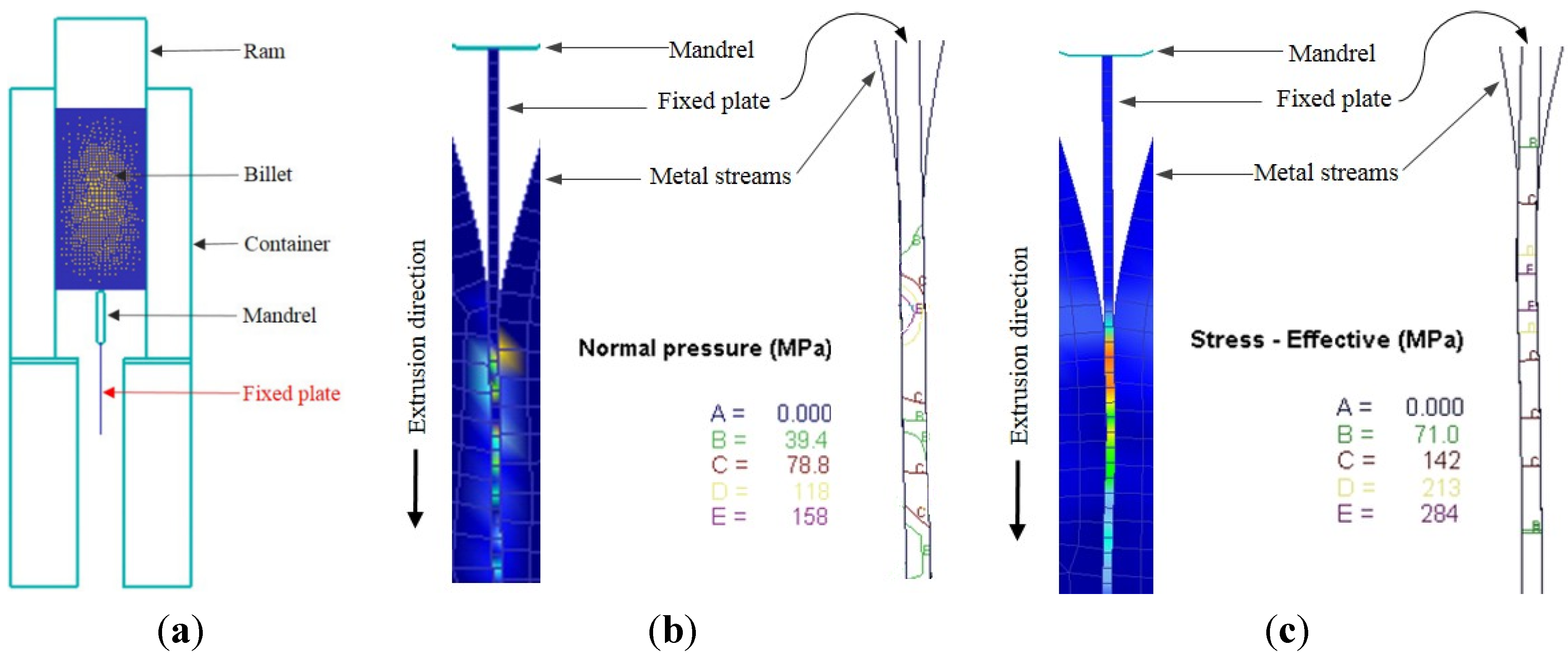

2.2. Material Modeling in Hot Extrusion of AA6063

2.3. Finite Element Modeling Approach

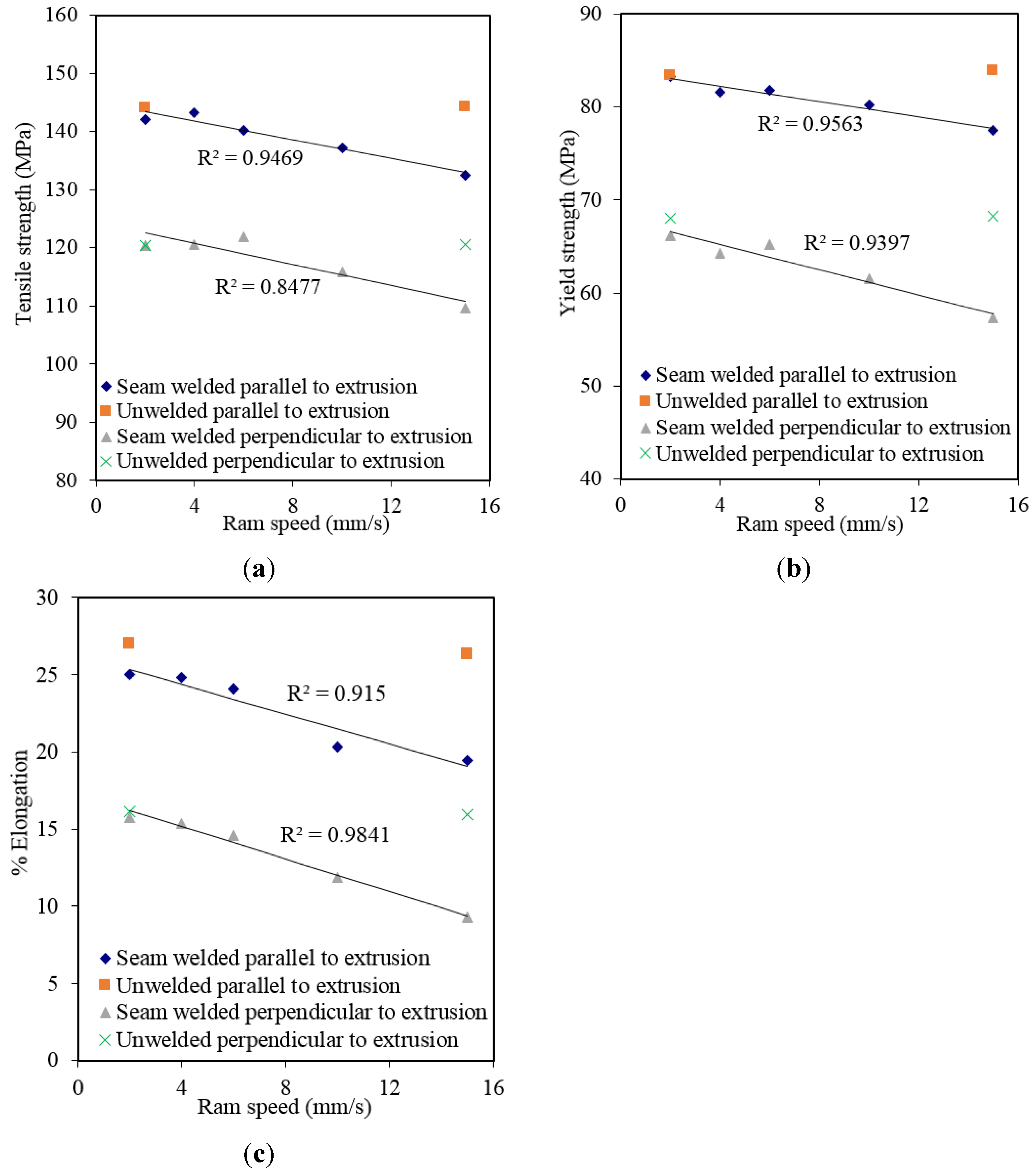

3. Results and Discussion

4. Conclusions

- Increasing ram speed negatively influences the seam-welded quality of AA6063. However, the strengths of the welded specimens parallel to extrusion direction are higher than the strengths of the welded specimen prepared perpendicular to extrusion direction.

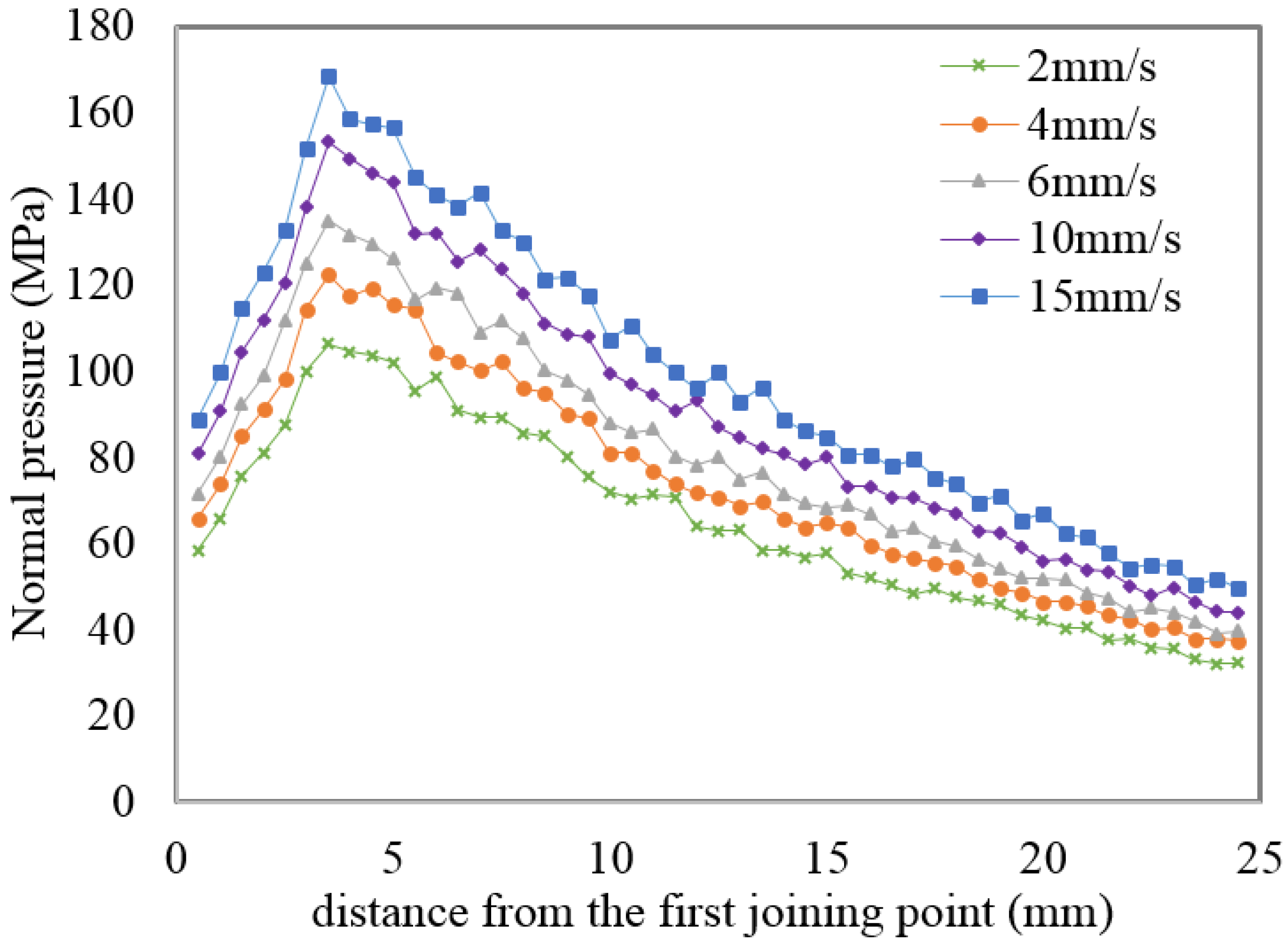

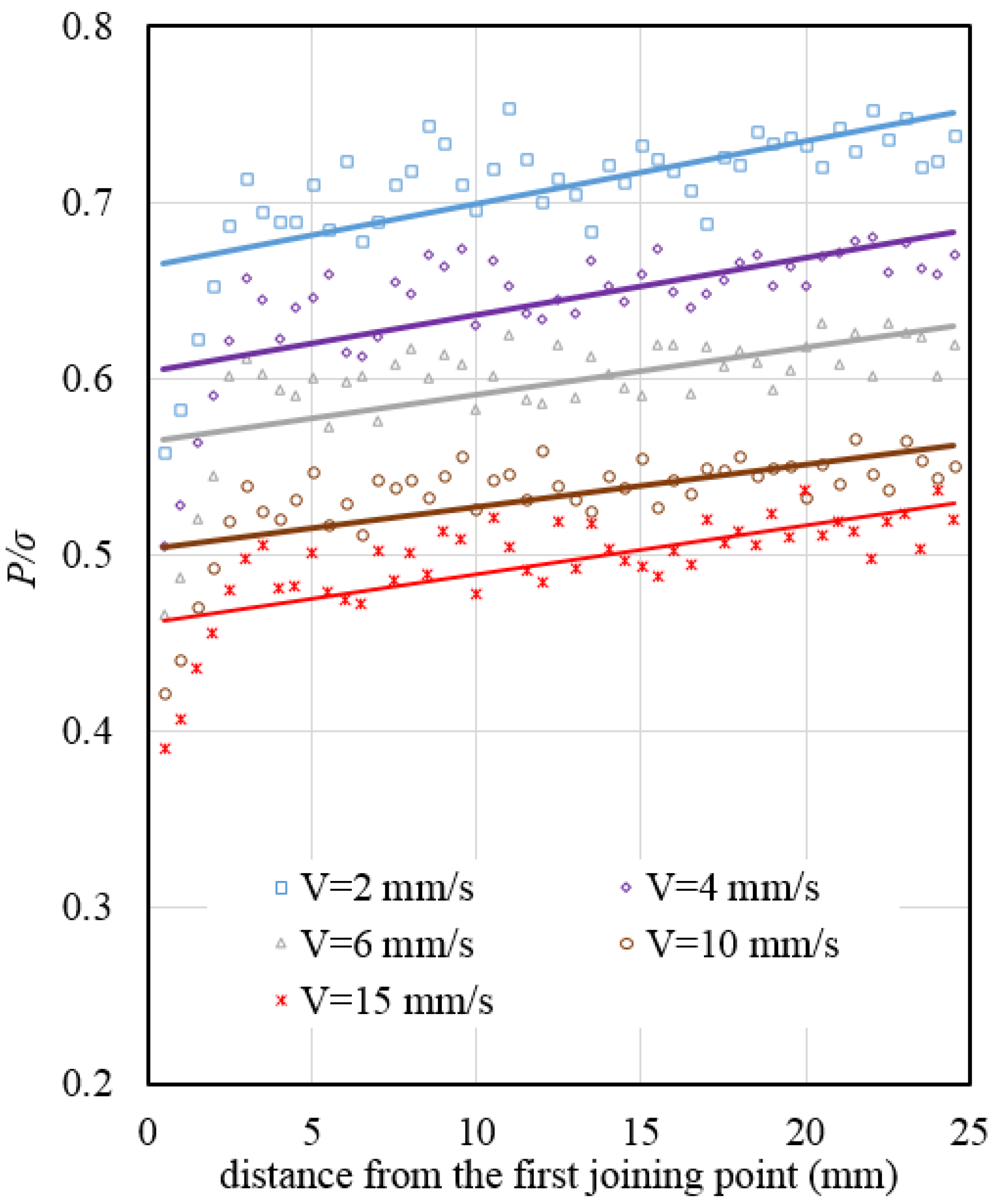

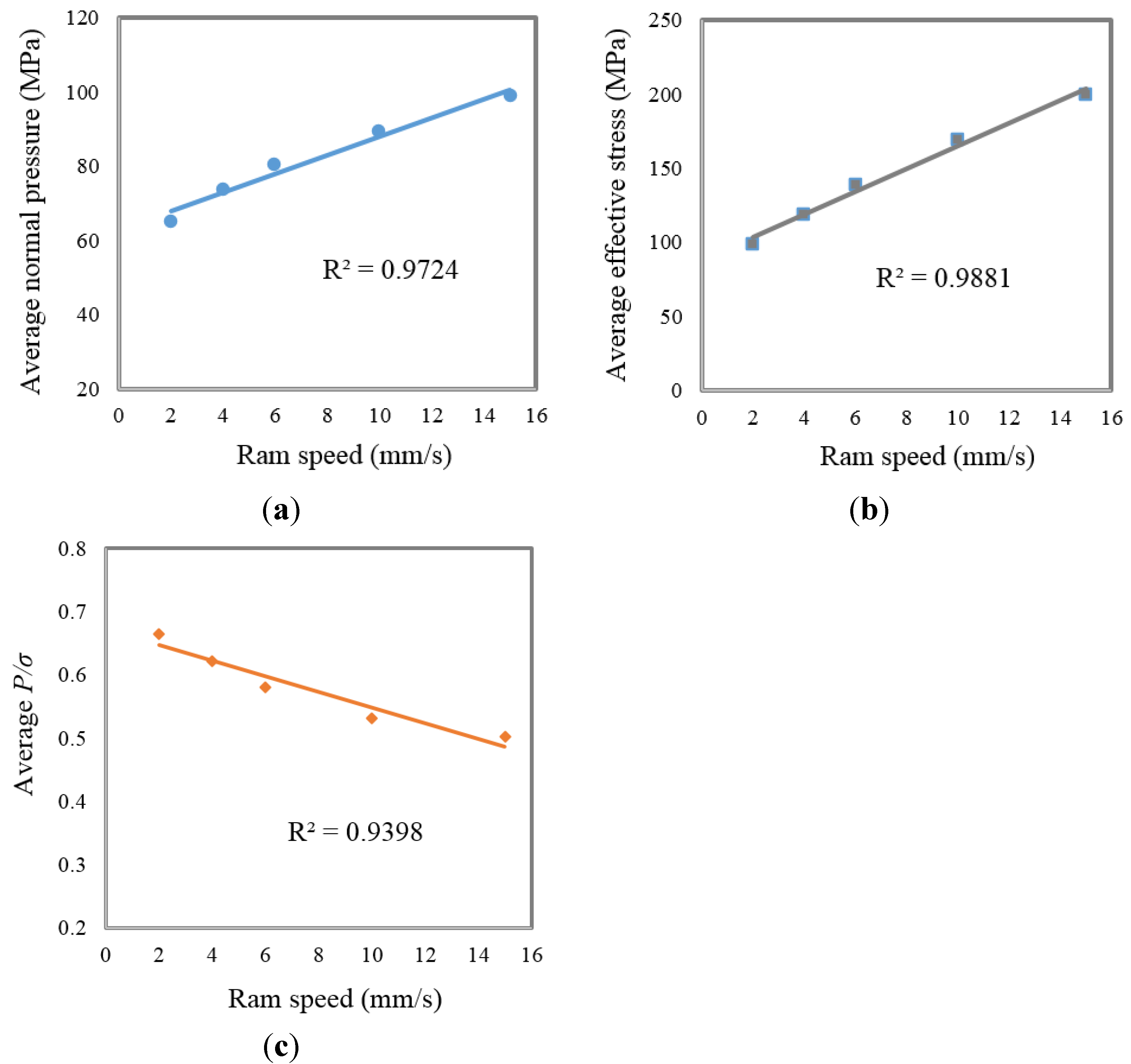

- With the increasing ram speed in numerical simulations, P and σ increased. However, the ratio P/σ, which is responsible for the quality of welding in extrusion, was decreased. This case was verified by performed experiments, which show that the strength of specimens decreased with increasing ram speed.

- The distributions of P and σ within the welding chamber are not uniform. They are low within the beginning of the welding chamber due to the fact that the metal streams are just starting to be joined. After reaching their maximum values, P and σ decrease toward the exit of the die. However, the (P/σ) ratio remains almost constant toward the exit of the die.

Acknowledgments

Author Contributions

Conflicts of Interest

References

- Tabatabaei, S.A.; Abrinia, K.; Givia, M.K.B.; Karami, P.; Mashhadi, M.M. Application of the equi-potential lines method in upper bound estimation of the extrusion pressure. Mater. Manuf. Process. 2013, 28, 271–275. [Google Scholar] [CrossRef]

- Bingol, S.; Ayer, O.; Altinbalik, T. Extrusion load prediction of gear-like profile for different die geometries using ANN and FEM with experimental verification. Int. J. Adv. Manuf. Technol. 2015, 76, 983–992. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W. Constitutive analysis of homogenized 7005 aluminum alloy at evaluated temperature for extrusion process. Mater. Des. 2015, 66, 129–136. [Google Scholar] [CrossRef]

- Gagliardi, F.; Citrea, T.; Ambrogio, G.; Filice, L. Influence of the process setup on the microstructure and mechanical properties evolution in porthole die extrusion. Mater. Des. 2014, 60, 274–281. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, G.; Yu, J.; Zhang, W.; Wu, T. Analysis and porthole die design for a multi-hole extrusion process of a hollow, thin-walled aluminum profile. Int. J. Adv. Manuf. Technol. 2014, 74, 383–392. [Google Scholar] [CrossRef]

- Zhao, G.; Chen, H.; Zhang, C.; Guan, Y. Multiobjective optimization design of porthole extrusion die using Pareto-based genetic algorithm. Int. J. Adv. Manuf. Technol. 2013, 69, 1547–1556. [Google Scholar] [CrossRef]

- Li, L.; Zhang, H.; Zhou, J.; Duszczyk, J.; Li, G.Y.; Zhong, Z.H. Numerical and experimental study on the extrusion through a porthole die to produce a hollow magnesium profile with longitudinal weld seams. Mater. Des. 2008, 29, 1190–1198. [Google Scholar] [CrossRef]

- Donati, L.; Tomesani, L. The prediction of seam welds quality in aluminum extrusion. J. Mater. Process. Technol. 2004, 153–154, 366–373. [Google Scholar] [CrossRef]

- Gagliardi, F.; Ambrogio, G.; Filice, L. On the die design in AA6082 porthole extrusion. CIRP Ann. Manuf. Technol. 2012, 61, 231–234. [Google Scholar] [CrossRef]

- Saniee, F.F.; Fakhar, N.; Karimi, M. Experimental, Analytical, and Numerical Studies on the Forward Extrusion Process. Mater. Manuf. Process. 2013, 28, 265–270. [Google Scholar] [CrossRef]

- Ceretti, E.; Giardini, C. Dvelopment and implementation of an algorithm for the simulation of material welding in extrusion process. In Proceedings of the 1st International Conference on Sustainable Manufacturing, Montreal, Canada, 17–18 October 2007.

- Xu, Y.; Misiolek, W.Z. Numerical modeling of extrusion welding in magnesium alloys. Key Eng. Mater. 2011, 491, 159–171. [Google Scholar] [CrossRef]

- Alharthi, N.; Bingol, S.; Ventura, A.; Misiolek, W.Z. Analysis of extrusion welding in magnesium alloys—Numerical predictions and metallurgical verification. Procedia Eng. 2014, 81, 658–663. [Google Scholar] [CrossRef]

- Clode, M.P. Material flow and microstructure development during extrusion of AA6063. In Proceedings of the Fifth International Aluminum Extrusion Technology Seminar, Chicago, IL, USA, 19–22 May 1992.

- Zhang, C.; Zhao, G.; Chen, Z.; Chen, H.; Kou, F. Effect of extrusion stem speed on extrusion process for a hollow aluminum profile. Mater. Sci. Eng. B 2012, 177, 1691–1697. [Google Scholar] [CrossRef]

- Fang, G.; Zhou, J.; Duszczyk, J. FEM simulation of aluminum extrusion through two-hole multi-step pocket dies. J. Mater. Process. Technol. 2009, 209, 1891–1900. [Google Scholar] [CrossRef]

- Xu, Y. Numerical modeling of extrusion welding in magnesium alloys. Master’s Thesis, Lehigh University, Bethlehem, PA, USA, 2011. [Google Scholar]

- Plata, M.; Piwnik, J. Theoretical and experimental analysis of seam weld formation in hot extrusion of aluminum alloys. In Proceedings of Seventh International Aluminum Extrusion Technology, Chicago, IL, USA, 16–19 May 2000.

© 2015 by the authors; licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bingöl, S.; Bozacı, A. Experimental and Numerical Study on the Strength of Aluminum Extrusion Welding. Materials 2015, 8, 4389-4399. https://doi.org/10.3390/ma8074389

Bingöl S, Bozacı A. Experimental and Numerical Study on the Strength of Aluminum Extrusion Welding. Materials. 2015; 8(7):4389-4399. https://doi.org/10.3390/ma8074389

Chicago/Turabian StyleBingöl, Sedat, and Atilla Bozacı. 2015. "Experimental and Numerical Study on the Strength of Aluminum Extrusion Welding" Materials 8, no. 7: 4389-4399. https://doi.org/10.3390/ma8074389